Quality analysis of prepreg tow for automated fiber placement and its influencing factors

-

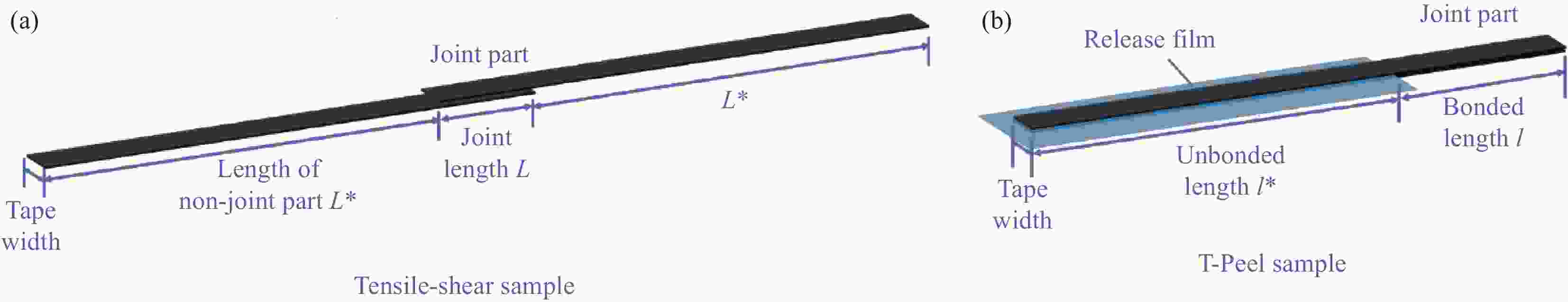

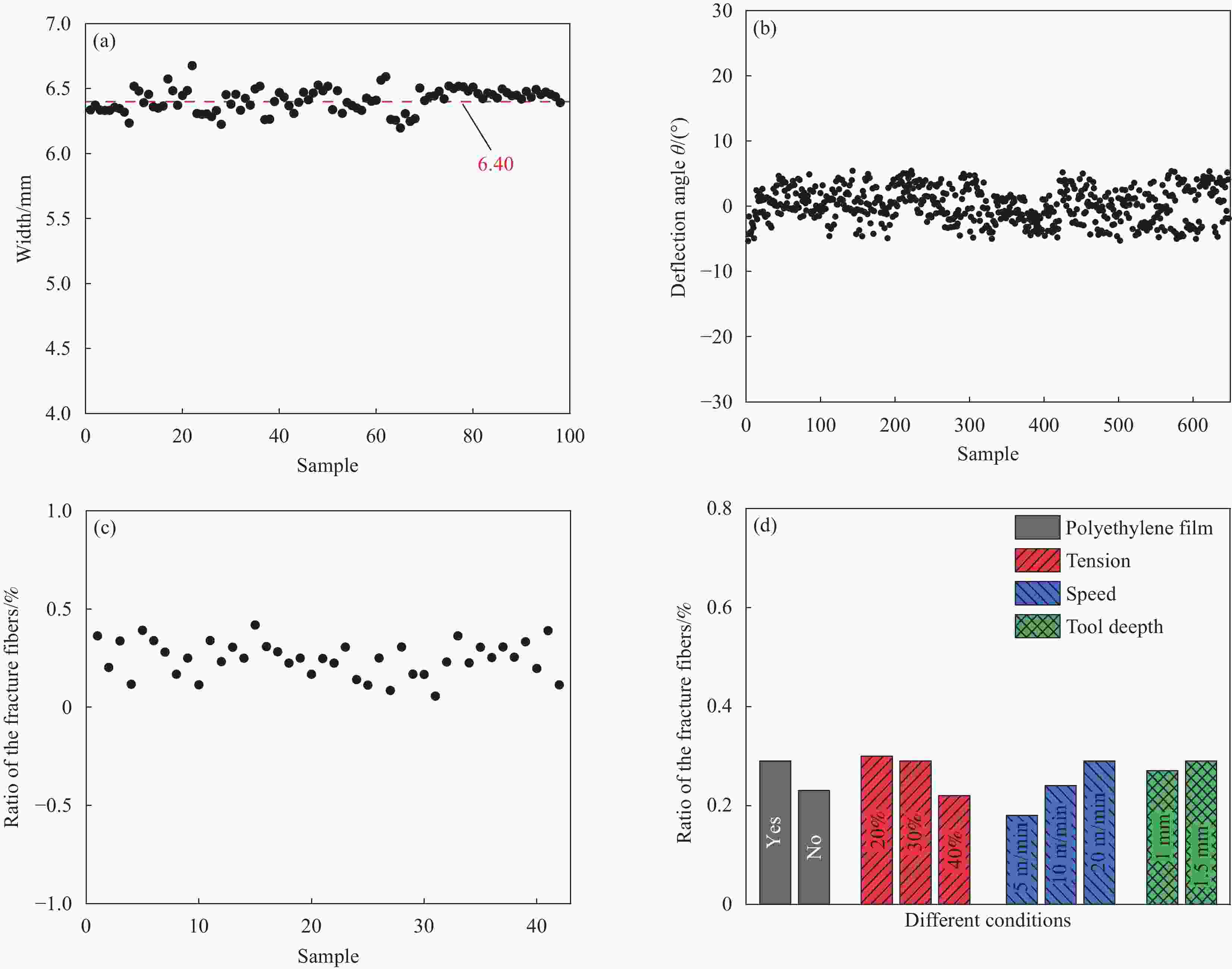

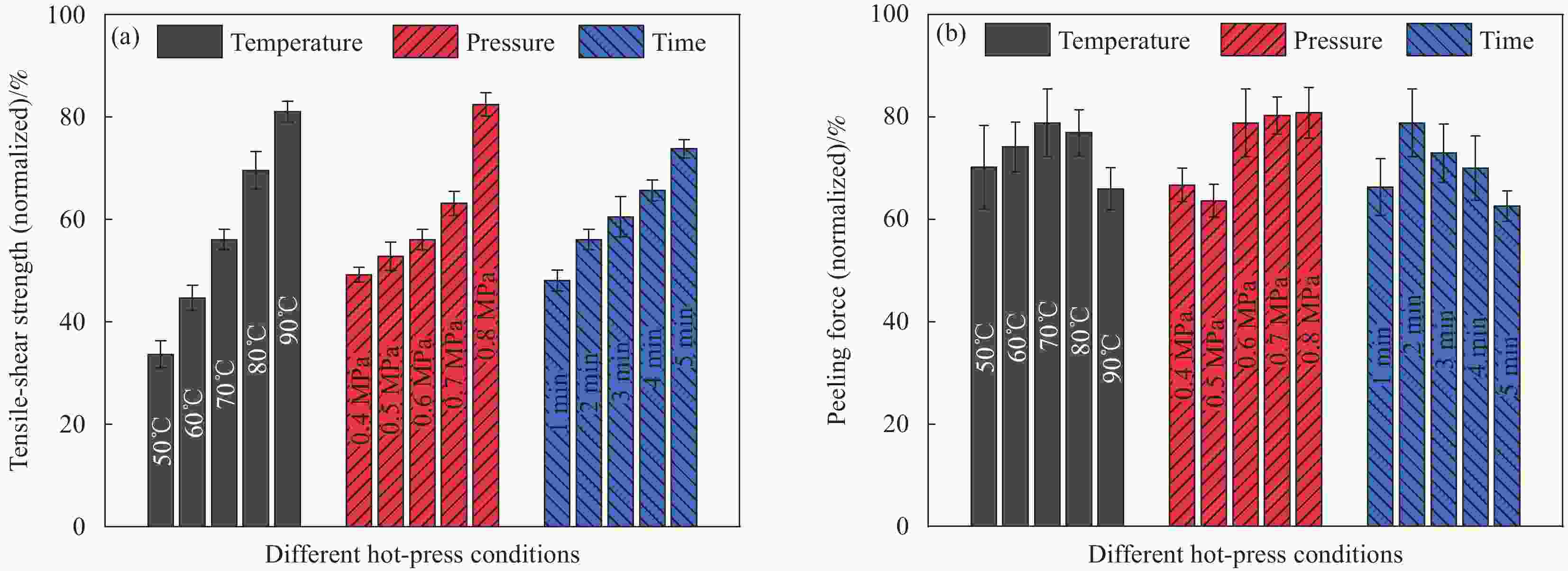

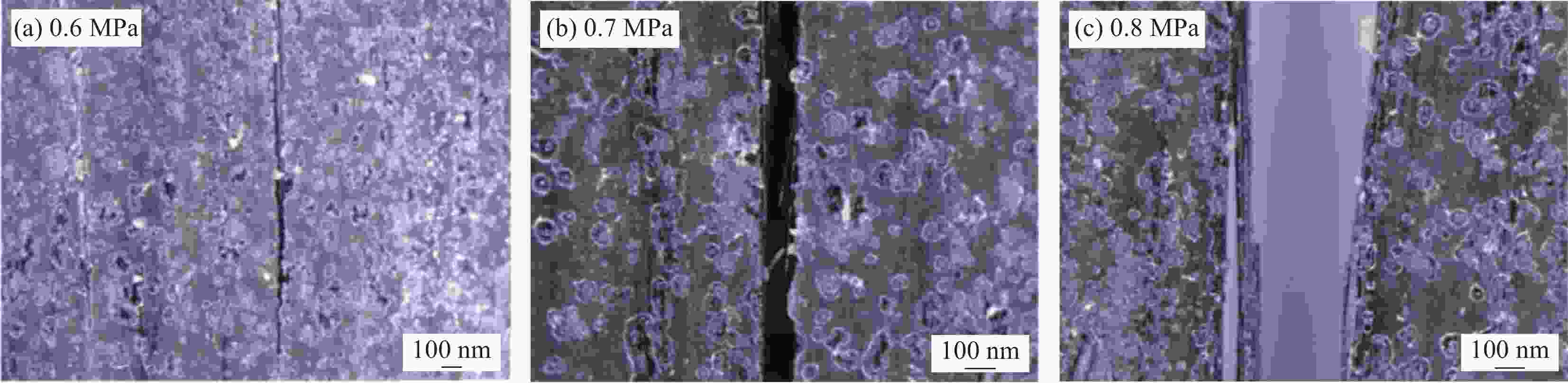

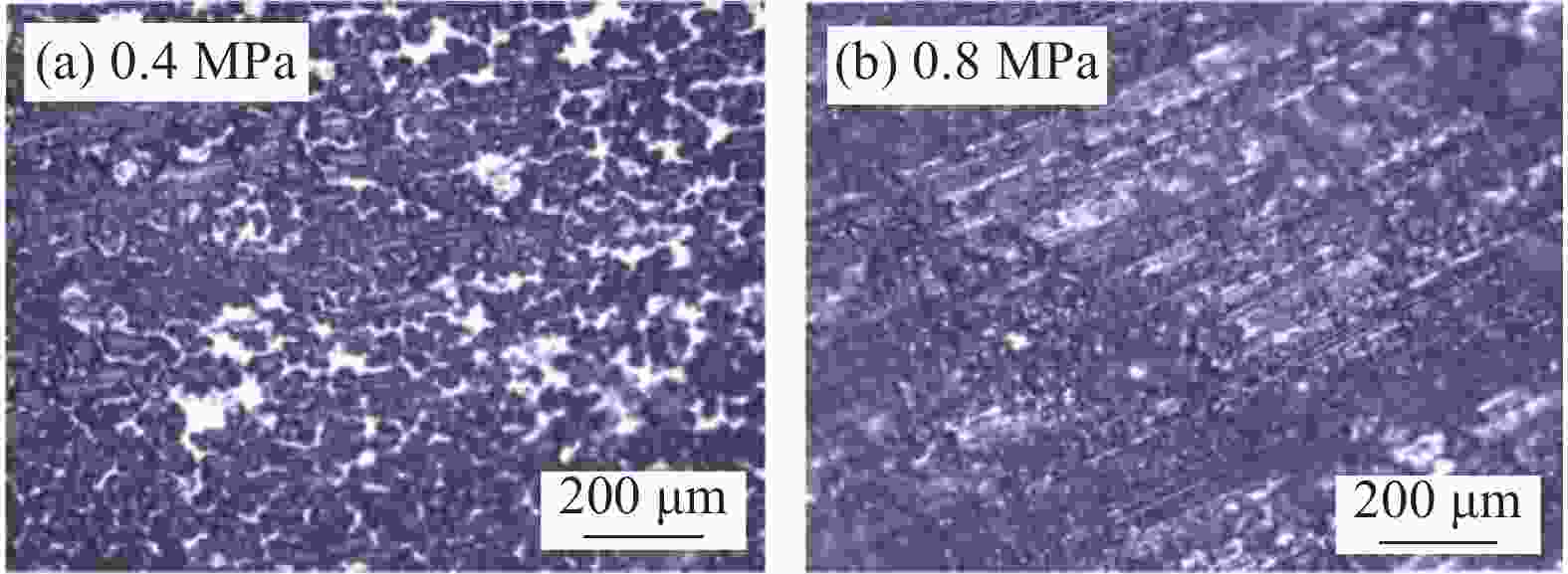

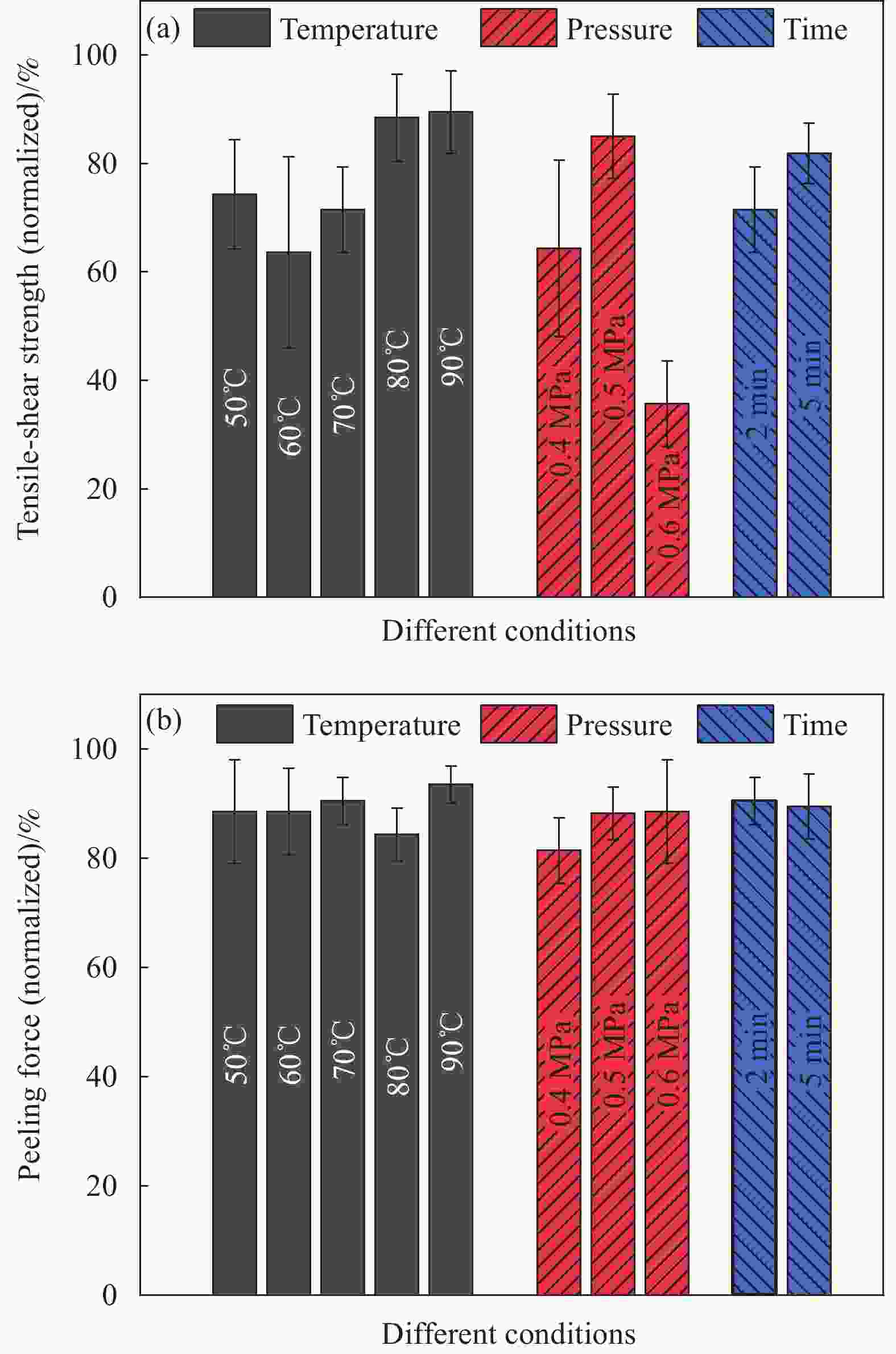

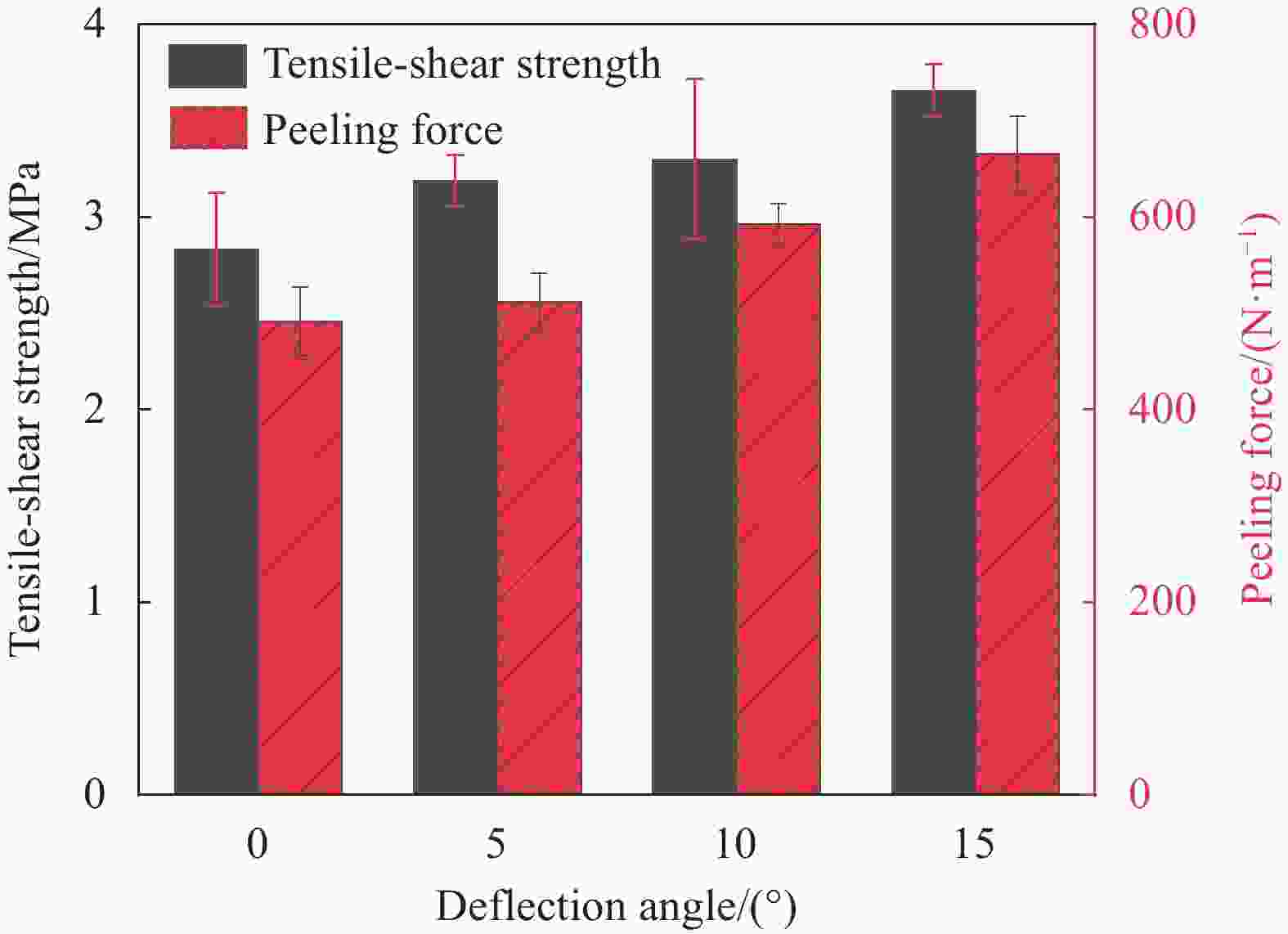

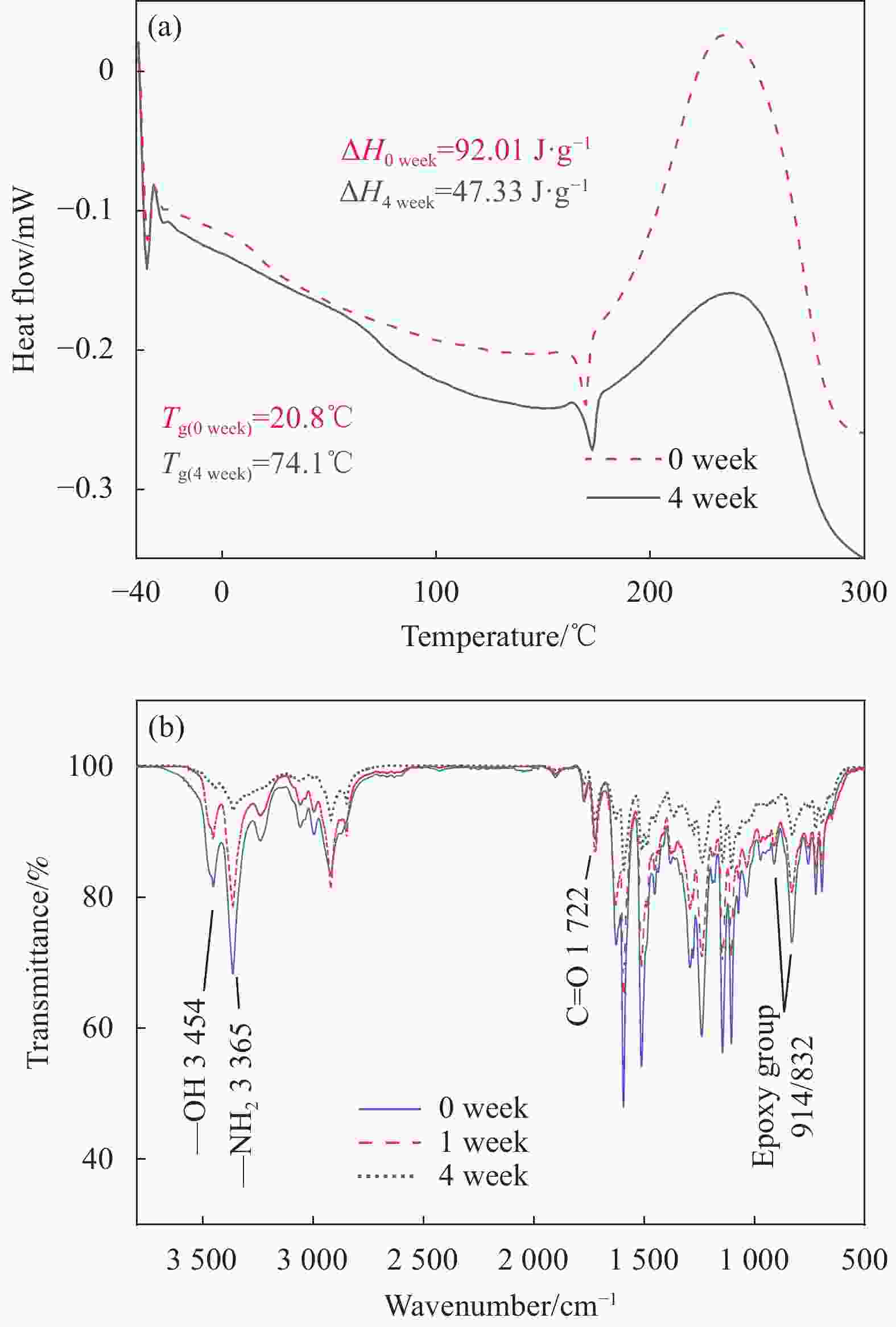

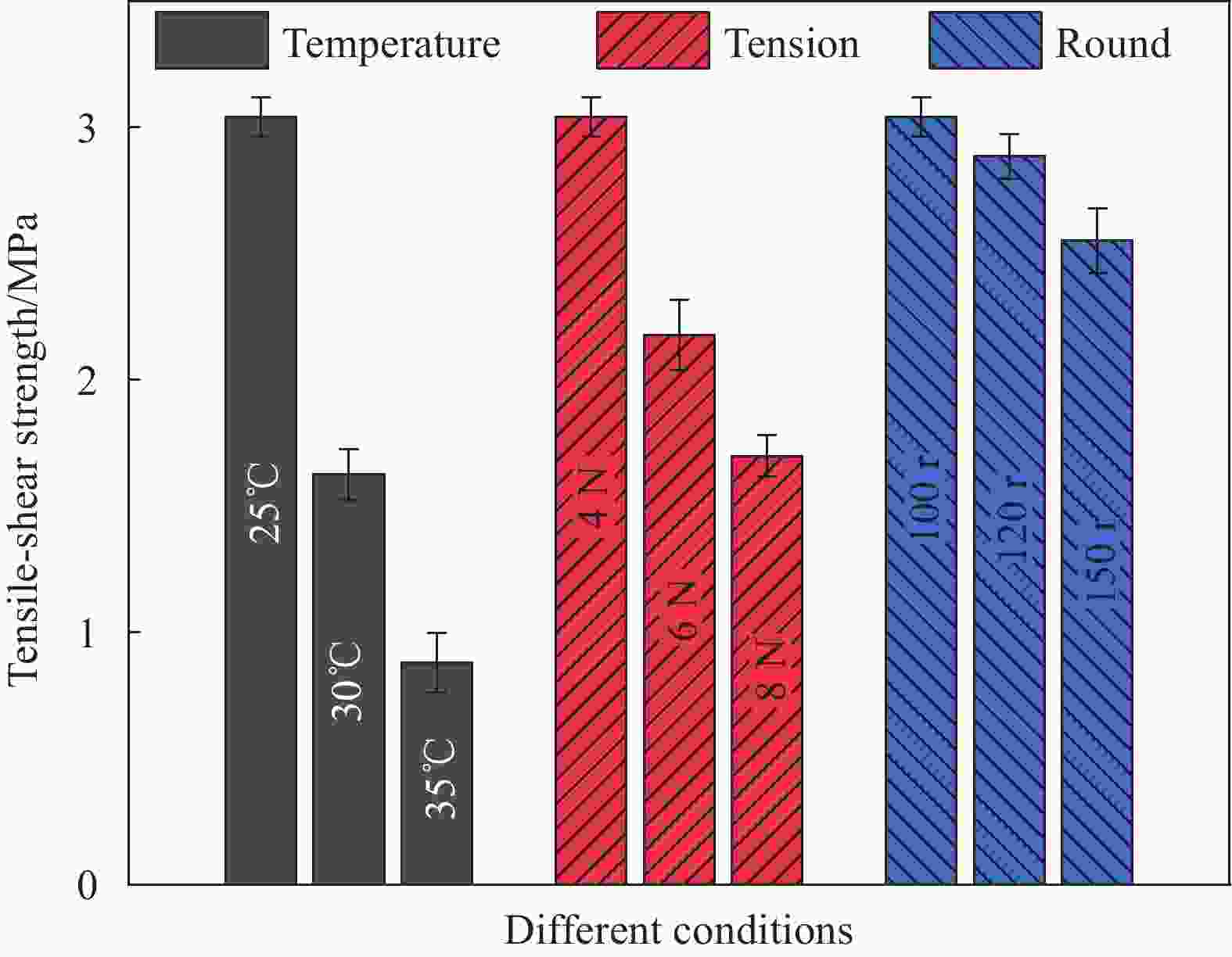

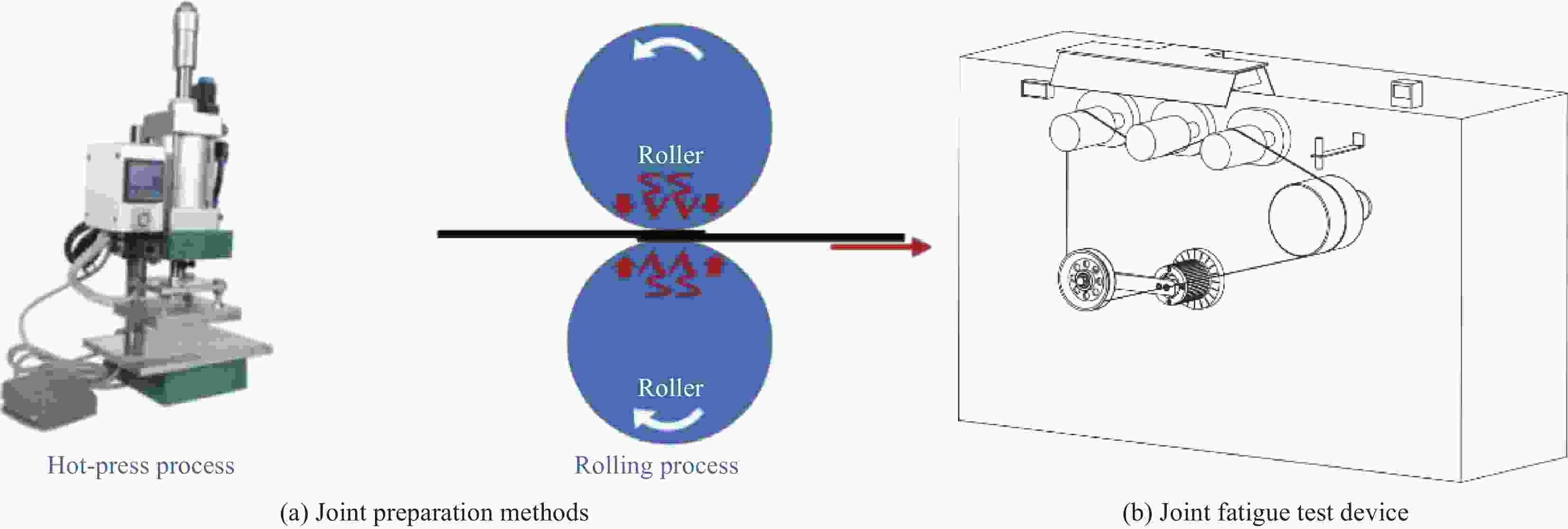

摘要: 近年来随着自动铺丝技术的快速发展和应用,对预浸窄带的需求量增加,但国内研究人员对有关预浸窄带质量的评价体系和分析方法尚未形成统一共识。本文采用多种方法对预浸窄带的质量进行了全面分析。通过图像法及称重法分析发现,国产窄带的宽度均匀性、接头处纤维平齐度、边缘断丝情况等分切质量均控制较好。研究了间歇式热压工艺和连续式辊压工艺对窄带接头质量的影响,通过拉剪强度和剥离强度分析发现,压接工艺温度和时间是影响其力学的关键因素,对比而言辊压工艺制得的接头性能较热压工艺具有更好的稳定性。同时,接头性能也受测试环境影响,其中环境湿度的作用大于温度。随着室温储存时间延长,窄带接头的力学性能先上升后下降,通过差热分析和红外光谱分析发现,这与界面处树脂的化学反应和固化程度增长密切相关。最后,对接头反复过辊后的疲劳损伤分析表明,接头处的拉剪强度随过辊温度、张力及圈数增加而下降。Abstract: In recent years, with the rapid development and application of automated fiber placement (AFP), the demand for prepreg tow has increased considerably. However, no consensus has been achieved on the evaluation system including the analysis method of the quality of prepreg tows in domestic. In this paper, the quality of prepreg slitting tows had been comprehensively analyzed by systematic methods. It was found that the slitting qualities of the domestic prepreg tows, including the width uniformity, the paralleling degree of fibers at the joint and the fiber fracture at the edge were all well controlled by using image and weight analysis. Effect of preparation methods, namely discontinuous hot-press process and continuous rolling process, on the quality of tow joint was investi-gated through the tensile-shear strength and peeling force testing. The results show that the process temperature and the time of duration are the key factors. In contrast, the joints made by continuous rolling process have more stable mechanical properties than those prepared by hot-press process. Meanwhile, the joint performance is impacted by the environmental conditions, wherein the humidity has more significant influence than the test temperature. With the prolongation of storage at room temperature, the mechanical properties of the joints first increased and then decreased. The DSC and IR characterization indicates that the property changes relate closely to chemical reactions and increasing curing degree of the resin matrix at the interface. The fatigue performance of the joint was tested by repeated roller passing and subsequent damage analysis. It reveals that the tensile-shear strengths of the fatigued joints decrease with increasing roller temperature, higher tension and more turns.

-

图 3 窄带分切质量的超景深显微图像:((a), (b)) 窄带宽度;((c), (d)) 边缘切断情况;((e), (f)) 接头处纤维偏转角

Figure 3. Ultra depth of field microscopic images for characterizing the prepreg slitting quality: ((a), (b)) Width analysis of the prepreg tow; ((c), (d)) Fracture fibers at the tow edge; ((e), (f)) Deflection angles between fibers at the joints

表 1 不同接头制备工艺的工艺参数设置

Table 1. List of different parameters from different methods for the fabrication of prepreg joint

Process Group set Time/min Temperature/℃ Pressure/MPa Hot-press process Constant temperature and pressure 1, 2, 3, 4, 5 70 0.6 Constant time and pressure 2 50, 60, 70, 80, 90 0.6 Constant time and temperature 2 70 0.4, 0.5, 0.6, 0.7, 0.8 Rolling process Constant temperature and pressure 2,5 70 0.6 Constant time and pressure 2 50, 60, 70, 80, 90 0.6 Constant time and temperature 2 70 0.4, 0.5, 0.6 -

[1] QURESHI Z, SWAIT T, SCAIFE R, et al. In situ consolidation of thermoplastic prepreg tape using automated tape placement technology: Potential and possibilities[J]. Composites Part B: Engineering,2014,66:255-267. [2] ZHANG L, WANG X, PEI J, et al. Review of automated fibre placement and its prospects for advanced composites[J]. Journal of Materials Science,2020,55(3):7121-7155. [3] SUN S Z, HAN Z Y, FU H Y, et al. Defect characteristics and online detection techniques during manufacturing of FRPs using automated fiber placement: A review[J]. Polymers,2020,12(6):1337. doi: 10.3390/polym12061337 [4] LI X Q, HALLETT, STEPHEN R W, et al. Modelling the effect of gaps and overlaps in automated fibre placement (AFP)-manufactured laminates[J]. Science and Engineering of Composite Materials,2015,22(2):115-129. doi: 10.1515/secm-2013-0322 [5] SREEHARI R, MICHAEL A S, SUBRAMANI S, et al. Simulations and experiments for automated fiber placement of prepreg slit tape: Wrinkle formation and fundamental observations[J]. Composites Part B: Engineering,2020,201:108287. [6] KERMANI N N, GARGITTER V, SIMACEK P, et al. Gap filling mechanisms during the thin ply automated tape placement process[J]. Composites Part A: Applied Science and Manufacturing,2021,147(3):106454. [7] 徐建, 李峰, 闫鸿琛, 等. 不同纤维面重预浸丝束分切工艺探索及优化[C]//第二十一届全国复合材料学术会议(NCCM-21)论文集. 呼和浩特: 中国航空学会, 2020: 79-82.XU Jian, LI Feng, YAN Hongchen, et al. Research on slitting of prepreg with different fiber areal weights and preparation optimization of prepreg tow[C]//National Conference on Composite Materials-21. Huhhot: Chinese Society of Aeronautics and Astronautics, 2020: 79-82(in Chinese). [8] MATSUMOTO T. Manufacture of tow prepreg for manufacture of pressure vessel, involves impregnating resin to tow using metering pumps to drive tow, hardening agent in preset content rate, and resin having preset viscosity at specified temperature: Japan, C08 J, JP2015098556[P]. 2018-07-17. [9] 张洋, 钟翔屿, 包建文. 先进树脂基复合材料自动丝束铺放技术研究现状及发展方向[J]. 航空制造技术, 2013(23):131-136, 140. doi: 10.3969/j.issn.1671-833X.2013.23.026ZHANG Yang, ZHONG Xiangyu, BAO Jianwen. Research status and future trend of automated fiber placement technology for advanced polymer matrix composites[J]. Aeronautical Manufacturing Technology,2013(23):131-136, 140(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.23.026 [10] 丁韬. 自动纤维铺放机[J]. 航空制造技术, 2007(9):60-64. doi: 10.16080/j.issn1671-833x.2007.09.007DING Tao. Automatic fiber laying machine[J]. Aeronauti-cal Manufacturing Technology,2007(9):60-64(in Chinese). doi: 10.16080/j.issn1671-833x.2007.09.007 [11] 孙天峰, 文立伟, 肖军, 等. 碳纤维预浸料自动分切复卷系统设计与研究[J]. 航空制造技术, 2015(16):66-70, 81. doi: 10.16080/j.issn1671-833x.2015.16.066SUN Tianfeng, WEN Liwei, XIAO Jun, et al. Design and research on automatic slitting and rewinding mechanism of carbon fiber prepreg[J]. Aeronautical Manufacturing Technology,2015(16):66-70, 81(in Chinese). doi: 10.16080/j.issn1671-833x.2015.16.066 [12] WEN L W, ZHU T F, QIN L H, et al. Deviation-rectifying control of carbon fiber prepreg slitting and winding machine[J]. Transactions of Nanjing University of Aeronautics & Astronautics,2018,35(3):547-555. [13] 陈思阳, 贾艳荣, 刘佳, 等. 自动化铺放材料的工艺性评价1-定性评价[J]. 纤维复合材料, 2021, 38(3):52-55. doi: 10.3969/j.issn.1003-6423.2021.03.011CHENG Siyang, JIA Yanrong, LIU Jia, et al. The process properties evaluation of automatic laying materials 1-Qualitative evaluation[J]. Fiber Composites,2021,38(3):52-55(in Chinese). doi: 10.3969/j.issn.1003-6423.2021.03.011 [14] TINO O. Fiber placement machine platform system having interchangeable head and creel assemblies: USA, US20090095410A1[P]. 2012-04-10. [15] 黄志军, 王显峰, 戴振东, 等. 自动铺放过程双马树脂预浸料温度与黏度[J]. 复合材料学报, 2012, 29(3):49-53. doi: 10.13801/j.cnki.fhclxb.2012.03.016HUANG Zhijun, WANG Xianfeng, DAI Zhendong, et al. Temperature and viscosity of bismaleimide resin prepregs in automated tape laying process[J]. Acta Materiae Compositae Sinica,2012,29(3):49-53(in Chinese). doi: 10.13801/j.cnki.fhclxb.2012.03.016 [16] GUTOWSKI T G, BONHOMME L. The mechanics of prepreg conformance[J]. Journal of Composite Materials,1988,22(3):204-223. doi: 10.1177/002199838802200301 [17] 严飙, 肖军, 文立伟, 等. 预浸带的快速热压接技术及其搭接性能研究[J]. 航空学报, 2012, 33(8):1554-1560.YAN Biao, XIAO Jun, WEN Liwei, et al. Study on hot-press fast-bonding technology for prepreg winding and its lap jointing performance[J]. Acta Aeronautica et Astronautica Sinica,2012,33(8):1554-1560(in Chinese). [18] SHI Y, TAO Y, ZHANG Y, et al. Research on hot-press splicing technology for composite prepreg tape[C]//International Conference on Innovative Design & Manufacturing. Montreal: IEEE, 2014: 143-148. [19] 史耀耀, 赵盼, 俞涛, 等. 一种基于滚轮的复合材料预浸胶带热压搭接装置: 中国, CN 201310188183. X[P]. 2013-08-14.SHI Yaoyao, ZHAO Pan, YU Tao, et al. Composite material pre-impregnation rubber belt hot-pressing and lapping device based on rollers: China, CN 103240877A[P]. 2013-08-14(in Chinese) [20] 黄晓川, 张建宝, 赵文宇, 等. 网格铺丝用预浸丝分切性能研究[J]. 航空制造技术, 2019, 62(4):75-78, 86. doi: 10.16080/j.issn1671-833x.2019.04.075HUANG Xiaochuan, ZHANG Jianbao, ZHAO Wenyu, et al. Research on slitting property of prepreg tow applied in automated fiber placement for grid[J]. Aeronautical Manufacturing Technology,2019,62(4):75-78, 86(in Chinese). doi: 10.16080/j.issn1671-833x.2019.04.075 [21] RAJAN S, SUTTON M A, WEHBE R, et al. Characterization of viscoelastic bending stiffness of uncured carbon-epoxy prepreg slit tape[J]. Composite Structures,2021,275(5):114295. [22] BUDELMANN D, SCHMIDT C, MEINERS D, et al. Prepreg tack: A review of mechanisms, measurement, and manufacturing implication[J]. Polymer Composites,2020,41:3440-3458. doi: 10.1002/pc.25642 [23] CROSSLEY R J, SCHUBEL P J, WARRIOR N A, et al. The experimental determination of prepreg tack and dynamic stiffness[J]. Composites Part A: Applied Science and Manufacturing,2012,43(3):423-434. doi: 10.1016/j.compositesa.2011.10.014 [24] ASTM. Standard guide for strength properties of adhesives in shear by tension loading of single-lap-joint laminated assemblies: ASTM D3165[S]. West Conshohocken: ASTM International, 2014. [25] ASTM. Standard test method for peel resistance of adhe-sives (T-peel test): ASTM D1876[S]. West Conshohocken: ASTM International, 2015. [26] ASTM. Standard test method for strength properties of tissue adhesives in T-peel by tension loading: ASTM F2256[S]. West Conshohocken: ASTM International, 2003. -

下载:

下载: