Effect of TaC on phase, microstructure and mechanical properties of Ti(C0.7N0.3)-based cermets

-

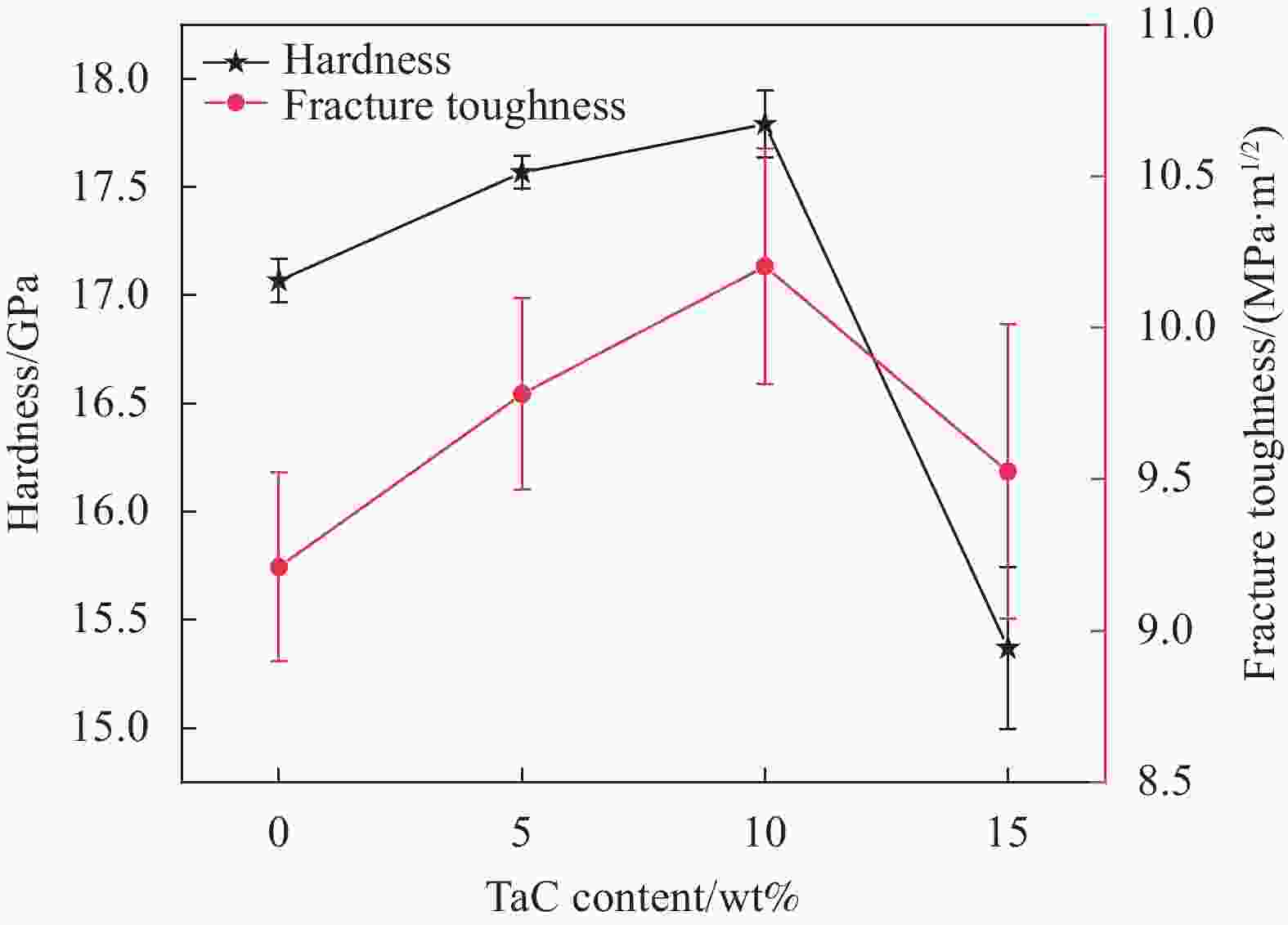

摘要: 为了制备高硬度高韧性的Ti(C0.7N0.3)基金属陶瓷,采用1600℃真空无压烧结制备了含TaC的Ti(C0.7N0.3)-WC-Mo2C-VC-AlN-Ni/Co系金属陶瓷,研究了不同TaC 含量(0wt%、5wt%、10wt%、15wt%)对金属陶瓷的物相、显微结构、力学性能的影响。结果表明,随着TaC含量增加,Ti(C0.7N0.3) (200)主峰逐渐向低角度偏移,环形相的厚度逐渐增大,金属陶瓷的维氏硬度和断裂韧性均先增大后减小。当TaC含量为10wt%时,核芯相细化,尺寸离散度最小,环形相发育更完整且均匀,金属陶瓷获得最高的维氏硬度和断裂韧性,分别为(17.79±0.15) GPa和(10.20±0.39) MPa·m1/2。

-

关键词:

- Ti(C0.7N0.3)基金属陶瓷 /

- TaC /

- 物相 /

- 显微结构 /

- 力学性能

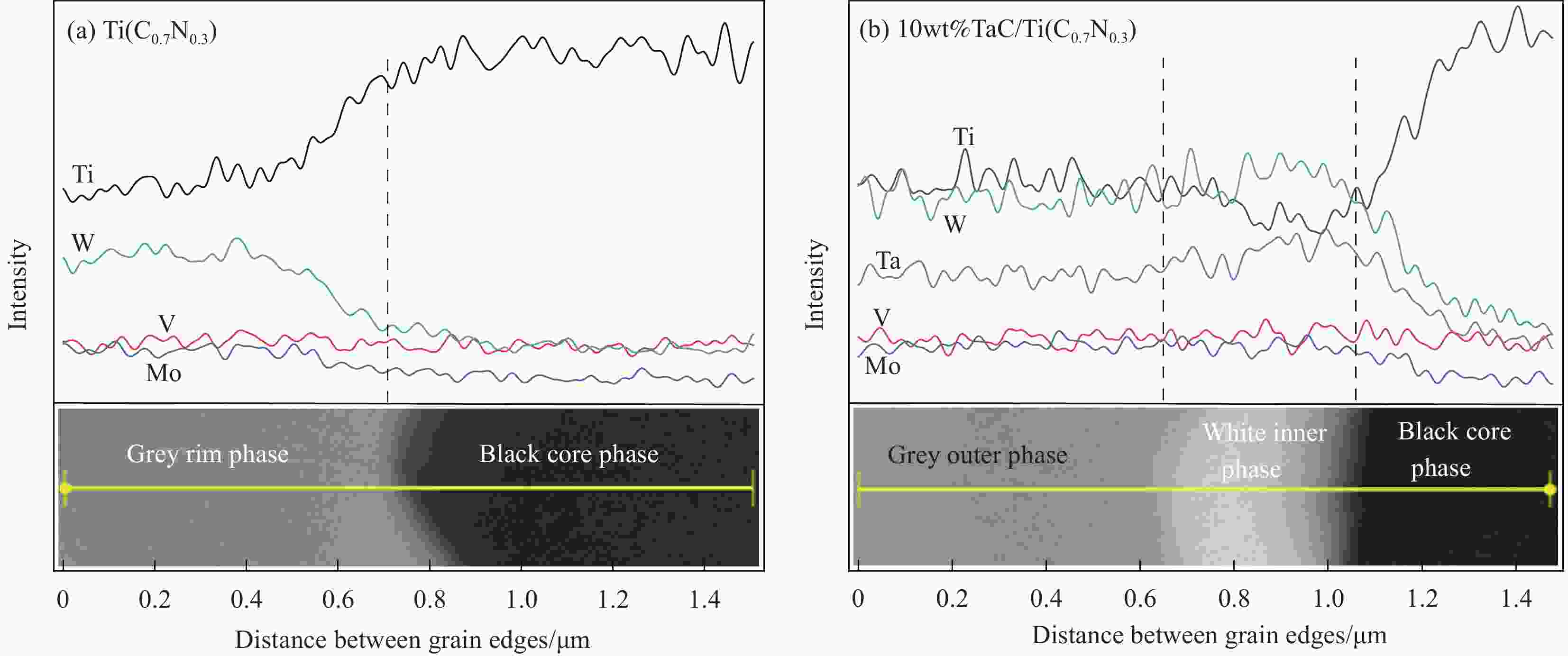

Abstract: In order to prepare Ti(C0.7N0.3)-based cermets with high hardness and high toughness, Ti(C0.7N0.3)-WC-Mo2C-VC-AlN-Ni/Co cermets containing TaC were prepared by vacuum pressureless sintering at 1600℃. The effects of different TaC content (0wt%, 5wt%, 10wt%, 15wt%) on the phase, microstructure and mechanical properties of cermets were investigated. The results show that with the increase of TaC content, the main peak of Ti(C0.7N0.3) (200) gradually shifts to a lower angle, the thickness of rim phase increase gradually and the Vickers hardness and fracture toughness of cermet firstly increased and then decreased. When 10wt% TaC is added, the core phase size of cermets is refined with the smallest, and the rim phase is more complete and uniform, leading to the maximum Vickers hardness ((17.79±0.15) GPa) and fracture toughness ((10.20±0.39) MPa·m1/2) of cermet.-

Key words:

- Ti(C0.7N0.3)-based cermets /

- TaC /

- phase /

- microstructure /

- mechanical properties

-

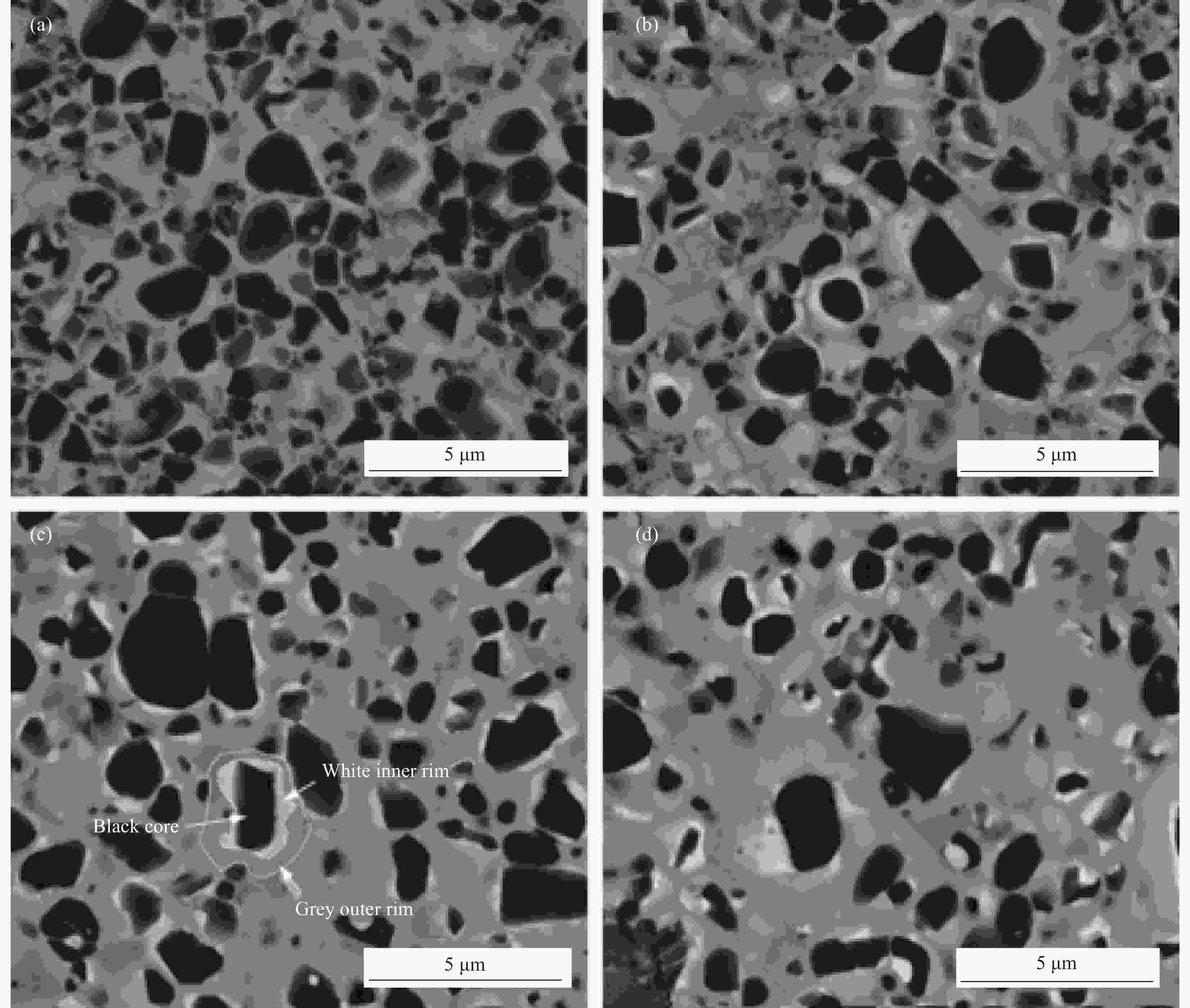

图 2 不同TaC含量的Ti(C0.7N0.3)基金属陶瓷的SEM-背散射电子成像(BSE)图像: (a) Ti(C0.7N0.3);(b) 5wt%TaC/Ti(C0.7N0.3);(c) 10wt%TaC/Ti(C0.7N0.3);(d) 15wt%TaC/Ti(C0.7N0.3)

Figure 2. SEM-backscattered electron (BSE) images of Ti(C0.7N0.3)-based cermets with different amounts of TaC: (a) Ti(C0.7N0.3); (b) 5wt%TaC/Ti(C0.7N0.3); (c) 10wt%TaC/Ti(C0.7N0.3); (d) 15wt%TaC/Ti(C0.7N0.3)

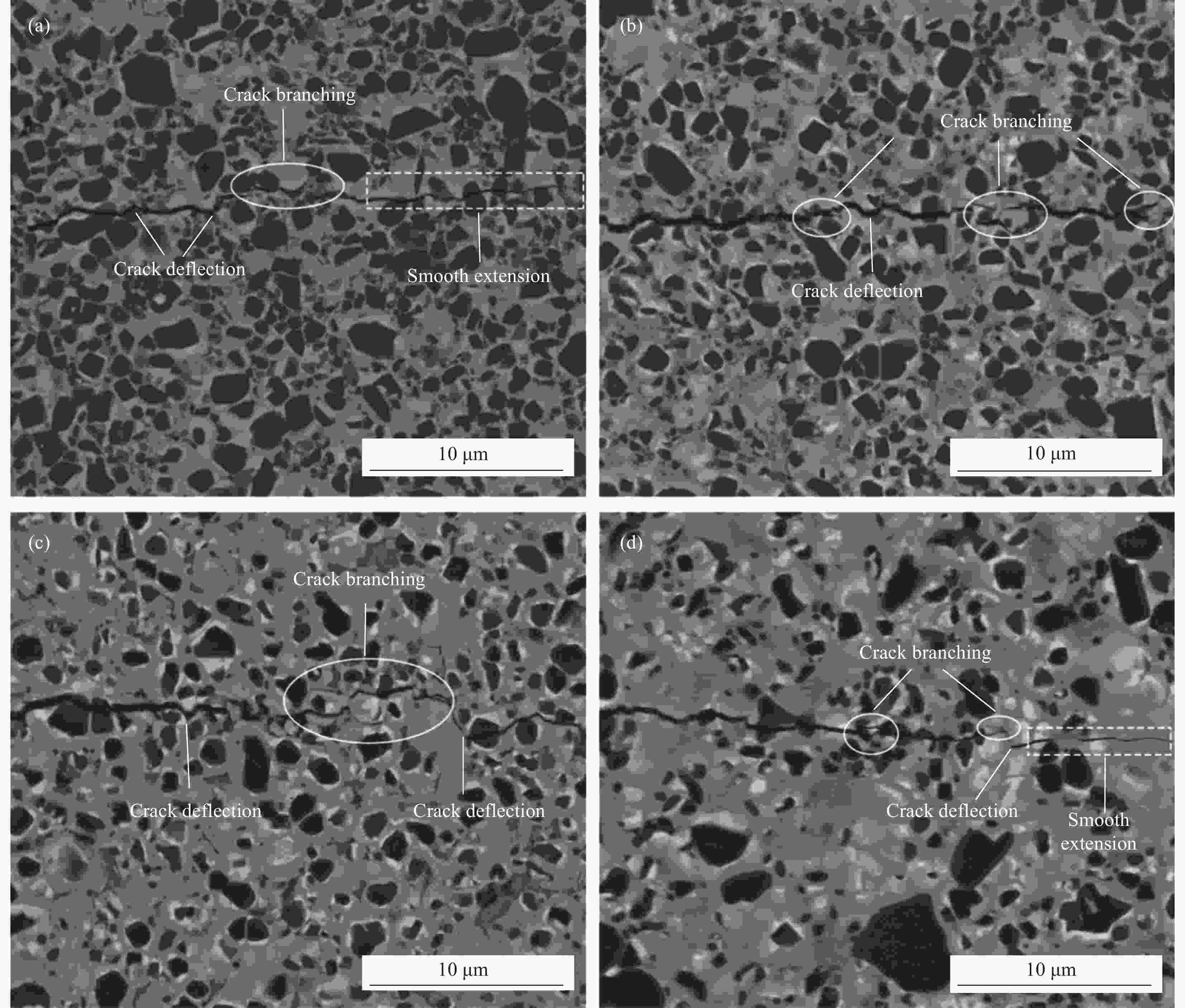

图 6 不同TaC含量的Ti(C0.7N0.3)基金属陶瓷的裂纹扩展:(a) Ti(C0.7N0.3);(b) 5wt%TaC/Ti(C0.7N0.3);(c) 10wt%TaC/Ti(C0.7N0.3);(d) 15wt%TaC/Ti(C0.7N0.3)

Figure 6. Crack propagation of Ti(C0.7N0.3)-based cermets with different amounts of TaC: (a) Ti(C0.7N0.3); (b) 5wt%TaC/Ti(C0.7N0.3); (c) 10wt%TaC/Ti(C0.7N0.3); (d) 15wt%TaC/Ti(C0.7N0.3)

表 1 Ti(C0.7N0.3)基金属陶瓷试样的原料配比

Table 1. Raw material ratio of Ti(C0.7N0.3)-based cermets sample

Sample Chemical composition/wt% Ti(C0.7N0.3) WC Co Ni VC Mo2C AlN TaC Ti(C0.7N0.3) 59 15 6.5 6.5 5 6.5 1.5 0 5wt%TaC/Ti(C0.7N0.3) 54 15 6.5 6.5 5 6.5 1.5 5 10wt%TaC/Ti(C0.7N0.3) 49 15 6.5 6.5 5 6.5 1.5 10 15wt%TaC/Ti(C0.7N0.3) 44 15 6.5 6.5 5 6.5 1.5 15 表 2 不同TaC含量的Ti(C0.7N0.3)基金属陶瓷的密度和相对密度

Table 2. Density and relative density of Ti(C0.7N0.3)-based cermets with different TaC contents

Sample Ti(C0.7N0.3) 5wt%TaC/Ti(C0.7N0.3) 10wt%TaC/Ti(C0.7N0.3) 15wt%TaC/Ti(C0.7N0.3) Density/(g·cm−3) 6.44 6.54 6.90 6.79 Relative density/% 99.98 99.86 99.52 95.77 -

[1] 刘宁. Ti(C,N)基金属陶瓷材料[M]. 合肥: 合肥工业大学出版社, 2009: 67-93.LIU Ning. Ti(C,N)-based cermets[M]. Hefei: Hefei University of Technology Press, 2009: 67-93(in Chinese). [2] WAN W C, XIONG J, LIANG M X. Effects of secondary carbides on the microstructure, mechanical properties and erosive wear of Ti(C,N)-based cermets[J]. Ceramics International,2017,43(1):944-952. doi: 10.1016/j.ceramint.2016.10.024 [3] 陈文琳, 刘宁, 晁盛. 添加碳化钛对超细Ti(C,N)基金属陶瓷显微结构和力学性能的影响[J]. 硅酸盐学报, 2007, 35(6):725-730. doi: 10.3321/j.issn:0454-5648.2007.06.012CHEN Wenlin, LIU Ning, CHAO Sheng. Effect of titanium carbide addition on microstructure and mechanical and mechanical properties of superfine Ti(C,N)-based ceramics[J]. Journal of the Chinese Ceramic Society,2007,35(6):725-730(in Chinese). doi: 10.3321/j.issn:0454-5648.2007.06.012 [4] ZHOU W, ZHENG Y, ZHAO Y J, et al. Densification behavior, microstructure evolution and mechanical properties of Ti(C,N)-based cermets fabricated by in situ carbothermal reduction of WO3 and subsequent liquid sintering[J]. International Journal of Refractory Metals & Hard Materials,2018,74:70-77. doi: 10.1016/j.ijrmhm.2018.03.004 [5] 宋金鹏, 高姣姣, 吕明. 颗粒弥散和核-壳共存的TiCN基金属陶瓷的制备[J]. 复合材料学报, 2020, 37(10):2552-2560. doi: 10.13801/j.cnki.fhclxb.20200617.003SONG Jinpeng, GAO Jiaojiao, LV Ming. Fabrication of TiCN-based cermet with a coexisted microstructure of particle dispersion and core-rim structure[J]. Acta Materiae Compositae Sinica,2020,37(10):2552-2560(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200617.003 [6] 陈文琳. 超细晶粒Ti(C,N)基金属陶瓷刀具与切削性能研究[D]. 合肥: 合肥工业大学, 2007.CHEN Wenlin. Research on tool and cutting performance of ultra-fine grain Ti(C,N)-based cermets[D]. Hefei: Hefei University of Technology, 2007(in Chinese). [7] 钟杰, 郑勇, 张一欣. 功能梯度Ti(C,N)基金属陶瓷制备技术[J]. 复合材料学报, 2009, 26(3):111-115. doi: 10.3321/j.issn:1000-3851.2009.03.020ZHONG Jie, ZHENG Yong, ZHANG Yixin. Fabrication technology of functionally graded Ti(C,N)-based cermets[J]. Acta Materiae Compositae Sinica,2009,26(3):111-115(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.03.020 [8] WU P, ZHENG Y, ZHAO Y L, et al. Effect of TaC addition on the microstructures and mechanical properties of Ti(C,N)-based cermets[J]. Materials & Design,2010,31(7):3537-3541. doi: 10.1016/j.matdes.2010.01.047 [9] XIONG J, GUO Z X, SHEN B L. The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC0.7N0.3 cermet[J]. Materials & Design,2007,28(5):1689-1694. doi: 10.1016/j.matdes.2006.03.005 [10] VERMA V, KUMAR B V M. Processing of TiCN–WC–Ni/Co cermets via conventional and spark plasma sintering technique[J]. Transactions of the Indian Institute of Metals,2017,70(3):843-853. doi: 10.1007/s12666-017-1069-y [11] KIANI S, YANG J M, KODAMBAKA S. Nanomechanics of refractory transition-metal carbides: A path to discovering plasticity in hard ceramics[J]. Journal of the American Ceramic Society,2015,98(8):2313-2323. doi: 10.1111/jace.13686 [12] ZHAO X R, ZHANG M X, ZUO D W, et al. Ti(C,N)-based cermet with different TaC/(TaC+WC) weight ration by in-situ reactive hot pressing: Microstructure and mechanical properties[J]. Materials Today Communications,2020,25:101661. doi: 10.1016/j.mtcomm.2020.101661 [13] KUMAR B V M, BASU B J. Tribochemistry in sliding wear of TiCN–Ni-based cermets[J]. Journal of Materials Research,2008,23(5):1214-1227. doi: 10.1557/JMR.2008.0165 [14] 詹斌, 刘宁. VC对纳米TiN改性Ti(C,N)基金属陶瓷组织和性能的影响[J]. 硬质合金, 2010, 27(4):214-220. doi: 10.3969/j.issn.1003-7292.2010.04.005ZHAN Bin, LIU Ning. Effect of VC on microstructure and properties of Ti(C,N)-based cermet modified by nano TiN[J]. Cemented Carbide,2010,27(4):214-220(in Chinese). doi: 10.3969/j.issn.1003-7292.2010.04.005 [15] XIONG H W, XIE D, CHEN J J. Ti(C,N)-based cermets with strengthened interfaces: Roles of secondary cubic carbides[J]. Journal of the American Ceramic Society,2020,103(3):1582-1592. doi: 10.1111/jace.16893 [16] XU L W, LIN N, ZHAO L B, et al. Improvement in wear and corrosion resistance of Ti(C,N)-based cermets via aluminum nitride additions[J]. Vacuum,2019,168:108849. doi: 10.1016/j.vacuum.2019.108849 [17] LIU N, XU Y D, LI Z H, et al. Effects of addition of TiN nanoparticles on microstructure and mechanical properties of TiC based cermets[J]. Materials Science and Technology,2002,18(5):586-590. doi: 10.1179/026708302225001769 [18] LIU A, LIU N. Effect of WC-Co granules on mechanical properties and microstructure of Ti(C,N)-based cermets[J]. Ceramics International,2016,42(14):15274-15284. doi: 10.1016/j.ceramint.2016.06.143 [19] LEE H C, GURLAND J. Hardness and deformation of cemented tungsten carbide[J]. Materials Science and Engineering,1978,33(1):125-133. doi: 10.1016/0025-5416(78)90163-5 [20] 刘文俊, 熊惟皓, 郑勇. Ti(C,N)基金属陶瓷断口形貌及增韧机理[J]. 中国有色金属学报, 2006, 16(5):800-804. doi: 10.3321/j.issn:1004-0609.2006.05.009LIU Wenjun, XIONG Weihao, ZHENG Yong. Fracture morphology and toughening mechanism of Ti(C,N)-based cermets[J]. The Chinese Journal of Nonferrous Metals,2006,16(5):800-804(in Chinese). doi: 10.3321/j.issn:1004-0609.2006.05.009 [21] ZHOU H J, HUANG C Z, ZOU B, et al. Effects of metal phases and carbides on the microstructure and mechanical properties of Ti(C,N)-based cermets cutting tool mate-rials[J]. Materials Science and Engineering A,2014,618:462-470. doi: 10.1016/j.msea.2014.09.052 -

下载:

下载: