Dynamic response and failure behaviors of woven fabrics under blast load

-

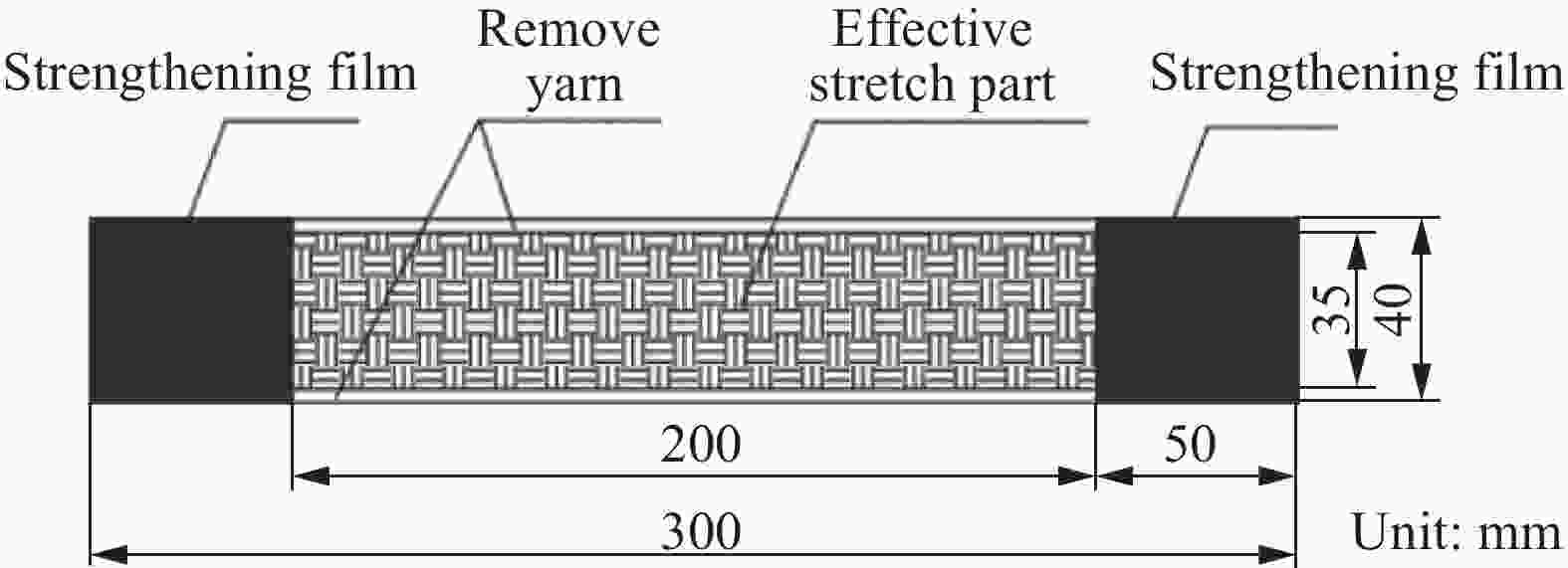

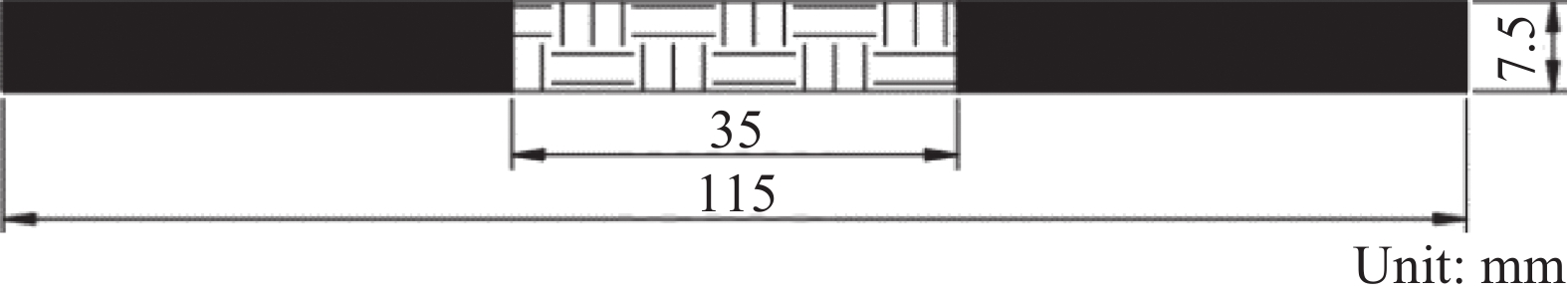

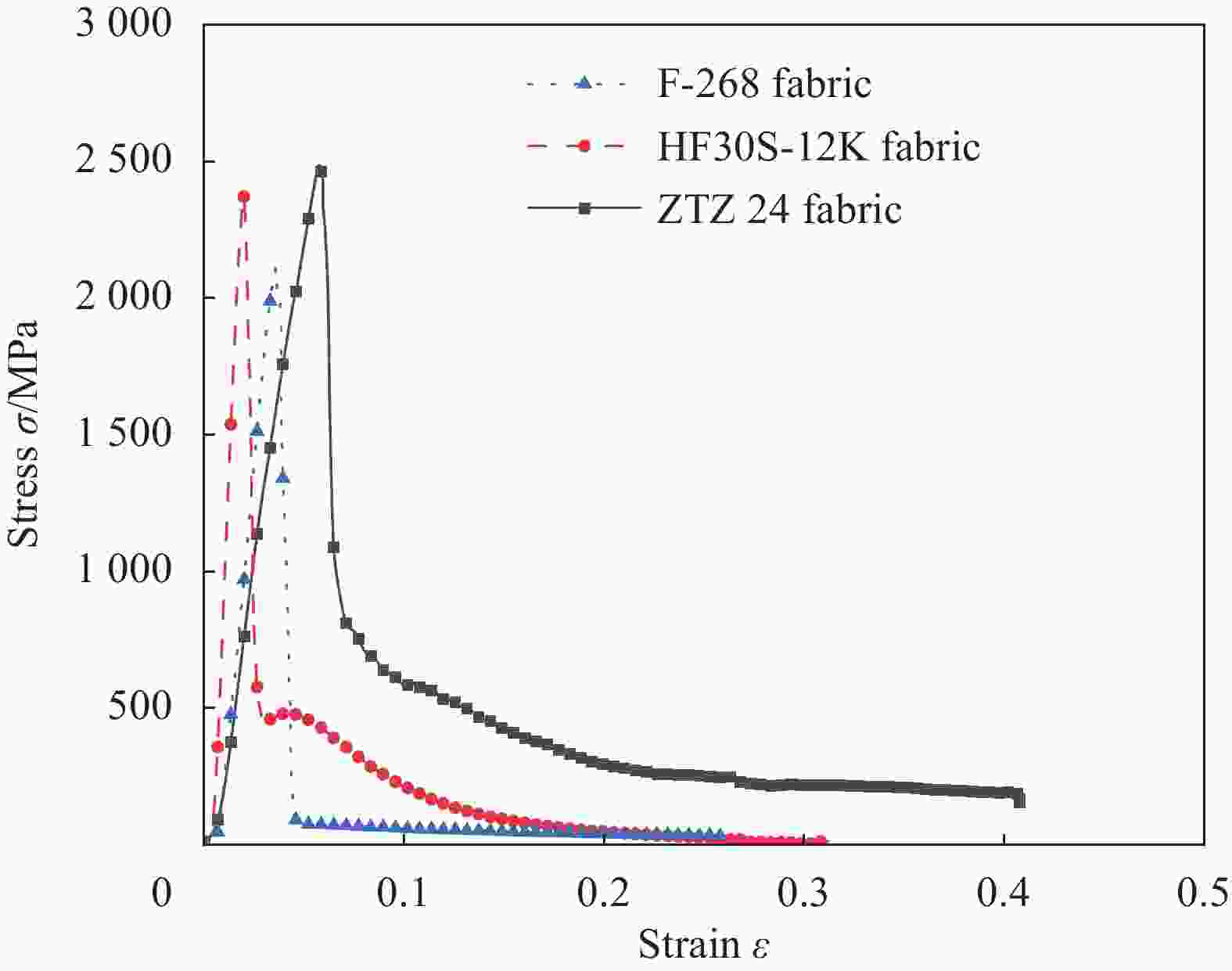

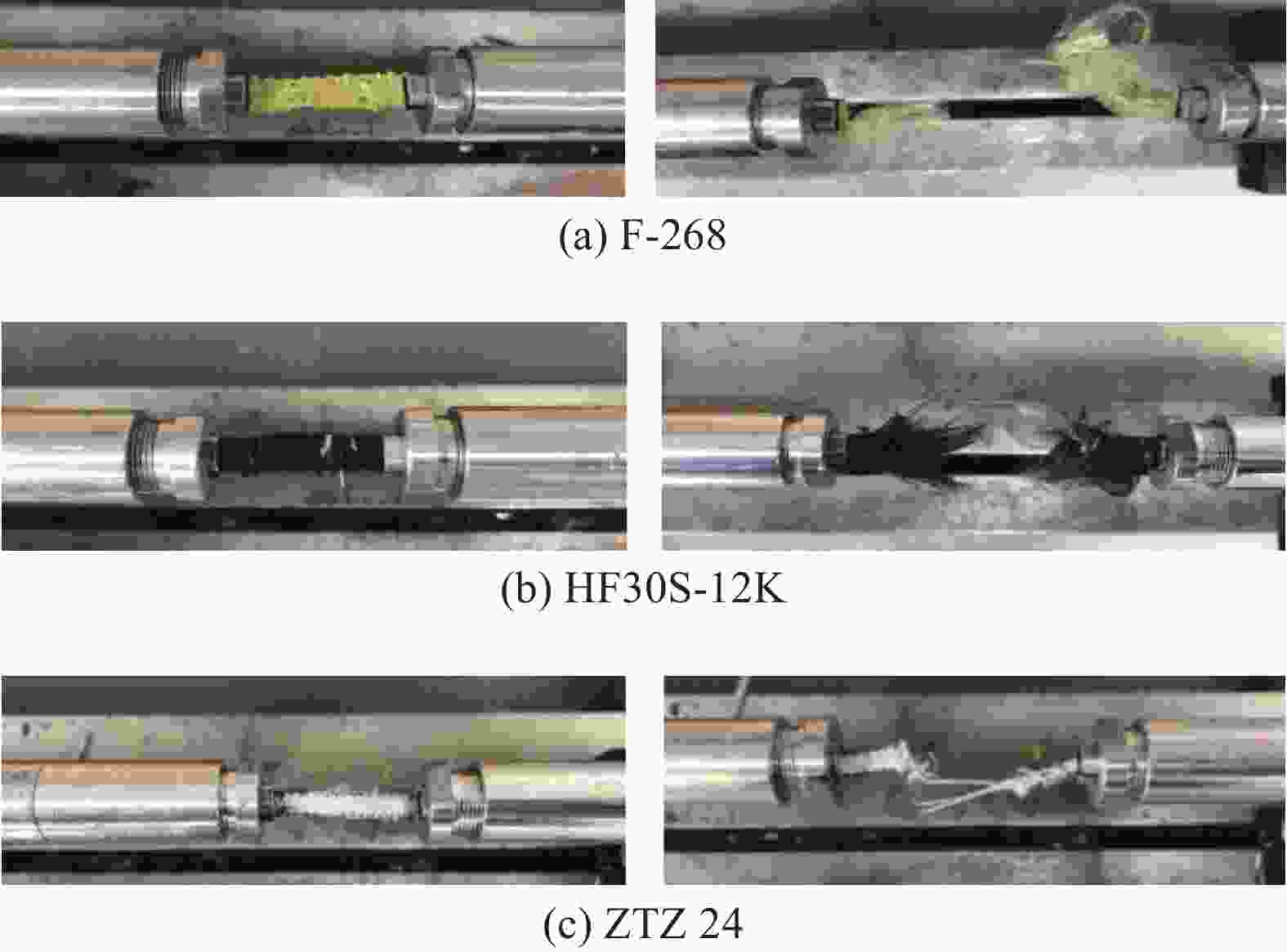

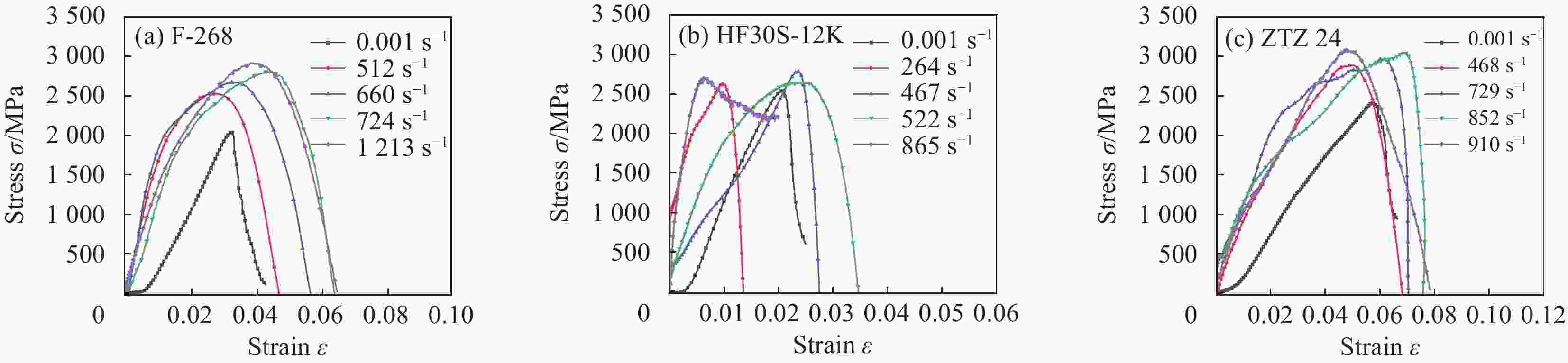

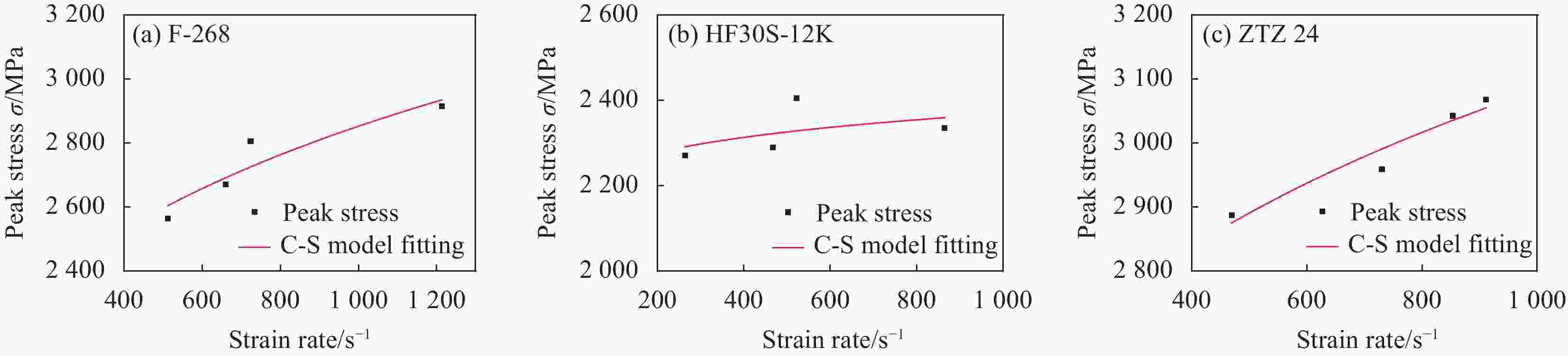

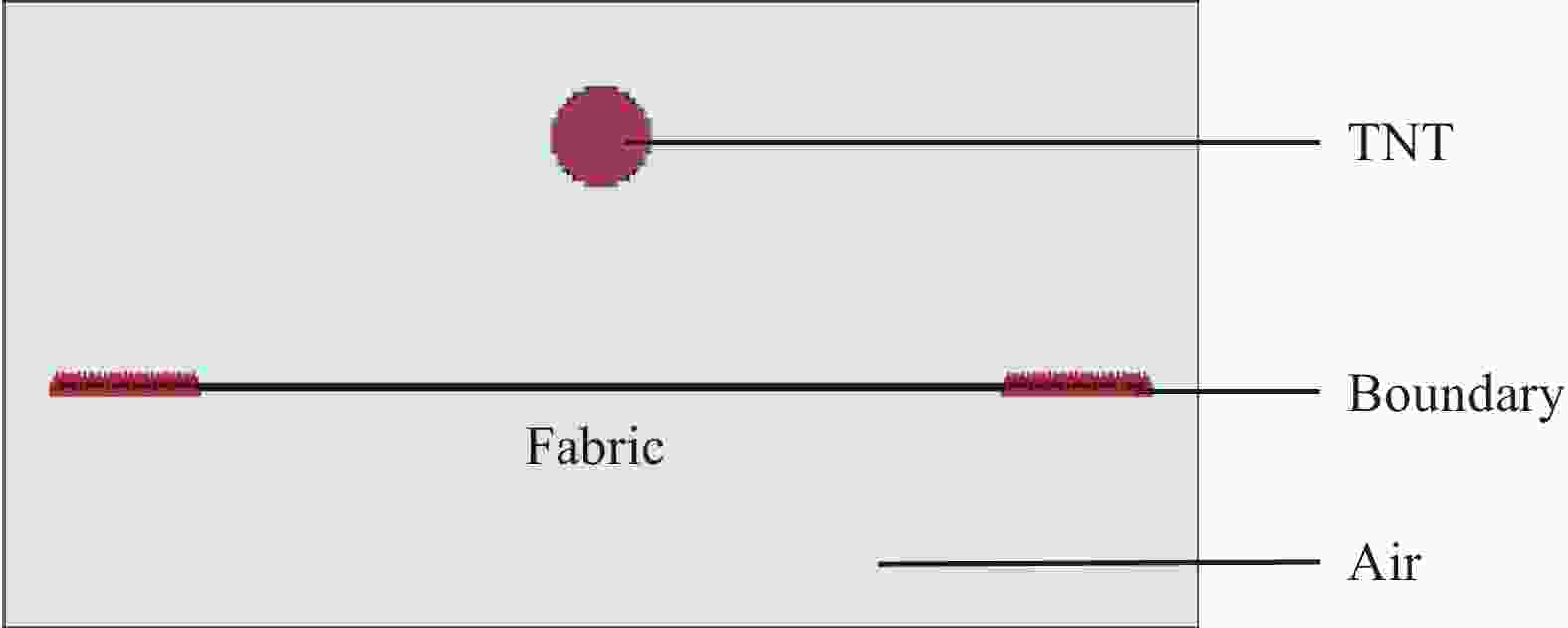

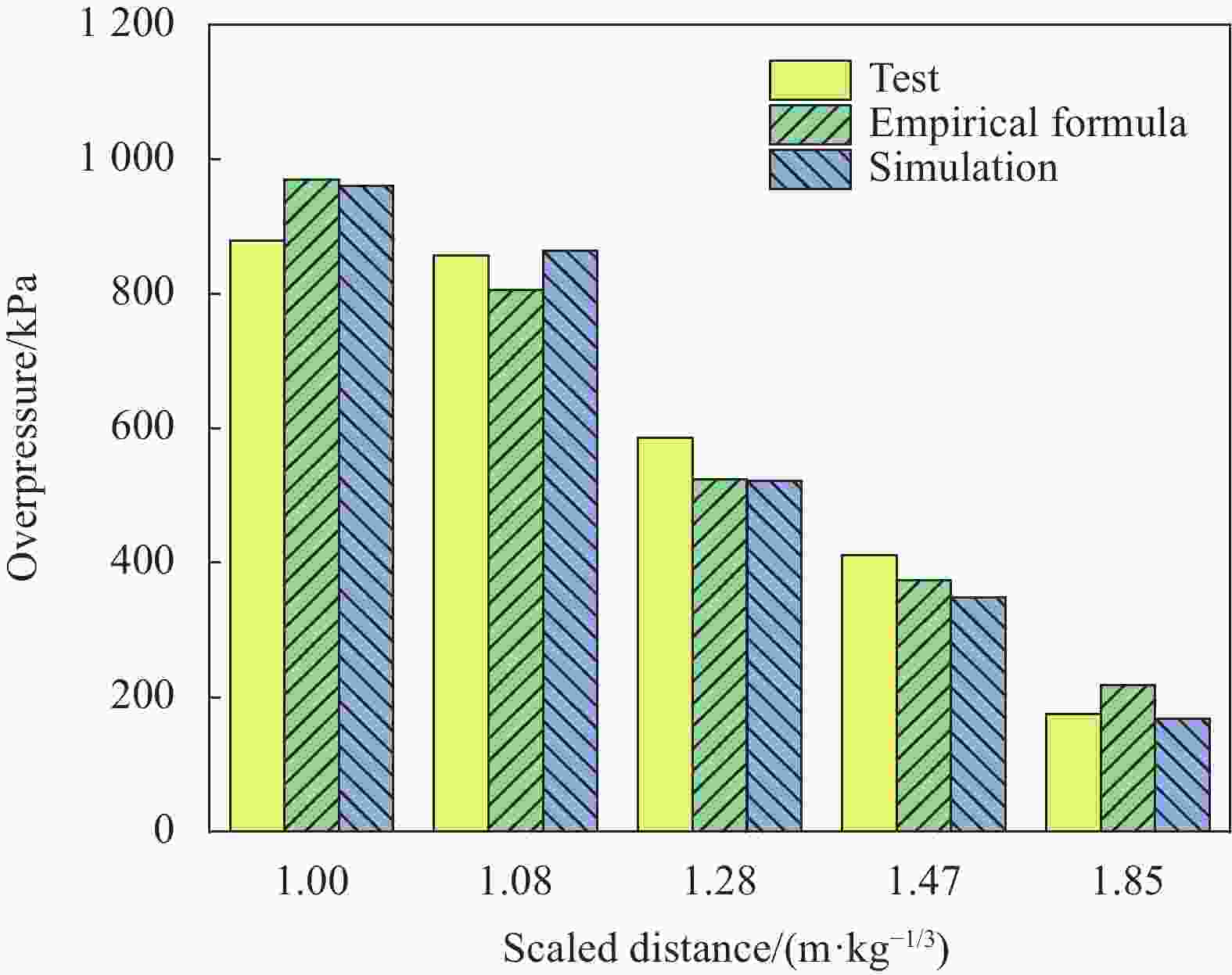

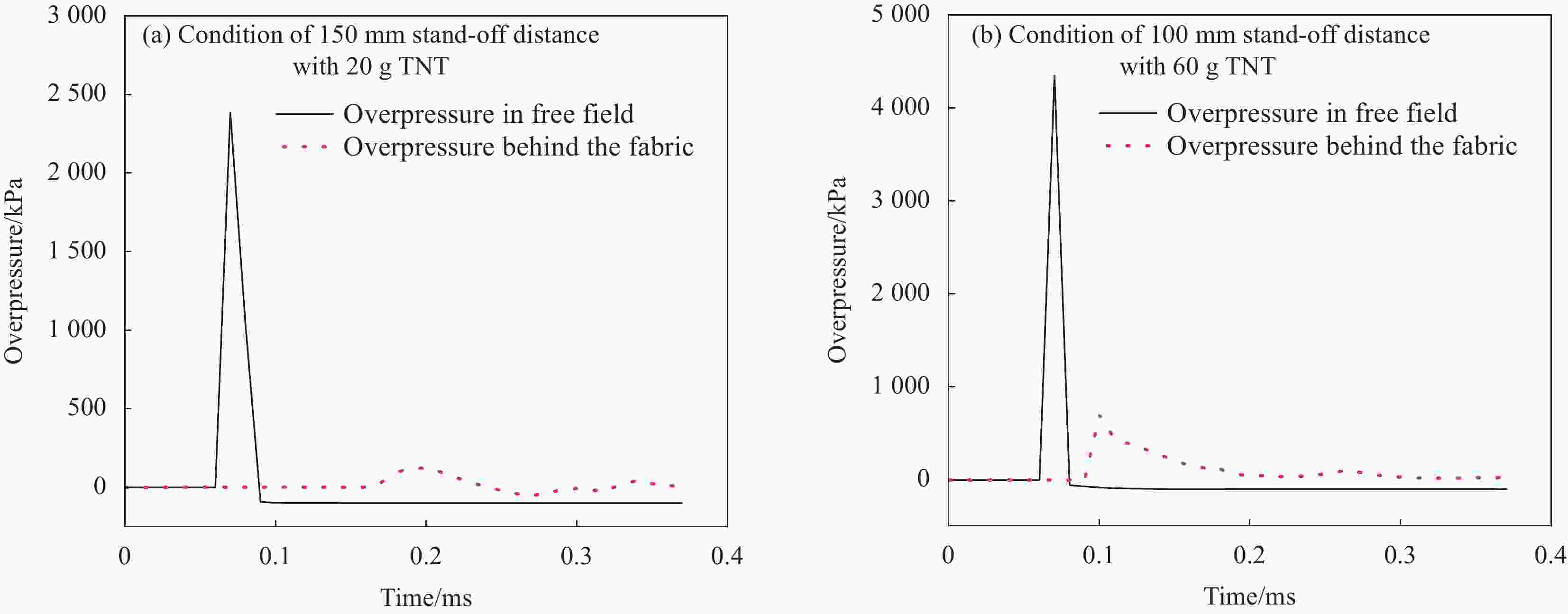

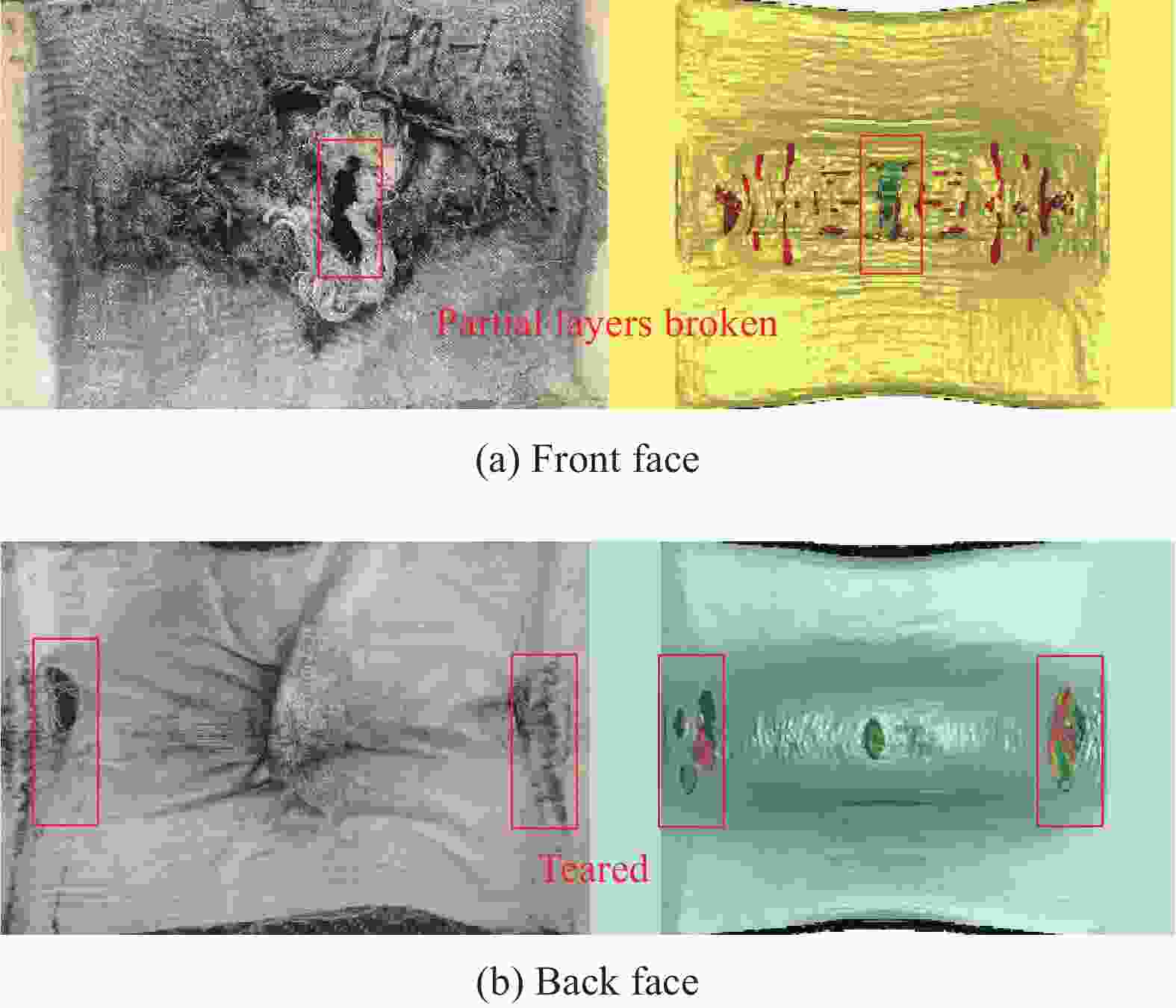

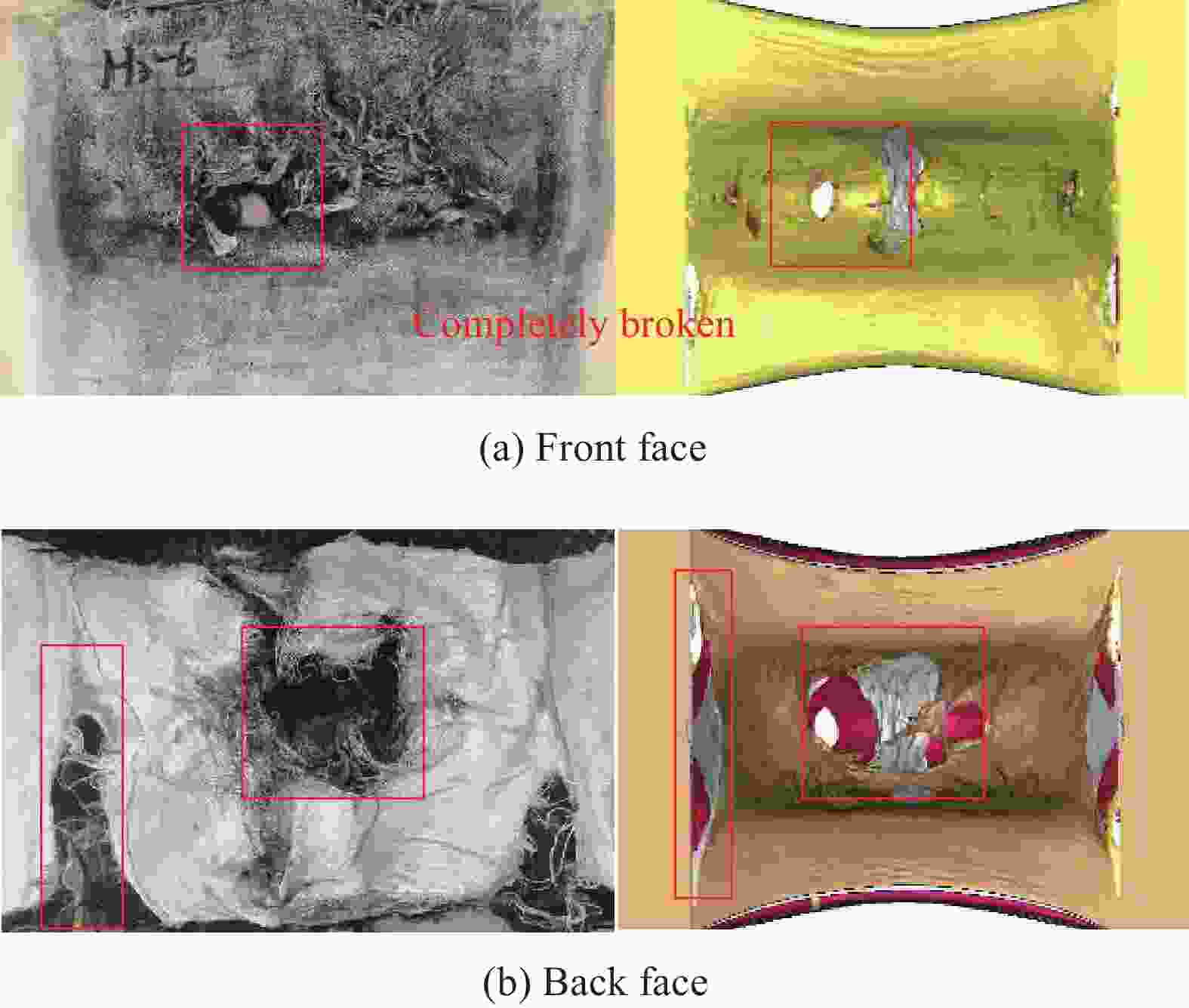

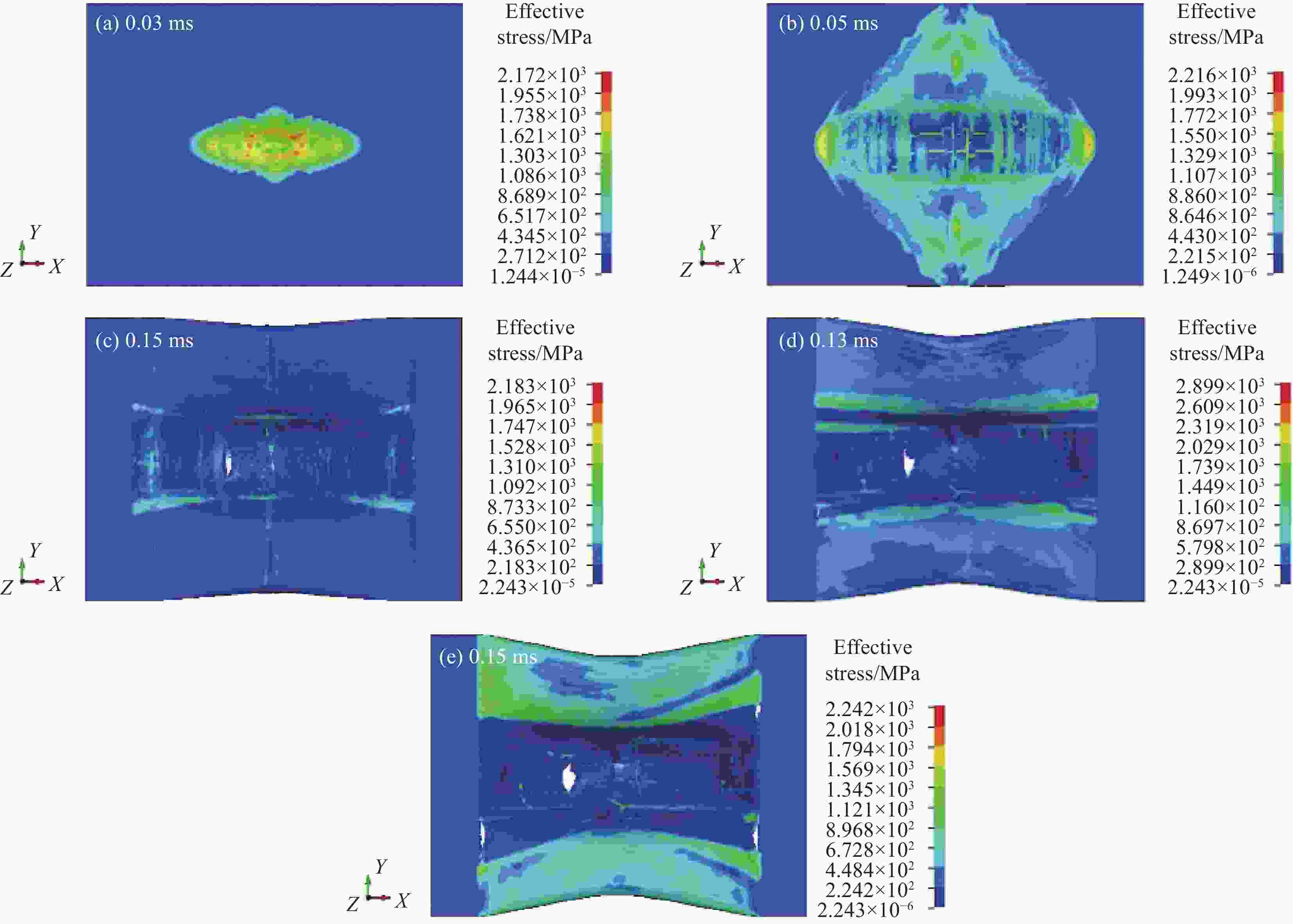

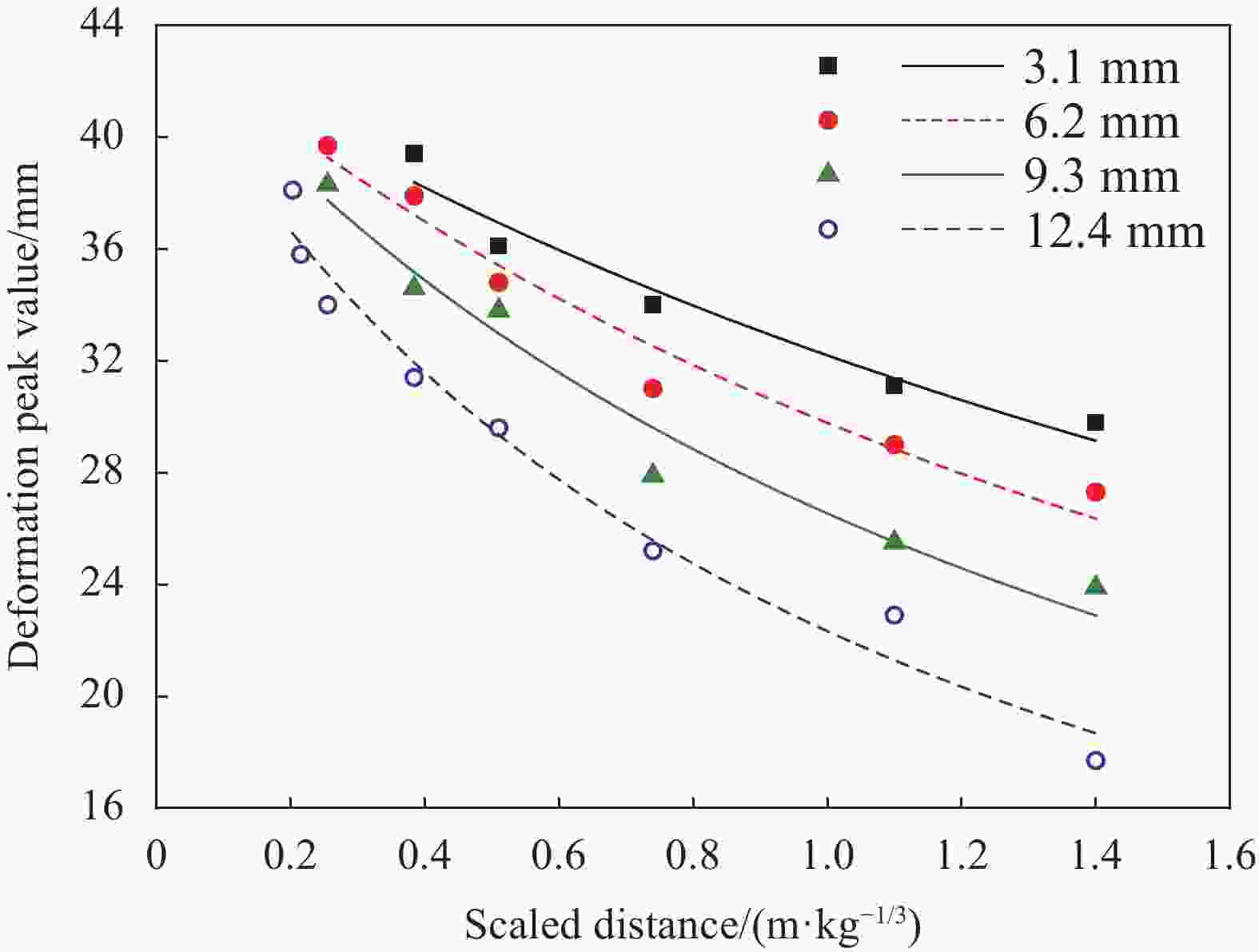

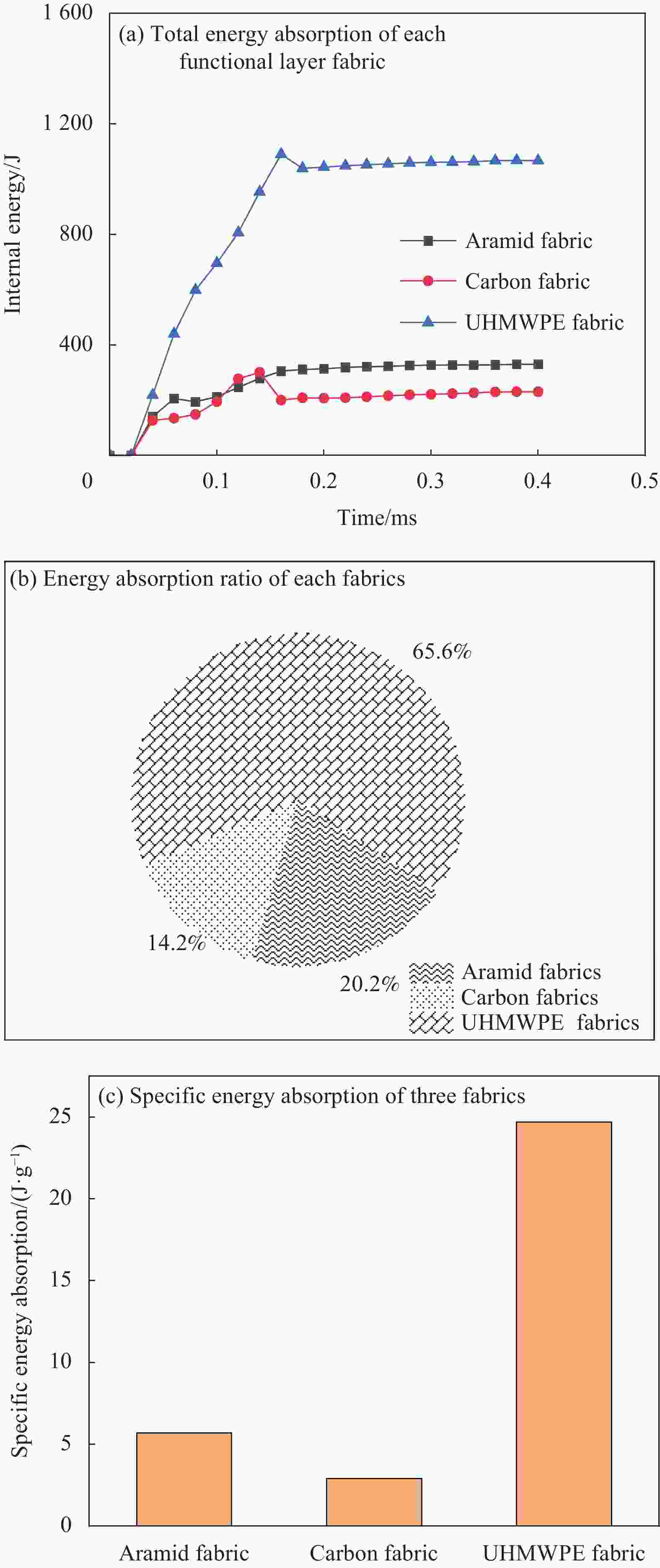

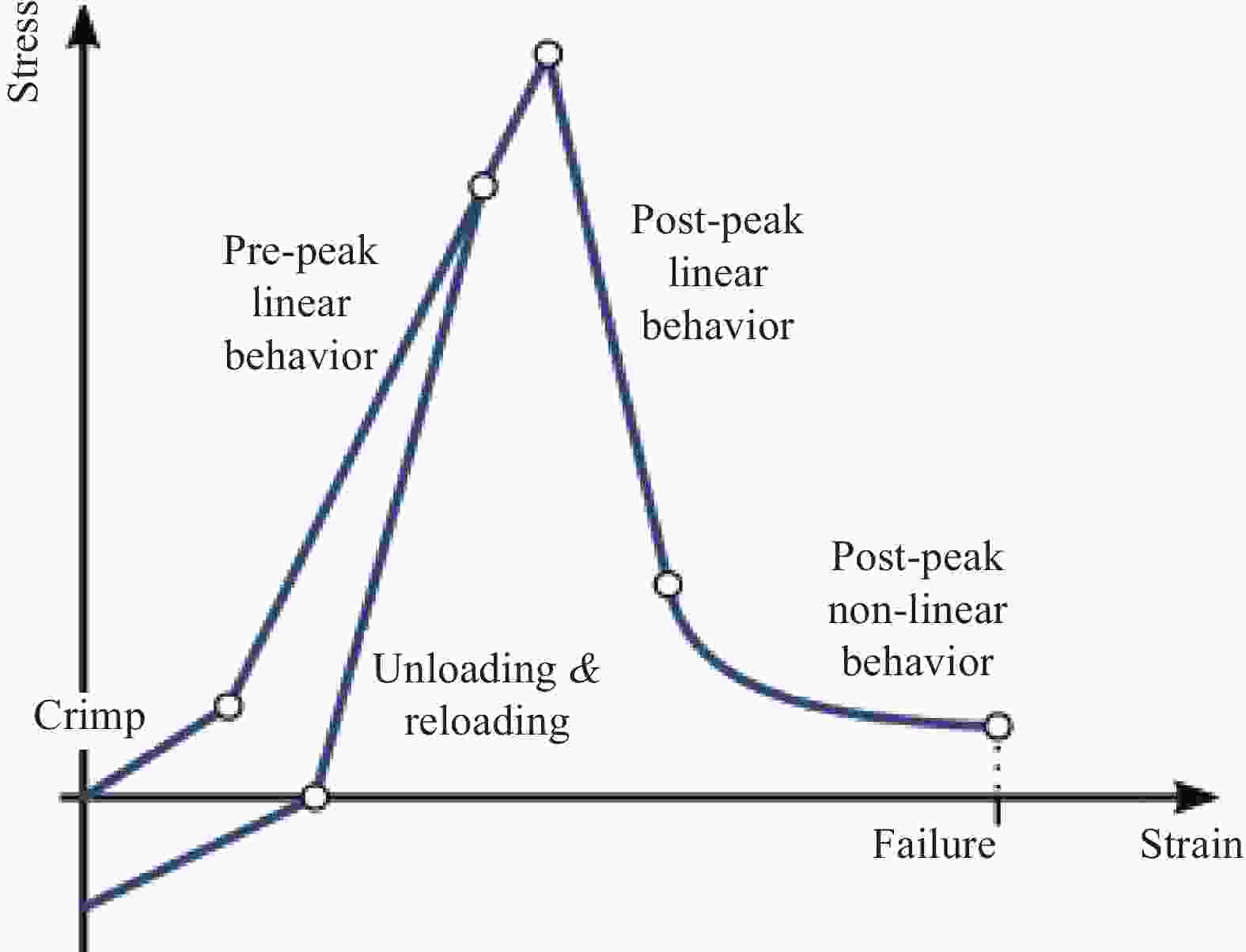

摘要: 为探究爆炸载荷下纤维织物的动态响应与失效行为,对3种平纹纤维织物进行了准静态及高应变率拉伸试验,获取了织物的力学性能参数,建立了织物材料的本构模型。采用任意欧拉-拉格朗日算法(ALE)算法,建立了织物爆炸冲击数值分析模型,研究了爆炸载荷下纤维织物的动态响应过程和失效模式,并与试验结果进行了对比,验证了模型的有效性,得到了织物的变形峰值与比例距离之间的关系以及混杂层叠织物中各织物的吸能量。结果表明,3种织物表现出不同程度的应变率敏感性,芳纶和超高分子量聚乙烯(Ultra-high molecular weight polyethylene,UHMWPE)纤维织物的失效应变和极限强度都随应变率的增加而增大,应变率效应明显,碳纤维织物的极限强度略有增加,应变率效应不明显。数值分析得到了与试验相同的织物失效模式:中心破孔和简支边界撕裂。在所研究工况范围内,织物的变形峰值与比例距离成反比例关系,且变形峰值超过39 mm时背爆面织物会发生失效;UHMWPE纤维织物层的比吸能达到24.7 J/g,分别是芳纶织物和碳纤织物的4.3倍和8.5倍。Abstract: In order to explore the dynamic response and failure behaviors of fiber fabrics under blast load, quasi-static and high strain rate tensile tests were carried out on three plain fabrics, the mechanical properties of the fabrics were obtained, and the constitutive model of the fabric was established. Using the Arbitrary Lagrangian-Eulerian (ALE) algorithm, a numerical analysis model of the fabric under blast was established, and the dynamic response process and failure modes of the fabric under blast load were studied. The results were compared with the test to verify the validity of the model. The relationship between the deformation peak value and the scaled distance and the energy absorption of each fabric in the hybrid stacked fabrics were obtained that can evaluate the anti-blast ability of the fabrics. The results show that the three kinds of fabrics exhibit different degrees of strain rate sensitivity. The failure strain and ultimate strength of aramid and ultra-high molecular weight polyethylene (UHMWPE) fiber fabrics under high strain rate load increase with the increase of strain rate, showing obvious strain rate effect. The ultimate strength of carbon fiber fabric increases slightly, and the strain rate effect is not obvious. The numerical analysis has obtained the same failure modes of the fiber fabric as the test: Central hole and simply supported boundary tearing. In the studied working conditions, the deformation peak value of the fabric is inversely proportional to the proportional distance, and the back burst surface fabric fails when the deformation peak value exceeds 39 mm. The specific energy absorption of the UHMWPE fiber fabric reaches 24.7 J/g, which is 4.3 times and 8.5 times that of aramid fabric and carbon fiber fabric.

-

Key words:

- fiber fabric /

- blast impact /

- numerical analysis /

- dynamic response /

- failure behaviors

-

表 1 各织物的主要物理参数

Table 1. Main physical parameters of each fabric

Material Aramid fiber fabric Carbon fiber fabric UHMWPE Grade F-268 HF30S-12K ZTZ 24 Yarn density/(g·(1000 m)−1) 166 800 126±10 Yarn body density/(g·cm−3) 1.44 1.8 0.97 Yarn breaking elongation/% ≥3.2 1.7-2.2 3-3.5 Yarn tensile modulus/GPa ≥125 245-270 105-110 Fabric thickness/mm 0.3 0.55 0.55 Fabric density/(yarns·(10 cm)−1) 65×65 30×30 87×87 Fabric surface density/(g·m−2) 210-220 480 235-245 Note: UHMWPE—Ultra-high molecular weight polyethylene. 表 2 织物经向和纬向参数

Table 2. Warp and weft parameters of each fabric

Test piece Peak load

/NUltimate strength

/MPaElastic modulus

/MPaElongation

/mmElongation at break

/%F-268 warp 4287.4 2076.3 68230.4 6.93 3.47 F-268 weft 4248.4 2061.6 68643.6 6.81 3.41 HF30S-12K warp 9931.8 2562.9 142959.9 4.92 2.46 HF30S-12K weft 8999.8 2318.8 139591.3 4.79 2.40 ZTZ 24 warp 9630.4 2500.8 47179.1 13.51 6.76 ZTZ 24 weft 9455.6 2473.4 46704.1 13.35 6.68 表 3 3种织物的材料模型参数输入值

Table 3. Input values of material model parameters of three kinds of fabric

Parameter F-268 HF30S-12K ZTZ 24 Density Ro/(g·mm−3) 7.2×10−4 8×10−4 4×10−4 Warp fiber elastic modulus Ea/MPa 68230.4 142959.9 47179.1 Weft fiber elastic modulus Eb/MPa 68643.6 139591.3 46704.1 Elastic modulus coefficient of warp crimp zone Ea,crf 0.041 0.150 0.275 Elastic modulus coefficient of weft crimp zone Eb,crf 0.041 0.150 0.275 Critical strain in warp crimp zone Ea,crp 0.005 0.003 0.024 Critical strain in the zonal crimp zone Eb,crp 0.005 0.003 0.024 Modulus of elasticity coefficient in meridional post-peak region Ea,sf −3.06 −1.6 −1.3 Elastic modulus coefficient in the weft post-peak zone Eb,sf −3.06 −1.6 −1.3 Peak warp strain εa,max 0.034 0.021 0.074 Peak weft strain εb,max 0.034 0.021 0.074 Initial stress in nonlinear region SIGPOST/MPa 92.7 553 656.9 Strain rate parameter C 188 103 190 Strain rate parameter P 5.8 33.2 8.5 Warp failure strain εa,fail 0.20 0.25 0.40 Weft failure strain εb,fail 0.20 0.25 0.40 表 4 TNT参数

Table 4. Parameters of TNT

Parameter Value Density/(103 kg·m−3) 1.63 Detonation velocity/(m·s−1) 6930 Detonation pressure/GPa 21 A/GPa 374 B/GPa 3.74 R1 4.15 R2 1.4 ω 0.35 E/(103 MJ·m−3) 7 Notes: A, B, R1, R2, ω—Constants characterizing TNT properties; E—Detonation energy per unit volume. 表 5 空气参数

Table 5. Parameters of air

Parameter Value Density/(kg·m−3) 1.29 C4 0.4 C5 0.4 C0,C1,C2,C3,C6 0 E0/(MJ·m−3) 0.25 Notes: C0-C6—Polynomial equation coefficients; E0—Initial internal energy. 表 6 不同比例距离Z下的超压峰值

Table 6. Peak overpressure at different scaled distances Z

Z

/(m·kg−1/3)Test

/kPaEmpirical formula

/kPaSimulation

/

kPa1.85 175.3 218.3 168.3 1.47 411.5 374.3 347.8 1.28 585.1 524.9 521.6 1.08 856.5 805.0 864.0 1.00 878.3 970.0 960.2 表 7 各厚度织物在不同比例距离下的变形峰值

Table 7. Deformation peak values of fabrics of each thickness at different scaled distances

Thickness of

fabric/mmStand-off

distance/

mmTNT mass/g Z/

(m·kg−1/3)Maximum

deformation/

mm100 60 0.255 Failure 150 60 0.384 39.4 200 60 0.51 36.1 3.1 200 20 0.74 34.0 300 20 1.1 32.5 300 10 1.4 30.1 100 80 0.232 Failure 100 60 0.255 39.7 150 60 0.384 37.9 6.2 200 60 0.51 34.8 200 20 0.74 31.0 300 20 1.1 29.0 300 10 1.4 27.3 100 80 0.232 Failure 100 60 0.255 38.3 150 60 0.384 34.6 9.3 200 60 0.51 33.8 200 20 0.74 27.9 300 20 1.1 25.5 300 10 1.4 23.9 100 150 0.19 Failure 100 120 0.203 38.1 100 100 0.215 35.8 100 60 0.255 34.0 12.4 150 60 0.384 31.4 200 60 0.51 29.6 200 20 0.74 25.2 300 20 1.1 22.9 300 10 1.4 17.7 -

[1] Federal Aviation Administration. Security considerations requirements for transport category airplanes: Far part 25 amendment No: 25-127[S]. Washington: Federal Aviation Administration, 2008. [2] Federal Aviation Administration. Least risk bomb location: FAA AC 25.795-6[S]. Washington: Federal Aviation Administration, 2008. [3] LANGDON G S, CANTWELL W J, GUAN Z W, et al. The response of polymeric composite structures to air-blast loading: A state-of-the-art[J]. International Materials Reviews,2014,59(3):159-177. doi: 10.1179/1743280413Y.0000000028 [4] YANG C C, NGO T, TRAN P. Influences of weaving architectures on the impact resistance of multi-layer fabrics[J]. Materials and Design,2015,85:282-295. doi: 10.1016/j.matdes.2015.07.014 [5] 翁浦莹. STF-Kevlar、UHMWPE织物复合形式及其防弹性能研究[D]. 杭州: 浙江理工大学, 2015.WENG Puying. Study on the composite form of STF-Kevlar and UHMWPE fabrics and their ballistic performance[D]. Hangzhou: Zhejiang Sci-Tech University, 2015(in Chinese). [6] ABTEW M A, BOUSSU F, BRUNIAUX P, et al. Ballistic impact mechanisms—A review on textiles and fibre reinforced composites impact responses[J]. Composite Structures,2019,223:110966. doi: 10.1016/j.compstruct.2019.110966 [7] 陈晓钢. 纺织基防弹防穿刺材料的研究回顾[J]. 纺织学报, 2019, 40(6):158-164. doi: 10.13475/j.fzxb.20190204507CHEN Xiaogang. Review of research on textile-based bullet-proof and puncture-proof materials[J]. Journal of Textile Research,2019,40(6):158-164(in Chinese). doi: 10.13475/j.fzxb.20190204507 [8] 何业茂, 焦亚男, 周庆, 等. 弹道防护用先进复合材料弹道响应的研究进展[J]. 复合材料学报, 2021, 38(5):1331-1347. doi: 10.13801/j.cnki.fhclxb.20201201.004HE Yemao, JIAO Ya'nan, ZHOU Qing, et al. Research progress on ballistic response of advanced composite for ballistic protection[J]. Acta Materiae Compositae Sinica,2021,38(5):1331-1347(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201201.004 [9] YANG Y F, CHEN X G. Investigation of energy absorption mechanisms in a soft armor panel under ballistic impact[J]. Textile Research Journal,2017,87(20):2475-2486. doi: 10.1177/0040517516671129 [10] YANG Y F, CHEN X G. Investigation of failure modes and influence on ballistic performance of ultra-high molecular weight polyethylene (UHMWPE) uni-directional laminate for hybrid design[J]. Composite Structures,2017,174(8):233-243. doi: 10.1016/j.compstruct.2017.04.033 [11] YANG Y F, CHEN X G. Influence of fabric architecture on energy absorption efficiency of soft armour panel under ballistic impact[J]. Composite Structures,2019,224(9):111015. doi: 10.1016/j.compstruct.2019.111015 [12] ZHAO Y, CAO M, TAN H X, et al. Hybrid woven carbon-dyneema composites under drop-weight and steel ball impact[J]. Composite Structures,2019,236:111811. doi: 10.1016/j.compstruct.2019.111811 [13] 袁子舜, 陆振乾, 许玥, 等. 超高分子量聚乙烯纤维平纹织物-单向布混合堆叠板的防弹机制[J]. 复合材料学报, 2022, 39(6):2707-2715. doi: 10.13801/j.cnki.fhclxb.20210625.001YUAN Zishun, LU Zhenqian, XU Yue, et al. Ballistic mechanism of the hybrid panels with UHMWPE woven fabrics and UD laminates[J]. Acta Materiae Compositae Sinica,2022,39(6):2707-2715(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210625.001 [14] 赵敏, 赵睿昕, 沈永明, 等. CFR嵌片对超高分子质量聚乙烯多层复合织物防爆性能的影响[J]. 纺织学报, 2014, 35(3):37-40.ZHAO Min, ZHAO Ruixin, SHEN Yongming, et al. Influence of CFR insert on explosion-proof performance of UHMWPE multi-compound fabric[J]. Journal of Textile Research,2014,35(3):37-40(in Chinese). [15] ZHANG Y, YAN D J, NIAN X Z, et al. Numerical analysis of rigid and flexible reflection of air shock wave[J]. Applied Mechanics Materials,2014,638-640:2010-2014. doi: 10.4028/www.scientific.net/AMM.638-640.2010 [16] ZHANG B, NIAN X Z, JIN F N, et al. Failure analyses of flexible ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced anti-blast wall under explosion[J]. Composite Structures,2018,184:759-774. doi: 10.1016/j.compstruct.2017.10.037 [17] MARKERT F, THOMMESEN J. Blastworthy textile-based luggage containers for aviation safety[J]. Safety and security analysis,2011,40:213557. [18] DONATO Z, SAMUELE A, ALESSANDRO B, et al. Textile-based luggage containers for onboard blast protection[J]. Sae International Journal of Aerospace,2011,4(2):690-698. doi: 10.4271/2011-01-2517 [19] GIOVANELLE M L. Advanced technologies for bombproof cargo containers and blast containment units for the retrofitting of passenger airplanes[J]. International Journal of Aviation Systems, Operations and Training,2015,2(1):33-47. doi: 10.4018/IJASOT.2015010103 [20] FILIPPO M, MARIA M P, PAOLO V. Blast actions in aircrafts: An integrated methodology for designing protection devices[J]. Engineering Structures,2018,175:895-911. doi: 10.1016/j.engstruct.2018.08.082 [21] STANHLECKER Z, MOBASHER B, RAJAN S D. Development of reliable modeling methodologies for engine fan blade out containment analysis: Part II— Finite element analysis[J]. International Journal of Impact Engineering,2009,36(3):447-459. doi: 10.1016/j.ijimpeng.2008.08.004 [22] 冯振宇, 裴惠, 迟琪琳, 等. Kevlar织物软壁包容环抗冲击数值仿真分析研究[J]. 振动与冲击, 2020, 39(10):15-23. doi: 10.13465/j.cnki.jvs.2020.10.003FENG Zhenyu, PEI Hui, CHI Qilin, et al. Numerical simulation analysis of impact resistance of Kevlar fabric soft wall containment ring[J]. Vibration and Shock,2020,39(10):15-23(in Chinese). doi: 10.13465/j.cnki.jvs.2020.10.003 [23] ASTM International. Standard test method for breaking force and elongation of textile fabrics (strip method): ASTM D5035—06[S]. West Conshohocken: ASTM, 2006. [24] 中国国家标准化管理委员会. 纺织品织物拉伸性能第1部分: 断裂强力和断裂伸长率的测定(条样法): GB/T 3923.1—2013[S]. 北京: 中国标准出版社, 2013.Standardization Administration of the People's Republic of China. Tensile properties of textile fabrics part 1: Determination of breaking strength and breaking elongation (strip method): GB/T 3923.1—2013[S]. Beijing: China Standards Press, 2013(in Chinese). [25] TAN V, ZENG X S, SHIM V. Characterization and constitutive modeling of aramid fibers at high strain rates[J]. International Journal of Impact Engineering,2008,35(11):1303-1313. doi: 10.1016/j.ijimpeng.2007.07.010 [26] COWPER G R, SYMONDS P S. Strain hardening and strain rate effect in the impact loading of cantilever beams[D]. Providence: Brown University, 1957. [27] SADOVSKYI M A. Mechanical action of air shock waves of explosion, based on experimenta data[M]. Moscow: Izd Akad Nauk SSSR, 1952. -

下载:

下载: