Research progress on construction and properties of polymer gradient materials

-

摘要: 聚合物梯度材料是成分或结构在某一维或多维方向上连续或准连续变化的具有复合功能的聚合物基材料。其梯度结构赋予了材料独特的优势,如:可调控成分的空间分布、可避免界面应力和兼容多种性能等。聚合物梯度材料连续变化的性能可满足多种使用需求,在航空航天、生物医药、电子信息、机械工程等领域都有广泛的应用。本文根据梯度的变化维度将其分为一维、二维和三维聚合物梯度材料,分别介绍了三种材料的制备方法、性能优势及应用领域。一维聚合物梯度纤维的梯度折射率提高了光纤传输的速度和距离,有助于光通信领域的发展。二维聚合物梯度材料主要分为涂层和薄膜材料,可通过表面修饰和场梯度的方法制备梯度结构,得到的梯度表面可提供一种高通量的平台来研究和优化材料与生物之间的相互作用。三维聚合物梯度材料包括聚合物梯度交联网络材料、聚合物梯度填充复合材料和聚合物梯度结晶材料,梯度结构可提高其力学性能、改善应力集中,拓展了聚合物在机械工程和生物医用领域的应用。最后,对聚合物梯度材料的制备、表征及应用等方面存在的挑战做出展望。Abstract: Polymer gradient materials are functional heterogeneous polymer-based materials, where their compositions or structures change continuously or quasi continuously in one or multi-dimensional direction. The gradient structure endows the material with unique advantages, such as adjustable spatial distribution of components, avoidance of interfacial stress and compatibility with a variety of properties. Polymer gradient materials have a wide range of applications in aerospace, biomedicines, electronic information, mechanical engineering and other fields. In this paper, they are divided into one-dimensional, two-dimensional and three-dimensional polymer gradient materials according to the variation dimension of gradient. The preparation methods, performance advantages and application fields of the three materials are introduced respectively. The gradient refractive index of one-dimensional polymer gradient fiber improves the speed and distance of optical fiber transmission and contributes to the development of optical communication field. Two-dimensional polymer gradient materials can be divided into the coating and thin film materials. Gradient structures can be prepared by surface modification and field gradient methods. The resulting gradient surface can provide a high-throughput platform to study and optimize the interaction between materials and organisms. Three-dimensional polymer gradient materials include gradient crosslinking network polymer materials, gradient filled polymer composites and gradient crystallization polymer materials. The gradient structure can improve their mechanical properties and stress concentration, and expand the applications of polymers in mechanical engineering and biomedical fields. Finally, the challenges in the preparation, characterization and application of polymer gradient materials are prospected.

-

Key words:

- polymer gradient materials /

- bionic structure /

- dimensionality /

- performance /

- research progress

-

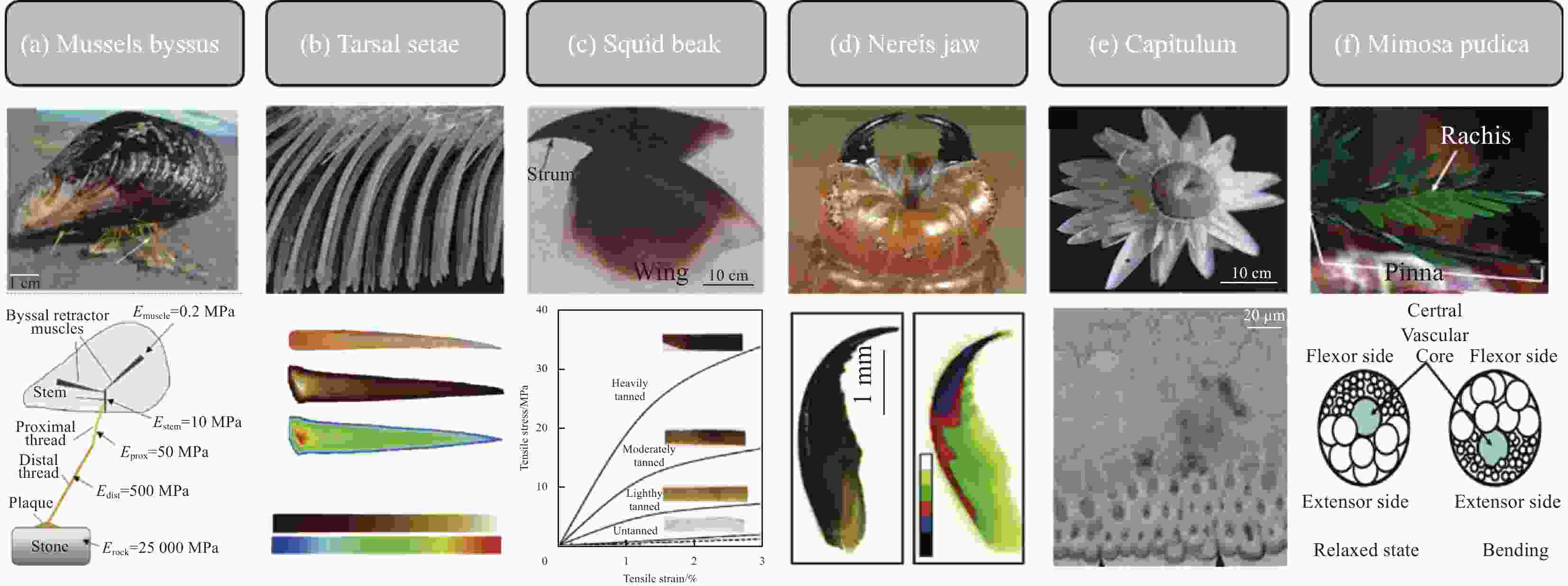

图 1 (a) 贻贝照片和贻贝足丝模量示意图[1];(b) 瓢虫刚毛SEM图像和AFM图像[21];(c) 鱿鱼喙照片和分层拉伸实验[23]:(d) 沙蚕颚照片和颚部Zn离子分布图[24];(e) 菊花苞片照片和组织SEM图像[27];(f) 含羞草照片和组织细胞示意图[28-29]

Figure 1. (a) Photographs of mussel and modulus of mussel byssus[1]; (b) SEM and AFM images of tarsal setae[21]; (c) Photographs of squid beak and tensile testing of differently tanned hydrated parts[23]; (d) Photographs of nereis jaw and Zn distribution in jaw[24]; (e) Photographs of capitulum and SEM images of bracts[27]; (f) Photographs of mimosa pudica and schematic diagram of a pulvinus cross section[28-29]

Emuscle—Modulus of the byssal retractor muscles; Estem—Modulus of the byssal stem; Eprox—Modulus of the byssal at the proximal end; Edist—Modulus of the byssal at the distal end; Erock—Modulus of the rock

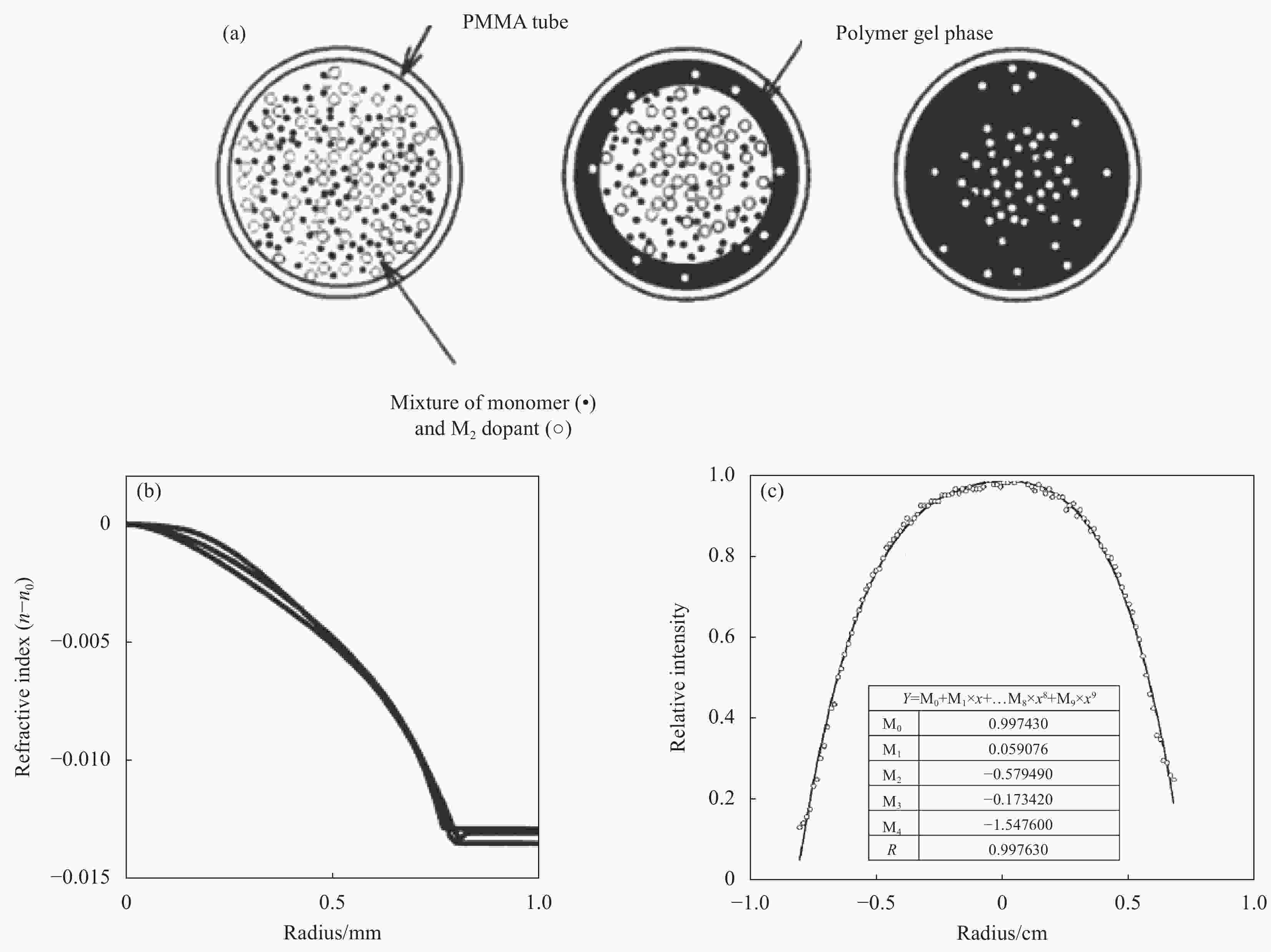

图 3 (a) 界面凝胶聚合中,掺杂分子扩散到聚合物凝胶相形成梯度分布示意图[47];(b) 甲基丙烯酸甲酯-邻苯二甲酸苄丁酯(MMA-BBP)系统折射率分布图[48];(c) 低温界面凝胶聚合法制备有机染料浓度分布图[50]

Figure 3. (a) Schematic representation of the diffusion of dopant molecules into polymer gel phase to form the graded-index distribution on the cross section of the polymerization tube in interfacial-gel polymerization[47]; (b) Refractive-index profile of methyl methacrylate-benzyl butyl phthalate (MMA-BBP) system GI preform[48]; (c) A radial profile of dye prepared via the low-temperature interfacial-gel polymerization[50]

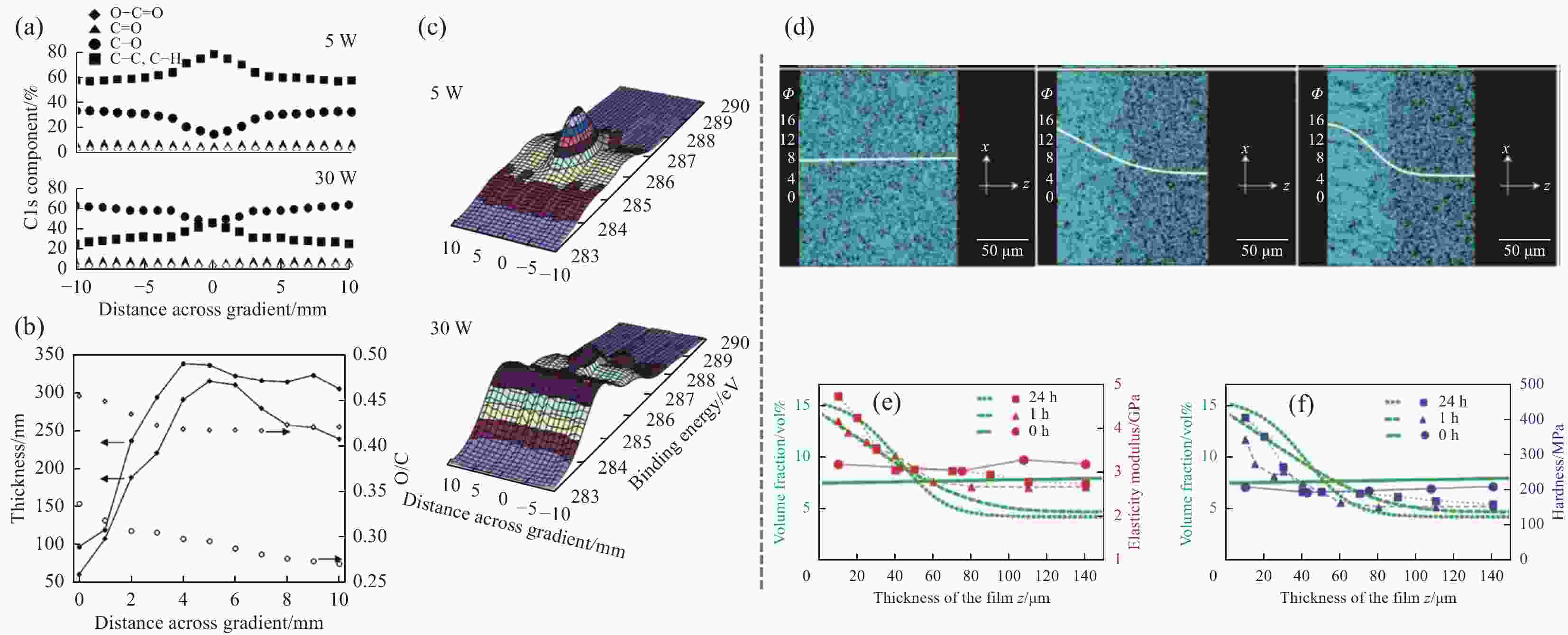

图 4 (a) C1s 的XPS图谱:表示四种成分的百分比与梯度膜中心距离的关系[43];(b) 梯度膜厚度(黑点线)和O/C元素比例(空心圆)[43];(c) 高分辨率C1s XPS光谱的3 D图[43];(d) 磁性颗粒体积分数为8vol%聚合物横截面SEM-EDX光谱图像,叠加曲线显示了样品横截面上的纳米颗粒体积分数[34];((e)、(f)) 不同时间段聚合物的纳米颗粒体积分数、弹性模量和硬度随薄膜厚度的变化[34]

Figure 4. (a) XPS C1s curves fitted component data presented as percentage C1 s component vs distance from the center of the gradient films[43]; (b) Film thickness (dark symbols) and O/C elemental ratio (hollow symbols) plotted across the DGpp gradients as a function of distance[43]; (c) 3 D plot of high-resolution C1s XPS spectra[43]; (d) Cross-sectional SEM-EDX spectral images of polymer with magnetic particle volume fraction of 8vol%, the superimposed curves indicate the nanoparticle volume fractions all along the sample cross-sections[34]; ((e), (f)) Nanoparticle volume fraction, elastic modulus and hardness of the polymer varied with the thickness of the film[34]

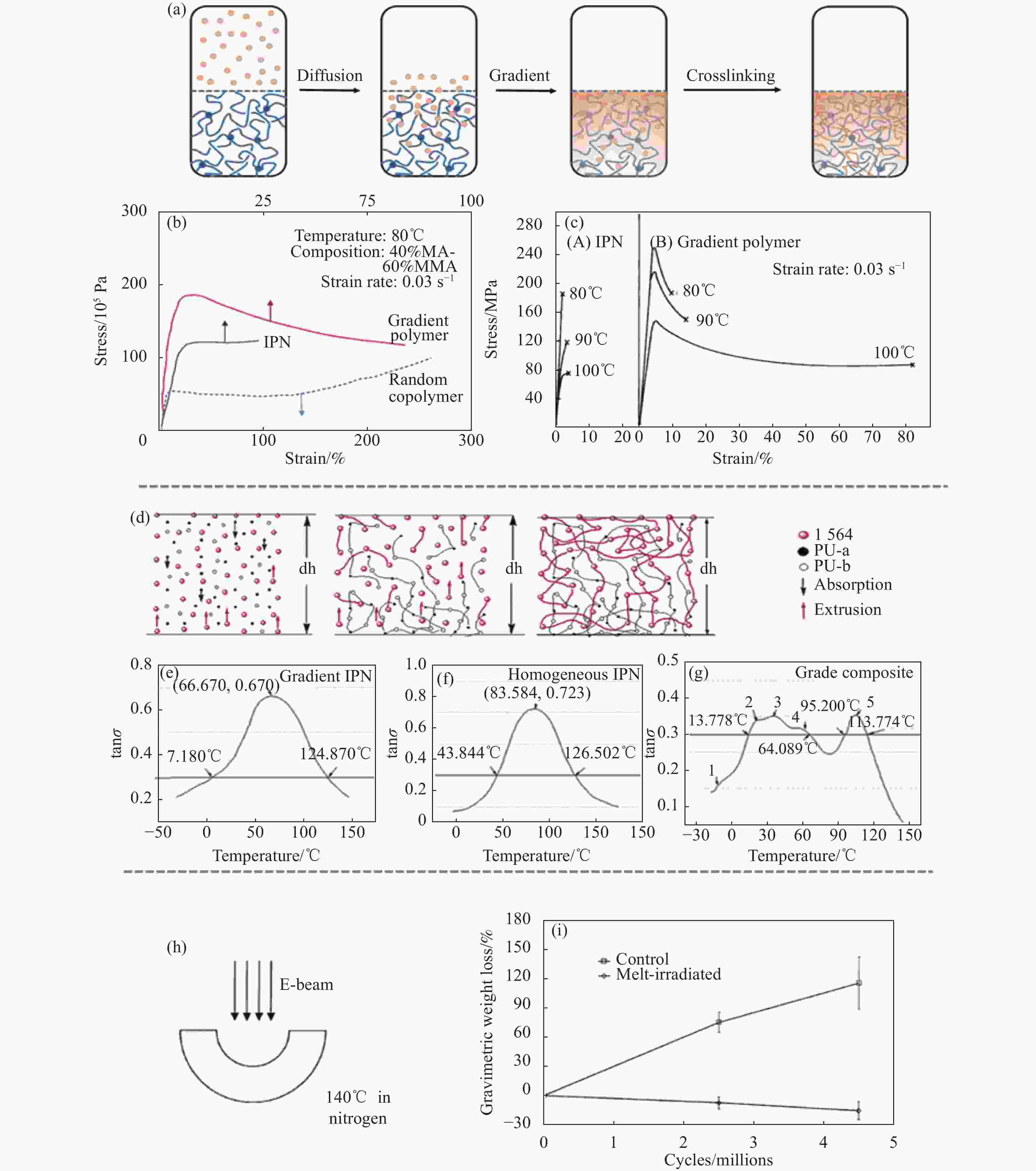

图 5 (a) 聚合物梯度交联网络简单扩散法制备过程示意图;(b) 梯度聚合物、互穿网络聚合物和MA-MMA无规共聚物(比率60/40)的应力-应变曲线[65];(c) 不同温度下梯度聚合物和互穿网络的应力-应变曲线[60];(d) 聚合物梯度交联网络自梯度法制备过程示意图[10];((e)~(g)) 三种交联网络的tanσ[10];(h) 辐照法制备交联密度梯度超高分子量聚乙烯(UHMWPE)髋臼组件的示意图[44];(i) 熔融辐照和传统制备UHMWPE衬垫的耐磨性测试数据[44]

Figure 5. (a) Schematic diagram of polymer gradient crosslinking network by simple diffusion; (b) Stress-stain curves of gradient polymer, interpenetrating networks and random copolymer of methyl methacrylate and methyl acrylate (ratio 60/40)[65]; (c) Stress-stain curves of gradient polymer and interpenetrating networks under different temperature[60]; (d) Schematic diagram of polymer gradient crosslinking network by the self-stratification mechanism[10]; ((e)-(g)) tanσ values of the three kinds of Interpenetrating polymer network materials[10]; (h) Schematic diagram of gradient crosslinking of ultra high molecular weight polyethylene (UHMWPE) using irradiation in molten state for total joint arthroplasty[44]; (i) Gravimetric weight loss data of melt-irradiated and control UHMWPE crosslinking polymer[44]

IPN—Interpenetrating polymer network; PU—Polyurethane; dh—Thickness of liquid resin

图 6 (a) 离心法制备样品流程图[35];(b) 样品制备过程的时间步骤示意图[35];(c) 样品离心30 min后纤维梯度的光学显微镜图[35];(d) 3 D打印导电聚乳酸梯度材料的混合制备过程示意图;(e) 在PLA和G-PLA的挤出比为19∶1到1∶19的情况下,施加10 V电压 300 s后的温度与位置关系图[11];(f) 用于在SiO2中生成梯度浓度的微流控网络的设计[70]

Figure 6. (a) Flow diagram of sample preparation by centrifugal method; (b) Sketch of the time steps for sample preparation[35]; (c) A light microscope pictures showing the gradient of sample, centrifuged after 30 min[35]; (d) Schematic representation of the mixed fabrication process of 3 D-printed conductive polylactic acid composites[35]; (e) Temperature vs position on the sheet with a varying extrusion ratios of PLA and G-PLA from 19∶1 to 1∶19, after applying 10 V for 300 s[11]; (f) Design of the microfluidic network used to generate a gradient in topography [70]

-

[1] WAITE J H, LICHTENEGGER H C, STUCKY G D, et al. Exploring molecular and mechanical gradients in structural bioscaffolds[J]. Biochemistry,2004,43(24):7653-7662. doi: 10.1021/bi049380h [2] DI LUCA A, LONGONI A, CRISCENTI G, et al. Toward mimicking the bone structure: Design of novel hierarchical scaffolds with a tailored radial porosity gradient[J]. Biofabrication,2016,8(4):045007. doi: 10.1088/1758-5090/8/4/045007 [3] REZNIKOV N, BILTON M, LARI L, et al. Fractal-like hierarchical organization of bone begins at the nanoscale[J]. Science,2018,360(6388):2189. doi: 10.1126/science.aao2189 [4] LI S, WANG K W. Plant-inspired adaptive structures and materials for morphing and actuation: A review[J]. Bioinspiration & Biomimetics,2016,12(1):011001. [5] NIINO M, MAEDA S. Recent development status of functionally gradient materials[J]. ISIJ International,1990,30(9):699-703. doi: 10.2355/isijinternational.30.699 [6] NAEBE M, SHIRVANIMOGHADDAM K. Functionally graded materials: A review of fabrication and properties[J]. Applied Materials Today,2016,5:223-245. doi: 10.1016/j.apmt.2016.10.001 [7] KAWASAKI A, WATANABE R. Concept and P/M fabrication of functionally gradient materials[J]. Ceramics International,1997,23(1):73-83. doi: 10.1016/0272-8842(95)00143-3 [8] BRONSTEIN L M, IVANOVSKAYA A, MATES T, et al. Bioinspired gradient materials via blending of polymer electrolytes and applying electric forces[J]. The Journal of Physical Chemistry B,2009,113(3):647-655. doi: 10.1021/jp8071348 [9] CLAUSSEN K U, SCHEIBEL T, SCHMIDT H-W, et al. Polymer gradient materials: can nature teach us new tricks?[J]. Macromolecular Materials and Engineering,2012,297(10):938-957. doi: 10.1002/mame.201200032 [10] LV X, HUANG Z, HUANG C, et al. Damping properties and the morphology analysis of the polyurethane/epoxy continuous gradient IPN materials[J]. Composites Part B: Engineering,2016,88:139-149. doi: 10.1016/j.compositesb.2015.10.040 [11] ZHUANG Y, SONG W, NING G, et al. 3 D–printing of materials with anisotropic heat distribution using conductive polylactic acid composites[J]. Materials & Design,2017,126:135-140. [12] KOIZUMI M. FGM activities in Japan[J]. Composites Part B: Engineering,1997,28(1):1-4. doi: 10.1016/S1359-835X(96)00086-3 [13] POMPE W, WORCH H, EPPLE M, et al. Functionally graded materials for biomedical applications[J]. Materials Science and Engineering: A,2003,362(1):40-60. [14] PEDRON S, PEINADO C, BOSCH P, et al. Microfluidic approaches for the fabrication of gradient crosslinked networks based on poly(ethylene glycol) and hyperbranched polymers for manipulation of cell interactions[J]. Journal of Biomedical Materials Research Part A,2011,96A(1):196-203. doi: 10.1002/jbm.a.32974 [15] MüLLER E, DRAŠAR Č, SCHILZ J, et al. Functionally graded materials for sensor and energy applications[J]. Materials Science and Engineering:A,2003,362(1-2):17-39. doi: 10.1016/S0921-5093(03)00581-1 [16] MARTIN G C, ENSSANI E, SHEN M. Mechanical behavior of gradient polymers[J]. Journal of Applied Polymer Science,1981,26(5):1465-73. doi: 10.1002/app.1981.070260503 [17] YANG Y Z, ZHANG H O, WANG G L, et al. Fabrication of functionally graded SOFC by APS[J]. Journal of Thermal Spray Technology,2007,16(5-6):768-775. doi: 10.1007/s11666-007-9132-6 [18] KARABANOVA L V, MIKHALOVSKY S V, LLOYD A W, et al. Gradient semi-interpenetrating polymer networks based on polyurethane and poly(vinyl pyrrolidone)[J]. Journal of Materials Chemistry,2005,15(4):499. doi: 10.1039/b410178b [19] WAITE J H. The formation of mussel byssus: Anatomy of a natural manufacturing process[J]. Results and problems in cell differentiation,1992,19:27-54. [20] HARRINGTON M J, WAITE J H. How nature modulates a fiber's mechanical properties: mechanically distinct fibers drawn from natural mesogenic block copolymer variants[J]. Advanced Materials,2009,21(4):440-444. doi: 10.1002/adma.200801072 [21] PEISKER H, MICHELS J, GORB S N. Evidence for a material gradient in the adhesive tarsal setae of the ladybird beetle Coccinella septempunctata[J]. Nature Communications,2013,4(1):1661. doi: 10.1038/ncomms2576 [22] MISEREZ A, LI Y, WAITE J H, et al. Jumbo squid beaks: Inspiration for design of robust organic composites[J]. Acta biomaterialia,2007,3(1):139-149. doi: 10.1016/j.actbio.2006.09.004 [23] MISEREZ A, SCHNEBERK T, SUN C, et al. The transition from stiff to compliant materials in Squid Beaks[J]. Science,2008,319(5871):1816-1819. doi: 10.1126/science.1154117 [24] BIRKEDAL H, BROOMELL C, KHAN R, et al. Zinc and mechanical prowess in the jaws of Nereis, a marine worm[J]. The Proceedings of the National Academy of Sciences,2005,874:9144-9149. [25] SEIDI A, RAMALINGAM M, ELLOUMI-HANNACHI I, et al. Gradient biomaterials for soft-to-hard interface tissue engineering[J]. Acta Biomaterialia,2011,7(4):1441-1451. doi: 10.1016/j.actbio.2011.01.011 [26] SHARMA R I, SNEDEKER J G. Biochemical and biomechanical gradients for directed bone marrow stromal cell differentiation toward tendon and bone[J]. Biomaterials,2010,31(30):7695-7704. doi: 10.1016/j.biomaterials.2010.06.046 [27] BOROWSKA-WYKRĘT D, RYPIEŃ A, DULSKI M, et al. Gradient of structural traits drives hygroscopic movements of scarious bracts surrounding Helichrysum bracteatum capitulum[J]. Annals of Botany,2017,119(8):1365-1383. doi: 10.1093/aob/mcx015 [28] VOLKOV A G, FOSTER J C, BAKER K D, et al. Mechanical and electrical anisotropy in Mimosa pudica pulvini[J]. Plant Signaling & Behavior,2010,5(10):1211-1221. [29] VOLKOV A G, FOSTER J C, ASHBY T A, et al. Mimosa pudica: Electrical and mechanical stimulation of plant movements[J]. Plant, Cell & Environment,2010,33(2):163-173. [30] DROR M, ELSABEE M Z, BERRY G C. Gradient interpenetrating polymer networks. I. Poly(ether urethane) and polyacrylamide IPN[J]. Journal of Applied Polymer Science,1981,26(6):1741-1757. doi: 10.1002/app.1981.070260601 [31] LIPATOV Y S, KARABANOVA L V. Gradient interpenetrating polymer networks[J]. Journal of Materials Science,1995,30(4):1095-1104. doi: 10.1007/BF01178451 [32] AKOVALI G. Studies with gradient polymers of polystyrene and poly(methyl acrylate)[J]. Journal of Applied Polymer Science,1999,73(9):1721-1725. doi: 10.1002/(SICI)1097-4628(19990829)73:9<1721::AID-APP12>3.0.CO;2-U [33] YEOM C K, LEE K H. A study on permeation behavior of a liquid mixture through PVA membranes having a crosslinking gradient structure in pervaporation[J]. Journal of Applied Polymer Science,1996,59(8):1271-1279. doi: 10.1002/(SICI)1097-4628(19960222)59:8<1271::AID-APP10>3.0.CO;2-9 [34] NARDI T, LETERRIER Y, KARIMI A, et al. A novel synthetic strategy for bioinspired functionally graded nanocomposites employing magnetic field gradients[J]. RSC Advances,2014,4(14):7246-7255. doi: 10.1039/c3ra46731g [35] KLINGSHIRN C, KOIZUMI M, HAUPERT F, et al. Structure and wear of centrifuged epoxy-resin/carbon fiber functionally graded materials[J]. Journal of Materials Science Letters,2000,19(3):263-266. doi: 10.1023/A:1006783330100 [36] CLAUSSEN K U, GIESA R, SCHMIDT H W. Longitudinal polymer gradient materials based on crosslinked polymers[J]. Polymer,2014,55(1):29-38. doi: 10.1016/j.polymer.2013.11.018 [37] CLAUSSEN K U, GIESA R, SCHEIBEL T, et al. Learning from nature: Synthesis and characterization of longitudinal polymer gradient materials inspired by Mussel Byssus threads[J]. Macromolecular Rapid Communications,2012,33(3):206-211. doi: 10.1002/marc.201100620 [38] 温变英, 吴刚, 侯少华. 新型聚合物基复合梯度材料的制备及材料结构性能[J]. 复合材料学报, 2004, 21(3):151-156. doi: 10.3321/j.issn:1000-3851.2004.03.029WEN Bianying, WU Gang, HOU Shaohua. Novel technique for preparing polymeric gradient materials and related structure properties[J]. Acta Materiae Compositae Sinica,2004,21(3):151-156(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.03.029 [39] WEN B, WU G, YU J. A flat polymeric gradient material: preparation, structure and property[J]. Polymer,2004,45(10):3359-3365. doi: 10.1016/j.polymer.2004.03.023 [40] MüLLER M, HUYNH Q-U, UHLMANN E, et al. Study of inkjet printing as additive manufacturing process for gradient polyurethane material[J]. Production Engineering,2014,8:25-32. doi: 10.1007/s11740-013-0504-0 [41] GARLAND A, FADEL G. Design and manufacturing functionally gradient material objects with an off the shelf three-dimensional printer: challenges and solutions[J]. Journal of Mechanical Design,2015,137(11):111407. doi: 10.1115/1.4031097 [42] LIN-GIBSON S, LANDIS F A, DRZAL P L. Combinatorial investigation of the structure-properties characterization of photopolymerized dimethacrylate networks[J]. Biomaterials,2006,27(9):1711-1717. doi: 10.1016/j.biomaterials.2005.10.040 [43] MENZIES D J, COWIE B, FONG C, et al. One-step method for generating PEG-like plasma polymer gradients: chemical characterization and analysis of protein interactions[J]. Langmuir,2010,26(17):13987-13994. doi: 10.1021/la102033d [44] MURATOGLU O, O'CONNOR D, BRAGDON C, et al. Gradient crosslinking of UHMWPE using irradiation in molten state for total joint arthroplasty[J]. Biomaterials,2002,23:717-724. doi: 10.1016/S0142-9612(01)00176-4 [45] LIU X Q, WANG Y S, ZHU J H. Epoxy resin/polyurethane functionally graded material prepared by microwave irradiation[J]. Journal of Applied Polymer Science,2004,94(3):994-999. doi: 10.1002/app.20755 [46] LSHIGURE T, HORIBE A, NIHEI E, et al. Low-loss high-bandwidth GI polymer optical fiber[M]. Amsterdam: Elsevier, 1994. [47] ZHANG Q, WANG P, ZHAI Y. Refractive index distribution of graded index Poly(methyl methacrylate) preform made by interfacial-gel polymerization[J]. Macromolecules,1997,30(25):7874-7879. doi: 10.1021/ma970379i [48] KOIKE Y. High-bandwidth graded-index polymer optical fibre[J]. Polymer,1991,32(10):1737-1745. doi: 10.1016/0032-3861(91)90356-N [49] CHEKANOV Y A, POJMAN J A. Preparation of functionally gradient materials via frontal polymerization[J]. Journal of Applied Polymer Science,2000,78(13):2398-2404. doi: 10.1002/1097-4628(20001220)78:13<2398::AID-APP170>3.0.CO;2-K [50] MASERE J, LEWIS L L, POJMAN J A. Optical gradient materials produced via low-temperature isothermal frontal polymerization[J]. Journal of Applied Polymer Science,2001,80(4):686-691. doi: 10.1002/1097-4628(20010425)80:4<686::AID-APP1145>3.0.CO;2-Y [51] MEREDITH J C, SORMANA J-L, KESELOWSKY B G, et al. Combinatorial characterization of cell interactions with polymer surfaces[J]. Journal of Biomedical Materials Research Part A,2003,66A(3):483-490. doi: 10.1002/jbm.a.10004 [52] MEREDITH J C, KARIM A, AMIS E J. High-throughput measurement of polymer blend phase behavior[J]. Macromolecules,2000,33(16):5760-5762. doi: 10.1021/ma0004662 [53] PENG X, JIN J, ERICSSON E M, et al. General method for ultrathin free-standing films of nanofibrous composite materials[J]. Journal of the American Chemical Society,2007,129(27):8625-8633. doi: 10.1021/ja0718974 [54] 成宏卜, 欧阳俊, 张伟, 等. 高储能密度铁电薄膜电容器研究进展[J]. 现代技术陶瓷, 2019, 40(4):9. doi: 10.16253/j.cnki.37-1226/tq.2019.04.003CHENG Hongbo, OUYANG Jun, ZHANG Wei, et al. Progress in ferroelectric thin film capacitors for high density energy storage[J]. Advanced Ceramics,2019,40(4):9(in Chinese). doi: 10.16253/j.cnki.37-1226/tq.2019.04.003 [55] 穆中国, 罗一丁. 聚合物梯度材料的制备及应用研究[J]. 化工新型材料, 2010, 5(38):37-39. doi: 10.3969/j.issn.1006-3536.2010.05.012MU Zhongguo, LUO Yiding. Study on preparation and application of gradient polymer materials[J]. New Chemical Materials,2010,5(38):37-39(in Chinese). doi: 10.3969/j.issn.1006-3536.2010.05.012 [56] ERKO M, HARTMANN M A, ZLOTNIKOV I, et al. Structural and mechanical properties of the arthropod cuticle: Comparison between the fang of the spider Cupiennius salei and the carapace of American lobster Homarus americanus[J]. Journal of Structural Biology,2013,183(2):172-179. doi: 10.1016/j.jsb.2013.06.001 [57] 倪萌, LEUNG M K H, SUMATHY K. 电解水制氢技术进展[J]. 能源环境保护, 2004, 18(5):5-9. doi: 10.3969/j.issn.1006-8759.2004.05.002NI M, LEUNG M K H, SUMATHY K,. Progress of hydrogen production through water electrolysis[J]. Energy Environmental Protection,2004,18(5):5-9(in Chinese). doi: 10.3969/j.issn.1006-8759.2004.05.002 [58] KOKKINIS D, BOUVILLE F, STUDART A R. 3 D printing of materials with tunable failure via bioinspired mechanical gradients[J]. Advanced Materials,2018,30(19):1705808. doi: 10.1002/adma.201705808 [59] KLEMPNER D. Interpenetrating polymer networks[J]. Composite Interfaces,1978,17(2):85-89. [60] AKOVALI G, BILIYAR K, SHEN M. Gradient polymers by diffusion polymerization[J]. Journal of Applied Polymer Science,1976,20(9):2419-2427. doi: 10.1002/app.1976.070200911 [61] EYRING H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates[J]. The Journal of Chemical Physics,1936,4(4):283-291. doi: 10.1063/1.1749836 [62] MATZ D J, GULDEMOND W G, COOPER S L. Delayed yielding in glassy polymers[J]. Journal of Polymer Science Part A: Polymer Physics,1972,10(10):1917-1930. doi: 10.1002/pol.1972.180101004 [63] ROBERTSON R E. On the cold-drawing of plastics[J]. Journal of Applied Polymer Science,1963,7(2):443-450. doi: 10.1002/app.1963.070070203 [64] LV X, HUANG Z, SHI M, et al. Composition distribution, damping and thermal properties of the thickness-continuous gradient epoxy/polyurethane interpenetrating polymer networks[J]. Applied Sciences,2017,7(2):135. doi: 10.3390/app7020135 [65] KRYSZEWSKI M. Gradient polymers and copolymers[J]. Polymers for Advanced Technologies,1998,9(4):244-259. doi: 10.1002/(SICI)1099-1581(199804)9:4<244::AID-PAT748>3.0.CO;2-J [66] KRUMOVA M, KLINGSHIRN C, HAUPERT F, et al. Microhardness studies on functionally graded polymer composites[J]. Composites Science and Technology,2001,61(4):557-563. doi: 10.1016/S0266-3538(00)00228-1 [67] 于思荣, 张新平, 何镇明. 离心铸造梯度功能材料的研究现状 [J]. 功能材料, 2000, 31(B05): 3.YU Sirong, ZHANG Xinpin, HE Zhenming. Development status of functionally gradient materials by centrifugal casting [J]. Journal of Functional Materials, 2000, 31(B05): 3(in Chinese). [68] BAFEKRPOUR E, SIMON G, HABSUDA J, et al. Fabrication and characterization of functionally graded synthetic graphite/phenolic nanocomposites[J]. Materials Science and Engineering A,2012,546:123-131. [69] BAFEKRPOUR E, SIMON G P, NAEBE M, et al. Preparation and properties of composition-controlled carbon nanofiber/phenolic nanocomposites[J]. Composites Part B:Engineering,2013,52:120-126. doi: 10.1016/j.compositesb.2013.03.007 [70] JEON N L, DERTINGER S K W, CHIU D T, et al. Generation of solution and surface gradients using microfluidic systems[J]. Langmuir,2000,16(22):8311-8316. doi: 10.1021/la000600b [71] 严大东, 张兴华. 聚合物结晶理论进展[J]. 物理学报, 2016, 65(18):188201. doi: 10.7498/aps.65.188201YAN Dadong, ZHANG Xinghua. Recent development on the theory of polymer crystallization[J]. Acta Physica. Sinica,2016,65(18):188201(in Chinese). doi: 10.7498/aps.65.188201 [72] KOIDE S, YAZAWA K, ASAKAWA N, et al. Fabrication of functionally graded bulk materials of organic polymer blends by uniaxial thermal gradient[J]. Journal of Materials Chemistry 2007, 17(6): 582-590. [73] 刘建学. 现代近红外光谱分析技术[M]. 北京: 科学出版社, 2008.LIU Jianxue. Near Infrared[M]. Beijing: Science Press, 2008(in Chinese). [74] EIDELMAN N, SIMON C G, JR. Characterization of combinatorial polymer blend composition gradients by ftir microspectroscopy[J]. Journal of research of the National Institute of Standards and Technology,2004,109(2):219-231. doi: 10.6028/jres.109.014 [75] KAUFMAN J D, MILLER G J, MORGAN E F, et al. Time-dependent mechanical characterization of poly(2-hydroxyethyl methacrylate) hydrogels using nanoindentation and unconfined compression[J]. Journal of Materials Research,2008,23(5):1472-4181. doi: 10.1557/JMR.2008.0185 [76] LAMBROS J, SANTARE M H, LI H, et al. A novel technique for the fabrication of laboratory scale model functionally graded materials[J]. Experimental Mechanics,1999,39(3):184-190. doi: 10.1007/BF02323551 -

下载:

下载: