Research on shape and force control technology for commercial aircraft CFRP fuselage panel assembly

-

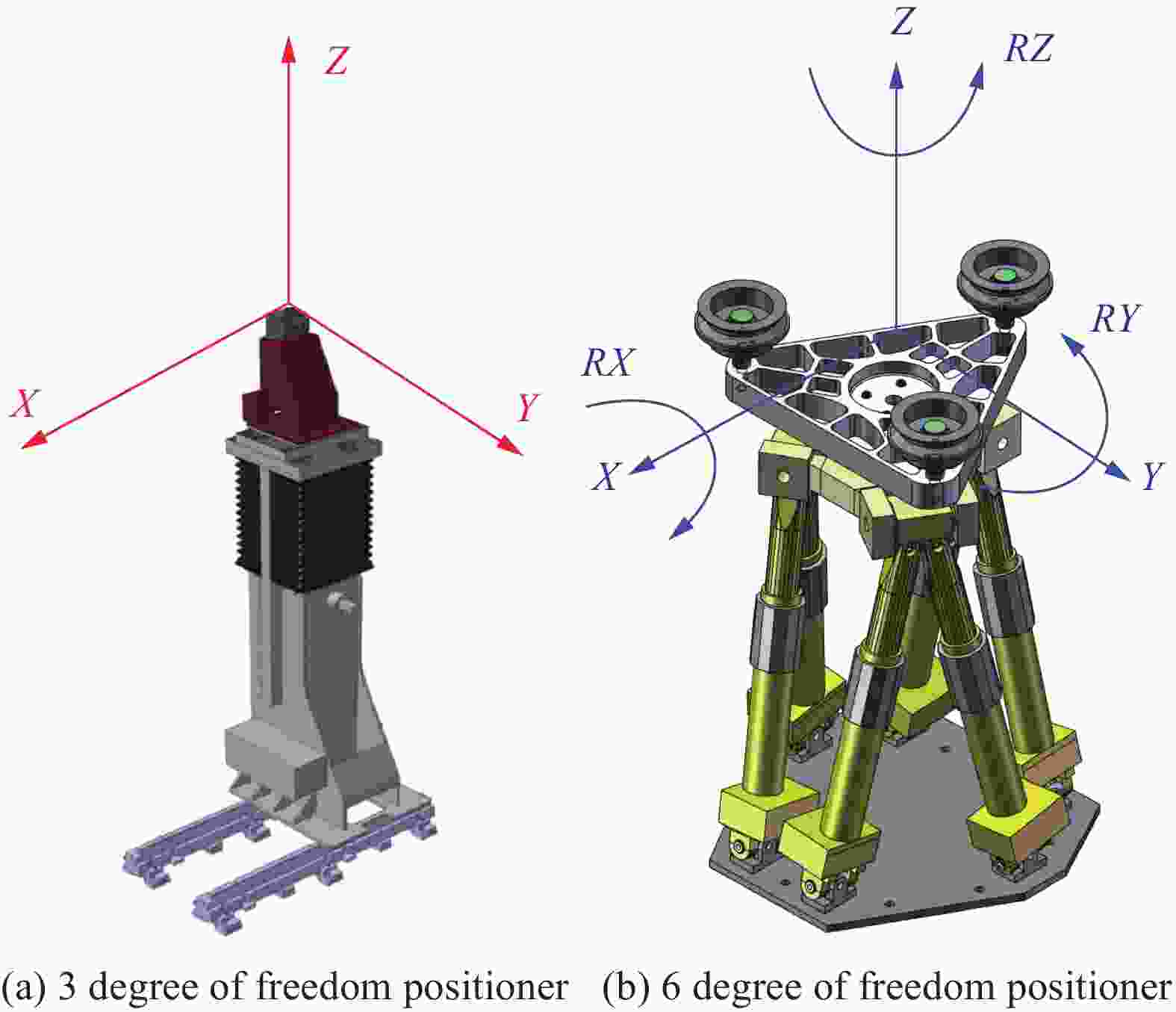

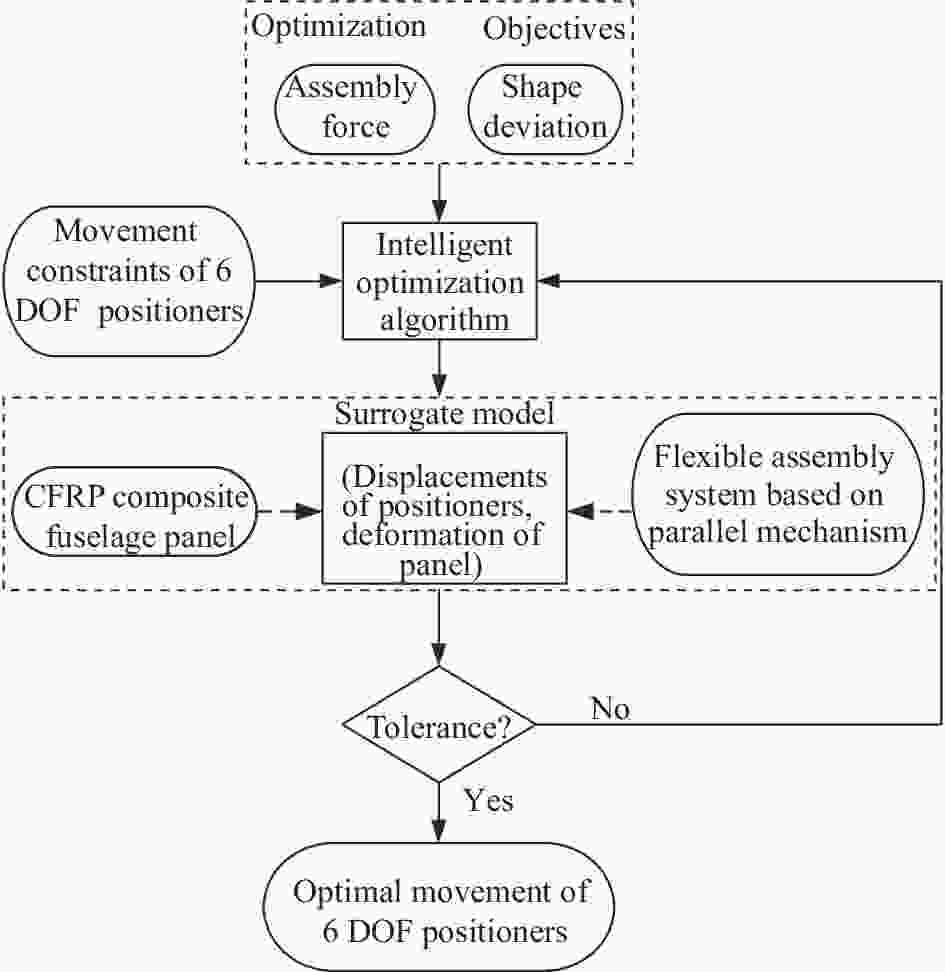

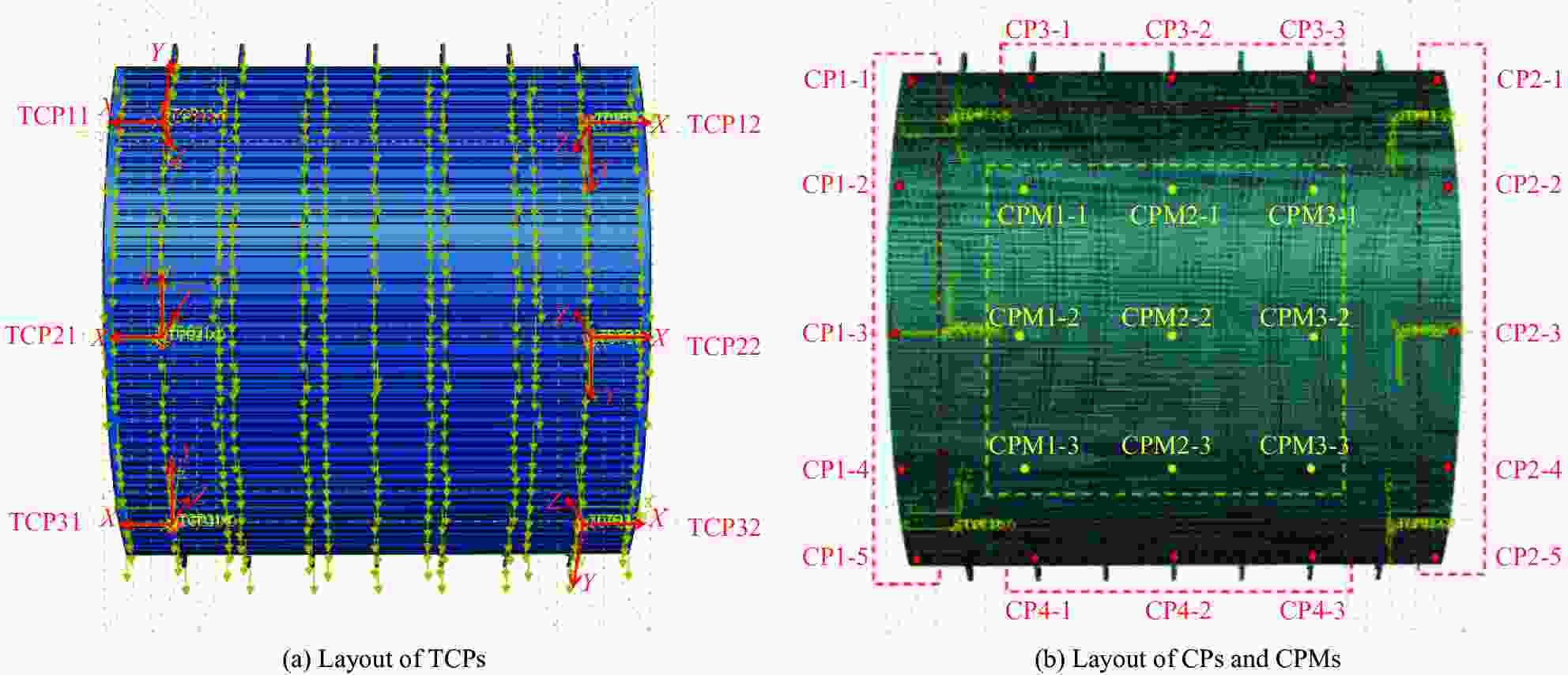

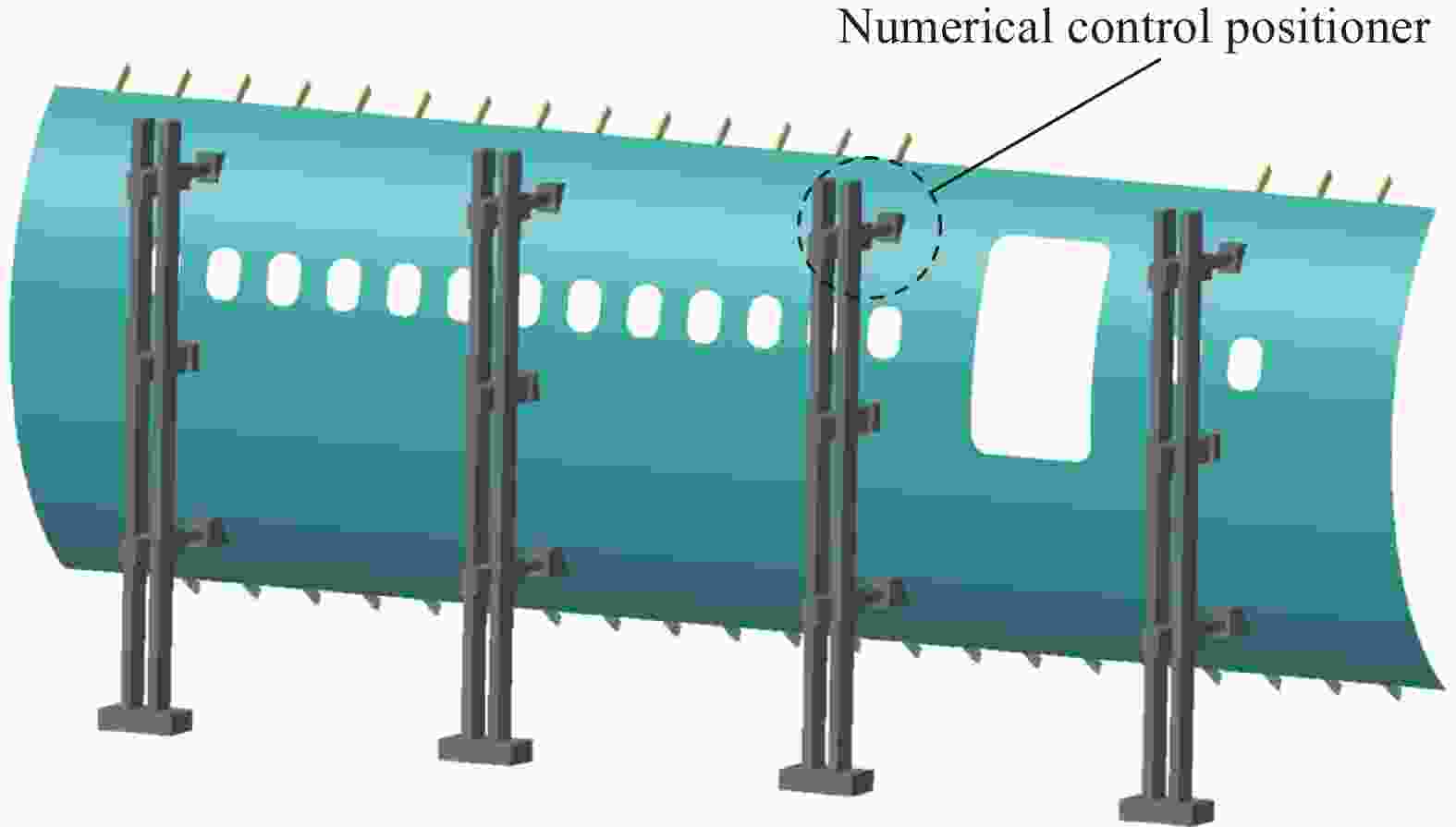

摘要: 为了更好地满足飞机安全性、经济性、舒适性和环保性的需求,以碳纤维增强树脂基复合材料为代表的轻质高强先进材料在新一代大型客机机体结构中得到了大量应用。复合材料机身壁板具有不同于传统金属材料机身壁板的装配工艺特点,因此,其对装配协调提出了新的要求。首先,概述了飞机复合材料机身壁板的制造工艺,分析了复合材料机身壁板装配协调技术现状与面临的问题。其次,探讨了适用于复合材料壁板的装配协调方法,并提出了一种面向复合材料机身壁板装配力形协同控制的全主动驱动柔性装配协调方法。最后,通过仿真和物理实验验证了该方法的有效性,实现了复合材料机身壁板力形协同优化控制。Abstract: In order to meet the requirements of safety, economy, comfortability, and environmental protection, high specific strength advanced material, represented by carbon fiber reinforced plastics (CFRP), has been widely used in the airframe of the new generation commercial aircraft. CFRP composite fuselage panels have different assembly characteristics in comparison with traditional metal fuselage panels, which put forward new requirements for aircraft assembly. This paper firstly summaries the manufacturing process of composite fuselage panel, and analyzes the current status and problems of composite fuselage panel assembly. Then, the methods in composite fuselage panel assembly is discussed, and a fully-active-drive flexible assembly method for force/shape control of composite fuselage panel assembly is proposed. Finally, the feasibility and effectiveness of the proposed method are verified by simulation and physical experiments, with optimized control of force/shape control reached.

-

Key words:

- CFRP /

- commercial aircraft fuselage panel /

- aircraft assembly /

- flexible tooling /

- force/shape control

-

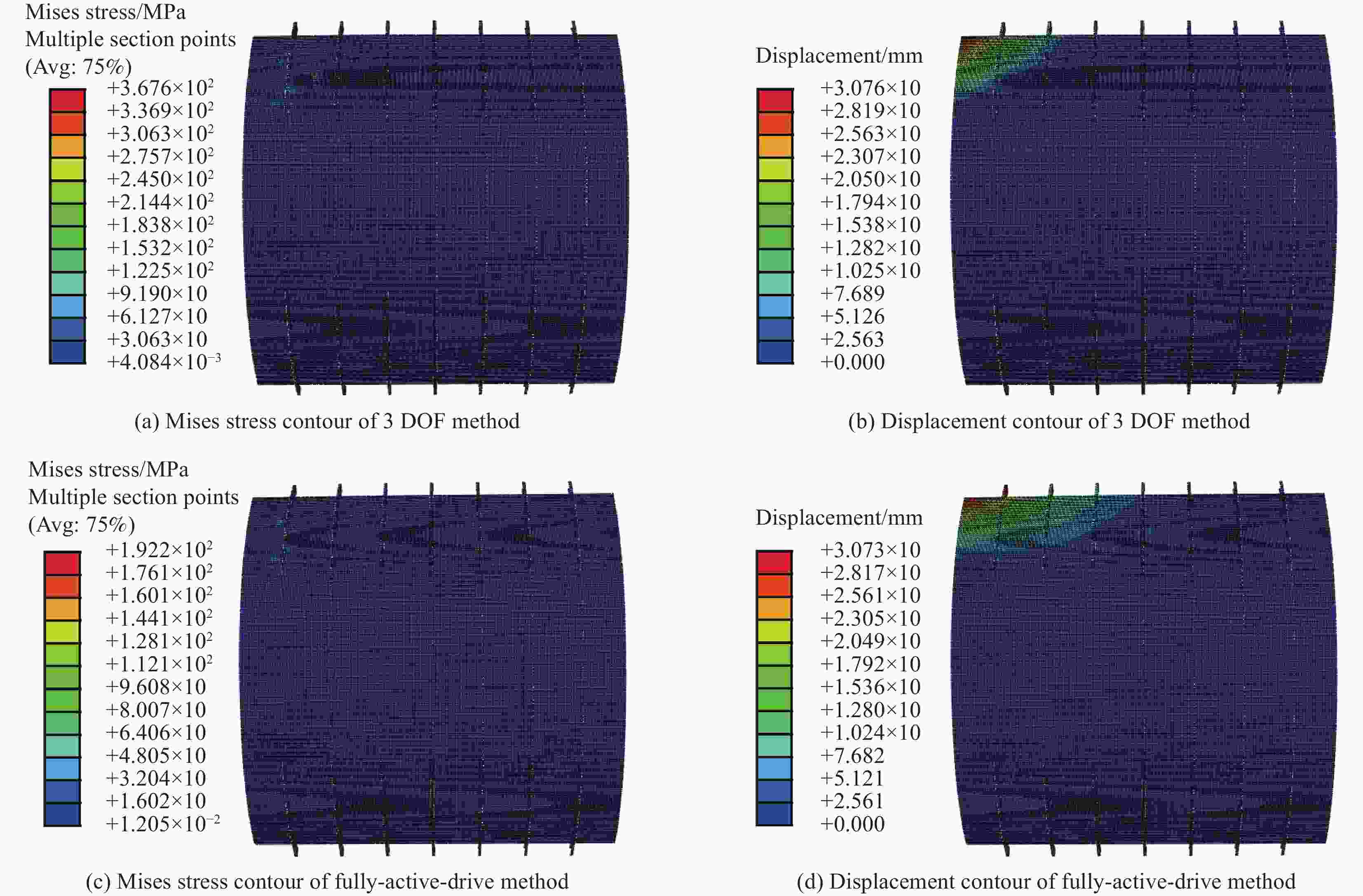

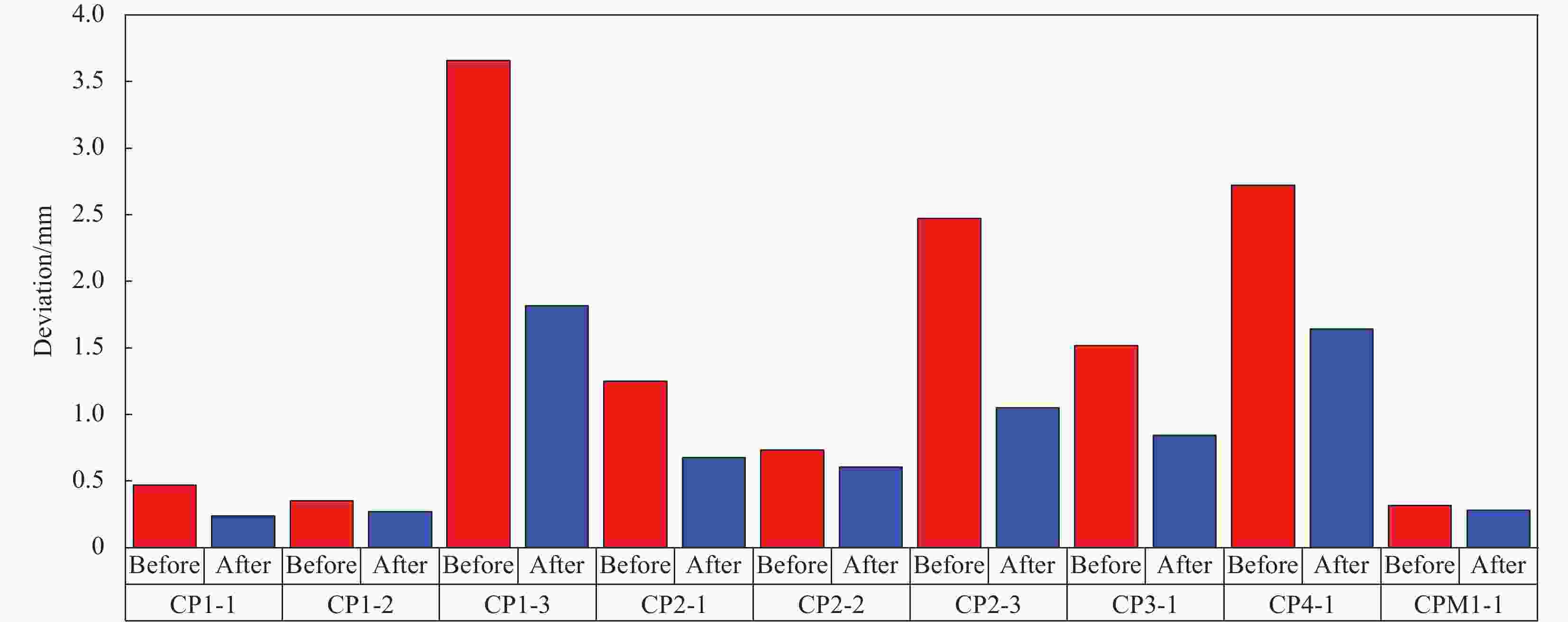

表 1 不同装配协调方法下有限元法(FEM)计算结果

Table 1. Finite element method (FEM) simulation results with different assembly method

Max

displacement/mmMax mises

stress/MPaFailure

index3 DOF 30.7567 367.6460 0.322 6 DOF 30.7280 192.2145 0.136 表 2 装配协调过程中各定位器装配力传感器数据

Table 2. Data of force sensors on positioners in assembly process

Positioner $\Delta {F_x}/{\text{N}}$ $ \Delta {F_y}/{\text{N}} $ $\Delta {F_{\textit{z}}}/{\text{N} }$ $\Delta {T_x}/{\text{N}} \cdot {\text{m}}$ $\Delta {T_y}{\text{/N}} \cdot {\text{m}}$ $\Delta {T_{\textit{z}}}/{\text{N} } \cdot {\text{m} }$ TCP11 −41.961 19.624 3.165 −3.337 12.919 −5.618 TCP12 10.282 39.851 −26.376 4.545 −12.102 2.291 TCP21 −7.256 9.540 48.994 −21.009 −10.124 −4.197 TCP22 −16.925 29.303 57.906 −14.923 9.543 3.445 TCP31 34.738 −47.685 −77.848 −18.173 1.637 5.339 TCP32 19.615 −35.563 −38.065 −14.636 −23.145 −2.430 Notes: $\Delta {F_x}$, $\Delta {F_y}$ and $\Delta {F_z}$—Variation of force in different directions; $\Delta {T_x}$, $\Delta {T_y}$ and $\Delta {T_z}$—Variation of torque in different directions. -

[1] NIU M C. 实用飞机复合材料结构设计与制造[M]. 程小全, 张纪奎, 译. 北京: 航空工业出版社, 2010: 2-4.NIU M C. Composite airframe structures[M]. CHENG Xiaoquan, ZHANG Jikui, translated. Beijing: Aviation Industry Press, 2010: 2-4(in Chinese). [2] 范玉青, 张丽华. 超大型复合材料机体部件应用技术的新进展−飞机制造技术的新跨越[J]. 航空学报, 2009, 30(3):534-543. doi: 10.3321/j.issn:1000-6893.2009.03.022FAN Yuqing, ZHANG Lihua. New development of extra large composite aircraft components application technology—Advance of aircraft manufacture technology[J]. Acta Aeronautica et Astronautica Sinica,2009,30(3):534-543(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.03.022 [3] 吴志恩. A350的复合材料构件制造[J]. 航空制造技术, 2013, 433(13):32-35. doi: 10.3969/j.issn.1671-833X.2013.13.003WU Zhien. Composite material components manufacturing in A350[J]. Aeronautical Manufacturing Technology,2013,433(13):32-35(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.13.003 [4] 杨乃宾, 梁伟. 大飞机复合材料结构设计导论[M]. 北京: 航空工业出版社, 2009: 94-97.YANG Naibin, LIANG Wei. Introduction to composite structural design for larger aircraft[M]. Beijing: Aviation Industry Press, 2009: 94-97(in Chinese). [5] COLEMAN R M. The effects of design, manufacturing processes and operations management on the assembly of aircraft composite structure[D]. Cambridge: Massachusetts Institute of Technology, 1991. [6] 翟雨农. 翼面类复合材料壁板装配连接理论及应力分析方法研究[D]. 北京: 北京航空航天大学, 2017.ZHAI Yunong. Research on joining theory and stress analytical method for composite wing panel assembly[D]. Beijing: Beihang University, 2017(in Chinese). [7] 王永军, 何俊杰, 元振毅, 等. 航空先进复合材料铺放及缝合设备的发展及应用[J]. 航空制造技术, 2015, 483(14):38-43.WANG Yongjun, HE Junjie, YUAN Zhenyi, et al. Development and application of placement and stitching equipments of aeronautical advanced composites[J]. Aeronautical Manufacturing Technology,2015,483(14):38-43(in Chinese). [8] 张朝晖, 周旗. 自动化设备和生产线在飞机复合材料零件制造中的应用[J]. 航空制造技术, 2013, 15:51-54. doi: 10.3969/j.issn.1671-833X.2013.15.008ZHANG Chaohui, ZHOU Qi. Application of automated equipments and production lines in aircraft composites parts manufacturing[J]. Aeronautical Manufacturing Technology,2013,15:51-54(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.15.008 [9] 常荣福. 飞机钣金零件制造技术[M]. 北京: 国防工业出版社, 1992: 43-71.CHANG Rongfu. Aircraft sheet metal parts manufacturing technology[M]. Beijing: National Defense Industry Press, 1992: 43-71(in Chinese). [10] 国防科学技术工业委员会. 复合材料件一般公差: HB7741—2004[S]. 北京: 中华人民共和国航空工业部, 2004.Technology and Industry for National Defense of China. General tolerances for composite parts: HB7741—2004[S]. Beijing: People ’s Republic of China Ministry of Aviation Industry, 2004(in Chinese). [11] 杨乃宾. 新一代大型客机复合材料结构[J]. 航空学报, 2008, 29(3):596-604. doi: 10.3321/j.issn:1000-6893.2008.03.010YANG Naibin. Composite structures for new generation large commercial jet[J]. Acta Aeronautica et Astronautica Sinica,2008,29(3):596-604(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.010 [12] 常仕军, 肖红, 侯兆珂, 等. 飞机复合材料结构装配连接技术[J]. 航空制造技术, 2010(6):96-99. doi: 10.3969/j.issn.1671-833X.2010.06.023CHANG Shijun, XIAO Hong, HOU Zhaoke, et al. Assembly and fastening technology for composites structure in aircraft[J]. Aeronautical Manufacturing Technology,2010(6):96-99(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.06.023 [13] 薛红前. 飞机装配工艺学[M]. 西安: 西北工业大学出版社, 2015: 92-93.XUE Hongqian. Aircraft assembly technology[M]. Xi’an: Northwestern Polytechnical University Press, 2015: 92-93(in Chinese). [14] 邱宏俊, 陶华, 高晓兵. 飞机数字化装配若干问题思考[J]. 航空制造技术, 2006(10):50-54. doi: 10.3969/j.issn.1671-833X.2006.01.007QIU Hongjun, TAO Hua, GAO Xiaobing. Considerations in aircraft digital assembly[J]. Aeronautical Manufacturing Technology,2006(10):50-54(in Chinese). doi: 10.3969/j.issn.1671-833X.2006.01.007 [15] WEN Y C, YUE X W, HUNT J H, et al. Feasibility analysis of composite fuselage shape control via finite element analysis[J]. Journal of Manufacturing Systems,2018,46:272-281. doi: 10.1016/j.jmsy.2018.01.008 [16] HUNT J H, WALLS S A, WHELAN D A. Fuselage manufacturing system: USA, US0074926 A1[P]. 2016-3-17. [17] ARISTA R, FALGARONE H. Flexible best fit assembly of large aircraft components. Airbus A350 XWB case study[M]//RIOS J. IFIP Advances in Information and Communication Technology. Cham: Springer International Publishing AG, 2017: 152-161. [18] FETTE M, SCHWAKE K, WULFSBERG J et al. Use of an innovate modular gripper system for flexible aircraft assembly operations: SAE Technical Paper 2016-01-2108[R]. Bremen: SAE International, 2016. [19] SCHWAKE K, WULFSBERG J. Robot-based system for handling of aircraft shell parts[J]. Procedia CIRP,2014,23:104-109. doi: 10.1016/j.procir.2014.10.081 [20] MULLER R, ESSER M, VETTE M. Reconfigurable handling systems as an enabler for large components in mass customized production[J]. Journal of Intelligent Manufacturing,2013,24:977-990. doi: 10.1007/s10845-012-0624-y [21] MULLER R, ESSER M, JANBEN M, et al. Reconfigurable handling system[J]. Production Engineering-Research and Development,2011,5:453-461. doi: 10.1007/s11740-011-0321-2 [22] MULLER R, RIEDEL M, VETTE M, et al. Reconfigurable self-optimising handling system [M]//RATCHEV S. IFIP Advances in Information and Communication Technology. Cham: Springer International Publishing AG, 2010: 255-262. [23] RIEDEL M, NEFZI M, CORVES B. Grasp planning for a reconfigurable parallel robot with an underactuated arm structure[J]. Mechanical Sciences,2010,1:33-42. doi: 10.5194/ms-1-33-2010 [24] RAMIREZ J, WOLLNACK J. Flexible automated assembly system for large CFRP-structures[J]. Procedia Technology,2014,15:447-455. doi: 10.1016/j.protcy.2014.09.004 [25] SCHMITT R, JATZKOWSKI P, JANSSEN M, et al. Self-optimi-zation in large scale assembly[J]. Procedia Engineering,2013,63:843-851. doi: 10.1016/j.proeng.2013.08.236 [26] SCHMITT R, CORVES B, LOSSEN P, et al. Cognition-enhanced, self-optimizing assembly systems[M]. London: Springer, 2017: 877-990. [27] BERTELSMEIER F, DETERT T, UBELHOR T, et al. Cooperating robot force control for positioning and untwisting of thin walled components[J]. Advances in Robotics and Automation,2017,6(3):1-7. [28] 严伟苗. 大型飞机壁板装配变形控制与校正技术研究[D]. 杭州: 浙江大学, 2015.YAN Weimiao. Study on technologies for controlling and correcting large aircraft panel assembly deformation[D]. Hangzhou: Zhejiang University, 2015(in Chinese). [29] BI Y B, YAN W M, KE Y L. Numerical study on predicting and correcting assembly deformation of a large fuselage panel during digital assembly[J]. Assembly Automation,2014,34(2):204-216. doi: 10.1108/AA-04-2013-037 [30] 陈文亮, 潘国威, 王珉. 基于力位协同控制的大飞机机身壁板装配调姿方法[J]. 航空学报, 2019, 40(2):522403.CHEN Wenliang, PAN Guowei, WANG Min. High precision positioning method for aircraft fuselage panel based on force/position control[J]. Acta Aeronautica et Astronautica Sinica,2019,40(2):522403(in Chinese). [31] 张秋月, 安鲁陵, 岳烜德, 等. 基于遗传算法的飞机复合材料结构装配压紧力大小与布局的优化[J]. 复合材料学报, 2019, 36(6):1546-1557.ZHANG Qiuyue, AN Luling, YUE Xuande, et al. Optimization of size and layout of pressing force for composite airframe structure assembly based on genetic algorithm[J]. Acta Materiae Compositae Sinica,2019,36(6):1546-1557(in Chinese). [32] 潘国威, 陈文亮, 王珉. 应用于飞机装配的并联机构技术发展综述[J]. 航空学报, 2019, 40(1):522572.PAN Guowei, CHEN Wenliang, WANG Min. A review of parallel kinematic mechanism technology for aircraft assembly[J]. Acta Aeronautica et Astronautica Sinica,2019,40(1):522572(in Chinese). -

下载:

下载: