Thermal-shock resistance of in-situ SiC nanowire-toughened SiC ceramics

-

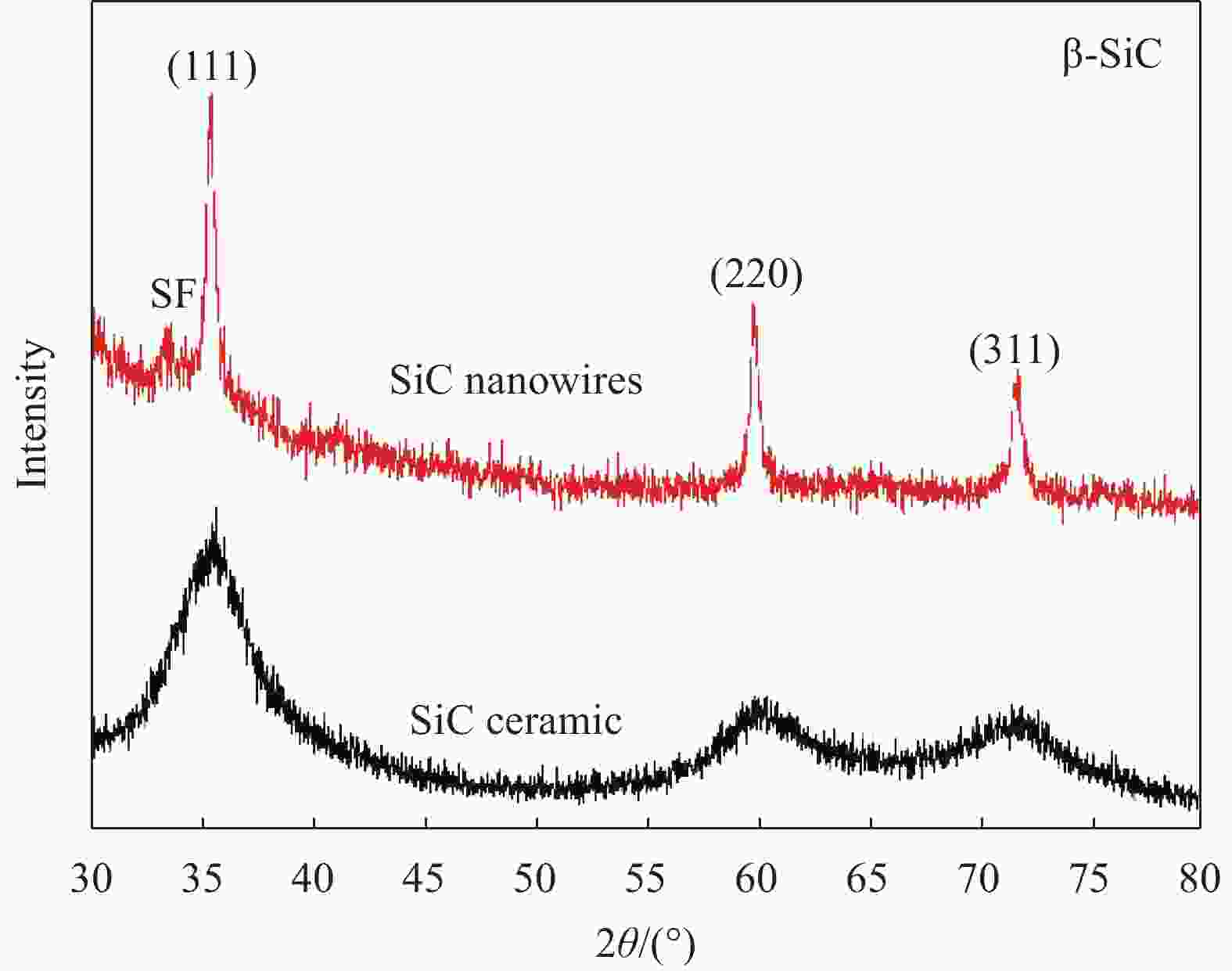

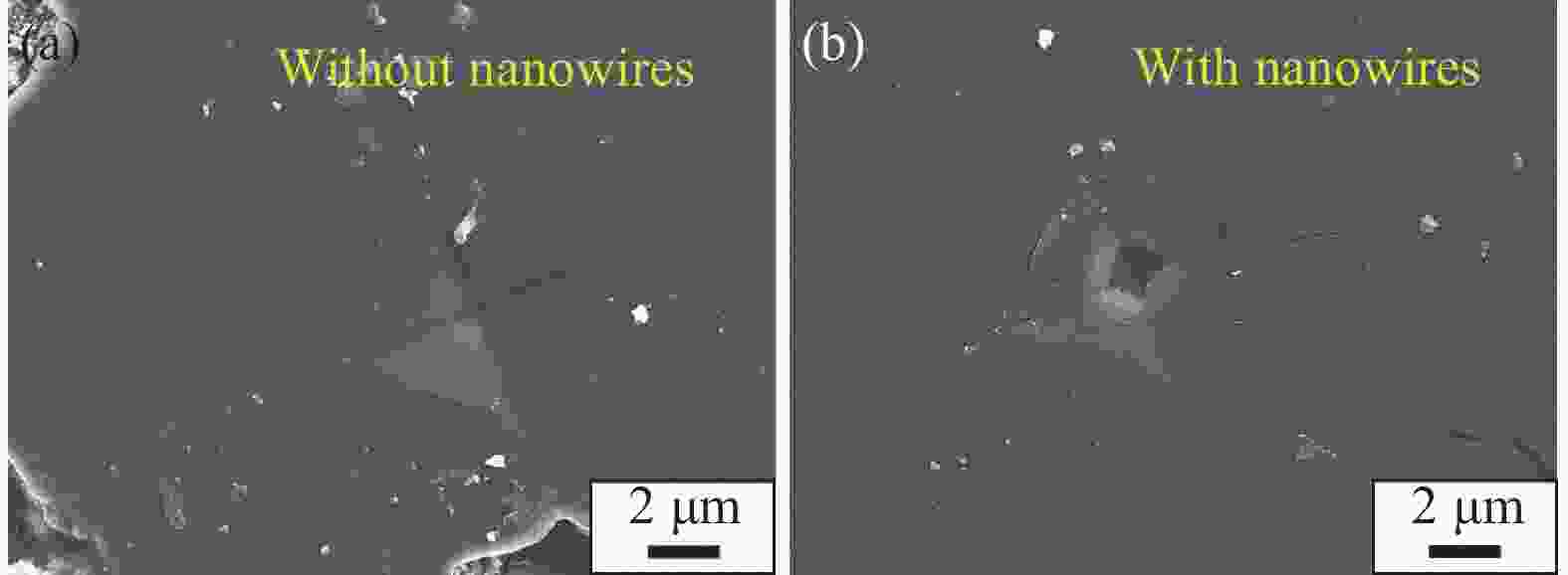

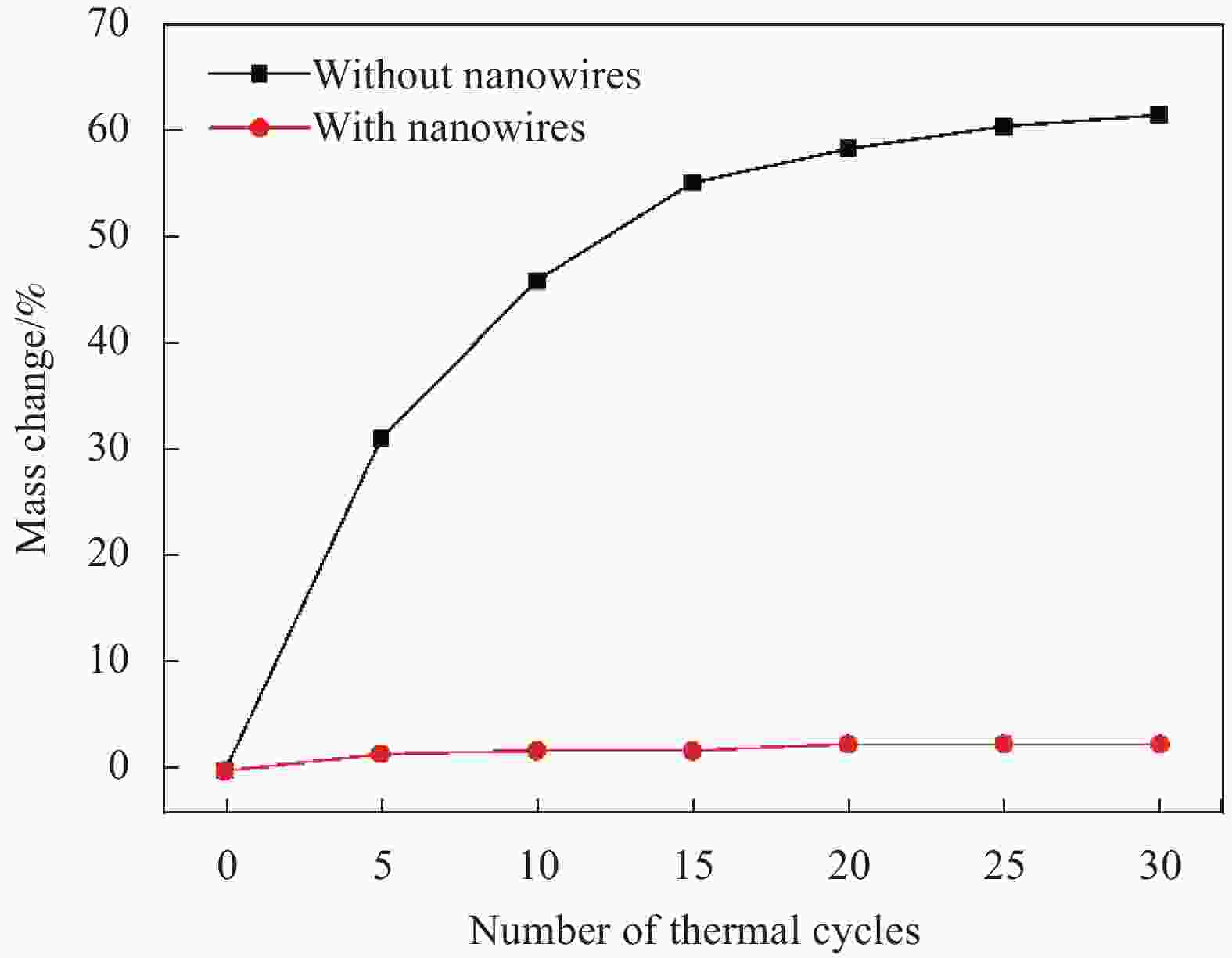

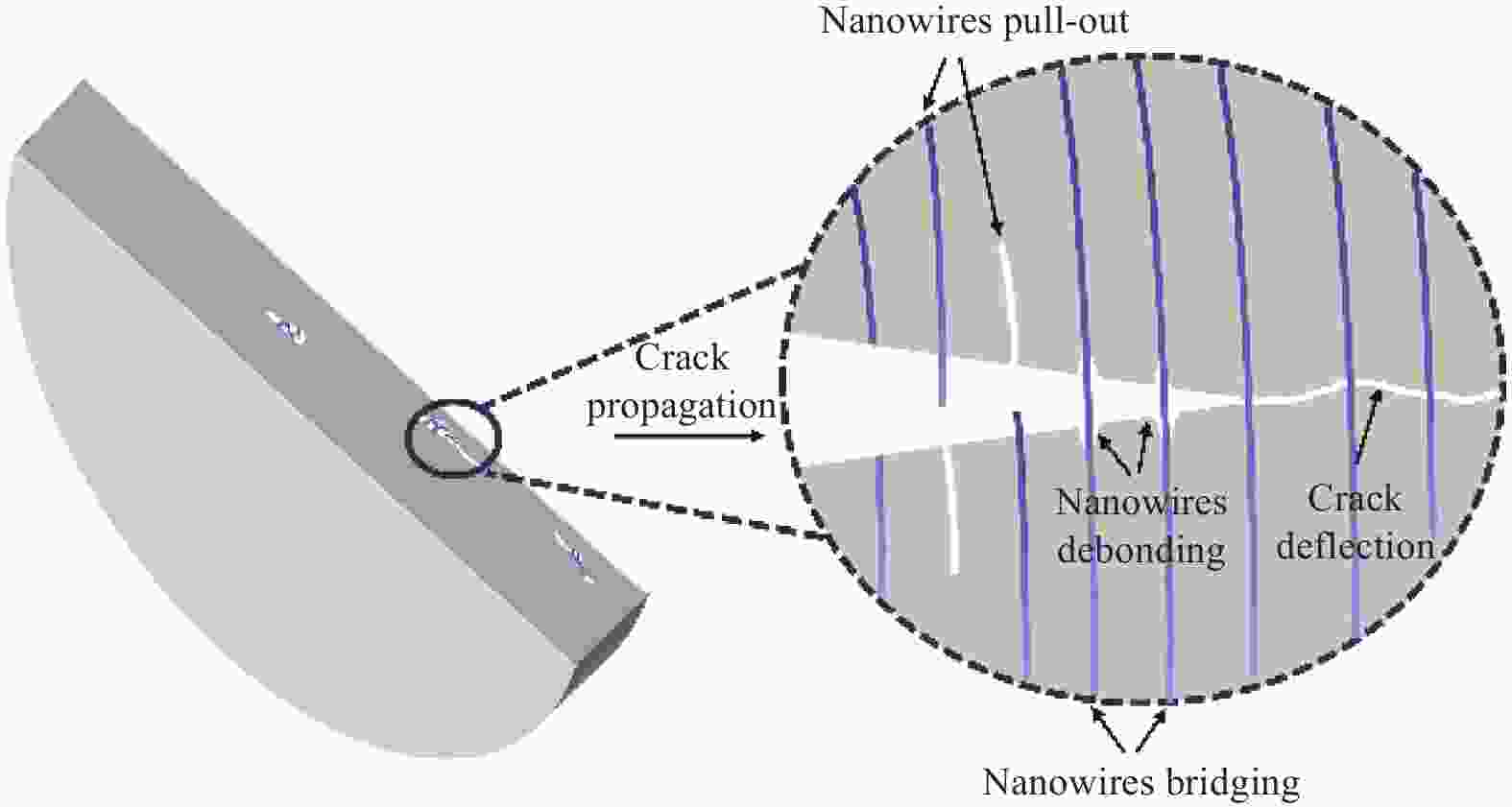

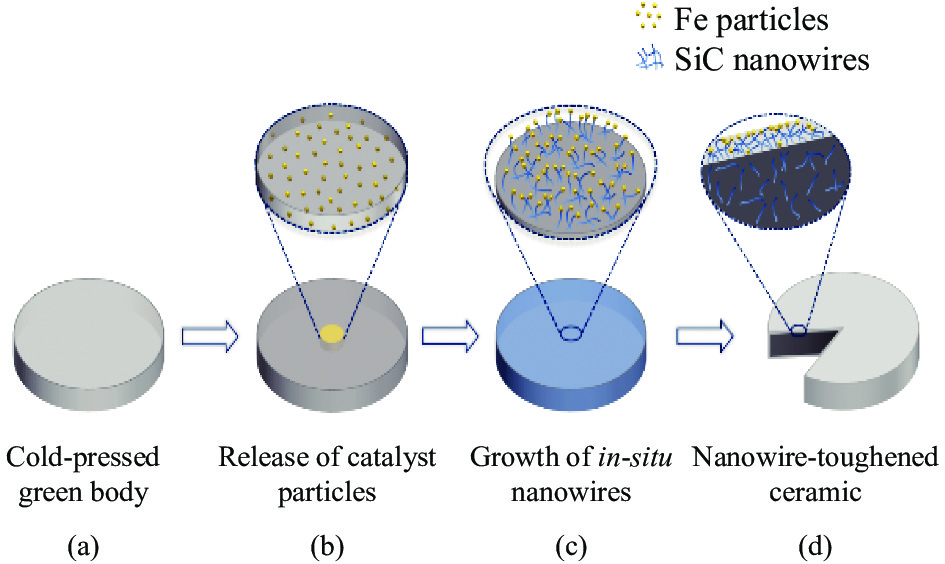

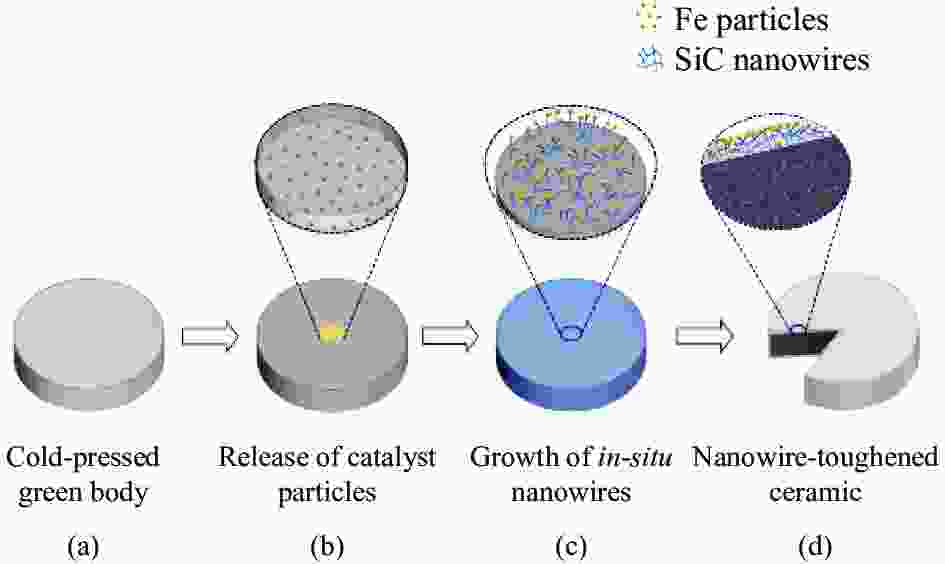

摘要: SiC陶瓷的本征脆性及其在高低温交变环境中抗热震能力的不足已成为制约其广泛应用的关键问题之一。本文以聚碳硅烷为前驱体、二茂铁为催化剂,通过前驱体转化法在制备低密度SiC陶瓷的同时在陶瓷中原位合成SiC纳米线,并采用前驱体浸渍裂解工艺将低密度陶瓷进一步致密化制备原位SiC纳米线增韧SiC陶瓷。实验结果表明,引入原位SiC纳米线后,SiC陶瓷的抗热震性能显著提升,经历30次“室温↔1500℃”的热震循环氧化后其氧化增重率仅为2.53%,相较于纳米线改性前的SiC陶瓷氧化增重率下降了59%。相应的微结构分析表明,合成的SiC纳米线为β-SiC晶型,其中包含部分堆垛层错。纳米线沿<111>方向择优生长,其生长遵循典型的“气-液-固”生长机制。SiC纳米线主要通过纳米线桥连和拔出增韧机制缓解陶瓷制备及高低温交变过程中产生的应力集中,减少裂纹数量和尺寸,进而提升陶瓷断裂韧性和抗热震性能。引入SiC纳米线后,SiC陶瓷内部平均裂纹长度由27.7 μm下降至18.2 μm,断裂韧性由3.76 MPa·m1/2增加至7.83 MPa·m1/2。Abstract: The brittleness and insufficient thermal-shock resistance are the critical problems for the extensive applications of SiC ceramics. Low-density SiC ceramics decorated with in-situ SiC nanowires were fabricated via the pyrolysis of polycarbosilane assisted by ferrocene. They were further densified by the technique of precursor infiltration and pyrolysis to prepare in-situ SiC nanowire-toughened SiC ceramics. The experimental results showed that, compared with the SiC ceramics without nanowires, the thermal shock resistance of the in-situ SiC nanowire-toughened SiC ceramics was improved significantly, whose oxidation mass gain was only 2.53% and decreased by 59% after 30 thermal cycles between room temperature and 1500 ℃. The corresponding microstructural analysis indicated that the synthesized SiC nanowires were β-SiC and contained some stacking faults. The β-SiC nanowires grew along the preferential orientation of <111> and its growth was governed by a vapor-liquid-solid mechanism. The in-situ SiC nanowires could effectively alleviate the stress concentration due to the ceramic preparation and the thermal cycles between high and low temperatures. The improved fracture toughness and thermal-shock resistance could be attributed to the toughening mechanism including nanowire bridging and pull-out, as well as the decrease of crack number and size in SiC ceramics. After the introduction of SiC nanowires, the average crack length of SiC ceramics decreased from 27.7 μm to 18.2 μm, and the fracture toughness increased from 3.76 MPa·m1/2 to 7.83 MPa·m1/2.

-

Key words:

- SiC ceramic /

- in-situ SiC nanowires /

- growth mechanism /

- polycarbosilane /

- thermal shock resistance

-

图 4 合成SiC纳米线的TEM结果:(a) 单根纳米线的明场像(BF)图像和相应的SAED花样;(b) 纳米线的HRTEM图像;(c) 纳米线尖端催化剂液滴的BF图像;(d) 催化剂液滴的EDS光谱

Figure 4. TEM results of the as-synthesized SiC nanowires: (a) Bright field (BF) image of a single nanowire and the corresponding SAED pattern; (b) HRTEM image of the nanowire; (c) BF image of a catalyst droplet attached at the tip of a nanowire; (d) EDS spectrum of the catalyst droplet

图 5 3次和6次“浸渍-裂解”循环后纳米线增韧SiC陶瓷的形貌和元素分布:(a) 3次循环后的低倍表面SEM图像;(b) 3次循环后的高倍表面SEM图像;(c) 6次循环后的低倍表面SEM图像;(d) 6次循环后的高倍截面SEM图像;(e) 图5(c)对应的氧元素面扫图

Figure 5. Morphologies and element distribution of the nanowire-toughened SiC ceramic after 3 and 6 cycles of “infiltration-pyrolysis”: (a) Low-magnification surface SEM image after 3 cycles; (b) High-magnification surface SEM image after 3 cycles; (c) Low-magnification surface SEM image after 6 cycles; (d) High-magnification cross-sectional SEM image after 6 cycles; (e) Corresponding element map of oxygen in Fig. 5(c)

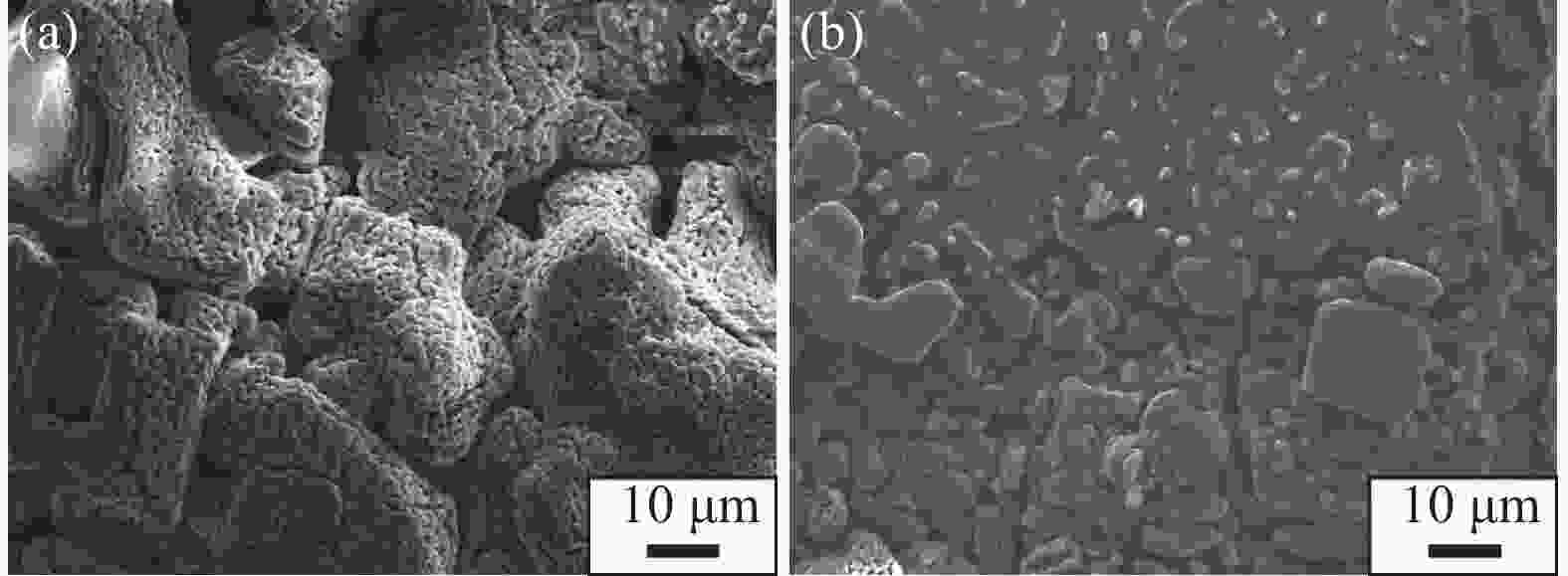

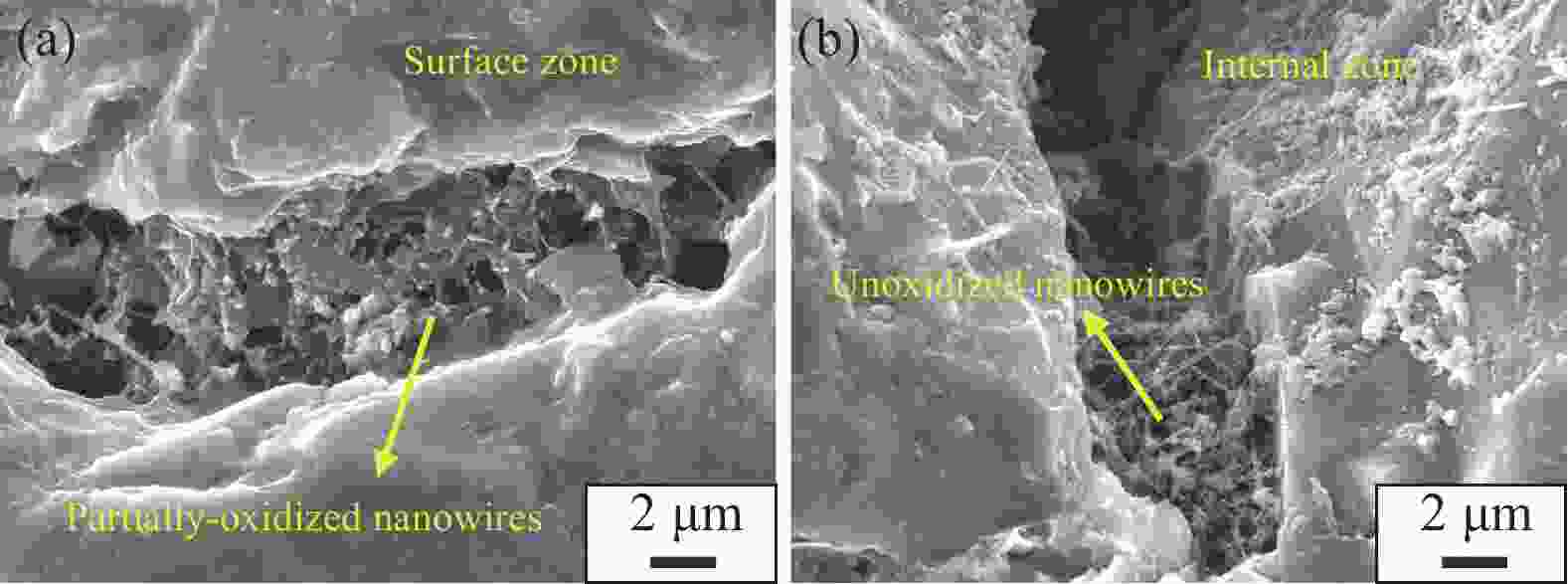

图 10 原位SiC纳米线增韧SiC陶瓷经历30次热震后的断口图像:(a) SiC陶瓷表面的部分氧化纳米线;(b) SiC陶瓷内部的未氧化纳米线

Figure 10. Fracture surface images of the in-situ SiC nanowire-toughened SiC ceramic after 30 thermal shock cycles: (a) Partially-oxidized nanowires in the surface zone of SiC ceramic; (b) Unoxidized nanowires in the internal zone of SiC ceramic

-

[1] HARRIS C I, SAVAGE S, KONSTANTINOV A, et al. Progress towards SiC products[J] Applied Surface Science, 2001, 184(1-4): 393-398. [2] SHAO J Q, LI M, CHANG K K, et al. Fabrication and characterization of SPS sintered SiC-based ceramic from Y3Si2C2-coated SiC powders[J]. Journal of the European Ceramic Society, 2018, 38(15): 4833-4841. [3] HARRIS G L. Properties of silicon carbide[M]. Britain: IPSEC, 1995. [4] BELMONTE M, NISTAL A, BOUTBIEN P, et al. Toughened and strengthened silicon carbide ceramics by adding graphene-based fillers[J]. Scripta Materialia, 2016, 113: 127-130. [5] HUAN Y H, JIANG D L, ZHANG X F, et al. Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering[J]. Journal of the European Ceramic, Society, 2018, 38(13): 4329-4337. [6] COPPOLA J A, BRADT R C. Thermal-shock damage in SiC[J]. Journal of the American Ceramic Society, 1973, 56(4): 214-218. [7] SHARMA A S, FITRIANI P, YOON D H. Microstructure-fracture behavior correlation of toughened SiCf/SiC compo-sites prepared by vacuum infiltration and hot pressing[J]. Ceramics International, 2016, 42(7): 8713-8723. [8] ZHUANG L, FU Q G, YU X. Improved thermal shock resis-tance of SiCnw/PyC core-shell structure-toughened CVD-SiC coating[J]. Journal of the European Ceramic Society, 2018, 38(7): 2808-2814. [9] XU Y R, ZANGVIL A, KERBER A. SiC nanoparticle-reinforced Al2O3 matrix composites: Role of intra- and intergranular particles[J]. Journal of the European Ceramic Society, 1997, 17(7): 921-928. [10] LYU X Y, YE F, CHENG L F, et al. Fabrication of SiC whisker-reinforced SiC ceramic matrix composites based on 3 D printing and chemical vapor infiltration technology[J]. Journal of the European Ceramic Society, 2019, 39(11): 3380-3386. [11] HUO C X, GUO L J, LI Y Y, et al. Effect of co-deposited SiC nanowires and carbon nanotubes on oxidation resistance for SiC-coated C/C composites[J]. Ceramics International, 2017, 43(2): 1722-1730. [12] PRAKASH J, SARKAR P S, BAHADUR J, et al. Effect of in-situ grown SiC nanowire and dense SiC on oxidation resis-tance of carbon fiber/SiC nanowire/SiC matrix composite in high temperature atmospheric environment[J]. Corrosion Science, 2018, 135: 46-56. [13] VOROTILO S, POTANIN A Y, LOGINOV P A, et al. Combustion synthesis of SiC-based ceramics reinforced by discrete carbon fibers with in situ grown SiC nanowires[J]. Ceramics International, 2020, 46(6): 7861-7870. [14] ZEKENTES K, ROGDAKIS K. SiC nanowires: Material and devices[J]. Journal of Physics D: Applied Physics, 2011, 44(13): 133001. [15] WONG E W, SHEEHAN P E, LIEBER C M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes[J] Science, 1997, 277: 1971-1975. [16] HAN X D, ZHANG Y F, ZHENG K, et al. Low-temperature in situ large strain plasticity of ceramic SiC nanowires and its atomic-scale mechanism[J]. Nano Letters, 2007, 7(2): 452-457. [17] QIANG X F, LI H J, LIU Y F, et al. Oxidation and erosion re-sistance of multi-layer SiC nanowires reinforced SiC coating prepared by CVD on C/C composites in static and aerodynamic oxidation environments[J]. Ceramics International, 2018, 44(14): 16227-16236. [18] ZHU Q, DONG X, HU J B, et al. High strength aligned SiC nanowire reinforced SiC porous ceramics fabricated by 3 D printing and chemical vapor infiltration[J]. Ceramics International, 2020, 46(5): 6978-6983. [19] RUAN J, YANG J S, DONG S M, et al. Interfacial optimization of SiC nanocomposites reinforced by SiC nanowires with high volume fraction[J]. Journal of the American Ceramic Society, 2019, 102: 5033-5037. [20] NAN B Y, LIU Y S, YOU Q W, et al. Microstructure and properties of porous SiC ceramics modified by CVI-SiC nanowires[J]. Advanced Engineering Materials, 2018, 21: 1800653. [21] WANG H Z, LI X D, MA J, et al. Multi-walled carbon nano-tube-reinforced silicon carbide fibers prepared by polymer-derived ceramic route[J]. Composites Part A: Applied Science and Manufacturing, 2012, 43(3): 317-324. [22] BILL J, HEIMANN D. Polymer-derived ceramic coatings on C/C-SiC composites[J]. Journal of the European Ceramic Society, 1996, 16(10): 1115-1120. [23] IONESCU E, KLEEBE H J, RIEDEL R. Silicon-containing polymer-derived ceramic nanocomposites (PDC-NCs): Preparative approaches and properties[J]. Chemical Society Reviews, 2012, 41: 5032-5052. [24] OTOISHI S, TANGE Y. Growth rate and morphology of silicon carbide whiskers from polycarbosilane[J]. Journal of Crystal Growth, 1999, 200(3-4): 467-471. [25] YOON B H, PARK C S, KIM H E, et al. In situ synthesis of porous silicon carbide (SiC) ceramics decorated with SiC nanowires[J]. Journal of the American Ceramic Society, 2007, 90(12): 3759-3766. [26] LI G Y, LI X D, WANG H, et al. SiC nanowires grown on activated carbon in a polymer pyrolysis route[J]. Materials Science and Engineering: B, 2010, 166(1): 108-112. [27] FU Q G, TAN B Y, ZHUANG L, et al. Significant improvement of mechanical properties of carbon/carbon compo-sites by in situ growth of SiC nanowires[J]. Materials Science and Engineering: A, 2016, 672: 121-128. [28] JU Z C, MA X C, FAN N, et al. High-yield synthesis of single-crystalline 3C-SiC nanowires by a facile autoclave route[J]. Materials Letters, 2007, 61: 3913-3915. [29] WANG L Y, LUO R Y, CUI G Y. Effect of pyrolysis tempera-ture on the mechanical evolution of SiCf/SiC composites fabricated by PIP[J]. Ceramics International, 2020, 46(2): 1297-1306. [30] EVANS A G, CHARLES E A. Fracture toughness determinations by indentation[J]. Journal of the American Ceramic Society, 1976, 59(7-8): 371-372. [31] KANG P C, ZHANG B, WU G H, et al. Synthesis of β-SiC nanowires by ball milled nanoparticles of silicon and carbon[J]. Journal of Alloys and Compounds, 2014, 604: 304-308. [32] WANG D H, XU D, WANG Q, et al. Periodically twinned SiC nanowires[J]. Nanotechnology, 2008, 19(21): 215602. [33] LY H Q, TAYLOR R, DAY R J, et al. Conversion of polycarbosilane (PCS) to SiC-based ceramic Part II. Pyrolysis and characterisation[J] Journal of Materials Science, 2001, 36(16): 4045-4057. [34] LI L, LI H J, LI Y Y, et al. A SiC-ZrB2-ZrC coating toughened by electrophoretically-deposited SiC nanowires to protect C/C composites against thermal shock and oxidation[J]. Applied Surface Science, 2015, 349: 465-471. -

下载:

下载: