Properties of bismaleimide resin modified by addition-curing phenolic and their composites

-

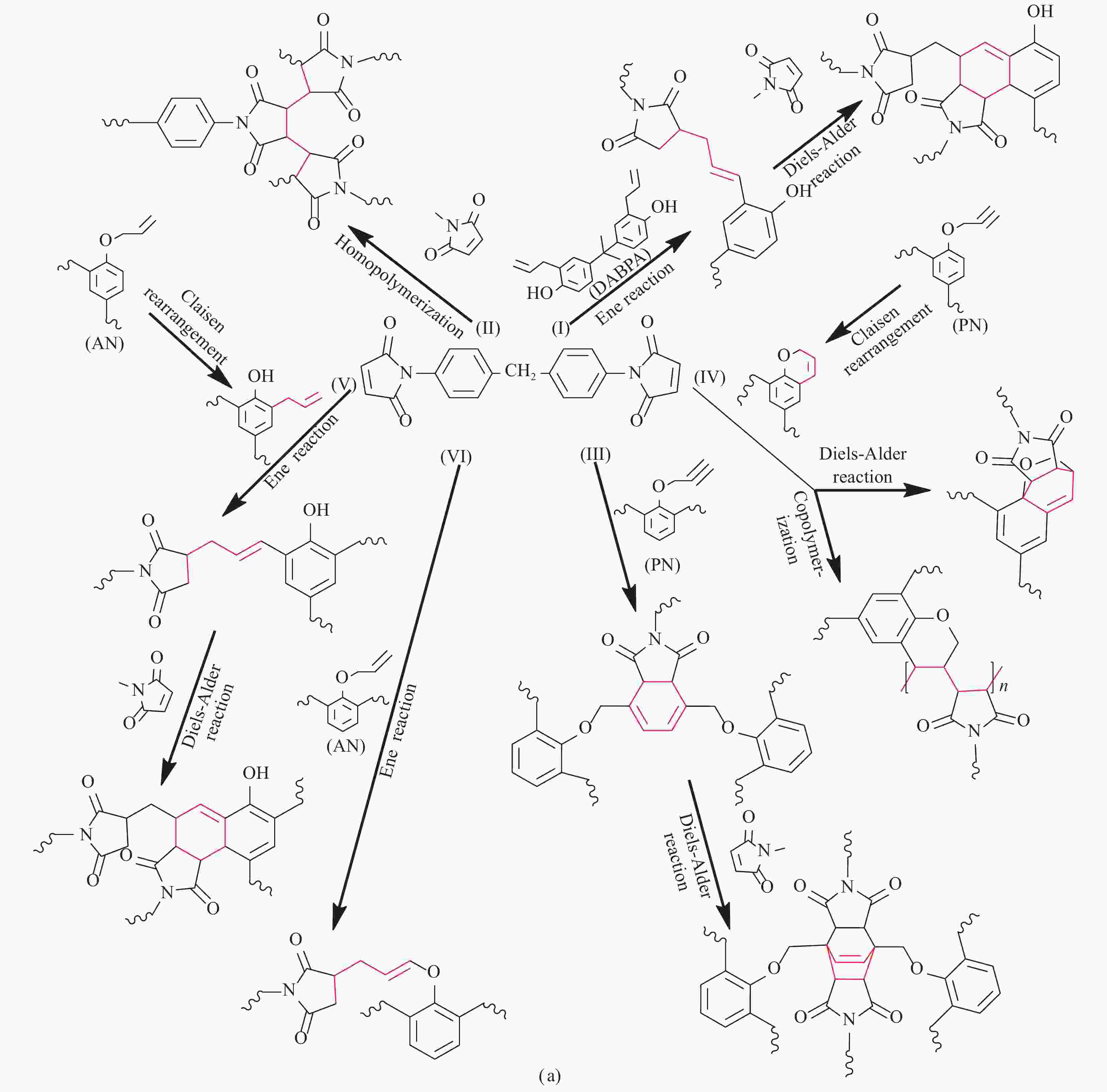

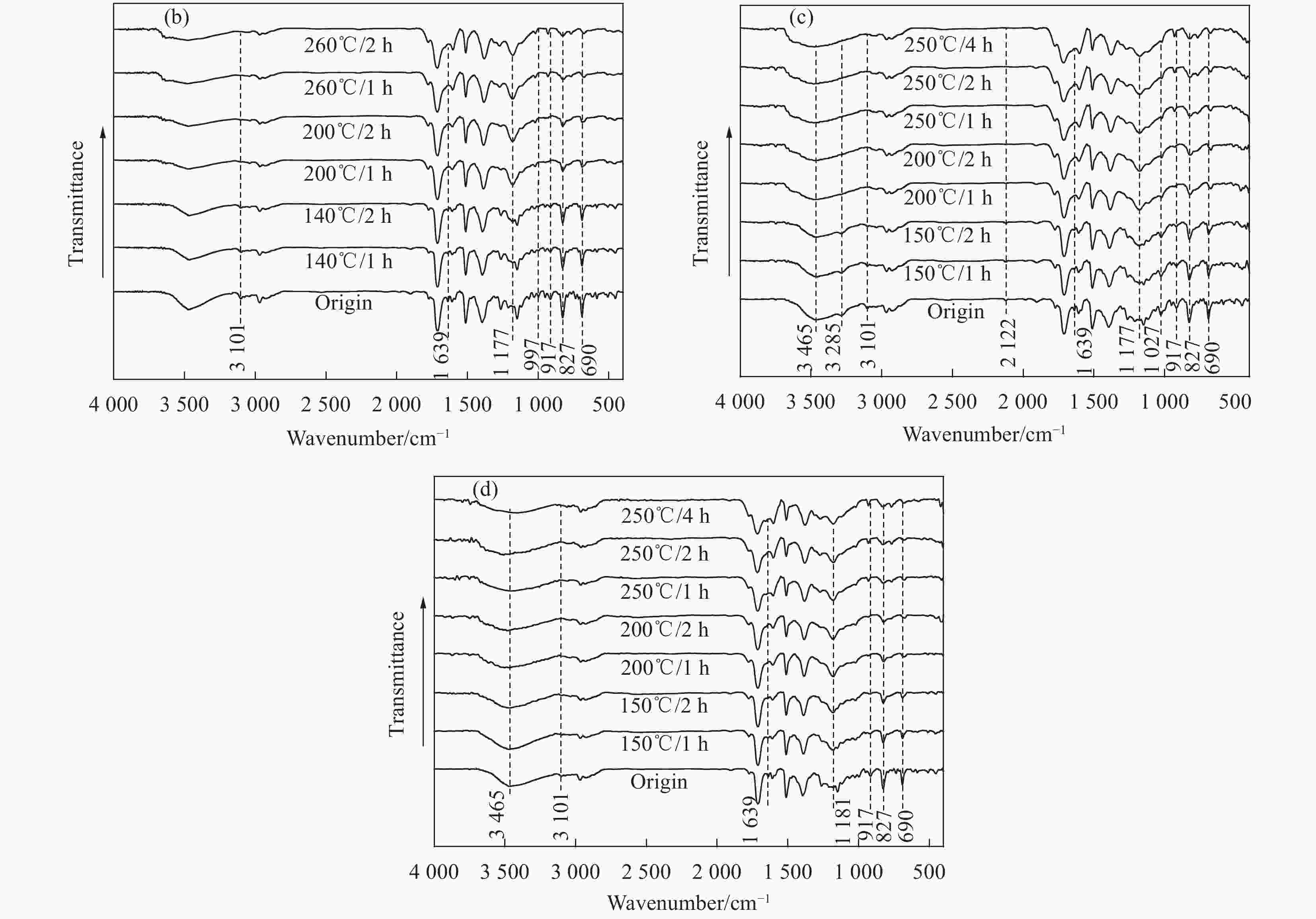

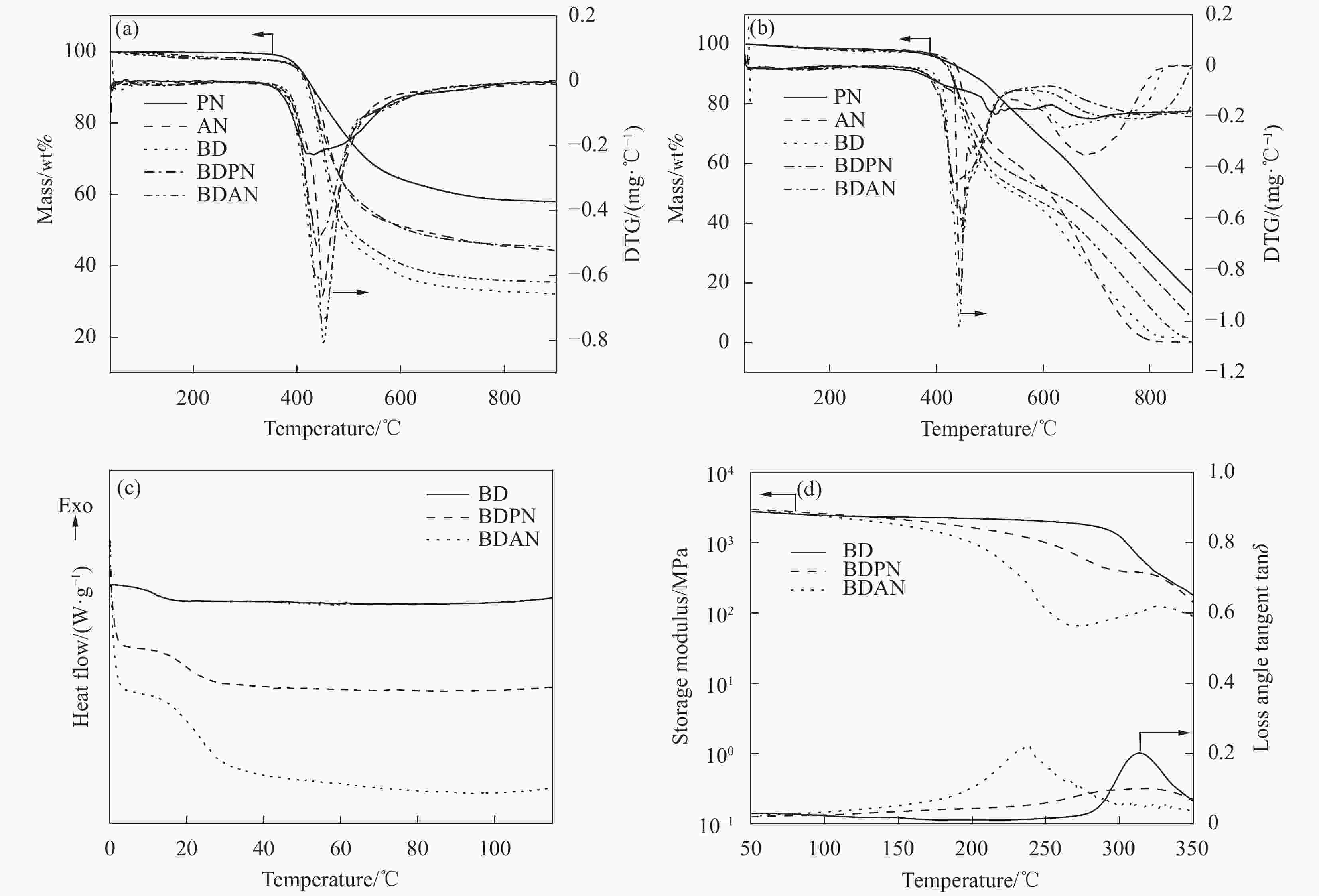

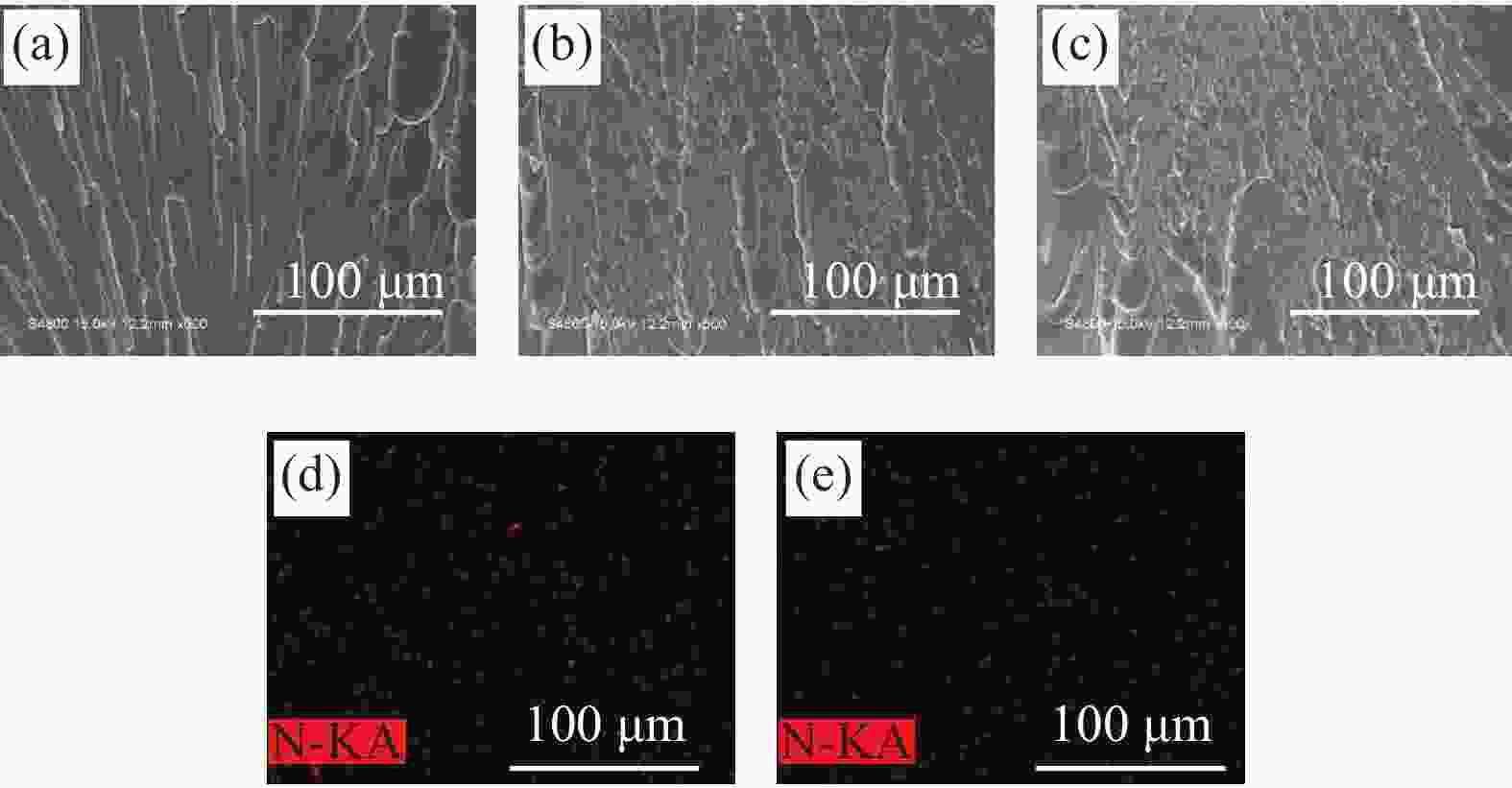

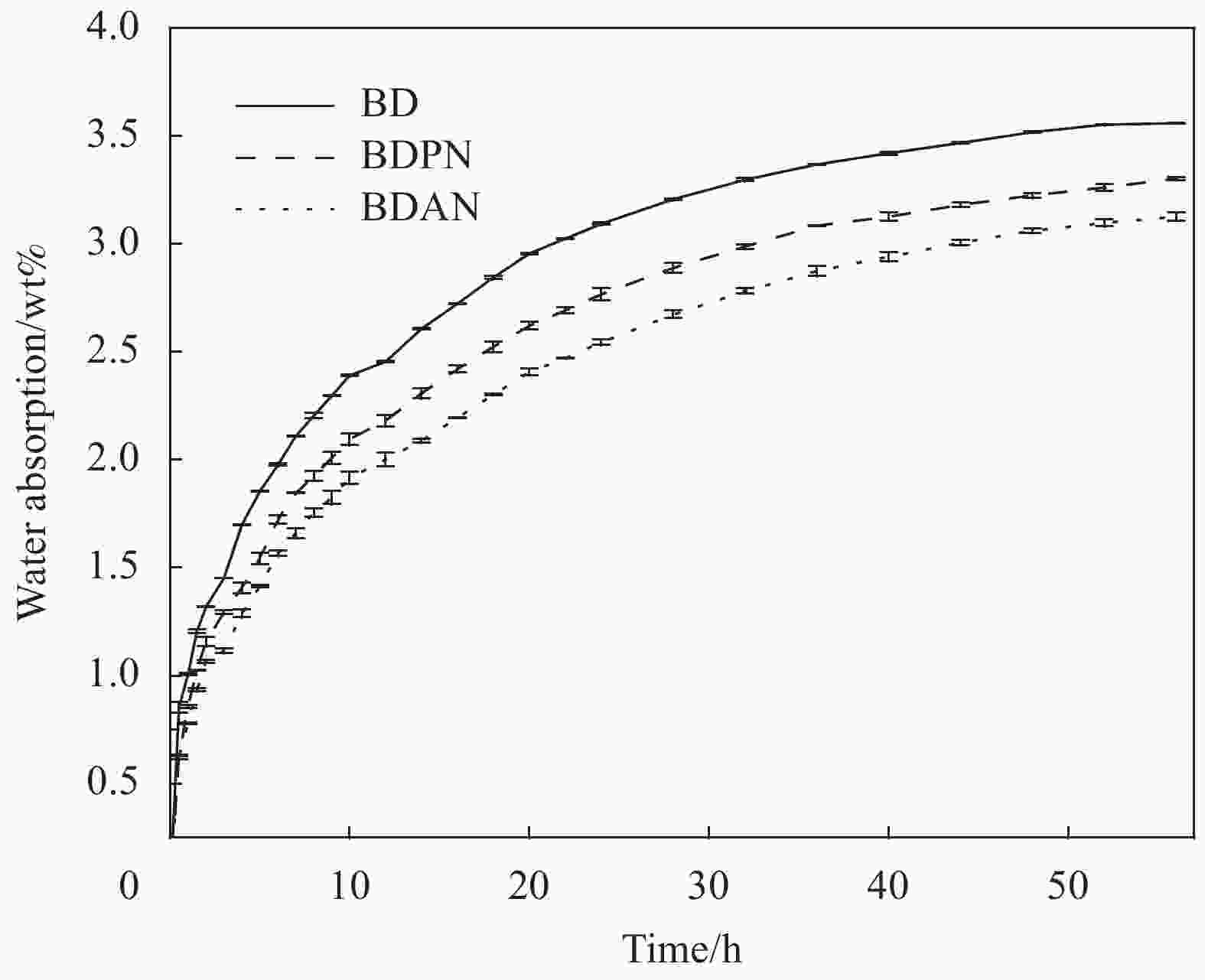

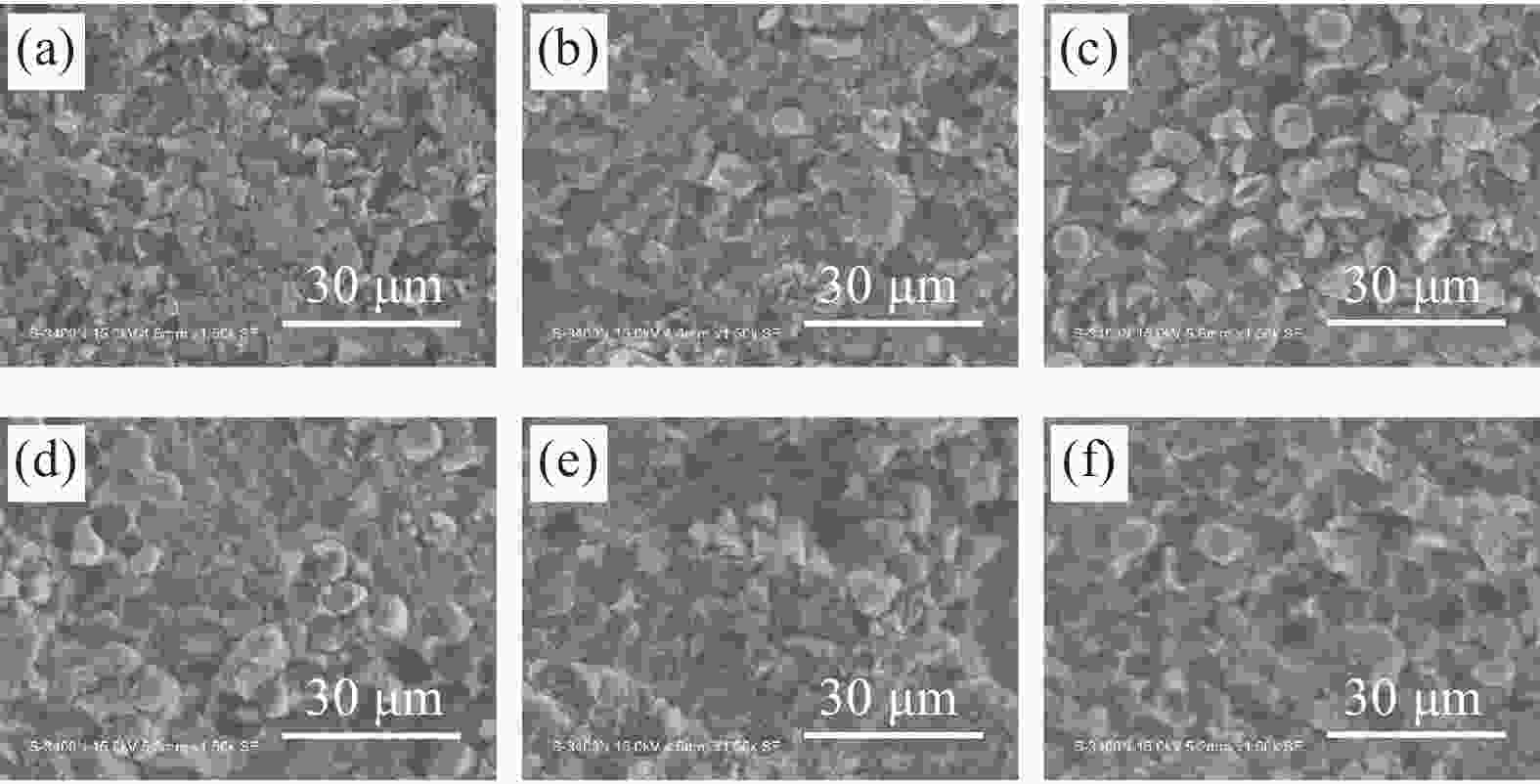

摘要: 双马来酰亚胺(BMI)树脂因其优异的性能已在航空航天、电子和其他工业领域获得应用,为满足其在高速飞行器结构件中需求,用加成型酚醛树脂改性BMI体系以改善其热-力学性能。通过Williamson醚化反应合成了炔丙基醚化酚醛树脂(PN)和烯丙基醚化酚醛树脂(AN),采用熔融共混法分别与N, N’-(4, 4’-亚甲基二苯基)双马来酰亚胺(BDM)和2, 2’-二烯丙基双酚A(DABPA)树脂体系(BD)共混,制备了三元热固性树脂:PN改性BD(BDPN)和AN改性BD(BDAN)。研究了两种加成型酚醛树脂改性的BD树脂体系的加工工艺性和固化行为的变化,并对改性前后固化树脂及其复合材料的热、力学性能进行了研究。结果表明:共混树脂体系都在极性溶剂中有好的溶解性,加工窗口都有50℃以上。BDPN和BDAN固化反应只有一个放热峰,最高放热峰值温度比BD树脂低。用FTIR跟踪验证了BD、BDPN和BDAN树脂体系发生的Ene、Diels-Alder、Claisen重排和炔基与马来酰亚胺环的聚合反应。PN热氧稳定性好,改性的BDPN固化树脂空气中质量损失5wt%的温度(Td5)高于400℃,800℃残留率(Yr800℃)由3.7%提升至23.1%。BD、BDPN和BDAN固化物的极限氧指数(LOI)分别为30.2%、32.5%和31.0%,都属难燃材料。BDPN和BDAN树脂浇铸体冲击强度和弯曲模量分别提高了19%和30%,但弯曲强度都因交联密度的下降而有所下降。BDPN和BDAN固化物的吸水率都低于BD树脂,沸水中40 h时BDPN和BDAN分别比BD树脂降低了8.6%和14%。室温下T300碳纤维增强BDAN复合材料(T300CF/BDAN)弯曲强度、弯曲模量和层间剪切强度(ILSS)高于BD基复合材料;200℃下T300CF/BDPN的弯曲强度达575 MPa,保留率高达98.6%。炔丙基醚化酚醛树脂改性双马来酰亚胺树脂体系有望应用于耐200℃的复合材料结构件,为耐热双马来酰亚胺树脂的制备提供新的途径。Abstract: Bismaleimide (BMI) resin has been widely used in aerospace, electronics and other industrial fields because of its excellent properties. In order to meet the needs of structural components for high-speed aircraft, the additional phenolic modifier is introduced to improve the thermo-mechanical properties of BMI resin. The propargyl etherified novolac (PN) and allyl etherified phenolic (AN) as an addition modifier were synthesized by Williamson etherification. The PN and AN were used to modify N, N'-(4, 4'-diphenylmethylane) bismaleimide (BDM)/2, 2'-diallyl bisphenol A (DABPA) resin system (BD) in melting mixing to obtain the ternary blended resins of BDPN and BDAN. The processability and cure reactions of the BDPN and BDAN were studied. The thermal property and mechanical property of the cured BD, BDPN and BDAN were further investigated. The results show that the ternary blended resins exhibit good solubility and meltability, and have an above 50℃ of process window. There is only a single exothermal peak in DSC curves of BDPN and BDAN. The peak temperatures of BDPN and BDAN are lower than that of BD. The Fourier transform infrared (FTIR) was used to monitor the curing reactions of BD, BDPN and BDAN resins. The reactions of Ene, Diels-Alder, Claisen rearrangement and addition of alkyne and maleimido group were detected during curing. The cured PN resin has good thermo-oxidative stability. The residual yield at 800℃ (Yr800℃) of cured BD in air increases from 3.7% to 23.1% after the BD resin was modified with PN resin. The temperature of 5wt% mass loss (Td5) of the cured BDPN in air is higher than 400℃. The limited oxygen index (LOI) of the cured BD, BDPN and BDAN resins are 30.2%, 32.5% and 31.0%, respectively. The cured resins are nonflammable. The impact strength and flexural modulus of the cured BD resin increase with addition of PN and AN resins. The impact strength and flexural modulus of the cured AN modified BD resin increase by 19% and 30% respec-tively. However, the flexural strength of the BDPN and BDAN resins decrease since the crosslinked density of the cured modified resins decline. The water absorption in boiling water of the cured BDPN and BDAN resins are lower than that of the cured BD resin, and decrease by 8.6% and 14% after 40 h. The flexural strength, flexural modulus and interlaminar shear strength (ILSS) of the T300 carbon fiber cloth (T300CF) reinforced BDAN composite (T300CF/BDAN) at room temperature are higher than that of the T300CF reinforced BD composite. The flexural strength of the T300CF/BDPN at 200℃ retains a 98.6% retention, reaches to 575 MPa. The propargyl etherified novolac can used to improve the heat properties of bismaleimide which is a new approach for modification of bismaleimides, and promising to be utilized in preparation of the structural components of composite with heat-resistance at 200℃.

-

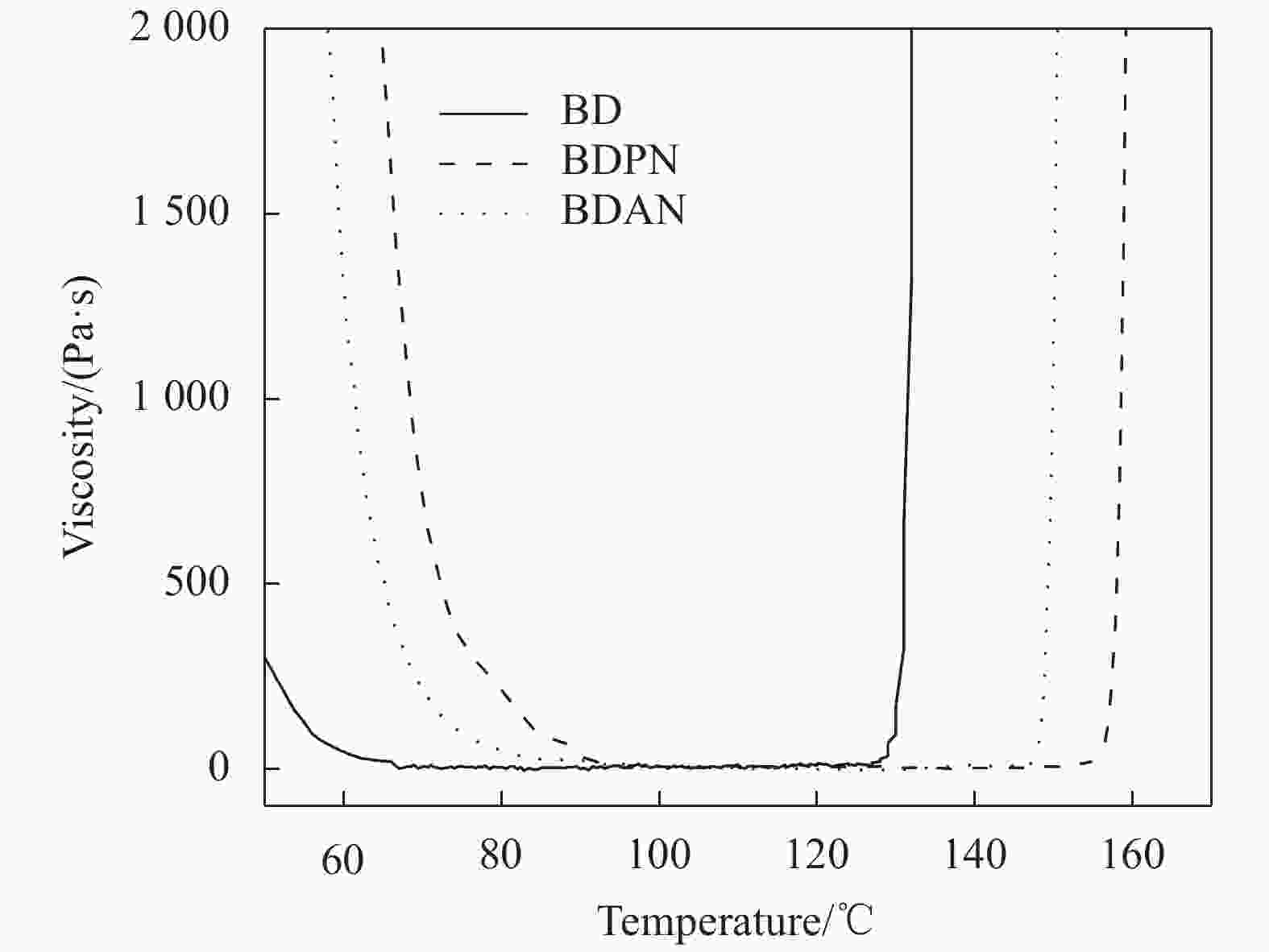

图 2 N, N’-(4, 4’-亚甲基二苯基)双马来酰亚胺(BDM)-2, 2’-二烯丙基双酚A(BD)、BD-炔丙基醚化酚醛树脂(PN)(BDPN)和BD-烯丙基醚化酚醛树脂(AN)(BDAN)共混树脂的黏温曲线

Figure 2. Viscosity of the N, N'-(4, 4'-diphenylmethylane)bismaleimide (BDM)-2, 2'-diallyl bisphenol A (BD), BD-propargyl etherified novolac (PN) (BDPN) and BD-allyl etherified phenolic (AN) (BDAN) blended resins against temperature

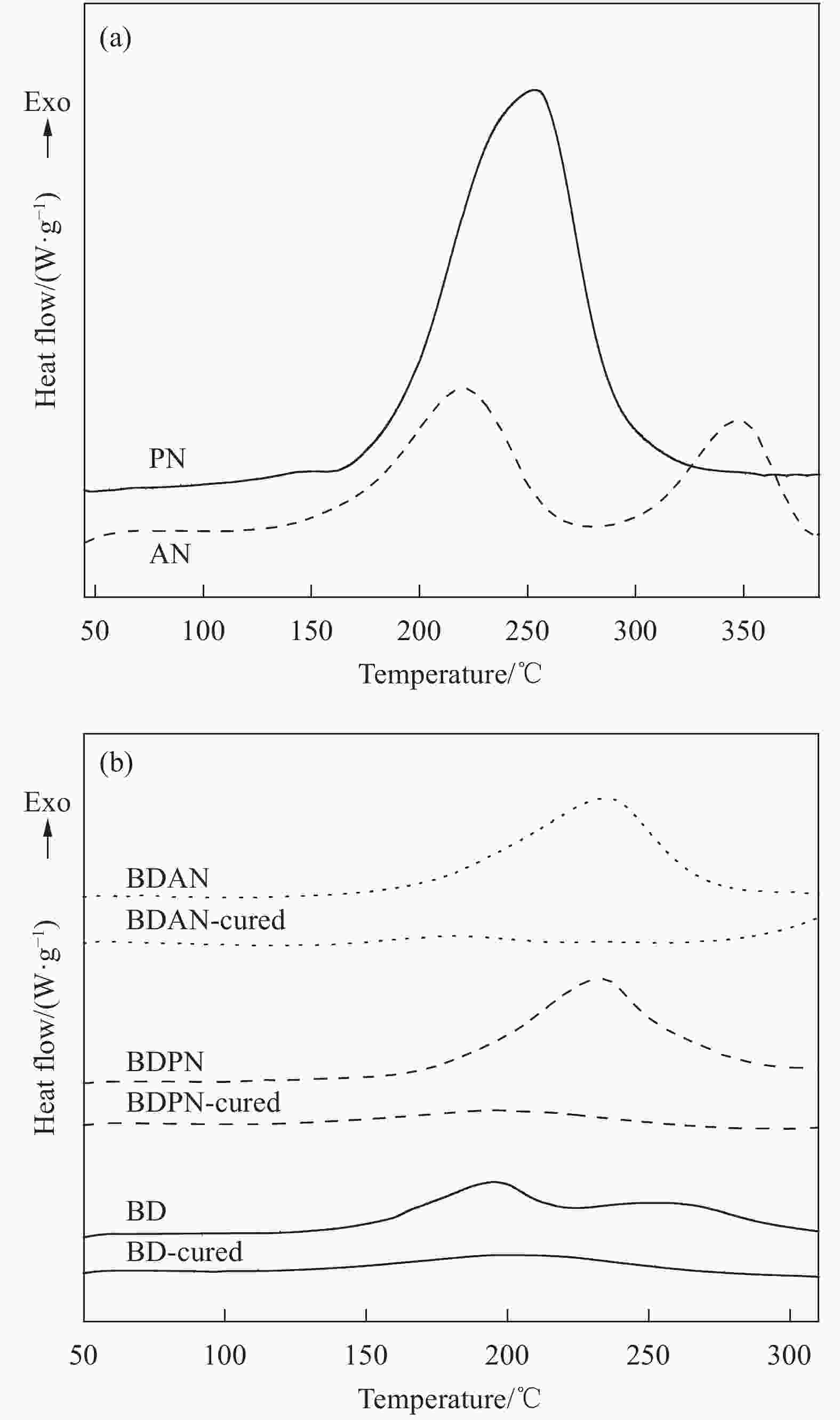

表 1 AN、PN和共混树脂的DSC数据结果

Table 1. DSC results of the AN, PN and blended resins

Resin Ti/℃ Tp1/℃ Tp2/℃ Tf/℃ ΔH/(J·g−1) ΔH-cured/(J·g−1) Retention of ΔH/% PN 188 253 − 329 659.3 − − AN 175 221 349 383 288.7 − − BD 145 196 248 287 402.0 49.9 12.4 BDPN 182 232 − 306 392.0 25.3 6.5 BDAN 175 235 − 289 299.3 13.5 4.5 Notes: Ti—Initial exothermic temperature; Tp1—First exothermic peak temperature; Tp2—Second exothermic peak temperature; Tf —End exothermic temperature; ΔH—Exothermic enthalpy of uncured resins; ΔH-cured—Exothermic enthalpy of cured resins. 表 2 PN、AN和共混树脂固化物的TGA、DTG、DMA及未固化树脂DSC数据结果

Table 2. TGA, DTG and DMA results of the cured PN, AN and blended resins and DSC results of the uncured resins

Resin N2 Air Tg-uncured/℃ Tg-cured/℃ MC Td5/℃ Yr800℃/% Tdmax/℃ Td5/℃ Yr800℃/% Tdmax/℃ PN 406 58.47 432 409 30.76 412 – – – AN 403 45.46 450 419 0.81 445 – – – BD 399 32.70 451 418 3.70 443 11.93 313 129.54 BDPN 403 45.84 438 408 23.13 438 20.32 320 130.14 BDAN 407 35.89 452 409 11.84 450 23.95 240 180.51 Notes: Td5—Temperature at 5wt% mass loss; Yr800℃—Residual yield at 800℃; Tdmax—Maximum temperature of thermogravimetric rate; Tg-uncured—Glass transition temperature of uncured resins; Tg-cured—Glass transition temperature of cured resins; MC—Average molecular mass of polymer between cross-linked nodes. 表 3 共混树脂的极限氧指数(LOI)

Table 3. Limit oxygen index (LOI) of the cured blended resins

Cured resin Yr600℃/% LOI (Van K-H) Real LOI BD 44.32 35.2 30.2 BDPN 51.58 38.1 32.5 BDAN 46.76 36.2 31.0 Notes: Yr600℃—Char yield at 600℃; Van K-H—An empirical equation used to reckon LOI value. 表 4 共混树脂浇铸体的力学性能

Table 4. Mechanical properties of blended resins

Cured resin Impact strength

/(kJ·m−2)Flexural strength

/MPaFlexural modulus

/GPaBD 14.70±1.35 151.00±5.48 3.00±0.24 BDPN 14.80±0.11 146.10±13.39 3.90±0.04 BDAN 17.50±0.79 139.00±7.07 3.90±0.06 表 5 T300碳纤维(T300CF)/共混树脂复合材料在室温及200℃下的力学性能

Table 5. Mechanical properties of T300 carbon fiber cloth (T300CF)/blended resin composites at room temperature and 200℃

Matrix Temperature/

℃Flexural

strength/MPaRetention of

flexural strength/%Flexural modulus/

GPaILSS/

MPaRetention of ILSS/

%BD 25 572.10±3.70 — 53.10±1.34 44.30±1.13 — BDPN 583.10±17.84 — 54.10±2.50 40.40±2.47 — BDAN 639.30±14.01 — 54.90±0.64 46.00±0.69 — BD 200 563.30±16.67 98.5 — 39.20±0.30 88.5 BDPN 575.00±10.00 98.6 — 32.10±0.44 79.4 BDAN 543.30±6.67 85.0 — 26.40±0.29 57.4 Note: ILSS—Interlaminar shear strength. 表 6 共混树脂的DMA分析结果

Table 6. DMA analysis results of blended resins

Cured resin Eg/MPa Er/MPa Eg/Er BD 1494.4 297.4 5.0 BDPN 399.1 212.2 1.9 BDAN 560.7 75.5 7.4 Notes: Eg—Modulus at the temperature T1 (T1=Tg–20℃) obtained from DMA data; Er—Modulus at the temperature T2 (T2=Tg+20℃) obtained from DMA data; Tg—glass transition temperature. -

[1] IREDALE R J, WARD C, HAMERTON I. Modern advances in bismaleimide resin technology: A 21st century perspective on the chemistry of addition polyimides[J]. Progress in Polymer Science,2017,69:1-21. doi: 10.1016/j.progpolymsci.2016.12.002 [2] GU J W, LIANG C B, DANG J, et al. Ideal dielectric thermally conductive bismaleimide nanocomposites filled with polyhedral oligomeric silsesquioxane functionalized nanosized boron nitride[J]. RSC Advances,2016,6(42):35809-35814. doi: 10.1039/C6RA04513H [3] DING Z J, YUAN L, GUAN Q B, et al. A reconfiguring and self-healing thermoset epoxy/chain-extended bismalei-mide resin system with thermally dynamic covalent bonds[J]. Polymer,2018,147:170-182. doi: 10.1016/j.polymer.2018.06.008 [4] WAGNER A, GOUZMAN I, ATAR N, et al. Cure kinetics of bismaleimides as basis for polyimide-like inks for PolyJet™-3D-printing[J]. Journal of Applied Polymer Science,2019,136(12):47244. doi: 10.1002/app.47244 [5] CHEN B H, YUAN L, GUAN Q B, et al. Preparation and mechanism of shape memory bismaleimide resins with high transition temperature, high toughness and good processability[J]. Journal of Materials Science,2018,53(15):10798-10811. doi: 10.1007/s10853-018-2367-4 [6] 夏连连. 含1, 3, 4-噁二唑结构不对称双马来酰亚胺及其改性树脂体系的研究[D]. 大连: 大连理工大学, 2015.XIA Lianlian. Studies on 1, 3, 4-oxadiazole-containing asymmetric bismaleimides and their modified resin systems[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [7] MORGAN R J, SHIN E E, ROSENBERG B, et al. Characterization of the cure reactions of bismaleimide composite matrices[J]. Polymer,1997,38(3):639-646. doi: 10.1016/S0032-3861(96)00542-3 [8] LIAO Y T, LIN C R, LIU W L. High-performance thermoplastic toughened BMI matrix system. II. Interface study[J]. Journal of Applied Polymer Science,2010,40(1112):2239-2242. [9] QIN H, MATHER P T, BAEK J B, et al. Modification of bisphenol-A based bismaleimide resin (BPA-BMI) with an allyl-terminated hyperbranched polyimide (AT-PAEKI)[J]. Polymer,2006,47(8):2813-2821. doi: 10.1016/j.polymer.2006.02.062 [10] ZHANG H, WANG L X, YUAN Q L, et al. Preparation and properties of bismaleimide resin blended with alkynyl-terminated modifiers[J]. High Performance Polymers,2021,33(10):1192-1204. doi: 10.1177/09540083211034118 [11] LINCOLN J E, MORGAN R J, SHIN E E, et al. Moisture absorption-network structure correlations in BMPM/DABPA bismaleimide composite matrices[J]. Journal of Advanced Materials,2000,32(4):24-34. [12] 亢雅君, 殷立新. 酚醛树脂基复合材料及工艺的新发展[J]. 材料科学与工程, 1996, 14(2):58-62.KANG Yajun, YIN Lixin. New developments on phenolic resin matrix composites and their process[J]. Materials Science and Engineering,1996,14(2):58-62(in Chinese). [13] YAN Y H, SHI X M, LIU J G, et al. Thermosetting resin system based on novolak and bismaleimide for resin-transfer molding[J]. Journal of Applied Polymer Science,2002,83(8):1651-1657. doi: 10.1002/app.10073 [14] REGHUNADHAN NAIR C P. Advances in addition-cure phenolic resins[J]. Progress in Polymer Science,2004,29:401-498. doi: 10.1016/j.progpolymsci.2004.01.004 [15] BINDU R L, REGHUNADHAN NAIR C P, NINAN K N. Addition-cure phenolic resins based on propargyl ether functional novolacs: Synthesis, curing and properties[J]. Polymer International,2001,50:651-658. doi: 10.1002/pi.679 [16] WANG M, WEI L, ZHAO T. A novel condensation-addition-type phenolic resin (MPN): Synthesis, characterization and evaluation as matrix of composites[J]. Polymer,2005,46(21):9202-9210. doi: 10.1016/j.polymer.2005.06.009 [17] NECHAUSOV S S, BULGAKOV B A, SOLOPCHENKO A V, et al. Thermosetting matrices for composite materials based on allyl/propagryl substituted novolac resins[J]. Journal of Polymer Research,2016,23:114. doi: 10.1007/s10965-016-1004-7 [18] YAO Y, ZHAO T, YU Y. Novel thermosetting resin with a very high glass-transition temperature based on bismaleimide and allylated novolac[J]. Journal of Applied Polymer Science,2005,97:443-448. doi: 10.1002/app.21671 [19] 罗振华, 杨明, 刘峰, 等. 一种耐高温加成固化型酚醛树脂作为复合材料基体的评价[J]. 复合材料学报, 2009, 26(1):13-18. doi: 10.3321/j.issn:1000-3851.2009.01.003LUO Zhenhua, YANG Ming, LIU Feng, et al. Evaluation of a high temperature-resistant, addition-curable phenolic resin as the matrix of composites[J]. Acta Materiae Compositae Sinica,2009,26(1):13-18(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.003 [20] 何先成, 包建文, 李晔, 等. 烯丙基酚醛改性双马来酰亚胺树脂的制备与性能[J]. 热固性树脂, 2013, 28(3):19-23.HE Xiancheng, BAO Jianwen, LI Ye, et al. Synthesis and properties of allyl novolac modified bismaleimide resin[J]. Thermosetting Resin,2013,28(3):19-23(in Chinese). [21] GOURI C, REGHUNADHAN NAIR C P, RAMASWAMY R. Reactive Alderene blend of diallyl bisphenol A novolac and bisphenol A bismaleimide: Synthesis, cure and adhesion studies[J]. Polymer International,2001,50:403-413. doi: 10.1002/pi.644 [22] 中国国家标准化管理委员会. 塑料 用氧指数法测定燃烧行为 第二部分: 室温试验: GB/T 2406.2—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Plastics—Determination of burning behaviour by oxygen index—Part 2: Ambient-temperature test: GB/T 2406.2—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [23] 中国国家标准化管理委员会. 树脂浇铸体性能试验方法: GB/T 2567—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Test methods for properties of resin casting boby: GB/T 2567—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [24] 中国国家标准化管理委员会. 塑料 悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics—Determination of izod impact strength: GB/T 1843—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [25] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fibre-reinforced plastics composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [26] 中华人民共和国工业和信息化部. 纤维增强塑料 短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国标准出版社, 2010.Ministry of Industry and Information Technology of the People’s Republic of China. Fibre-reinforced plastics composites—Determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [27] WANG D S, XIONG X H, REN R, et al. Characterization and properties of high-temperature resistant structure adhe-sive based on novel toughened bismaleimide resins[J]. High Performance Polymers,2021,33(5):488-496. doi: 10.1177/0954008320970271 [28] WANG M C, WEI L H, ZHAO T. Addition-curable propargyl-containing novolac-type phenolic resin: Its synthesis, characterization, cure, and thermal properties[J]. Journal of Applied Polymer Science,2006,99(3):1010-1017. doi: 10.1002/app.22592 [29] NAIR C P R, KRISHNAN K, NINAN K N. Differential scanning calorimetric study on the Claisen rearrangement and thermal polymerisation of diallyl ether of bisphenols[J]. Thermochimica Acta,2000,359(1):61-67. doi: 10.1016/S0040-6031(00)00504-9 [30] PHELAN J C, SUNG C S P. Cure characterization in bis(maleimide)/diallylbisphenol a resin by fluorescence, FTIR, and UV-reflection spectroscopy[J]. Macromolecules,1997,30(22):6845-6851. doi: 10.1021/ma961887f [31] MARIE F, GRENIER L, LOUIS D C. Study of molten-state polymerization of bismaleimide monomers by solid-state 13C NMR and FTIR[J]. Polymer,1998,39(10):1833-1843. doi: 10.1016/S0032-3861(97)00477-1 [32] GARCIA G, NAVARRO A, GRANADINO-ROLDAN J M, et al. Molecular structure, conformational preferences and vibrational analysis of 2-hydroxystyrene: A computational and spectroscopic research[J]. Chemical Physics,2010,374:62-76. doi: 10.1016/j.chemphys.2010.06.014 [33] AUTREY D, CHOO J, LAANE J. Spectroscopic determination of the ring-twisting potential energy function of 1, 3-cyclohexadiene and comparison with AB initio calculations[J]. Journal of Physical Chemistry A,2001,105(45):10230-10236. doi: 10.1021/jp012170j [34] JIANG H, WANG R M, FARHAN S, et al. Properties and curing behavior of reactive blended allyl novolak with bismaleimide using dicumyl peroxide as a novel curing agent[J]. Journal of Applied Polymer Science,2015,132(15):41829. [35] NIELSEN L E. Cross-linking-effect on physical properties of polymers[J]. Journal of Macromolecular Science, Part C,1969,3(1):69-103. doi: 10.1080/15583726908545897 [36] BARANEK A D, KENDRICK L L, NARAYANAN J, et al. Flexible aliphatic-bridged bisphenol-based polybenzoxazines[J]. Polymer Chemistry,2012,3(10):2892-2900. doi: 10.1039/c2py20498c [37] 蔡洪能, 靖宫, 中田政之, 等. 玻璃纤维增强树脂基复合材料弯曲强度时间温度相关性[J]. 复合材料学报, 2005, 22(5):178-183. doi: 10.3321/j.issn:1000-3851.2005.05.028CAI Hongneng, MIYANO Y, NAKADA M, et al. Time-temperature dependence of flexural strength of glass fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2005,22(5):178-183(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.05.028 [38] ZHANG X D, LIU G, DANG G D, et al. Properties of carbon fibre/bismaleimide composites exsitu toughened with phosphorous-containing poly(arylene ether ketone) film[J]. High Performance Polymers,2016,29(5):533-543. -

下载:

下载: