Thermophysical properties of SiC particles reinforced graphite flakes/Al composites

-

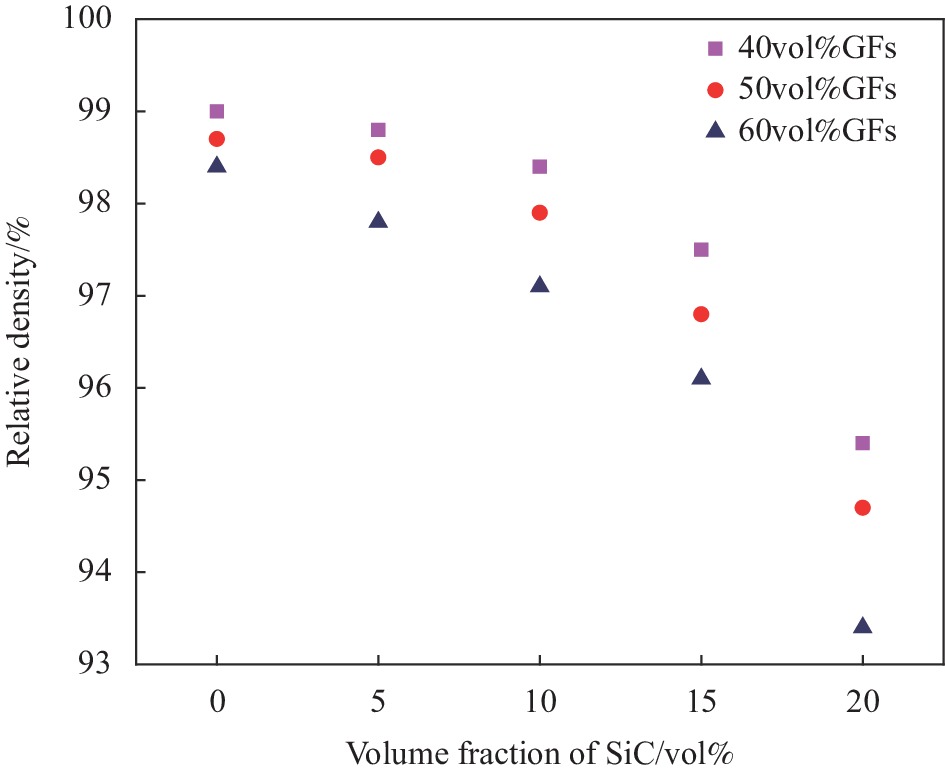

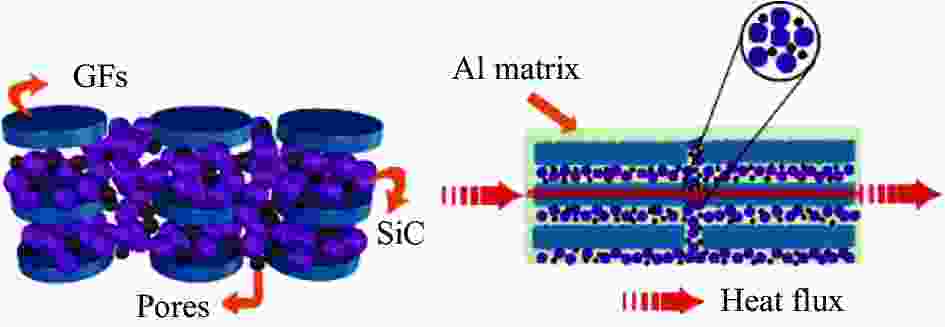

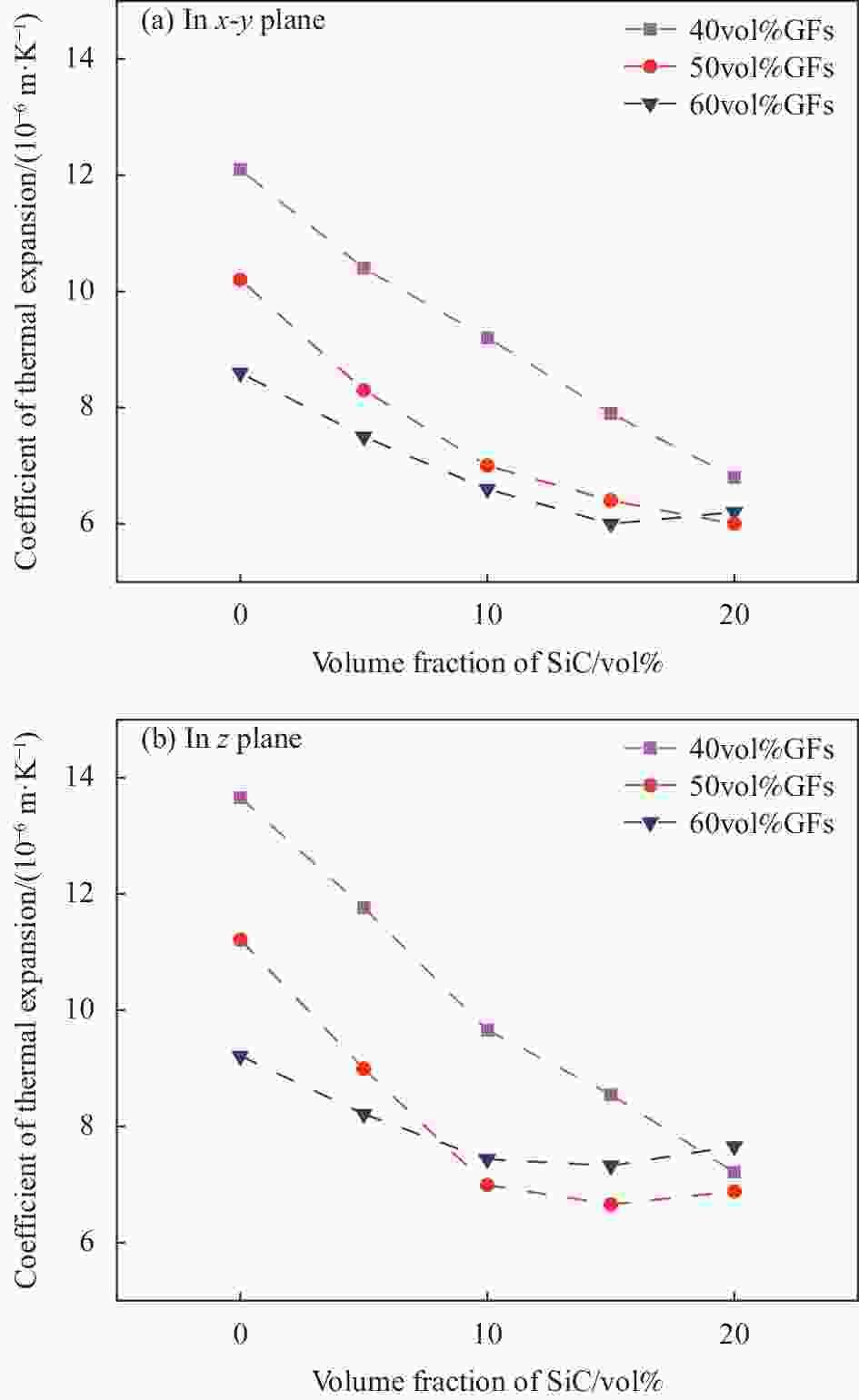

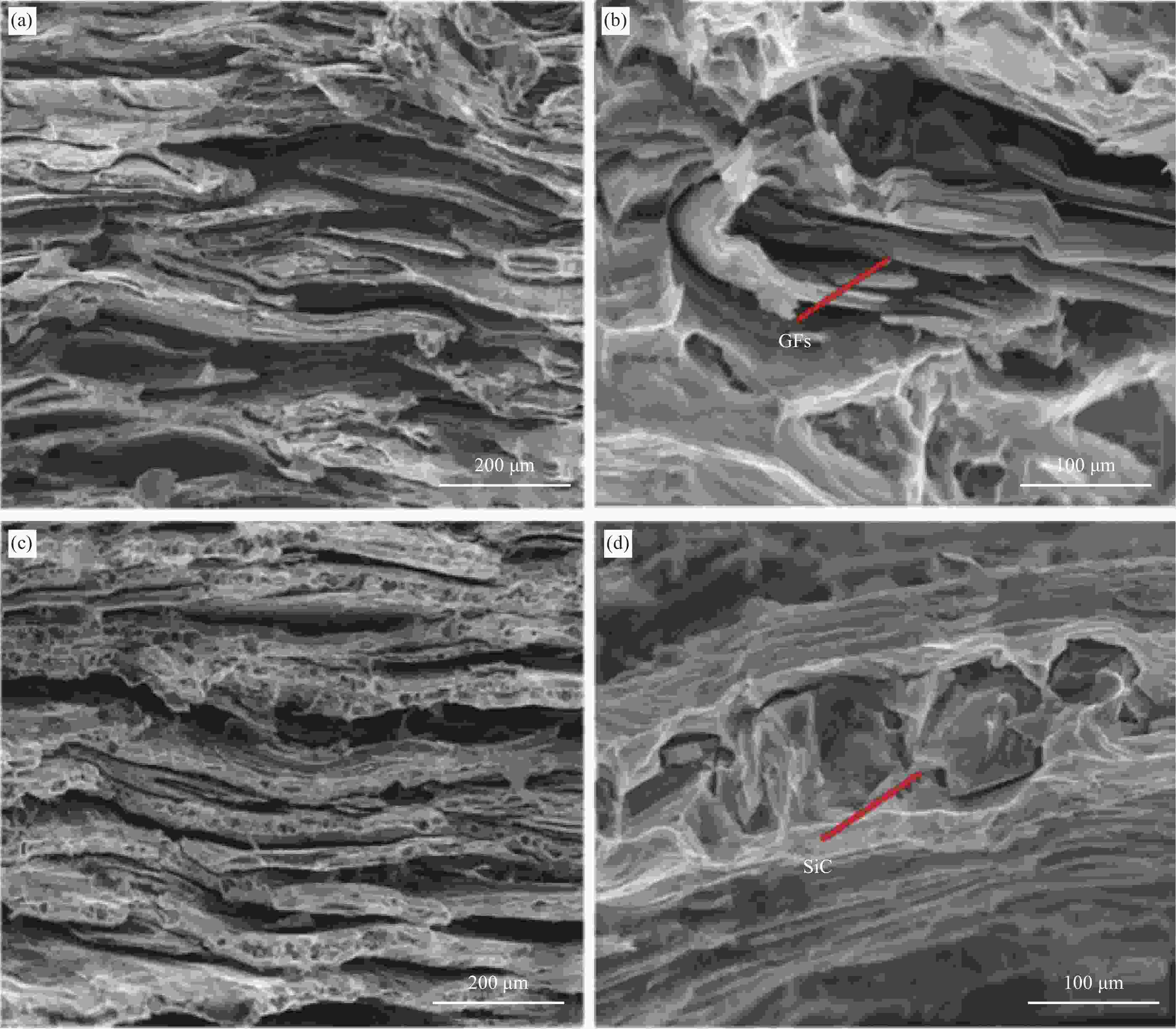

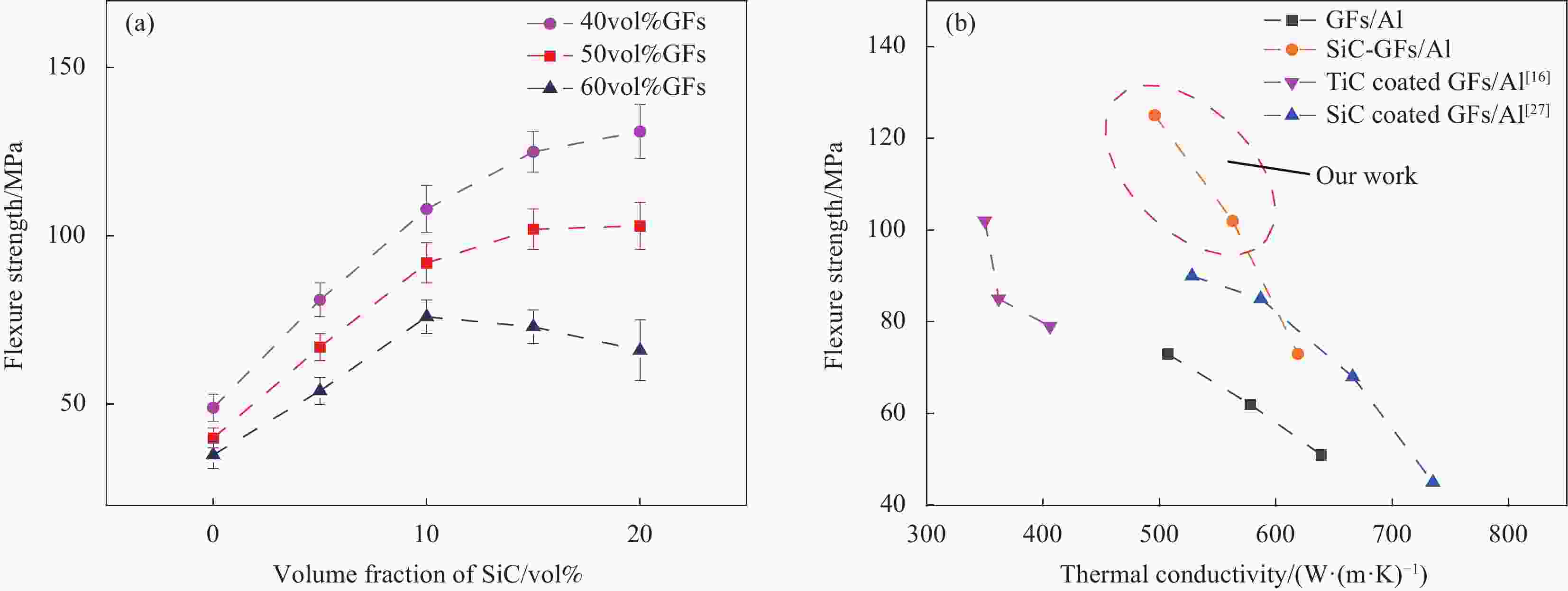

摘要: 片层石墨/铝复合材料具有低密度、高热导率的优点,但力学性能较差,目前无法作为一种可商业化应用的电子封装材料。为了改善片层石墨/铝复合材料的热物理性能,采用真空热压法制备了碳化硅颗粒增强石墨/铝复合材料,研究了碳化硅的含量对复合材料热导率、热膨胀系数和抗弯强度的影响。结果表明,经过高频振荡工艺,碳化硅-石墨/铝复合材料中石墨的排列取向良好。添加碳化硅颗粒能明显降低复合材料的热膨胀系数,提高抗弯强度,略微降低热导率。随着碳化硅颗粒体积分数增加,碳化硅-石墨/铝复合材料内部会逐渐出现孔洞缺陷,相对密度下降。当碳化硅和石墨的体积分数分别为15vol%、50vol%时,碳化硅-石墨/铝复合材料具有最优热物理性能,此时x-y方向热导率为536 W/(m·K)、热膨胀系数为6.4×10−6 m/K,抗弯强度为102 MPa,是一种十分具有商业前景的电子封装材料。Abstract: The graphite flakes/Al composite has the advantages of low density and high thermal conductivity, but it cannot be used as a kind of commercial electronic packaging material due to its poor mechanical properties at present. In order to improve the thermophysical properties of graphite flakes/Al composite, the SiC particles reinforced graphite flakes/Al composites were prepared via vacuum hot-pressing process. The effect of the different content of SiC on the thermal conductivity, coefficient of thermal expansion, and flexure strength of the SiC-graphite flakes/Al composites were studied. The result shows that the high-frequency vibration process contributes to the good orientation of graphite flakes in the composites. The SiC particles can significantly reduce the coefficient of thermal expansion, increase the flexure strength, and slightly decrease the thermal conductivity of the composites. However, as the volume fraction of SiC particles increases, many pores and defects are gradually foamed in the SiC-graphite flakes/Al composites, causing the decrease of the relative density. When the volume fraction of SiC and graphite flakes are 15vol% and 50vol%, respectively, the thermal conductivity in x-y plane, coefficient of thermal expansion and flexure strength of the SiC-graphite flakes/Al composite are 536 W/(m·K) and 6.4×10-6 m/K and 102 MPa, respectively, exhibiting the best comprehensive thermophysical properties, which can be a kind of electronic packaging material with very commercial prospect.

-

表 1 不同碳化硅-石墨/铝(SiC-GFs/Al)复合材料中碳化硅和石墨的体积分数

Table 1. Volume fractions of SiC and GFs in SiC-graphite flakes/Al (SiC-GFs/Al) composites

No SiC/vol% GFs/vol% Al/vol% 1 0 40 60 2 5 40 55 3 10 40 50 4 15 40 45 5 20 40 40 6 0 50 50 7 5 50 45 8 10 50 40 9 15 50 35 10 20 50 30 11 0 60 40 12 5 60 35 13 10 60 30 14 15 60 25 15 20 60 20 表 2 碳化硅、石墨和铝的物理参数

Table 2. Physical parameters of SiC, GFs and Al

Materials ρ/(kg·m−3) Cp/

(J·(kg·K)−1)TC/

(W·(m·K)−1)CTE/

(10−6 m·K−1)SiC[19] 3210 290 248 4.6 GFs[20-21] 2260 710 1000x-y 38z −1.5x-y 25z Al [22] 2700 895 237 23.5 Notes: ρ—Density of the materials; Cp—Specific heat; TC—Thermal conductivity; CTE—Coefficient of thermal expansion; Superscripts “x-y” and “z”—Direction parallel and perpendicular to the GFs (002) crystal plane. -

[1] 宋业建, 郜昊强. 纯电动汽车技术现状和发展趋势分析[J]. 汽车实用技术, 2019(21):21-23. doi: 10.16638/j.cnki.1671-7988.2019.21.007SONG Yejian, GAO Haoqiang. Analysis of technology status and development trend of electric vehicle[J]. Automobile Applied Technology,2019(21):21-23(in Chinese). doi: 10.16638/j.cnki.1671-7988.2019.21.007 [2] 王丹, 续丹, 曹秉刚. 电动汽车关键技术发展综述[J]. 中国工程科学, 2013, 15(1):68-72. doi: 10.3969/j.issn.1009-1742.2013.01.014WANG Dan, XU Dan, CAO Binggang. Overview on key techniques of electric vehicle[J]. Strategic Study of CAE,2013,15(1):68-72(in Chinese). doi: 10.3969/j.issn.1009-1742.2013.01.014 [3] WU Y B, LIU G Y, XU N H, et al. Thermal resistance analysis and simulation of IGBT module with high power density[J]. Applied Mechanics & Materials,2013,(303-306):1902-1907. doi: 10.4028/www.scientific.net/AMM.303-306.1902 [4] 王坚, 张迪德, 古强. IGBT不同导热材料导热性能研究[J]. 客车技术, 2019(4):8-11.WANG Jian, ZHANG Dide, GU Qiang. Study on thermal conductivity of different thermal conduction materials in IGBT[J]. Bus Technology,2019(4):8-11(in Chinese). [5] HUANG Q Q, LI X X, ZHANG G Q, et al. Thermal management of lithium-ion battery pack through the application of flexible form-stable composite phase change materials[J]. Applied Thermal Engineering,2021,18(part 1):116151. doi: 10.1016/j.applthermaleng.2020.116151 [6] FENG C P, CHEN L B, TIAN G L, et al. Multifunctional thermal management materials with excellent heat dissipation and generation capability for future electronics[J]. ACS Applied Materials & Interfaces,2019,11(20):18739-18745. doi: 10.1021/acsami.9b03885 [7] 张晓辉, 王强. 电子封装用金属基复合材料的研究现状[J]. 微纳电子技术, 2018, 55(1):18-25, 44. doi: 10.13250/j.cnki.wndz.2018.01.004ZHANG Xiaohui, WANG Qiang. Research status of metal matrix composites for electronic packaging[J]. Micronanoelectronic Technology,2018,55(1):18-25, 44(in Chinese). doi: 10.13250/j.cnki.wndz.2018.01.004 [8] LEE H S, JEON K Y, KIM H Y, et al. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications[J]. Journal of Materials Science,2000,35(24):6231-6236. doi: 10.1023/A:1026749831726 [9] LEE H S, HONG S H. Pressure infiltration casting process and thermophysical properties of high-volume fraction SiCp/Al metal matrix composites[J]. Materials Science and Technology,2003,19(8):1057-1064. doi: 10.1179/026708303225004396 [10] QU X H, ZHANG L, WU M, et al. Review of metal matrix composites with high thermal conductivity for thermal management applications[J]. Progress in Natural Science: Materials International,2011,21(3):189-197. doi: 10.1016/S1002-0071(12)60029-X [11] LI W, LIU Y, WU G. Preparation of graphite flakes/Al with preferred orientation and high thermal conductivity by squeeze casting[J]. Carbon,2015,95:545-551. doi: 10.1016/j.carbon.2015.08.063 [12] PRIETO R, MOLINA J M, NARCISO J, et al. Thermal conductivity of graphite flakes-SiC particles/metal composites[J]. Composites Part A: Applied Science & Manufacturing,2011,42(12):1970-1977. [13] JIA H, FAN J, LIU Y, et al. Interfacial structure of carbide-coated graphite/Al composites and its effect on thermal conductivity and strength[J]. Materials,2021,14(7):1721. doi: 10.3390/ma14071721 [14] LIU Q, HE Z, CHENG J, et al. Theoretical and predictive modeling of interfacial thermal conductance and thermal conductivity in graphite flake/Al composites[J]. Composite Interfaces,2021,28(1):101-114. doi: 10.1080/09276440.2020.1726135 [15] CHEN J, HUANG I S. Thermal properties of aluminum-graphite composites by powder metallurgy[J]. Compo-sites Part B: Engineering,2013,44(1):698-703. doi: 10.1016/j.compositesb.2012.01.083 [16] WANG C, BAI H, XUE C, et al. On the influence of carbide coating on the thermal conductivity and flexural strength of X (X=SiC, TiC) coated graphite/Al composites[J]. RSC Advances,2016,6(109):107483-107490. doi: 10.1039/C6RA21754K [17] 黄凯, 白华, 朱英彬, 等. 石墨表面化学镀Cu对天然鳞片石墨/Al复合材料热物理性能的影响 [J]. 复合材料学报, 2018, 35(4): 920-926.HUANG Kai, BAI Hua, ZHU Yinbing, et al. Thermal conductivity and mechanical properties of flake graphite/Al composite with electroless Cu plating on graphite surface[J]. Acta Materiae Compositae Sinica, 2018, 35(4): 920-926(in Chinese). [18] 曾凡坤, 宁越洋, 马洪兵, 等. 添加铜网对片层石墨/Al复合材料热物理性能的影响[J]. 复合材料学报, 2019, 36(10):2357-2363.ZENG Fankun, NING Yueyang, MA Hongbing, et al. Preparation and thermophysical properties of aligned graphite flake/Cu composites[J]. Acta Materiae Compositae Sinica,2019,36(10):2357-2363(in Chinese). [19] CHU K, JIA C, TIAN W, et al. Thermal conductivity of spark plasma sintering consolidated SiCp/Al composites containing pores: Numerical study and experimental validation[J]. Composites Part A: Applied Science and Manufacturing,2010,41(1):161-167. doi: 10.1016/j.compositesa.2009.10.001 [20] YUAN G, LI X, DONG Z, et al. Graphite blocks with preferred orientation and high thermal conductivity[J]. Carbon,2012,50(1):175-182. doi: 10.1016/j.carbon.2011.08.017 [21] PRASHER R. Thermal boundary resistance and thermal conductivity of multiwalled carbon nanotubes[J]. Physical Review B, 2008, 77(7): 075424. [22] TAN Z Q, LI Z Q, XIONG D B, et al. A predictive model for interfacial thermal conductance in surface metallized diamond aluminum matrix composites[J]. Materials & Design,2014,55:257-262. doi: 10.1016/j.matdes.2013.09.060 [23] 全国钢标准化技术委员会. 金属弯曲试验方法: GB/T 232—2010[S]. 北京: 中国标准出版社, 2010.National Technical Committee on Steel Standardization. Metallic materials—Bend test: GB/T 232—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [24] NAN C, BIRRINGER R, CLARKE D R, et al. Effective thermal conductivity of particulate composites with interfacial thermal resistance[J]. Journal of Applied Physics,1997,81(10):6692-6699. doi: 10.1063/1.365209 [25] TRUONG H V, ZINSMEISTER G E. Experimental study of heat transfer in layered composites[J]. International Journal of Heat and Mass Transfer,1978,21(7):905-909. doi: 10.1016/0017-9310(78)90182-5 [26] ZHOU C, JI G, CHEN Z, et al. Fabrication, interface characterization and modeling of oriented graphite flakes/Si/Al composites for thermal management applications[J]. Materials & Design,2014,63:719-728. doi: 10.1016/j.matdes.2014.07.009 [27] XUE C, BAI H, TAO P F, et al. Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nano-layer on graphite surface[J]. Materials & Design,2016,108:250-258. doi: 10.1016/j.matdes.2016.06.122 -

下载:

下载: