Effect of activator on lithium storage performance of porous carbon materials prepared from soybean hulls

-

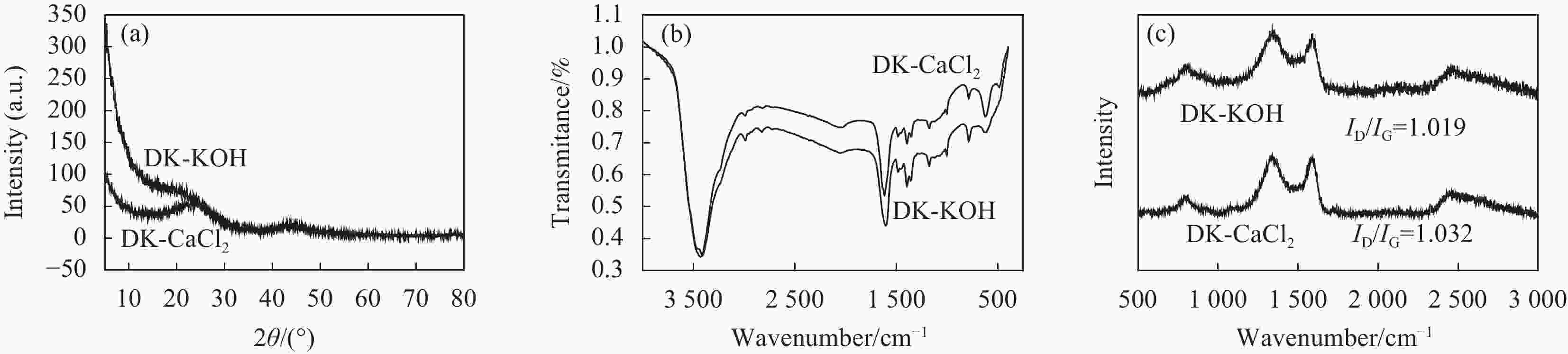

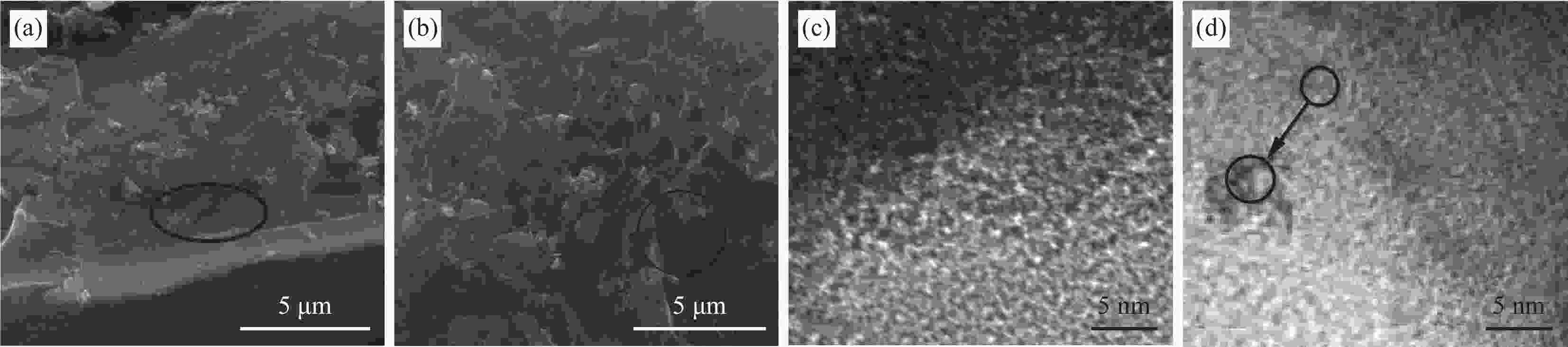

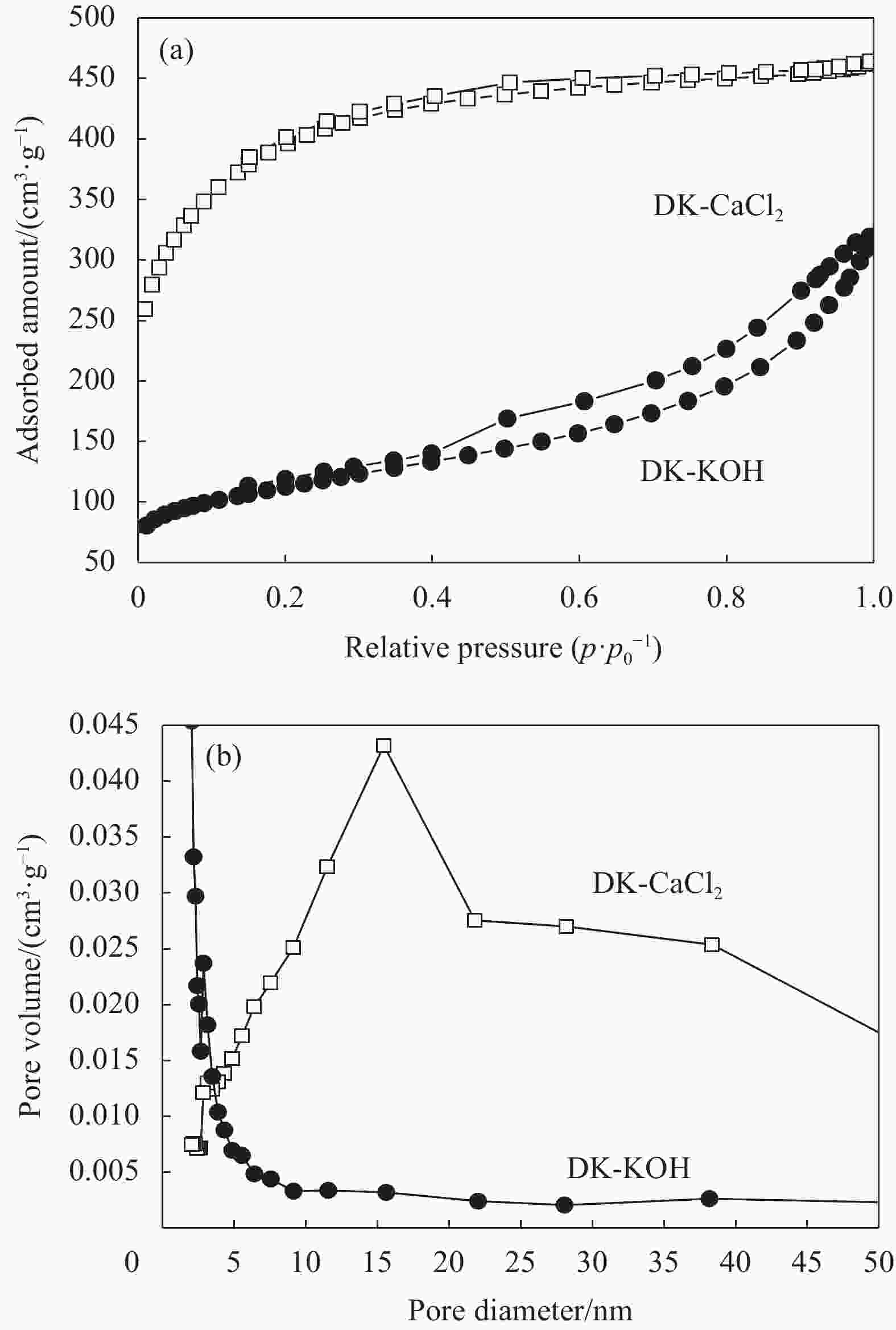

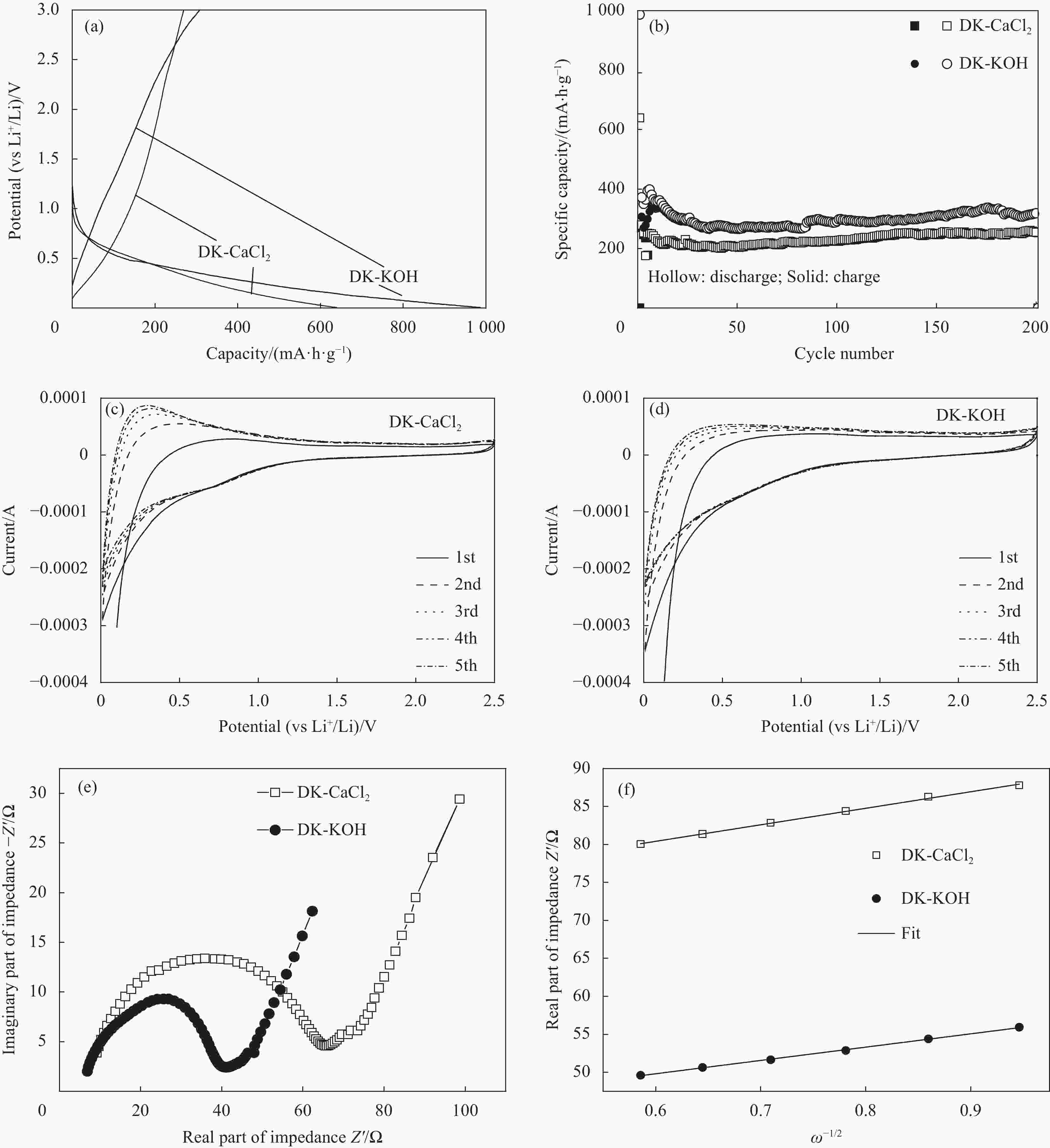

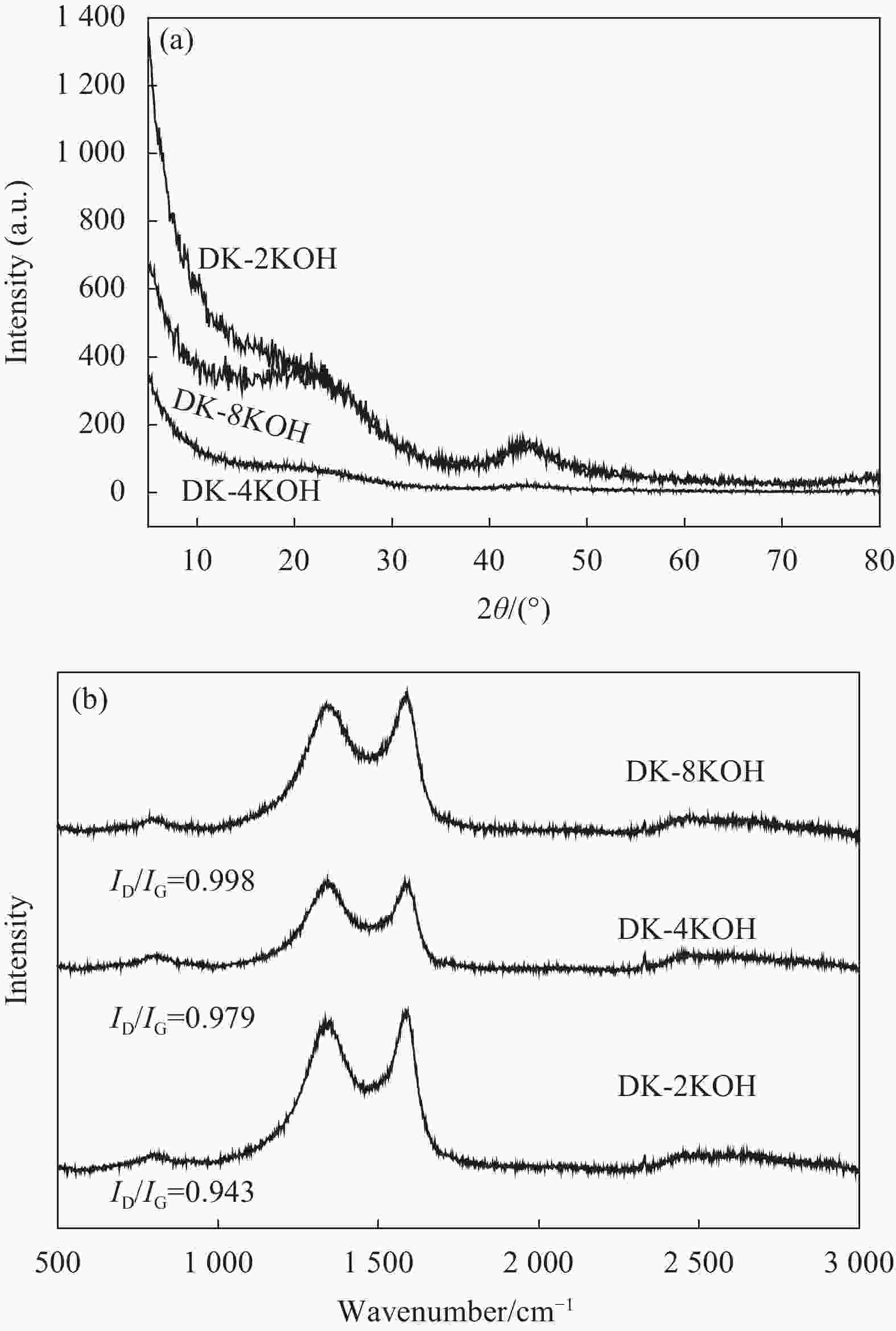

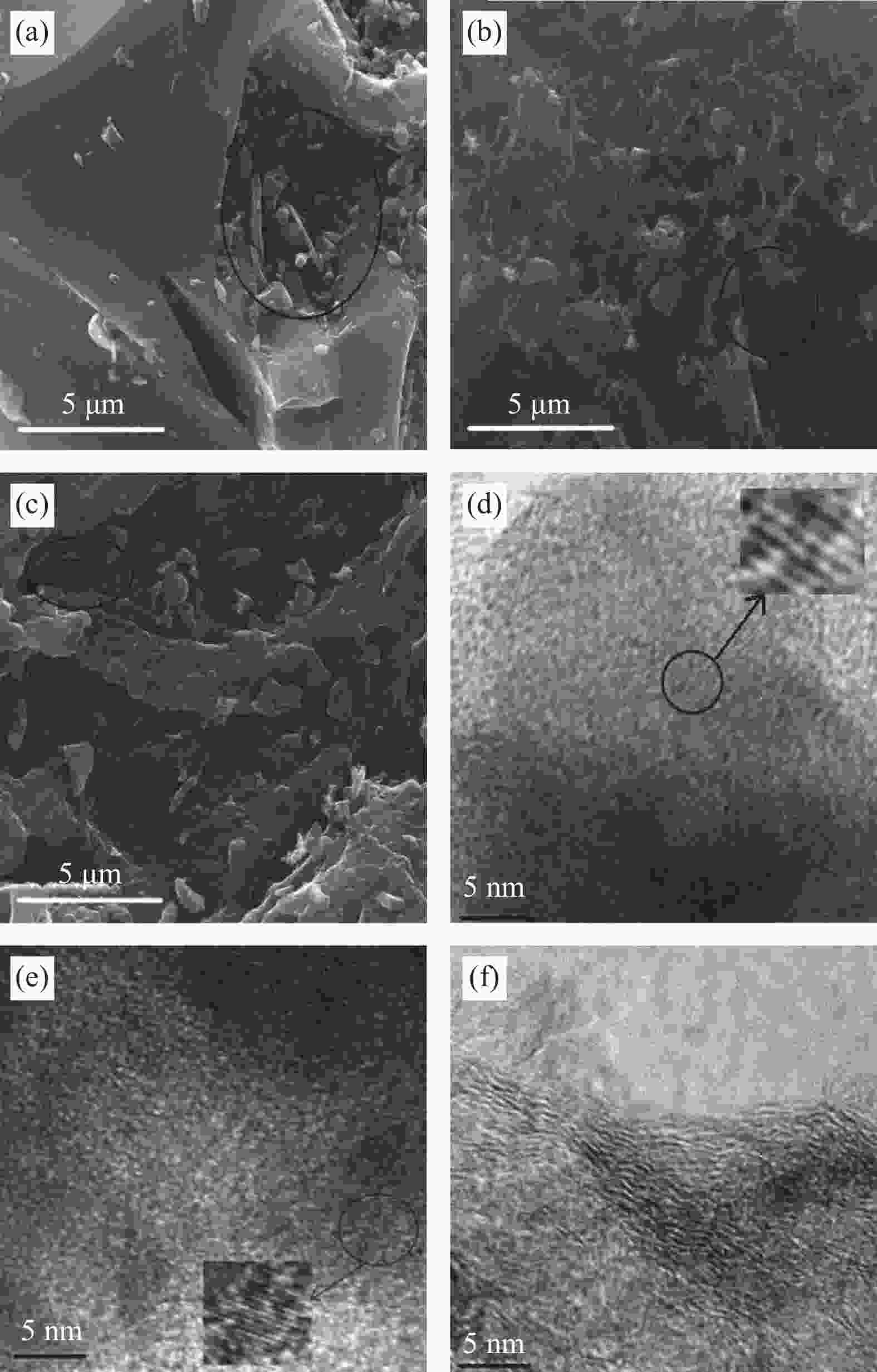

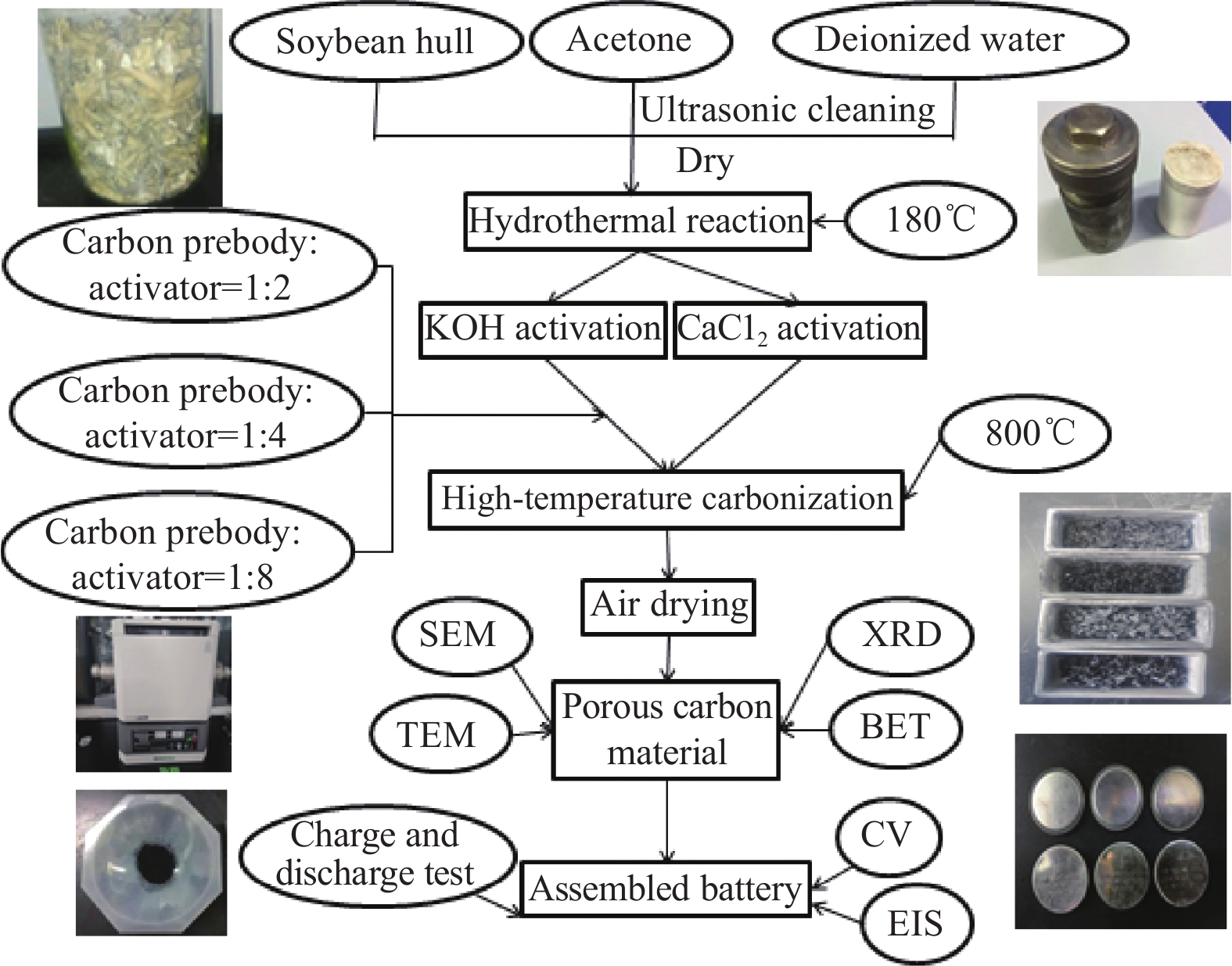

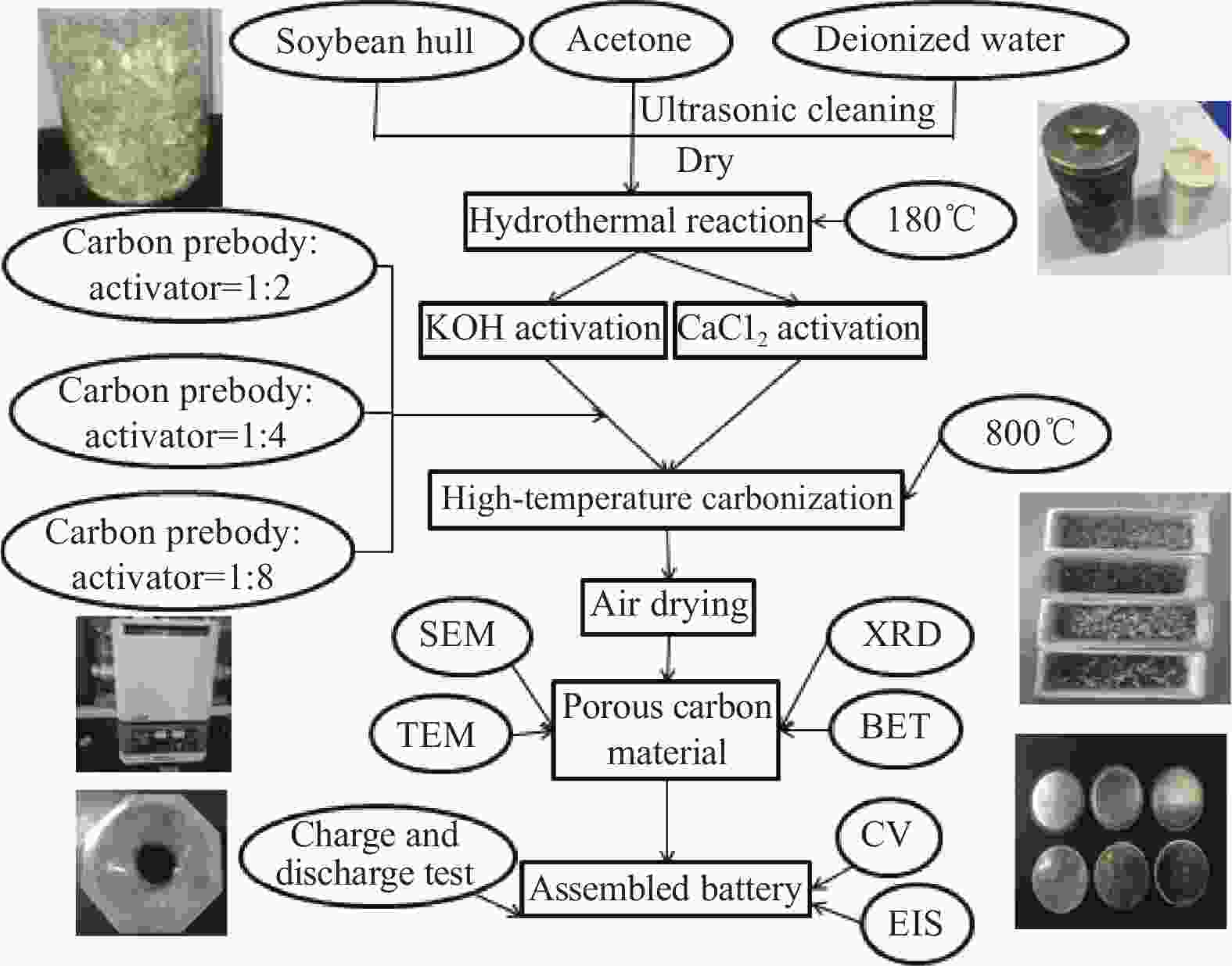

摘要: 生物质多孔碳材料因来源广泛、性价比高,被广泛应用在锂离子电池中,而制备过程中使用的活化剂对材料储锂性能影响较大。因此,以大豆壳为碳源,在不同工艺条件下制备多孔碳材料,通过结构表征和电化学性能测试,考察活化剂对多孔碳材料储锂性能的影响。研究表明:(1)当电流密度为185 mA·g−1,电压范围为0~3.0 V时,经CaCl2活化的多孔碳材料(DK-CaCl2)的首次放充电比容量为639.0/269.5 mA·h·g−1,而KOH活化的多孔碳(DK-KOH)的首次放充电比容量为986.7/307.5 mA·h·g−1;(2)大豆壳∶KOH的质量比分别为1∶2、1∶4和1∶8时,得到的多孔碳的首次放充电比容量为544.9/136.8、986.7/307.5和375.1/93.4 mA·h·g−1,200次循环后放电比容量分别为88.8、318.9和94.7 mA·h·g−1。这说明不同活化剂及不同活化比例制备的多孔碳材料储锂性能不同,这是由于材料的比表面积不同,导致了电化学性能的不同。Abstract: Biomass porous carbon materials are widely used in lithium ion batteries due to their wide sources and high cost performance, while activators used in the preparation process have a great influence on the lithium storage performance of materials. Therefore, using soybean shell as carbon source, porous carbon materials were prepared under different technological conditions, and the effect of activator on lithium storage performance of porous carbon materials was investigated through structural characterization and electrochemical performance tests. It may be shown as follows: (1) When the current density is 185 mA·g−1, the initial discharge and charge specific capacity of CaCl2-activated porous carbon (DK-CaCl2) is 639.0/269.5 mA·h·g−1, while that of KOH activated porous carbon (DK-KOH) is 986.7/307.5 mA·h·g−1; (2) When the mass ratios of soybean shell to KOH are 1∶2, 1∶4 and 1∶8, the first specific capacities of the obtained porous carbon are 544.9/136.8, 986.7/307.5 and 375.1/93.4 mA·h·g−1, after 200 cycles, their discharges retain 88.8, 318.9 and 94.7 mA·h·g−1, respectively. This indicates that the lithium storage performance of porous carbon materials prepared with different activators and activation ratios are different, which is due to the different specific surface area of materials, resulting in different electrochemical performance.

-

Key words:

- activator /

- lithium ion battery /

- biomass porous carbon /

- CaCl2 /

- KOH

-

图 5 (a) 材料的首次充放电性能图;(b) 循环性能图;(c) DK-CaCl2的CV图;(d) DK-KOH的CV图;(e) EIS图;(f) 不同荷电状态下角频率平方根的倒数(ω−1/2)与Z'的关系

Figure 5. (a) Initial charge-discharge performance diagram; (b) Cyclic performance diagram; (c) CV diagram of DK-CaCl2; (d) CV diagram of DK-KOH; (e) EIS of DK-CaCl2 and DK-KOH materials; (f) Relationship between Z' and reciprocal of square root of angular frequency (ω−1/2) under different states of charge

图 8 (a)材料的首次充放电性能图;(b)循环性能图;(c) DK-2KOH的CV图;(d) DK-4KOH 的CV图;(e) DK-8KOH 的CV图;(f) EIS图;(g)不同荷电状态下角频率的平方根的倒数(ω−1/2)与Z'的关系

Figure 8. (a) Initial charge-discharge performance diagram; (b) Cyclic performance diagram; (c) CV diagram of DK-2KOH; (d) CV diagram of DK-4KOH; (e) CV diagram of DK-8KOH; (f) EIS diagram; (g) Relationship between Z' and reciprocal of square root of angular frequency (ω−1/2) under different states of charge

表 1 DK-CaCl2和 DK-KOH的拟合线性数据

Table 1. Fitting linear data of DK-CaCl2 and DK-KOH

Material Intercept Slope DK-CaCl2 67.37 21.75 DK-KOH 39.31 17.52 表 2 DK-2KOH、DK-4KOH和DK-8KOH的拟合线性数据

Table 2. Fitting linear data of DK-2KOH, DK-4KOH and DK-8KOH

Material Intercept Slope DK-2KOH 62.32 45.18 DK-4KOH 40.23 16.14 DK-8KOH 92.57 102.00 -

[1] 岳红伟, 陈淑君, 吴培成, 等. 竹基碳纤维/MoS2锂离子电池负极材料[J]. 复合材料学报, 2021, 38(11):3590-3597. doi: 10.13801/j.cnki.fhclxb.20210129.003YUE Hongwei, CHEN Shujun, WU Peicheng, et al. Bamboo-based carbon fibers/MoS2 composite as an anode material for lithium ion batteries[J]. Acta Materiae Compositae Sinica,2021,38(11):3590-3597(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210129.003 [2] 伍涛, 彭希林. 黄豆渣基多孔碳在超级电容器中的应用研究进展[J]. 轻工标准与质量, 2020(2):120-122. doi: 10.19541/j.cnki.issn1004-4108.2020.02.024WU Tao, PENG Xilin. Research progress on application of soybean dregs based porous carbon in supercapacitor[J]. Light Industry Standard & Quality,2020(2):120-122(in Chinese). doi: 10.19541/j.cnki.issn1004-4108.2020.02.024 [3] 张春艳, 余浩, 潘乐. 绿茶渣基生物质碳材料的制备及其在锂电负极材料中的应用[J]. 黄山学院学报, 2019, 21(5):31-34.ZHANG Chunyan, YU Hao, PAN Le. Preparation of green tea residue based biomass carbon material and its application in lithium anode material[J]. Journal of Huangshan University,2019,21(5):31-34(in Chinese). [4] 刘建华. 葵花盘与海带活性炭制备及在重金属吸附/锂离子电池负极材料/电催化氧化方面应用[D]. 合肥: 合肥工业大学, 2019.LIU Jianhua. Preparation of sunflower disk and kelp activated carbon and its application in heavy metal adsorption/anode material for lithium ion battery/electrocatalytic oxidation[D]. Hefei: Hefei University of Technology, 2019(in Chinese). [5] 王守疆, 王孝恩, 东玉武. 氯化钙活化法从玉米芯生产活性炭[J]. 山东化工, 1994(1):16-17.WANG Shoujiang, WANG Xiaoen, DONG Yuwu. Production of activated carbon from corn cob by calcium chloride activation method[J]. Shandong Chemical Industry,1994(1):16-17(in Chinese). [6] 朱留凯, 昌莹鸽, 种元辉, 等. 生物质活性炭的改性方法研究进展[J]. 应用化工, 2021, 50(7):1900-1904. doi: 10.3969/j.issn.1671-3206.2021.07.035ZHU Liukai, CHANG Yingge, ZHONG Yuanhui, et al. Research progress on modification methods of biomass activated carbon[J]. Applied Chemical Industry,2021,50(7):1900-1904(in Chinese). doi: 10.3969/j.issn.1671-3206.2021.07.035 [7] 邵将, 刘铭瑄, 孙宇杭. 利用花生壳化学活化法制备活性炭的研究[J]. 辽宁化工, 2018, 47(8):736-738. doi: 10.3969/j.issn.1004-0935.2018.08.004SHAO Jiang, LIU Mingxuan, SUN Yuhang. Preparation of activated carbon by chemical activation of peanut shell[J]. Liaoning Chemical Industry,2018,47(8):736-738(in Chinese). doi: 10.3969/j.issn.1004-0935.2018.08.004 [8] 牛树章, 吴思达, 吕伟. 一步硬模板法制备层次孔炭及其在锂硫电池中的应用[J]. 新型炭材料, 2017, 32(4):289-296. doi: 10.1016/S1872-5805(17)60123-9NIU Shuzhang, WU Sida, LV Wei. Preparation of layered porous carbon by one-step hard template method and its application in lithium sulfur battery[J]. Novel Carbon Materials,2017,32(4):289-296(in Chinese). doi: 10.1016/S1872-5805(17)60123-9 [9] 普孝钦. 软模板法合成介孔碳材料的研究进展[J]. 内蒙古石油化工, 2018, 44(4):26-28.PU Xiaoqin. Research progress in synthesis of mesoporous carbon materials by soft template method[J]. Inner Mongolia Petrochemical Industry,2018,44(4):26-28(in Chinese). [10] 杨丽娟. 生物质活性炭的制备及应用发展研究[J]. 黑龙江科学, 2018, 9(18):44-45. doi: 10.3969/j.issn.1674-8646.2018.18.018YANG Lijuan. Preparation and application of biomass activated carbon[J]. Science China,2018,9(18):44-45(in Chinese). doi: 10.3969/j.issn.1674-8646.2018.18.018 [11] 李纯. 玉米秸秆基生物质碳材料的制备及其电化学性能研究[D]. 长春: 吉林大学, 2018.LI Chun. Preparation and electrochemical performance of biomass carbon materials based on corn straw[D]. Changchun: Jilin University, 2018(in Chinese). [12] 何健威. 多羰基聚酰亚胺电极材料的电化学性能及热性能研究[D]. 武汉: 武汉理工大学, 2020.HE Jianwei. Electrochemical and thermal properties of polycarbonyl polyimide electrode materials[D]. Wuhan: Wuhan University of Technology, 2020(in Chinese). [13] 朱志文, 郭贤慧. 羰基化合物作为有机电极材料在钠离子电池中的研究进展[J]. 河南化工, 2019, 36(4):9-12.ZHU Zhiwen, GUO Xianhui. Research progress of carbonyl compounds as organic electrode materials in sodium ion battery[J]. Henan Chemical Industry,2019,36(4):9-12(in Chinese). [14] 陈昊月, 吕林泽, 王艳. 羧基个数对共轭羰基化合物储锂性能的影响研究[J]. 中国新技术新产品, 2021(2):4-8. doi: 10.3969/j.issn.1673-9957.2021.02.002CHEN Haoyue, LV Linze, WANG Yan. Effect of carboxyl number on lithium storage performance of conjugated carbonyl compounds[J]. China New Technology and New Products,2021(2):4-8(in Chinese). doi: 10.3969/j.issn.1673-9957.2021.02.002 [15] 徐勇. 含氧共轭双键化合物的设计合成及其作为锂/钠离子电池负极材料的性能研究[D]. 赣州: 江西理工大学, 2020.XU Yong. Design and synthesis of oxygen-containing conjugated double bond compounds and their properties as anode materials for lithium/sodium ion batteries[D]. Ganzhou: Jiangxi University of Science and Technology, 2020(in Chinese). [16] 罗路, 邓剑平, 罗凌聪, 等. 豆壳基炭材料的响应面优化设计及电化学特性[J]. 农业工程学报, 2021, 37(10): 277-283.LUO Lu, DENG Jianping, LUO Lingcong, et al. Optimization design of response surface and electrochemical properties of bean shell based carbon materials[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(10): 277-283(in Chinese). [17] ZAWA T A, ADITYA F T, SHUTO K, et al. Improving the performance of Li-ion battery carbon anodes by in-situ immobilization of SiOx nanoparticles[J]. Materials Research Bulletin,2019,112:16-21. doi: 10.1016/j.materresbull.2018.11.044 [18] 王建波. 大豆秸秆纤维素和半纤维素含量近红外检测模型研究与建立[D]. 哈尔滨: 东北农业大学, 2016.WANG Jianbo. Research and establishment of near infrared detection model for cellulose and hemicellulose content in soybean straw[D]. Harbin: Northeast Agricultural University, 2016(in Chinese). [19] 谢潇. 氮气吸附法在测定材料比表面积和孔径分布方面的应用原理[J]. 科技与创新, 2019(9):7-8, 12.XIE Xiao. Application principle of nitrogen adsorption method in determination of specific surface area and pore size distribution of materials[J]. Science and Technology and Innovation,2019(9):7-8, 12(in Chinese). [20] 明晶. 几种矿物药的X射线衍射、拉曼光谱及近红外光谱法鉴别研究[D]. 武汉: 湖北中医药大学, 2018.MING Jing. Identification of several mineral drugs by X-ray diffraction, Raman spectroscopy and near infrared spectroscopy[D]. Wuhan: Hubei University of Chinese Medicine, 2018(in Chinese). [21] 晏鹏. 生物质衍生碳基材料的制备及其电化学储能研究[D]. 镇江: 江苏科技大学, 2020.YAN Peng. Preparation and electrochemical energy storage of biomass-derived carbon-based materials[D]. Zhenjiang: Jiangsu University of Science and Technology, 2020(in Chinese). [22] 陈沿宏, 徐一刚, 马强. 碳纳米管及其在锂离子电池中的应用探析[J]. 轻工科技, 2021, 37(1):37-38.CHEN Yanhong, XU Yigang, MA Qiang. Carbon nanotubes and their application in lithium ion battery[J]. Light Industry Science and Technology,2021,37(1):37-38(in Chinese). [23] 关中相. 汉麻秸秆基生物质碳用于锂离子电池负极及其电化学性能研究[D]. 长春: 吉林大学, 2020.GUAN Zhongxiang. Study on the anode and electrochemical performance of lithium ion battery based on Hemp straw biomass carbon[D]. Changchun: Jilin University, 2020(in Chinese). [24] ZHANG X, HUANG Q Y, ZHANG M, et al. Pine wood-derived hollow carbon fibers@NiO@rGO hybrids as sustainable aodes for lithium-ion batteries[J]. Journal of Alloys and Compounds,2020,822:153718. doi: 10.1016/j.jallcom.2020.153718 [25] 孟伟巍. 基于金属钛的钛酸锂负极材料制备及电化学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.MENG Weiwei. Preparation and electrochemical properties of lithium titanate anode materials based on titanium[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [26] LI C, ZHANG Y Z, LIN C H, et al. Hierarchically porous nitrogen-rich carbon derived from wheat straw as an ultra-high-rate anode for lithium ion batteries[J]. Journal of Materials Chemistry A,2014,2(25):9684-9690. doi: 10.1039/C4TA00501E [27] WANG J C, KASKEL S. KOH activation of carbon-based materials for energy storage[J]. Journal of Materials Che-mistry,2012,22(45):23710-23725. doi: 10.1039/C2JM34066F [28] HWANG Y J, JEONG S K, NAHM K S, et al. Pyrolytic carbon derived from coffee shells as anode materials for lithium batteries[J]. Journal of Physics & Chemistry of Solids,2007,68(2):182-188. doi: 10.1016/j.jpcs.2006.10.007 -

下载:

下载: