Research progress of ultrashort pulse laser precision machining fiber reinforced resin matrix composite materials

-

摘要: 纤维增强树脂基复合材料具有轻质量、高强度、耐腐蚀和抗疲劳等优点,被广泛地应用在航空航天、风电及汽车等领域。然而纤维树脂复合材料是各向异性的非均质材料,属于典型的难加工材料,现有的加工技术存在热影响区过大、分层、起毛等问题,成为航空航天工业领域的精密加工技术瓶颈。超短脉冲激光加工作为一种新型加工技术,具有无热传递、不受物质种类限制、微小尺度、可控性强、非接触等优点,有望实现纤维复合材料的精细加工。本文在介绍目前激光加工纤维复合材料研究工作的基础上,讨论了超短脉冲激光加工以碳纤维增强树脂基复合材料为主的纤维复合材料的作用机制和提高加工质量的几种方法,指出了以突破航天工业高精度加工技术瓶颈为目的的超短脉冲激光精细加工纤维增强树脂基复合材料的研究方向、内容和科学问题,为后续实现符合航天工业高精度及大尺度要求的精密加工提供了技术路线和可能的解决方案。

-

关键词:

- 超短脉冲激光 /

- 纤维增强树脂基复合材料 /

- 热影响区 /

- 微加工 /

- 冷切削

Abstract: Fiber reinforced resin matrix composites are widely used in aerospace, wind power and automobile industry due to the advantages of light weight, high strength, corrosion resistance, fatigue resistance etc. However, as heterogeneous anisotropic materials, fiber-reinforced composites are difficult to process. Traditional processing methods can lead to problems like excessive heat affected zone, delamination and fuzzing, which are difficult to meet the requirements of high-precision processing in the aeronautic and astronautic industry. As a new processing technique, ultrashort pulse laser processing has the advantages of micro scale, strong controllability, no material restriction and non-contact. It is expected to realize the high-precision processing of fiber composites. In this paper, on the basis of the current research on ultrafast laser processing carbon fiber reinforced polymer (CFRP) was reviewed, and the mechanisms of ultrafast laser processing CFRP and methods to improve the machining quality were discussed. Further, the research direction and content for the purpose of breaking through the bottleneck of high-precision machining technology in aerospace industry are prospected, which provides a technical route and possible solutions for precision machining meeting the high-precision and large-scale requirements of the aerospace industry. -

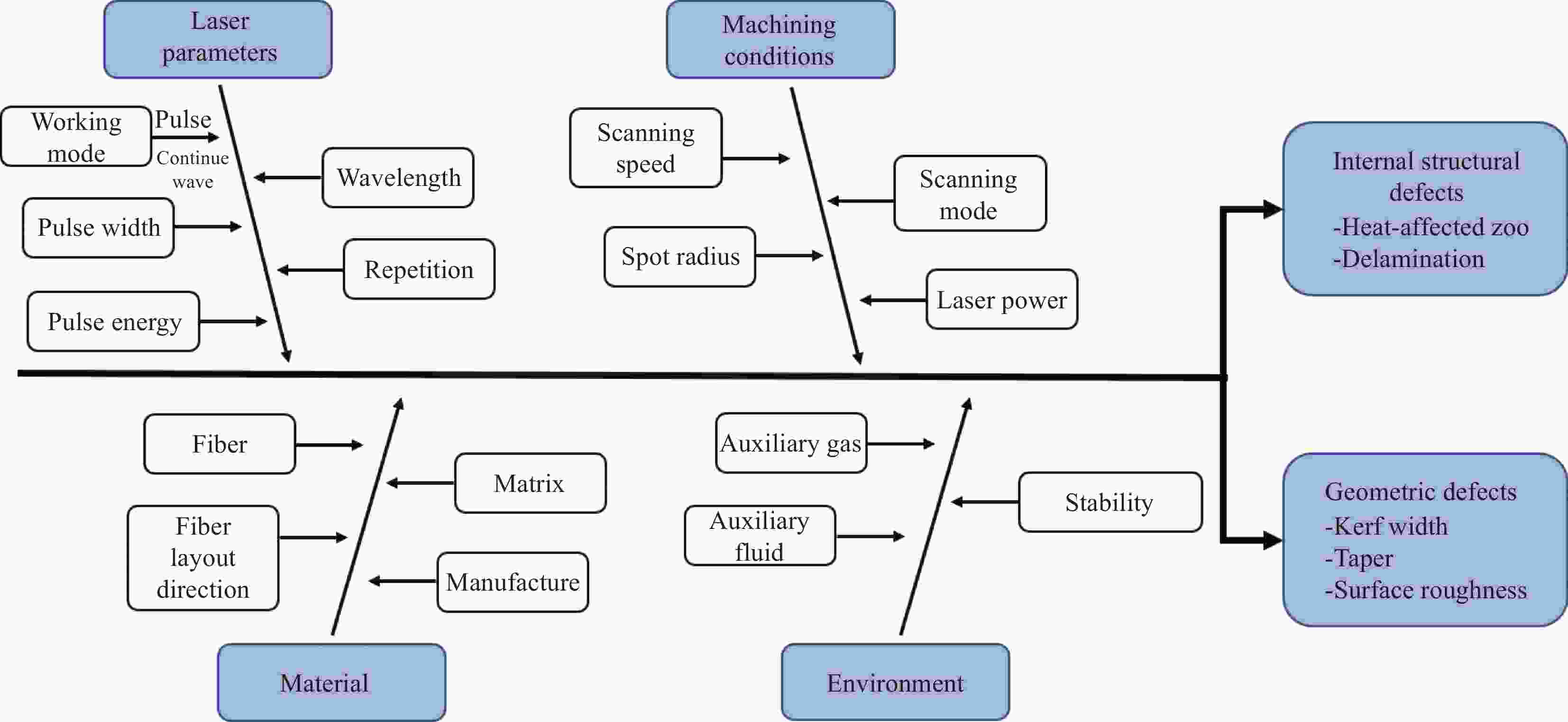

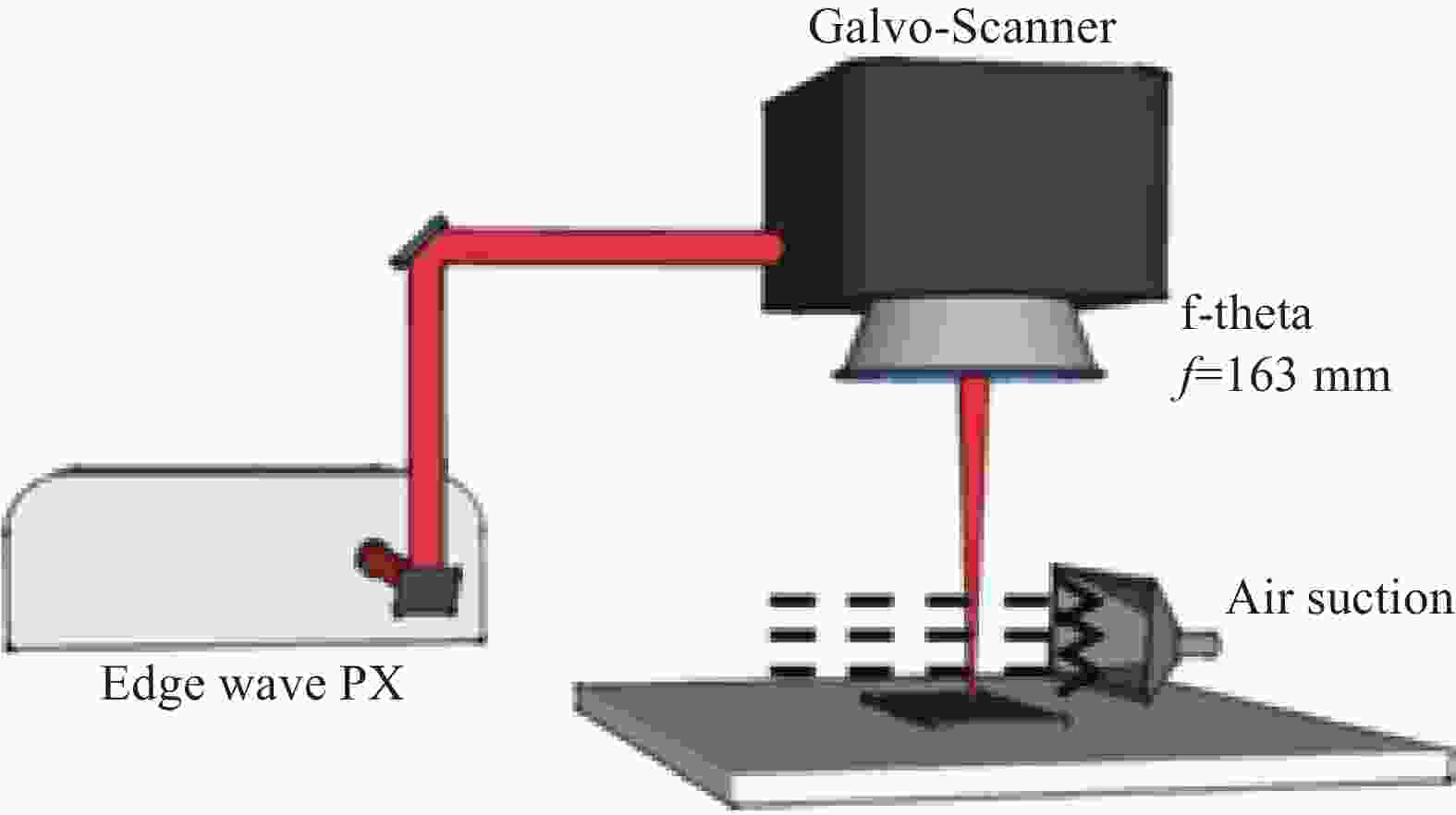

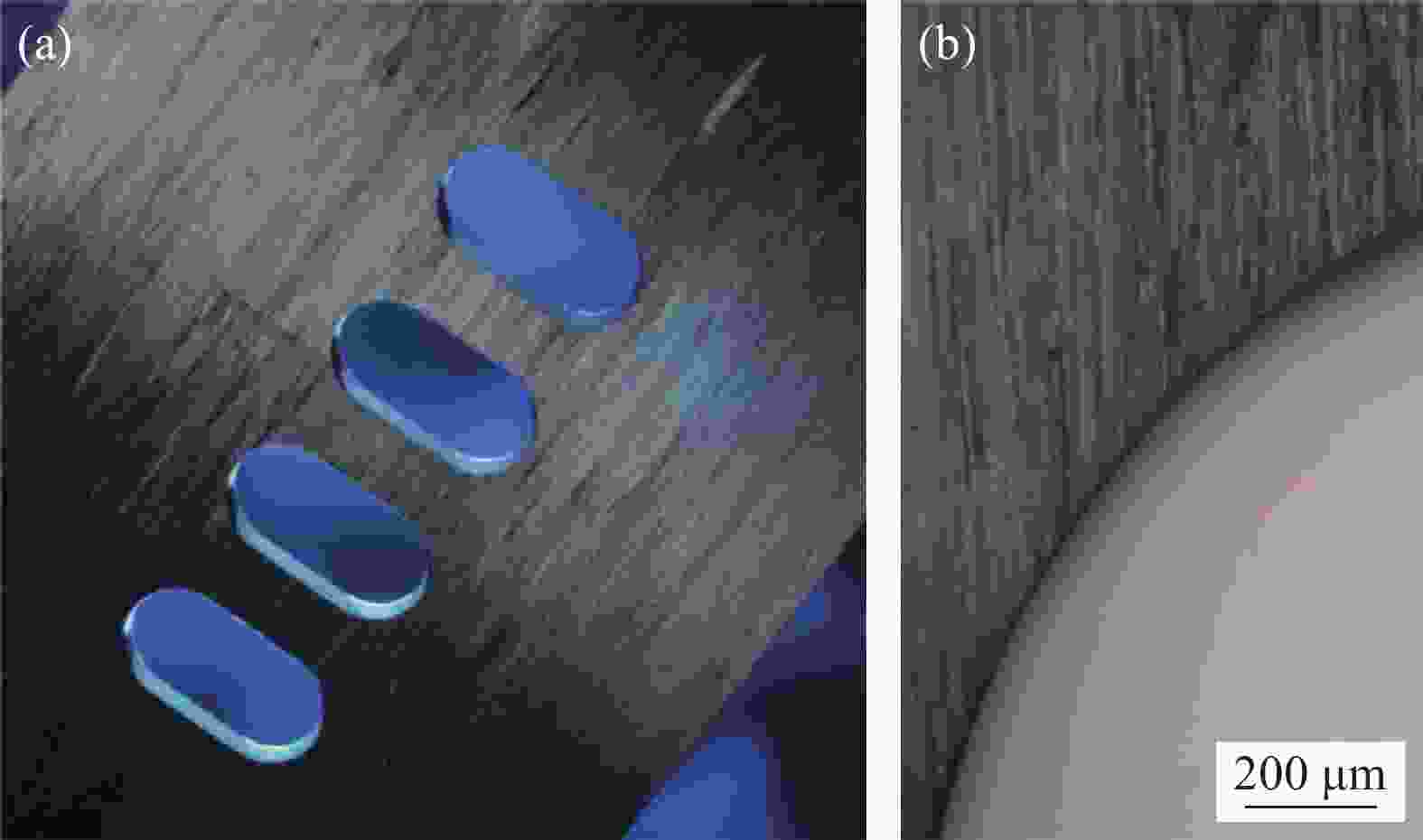

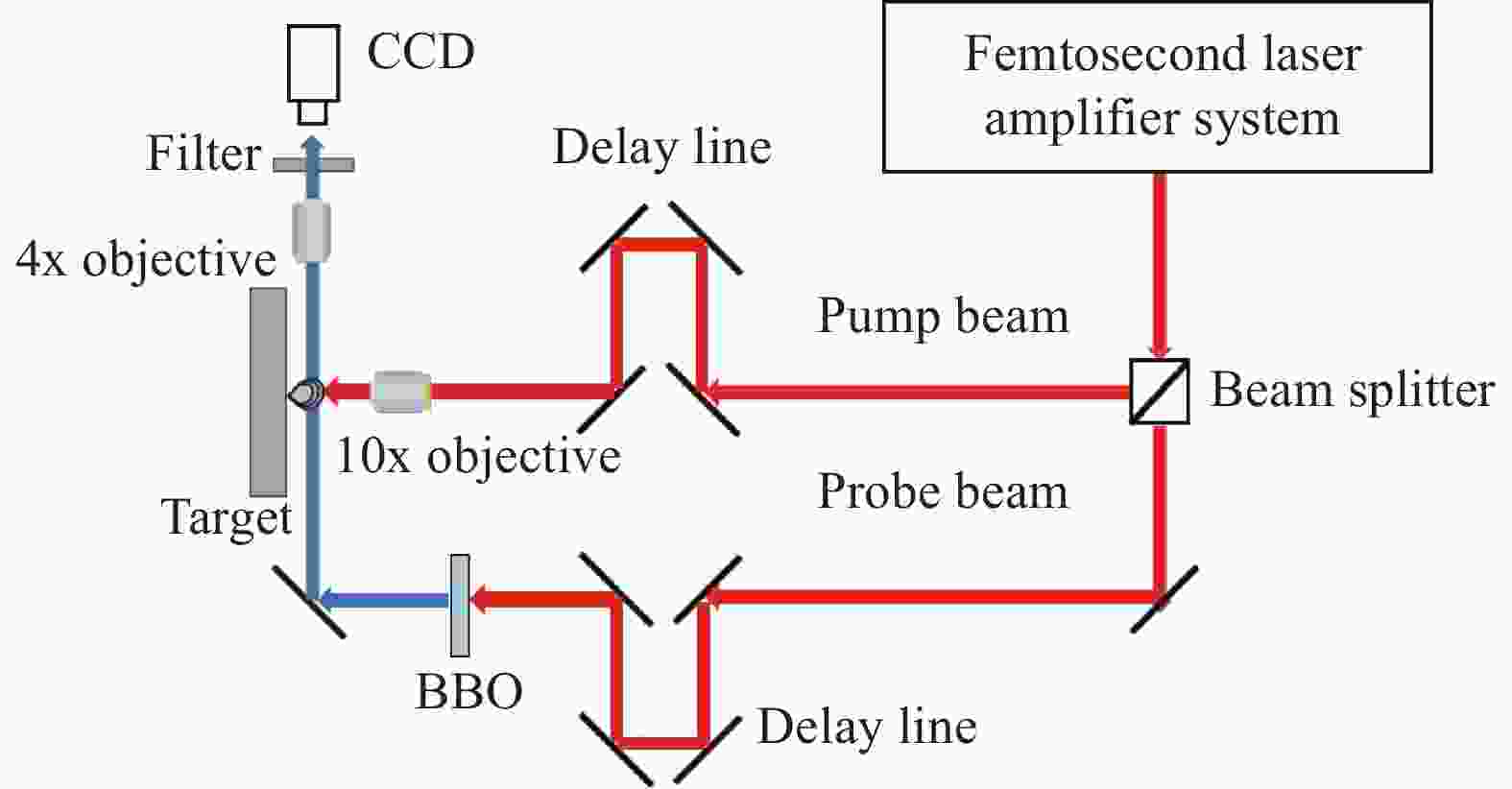

图 11 (a) 实验光路图;(b) 孔边缘HAZ形貌[26]

Figure 11. (a) Experimental optical path diagram; (b) Morphologies of the HAZ at the edge of the hole

图 13 热电阻模型:(a) 平行于纤维轴的热传导;(b) 垂直于纤维轴的热传导;(c) 激光平行纤维方向切割示意图;(d) 激光垂直纤维方向切割示意图

Rm—Matrix's resistance; Rf—Fiber's resistance

Figure 13. Thermal resistance model: (a) Heat conduction parallel to the fiber axis; (b) Heat conduction perpendicular to the fiber axis; (c) Laser cutting parallel to the fiber direction; (d) Laser cutting perpendicular to the fiber direction

表 1 激光与非金属相互作用光电离方式

Table 1. Photoionization mode of laser nonmetal interaction

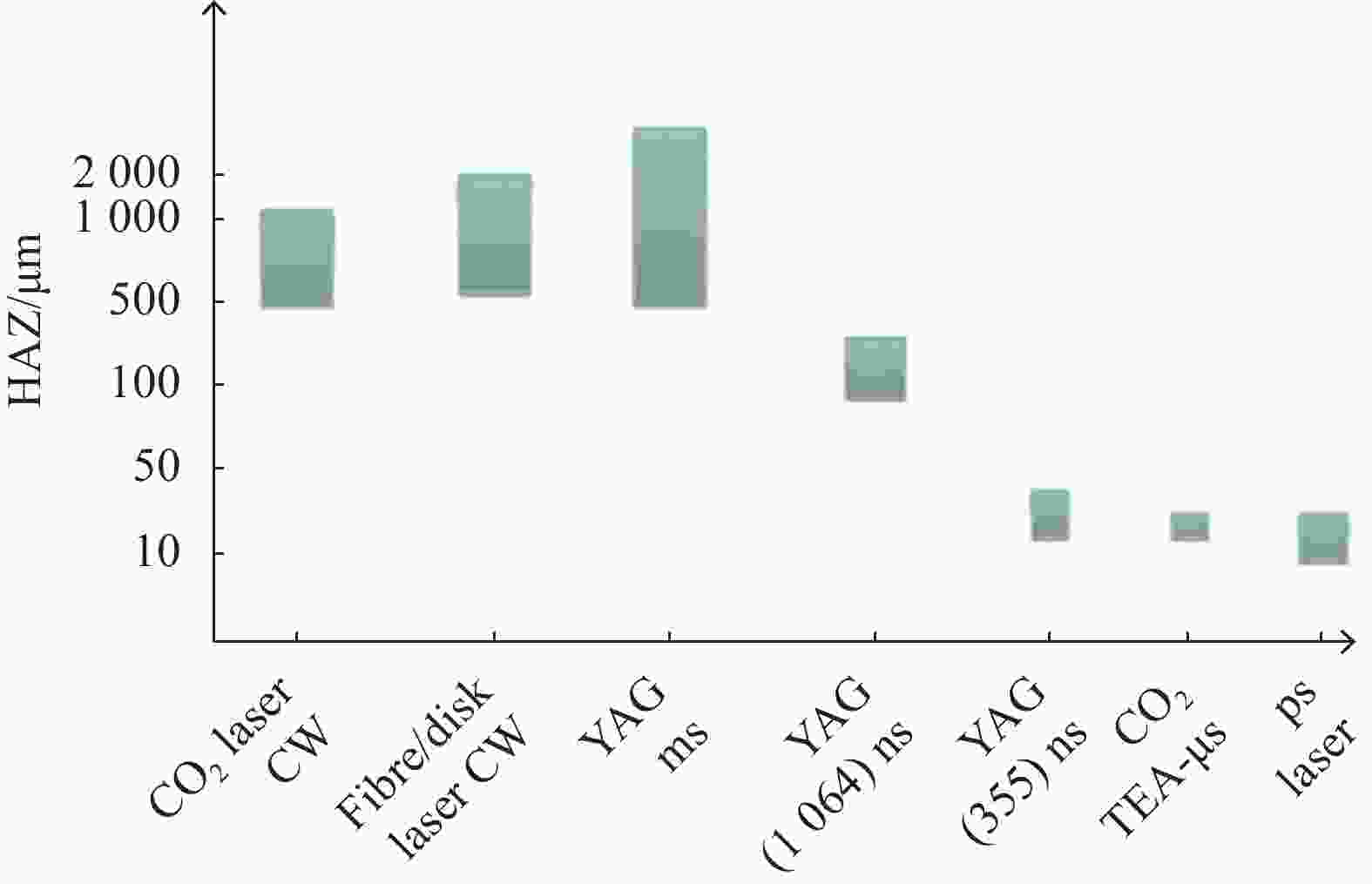

Laser type Power density/(W·cm−2) Ionization mechanisms Ionizations Long pulse laser <1013 Linear effect Linear ionization, impact ionization Ultrafast laser >>1013 Nonlinear effect Multiphoton ionization, tunneling ionization 表 2 各种激光源切割AFRP与CFRP的典型热影响区尺度[25]

Table 2. Typical heat affected zone for laser cutting AFRP and CFRP sheets[25]

CO2 laser ns laser ps/fs laser AFRP/mm 0.5-1.0 0.5-1.0 0.01-0.1 CFRP/mm 1.0-2.0 1.0-2.0 0.01-0.1 表 3 不同类型激光切割CFRP的HAZ

Table 3. HAZ of CFRP cut by different types of laser

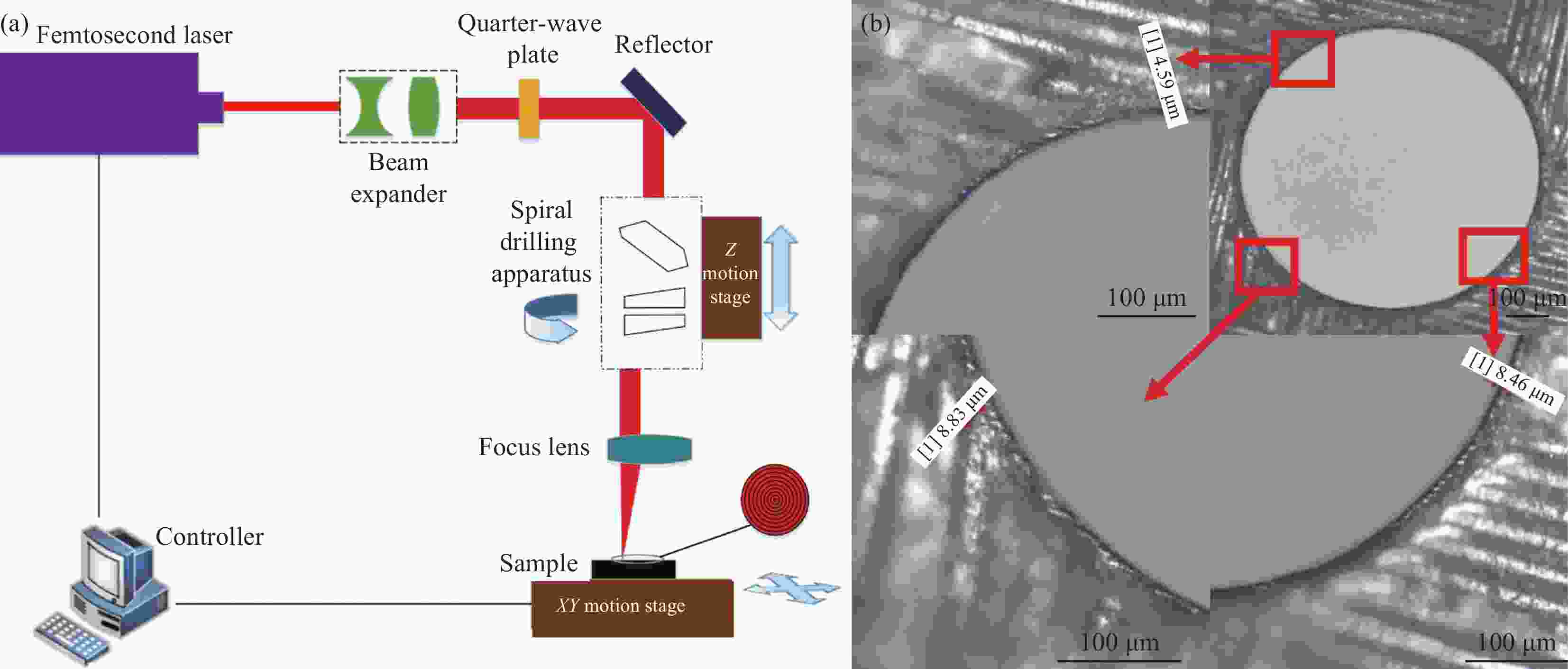

Laser type Wavelength Pulse length Machining condition HAZ Refs. Nd:YAG laser 1064 nm 10 ps Average power 80 W

Repetition rate 0.2-10 MHz

Focus diameter 70 μm<5 μm [23] Femtosecond laser (1028±5) nm 290 fs Pulse energy >0.2 mJ

Maximum average power 10 W

Maximum repetition rate 1100 kHz<10 μm [26] TEA CO2 laser 10.6 μm 8 μs Average power 300 W

Maximum average power 2 J

Pulse repetition rate 150 Hz~10 μm [24] Femtosecond laser 343 nm 500 fs Average power 0-15 W

Repetition rate 1 Hz-2 MHz

Focus diameter 10 μm<25 μm [27] Ytterbium fiber laser 1.06 μm 5 ns Average laser power 30 W

Pulse repetition rate 30 kHz

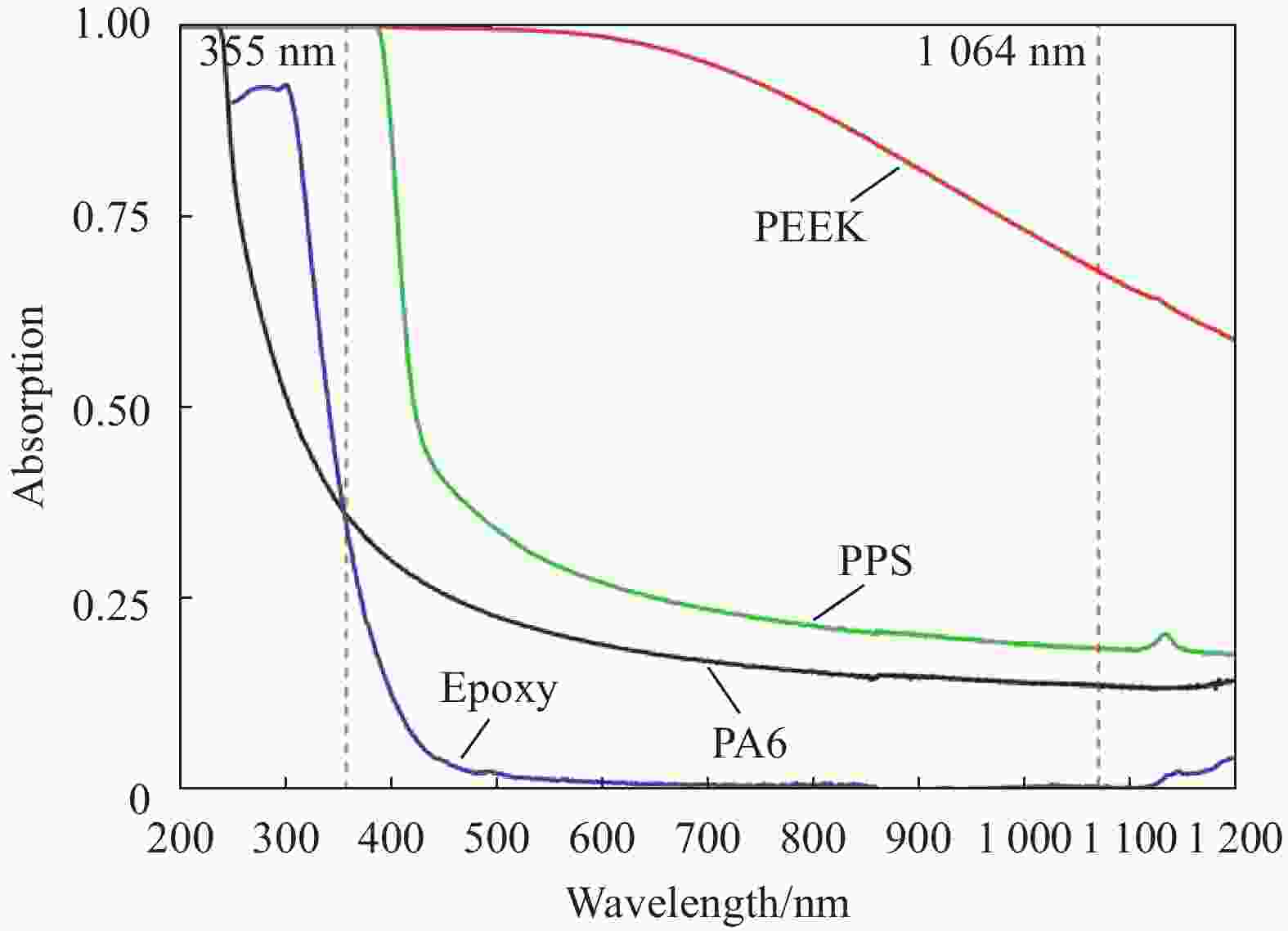

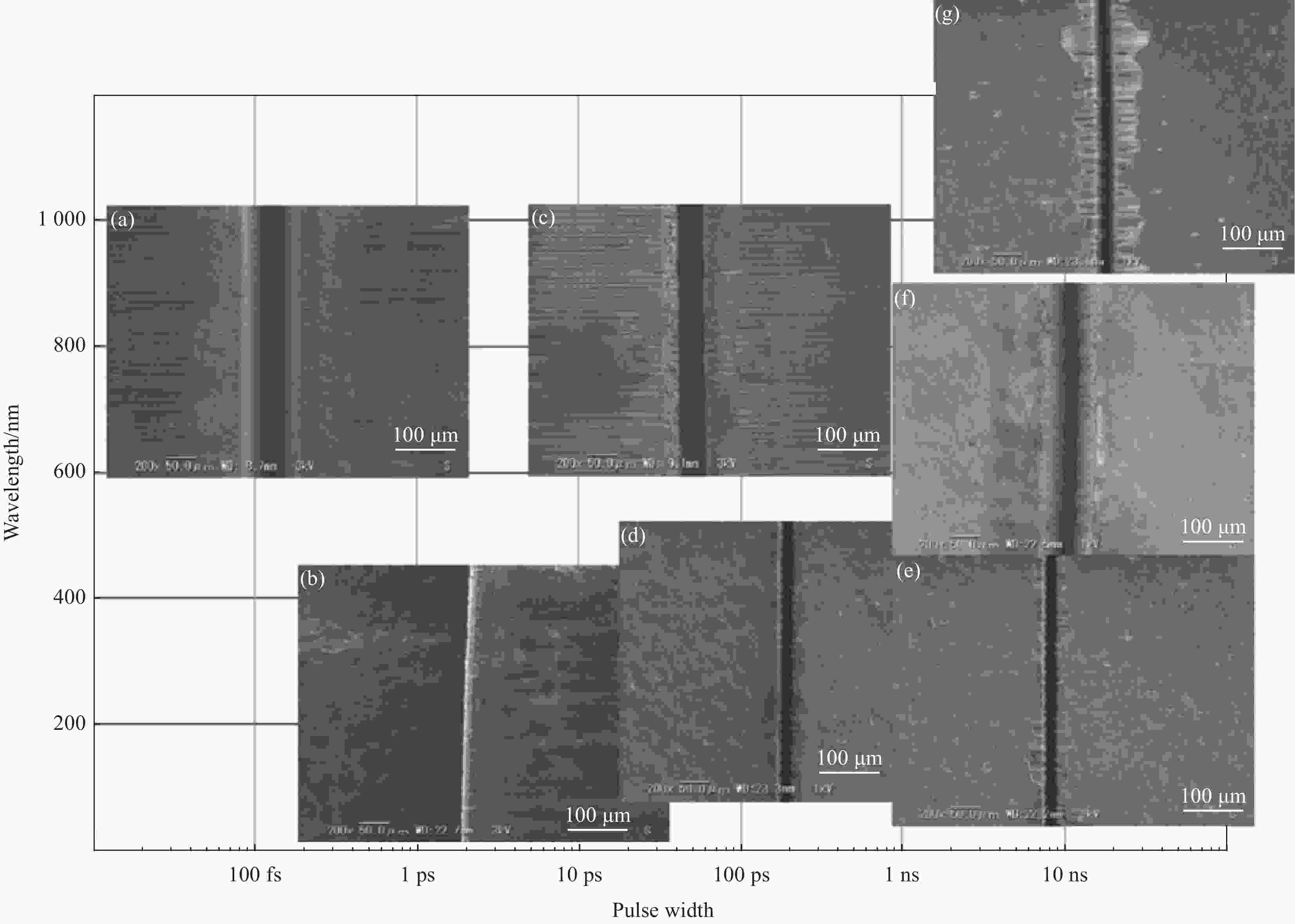

Scanning speed 0.5-1.5 m/s<50 μm [28] Nanosecond UV laser 355 nm 50 ns Average power 0.02-20.61 W

Repetition rate 20-100 MHz

Pulse energy 0.4 mJ<50 μm [29] Quasi continue wave (QCW) fiber laser (1070±5) nm QCW Modulation frequency 50 kHz

Pulse energy 45 J

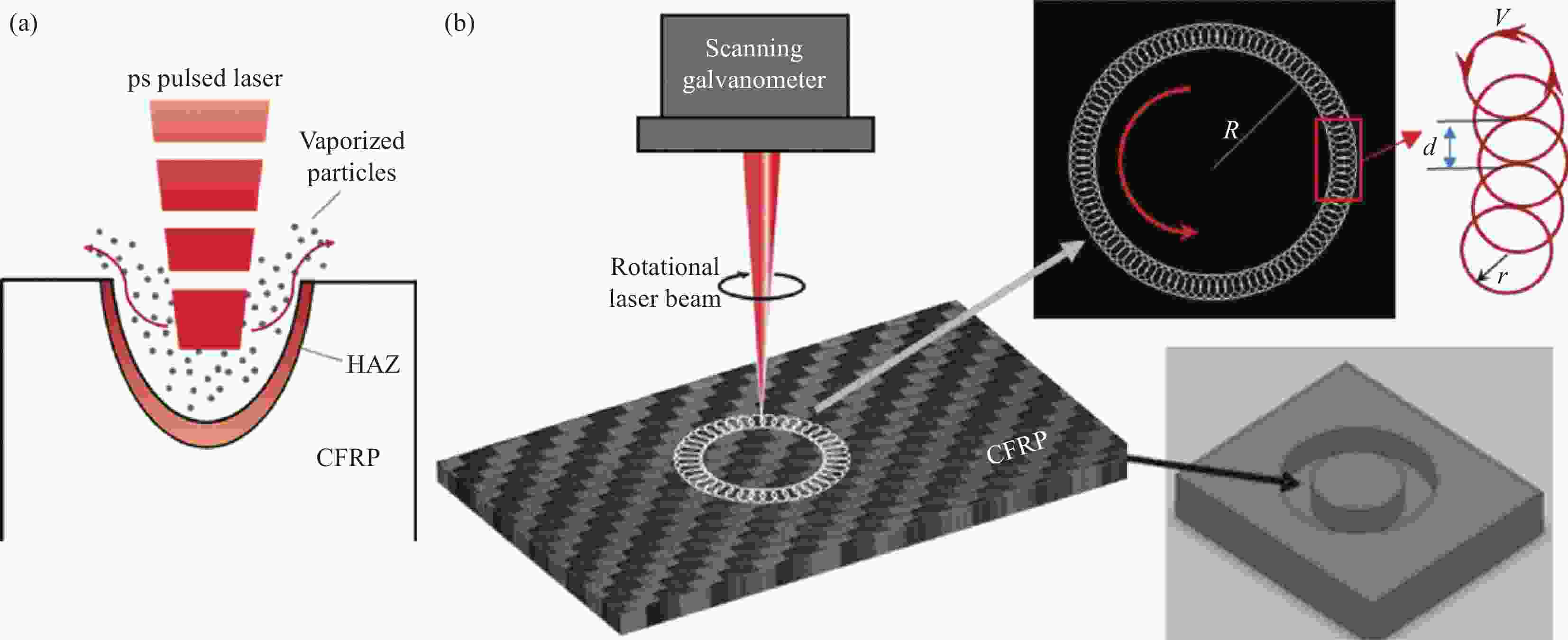

Average power 450 W~300 μm [30] -

[1] 王振林, 孙浩, 何芳, 等. 纤维增强树脂基复合材料制造技术研究进展[J]. 化学与粘合, 2020, 42(5):377-382. doi: 10.3969/j.issn.1001-0017.2020.05.017WANG Zhenlin, SUN Hao, HE Fang, et al. Research progress in manufacturing technology of fiber reinforced resin based composites[J]. Chemistry and Adhesion,2020,42(5):377-382(in Chinese). doi: 10.3969/j.issn.1001-0017.2020.05.017 [2] 张瑄珺, 王健超, 沈佳骏. 碳纤维复合材料激光加工热损伤问题的研究现状[J]. 应用激光, 2019, 39(6):1041-1044.ZHANG Xuanjun, WANG Jianchao, SHEN Jiajun. Research status of thermal damage in laser processing of carbon fiber reinforced plastic[J]. Applied Laser,2019,39(6):1041-1044(in Chinese). [3] HASHIZU M, HAYAKAWA S, ITOIGAWA F. Influence of short-circuitng on machined surface quality in electrical discharge machining of carbon fiber reinforced plastics[J]. Procedia CIRP,2020,95:403-407. doi: 10.1016/j.procir.2020.02.322 [4] 王文亭, 胡冰, 王明伟. 飞秒激光精细加工含能材料[J]. 物理学报, 2013, 62(6):060601. doi: 10.7498/aps.62.060601WANG Wenting, HU Bing, WANG Mingwei. Femtosecond laser fine machining of energetic materials[J]. Acta Physica Sinica,2013,62(6):060601(in Chinese). doi: 10.7498/aps.62.060601 [5] OLIVEIRA V, SHARMA S, DE MOURA M, et al. Surface treatment of CFRP composites using femtosecond laser radiation[J]. Optics and Lasers in Engineering,2017,94:37-43. doi: 10.1016/j.optlaseng.2017.02.011 [6] WANG P, ZHANG Z, LIU D, et al. Comparative investigations on machinability and surface integrity of CFRP plate by picosecond laser vs laser induced plasma micro-drilling[J]. Optics & Laser Technology,2022,151:108022. [7] CHOI I, LEE S J, SHIN D, et al. Green picosecond laser machining of thermoset and thermoplastic carbon fiber reinforced polymers[J]. Micromachines,2021,12(2):205. doi: 10.3390/mi12020205 [8] 邱一, 刘壮, 李元成, 等. CFRP 复材飞秒激光小孔加工工艺研究[J]. 激光与红外, 2022, 52(2):196-201. doi: 10.3969/j.issn.1001-5078.2022.02.008QIU Yi, LIU Zhuang, LI Yuancheng, et al. Technological investigation of femtosecond laser drilling of CFRP composite[J]. Laser & Infarared,2022,52(2):196-201(in Chinese). doi: 10.3969/j.issn.1001-5078.2022.02.008 [9] 杨建军. 飞秒激光超精细 “冷” 加工技术及其应用 (Ⅰ)[J]. 激光与光电子学进展, 2004, 41(3):42-52.YANG Jianjun. Femtosecond laser “cold” micro-machining and its advanced applications[J]. Laser & Optoelectronics Progress,2004,41(3):42-52(in Chinese). [10] CHEN W, LAI W, WANG Y, et al. Ultrafast laser engraving method to fabricate gravure plate for printed metal-mesh touch panel[J]. Micromachines,2015,6(10):1483-1489. doi: 10.3390/mi6101433 [11] 李佳群, 闫剑锋, 李欣, 等. 透明介质材料的超快激光微纳加工研究进展[J]. 中国激光, 2021, 48(2):0202019. doi: 10.3788/CJL202148.0202019LI Jiaqun, YAN Jianfeng, LI Xin, et al. Research advancement on ultrafast laser microprocessing of transparent dielectrics[J]. Chiness Journal of Lasers,2021,48(2):0202019(in Chinese). doi: 10.3788/CJL202148.0202019 [12] CHEN Z, YANG J, LIU H, et al. A short review on functionalized metallic surfaces by ultrafast laser micromachining[J]. The International Journal of Advanced Manufacturing Technology,2022,119(11-12):6919-6948. [13] CAO Q, WANG Z, HE W, et al. Fabrication of super hydrophilic surface on alumina ceramic by ultrafast laser microprocessing[J]. Applied Surface Science,2021,557:149842. doi: 10.1016/j.apsusc.2021.149842 [14] PENILLA E, DEVIA-CRUZ L, WIEG A, et al. Ultrafast laser welding of ceramics[J]. Science,2019,365(6455):803-808. doi: 10.1126/science.aaw6699 [15] SHEN N, DATTA D, SCHAFFER C B, et al. Ablation of cytoskeletal filaments and mitochondria in live cells using a femtosecond laser nanoscissor[J]. Mechanics & Che-mistry of Biosystems,2005,2(1):17 - 25. [16] ROESKE F, BENTEROU J, LEE R, et al. Cutting and machining energetic materials with a femtosecond laser[J]. Propellants, Explosives, Pyrotechnics: An International Journal Dealing with Scientific and Technological Aspects of Energetic Materials,2003,28(2):53-57. [17] 苏笑星. 飞秒激光调控材料电子动态和光学性质的第一性原理研究[D]. 北京: 北京理工大学, 2018.SU Xiaoxing. First-principle simulations of electron dynamics and optical properties modulation of materials by femtosecond laser pulse[D]. Beijing: Beijing Institute of Technology, 2018(in Chinese). [18] ANISIMOV S, KAPELIOVICH B, PERELMAN T. Electron emission from metal surfaces exposed to ultrashort laser pulses[J]. JETP Letters,1974,66(2):375-377. [19] GLEZER E N, MAZUR E. Ultrafast-laser driven micro-explosions in transparent materials[J]. Applied Physics Letters,1997,71(7):882-884. doi: 10.1063/1.119677 [20] LIU J. Simple technique for measurements of pulsed Gaussian-beam spot sizes[J]. Optics Letters,1982,7(5):196-198. doi: 10.1364/OL.7.000196 [21] SATO Y, TSUKAMOTO M, MATSUOKA F, et al. Thermal effect on CFRP ablation with a 100 W class pulse fiber laser using a PCF amplifier[J]. Applied Surface Science,2017,417:250-255. doi: 10.1016/j.apsusc.2017.03.286 [22] LAU W S, LEE W B, PANG S. Pulsed Nd : YAG laser cutting of carbon fibre composite materials[J]. CIRP Annals,1990,39(1):179-182. doi: 10.1016/S0007-8506(07)61030-0 [23] FINGER J, WEINAND M, WORTMANN D. Ablation and cutting of carbon-fiber reinforced plastics using picosecond pulsed laser radiation with high average power[J]. Journal of Laser Applications,2013,25(4):042007. doi: 10.2351/1.4807082 [24] SALAMA A, LI L, MATIVENGA P, et al. TEA CO2 laser machining of CFRP composite[J]. Applied Physics A: Materials Science & Processing,2016,122(5):1-19. [25] 张开虎, 于洋, 张夏明, 等. 纤维增强树脂基复合材料激光切割热影响探析[J]. 导航与控制, 2019, 18(5):60-66.ZHANG Kaihu, YU Yang, ZHANG Xiaming, et al. Laser cutting induced heat affected zone in fiber reinforced polymer: A comparative analysis[J]. Navigation and Control,2019,18(5):60-66(in Chinese). [26] JIANG H, MA C, LI M, et al. Femtosecond laser drilling of cylindrical holes for carbon fiber-reinforced polymer (CFRP) composites[J]. Molecules,2021,26(10):2953. doi: 10.3390/molecules26102953 [27] LI Y, SHEN Y, HUANG Y, et al. Research on UV femtosecond pulsed laser cutting carbon fiber composite materials[C]//Proceedings of the 24th National Laser Conference & Fifteenth National Conference on Laser Technology and Optoelectronics. SPIE: 2020, 11717: 552-557. [28] KOTOV S. Dimensional processing of composite materials by picosecond pulsed ytterbium fiber laser[C]//Journal of Physics: Conference Series. National Research Nuclear University "MEPhI": IOP Publishing, 2017, 941(1): 012039. [29] WANG Y, HU J, LI K. Defect control strategy of carbon fiber reinforced polymer during nanosecond ultraviolet laser processing[J]. Materials Research Express,2019,6(8):085608. doi: 10.1088/2053-1591/ab1696 [30] LEONE C, MINGIONE E, GENNA S. Laser cutting of CFRP by quasi-continuous wave (QCW) fibre laser: Effect of process parameters and analysis of the HAZ index[J]. Composites Part B: Engineering,2021,224:109146. doi: 10.1016/j.compositesb.2021.109146 [31] ROMOLI L, FISCHER F, KLING R. A study on UV laser drilling of PEEK reinforced with carbon fibers[J]. Optics and Lasers in Engineering,2012,50(3):449-457. doi: 10.1016/j.optlaseng.2011.10.008 [32] FUJITA M, OHKAWA H, SOMEKAWA T, et al. Wavelength and pulsewidth dependences of laser processing of CFRP[J]. Physics Procedia,2016,83:1031-1036. doi: 10.1016/j.phpro.2016.08.108 [33] GEBAUER J, BURKHARDT M, FRANKE V, et al. On the ablation behavior of carbon fiber-reinforced plastics during laser surface treatment using pulsed lasers[J]. Materials,2020,13(24):5682. doi: 10.3390/ma13245682 [34] 杨剑, 张瑞, 赵煜, 等. 皮秒激光切割 AFRP 复合材料实验研究[J]. 复合材料学报, 2022, 39(1):149-160.YANG Jian, ZHANG Rui, ZHAO Yu, et al. Experimental study on picosecond laser cutting AFRP composites[J]. Acta Materiae Compositae Sinica,2022,39(1):149-160(in Chinese). [35] 盖晓晨. 飞秒激光微加工的系统建立及工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.GAI Xiaochen. Research on experimental system and technique of femtosecond laser micromachining[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [36] OUYANG W, JIAO J, XU Z, et al. Experimental study on CFRP drilling with the picosecond laser “double rotation” cutting technique[J]. Optics & Laser Technology,2021,142:107238. [37] LI W, ZHANG G, HUANG Y, et al. UV laser high-quality drilling of CFRP plate with a new interlaced scanning mode[J]. Composite Structures,2021,273:114258. doi: 10.1016/j.compstruct.2021.114258 [38] NEGARESTANI R, LI L, SEZER H, et al. Nano-second pulsed DPSS Nd : YAG laser cutting of CFRP composites with mixed reactive and inert gases[J]. The International Journal of Advanced Manufacturing Technology,2010,49(5):553-566. [39] KONONENKO T, FREITAG C, KOMLENOK M, et al. Oxygen-assisted multipass cutting of carbon fiber reinforced plastics with ultra-short laser pulses[J]. Journal of Applied Physics,2014,115(10):103107. doi: 10.1063/1.4868385 [40] SATO Y, TSUKAMOTO M, MATSUOKA F, et al. Experimental investigation of CFRP cutting with nano second laser under air and Ar gas ambienc[C]//Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XX. San Francisco: SPIE: 2015, 9350: 93-99. [41] 花银群, 肖淘, 薛青, 等. 激光切割碳纤维复合材料的实验研究[J]. 激光技术, 2013, 37(5):565-570. doi: 10.7510/jgjs.issn.1001-3806.2013.05.002HUA Yinqun, XIAO Tao, XUE Qing, et al. Experimental study about laser cutting of carbon fiber reinforced polymer[J]. Laser Technology,2013,37(5):565-570(in Chinese). doi: 10.7510/jgjs.issn.1001-3806.2013.05.002 [42] TANGWARODOMNUKUN V, KHAMWISET K, QI H. Investigation into laser machining of carbon fiber reinforced plastic in a flowing water layer[J]. The International Journal of Advanced Manufacturing Technology,2019,104(9):3629-3645. [43] KAAKKUNEN J, SILVENNOINEN M, PAIVASAARI K, et al. Water-assisted femtosecond laser pulse ablation of high aspect ratio holes[J]. Physics Procedia,2011,12:89-93. doi: 10.1016/j.phpro.2011.03.110 [44] 汪建新, 吴耀文, 张广义, 等. 碳纤维增强复合材料水导激光切割试验研究[J]. 中国机械工程, 2021, 32(13):1608-1616.WANG Jianxin, WU Yaowen, ZHANG Guangyi, et al. The experimental research on carbon fiber reinforced plastic cutting by using waterjet guided laser processing[J]. China Mechanical Engineering,2021,32(13):1608-1616(in Chinese). [45] 霍秀兵, 徐强, 王海波, 等. 简析树脂基碳纤维复合材料制孔缺陷以及钻削工艺[J]. 当代化工研究, 2021, 16:142-144. doi: 10.3969/j.issn.1672-8114.2021.22.047HUO Xiubing, XU Qiang, WANG Haibo, et al. Brief analysis of hole-making defects and drilling technology of resin-based carbon fiber composites[J]. Modern Chemical Research,2021,16:142-144(in Chinese). doi: 10.3969/j.issn.1672-8114.2021.22.047 [46] 韩旭, 王续跃. 双层碳纤维复合板材激光切割试验研究[J]. 现代机械, 2019(4):50-56. doi: 10.13667/j.cnki.52-1046/th.2019.04.013HAN Xu, WANG Xuyue. Experimental study on laser cutting of double-layer carbon fiber reinforced plastics sheets[J]. Modern Machinery,2019(4):50-56(in Chinese). doi: 10.13667/j.cnki.52-1046/th.2019.04.013 [47] PAN C, HOCHENG H. The anisotropic heat-affected zone in the laser grooving of fiber-reinforced composite material[J]. Journal of Materials Processing Technology,1996,62(1-3):54-60. doi: 10.1016/0924-0136(95)02192-2 [48] JUNG K W, KAWAHITO Y, KATAYAMA S. Ultra-high speed disk laser cutting of carbon fiber reinforced plastics[J]. Journal of Laser Applications,2012,24(1):012007. doi: 10.2351/1.3673521 [49] STAEHR R, BLUEMEL S, HANSEN P, et al. The influence of moisture content on the heat affected zone and the resulting in-plane shear strength of laser cut thermoplastic CFRP[J]. Plastics, Rubber and Composites,2015,44(3):111-116. doi: 10.1179/1743289814Y.0000000114 [50] ZHENG L, WANG L, LU M, et al. Research on laser precision cutting of carbon fiber reinforced polymer for satellite[C]//24th National Laser Conference & Fifteenth National Conference on Laser Technology and Optoelectronics. Shanghai: SPIE: 2020, 11717: 814-819. [51] 路明雨, 张明, 张开虎, 等. 高模量碳纤维增强树脂基复合材料的皮秒激光加工阈值特性[J]. 复合材料学报, 2021, 38(11): 3601-3609.LU Mingyu, ZHANG Ming, ZHANG Kaihu, et al. Threshold properties of high modulus carbon fiber reinforced plastic composite with picosecond laser processing[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3601-3609(in Chinese). [52] KUMAR D, SINGH K K. Effect of nanofiller on fibre laser drilling quality of carbon fibre reinforced polymer compo-site laminates[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering,2019,233(4):857-870. doi: 10.1177/0954408918812253 [53] CANISIUS M, HERZOG D, SCHMIDT-LEHR M, et al. Laser cutting of carbon fiber-reinforced plastic with an absorber transparent for visible spectrum[J]. Journal of Laser Applications,2015,27(3):032003. doi: 10.2351/1.4916532 [54] 宋抒航. 碳纤维复合材料激光切割实验研究[J]. 机械制造, 2015, 53(613):49-51. doi: 10.3969/j.issn.1000-4998.2015.09.016SONG Shuhang. Experimental study on laser cutting of carbon fiber composites[J]. Machine Manufacturing,2015,53(613):49-51(in Chinese). doi: 10.3969/j.issn.1000-4998.2015.09.016 [55] YU Z, XU L, CAO W, et al. Study on picosecond laser processing of blind holes in carbon fiber-reinforced plastics[J]. Applied Physics A: Materials Science & Processing ,2020,126(12):1-10. [56] NEGARESTANI R, SUNDAR M, SHEIKH M, et al. Numeri-cal simulation of laser machining of carbon-fibre-reinforced composites[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2010,224(7):1017-1027. doi: 10.1243/09544054JEM1662 [57] XU L, LU J, LI K, et al. Removal mechanism of CFRP by laser multi direction interaction[J]. Optics & Laser Technology,2021,143:107281. [58] 马维刚, 王海东, 张兴, 等. 飞秒脉冲激光加热金属薄膜的理论和实验研究[J]. 物理学报, 2011, 60(6):421-427. doi: 10.7498/aps.60.064401MA Weigang, WANG Haidong, ZHANG Xing, et al. Theoretical and experimental study of femtosecond pulse laser heating on thin metal film[J]. Acta Physica Sinica,2011,60(6):421-427(in Chinese). doi: 10.7498/aps.60.064401 [59] 纪利平, 宋梓钰, 孙亚萍, 等. 基于COMSOL的皮秒激光单脉冲烧蚀铜片[J]. 激光与光电子学进展, 2018, 55(10):101402.JI Liping, SONG Ziyu, SUN Yaping, et al. Single-shot picosecond laser ablation of copper based on COMSOL[J]. Laser & Optoelectronics Progress,2018,55(10):101402(in Chinese). [60] WU Y, CHEN F, DU G, et al. Ultrafast thermalization dynamics of gold-coated fused silica irradiated by a femtosecond laser[J]. Applied Thermal Engineering,2014,71(1):56-61. doi: 10.1016/j.applthermaleng.2014.06.011 [61] HU J, XU H, LI C. Laser absorption of carbon fiber reinforced polymer with randomly distributed carbon fibers[J]. Laser Physics,2018,28(3):036002. doi: 10.1088/1555-6611/aa9d07 [62] ZHANG N, ZHU X, YANG J, et al. Time-resolved shadowgraphs of material ejection in intense femtosecond laser ablation of aluminum[J]. Physical Review Letters,2007,99(16):167602. doi: 10.1103/PhysRevLett.99.167602 [63] WANG M W, WANG X L, ZHAI H C. Pulsed digital micro-holography of femto-second order by double-wavelength recording[J]. Optoelectronics Letters,2007,3(2):133-135. doi: 10.1007/s11801-007-7011-5 [64] 丁铠文, 王聪, 罗志, 等. 超快激光光束整形原理与方法及其在功能性微结构制造中的应用[J]. 中国激光, 2021, 48(2):0202005. doi: 10.3788/CJL202148.0202005DING Kaiwen, WANG Cong, LUO Zhi, et al. Principle and method of ultrafast laser beam shaping and its application in functional microstructure fabrication[J]. Chinese Jour-nal of Lasers,2021,48(2):0202005(in Chinese). doi: 10.3788/CJL202148.0202005 [65] WANG M, YU Z, ZHANG N, et al. Drilling high aspect ratio holes by femtosecond laser filament with aberrations[J]. Frontiers of Optoelectronics,2021,14(4):522-528. doi: 10.1007/s12200-021-1214-4 [66] 付丽丽, 常峻巍, 陈佳琪, 等. 平顶飞秒激光经圆锥透镜在熔融石英中成丝及超连续辐射[J]. 物理学报, 2020, 69(4):110-114. doi: 10.7498/aps.69.20191350FU Lili, CHANG Junwei, CHEN Jiaqi, et al. Filamentation and supercontinuum emission generated from flattened femtosecond laser beam by use of axicon in fused silica[J]. Acta Physica Sinica,2020,69(4):110-114(in Chinese). doi: 10.7498/aps.69.20191350 -

下载:

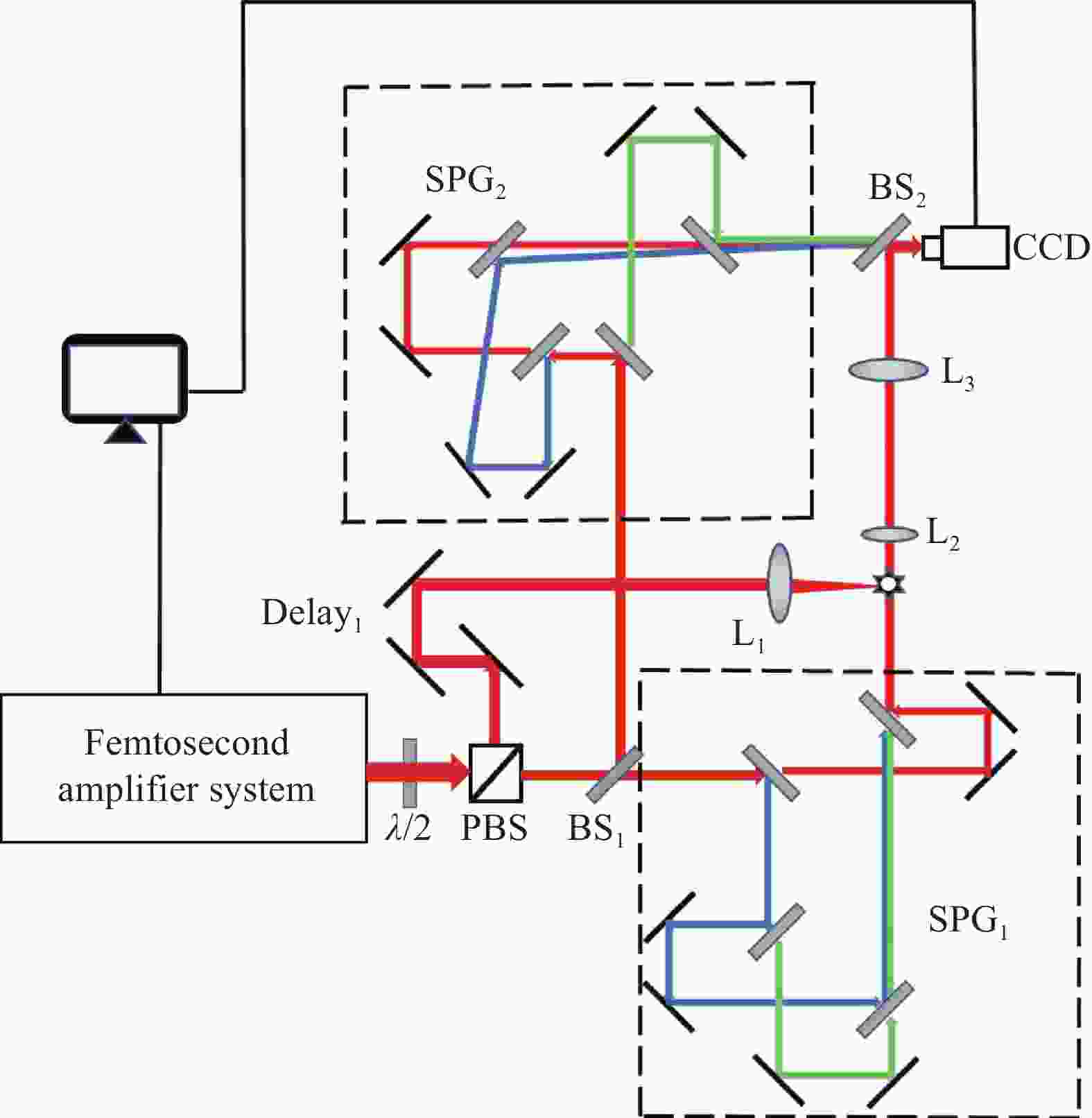

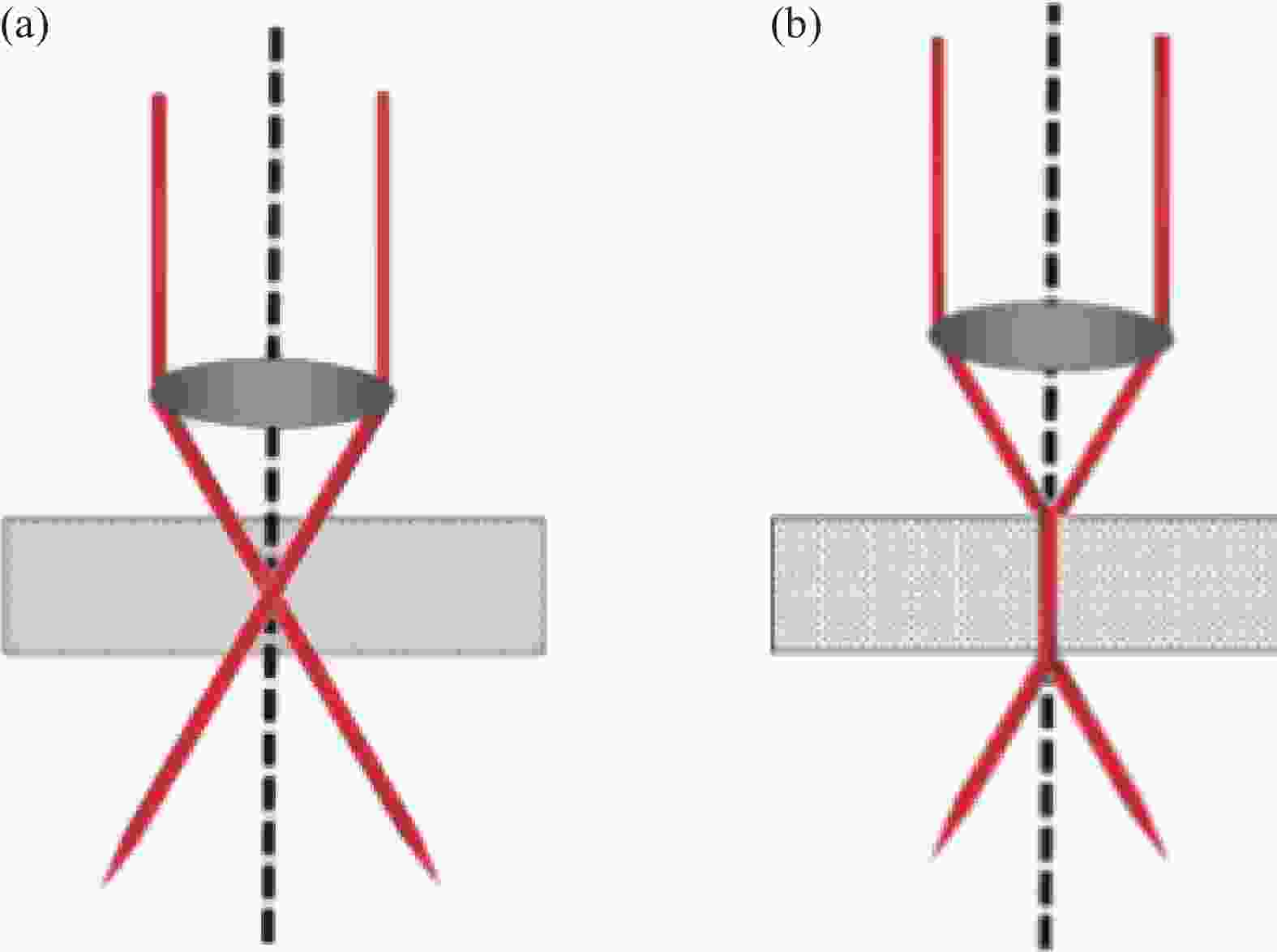

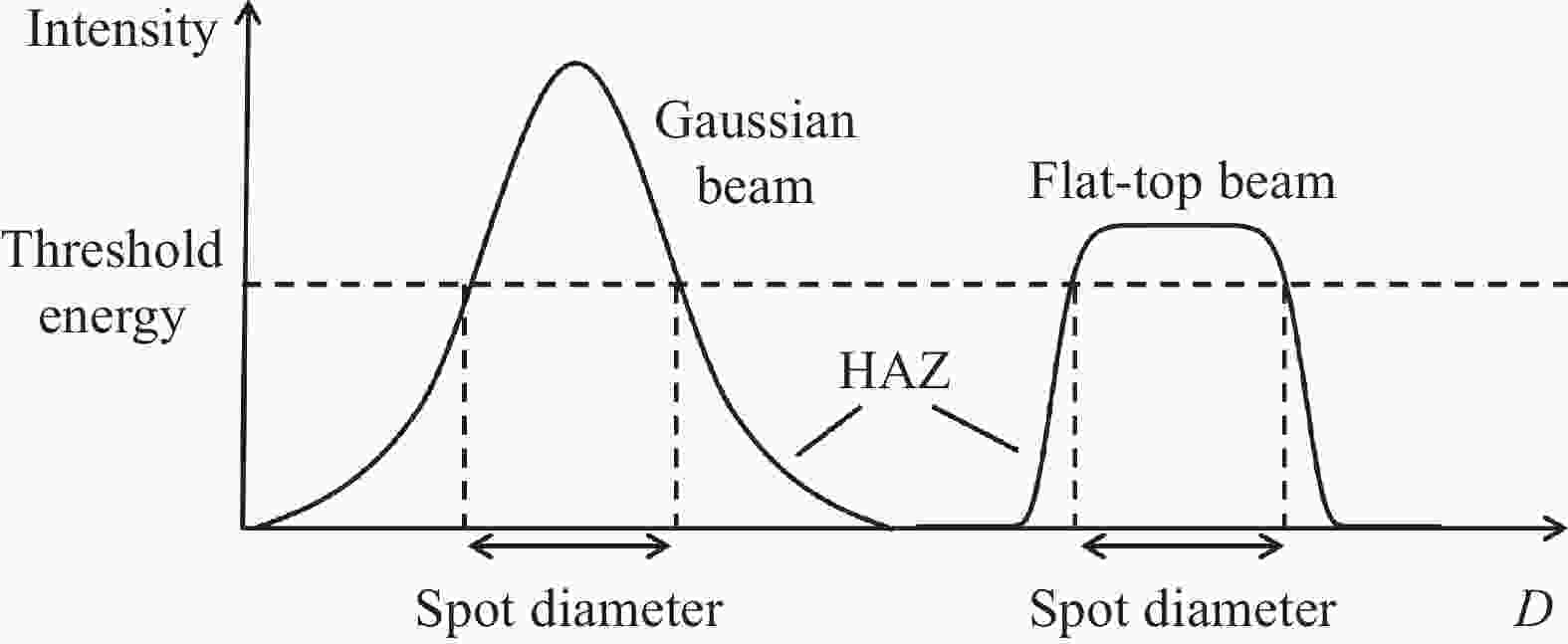

下载: