Mechanical properties of emulsified asphalt rubber concrete

-

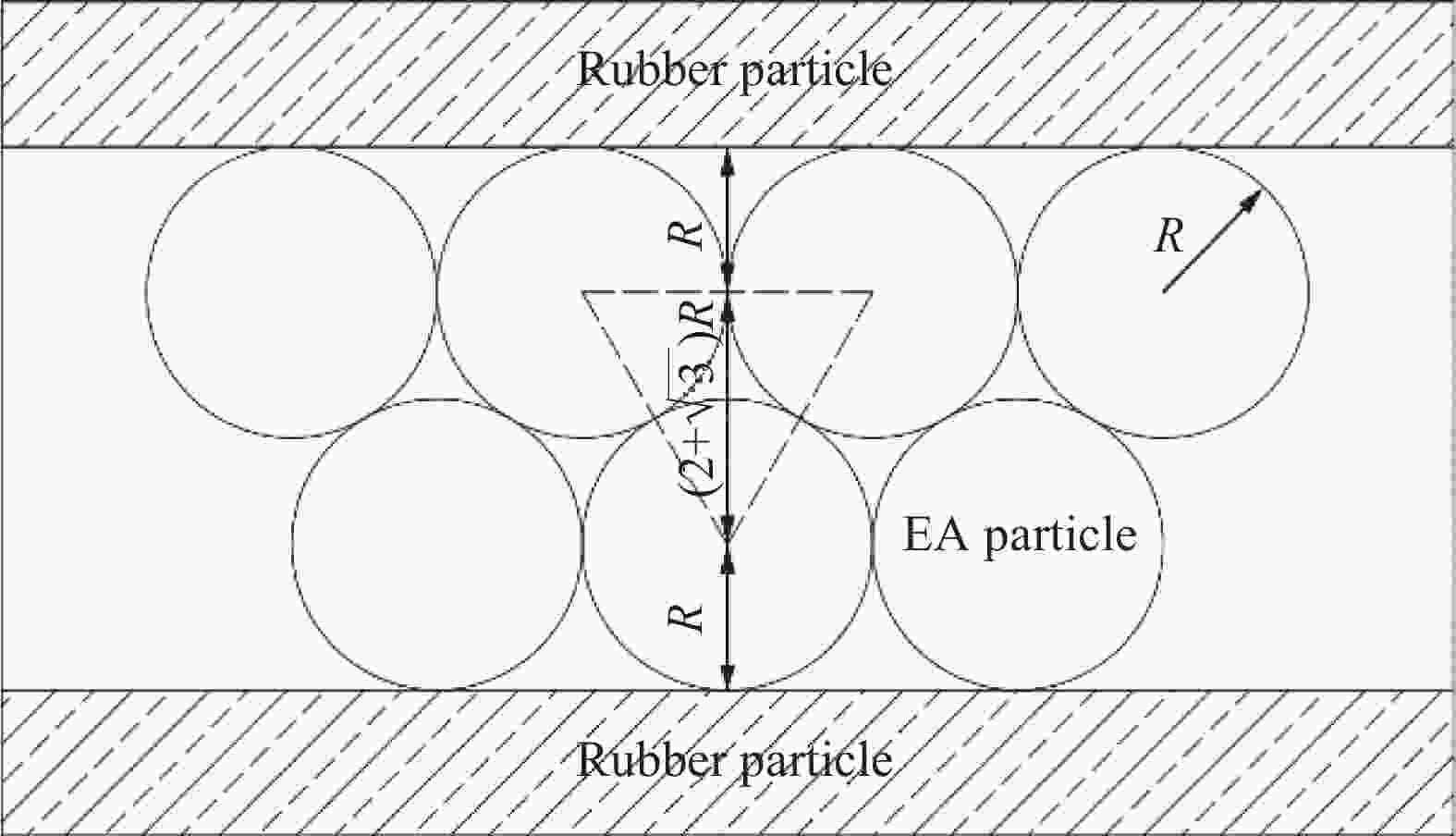

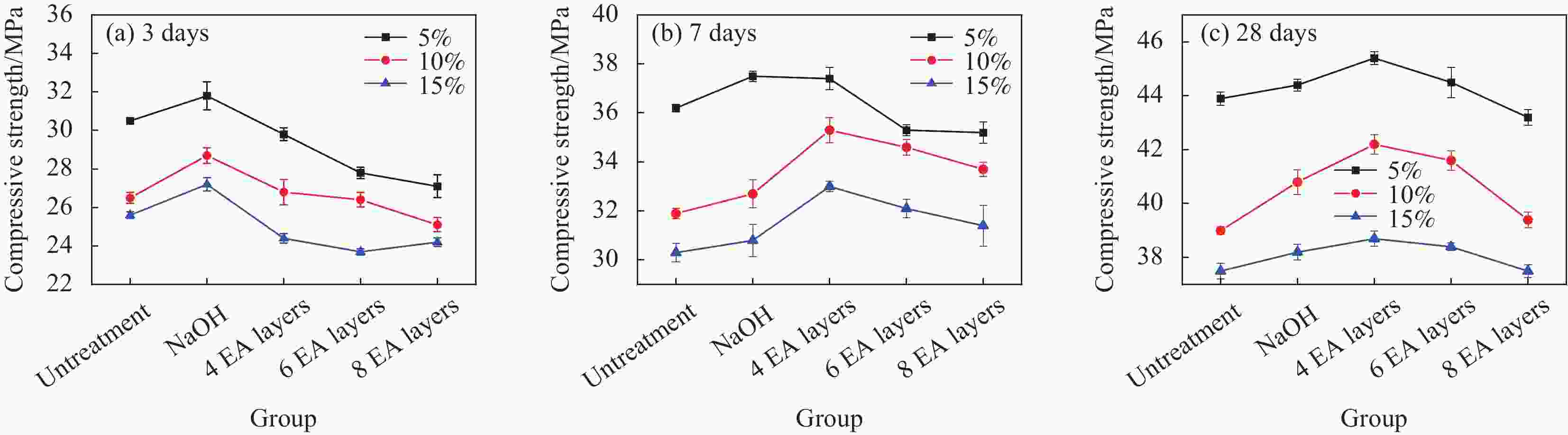

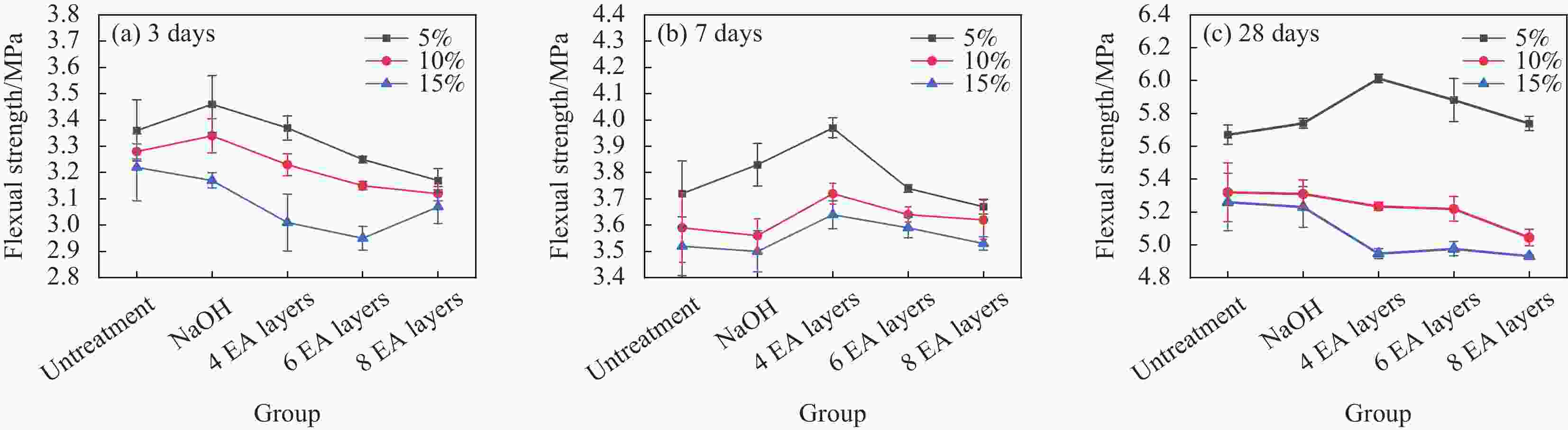

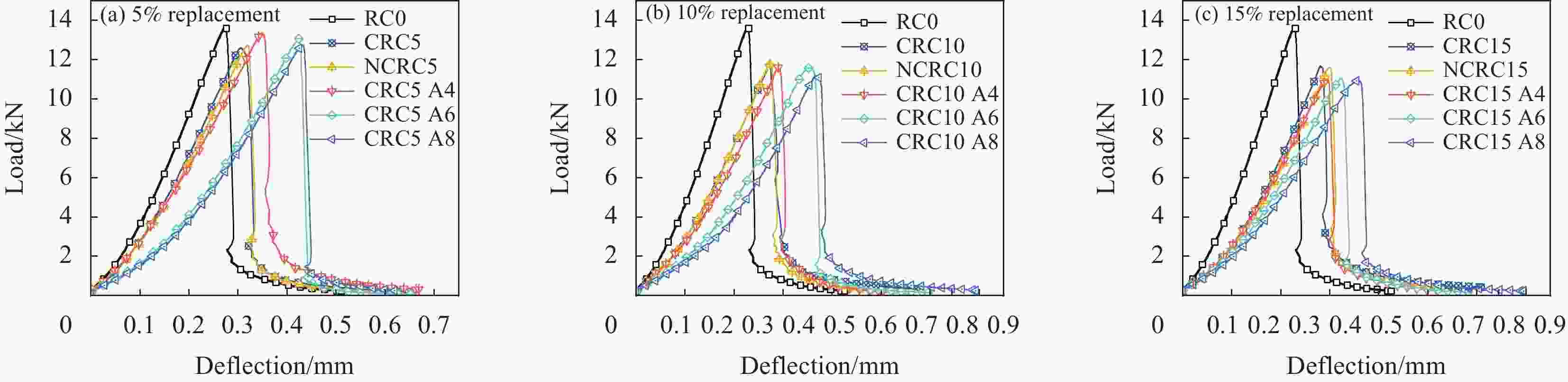

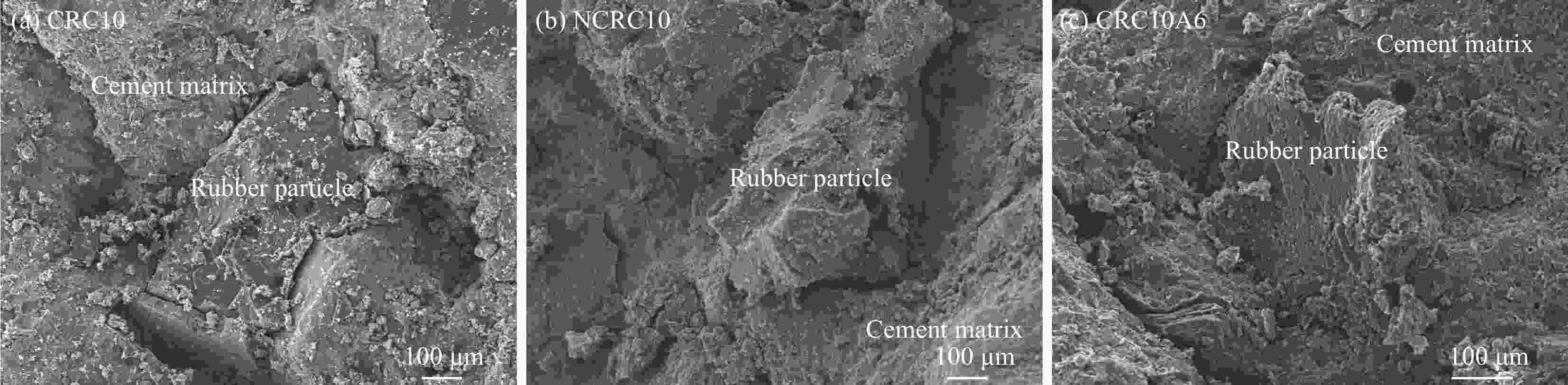

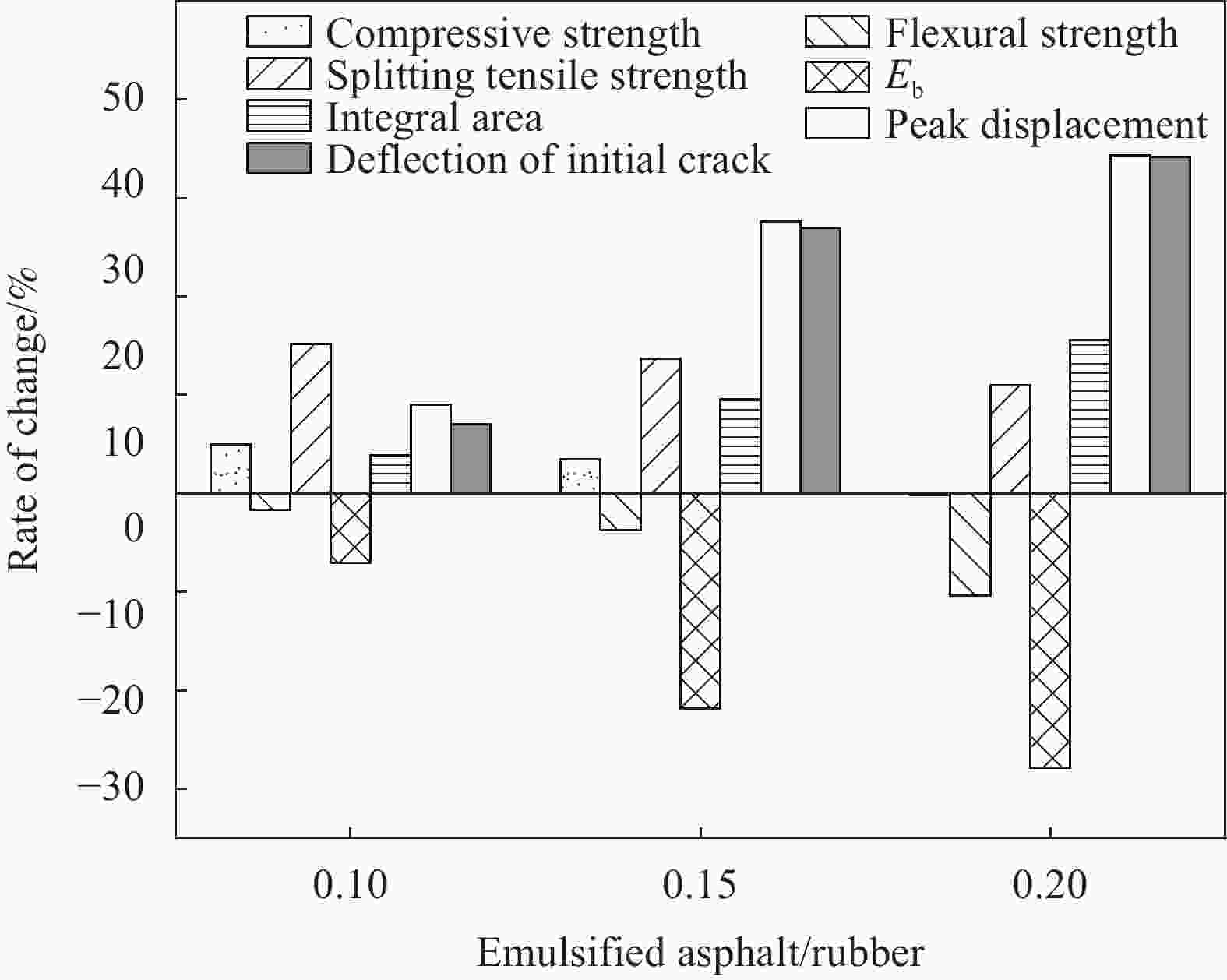

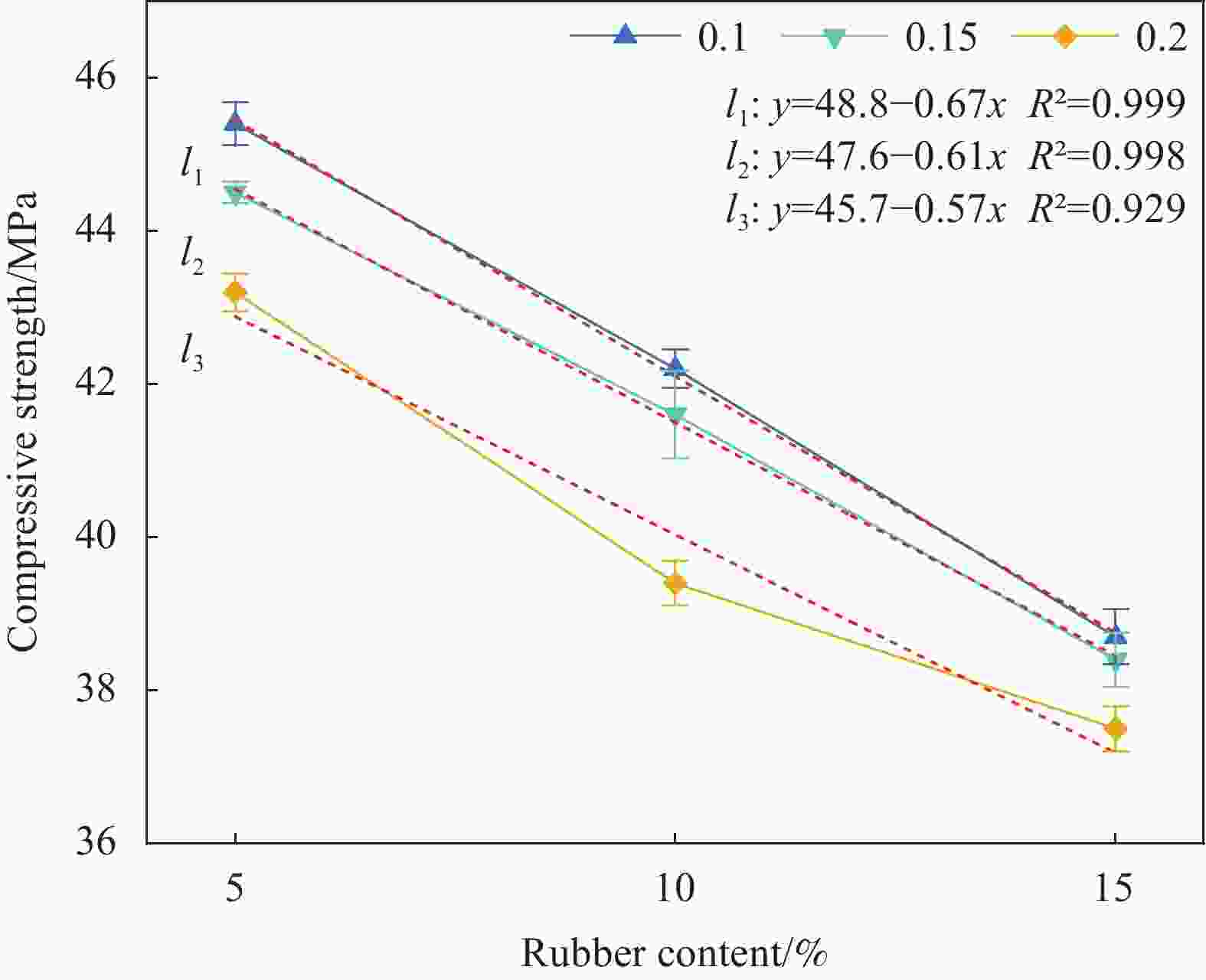

摘要: 对用乳化沥青(Emulsified asphalt,EA)改善橡胶混凝土(Crumb rubber concrete,CRC)的力学性能进行了研究。通过抗压、抗折、劈裂抗拉和三点弯曲试验,研究了5%、10%和15% 3种橡胶掺量(等体积取代细骨料)下,EA理论计算成膜覆盖橡胶颗粒表面4层、6层和8层膜对应不同EA掺量对CRC力学性能的影响。试验结果发现,对比未预处理CRC和NaOH预处理CRC两个对照组:掺入不同掺量EA后,不同橡胶掺量的CRC的抗压强度和劈裂抗拉强度均有较大提高,CRC的峰值位移显著增大,弯曲弹性模量Eb明显降低;乳化沥青与橡胶质量比为0.15(6层EA膜)时,3种橡胶掺量下CRC较未预处理组相比抗压强度平均提高3.5%,峰值位移提高27.6%,Eb降低21.8%,乳化沥青橡胶混凝土具有较突出的力学性能复合效应。Abstract: The effects of emulsified asphalt (EA) on the mechanical properties of crumb rubber concrete (CRC) were explored. The fine aggregate was replaced with 5%, 10% and 15% rubber by volume in concrete, and different EA contents corresponding to 4, 6 and 8 layers of films covering the surface of rubber particles according to theoretical calculation were studied. The results of compressive strength, flexural strength, splitting tensile strength and three-point bending experiments show that, compared with the unpretreated CRC and NaOH pretreated CRC, the compressive strength and splitting tensile strength of the CRC with different rubber contents are greatly improved by adding different amounts of EA, the peak displacement increases and the flexural elastic modulus Eb decreases significantly; when the mass ratio of emulsified asphalt to rubber is 0.15 (6 layers of EA film), compared with the unpretreated CRC, the average increase in compressive strength is 3.5%, the peak displacement is 27.6%, and Eb is 21.8% lower for CRC at three rubber contents, emulsified asphalt-rubber concrete has a more prominent composite effect of mechanical properties.

-

Key words:

- rubber particle /

- concrete /

- emulsified asphalt /

- mechanical properties /

- recycle

-

表 1 混凝土配合比

Table 1. Mix proportion of concrete

(kg·m−3) Type Specimen

denotationCement Water Coarse

aggregateFine

aggregateRubber

particlesEmulsified

asphaltPC RC0 450 180 1152.73 622.48 0 — Rubber concrete CRC5 450 180 1152.73 591.36 11.35 — CRC10 450 180 1152.73 560.23 22.70 — CRC15 450 180 1152.73 529.11 34.05 — NaOH treatment NCRC5 450 180 1152.73 591.36 11.35 — NCRC10 450 180 1152.73 560.23 22.70 — NCRC15 450 180 1152.73 529.11 34.05 — EA

treatmentCRC5 A4 450 179.50 1152.73 591.36 11.35 1.14 CRC5 A6 450 179.24 1152.73 591.36 11.35 1.71 CRC5 A8 450 178.99 1152.73 591.36 11.35 2.28 CRC10 A4 450 178.99 1152.73 560.23 22.70 2.28 CRC10 A6 450 178.48 1152.73 560.23 22.70 3.42 CRC10 A8 450 177.98 1152.73 560.23 22.70 4.56 CRC15 A4 450 178.31 1152.73 529.11 34.05 3.42 CRC15 A6 450 177.46 1152.73 529.11 34.05 5.13 CRC15 A8 450 176.62 1152.73 529.11 34.05 6.84 Notes: PC—Plain concrete; (N)CRC5, (N)CRC10, (N)CRC15—Rubber volume substitution ratios of 5%, 10% and 15%, respectively; CRC—Crumb rubber concrete; A4, A6, A8—Layer of emulsified asphalt (EA) of 4, 6 and 8, respectively. 表 2 橡胶混凝土弯曲韧性参数

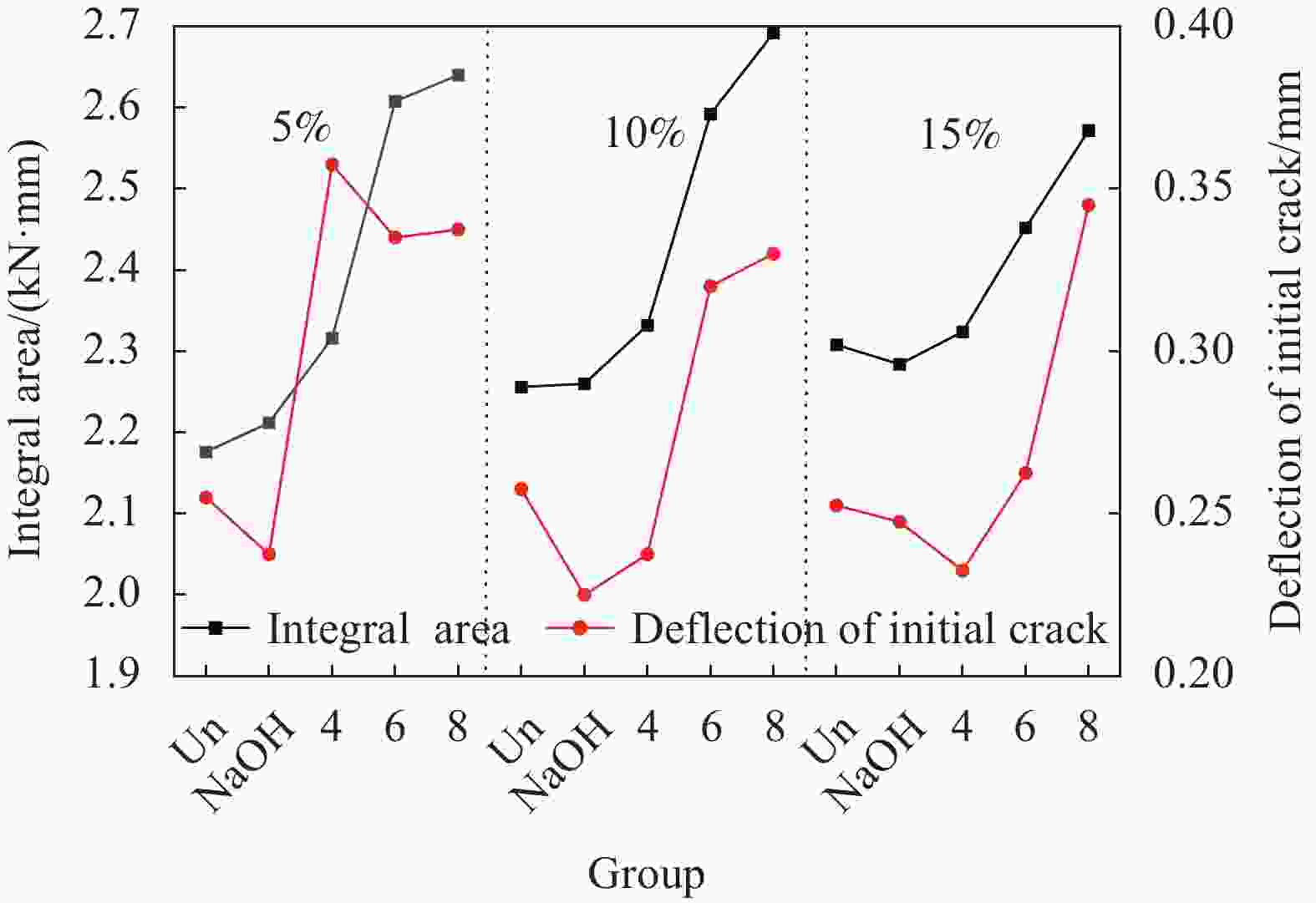

Table 2. Flexural toughness parameters of crumb rubber concrete

Type Specimen

denotationEb/

GPaIntegral area/

(kN·mm)Peak load/

kNPeak displacement/

mmDeflection of

initial crack/mmPC RC0 3.30 1.960 13.791 0.273 0.239 Rubber

concreteCRC5 2.69 2.118 12.609 0.307 0.269 CRC10 2.35 2.132 11.823 0.326 0.289 CRC15 2.22 2.111 11.695 0.337 0.302 NaOH

treatmentNCRC5 2.63 2.052 12.753 0.320 0.278 NCRC10 2.30 1.997 11.808 0.330 0.290 NCRC15 2.01 2.089 11.623 0.360 0.296 EA

treatmentCRC5 A4 2.52 2.534 13.362 0.351 0.304 CRC5 A6 1.99 2.441 12.071 0.424 0.377 CRC5 A8 1.90 2.452 11.752 0.431 0.385 CRC10 A4 2.17 2.045 11.631 0.350 0.308 CRC10 A6 1.78 2.379 11.596 0.422 0.373 CRC10 A8 1.88 2.416 11.210 0.439 0.398 CRC15 A4 1.90 2.027 10.992 0.354 0.306 CRC15 A6 1.62 2.154 11.056 0.388 0.338 CRC15 A8 1.71 2.484 10.959 0.431 0.368 Note: Eb—Bending modulus of elasticity. -

[1] 中国轮胎循环利用协会.《中国轮胎循环利用行业“十四五”发展规划》征求行业意见[J]. 中国轮胎资源综合利用, 2020(11): 12-19.China Tire Recycling Association. Soliciting industry opinions for "the 14th five-year development plan of China’s Tire Recycling Industry"[J]. China Tire Resources Recycling, 2020(11): 12-19(in Chinese). [2] ELDIN N N, SENOUCI A B. Use of scrap tires in road construction[J]. Journal of Construction Engineering and Management,1992,118(3):561-576. doi: 10.1061/(ASCE)0733-9364(1992)118:3(561) [3] ELDIN N N, SENOUCI A B. Rubber-tire particles as concrete aggregate[J]. Journal of Materials in Civil Engineering,1993,5(4):478-496. doi: 10.1061/(ASCE)0899-1561(1993)5:4(478) [4] 张海波, 管学茂, 刘小星, 等. 废旧橡胶颗粒对混凝土强度的影响及界面分析[J]. 材料导报, 2009, 23(8):65-67. doi: 10.3321/j.issn:1005-023X.2009.08.020ZHANG Haibo, GUAN Xuemao, LIU Xiaoxing, et al. Study on compressive strength and interface of rubberized concrete[J]. Materials Reports,2009,23(8):65-67(in Chinese). doi: 10.3321/j.issn:1005-023X.2009.08.020 [5] TIAN S, ZHANG T, LI Y. Research on modifier and modified process for rubber-particle used in rubberized concrete for road[J]. Advanced Materials Research,2011,243:4125-4130. [6] SEGRE N, JOEKES I. Use of tire rubber particles as addition to cement paste[J]. Cement and Concrete Research,2000,30(9):1421-1425. doi: 10.1016/S0008-8846(00)00373-2 [7] MEDDAH A, BEDDAR M, BALI A. Use of shredded rubber tire aggregates for roller compacted concrete pavement[J]. Journal of Cleaner Production,2014,72:187-192. doi: 10.1016/j.jclepro.2014.02.052 [8] KASHANI A, NGO T D, HEMACHANDRA P, et al. Effects of surface treatments of recycled tyre crumb on cement-rubber bonding in concrete composite foam[J]. Construction and Building Materials,2018,171:467-473. doi: 10.1016/j.conbuildmat.2018.03.163 [9] YOUSSF O, HASSANLI R, MILLS J E, et al. Influence of mixing procedures, rubber treatment, and fibre additives on rubcrete performance[J]. Journal of Composites Science,2019,3(2):41. doi: 10.3390/jcs3020041 [10] GUO S, DAI Q, SI R, et al. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire[J]. Journal of Cleaner Production,2017,148:681-689. doi: 10.1016/j.jclepro.2017.02.046 [11] LI Z, LI F, LI J S L. Properties of concrete incorporating rubber tyre particles[J]. Magazine of Concrete Research,1998,50(4):297-304. doi: 10.1680/macr.1998.50.4.297 [12] OSSOLA G, WOJCIK A. UV modification of tire rubber for use in cementitious composites[J]. Cement and Concrete Composites,2014,52:34-41. doi: 10.1016/j.cemconcomp.2014.04.004 [13] 何亮, 刘誉贵, 牟元华. 橡胶改性及其对橡胶水泥基质材料性能的影响[J]. 硅酸盐通报, 2017, 36(3):936-941.HE Liang, LIU Yugui, MOU Yuanhua. Rubber modification and its influence on the properties of rubber cement matrix[J]. Bulletin of the Chinese Ceramic Society,2017,36(3):936-941(in Chinese). [14] LI Y, ZHANG X, WANG R, et al. Performance enhancement of rubberised concrete via surface modification of rubber: A review[J]. Construction and Building Materials,2019,227:116691. doi: 10.1016/j.conbuildmat.2019.116691 [15] HUANG B, SHU X, LI G. Laboratory investigation of portland cement concrete containing recycled asphalt pavements[J]. Cement and Concrete Research,2005,35(10):2008-2013. doi: 10.1016/j.cemconres.2005.05.002 [16] 李朝元, 刘赞群, 陈娟,等. 水泥-乳化沥青-橡胶颗粒砂浆拉伸性能研究[J]. 硅酸盐通报, 2020, 39(8):2549-2556.LI Chaoyuan, LIU Zanqun, CHEN Juan, et al. Tensile properties of cement-emulsified-rubber particle mortar[J]. Bulletin of the Chinese Ceramic Society,2020,39(8):2549-2556(in Chinese). [17] OIKONOMOU N, MAVRIDOU S. Improvement of chloride ion penetration resistance in cement mortars modified with rubber from worn automobile tires[J]. Cement and Concrete Composites,2009,31(6):403-407. doi: 10.1016/j.cemconcomp.2009.04.004 [18] BING C, NING L. Experimental research on properties of fresh and hardened rubberized concrete[J]. Journal of Materials in Civil Engineering,2014,26(8):04014040. doi: 10.1061/(ASCE)MT.1943-5533.0000923 [19] 叶青. 水泥乳化沥青混凝土凝结硬化机理及微观结构研究[D]. 西安: 长安大学, 2012.YE Qin. Study on setting and hardening mechanism and microstructure of cement emulsified asphalt concrete[D]. Xi'an: Chang’an University, 2012(in Chinese). [20] 中华人民共和国住房和城乡建设部. 混凝土力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building, 2019(in Chinese). [21] MOHAMMADI I, KHABBAZ H, VESSALAS K. Enhancing mechanical performance of rubberised concrete pavements with sodium hydroxide treatment[J]. Materials and Structures,2016,49(3):813-827. doi: 10.1617/s11527-015-0540-7 [22] 中华人民共和国住房和城乡建设部. 纤维混凝土应用技术规程: JGJ/T 221—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Technical specification for application of fibber reinforced concrete: JGJ/T 221—2010[S]. Beijing: China Architecture & Building Press, 2010(in Chinese). [23] 毛子铭. 阳离子乳化沥青对水泥浆体微结构、力学及耐久性能的影响[D]. 扬州: 扬州大学, 2020.MAO Ziming. Effect of cationic asphalt emulision on microstructure, mechanical properties and durability of cement paste[D]. Yangzhou: Yangzhou University, 2020(in Chinese). [24] 中华人民共和国交通运输部. 公路水泥混凝土路面设计规范: JTG D40—2011[S]. 北京: 中国建筑工业出版社, 2011.Ministry of Transport of the People's Republic of China. Specifications for design of highway cement concrete pavement: JTG D40—2011[S]. Beijing: China Architecture & Building Press, 2011(in Chinese). [25] 刘方, 王宝民, 袁晓洒, 等. 掺加废旧橡胶颗粒混凝土的韧性试验研究[J]. 混凝土, 2019(3):78-81, 85. doi: 10.3969/j.issn.1002-3550.2019.03.019LIU Fang, WANG Baomin, YUAN Xiaosa, et al. Experimental study on toughness of concrete containing scrap rubber[J]. Concrete,2019(3):78-81, 85(in Chinese). doi: 10.3969/j.issn.1002-3550.2019.03.019 -

下载:

下载: