Failure mechanism of hybrid fiber networks

-

摘要: 纤维网络材料是一类广泛存在且具有重要应用前景的多功能轻质材料。目前研究主要集中于单一纤维网络材料,但实际应用中大部分纤维网络都是由不同性质纤维构成的混杂纤维网络,其性能和功能的设计空间更大,但失效机制也更复杂。为了进一步提升纤维网络材料的力学性能,深入研究混杂纤维网络的失效过程及失效机制非常重要。为此,本文建立了综合考虑纤维和纤维间连接力学性能的混杂纤维网络模型,系统地研究了混杂纤维网络的失效过程,并讨论分析了纤维混杂比例、纤维间连接强度及纤维总体积分数等因素的影响。结果表明,对于典型混杂纤维网络而言,随着纤维组分的变化,网络的失效存在连接损伤主导、连接与纤维损伤共同主导及纤维损伤主导三类不同的失效模式。其中,由连接和纤维损伤共同主导的失效,损伤分散于整个网络,连接和纤维会表现出协同作用,因此网络具有更好的韧性和强度。由此可见,混杂纤维网络力学性能的设计空间远大于单一纤维网络,具有更广阔的应用前景。Abstract: Fiber network material is a kind of multifunctional lightweight material which exists widely and has important application prospect. At present, researches mainly focus on networks consisting of one type of fibers. However, in practice, most fiber networks are hybrid fiber networks composed of fibers with different properties, which have larger performance and function design space but more complex failure mechanism. In order to further improve the mechanical properties of fiber networks, it is very important to study the failure process and failure mechanism of hybrid fiber networks. Therefore, the hybrid fiber network model was established in this paper to take account of both the mechanical properties of fibers and the inter-fiber connections. Based on the model, the failure process of hybrid fiber networks was systematically studied, and the effects of the fiber mixture ratio, the strength of inter-fiber connections and the total fiber volume fraction were analyzed. The results show that for typical hybrid fiber networks, there are three failure modes: inter-fiber connection dominated failure, inter-fiber connection and fiber co-dominated failure, and fiber dominated failure, with the variation of fiber mixture ratio. When the failure is co-dominated by the connection and fiber damages, the damages disperse throughout the network, and the network presents better toughness and strength. Therefore, the design space of mechanical properties of hybrid fiber network is much larger than that of networks consisting of only one type of fibers, and the hybrid network exhibits a wider application prospect.

-

Key words:

- hybrid fiber networks /

- composite materials /

- strength /

- toughness /

- failure mechanis

-

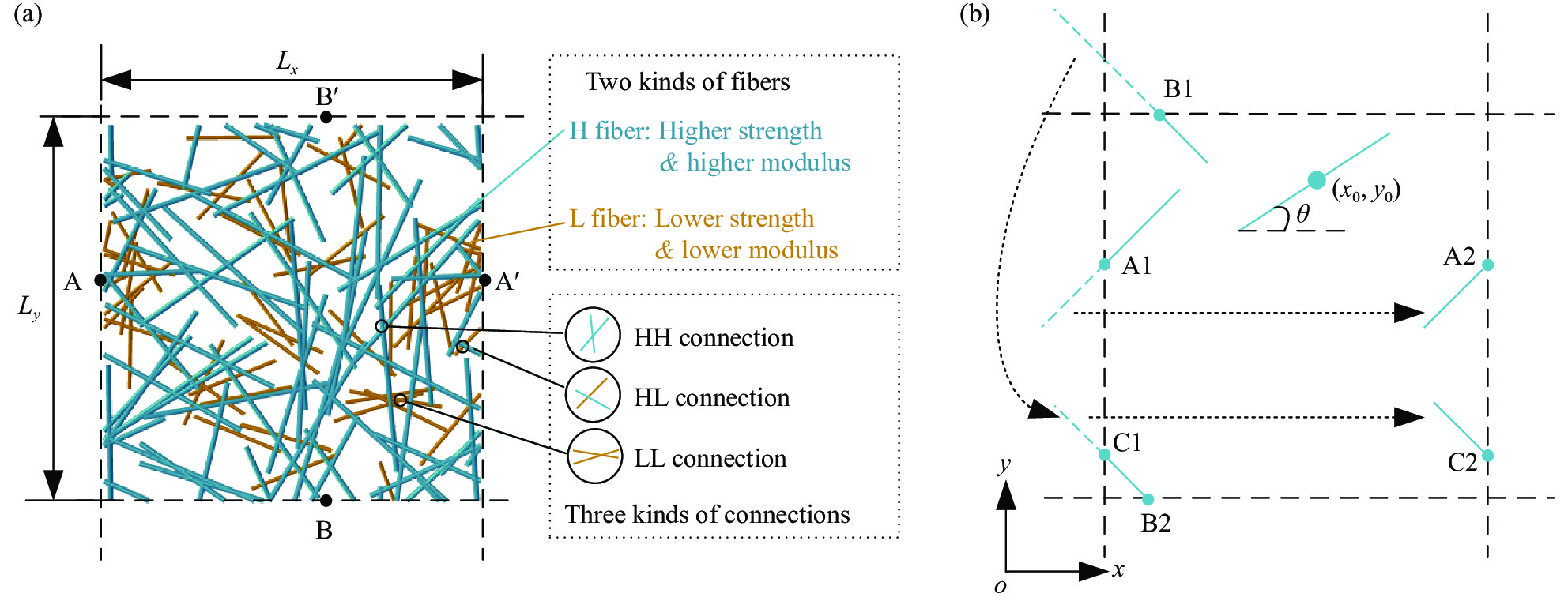

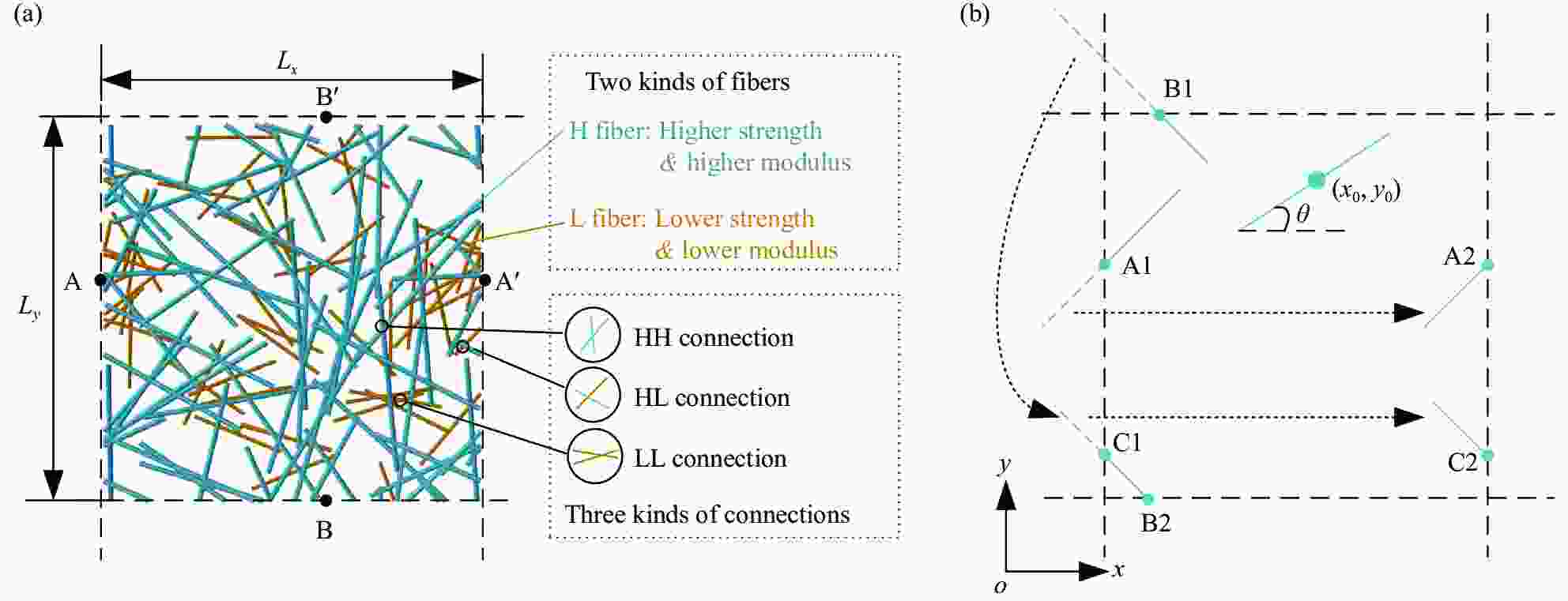

图 1 混杂纤维网络模型:(a) 网络代表性面积单元(RAE)示意图;(b) 周期性代表单元建模过程示意图

Figure 1. Hybrid fiber networks: (a) Representative area element (RAE) of fiber networks; (b) Schematic diagram of the modeling process of a periodic RAE

Lx×Ly—Size of the representative area element; θ—Angle between the fiber and x-axis; A', B'—Corresponding point of A, B for the period boundray; A2, B2 and C2—Corresponding point of A1, B1 and C1

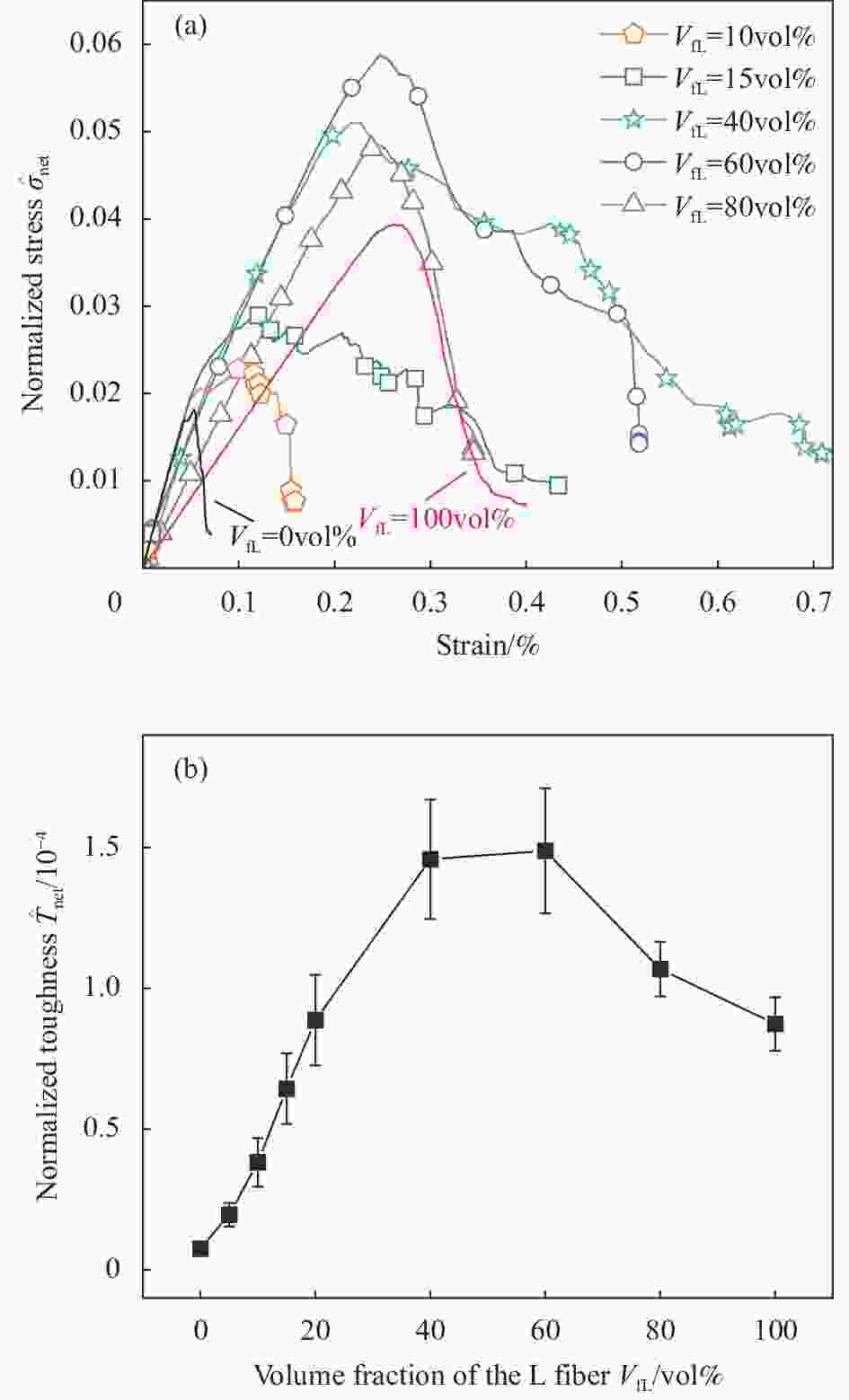

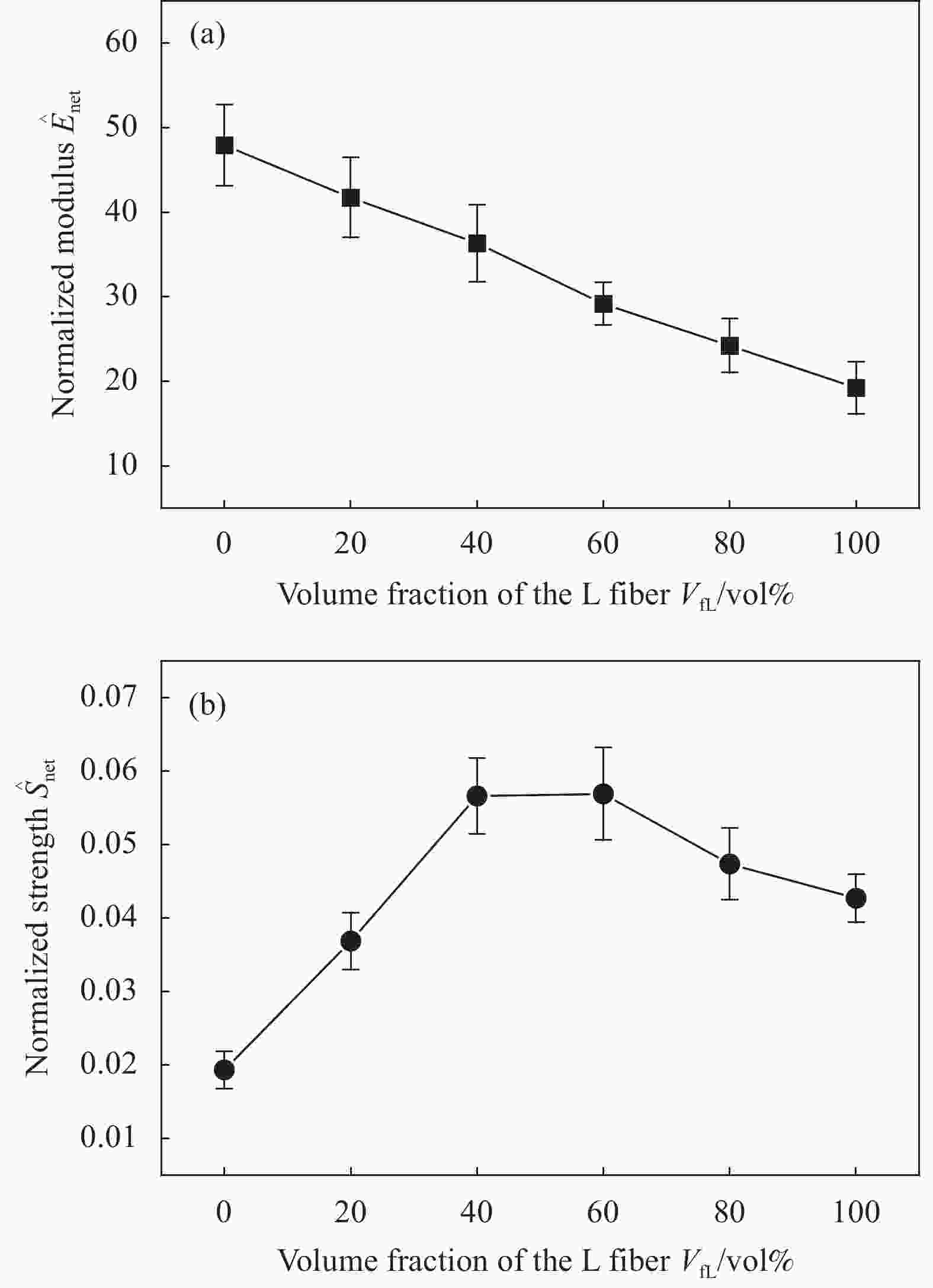

图 2 纤维总体积分数Vf=40vol%时不同低刚度L纤维体积占比VfL对应的应力-应变曲线 (a) 和网络韧性随低刚度L纤维体积占比VfL的变化规律 (b)

Figure 2. Stress-strain curves of networks with different volume fractions of the L fiber VfL (a) and toughness with variable volume fractions of the L fiber VfL for the networks (b) with the total fiber volume fraction Vf=40vol%

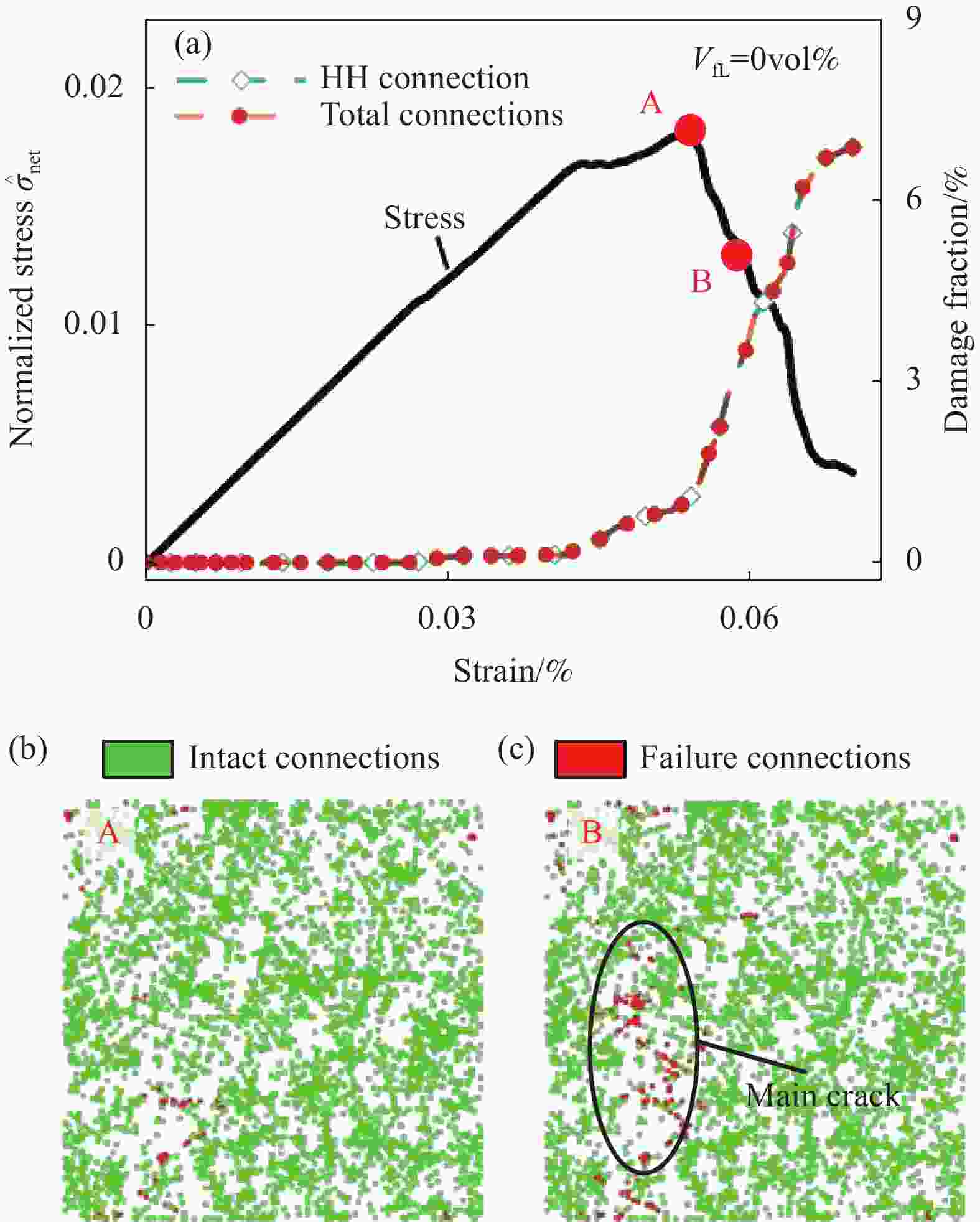

图 3 低刚度L纤维体积占比VfL=0vol%时纤维网络应力-应变曲线和损伤-应变曲线 (a)、网络应力

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (A点)时的损伤分布 (b) 和网络应力${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (B点)时的损伤分布 (c)Figure 3. Stress-strain curve and damage fraction-strain curves (a), damage distributions when the stress of the network

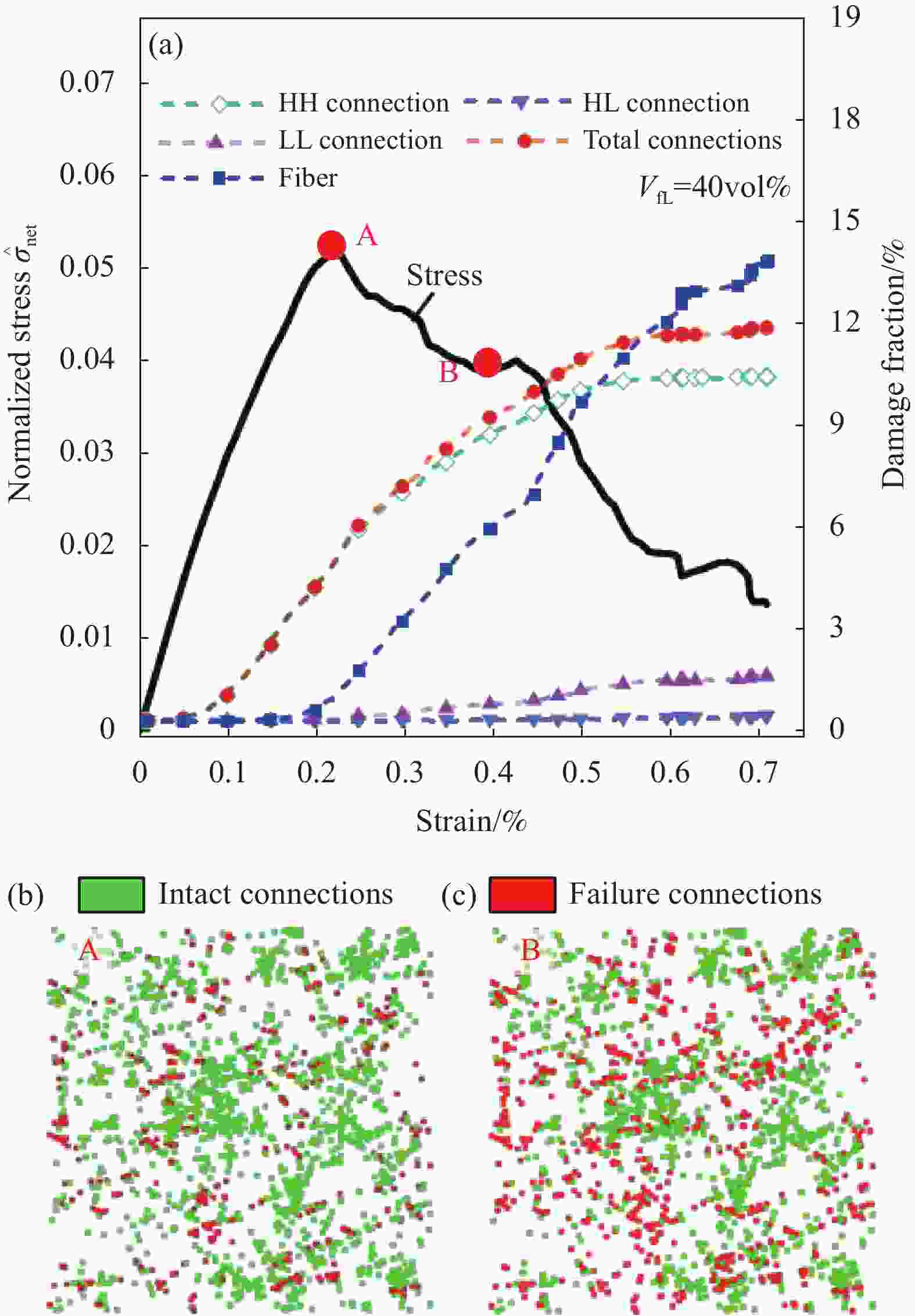

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (point A) (b) and damage distributions when${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (point B) (c) for the networks with the volume fraction of the L fiber VfL=0vol%图 4 低刚度L纤维体积占比VfL=40vol%时纤维网络应力-应变曲线和损伤-应变曲线 (a)、网络应力

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (A点)时损伤分布 (b) 及网络应力${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (B点)时损伤分布 (c)Figure 4. Stress-strain curve and damage fraction-strain curves (a), damage distributions when the stress of the network

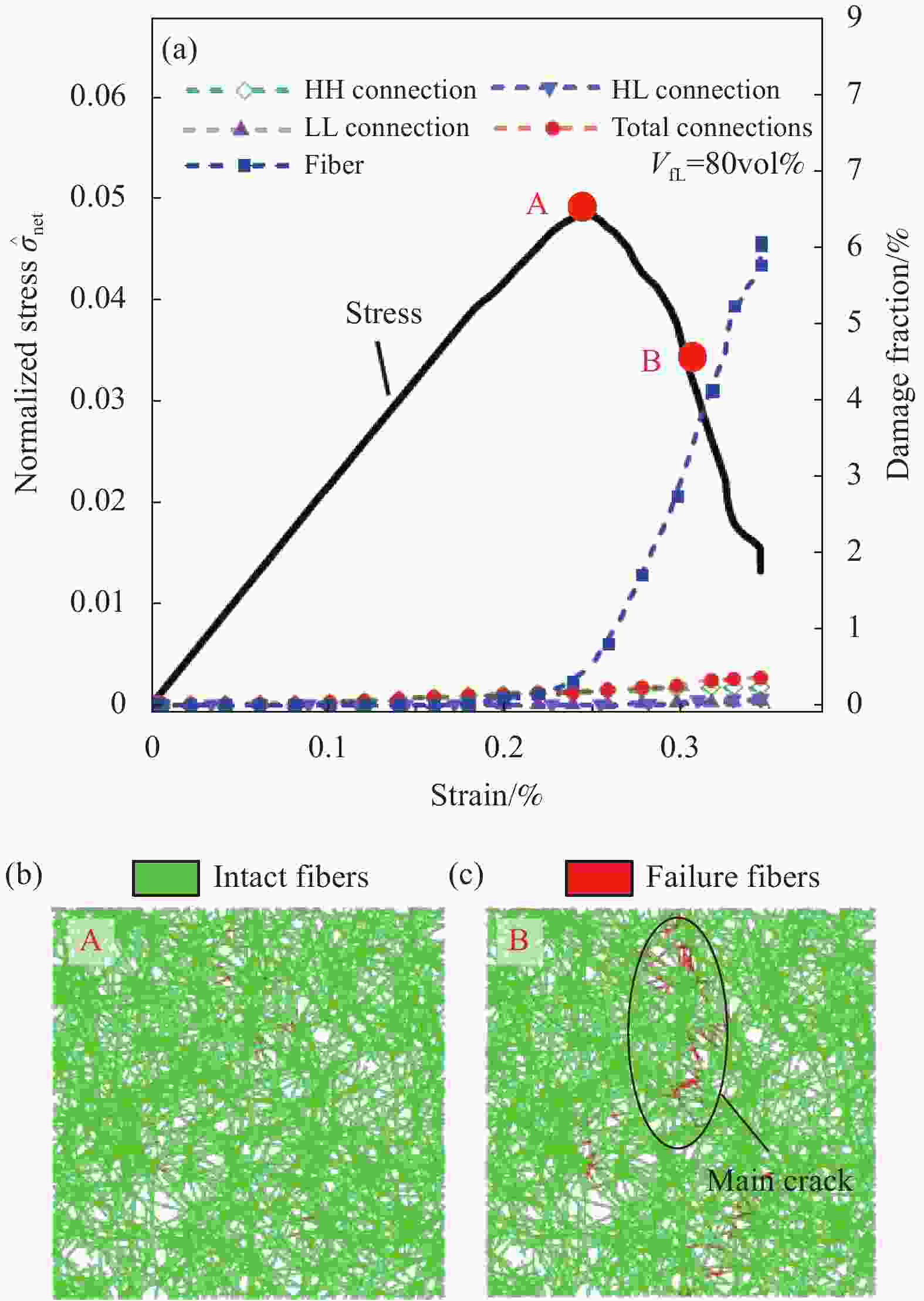

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (point A) (b) and damage distributions when${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (point B) (c) for the networks with the volume fraction of the L fiber VfL=40vol%图 5 低刚度L纤维体积占比VfL=80vol%时纤维网络应力-应变曲线和损伤-应变曲线 (a)、网络应力

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (A点)时损伤分布 (b) 和网络应力${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (B点)时损伤分布 (c)Figure 5. Stress-strain curve and damage fraction-strain curves (a), damage distributions when the stress of the network

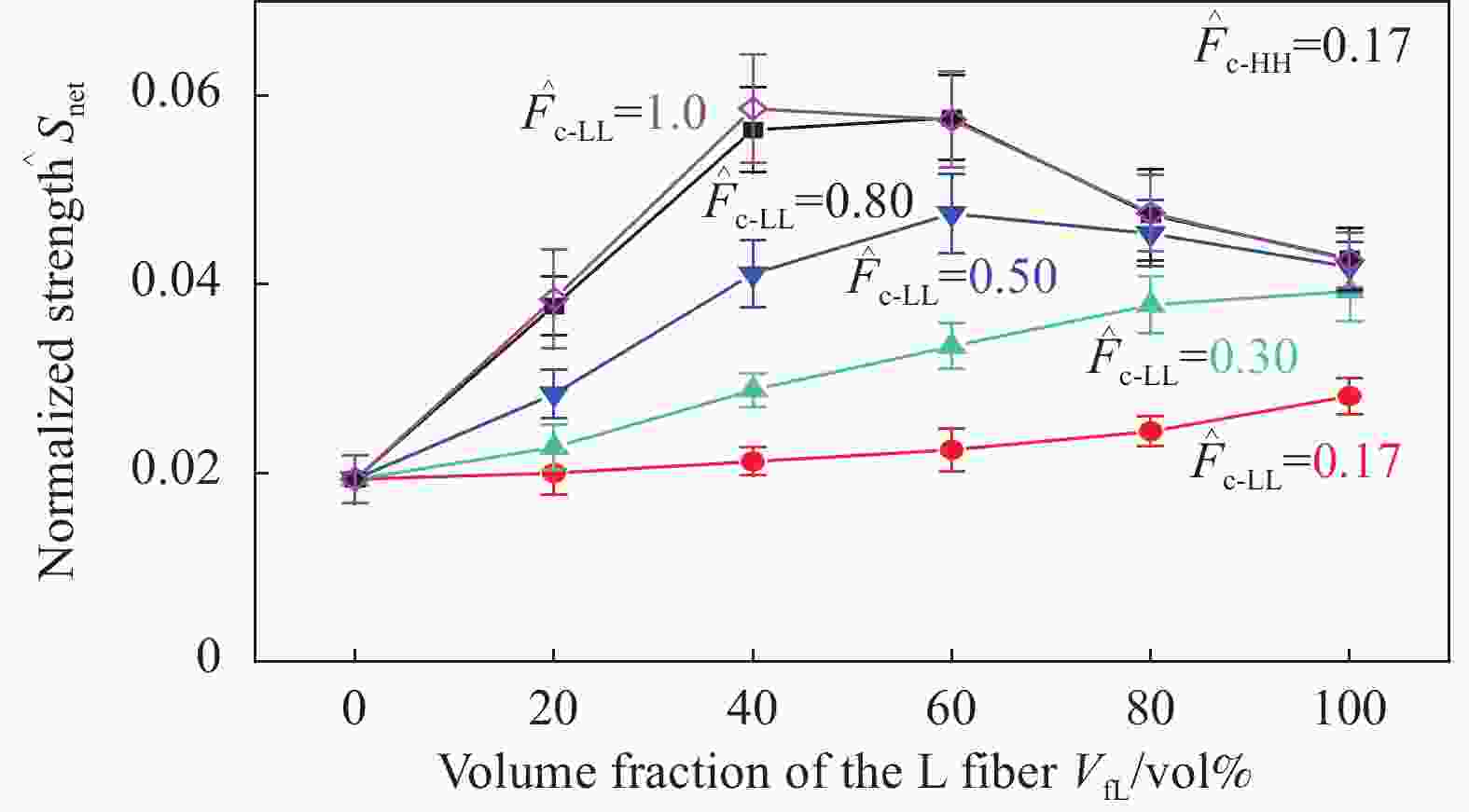

${\sigma _{{\text{net}}}} = \sigma _{{\text{net}}}^{\max }$ (point A) (b) and damage distributions when${\sigma _{{\text{net}}}}{\text{ = }}0.7\sigma _{{\text{net}}}^{{\text{max}}}$ (point B) (c) for the networks with the volume fraction of the L fiber VfL=80vol%图 7 混杂纤维网络中LL连接强度变化时网络强度随低刚度L纤维体积占比VfL的变化规律(纤维总体积分数Vf=40vol%)

Figure 7. Strength of networks with variable strength of the LL connection and variable volume fractions of the L fiber (Total fiber volume fraction Vf=40vol%)

${\hat F_{{\text{c-HL}}}} $—Dimensionless strength of HH connection; ${\hat F_{{\text{c-HH}}}} $—Dimensionless strength of LL connection

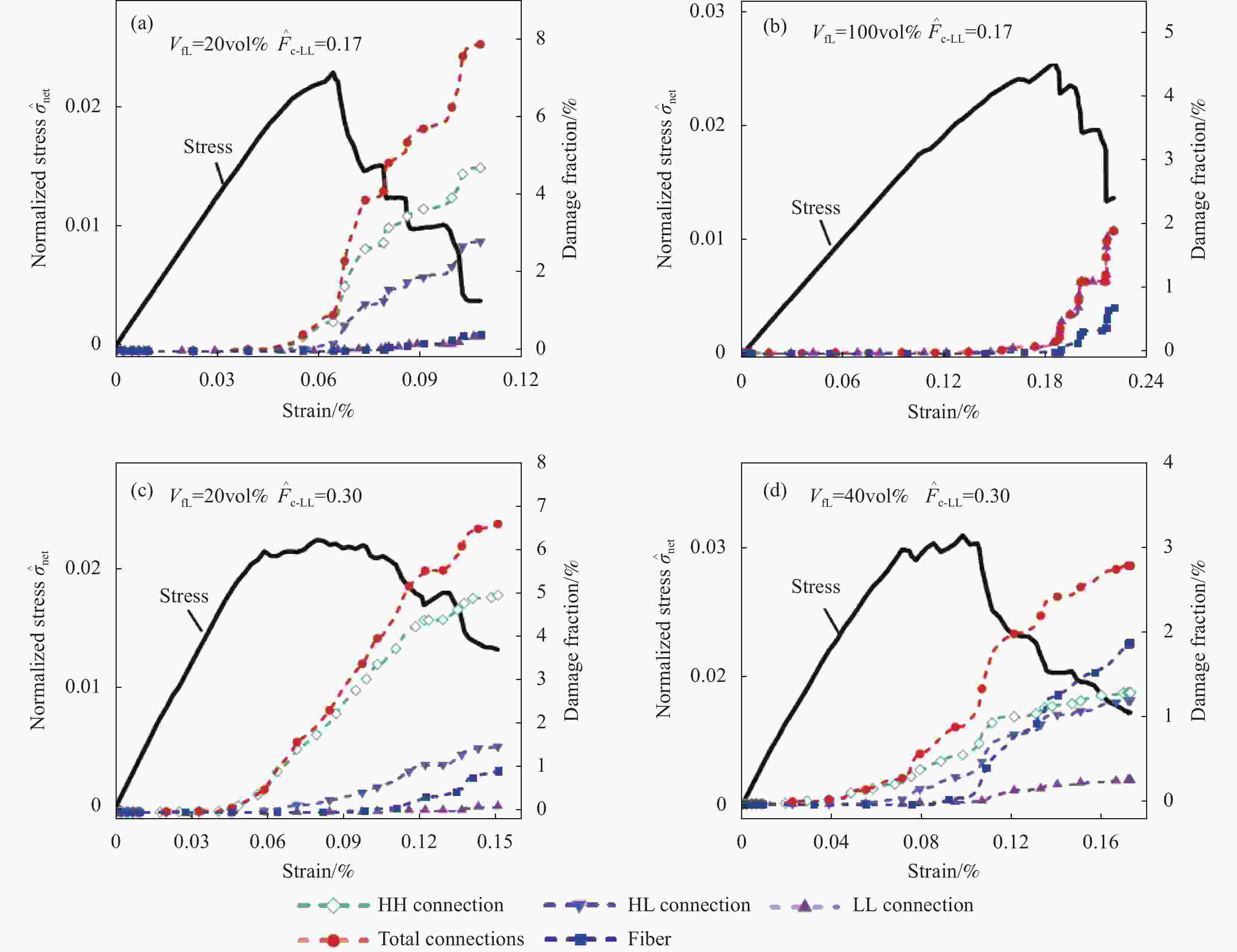

图 8 纤维总体积分数Vf=40vol%时不同无量纲强度

${\hat F_{{\rm{c - LL}}}}$ 及L纤维体积占比VfL下纤维网络应力-应变曲线和损伤-应变曲线:(a)${\hat F_{{\rm{c - LL}}}} = 0.17$ ,VfL=20vol%;(b)${\hat F_{{\rm{c - LL}}}} = 0.17$ ,VfL =100vol%;(c)${\hat F_{{\rm{c - LL}}}} = 0.3$ ,VfL =20vol%;(d)${\hat F_{{\rm{c - LL}}}} = 0.3$ ,VfL =40vol%Figure 8. Stress-strain curves and damage fraction-strain curves of fiber networks with variable dimensionless connection strength

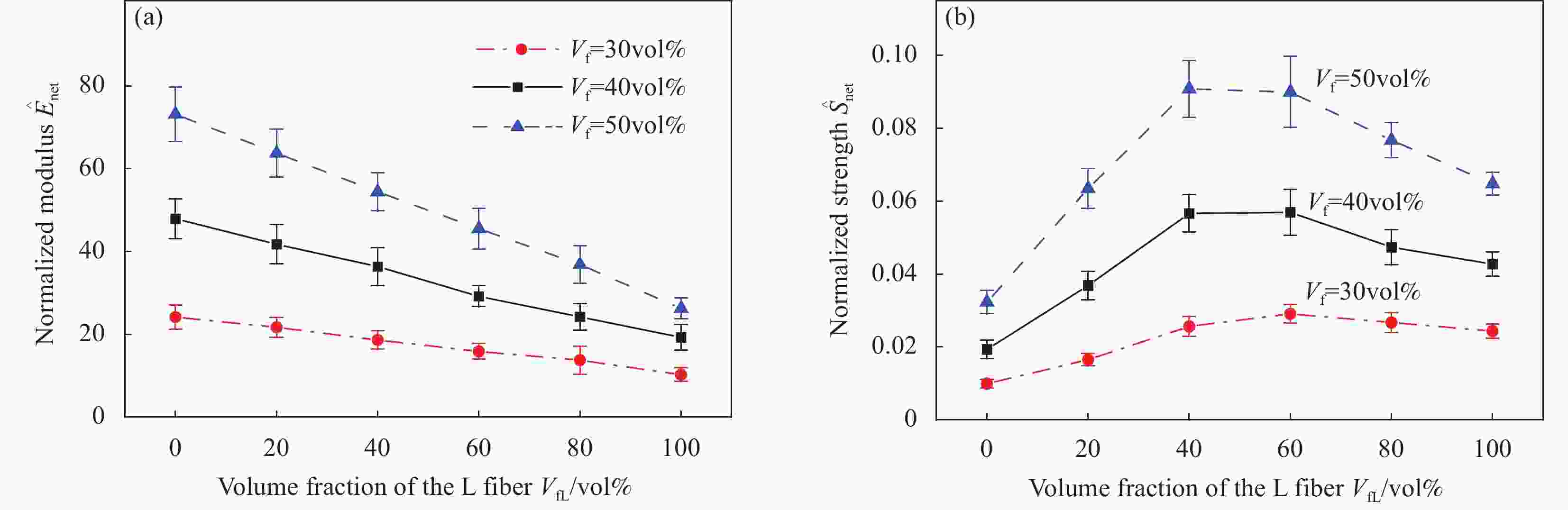

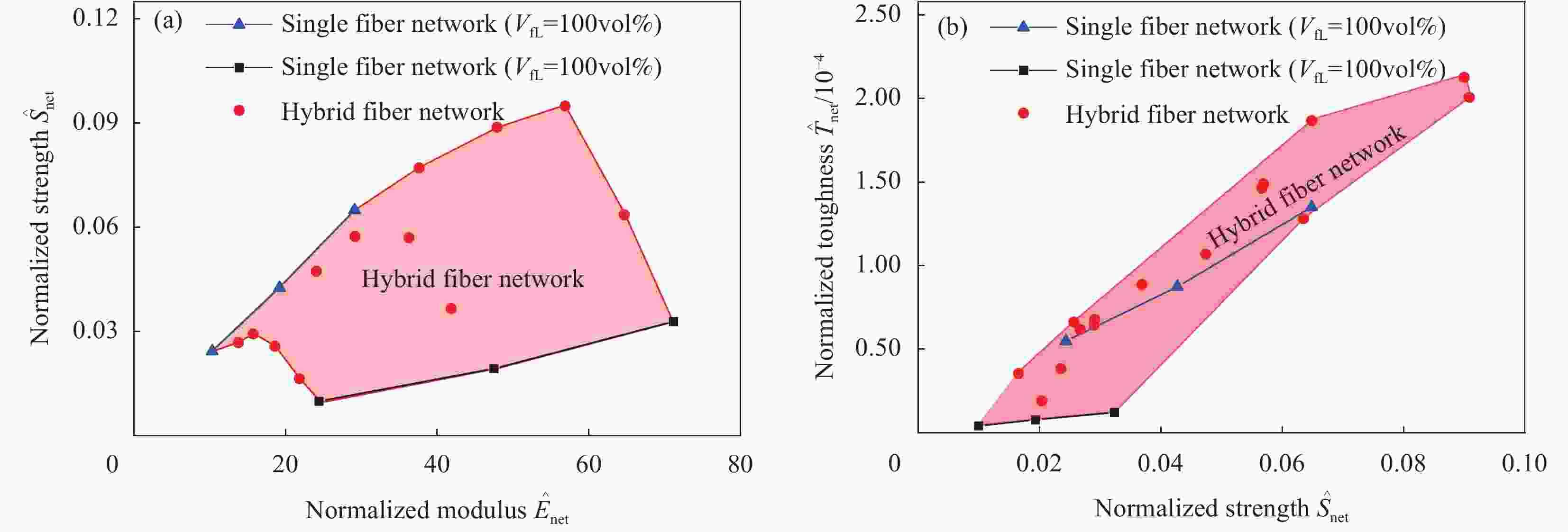

${\hat F_{{\rm{c - LL}}}}$ and volume fractions of the L fiber VfL for the total fiber volume fraction Vf=40vol%: (a)${\hat F_{{\rm{c - LL}}}} = 0.17$ , VfL=20vol%; (b)${\hat F_{{\rm{c - LL}}}} = 0.17$ , VfL=100vol%; (c)${\hat F_{{\rm{c - LL}}}} = 0.3$ , VfL=20vol%; (d)${\hat F_{{\rm{c - LL}}}} = 0.3$ , VfL=40vol%图 10 纤维总体积分数Vf从30vol%至50vol%变化时单一纤维网络和混杂纤维网络的模量-强度可设计空间 (a) 和强度-韧性可设计空间 (b) (区域边界由线性插值获得)

Figure 10. Modulus-strength phase diagram (a) and strength-toughness phase diagram of networks (b) for the fiber networks with the total fiber volume fraction Vf changing from 30vol% to 50vol% (Region boundary is obtained by linear interpolation)

表 1 纤维的力学及几何参数

Table 1. Mechanical and geometric parameters for fibers

Fiber type Modulus Ef/GPa $\rm Strength\;\sigma _{\text{f} }^{\text{b} } /MPa$ Length lf/mm Diameter df/μm H 134 3000 1.0 10.0 L 35 150 0.5 7.1 表 2 纤维间连接的本构和参数

Table 2. Constitutive relations and the relative parameters for connections

Type Stiffness kc/(N·mm−1) Failure load $ F_{\text{c}}^{\text{b}} $/mN HH 8.7 1.0 HL 8.7 4.8 LL 8.7 4.8 Notes: Δuc—Relative displacement of two nodes of a connected element; $F^{\rm{b}}_{\text{ c-LL}} $, $F^{\rm{b}}_{\text{ c-HL}} $, $F^{\rm{b}}_{\text{c-HH}} $—Critical failure load of LL connection, HL connection and HH connection. -

[1] ZHANG Y, DEBENEDICTIS E P, KETEN S. Cohesive and adhesive properties of crosslinked semiflexible biopolymer networks[J]. Soft Matter,2019,15(18):3807-3816. doi: 10.1039/C8SM02277A [2] 左志慧, 胡江天. 细胞骨架生物力学的研究进展[J]. 医学综述, 2013, 19(19):3457-3459. doi: 10.3969/j.issn.1006-2084.2013.19.001ZUO Zhihui, HU Jiangtian. Research advances in cytoskeletal biomechanics[J]. Medical Recapitulate,2013,19(19):3457-3459(in Chinese). doi: 10.3969/j.issn.1006-2084.2013.19.001 [3] MENG Q, SHI X. A microstructure-based constitutive model of anisotropic cellulose nanopaper with aligned nano-fibers[J]. Extreme Mechanics Letters,2021,43:101158. doi: 10.1016/j.eml.2020.101158 [4] LI Y, STAPLETON S E, REESE S, et al. Anisotropic elastic-plastic deformation of paper: Out-of-plane model[J]. International Journal of Solids and Structures,2018,130-131:172-182. doi: 10.1016/j.ijsolstr.2017.10.003 [5] WU X, XU Y, HU Y, et al. Microfluidic-spinning construction of black-phosphorus-hybrid microfibres for non-woven fabrics toward a high energy density flexible supercapacitor[J]. Nature Communications,2018,9(1):1-11. doi: 10.1038/s41467-017-02088-w [6] ALEMOUR B, BADRAN O, HASSAN M R. A review of using conductive composite materials in solving lightening strike and ice accumulation problems in aviation[J]. Journal of Aerospace Technology and Management,2019,11:e1919. [7] JI H, ZHAO R, ZHANG N, et al. Lightweight and flexible electrospun polymer nanofiber/metal nanoparticle hybrid membrane for high-performance electromagnetic interference shielding[J]. NPG Asia Materials,2018,10(8):749-760. doi: 10.1038/s41427-018-0070-1 [8] 蔡艳芝, 王源, 成来飞, 等. CNT纸/SiC对称梯度层状复合材料的高温电磁屏蔽性能和介电性能[J]. 复合材料学报, 2020, 37(11):2877-3459. doi: 10.13801/j.cnki.fhclxb.20200723.001CAI Yanzhi, WANG Yuan, CHENG Laifei, et al. High-temperature electromagnetic shielding and dielectric properties of CNT buckypaper/SiC symmetric graded laminated composite[J]. Acta Materiae Compositae Sinica,2020,37(11):2877-3459(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200723.001 [9] FAN M, WU L, HU Y, et al. A highly stretchable natural rubber/buckypaper/natural rubber (Nr/N-Bp/Nr) sandwich strain sensor with ultrahigh sensitivity[J]. Advanced Composites and Hybrid Materials,2021,4(4):1039-1047. doi: 10.1007/s42114-021-00298-x [10] HEYDEN S, GUSTAFSSON P J. Simulation of fracture in a cellulose fibre network[J]. Journal of Pulp and Paper Science,1998,24(5):160-165. [11] CHEN N, KOKER M K A, UZUN S, et al. In-situ X-ray study of the deformation mechanisms of non-woven polypropylene[J]. International Journal of Solids and Structures,2016,97-98:200-208. doi: 10.1016/j.ijsolstr.2016.07.028 [12] DEOGEKAR S, ISLAM M R, PICU R C. Parameters controlling the strength of stochastic fibrous materials[J]. International Journal of Solids and Structures,2019,168:194-202. doi: 10.1016/j.ijsolstr.2019.03.033 [13] BORODULINA S, MOTAMEDIAN H R, KULACHENKO A. Effect of fiber and bond strength variations on the tensile stiffness and strength of fiber networks[J]. International Journal of Solids and Structures,2018,154:19-32. doi: 10.1016/j.ijsolstr.2016.12.013 [14] DEOGEKAR S, PICU R C. On the strength of random fiber networks[J]. Journal of the Mechanics and Physics of Solids,2018,116:1-16. [15] KULACHENKO A, UESAKA T. Direct simulations of fiber network deformation and failure[J]. Mechanics of Materials,2012,51:1-14. doi: 10.1016/j.mechmat.2012.03.010 [16] SHAHSAVARI A S, PICU R C. Exceptional stiffening in composite fiber networks[J]. Physical Review E,2015,92(1):012401. doi: 10.1103/PhysRevE.92.012401 [17] RAUB C B, SURESH V, KRASIEVA T, et al. Noninvasive assessment of collagen gel microstructure and mechanics using multiphoton microscopy[J]. Biophysical Journal,2007,92(6):2212-2222. doi: 10.1529/biophysj.106.097998 [18] NAIK N, CAVES J, CHAIKOF E L, et al. Generation of spatially aligned collagen fiber networks through microtransfer molding[J]. Advanced Healthcare Materials,2014,3(3):367-374. doi: 10.1002/adhm.201300112 [19] FLETCHER D A, MULLINS R D. Cell mechanics and the cytoskeleton[J]. Nature,2010,463:485-492. doi: 10.1038/nature08908 [20] BAI M, MISSEL A R, LEVINE A J, et al. On the role of the filament length distribution in the mechanics of semiflexible networks[J]. Acta Biomaterialia,2011,7(5):2109-2118. doi: 10.1016/j.actbio.2010.12.025 [21] LIN Y C, KOENDERINK G H, MACKINTOSH F C, et al. Control of non-linear elasticity in F-actin networks with microtubules[J]. Soft Matter,2011,7(3):902-906. doi: 10.1039/C0SM00478B [22] BAI M, MISSEL A R, KLUG W S, et al. The mechanics and affine-nonaffine transition in polydisperse semiflexible networks[J]. Soft Matter,2011,7(3):907-914. doi: 10.1039/C0SM00496K [23] POURJAVADI A, MAZAHERI T Z, SALAMI H, et al. Both tough and soft double network hydrogel nanocomposite based on O-carboxymethyl chitosan/poly(vinyl alcohol) and graphene oxide: A promising alternative for tissue engineering[J]. Polymer Engineering & Science,2020,60(5):889-899. [24] GONG J P, KATSUYAMA Y, KUROKAWA T, et al. Double-network hydrogels with extremely high mechanical strength[J]. Advanced Materials,2003,15(14):1155-1158. doi: 10.1002/adma.200304907 [25] YANG J, KANG Q, ZHANG B, et al. Strong, tough, anti-freezing, non-drying and sensitive ionic sensor based on fully physical cross-linked double network hydrogel[J]. Materials Science and Engineering: C,2021,130:112452. doi: 10.1016/j.msec.2021.112452 [26] 李小林, 樊新波, 王建锋. 加工芳纶纳米纤维/聚乙烯醇水凝胶制备高强度复合薄膜[J]. 复合材料学报, 2021, 38(12):3986-3995. doi: 10.13801/j.cnki.fhclxb.20210205.001LI Xiaolin, FAN Xinbo, WANG Jianfeng. Processing aramid nanofiber/poly(vinyl alcohol) hydrogel into high-strength composite films[J]. Acta Materiae Compositae Sinica,2021,38(12):3986-3995(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210205.001 [27] 杨斌. 对位芳纶浆粕性能结构表征及成纸性能研究[D]. 西安: 陕西科技大学, 2013.YANG Bin. Characterization and research of PPTA-pulp properties and structure and sheet forming performance[D]. Xi'an: Shanxi University of Science and Technology, 2013(in Chinese). [28] YAO L R, ZHAO W T, XU S Q, et al. The preparation of aramid paper and its properties[J]. Advanced Materials Research, 2013, 796: 290-293. [29] CHEN Y L, PAN F, GUO Z Y, et al. Stiffness threshold of randomly distributed carbon nanotube networks[J]. Journal of the Mechanics and Physics of Solids,2015,84:395-423. doi: 10.1016/j.jmps.2015.07.016 [30] PAN F, CHEN Y, QIN Q. Stiffness thresholds of buckypapers under arbitrary loads[J]. Mechanics of Materials,2016,96:151-168. doi: 10.1016/j.mechmat.2016.02.008 [31] PAN F, ZHANG F, CHEN Y, et al. In-plane and out-of-plane stiffness of 2D random fiber networks: Micromechanics and non-classical stiffness relation[J]. Extreme Mechanics Letters,2020,36:100658. doi: 10.1016/j.eml.2020.100658 [32] MAGNUSSON M S. Investigation of interfibre joint failure and how to tailor their properties for paper strength[J]. Nordic Pulp & Paper Research Journal,2016,31(1):109-122. [33] GOUTIANOS S, MAO R, PEIJS T. Effect of inter-fibre bonding on the fracture of fibrous networks with strong interactions[J]. International Journal of Solids and Structures,2018,136-137:271-278. doi: 10.1016/j.ijsolstr.2017.12.020 [34] FISCHER W J, ZANKEL A, GANSER C, et al. Imaging of the formerly bonded area of individual fibre to fibre joints with SEM and AFM[J]. Cellulose,2014,21(1):251-260. doi: 10.1007/s10570-013-0107-0 [35] MAGNUSSON M S, ZHANG X, ÖSTLUND S. Experimental evaluation of the interfibre joint strength of papermaking fibres in terms of manufacturing parameters and in two different loading directions[J]. Experimental Mechanics,2013,53(9):1621-1634. doi: 10.1007/s11340-013-9757-y [36] HEYDEN S. Network modelling for evaluation of mechani-cal properties of cellulose fibre fluff[D]. Lund: Lund University, 2000. [37] RIGDAHL M, WESTERLIND B, HOLLMARK H. Analysis of cellulose networks by the finite element method[J]. Jour-nal of Materials Science,1984,19(12):3945-3952. doi: 10.1007/BF00980758 [38] ÅSTRÖM J, SAARINEN S, NISKANEN K, et al. Microscopic mechanics of fiber networks[J]. Journal of Applied Physics,1994,75(5):2383-2392. doi: 10.1063/1.356259 [39] CHAVOSHNEJAD P, RAZAVI M J. Effect of the interfiber bonding on the mechanical behavior of electrospun fibrous mats[J]. Scientific Reports,2020,10(1):1-10. doi: 10.1038/s41598-019-56847-4 [40] NEGI V, PICU R. Tensile behavior of non-crosslinked networks of athermal fibers in the presence of entanglements and friction[J]. Soft Matter,2021,17(45):10186-10197. doi: 10.1039/D0SM01297A [41] RIDRUEJO A, GONZÁLEZ C, LLORCA J. Damage micromechanisms and notch sensitivity of glass-fiber non-woven felts: An experimental and numerical study[J]. Journal of the Mechanics and Physics of Solids,2010,58(10):1628-1645. doi: 10.1016/j.jmps.2010.07.005 [42] SHAHSAVARI A S, PICU R C. Size effect on mechanical behavior of random fiber networks[J]. International Journal of Solids and Structures,2013,50(20):3332-3338. [43] SUN J, ZHAO X H, ILLEPERUMA W R K, et al. Highly stretchable and tough hydrogels[J]. Nature,2012,489(7414):133-136. doi: 10.1038/nature11409 -

下载:

下载: