Recent advances in 3D printed fiber reinforced composites: Processing technique and mechanical performance

-

摘要: 3D打印可实现纤维增强复合材料复杂结构的一体化成型,无需模具,可显著降低先进复合材料的制造时间和成本。本文综述了3D打印纤维增强复合材料工艺和力学性能的最新研究进展,对纤维增强复合材料3D打印工艺、打印设备、打印材料和力学性能等方面开展了详细的分析和阐述,重点介绍了熔融沉积工艺成型连续纤维增强复合材料的最新研究进展,并与传统工艺制备的复合材料力学性能进行了对比和分析。最后,针对纤维增强复合材料3D打印技术的未来发展进行了展望。Abstract: 3D printing is an innovative additive manufacturing technology, enabling the integrated moulding of composite structure with a complex contour. 3D printing eliminates the need for the expensive moulds, which can greatly reduce the manufacturing costs and time. This paper reviewed the recent research progress of processing techniques and mechanical performance of 3D printed fiber reinforced composite. Processing techniques, printing equipment, printing materials and mechanical properties of the printed composites were analyzed and discussed in details. More focuses were paid on the recent advances in the continuous fiber reinforced composite prepared by a fused filament fabrication method. Mechanical performance of the composites manufactured by 3D printing and traditional manufacturing techniques were compared. Finally, the existing issues in the research of 3D printed fiber reinforced composites were summarized with the outline of a roadmap for the future research trend in this field.

-

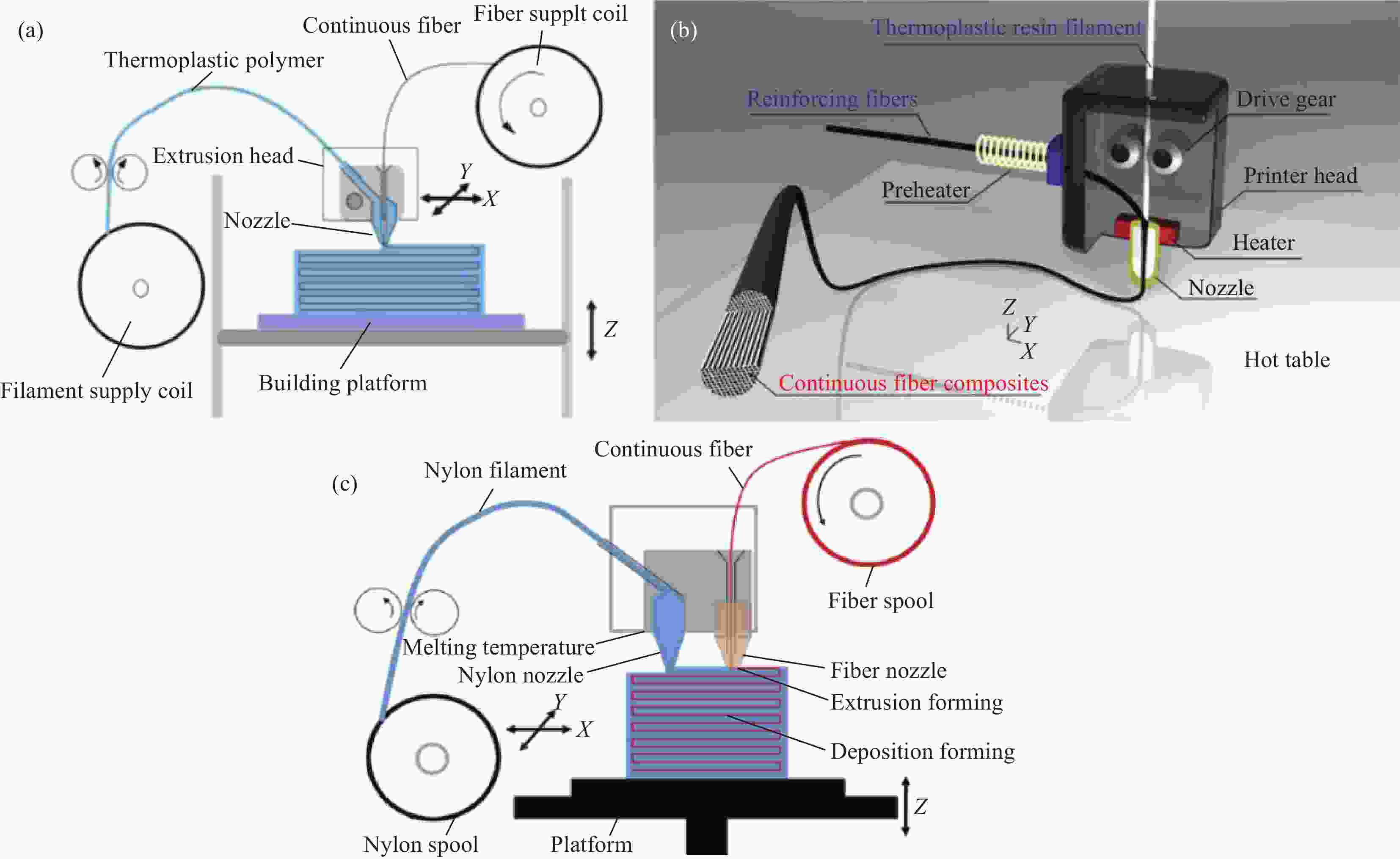

图 2 打印设备及制品图片:(a) 斐帛科技桌面级打印机COMBOT-I[37];(b) Markforged公司的桌面级打印机MarkTwo[9];((c)、(d)) Arevo公司的多自由度打印系统AQUA及其打印的自行车架 [12];(e) 按比例缩小的悬挂板的拓扑分析过程;(f) 悬挂板的打印路径和3D打印的悬浮板[39]

Figure 2. Photos of printing equipments and products: (a) Fibertech desktop printer COMBOT-I [37]; (b) Markforged's desktop printer MarkTwo [9]; ((c),(d)) Multi-degree-of-freedom printing system AQUA from Arevo and its 3D printed bike frame[12]; (e) Topological analyzing process of the scaled-down suspension plate; (f) Printing path of the suspension plate and 3D printed suspension plate[39]

图 4 (a) 不同层厚、纤维含量的层间剪切强度(ILSS)样品;(b) 不同层厚、纤维含量和构建方向的缺口冲击样品[78,79]

Figure 4. (a) Interlaminar shear strength (ILSS) samples with different layer thicknesses and fibre volume contents; (b) Notched impact samples with different build orientations, layer thicknesses and fibre volume contents[78,79]

Lt—Layer thicknesses

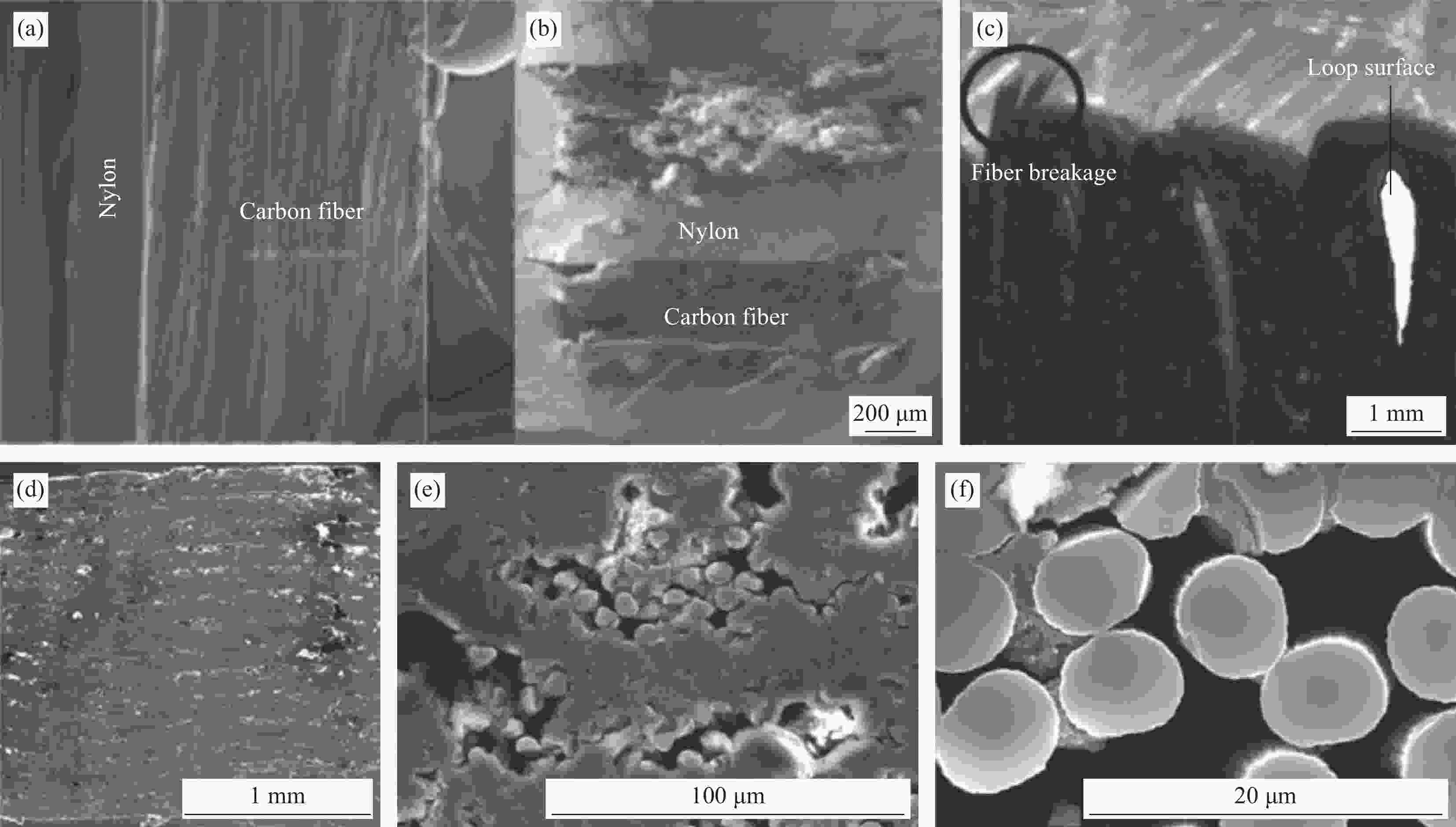

图 5 不同方向的连续碳纤维/尼龙复合材料的SEM图像:(a) 俯视图;(b) 截面图;(c) 打印的碳纤维丝束在转弯处的纤维断裂;((d)~(f)) 打印复合材料中存在的孔隙[63]

Figure 5. SEM images of different views of carbon fiber/Nylon composites: (a) Top view; (b) Cross-sectional view; (c) Single carbon fiber printed layer with fiber breakage at the curvature; ((d)-(f)) Magnified cross-section showing porosity[63]

表 1 3D打印纤维增强复合材料的制备工艺、材料类型和优缺点[15]

Table 1. Summary of 3D printed fibre-reinforced composites for processing techniques, material types, advantages and disadvantages[15]

Processing techniques Material types Advantages Disadvantages Material extrusion

(FFF, LDM)FFF

Continuous filaments of

thermoplastic polymers

LDM

A concentrated dispersion

of particles in liquidLow cost,

Easy fabrication,

Multi-material capabilityObvious layer-

by-layer effect,

Nozzle clogging at high

fibre volumeVat photopoly-

merization

(SLA)A resin with

photoactive

monomersFine resolution,

Random alignment of discontinuous fibres for isotropic mechanical propertyVery limited materials,

Fibre sedimentation in resin,

UV penetration issue,

Bubble formation causing

pores to formPowder bed fusion

(SLS)Compacted fine

powdersFine resolution,

Unused powder

can be reused,

High loading of reinforcementSlow printing,

Expensive,

High porosity in the

binder method,

Long and continuous fibre reinforcement not possible,

Rough surfaceLaminated object

manufacturing

(LOM, CBAM)Polymer composite

in sheetHigh-strength parts can be produced,

Low cost,

No post processing,

No need for support structuresHigh material wastage,

Difficult to build complex

internal cavitiesNotes: FFF—Fused wire manufacturing; LDM—Liquid deposition molding; SLA—Solid light curing; SLS—Selective laser sintering; LOM—Laminated solid manufacturing technology; CBAM—Composite material based additive manufacturing technology. 表 2 一些用于3D打印材料的物理性能

Table 2. Physical properties of some materials used for 3D printing

Materials Physical and mechanical properties Resource Density/

(g·cm−3)Diameter of printing filament/mm Tensile modulus/

GPaFlexural modulus/

GPaMatrix PA6 1.10 1.75 0.9 2.9 [42] PLA 1.24 1.75 2.0 0.8 [42] ABS 1.04 1.75 1.0 2.40 [42] PEEK 1.30 1.75 3.7 3.6 [43] E-54 − − − − [22] EP-671 − − − − [23] Continuous fiber Carbon fiber 1.30 0.40 54.0 51.0 [42] Glass fiber 2.40 0.30 21.0 22.0 [42] Kevlar fiber 1.20 0.30 27.0 26.0 [42] Jute fiber 1.46 0.80 5.0 − [42] Flax fiber 1.35-1.50 0.30 23.0 − [40, 44] Notes: PA6—Nylon 6; PLA—Poly lactic acid; ABS—Styrene-acrylonitrile-polybutadiene copolymer; PEEK—Polyether-ether-ketone; EP—Epoxy. 表 3 ILSS样品的打印参数和层间剪切强度[79]

Table 3. Printing parameters and interlaminar shear strength of ILSS samples[79]

Sample Fiber volume fraction

(vol%, number of fiber layers/number of layers)ILSS/MPa Carbon

fiberType A 26.8(18/48) 22.2 Type B 72.4(46/48) 31.9 Kevlar

fiberType A 27.5(22/60) 13.7 Type B 73.8(58/60) 14.3 Glass

fiberType A 27.2(22/60) 13.9 Type B 73.4(58/60) 21.0 表 4 缺口冲击样品的打印参数和冲击强度[78]

Table 4. Printing parameters and impact strength of notched impact samples[78]

Sample

Build orientationFiber volume

fraction/vol%Impact strength/

(kJ·m−2)Flat On-edge Flat On-edge Carbon

fiberType A 3.4 3.4 22.2 24.7 Type B 24.9 24.8 33.2 59.8 Type C 53.2 33.2 57.5 82.3 Kevlar

fiberType A 8.6 7.8 30.1 36.4 Type B 29.5 29.5 83.7 95.1 Type C 56.1 34.7 125.5 184.8 Glass

fiberType A 8.4 7.8 74.2 86.3 Type B 29.2 29.7 206.7 246.2 Type C 55.6 34.3 271.2 281.0 表 5 注塑、模压与3D打印工艺成型的碳纤维增强复合材料的力学性能对比

Table 5. Comparison of mechanical properties of carbon fibre reinforced compositesby injection molding, compression molding and 3D printing

Sample Fiber volume fraction/vol% Tensile modulus/

GPaTensile strength/

MPaFlexural modulus/

GPaFlexural strength/

MPaMode I

GIC−i/

(J·m−2)Mode I

GIC−p/

(J·m−2)Ref. CCF/ABS-3DP 10 − 127 − 147 − − [85] CCF/ABS-IM − 140 − 200 − − CCF/PA6-3DP 35 61.0 767 35.8 546 118.5 1467 [83] CCF/PA6-3DP-CM 83.2 940 57.3 1052 225.1 472 3DP 35 − − 52.1 583 − − [87] 3DP-CM − − 69.2 950 − − Notes: CCF—Continuous carbon fiber; ABS—Acrylonitrile butadiene styrene; PA6—Polyamide 6; 3DP—3D powder bonding; GIC−i—Interlaminar fracture toughness values for delamination initiation; GIC−p—Interlaminar fracture toughness after molding; IM—Injection molding; CM—Compression moulding. -

[1] VAN DE WERKEN N, TEKINALP H, KHANBOLOUKI P, et al. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective[J]. Additive Manufacturing,2020,31:100962. doi: 10.1016/j.addma.2019.100962 [2] ABDELWAHAB M A, TAYLOR S, MISRA M, et al. Thermo-mechanical characterization of bioblends from polylactide and poly(butylene adipate-co-terephthalate) and lignin[J]. Macromolecular Materials and Engineering,2015,300(3):299-311. doi: 10.1002/mame.201400241 [3] ABANILLA M A, KARBHARI V M, LI Y. Interlaminar and intralaminar durability characterization of wet layup carbon/epoxy used in external strengthening[J]. Composites Part B: Engineering,2006,37(7-8):650-661. doi: 10.1016/j.compositesb.2006.02.023 [4] ABANILLA M A, LI Y, KARBHARI V M. Durability characterization of wet layup graphite/epoxy composites used in external strengthening[J]. Composites Part B: Engineering,2006,37(2-3):200-212. [5] HAN S H, OH H J, KIM S S. Evaluation of the impregnation characteristics of carbon fiber-reinforced composites using dissolved polypropylene[J]. Composites Science and Technology,2014,91:55-62. doi: 10.1016/j.compscitech.2013.11.021 [6] ABDALLA F H, MUTASHER S A, KHALID Y A, et al. Design and fabrication of low cost filament winding machine[J]. Materials & Design,2007,28(1):234-239. [7] CHEN C H, MA C C M. Pultruded fiber-reinforced polyurethane composites. 3. Static mechanical, thermal, and dynamic-mechanical properties[J]. Composites Science and Technology,1994,52(3):427-432. doi: 10.1016/0266-3538(94)90177-5 [8] PAPARGYRIS D A, DAY R J, NESBITT A, et al. Comparison of the mechanical and physical properties of a carbon fibre epoxy composite manufactured by resin transfer moulding using conventional and microwave heating[J]. Composites Science and Technology,2008,68(7-8):1854-1861. doi: 10.1016/j.compscitech.2008.01.010 [9] Markforged. The backbone of aluminum-strength composite parts [EB/OL]. (2021)[2021-06-11] https://markforged.com/materials/continuous-fibers/continuous-carbon-fiber [10] DICKSON A N, BARRY J N, MCDONNELL K A, et al. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing[J]. Additive Manufacturing,2017,16:146-152. doi: 10.1016/j.addma.2017.06.004 [11] Desktop Metal. Press release-desktop metal set to transform continuous fiber 3d printing[EB/OL]. (2020) [2020-06-11]https://www.desktopmetal.com/press/press-release-desktop-metal-set-to-transform-continuous-fiber-3d-printing [12] AREVO. Robots with ded technology[EB/OL]. (2021) [2021-06-11]https://www.arevo.com/technology?lang=en [13] 9TLABS. Red seriesTM, your all-in-one solution for digital composite production[EB/OL]. (2021) [2021-06-11]https://www.9tlabs.com/news/2020/3/13/red-series [14] Anisoprint. CCF&CBF[EB/OL]. (2021) [2021-06-11]https://anisoprint.com/product-cf [15] GOH G D, YAP Y L, AGARWALA S, et al. Recent progress in additive manufacturing of fiber reinforced polymer composite[J]. Advanced Materials Technologies,2019,4(1):1800271. doi: 10.1002/admt.201800271 [16] TURNER B N, STRONG R, GOLD S A. A review of melt extrusion additive manufacturing processes: I — Process design and modeling[J]. Rapid Prototyping Journal,2014,20(3):192-204. doi: 10.1108/RPJ-01-2013-0012 [17] TURNER B N, GOLD S A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness[J]. Rapid Prototyping Journal,2015,21(3):250-261. doi: 10.1108/RPJ-02-2013-0017 [18] SINGH S, SINGH G, PRAKASH C, et al. Current status and future directions of fused filament fabrication[J]. Journal of Manufacturing Processes,2020,55:288-306. doi: 10.1016/j.jmapro.2020.04.049 [19] MATSUZAKI R, UEDA M, NAMIKI M, et al. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation[J]. Scientific Reports,2016,6:1-7. doi: 10.1038/s41598-016-0001-8 [20] MEI H, ALI Z, YAN Y K, et al. Influence of mixed isotropic fiber angles and hot press on the mechanical properties of 3D printed composites[J]. Additive Manufacturing,2019,27:150-158. doi: 10.1016/j.addma.2019.03.008 [21] COMPTON B G, LEWIS J A. 3D-printing of lightweight cellular composites[J]. Additive Manufacturing,2014,26(34):5930-5935. [22] HAO W, LIU Y, ZHOU H, et al. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites[J]. Polymer Testing,2018,65:29-34. doi: 10.1016/j.polymertesting.2017.11.004 [23] MING Y, ZHANG S, HAN W, et al. Investigation on process parameters of 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites[J]. Additive Manu-facturing,2020,33:101184. doi: 10.1016/j.addma.2020.101184 [24] MING Y K, DUAN Y G, ZHANG S Q, et al. Self-heating 3D printed continuous carbon fiber/epoxy mesh and its application in wind turbine deicing[J]. Polymer Testing,2020,82:106309. doi: 10.1016/j.polymertesting.2019.106309 [25] MELCHELS F P W, FEIJEN J, GRIJPMA D W. A review on stereolithography and its applications in biomedical engineering[J]. Biomaterials,2010,31(24):6121-6130. doi: 10.1016/j.biomaterials.2010.04.050 [26] RENAULT T, OGALE A, DOOLEY R L, et al. Photolithography for composites manufacturing. Continuous glass fiber/polycrylate composites[J]. SAMPE Quarterly (Society of Aerospace Material and Process Engineers),1991,22:19-25. [27] INVERNIZZI M, NATALE G, LEVI M, et al. UV-assisted 3D printing of glass and carbon fiber-reinforced dual-cure polymer composites[J]. Materials,2016,9(7):538. doi: 10.3390/ma9070538 [28] Continuous Composites. Into free space with CF3D[EB/OL]. (2021)[2021-06-11].https://www.continuouscomposites.com [29] HABERER M, ZAK G, PARK C B, et al. Fluid mechanics of slot-coating in photopolymer-based rapid composites manufacturing[J]. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science,2003,217(1):65-79. doi: 10.1243/095440603762554622 [30] WANG Y, XU Z, WU D, et al. Current status and prospects of polymer powder 3D printing technologies[J]. Materials,2020,13(10):2046. [31] ATHREYA S R, KALAITZIDOU K, DAS S. Mechanical and microstructural properties of Nylon-12/carbon black composites: Selective laser sintering versus melt compounding and injection molding[J]. Composites Science and Technology,2011,71(4):506-510. doi: 10.1016/j.compscitech.2010.12.028 [32] ARAI S, TSUNODA S, KAWAMURA R, et al. Comparison of crystallization characteristics and mechanical properties of poly(butylene terephthalate) processed by laser sintering and injection molding[J]. Materials & Design,2017,113:214-222. [33] KLOSTERMAN D, CHARTOFF R, GRAVES G, et al. Interfacial characteristics of composites fabricated by laminated object manufacturing[J]. Composites Part A: Applied Science and Manufacturing,1998,29(9-10):1165-1174. doi: 10.1016/S1359-835X(98)00088-8 [34] CHAPIRO M. Current achievements and future outlook for composites in 3D printing[J]. Reinforced Plastics,2016,60(6):372-375. doi: 10.1016/j.repl.2016.10.002 [35] TEKINALP H L, KUNC V, VELEZ-GARCIA G M, et al. Highly oriented carbon fiber-polymer composites via additive manufacturing[J]. Composites Science and Technology,2014,105:144-150. doi: 10.1016/j.compscitech.2014.10.009 [36] TIAN X Y, LIU T, YANG C, et al. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites Part A: Applied Science and Manufacturing,2016,88:198-205. doi: 10.1016/j.compositesa.2016.05.032 [37] HOU Z H, TIAN X Y, ZHENG Z Q, et al. A constitutive model for 3D printed continuous fiber reinforced composite structures with variable fiber content[J]. Composites Part B: Engineering,2020,189:107893. doi: 10.1016/j.compositesb.2020.107893 [38] HOU Z H, TIAN X, ZHANG J, et al. 3D printed continuous fibre reinforced composite corrugated structure[J]. Composite Structures,2018,184:1005-1010. doi: 10.1016/j.compstruct.2017.10.080 [39] LI N Y, LINK G, WANG T, et al. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures[J]. Composites Part B: Engineering,2020,182:107612. doi: 10.1016/j.compositesb.2019.107612 [40] LE DUIGOU A, BARBE A, GUILLOU E, et al. 3D printing of continuous flax fibre reinforced biocomposites for structural applications[J]. Materials & Design,2019,180:1-8. [41] OMRANI F, WANG P, SOULAT D, et al. Mechanical properties of flax-fibre-reinforced preforms and composites: Influence of the type of yarns on multi-scale characterisations[J]. Composites Part A: Applied Science and Manufacturing,2017,93:72-81. doi: 10.1016/j.compositesa.2016.11.013 [42] KABIR S M F, MATHUR K, SEYAM A F M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties[J]. Composite Structures,2020,232:111476. [43] LI W J, SANG L, JIAN X G, et al. Influence of sanding and plasma treatment on shear bond strength of 3D-printed PEI, PEEK and PEEK/CF[J]. International Journal of Adhesion and Adhesives,2020,100:102614. doi: 10.1016/j.ijadhadh.2020.102614 [44] RAMESH M. Flax (Linum usitatissimum L. ) fibre reinforced polymer composite materials: A review on preparation, properties and prospects[J]. Progress in Materials Science,2019,102:109-166. doi: 10.1016/j.pmatsci.2018.12.004 [45] MATSUZAKI R, NAKAMURA T, SUGIYAMA K, et al. Effects of set curvature and fiber bundle size on the printed radius of curvature by a continuous carbon fiber composite 3D printer[J]. Additive Manufacturing,2018,24:93-102. doi: 10.1016/j.addma.2018.09.019 [46] BILLAH K M M, LORENZANA F A R, MARTINEZ N L, et al. Thermomechanical characterization of short carbon fiber and short glass fiber-reinforced ABS used in large format additive manufacturing[J]. Additive Manufacturing,2020,35:101299. doi: 10.1016/j.addma.2020.101299 [47] 邓斌, 黄文艺, 邓鑫. 3D打印用聚合物材料的进展[J]. 塑料, 2019, 48(4):127-131.DEND Bin, HUANG Wenyi, DENG Xin, et al. Research progress of polymer materials for 3D printing[J]. Plastics,2019,48(4):127-131(in Chinese). [48] 蔡云冰, 刘志鹏, 张子龙, 等. 聚乳酸材料在3D打印中的研究与应用进展[J]. 应用化工, 2019, 48(4):127-131.CAI Yunbing, LIU Zhipeng, ZHANG Zilong, et al. Research and application of polylactic acid in 3D Printing[J]. Applied Chemical Industry,2019,48(4):127-131(in Chinese). [49] HEIDARI-RARANI M, RAFIEE-AFARANI M, ZAHEDI A M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites[J]. Composites Part B: Engineering,2019,175:107147. doi: 10.1016/j.compositesb.2019.107147 [50] 梁晓静, 于晓燕. 3D打印用高分子材料及其复合材料的研究进展[J]. 高分子通报, 2018(4):27-35.LIANG Xiaojing, YU Xiaoyan. Research progress of polymer and polymer composite materials for 3D printing[J]. Polymer Bulletin,2018(4):27-35(in Chinese). [51] LIAO G X, LI Z X, CHENG Y C, et al. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling[J]. Materials & Design,2018,139:283-292. [52] YANG C C, WANG B J, LI D C, et al. Modelling and characterisation for the responsive performance of CF/PLA and CF/PEEK smart materials fabricated by 4 D printing[J]. Virtual and Physical Prototyping,2017,12:69-76. doi: 10.1080/17452759.2016.1265992 [53] 齐俊梅, 姚雪丽, 陈辉辉, 等. 3D打印聚合物材料的研究进展[J]. 热固性树脂, 2019, 34(2):60-63.QI Junmei, YAO Xueli, CHEN Huihui, et al. Research progress of polymer and polymer composite materials for 3D printing technology[J]. Thermosetting Resin,2019,34(2):60-63(in Chinese). [54] 陈杰, 马春柳, 刘邦, 等. 热固性树脂及其固化剂的研究进展[J]. 塑料科技, 2019, 47(2):95-102.CHEN Jie, MA Chunliu, LIU Bang, et al. Research progress of thermosetting resins and their curing agents[J]. Plastics Science and Technology,2019,47(2):95-102(in Chinese). [55] SHI B, SHANG Y, ZHANG P, et al. Dynamic capillary-driven additive manufacturing of continuous carbon fiber composite[J]. Matter,2020,2(6):1594-1604. doi: 10.1016/j.matt.2020.04.010 [56] MA H, LI Y, SHEN Y, et al. Effect of linear density and yarn structure on the mechanical properties of ramie fiber yarn reinforced composites[J]. Composites Part A: Applied Science and Manufacturing,2016,87:98-108. doi: 10.1016/j.compositesa.2016.04.012 [57] SAAIDIA A, BEZAZI A, BELBAH A, et al. Mechano-physical properties and statistical design of jute yarns[J]. Measurement,2017,111:284-294. doi: 10.1016/j.measurement.2017.07.054 [58] GIORGINI L, BENELLI T, MAZZOCCHETTI L, et al. Pyrolysis as a way to close a CFRC life cycle: Carbon fibers recovery and their use as feedstock for a new composite production [C]//7th Internatinal Conference on Times of Polymers and Composites (Top). Ischia: AIP Conference Proceedings, 2014: 354-357. [59] LONG Y, ZHANG Z, FU K, et al. Efficient plant fibre yarn pre-treatment for 3D printed continuous flax fibre/poly(lactic) acid composites[J]. Composites Part B: Engineering,2021,227:109389. doi: 10.1016/j.compositesb.2021.109389 [60] KOUSHKI P, KWOK T H, HOF L, et al. Reinforcing silicone with hemp fiber for additive manufacturing[J]. Composites Science and Technology,2020,194:108139. doi: 10.1016/j.compscitech.2020.108139 [61] AZAROV A V, ANTONOV F K, VASIL’EV V V, et al. Development of a two-matrix composite material fabricated by 3D printing[J]. Polymer Science:Series D,2017,10(1):87-90. doi: 10.1134/S1995421217010026 [62] 周典瑞, 高亮, 霍红宇, 等. 热塑性树脂基复合材料用碳纤维上浆剂研究进展[J]. 复合材料学报, 2020, 37(8):1785-1795.ZHOU Dianrui, GAO Liang, HUO Hongyu, et al. Research of carbon fiber sizing agents for thermoplastic composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1785-1795(in Chinese). [63] LI N Y, LI Y G, LIU S T. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing[J]. Journal of Materials Processing Technology,2016,238:218-225. doi: 10.1016/j.jmatprotec.2016.07.025 [64] LIU T F, TIAN X Y, ZHANG M Y, et al. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites[J]. Composites Part A: Applied Science and Manufacturing,2018,114:368-376. doi: 10.1016/j.compositesa.2018.09.001 [65] AEGERTER N, VOLK M, MAIO C, et al. Pultrusion of hybrid bicomponent fibers for 3D printing of continuous fiber reinforced thermoplastics[J]. Advanced Industrial and Engineering Polymer Research,2021,4(4):224-234. [66] 刘腾飞, 田小永, 薛莲. 连续碳纤维增强尼龙6复合材料3D打印装备与参数调控[J]. 机械工业标准化与质量, 2020(3):27-30, 38. doi: 10.3969/j.issn.1007-6905.2020.08.008LIU Tengfei, TIAN Xiaoyong, XUE Lian. Continuous carbon fiber reinforced nylon 6 composite: 3D printing equipment and parameter control[J]. Journal of Standardization and Quality in the Machinery Industry,2020(3):27-30, 38(in Chinese). doi: 10.3969/j.issn.1007-6905.2020.08.008 [67] FERNANDEZ-VICENTE M, CALLE W, FERRANDIZ S, et al. Effect of Infill parameters on tensile mechanical behavior in desktop 3D printing[J]. 3D Printing and Additive Manufacturing,2016,3(3):183-192. doi: 10.1089/3dp.2015.0036 [68] VAEZI M, CHUA C K. Effects of layer thickness and binder saturation level parameters on 3D printing process[J]. International Journal of Advanced Manufacturing Technology,2011,53(1-4):275-284. doi: 10.1007/s00170-010-2821-1 [69] ADUMITROAIE A, ANTONOV F, KHAZIEV A, et al. Novel continuous fiber Bi-matrix composite 3D printing technology[J]. Materials,2019,12(18):3011. doi: 10.3390/ma12183011 [70] AKHOUNDI B, BEHRAVESH A H, SAED A B. Improving mechanical properties of continuous fiber-reinforced thermoplastic composites produced by FDM 3D printer[J]. Journal of Reinforced Plastics and Composites,2019,38(3):99-116. doi: 10.1177/0731684418807300 [71] HU Q X, DUAN Y C, ZHANG H G, et al. Manufacturing and 3D printing of continuous carbon fiber prepreg filament[J]. Journal of Materials Science,2018,53(3):1887-1898. doi: 10.1007/s10853-017-1624-2 [72] CHEN K, YU L G, CUI Y H, et al. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites[J]. Thin-Walled Structures,2021,164:107717. doi: 10.1016/j.tws.2021.107717 [73] UEDA M, WATANABE Y, MUKAI Y, et al. Three-dimensional printing of locally bendable short carbon fiber reinforced polymer composites[J]. Advanced Industrial and Engineering Polymer Research,2021,4(4):264-269. [74] MEI H, ALI Z, ALI I, et al. Tailoring strength and modulus by 3D printing different continuous fibers and filled structures into composites[J]. Advanced Composites and Hybrid Materials,2019,2(2):312-319. doi: 10.1007/s42114-019-00087-7 [75] PENG Y, WU Y Y, LI S X, et al. Tailorable rigidity and energy-absorption capability of 3D printed continuous carbon fiber reinforced polyamide composites[J]. Composites Science and Technology,2020,199:108337. doi: 10.1016/j.compscitech.2020.108337 [76] KRZIKALLA D, MESICEK J, HALAMA R, et al. On flexural properties of additive manufactured composites: Experimental, and numerical study[J]. Composites Science and Technology,2022,218:109182. doi: 10.1016/j.compscitech.2021.109182 [77] ARAYA-CALVO M, LOPEZ-GOMEZ I, CHAMBERLAIN-SIMON N, et al. Evaluation of compressive and flexural properties of continuous fiber fabrication additive manufacturing technology[J]. Additive Manufacturing,2018,22:157-164. [78] CAMINERO M A, CHACON J M, GARCIA-MORENO I, et al. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Composites Part B: Engineering,2018,148:93-103. doi: 10.1016/j.compositesb.2018.04.054 [79] CAMINERO M A, CHACON J M, GARCIA-MORENO I, et al. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Polymer Testing,2018,68:415-423. doi: 10.1016/j.polymertesting.2018.04.038 [80] IRAGI M, PASCUAL-GONZALEZ C, ESNAOLA A, et al. Ply and interlaminar behaviours of 3D printed continuous carbon fibre-reinforced thermoplastic laminates; effects of processing conditions and microstructure[J]. Additive Manufacturing,2019,30:100884. [81] HE Q, WANG H, FU K, et al. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance[J]. Composites Science and Technology,2020,191:108077. doi: 10.1016/j.compscitech.2020.108077 [82] NING F D, CONG W L, HU Y B, et al. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties[J]. Journal of Composite Materials,2017,51(4):451-462. doi: 10.1177/0021998316646169 [83] YANG C, TIAN X, LIU T, et al. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance[J]. Rapid Prototyping Journal,2017,23(1):209-215. doi: 10.1108/RPJ-08-2015-0098 [84] GOH G D, DIKSHIT V, NAGALINGAM A P, et al. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics[J]. Materials & Design,2018,137:79-89. [85] PARANDOUSH P, TUCKER L, ZHOU C, et al. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites[J]. Materials& Design,2017,131:186-195. [86] EICHENHOFER M, WONG J C H, ERMANNI P. Exploiting cyclic softening in continuous lattice fabrication for the additive manufacturing of high performance fibre-reinforced thermoplastic composite materials[J]. Composites Science and Technology,2018,164:248-259. doi: 10.1016/j.compscitech.2018.05.033 [87] UEDA M, KISHIMOTO S, YAMAWAKI M, et al. 3D compaction printing of a continuous carbon fiber reinforced thermoplastic[J]. Composites Part A: Applied Science and Manufacturing,2020,137:105985. doi: 10.1016/j.compositesa.2020.105985 [88] LI H M, LIU B S, GE L, et al. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum[J]. Composites Part B: Engineering,2021,225:109277. doi: 10.1016/j.compositesb.2021.109277 -

下载:

下载: