Theoretical modeling and experimental study on nanosecond laser machining of Kevlar fiber reinforced plastics

-

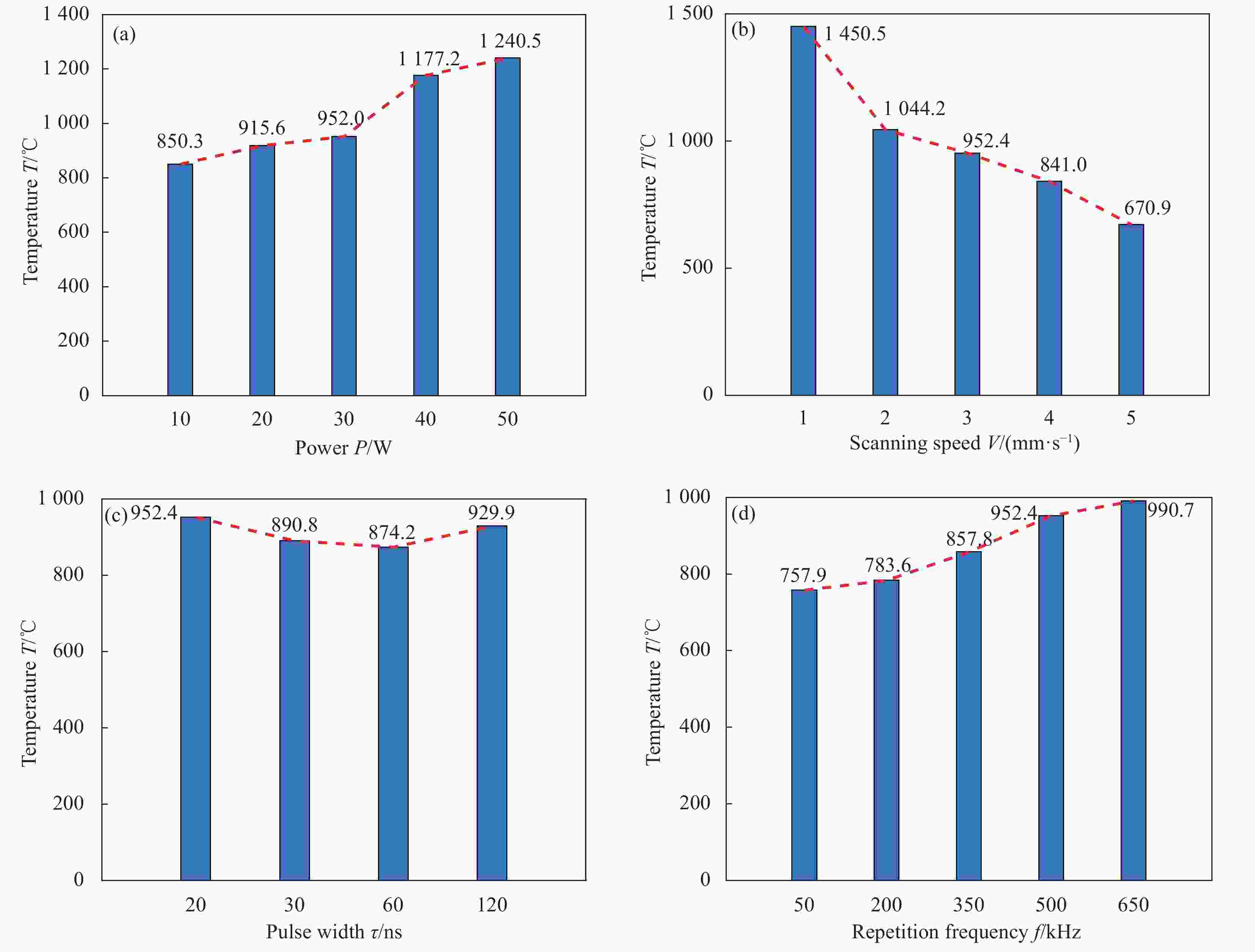

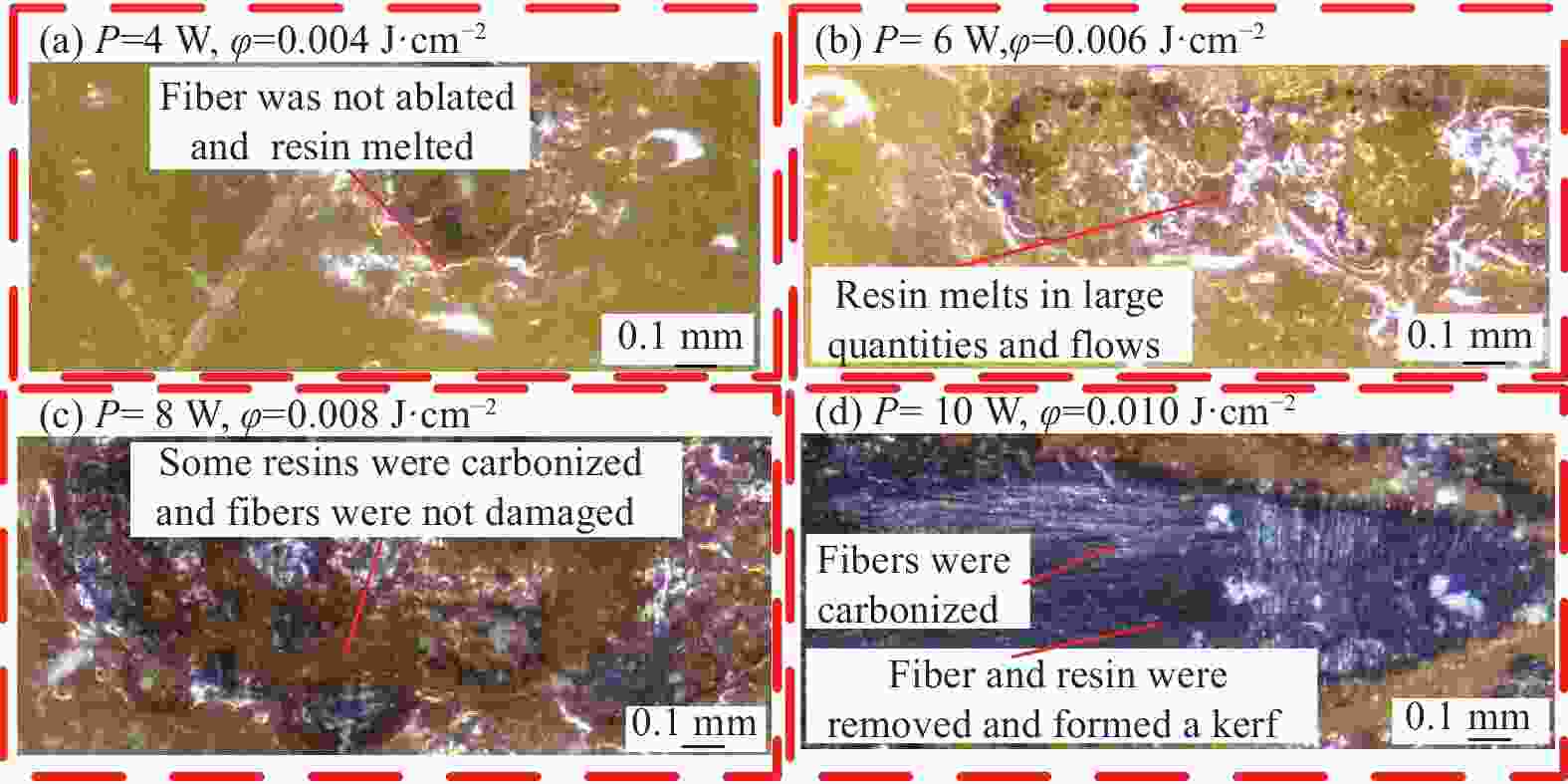

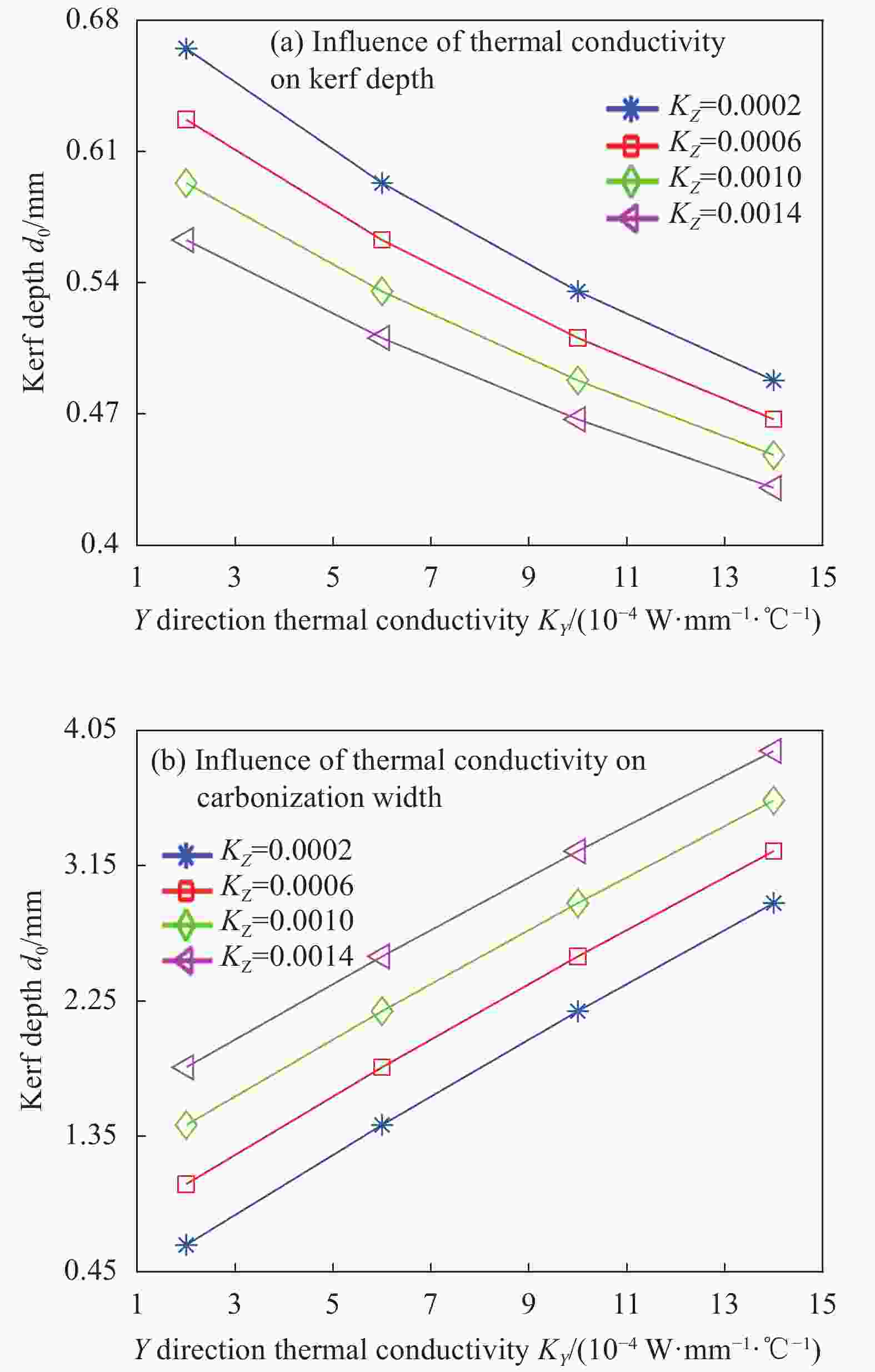

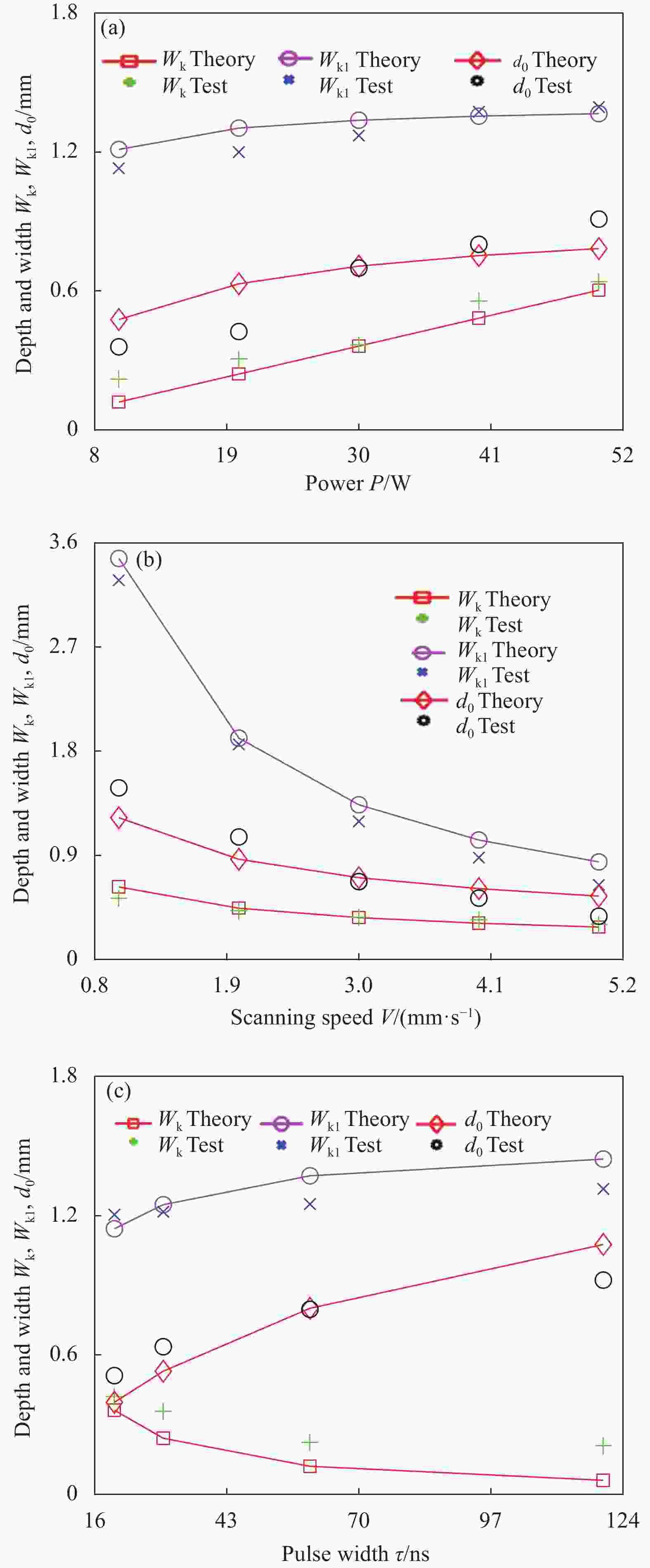

摘要: 纳秒激光加工在纤维增强树脂基复合材料的加工中应用广泛,但在对温度较敏感的Kevlar纤维增强树脂基复合材料(KFRP)的激光加工中,极易产生不可控的热损伤。针对KFRP的纳秒激光切割,分析激光加工过程中的温度演变过程,根据激光加工烧蚀阈值理论,分析KFRP的烧蚀阈值及烧蚀机制,并基于热传导中的能量守恒定律、质量守恒及动量守恒,分别建立Kevlar纤维和树脂基体热影响区的损伤预测模型。结果表明,KFRP激光加工热影响区存在显著差异,可以通过切削温度变化规律明显区分激光加工不同损伤区域;Kevlar纤维的烧蚀阈值为0.01 J·cm−2,环氧树脂基体的烧蚀阈值为0.005 J·cm−2;切缝宽度、切缝深度、炭化区宽度的理论预测模型与实验结果基本吻合,激光加工工艺参数对热影响区影响显著,其中,激光功率对切缝宽度的影响最大,扫描速度对切缝深度、炭化区宽度的影响最显著,但脉冲宽度和重复频率对热影响区影响较小。

-

关键词:

- Kevlar纤维增强树脂复合材料(KFRP) /

- 纳秒激光切削 /

- 烧蚀阈值 /

- 热影响区 /

- 切削温度

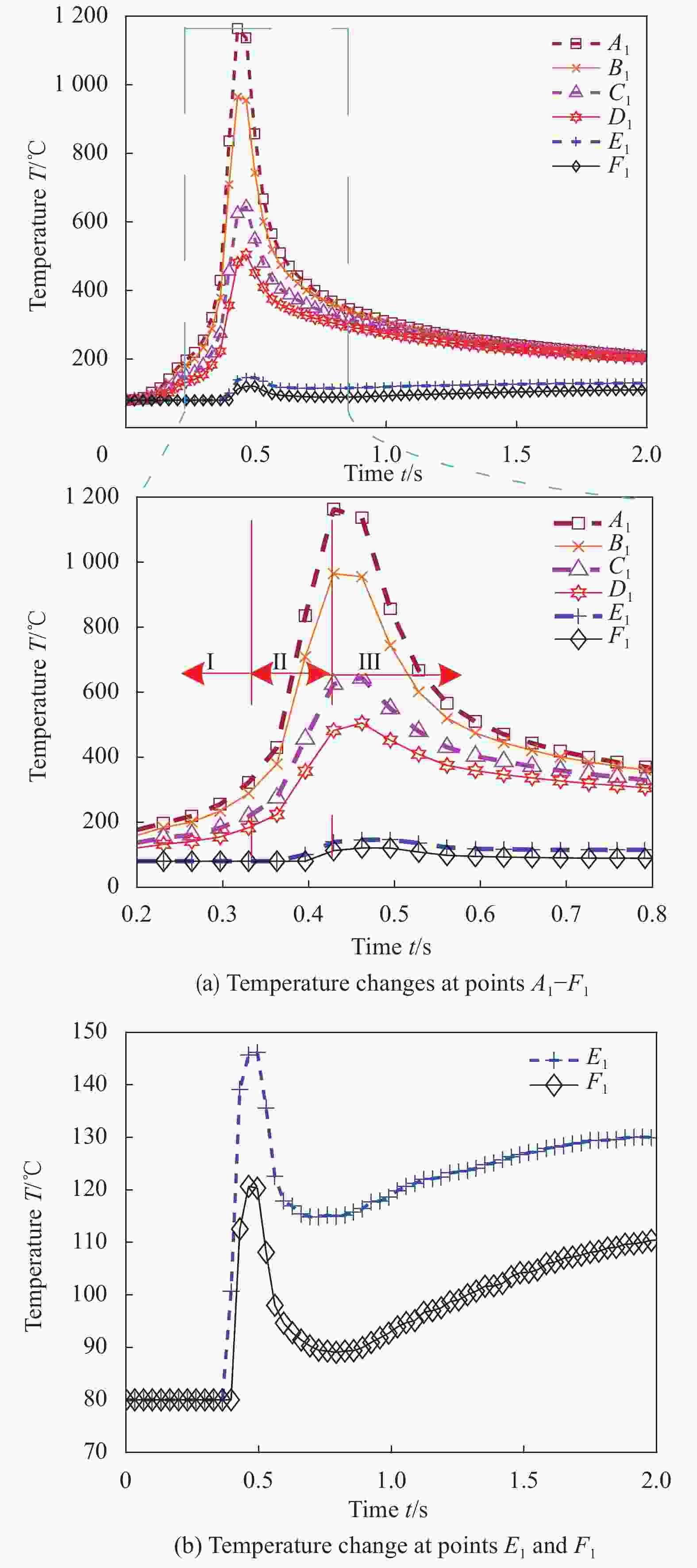

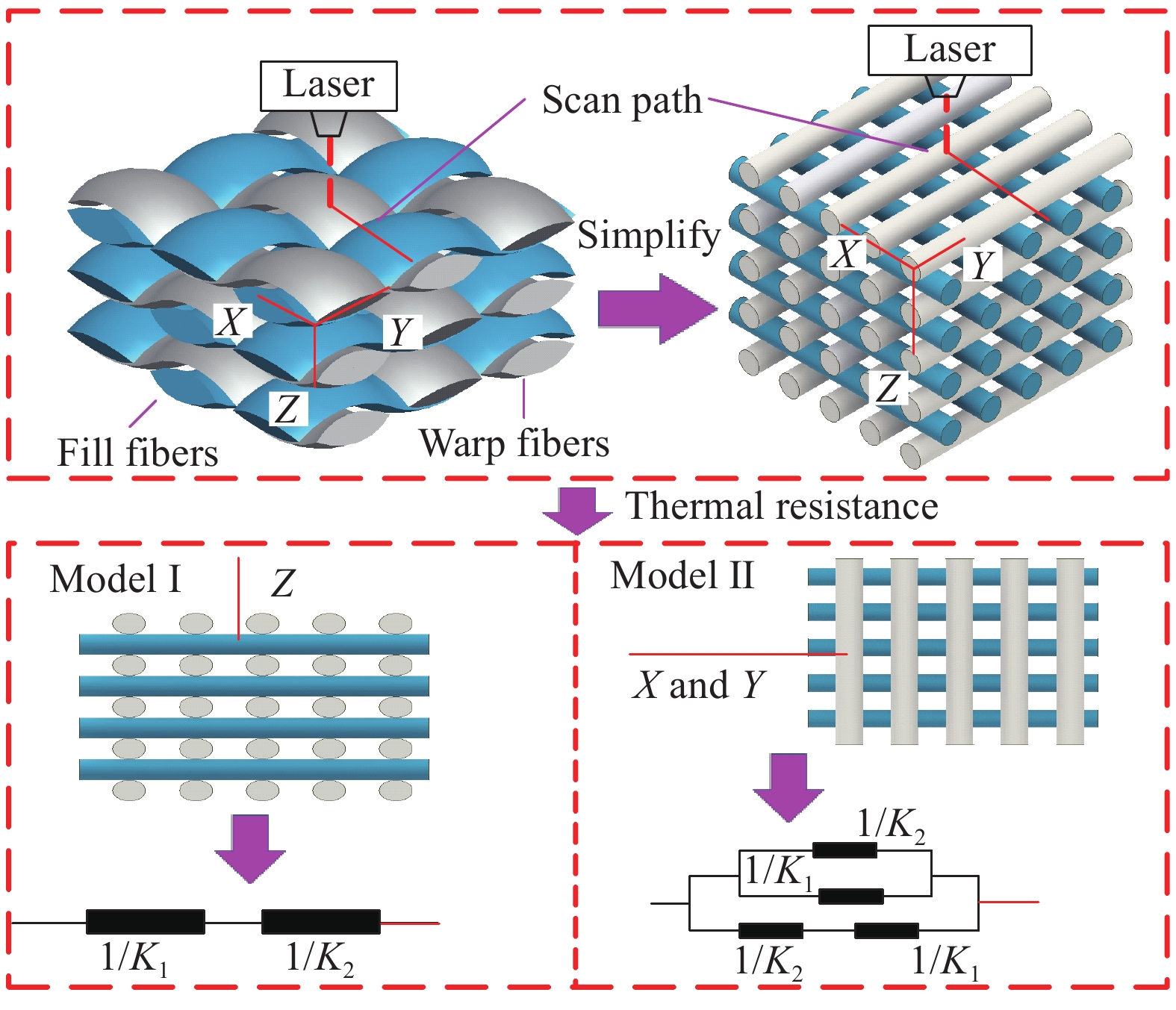

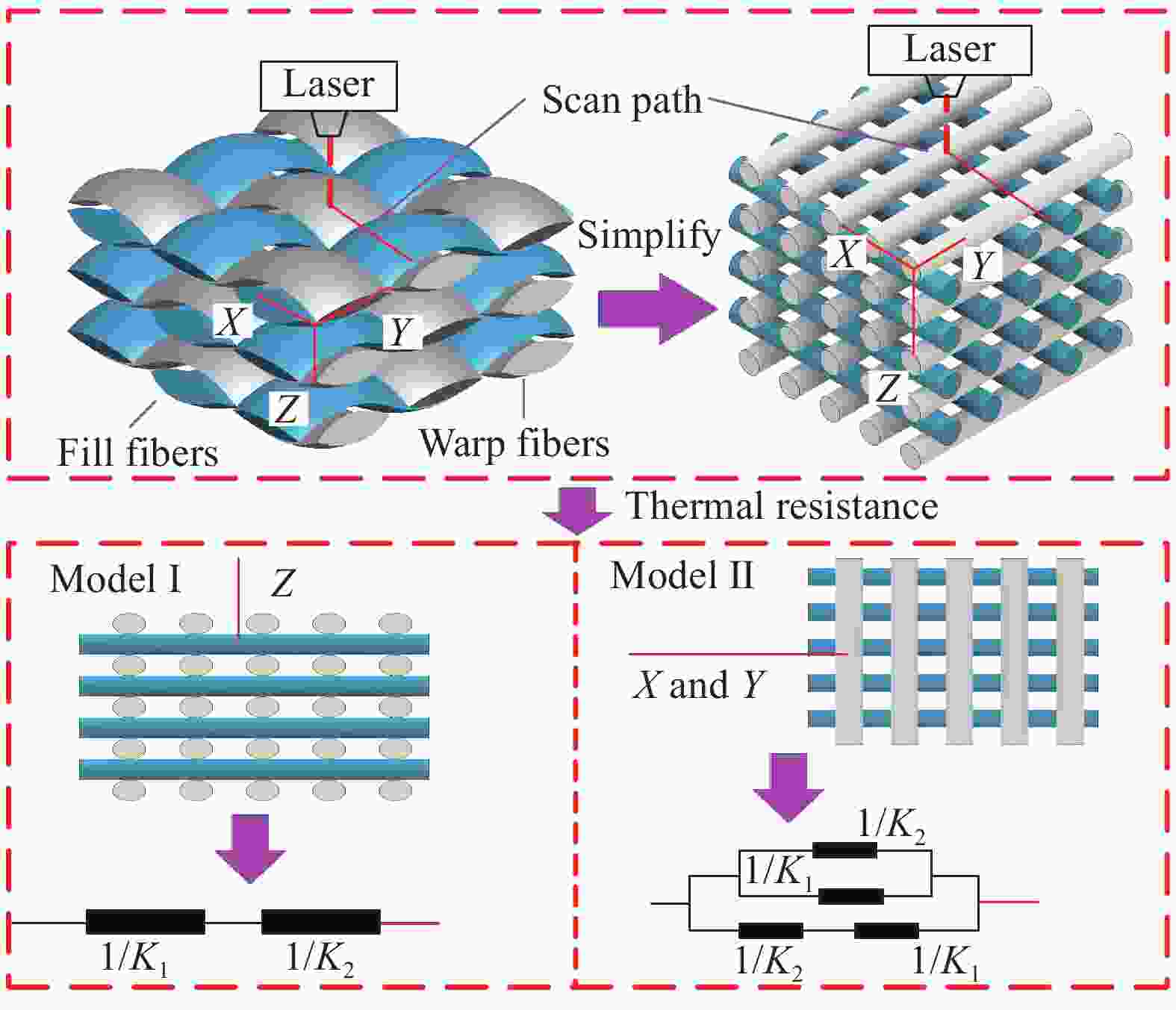

Abstract: Nanosecond laser processing is widely used in the processing of fiber-reinforced composites, but it is easy to produce uncontrollable thermal damage in the laser processing of Kevlar fiber reinforced plastics (KFRP), owing to its poor high temperature resistance. During the nanosecond laser cutting of KFRP, the temperature evolution process was analyzed. According to the ablation threshold theory of laser processing, the ablation threshold and the ablation mechanism were analyzed. Based on the conservation law of energy in heat conduction, the conservation of mass and the conservation of momentum, the damage prediction models of the Kevlar fiber and the resin matrix in the heat-affected zone were established, respectively. The results show that there are significant differences in the heat-affected zone of KFRP laser machining, and the different damage zones can be distinguished by the change law of cutting temperature. The ablation threshold of the Kevlar fiber and that of the epoxy resin matrix are 0.01 J·cm−2 and 0.005 J·cm−2, respectively. The theoretical model of the kerf width, the kerf depth and the carbonization zone width is consistent with the experimental result. The heat-affected zone is significantly affected by the laser processing process parameters. Among them, the kerf width is most significantly affected by the laser power, the kerf depth and the width of the carbonization zone are most significantly affected by the scanning speed. But, the heat-affected zone is little affected by the pulse width and the repetition frequency. -

表 1 Kevlar纤维增强树脂基复合材料(KFRP)的特征参数[10, 26]

Table 1. Performance parameters of Kevlar fiber reinforced plastics (KFRP)[10, 26]

Performance parameter Value Density of Kevlar fiber ρ1/(g·mm−3) 1.44×10−6 Density of epoxy matrix ρ2/(g·mm−3) 1.20×10−6 Specific heat capacity of Kevlar fiber

C1/(J·kg−1·℃−1)1398.46 Specific heat capacity of epoxy resin

C2/(J·kg−1·℃−1)1884.00 Environment temperature T0/℃ 25 Melting temperature of epoxy resin Tm/℃ 90 Vaporizer temperature of epoxy resin T2/℃ 425 Carbonization temperature of Kevlar fiber T1/℃ 427 Thermal conductivity of Kevlar fiber

K1/(W·mm−1·℃−1)1.57×10−3 Thermal conductivity of epoxy resin

K2/(W·mm−1·℃−1)2.00×10−4 Energy absorption rate A 0.6 Transition latent heat of epoxy resin Qv2/(J·kg−1) 1×106 Coefficient of overheating in melting ημ 0.01 Density of assisted gas ρg/(kg·m−3) 2.786 Molecular diameter of assisted gas σ/mm 3.75×10−7 Pressure of assisted gas Pg/Pa 2.98×105 Pressure drop coefficient F 0.5 表 2 激光加工工艺参数

Table 2. Laser machining process parameters

Number P/W V/(mm·s−1) f/kHz τ/ns 1 10 3 200 20 2 20 3 200 20 3 30 3 200 20 4 40 3 200 20 5 50 3 200 20 6 30 1 200 20 7 30 2 200 20 8 30 3 200 20 9 30 4 200 20 10 30 5 200 20 11 30 3 350 20 12 30 3 500 20 13 30 3 650 20 14 30 3 200 30 15 30 3 200 60 16 30 3 200 120 Notes: P—Laser power; V—Scanning speed; f—Repetition frequency; τ—Pulse width. -

[1] DELLERBA M, GALANTUNCCI L M, MIGLIETTA S. An experimental study on laser drilling and cutting of composite materials for the aerospace industry using excimer and CO2 sources[J]. Composites Manufacturing,1992,3(1):14-19. doi: 10.1016/0956-7143(92)90178-W [2] 张开虎, 于洋, 张夏明, 等. 纤维增强树脂基复合材料激光切割热影响探析[J]. 导航与控制, 2019, 18(5):60-83.ZHANG K H, YU Y, ZHANG X M, et al. Laser cutting induced heat affected zone in fiber reinforced polymer: A comparative analysis[J]. Navigation and Control,2019,18(5):60-83(in Chinese). [3] 王贵兵, 刘仓理. 凯芙拉环氧复合材料烧蚀阈值实验研究[J]. 激光技术, 2003, 27(5):457-459. doi: 10.3969/j.issn.1001-3806.2003.05.027WANG G B, LIU C L. Experimental research of the ablation threshold of Kevlar/epoxy[J]. Laser Technology,2003,27(5):457-459(in Chinese). doi: 10.3969/j.issn.1001-3806.2003.05.027 [4] 路明雨, 张明, 张开虎, 等. 高模量碳纤维增强树脂基复合材料的皮秒激光加工阈值特性[J]. 复合材料学报, 2021, 38(11):3601-3609.LU M Y, ZHANG M, ZHANG K H, et al. Threshold properties of high modulus carbon fiber reinforced plastic composite with picosecond laser processing[J]. Acta Materiae Compositae Sinica,2021,38(11):3601-3609(in Chinese). [5] 庞思勤, 刘伟成. 激光加工高性能复合材料的工艺与机理研究[J]. 兵工学报, 1992, 4:84-91.PANG S Q, LIU W C. A study on the process and mecha-nisms of laser machining of high-performance composites[J]. Acta Armamentarii,1992,4:84-91(in Chinese). [6] 张永强, 王贵兵, 唐小松, 等. 两种纤维增强复合材料连续激光烧蚀阈值测量及吸收特性分析[J]. 强激光与粒子束, 2009, 21(2):199-202.ZHANG Y Q, WANG G B, TANG X S, et al. Ablation threshold measurement and absorption characteristic analysis of two fiber reinforced composites irradiated by CW laser[J]. High Power Laser and Particle Beams,2009,21(2):199-202(in Chinese). [7] 王贵兵, 罗飞, 刘仓理, 等. 芳纶纤维复合材料激光烧蚀损伤形貌研究[J]. 激光技术, 2006, 30(2):168-169. doi: 10.3969/j.issn.1001-3806.2006.02.002WANG G B, LUO F, LIU C L, et al. The research of the ablation morphology of the composite reinforced by polyaryl amidde fibers irradiated by laser[J]. Laser Technology,2006,30(2):168-169(in Chinese). doi: 10.3969/j.issn.1001-3806.2006.02.002 [8] LEONE C, PAPA I I, TAGLIAFERRI F, et al. Investigation of CFRP laser milling using a 30 W Q-switched Yb: YAG fiber laser: Effect of process parameters on removal mecha-nisms and HAZ formation[J]. Composites Part A: Applied Science and Manufacturing,2013,55:129-142. [9] AL-SULAIMAN F, YILBAS B S, KARAKAS F C, et al. Laser hole cutting in Kevlar: Modeling and quality assessment[J]. The International Journal of Advanced Manufacturing Technology,2008,38:1125-1136. doi: 10.1007/s00170-007-1167-9 [10] AL-SULAIMAN F, YILBAS B S, AHSAN M, et al. CO2 laser cutting Kevlar laminate: Influence of assisting gas pressure[J]. International Journal of Advanced Manufacturing Technology,2009,45:62-70. doi: 10.1007/s00170-009-1945-7 [11] CHEN L M, LI M J, Yang X J, et al. Thermal defect characterization and heat conduction modeling during fiber laser cutting carbon fiber reinforced polymer laminates[J]. Archives of Civil and Mechanical Engineering,2020,20(61):1-14. [12] GAUTAN G D, DHANANIJAY R, MISHRA. Evaluation of geometrical quality characteristics in pulsed Nd: YAG laser cutting of Kevlar-29/basalt fiber reinforced hybrid compo-site using grey relational analysis based on genetic algorithm[J]. FME Transactions,2019,47:560-575. doi: 10.5937/fmet1903560G [13] GAUTAN G D, PANDEY A K. Teaching learning algorithm based optimization of kerf deviations in pulsed Nd: YAG laser cutting of Kevlar-29 composite laminates[J]. Infrared Physics & Technology,2018,89:203-217. [14] 熊厚. 纳秒激光薄铝板精密打孔研究[D]. 武汉: 湖北工业大学, 2016.XIONG H. Nanosecond laser drilling of thin aluminum sheets[D]. Wuhan: Hubei University of Technology, 2016(in Chinese). [15] 李平雪, 辛承聪, 高健, 等. 皮秒激光加工研究进展与展望[J]. 激光与红外, 2008, 48(10):1196-1203.LI P X, XIN C C, GAO J, et al. Research progress and development of picosecond laser processing[J]. Laser & Infrared,2008,48(10):1196-1203(in Chinese). [16] PECHOLT B, VENDAN M, DONG Y Y. Ultrafast laser micromachining of 3C-SiC thin films for MEMS device fabrication[J]. International Journal of Advanced Manufacturing,2008(39):239-250. [17] 焦浩文, 陈冰, 罗良, 等. 纳秒激光加工2.5维Cf/SiC复合材料的烧蚀孔洞特征[J]. 中国机械工程, 2020, 31(8):983-990. doi: 10.3969/j.issn.1004-132X.2020.08.014JIAO H W, CHEN B, LUO L, et al. Ablation hole characteris-tic of 2.5-dimensional Cf/SiC composites processed by nanosecond laser[J]. China Mechanical Engineering,2020,31(8):983-990(in Chinese). doi: 10.3969/j.issn.1004-132X.2020.08.014 [18] ZHENG B, JIANG G, WANG W, et al. Ablation experiment and threshold calculation of titanium alloy irradiated by ultra-fast pulse lase[J]. AIP Advances,2014,4(3):1-9. [19] 李晓溪, 贾天卿, 冯东海, 等. 超短脉冲激光照射下氧化铝的烧蚀机理[J]. 物理学报, 2004, 53(7):2154-2158. doi: 10.3321/j.issn:1000-3290.2004.07.025LI X X, JIA T Q, FENG D H, et al. The mechanism of ablation of sapphire by an ultrashort pulse laser[J]. Acta Phy-sica Sinica,2004,53(7):2154-2158(in Chinese). doi: 10.3321/j.issn:1000-3290.2004.07.025 [20] 梁建超. 飞秒激光与材料相互作用的能量建模及加工形貌研究[D]. 天津: 天津大学, 2018.LIANG J C. Study on energy for the interaction between femtosecond laser and material and processing and morphuology[D]. Tianjin: Tianjin University, 2018(in Chinese). [21] 王昊君. 纳秒激光抛光钛合金Ti6Al4V作用机理及实验研究[D]. 武汉: 湖北工业大学, 2020.WANG H J. Experimental study on nanosecond laser polishing of Ti6AI4V alloy[D]. Wuhan: Hubei University of Technology, 2020(in Chinese). [22] KAR A, SCOTT J E, LATHAM W P. Theoretical and experimental studies of thick-section cutting with a chemical oxygen-iodine laser (COIL)[J]. Journal of Laser Applications,1996,8:125-133. doi: 10.2351/1.4745413 [23] KAR A, ROTHENFLUE J A, LATHAM W P. Scaling laws for thick-section cutting with a chemical oxygen-iodine laser[J]. Journal of Laser Applications,1997,9(6):279. doi: 10.2351/1.4745470 [24] GEORGE S, SPRINGER. Thermal conductivities of unidirectional materials[J]. Materials,1967,1:166-173. [25] UHLAMNN E, SPUR G, HOCHENG H, et al. The extent of laser-induced thermal damage of UD and crossply compo-site laminates[J]. International Journal of Machine Tools & Manufacture,1999,39:639-650. [26] 赵明生. 机械工程手册 [M]. 北京: 机械工业出版社, 1996.ZHAO M S. Mechanical engineering handbook[M]. Beijing: China Machine Press, 1996(in Chinese). [27] 杨剑, 张瑞, 赵煜, 等. 皮秒激光切割AFRP复合材料实验研究[J]. 复合材料学报, 2011, 39(1):147-157.YANG J, ZHANG R, ZHAO Y, et al. Experimental study on picosecond laser cutting AFRP composites[J]. Acta Materae Compositae Sinica,2011,39(1):147-157(in Chinese). [28] YILBAS B S, AL-SULAIMAN F, KARAKAS C, et al. Laser cutting of multilayered Kevlar plates[J]. Journal of Materials Engineering and Performance,2007,16:663-671. doi: 10.1007/s11665-007-9107-2 -

下载:

下载: