Compatibilization of poly(lactic acid)-poly(butylene succinate) blends by using organic modified montmorillonite as a compatibilizer

-

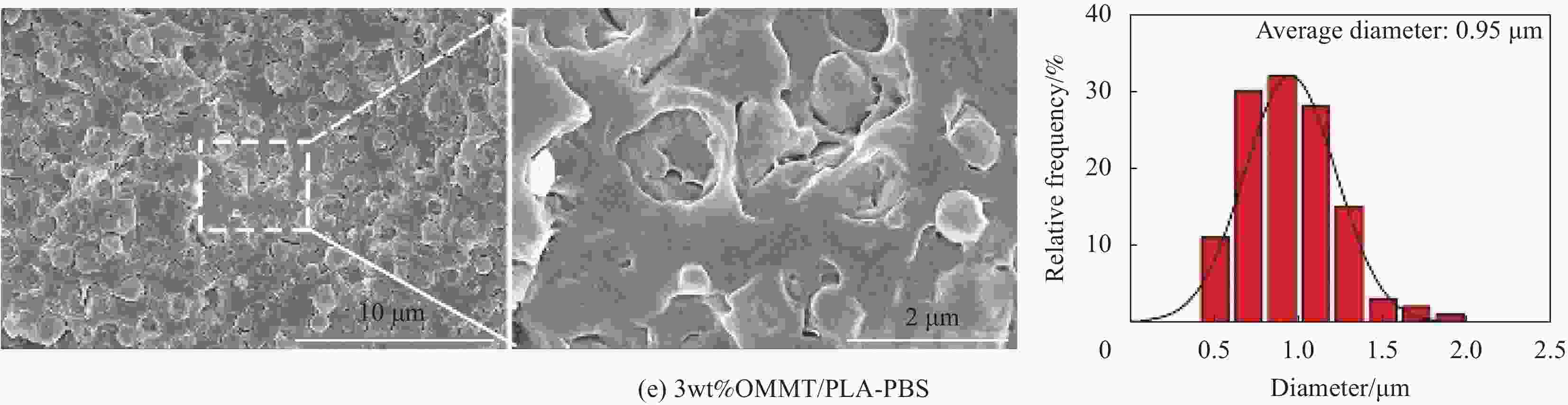

摘要: 为了获得综合性能优良的聚乳酸基生物可降解复合材料,利用二甲基双十八烷基氯化铵有机改性蒙脱土(OMMT)作为非反应型增容剂,通过直接熔融共混法制备了有机改性蒙脱土/聚乳酸-聚丁二酸丁二醇酯(OMMT/PLA-PBS)复合材料,研究了OMMT含量对PLA-PBS共混体系的增容效果及其对力学性能的影响规律。微观结构表明,OMMT能够显著降低分散相PBS的粒径和均匀粒径分布,分布在PLA与PBS相界面处的OMMT,起到了类似嵌段共聚物的增容作用,增加了PLA与PBS之间的黏结力。动态流变结果表明,当OMMT含量为3wt%时,OMMT在PLA-PBS共混物中形成三维网络结构。动态热机械性能结果显示,添加OMMT后,OMMT/PLA-PBS复合材料中PLA相与PBS相对应的玻璃化转变温度相互靠拢,当OMMT含量为1wt%时,PLA与PBS的玻璃化转变温度相互靠拢的幅度最大,增容效果最好。热性能数据表明,加入OMMT后,复合材料中PLA的结晶度出现先增加后降低的变化趋势,在OMMT含量为1wt%时,PLA结晶度达到最大值12.7%。力学性能结果表明,当OMMT含量为1wt%时,OMMT/PLA-PBS复合材料的综合力学性能达到最佳,拉伸强度和冲击强度分别为62.5 MPa和12.6 kJ/m2,较PLA-PBS共混物分别提高了32.1%和80%。Abstract: In order to obtain excellent properties of poly (lactic acid) based biodegradable composite, organic modified montmorillonite (OMMT) with dimethyl dioctadecyl ammonium chloride was used as a non-reactive compatibilizer. The organic modified montmorillonite/poly(lactic acid)-poly(butylene succinate) (OMMT/PLA-PBS) composites were prepared by direct melt blending method. The effect of OMMT contents on compatibility between PLA and PBS, and mechanical properties of the composites were investigated in this work. Morphological analyses reveal that OMMT can significantly reduce the particle size and result in uniform distribution of the dispersed phase PBS. The OMMT distributes in the interface between PLA and PBS can act as compatibilizer similar to block copolymer and increases interface adhesion between PLA and PBS. The dynamic rheological results indicate that OMMT forms a three-dimensional network structure at 3wt% OMMT. From dynamic thermo-mechanical analysis, glass transition temperatures of PLA and PBS in the composites get closer with the addition of OMMT. At 1wt%, the degree of glass transition temperature convergence is maximum, corresponding to the best compatibilization. Thermal data show that the crystallinity of PLA in composites first increases and then decreases by addition of OMMT. The crystallinity of PLA reaches maximum of 12.7% at 1wt%. The results of mechanical properties show that the comprehensive mechanical properties of OMMT/PLA-PBS composites reach the best when the OMMT content is 1wt%. The tensile strength and impact strength are 62.5 MPa and 12.6 kJ/m2, respectively, which are 32.1% and 80% higher than those of the PLA-PBS blend.

-

表 1 有机改性蒙脱土/聚乳酸-聚丁二酸丁二醇酯(OMMT/PLA-PBS)复合材料组成配比

Table 1. Formulation of organic modified montmorillonite/poly(lactic acid)-poly(butylene succinate) (OMMT/PLA-PBS) composites

wt% Samples Mass fraction of PLA Mass fraction of PBS Mass fraction of OMMT PLA-PBS 80 20 0 0.5wt%OMMT/PLA-PBS 80 20 0.5 1wt%OMMT/PLA-PBS 80 20 1 2wt%OMMT/PLA-PBS 80 20 2 3wt%OMMT/PLA-PBS 80 20 3 表 2 从损耗模量和力学损耗角正切得到PLA、PBS和OMMT/PLA-PBS复合材料的玻璃化转变温度

Table 2. Glass transition temperature of PLA, PBS and OMMT/PLA-PBS composites obtained from loss modulus and loss tangent

Sample Loss modulus G'' Loss tangent tanδ Tg, PBS/℃ Tg, PLA/℃ Tg, PBS/℃ Tg, PLA/℃ PLA — 61.0 — 67.3 PLA-PBS −22.5 60.5 −17.6 66.9 0.5wt%OMMT/PLA-PBS −21.7 60.4 −17.5 66.5 1wt%OMMT/PLA-PBS −18.4 58.5 −16.1 64.4 2wt%OMMT/PLA-PBS −18.4 59.6 −16.3 65.8 3wt%OMMT/PLA-PBS −19.4 60.1 −17.8 65.7 PBS −22.4 — −17.8 — Notes: Tg, PBS—Glass transition temperature of PBS phase; Tg, PLA—Glass transition temperature of PLA phase. 表 3 从DSC热流曲线得到的OMMT/PLA-PBS复合材料的热性能参数

Table 3. Thermal data obtained from the DSC heat flow curves of OMMT/PLA-PBS composites

Sample Tg, PLA/°C Tcc, PLA/°C Tm, PBS/°C Tm, PLA/°C Xc ,PLA/% PLA-PBS 59.3 117.7 111.9 151.2 1.2 0.5wt%OMMT/PLA-PBS 60.1 117.0 114.3 149.9/155.4 7.1 1wt%OMMT/PLA-PBS 62.8 116.7 114.1 149.5/154.9 12.7 2wt%OMMT/PLA-PBS 59.8 117.1 114.1 149.7/154.9 8.8 3wt%OMMT/PLA-PBS 59.3 116.5 114.2 149.5/155.6 7.0 Notes: Tg—Glass transition temperature; Tcc—Cold crystallization temperature; Tm—Melting temperature; Xc—Degree of crystallinity. -

[1] CASTRO-AGUIRRE E, INIGUEZ-FRANCO F, SAMSUDIN H, et al. Poly(lactic acid)-mass production, processing, industrial applications, and end of life[J]. Advanced Drug Delivery Reviews,2016,107:333-366. doi: 10.1016/j.addr.2016.03.010 [2] HAMAD K, KASEEM M, AYYOOB M, et al. Polylactic acid blends: The future of green, light and tough[J]. Progress in Polymer Science,2018,85:83-127. doi: 10.1016/j.progpolymsci.2018.07.001 [3] CHAI J L, WANG G L, LI B, et al. Strong and ductile poly (lactic acid) achieved by carbon dioxide treatment at room temperature[J]. Journal of CO2 Utilization,2019,33:292-302. doi: 10.1016/j.jcou.2019.06.006 [4] 夏明凤, 杨月, 付国良, 等. 高性能超韧聚乳酸共混物的研究进展[J]. 高分子材料科学与工程, 2018, 34(10):178-183.XIA Mingfeng, YANG Yue, FU Guoliang, et al. Progress of high-performance super-tough poly(lactic acid) blends[J]. Polymer Materials Science and Engineering,2018,34(10):178-183(in Chinese). [5] NOFAR M, SACLIGIL D, CARREAU P J, et al. Poly (lactic acid) blends: Processing, properties and applications[J]. International Journal of Biological Macromolecules,2019,125:307-360. doi: 10.1016/j.ijbiomac.2018.12.002 [6] GIGLI M, FABBRI M, LOTTI N, et al. Poly(butylene succinate)-based polyesters for biomedical applications: A review[J]. European Polymer Journal,2016,75:431-460. doi: 10.1016/j.eurpolymj.2016.01.016 [7] ZHANG X C, LIU Q, SHI J F, et al. Distinctive tensile properties of the blends of poly(L-lactic acid) (PLLA) and poly(butylene succinate) (PBS)[J]. Journal of Polymers and The Environment,2018,26(4):1737-1744. doi: 10.1007/s10924-017-1064-8 [8] OSTROWSKA J, SADURSKI W, PALUCH M, et al. The effect of poly(butylene succinate) content on the structure and thermal and mechanical properties of its blends with polylactide[J]. Polymer International,2019,68(7):1271-1279. doi: 10.1002/pi.5814 [9] SU S, KOPITZKY R, TOLGA S, et al. Polylactide (PLA) and its blends with poly(butylene succinate) (PBS): A brief review[J]. Polymers, 2019, 11(7): 1193. [10] DI LORENZO M L. Poly(l-lactic acid)/poly(butylene succinate) biobased biodegradable blends[J]. Polymer Reviews,2021,61(3):457-492. doi: 10.1080/15583724.2020.1850475 [11] ZHANG B, SUN B, BIAN X C, et al. High melt strength and high toughness PLLA/PBS blends by copolymerization and in situ reactive compatibilization[J]. Industrial & Engineering Chemistry Research,2017,56(1):52-62. [12] XUE B, HE H Z, HUANG Z X, et al. Fabrication of super-tough ternary blends by melt compounding of poly(lactic acid) with poly(butylene succinate) and ethylene-methyl acrylate-glycidyl methacrylate[J]. Composites Part B: Engineering,2019,172:743-749. doi: 10.1016/j.compositesb.2019.05.098 [13] ZHANG W, XU Y, WANG P L, et al. Copolymer P(BS-co-LA) enhanced compatibility of PBS/PLA composite[J]. Journal of Polymers and The Environment,2018,26(7):3060-3068. doi: 10.1007/s10924-018-1180-0 [14] DING Y, FENG W T, HUANG D, et al. Compatibilization of immiscible PLA-based biodegradable polymer blends using amphiphilic di-block copolymers[J]. European Polymer Journal,2019,118:45-52. doi: 10.1016/j.eurpolymj.2019.05.036 [15] HUITRIC J, VILLE J, MEDERIC P, et al. Solid-state morphology, structure, and tensile properties of polyethylene/polyamide/nanoclay blends: Effect of clay fraction[J]. Polymer Testing,2017,58:96-103. doi: 10.1016/j.polymertesting.2016.12.020 [16] AMMAR A, ELZATAHRY A, Al-MAADEED M, et al. Nanoclay compatibilization of phase separated polysulfone/polyimide films for oxygen barrier[J]. Applied Clay Science,2017,137:123-134. doi: 10.1016/j.clay.2016.12.012 [17] GUO J B, XU Y, HE W D, et al. Phase morphology evolution and compatibilization of immiscible polyamide 6/polystyrene blends using nano-montmorillonite[J]. Polymer Engineering & Science,2018,58(5):752-758. [18] DING W J, ZHOU Y F, WANG W Q, et al. The reactive compatibilization of montmorillonite for immiscible anionic polyamide 6/polystyrene blends via in situ polymerization[J]. Polymer-Plastics Technology and Materials,2020,59(8):884-894. doi: 10.1080/25740881.2019.1708101 [19] GENOYER J, YEE M, SOULESTIN J, et al. Compatibilization mechanism induced by organoclay in PMMA/PS blends[J]. Journal of Rheology,2017,61(4):613-626. doi: 10.1122/1.4982701 [20] 柯贤忠, 刘治田, 胡芹, 等. 有机改性蒙脱土的制备及其对聚乙烯-聚苯乙烯相态和力学性能的影响[J]. 复合材料学报, 2019, 36(7):1650-1657.KE Xianzhong, LIU Zhitian, HU Qin, et al. Preparation of organic modified montmorillonite and its effect on phase morphology and mechanical properties of polyethylene-polystyrene[J]. Acta Materiae Compositae Sinica,2019,36(7):1650-1657(in Chinese). [21] BHATIA A, GUPTA R K, BHATTACHARYA S N, et al. Effect of clay on thermal, mechanical and gas barrier properties of biodegradable poly(lactic acid)/poly(butylene succinate) (PLA/PBS) nanocomposites[J]. International Polymer Processing,2010,25(1):5-14. doi: 10.3139/217.2214 [22] YANG Y C, LI X Y, ZHANG Q Q, et al. Foaming of poly(lactic acid) with supercritical CO2: The combined effect of crystallinity and crystalline morphology on cellular structure[J]. The Journal of Supercritical Fluids,2019,145:122-132. doi: 10.1016/j.supflu.2018.12.006 [23] 中国国家标准化管理委员会. 塑料 拉伸性能的测定: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Plastics: Determination of tensile properties: GB/T 1040.2—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [24] 中国国家标准化管理委员会. 塑料 简支梁冲击性能的测定: GB/T 1043.1—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics: Determination of charpy impact properties: GB/T 1043.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [25] DENG Y, THOMAS N L. Blending poly(butylene succinate) with poly(lactic acid): Ductility and phase inversion effects[J]. European Polymer Journal,2015,71:534-546. doi: 10.1016/j.eurpolymj.2015.08.029 [26] NOFAR M, HEUZEY M C, CARREAU P J, et al. Effects of nanoclay and its localization on the morphology stabilization of PLA/PBAT blends under shear flow[J]. Polymer,2016,98:353-364. doi: 10.1016/j.polymer.2016.06.044 [27] VILLE J, MEDERIC P, HUITRIC J, et al. Structural and rheological investigation of interphasein polyethylene/polyamide/nanoclay ternary blends[J]. Polymer,2012,53(8):1733-1740. [28] SALEHIYAN R, HYUN K. Effect of organoclay on non-linear rheological properties of poly(lactic acid)/poly(caprolactone) blends[J]. Korean Journal of Chemical Engineering,2013,30(5):1013-1022. doi: 10.1007/s11814-013-0035-6 [29] OJIJO V, RAY S S, SADIKU R. Effect of nanoclay loading on the thermal and mechanical properties of biodegradable polylactide/poly (butylene succinate)-co-adipate blend composites[J]. ACS Applied Materials & Interfaces,2012,4(5):2395-2405. [30] OJIJO V, MALWELA T, RAY S S, et al. Unique isothermal crystallization phenomenon in the ternary blends of biopolymers polylactide and poly (butylene succinate)-co-adipate and nano-clay[J]. Polymer,2012,53(2):505-518. doi: 10.1016/j.polymer.2011.12.007 -

下载:

下载: