Preparation and properties of BNmf-Si3N4w/Si3N4 composites

-

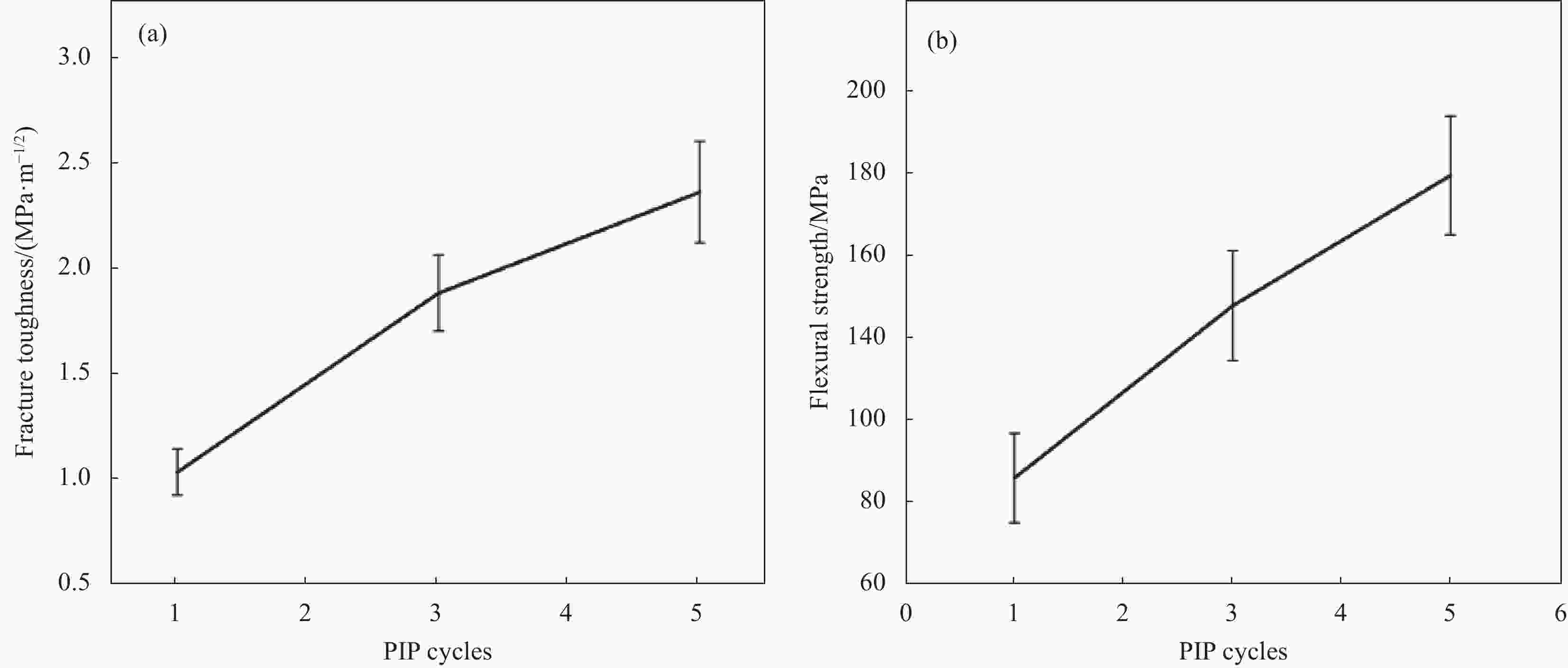

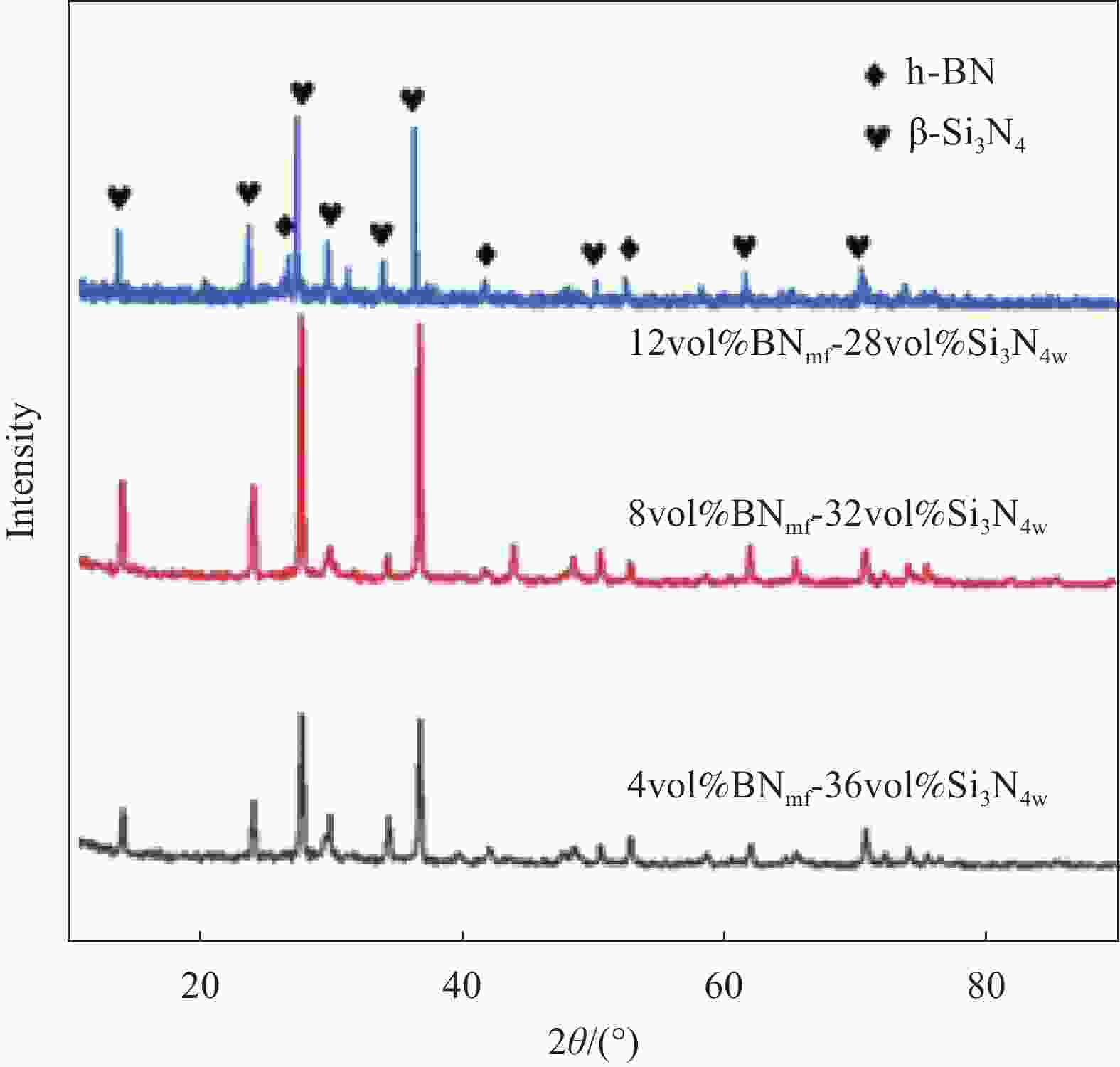

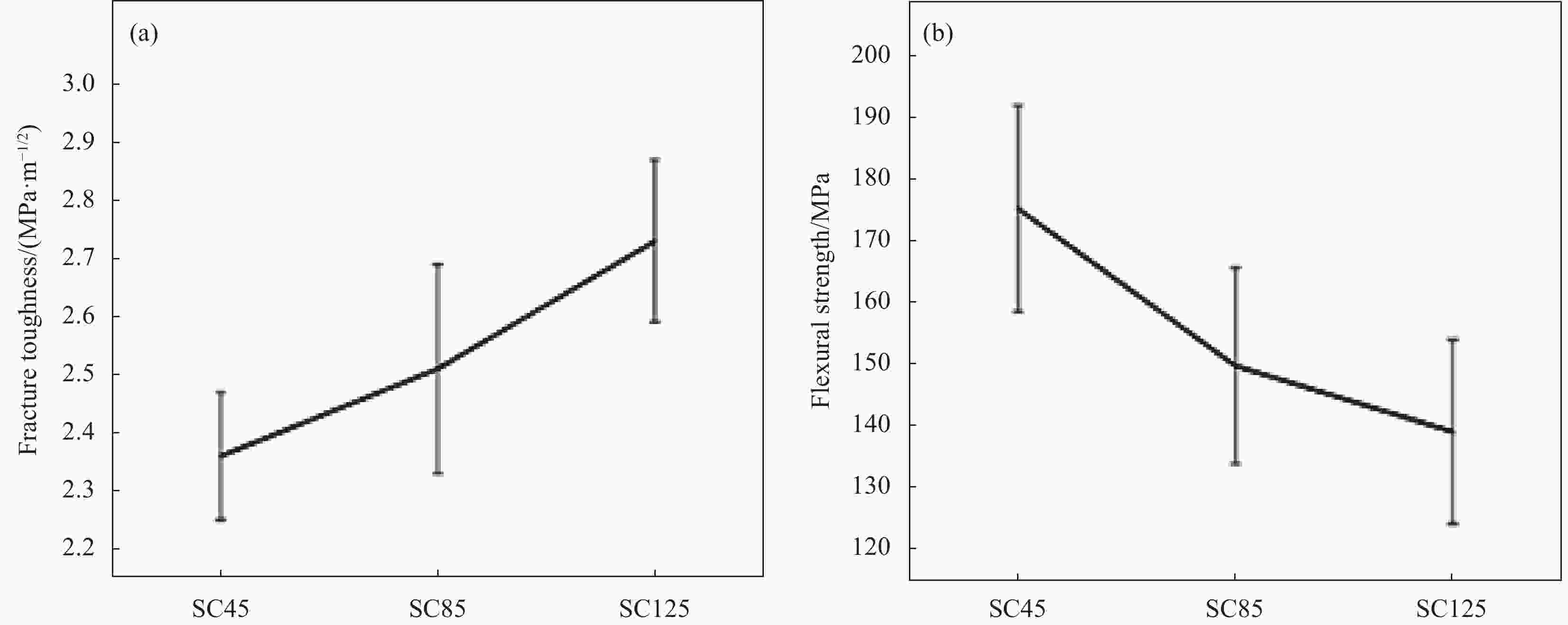

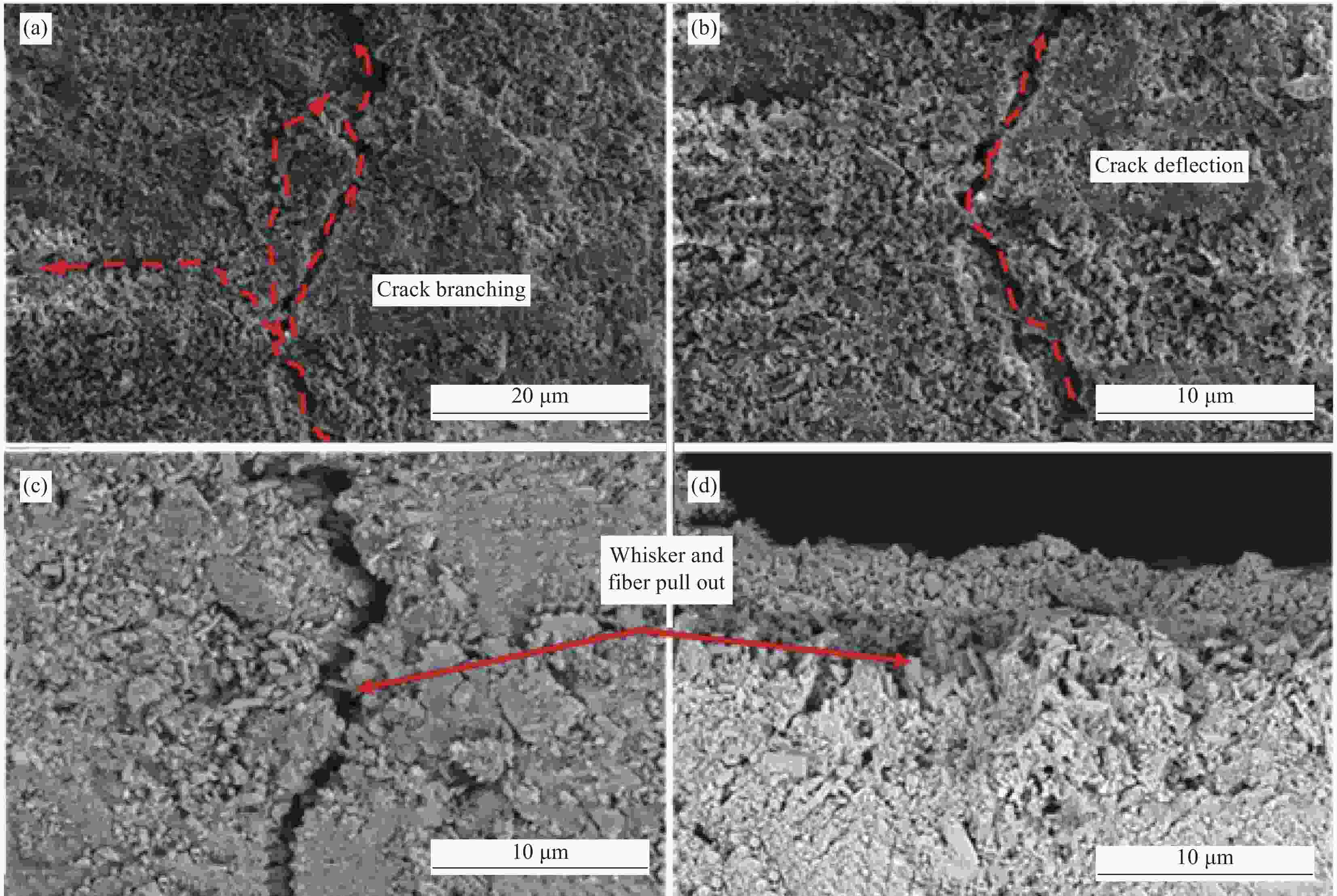

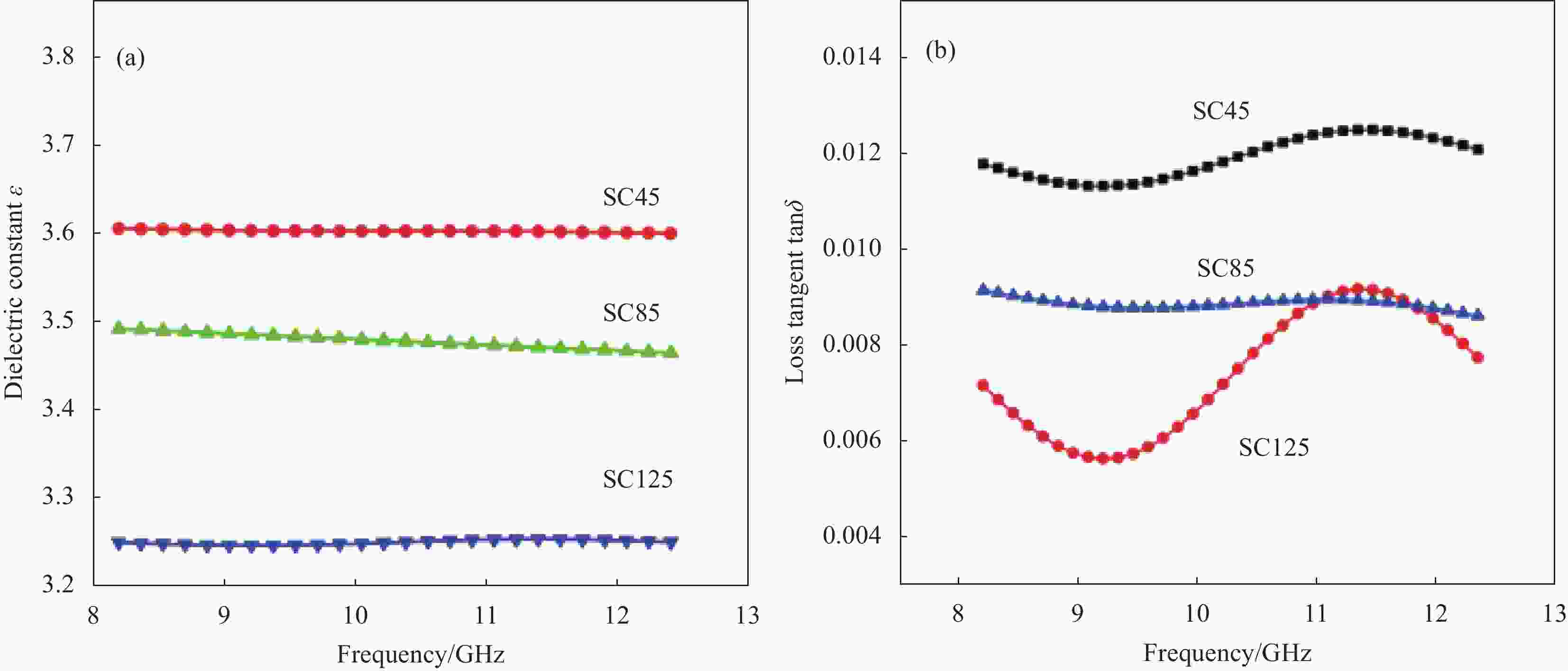

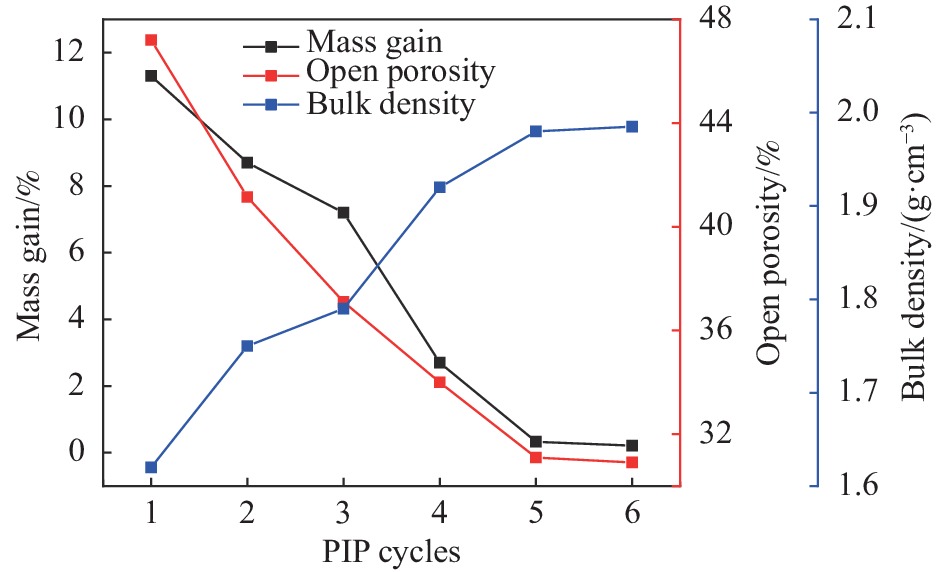

摘要: 为制备一种介电性能和力学性能优异的高温透波材料,采用凝胶注模(GC)结合先驱体浸渍裂解(PIP)工艺制备了BNmf-Si3N4w/Si3N4复合材料。研究了浸渍裂解次数及BNmf含量对复合材料的力学性能与介电性能的影响。结果表明:(1) 随着PIP循环次数增加,复合材料的密度增大,气孔率降低,氮化硅基体逐渐形成三维网络结构包裹在复相微米增强体周围,复合材料力学性能提升;(2) 当BNmf含量从4vol%增加到12vol%时,弯曲强度从175.5 MPa降低到139.3 MPa,断裂韧性从2.36 MPa·m1/2增加到2.73 MPa·m1/2,介电常数从3.62下降到3.25,介电损耗角正切从0.012下降到0.007;(3) BNmf-Si3N4w/Si3N4复合材料的强韧化机制主要为裂纹分叉、裂纹偏转及BNmf及Si3N4w的拔出,三种机制有效降低主裂纹对复合材料的损害。Abstract: To prepare a high-temperature wave-transparent material with excellent dielectric and mechanical properties, the BNmf-Si3N4w/Si3N4 composite material was prepared by gel-casting (GC) and precursor infiltration and pyrolysis (PIP) process. The effects of the cycles of PIP and the BNmf content on the mechanical properties and dielectric properties of composite materials were studied. The results show that: (1) As the number of PIP cycles increases, the density of the composite material increases, the porosity decreases, and the mechanical properties improve. The silicon nitride matrix gradually forms a three-dimensional network structure wrapped around the multiphase micro-reinforcement; (2) When the content of BNmf increases from 4vol% to 12vol%, the bending strength decreases from 175.5 MPa to 139.3 MPa, and the fracture toughness increases from 2.36 MPa·m1/2 to 2.73 MPa·m1/2, the dielectric constant decreases from 3.62 to 3.25, and the dielectric loss tangent decreases from 0.012 to 0.007; (3) The strengthening and toughening mechanisms of BNmf-Si3N4w/Si3N4 composites are mainly crack bifurcation, crack deflection, and pull-out of BNmf and Si3N4w. Three mechanisms effectively reduce the damage of the main crack to the composite.

-

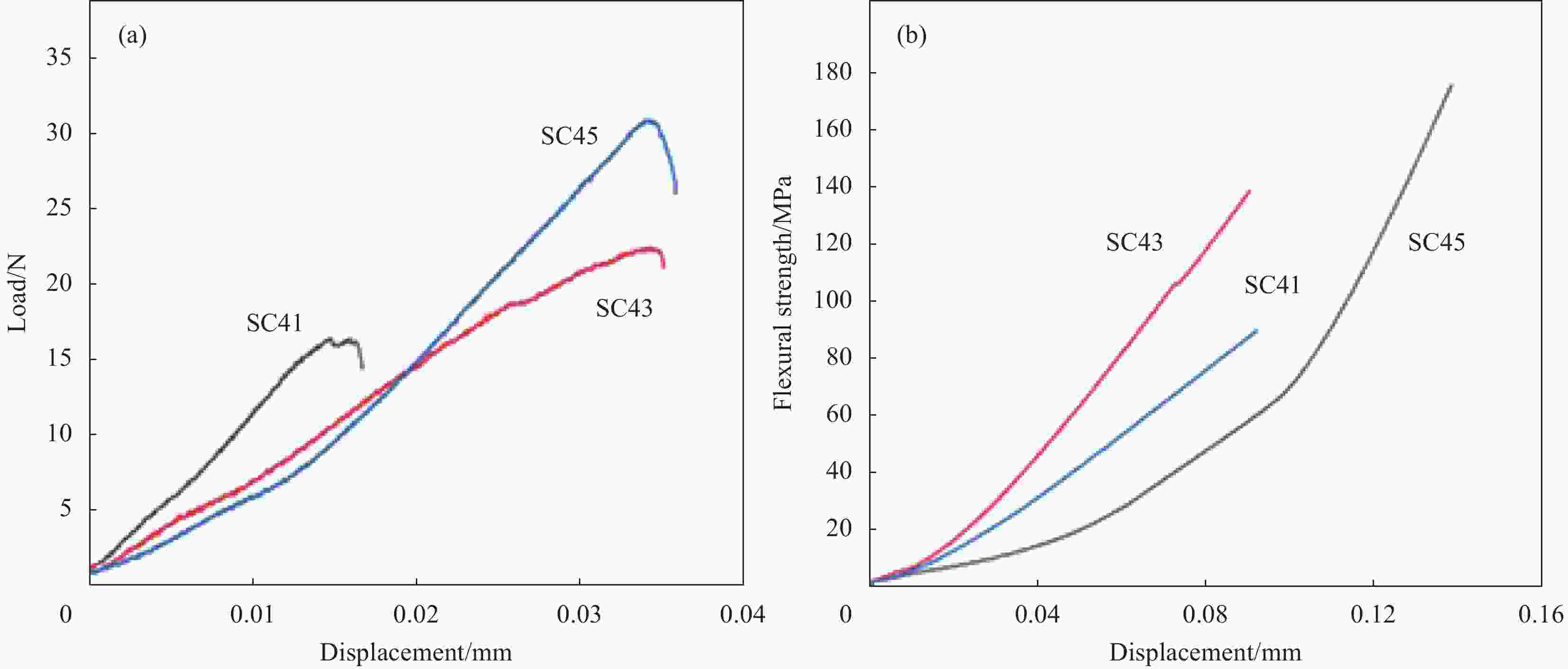

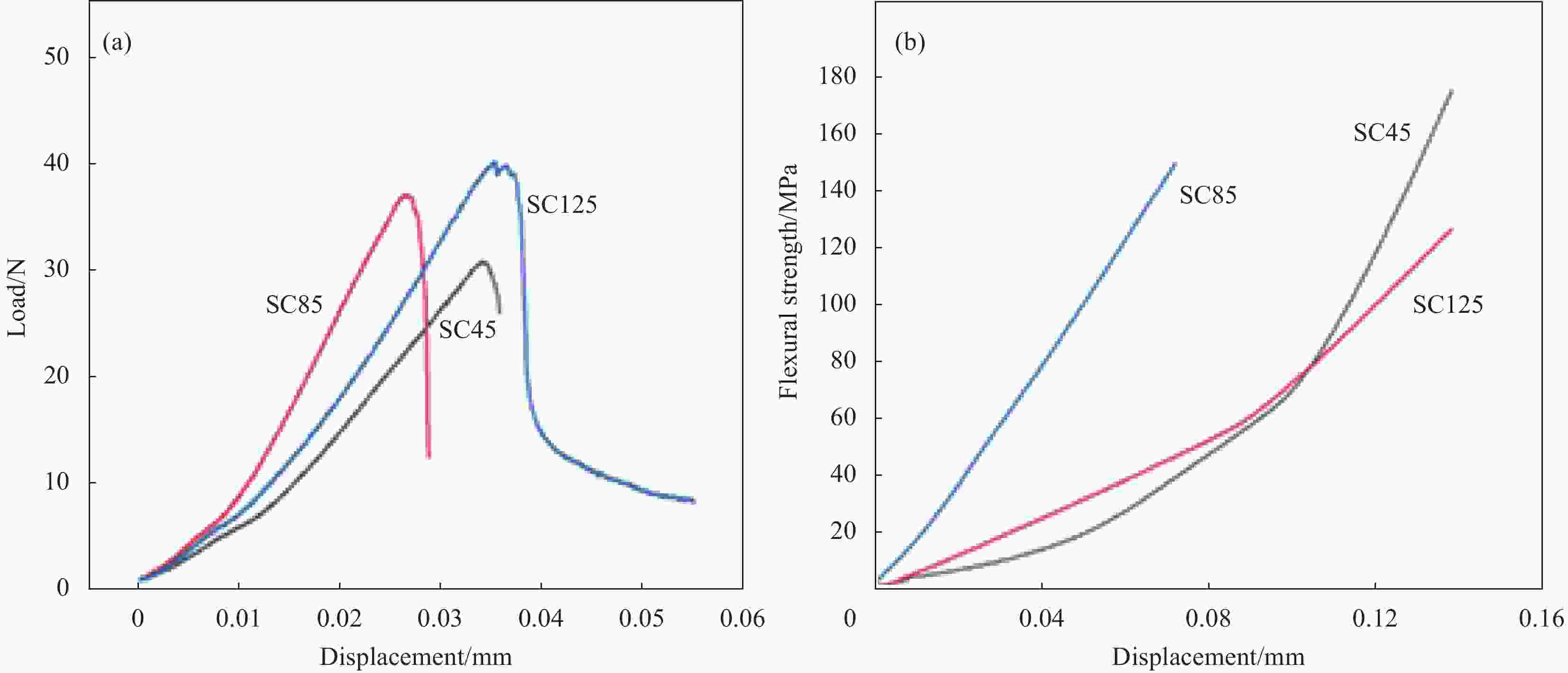

图 3 不同PIP循环次数的BNmf-Si3N4w/Si3N4复合材料的力学性能测试曲线:(a) 断裂韧性的载荷-位移曲线;(b) 三点弯的应力-位移曲线

Figure 3. Mechanical properties measurement curves of BNmf-Si3N4w/Si3N4 composites with different PIP cycles: (a) Load-displacement curves of fracture toughness samples; (b) Stress-displacement curves of three-point bending samples

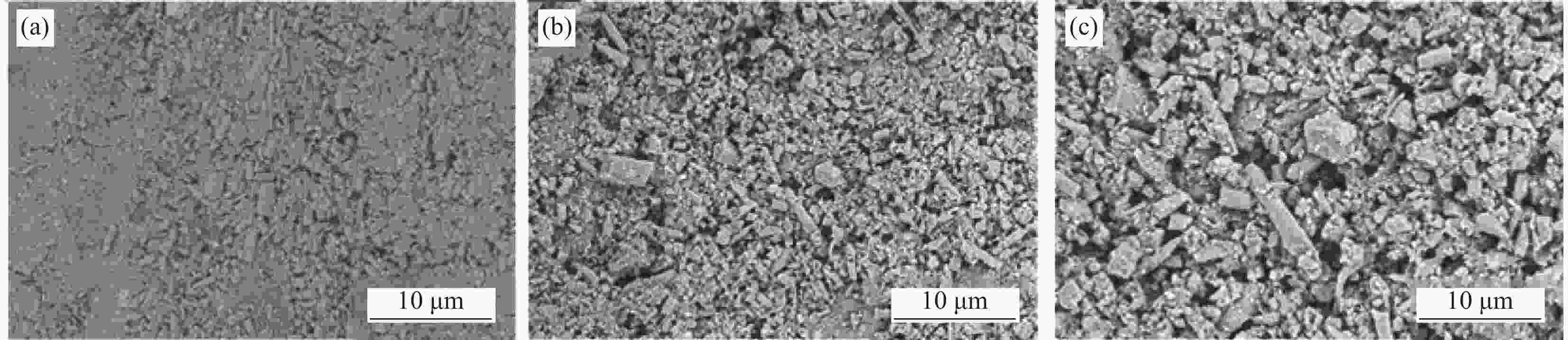

图 6 不同增强体配比BNmf-Si3N4w/Si3N4复合材料抛光表面的SEM图像:(a) 4vol%BNmf-36vol%Si3N4w;(b) 8vol%BNmf-32vol%Si3N4w;(c) 12vol%BNmf-28vol%Si3N4w

Figure 6. SEM images of polished surfaces of BNmf-Si3N4w/Si3N4 composite materials with different reinforcement ratios: (a) 4vol%BNmf-36vol%Si3N4w; (b) 8vol%BNmf-32vol%Si3N4w; (c) 12vol%BNmf-28vol%Si3N4w

图 7 不同增强体配比BNmf-Si3N4w/Si3N4复合材料的力学性能测试曲线:(a) 断裂韧性载荷-位移曲线;(b) 三点弯应力-位移曲线

Figure 7. Mechanical properties measurement curves of BNmf-Si3N4w/Si3N4 composites with different reinforcement ratios: (a) Load-displacement curves of fracture toughness samples; (b) Stress-displacement curves of three-point bending samples

表 1 BNmf-Si3N4w预制体的命名

Table 1. Naming of BNmf-Si3N4w preform

BNmf/vol% PIP cycles SC41 4 1 SC43 4 3 SC45 4 5 SC85 8 5 SC124 12 5 Note: PIP—Precursor infiltration pyrolysis. -

[1] JOHNSON C R, JASIK H. Antenna engineering handbook[M]. New York: McGraw-Hill Book Company,1984. [2] ZHANG X Y, LI N, LAN T, et al. In-situ reaction synthesis of porous Si2N2O-Si3N4 multiphase ceramics with low dielectric constant via silica poly-hollow microspheres[J]. Ceramics International,2017,43:4235-4240. [3] 彭望泽. 防空导弹天线罩[M]. 北京: 中国航天出版社, 1993.PENG Wangze. Air defense missile radome[M]. Beijing: China Astronautic Publishing House, 1993(in Chinese). [4] 杜耀惟. 天线罩电信设计方法[M]. 北京: 国家工业出版社, 1993.DU Yaowei. The design method of telecom radome[M]. Beijing: National Defence Industry Press, 1993(in Chinese). [5] 杨洁颖, 吕毅, 张春波, 等. 飞行器用透波材料及天线罩技术研究进展[J]. 宇航材料工艺, 2015(4):6-9.YANG Jieying, LV Yi, ZHANG Chunbo, et al. Improvements of microwave transparent composites and aircraft radome[J]. Aerospace Materials & Technology,2015(4):6-9(in Chinese). [6] 柳敏静, 郭东明, 康仁科, 等. 天线罩系统电气性能分析[J]. 大连理工大学学报, 2005, 45(1):39-44.LIU Minjing, GUO Dongming, KANG Renke, et al. Analytical method of electrical performance of antenna radome system[J]. Journal of Dalian University of Technology,2005,45(1):39-44(in Chinese). [7] 卢嘉德. 固体火箭发动机复合材料技术的进展及其应用前景[J]. 固体火箭技术, 2001, 24(1):46-52.LU Jiade. The progress and application prospect of composite techniques for SRM[J]. Journal of Solid Rocket Technology,2001,24(1):46-52(in Chinese). [8] 庄南征, 闭业波, 张啸天. 雷达天线罩电性能设计和结构设计分析[C]. 第十八届玻璃钢/复合材料学术年会论文集, 北京: 中国硅酸盐学会, 2010.ZHUANG Nanzheng, BI Yebo, ZHANG Xiaotian. Analysis on the electrical properties and structure design of radome[C]. Proceedings of the 18th Annual FRP/Composites Conference, Beijing: The Chinese Ceramic Society, 2010(in Chinese). [9] 沈强, 陈斐, 闫法强, 等. 新型高温陶瓷天线罩材料的研究进展[J]. 材料导报, 2006, 20(9):1-4.SHEN Qiang, CHEN Fei, YAN Faqiang, et al. Progress on new type high temperature ceramic missiles radome materials[J]. Materials Review,2006,20(9):1-4(in Chinese). [10] 沈观林, 胡更开. 复合材料力学[M]. 北京: 清华大学出版社, 2006.SHEN Guanlin, HU Gengkai. mechanics of composit materials[M]. Beijing: Tsinghua University Press, 2006(in Chinese). [11] 陈虹, 胡利明, 贾光耀, 等. 陶瓷天线罩材料的研究进展[J]. 硅酸盐通报, 2002, 21(4):40-44.CHEN Hong, HU Liming, JIA Guangyao, et al. Progress on the radome materials of ceramic for missiles[J]. Bulletin of the Chinese Ceramic Society,2002,21(4):40-44(in Chinese). [12] 李端, 张长瑞, 李斌, 等. 氮化硼透波材料的研究进展与展望[J]. 硅酸盐通报, 2010, 29(5):1072-1078, 1085.LI Duan, ZHANG Changrui, LI Bin, et al. Progress and prospect of wave-transparent boron nitride materials[J]. Bulletin of the Chinese Ceramic Society,2010,29(5):1072-1078, 1085(in Chinese). [13] 胡伟, 邬浩, 王萍萍, 等. 陶瓷天线罩材料的研制进展[J]. 玻璃钢, 2010(3):16-23.HU Wei, WU Hao, WANG Pingping, et al. Progress on the radome materials of ceramic for missiles[J]. Fiber Reinforced Plastics/Composites,2010(3):16-23(in Chinese). [14] OOI N, RAJAN V, GOTTLIEB J, et al. Structural properties of hexagonal boron nitride[J]. Modelling & Simulation in Materials Science & Engineering, 2006, 14(3): 515–535. [15] JANNEY M A, OMATETE O O, WALLS C A, et al. Westmoreland, development of low-toxicity gelcasting systems[J]. Journal of the American Ceramic Society, 1998, 81(3): 581–591. [16] GILISSEN R, ERAUW J P, SMOLDERS A, et al. Gelcasting, a near net shape technique[J]. Materials & Design, 2000, 21(4): 251–257. [17] 郭文利, 徐廷献, 李爱华. 纳米氮化硅制备天线罩材料介电性能的研究[J]. 硅酸盐学报, 2003, 31(7):698-701.GUO Wenli, XU Tingxian, LI Aihua. Research on the dielectric properties of radome material made with nanometer silicon nitride[J]. Journal of the Chinese Ceramic Society,2003,31(7):698-701(in Chinese). [18] 薛义丹, 徐廷献, 郭文利, 等. 注凝成型(gelcasting)工艺及其新发展[J]. 硅酸盐通报, 2003, 22(5):69-73.XUE Yidan, XU Tingxian, GUO Wenli, et al. Technology of gelcasting and its development[J]. Bulletin of the Chinese Ceramic Society,2003,22(5):69-73(in Chinese). [19] CHEW K W, SELLINGER A, LAINE R M. Processing aluminum nitride-silicon carbide composites via polymer infiltration and pyrolysis of polymethylsilane[J]. Journal of the American Ceramic Society,2010,82(4):857-866. [20] NAMAZU T, ISHIKAWA T, HASEGAWA Y. Influence of polymer infiltration and pyrolysis process on mechanical strength of polycarbosilane-derived silicon carbide ceramics[J]. Journal of Materials Science,2011,46(9):3046-3051. [21] NECHANICKY M A, CHEW K W, SELLINGER A, et al. α-Silicon carbide/β-silicon carbide particulate composites via polymer infiltration and pyrolysis (PIP) processing using polymethylsilane[J]. Journal of the European Ceramic Society,2000,20(4):441-451. [22] GONCHARENKO A V, LOZOVSKI V Z, VENGER E F. Lichtenecker’s equation: Applicability and limitations[J]. Optics Communications,2000,174(1-4):19-32. [23] REGALADO C M. A physical interpretation of logarithmic TDR calibration equations of volcanic soils and their solid fraction permittivity based on Lichtenecker’s mixing formulae[J]. Geoderma,2004,123(1-2):41-50. [24] 国家质量技术监督局. 致密定形耐火制品体积密度、显气孔率和真气孔率试验方法: GB/T2997—2000[S]. 北京: 中国标准出版社, 2000.State bureau of quality and technical supervision. Test method for bulk density, apparent porosity and true porosity of dense shaped refractory products: GB/T2997—2000[S]. Beijing: China Standards Press, 2000(in Chinese). [25] LI M, ZHANG C, YE F, et al. Evolution of microstructure and properties of Si3N4 whisker reinforced composites during densification by polymer infiltration and pyrolysis[J]. Journal of the European Ceramic Society,2022,42:2146-2156. [26] 马茸茸, 张电, 刘一军, 等. 多孔氮化硅陶瓷的研究进展及构效关系中的矛盾平衡[J]. 材料导报, 2020, 34(9):9101-9109.MA Rongrong, ZHANG Dian, LIU Yijun, et al. Research progress and contradictory equilibrium of structure-perfor-mance relationship of porous silicon nitride ceramics[J]. Materials Reports,2020,34(9):9101-9109(in Chinese). [27] 崔雪峰, 李建平, 李明星, 等. 氮化物基陶瓷高温透波材料的研究进展[J]. 航空材料学报, 2020, 40(1):21-34.CUI Xuefeng, LI Jianping, LI Mingxing, et al. Research progress of nitride based ceramic high temperature wave transparent materials[J]. Journal of Aeronautical Materials,2020,40(1):21-34(in Chinese). -

下载:

下载: