Experiment study on mechanical properties of fly ash ceramsite lightweight aggregate concrete under triaxial compression

-

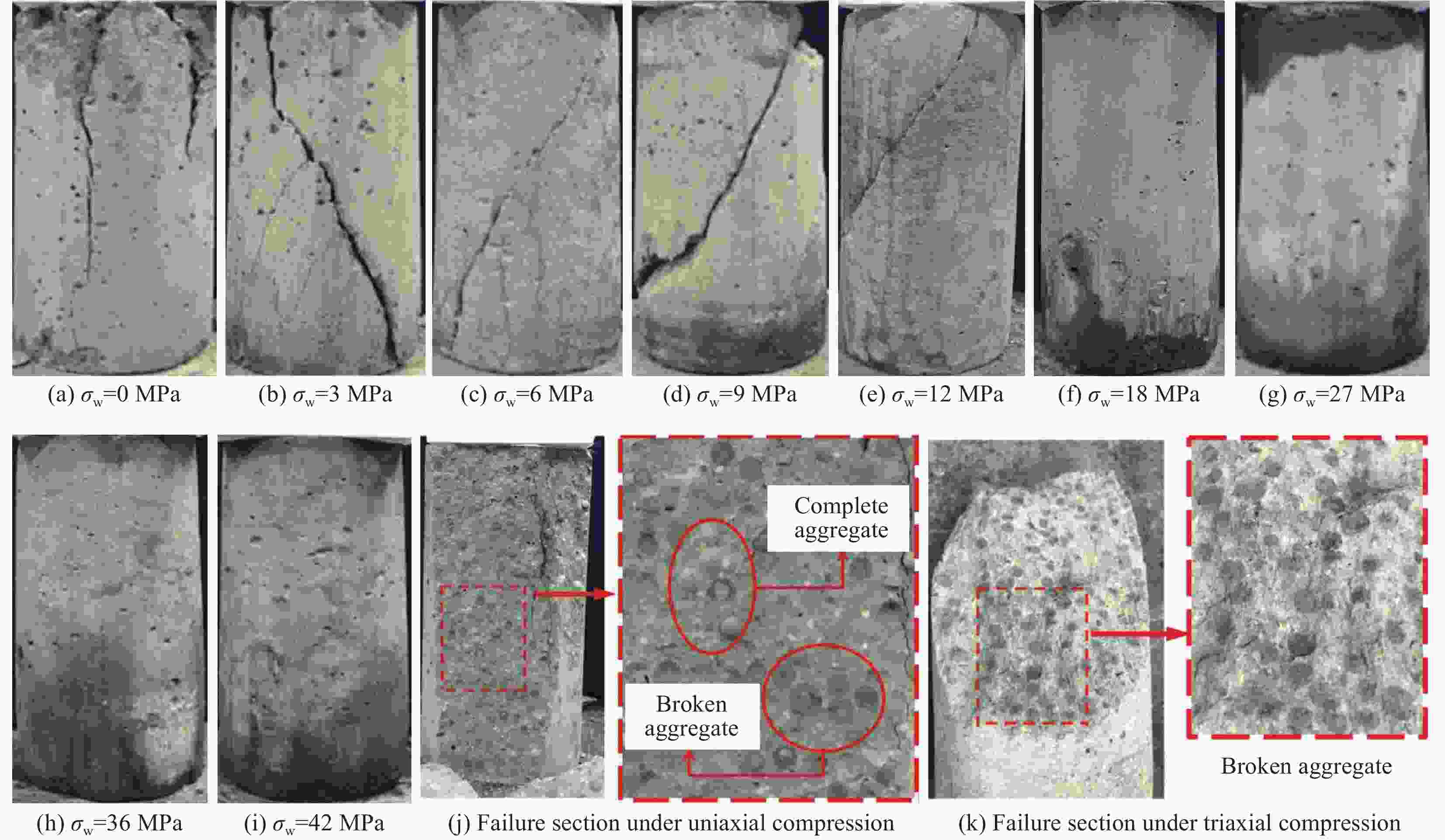

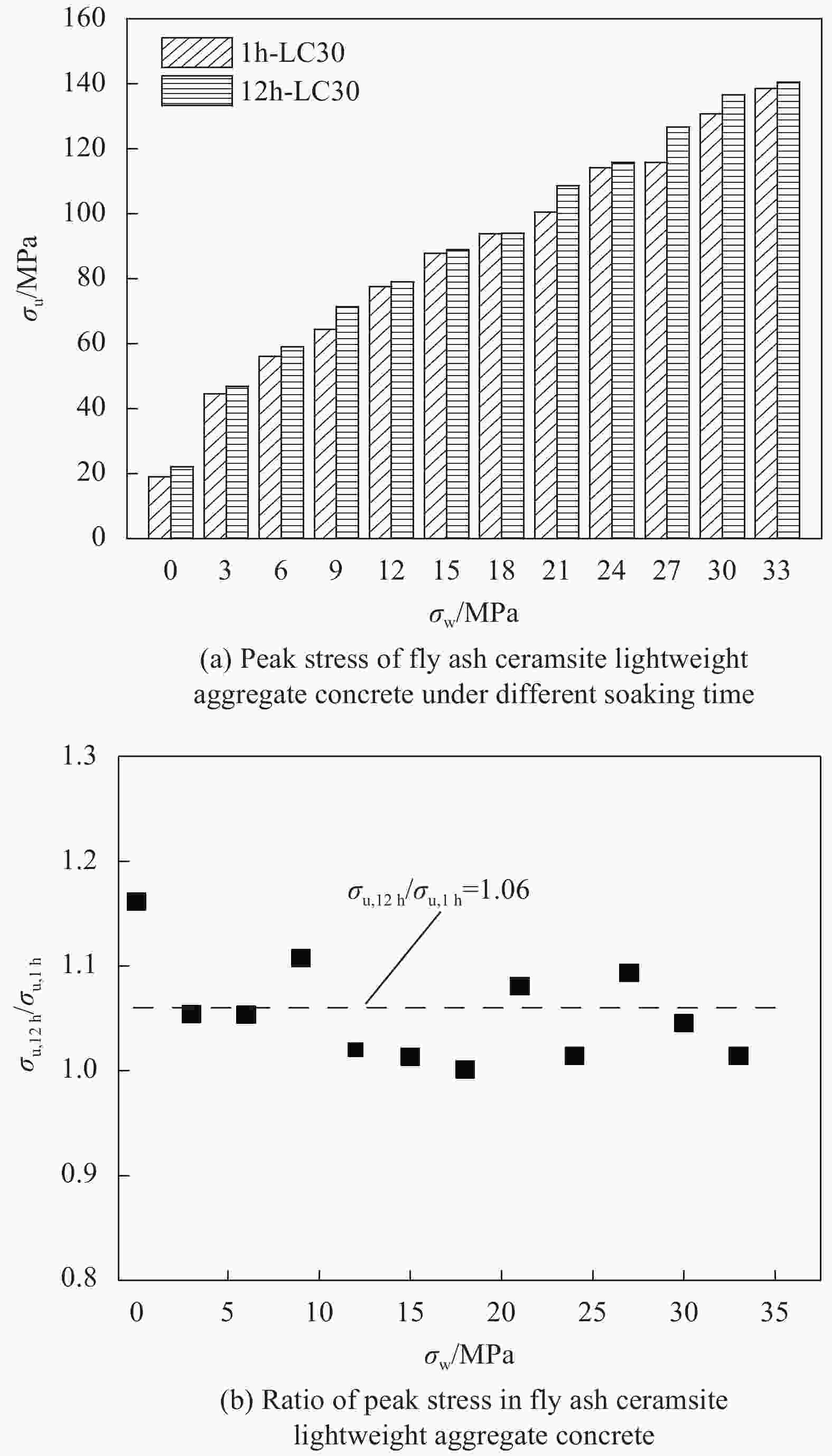

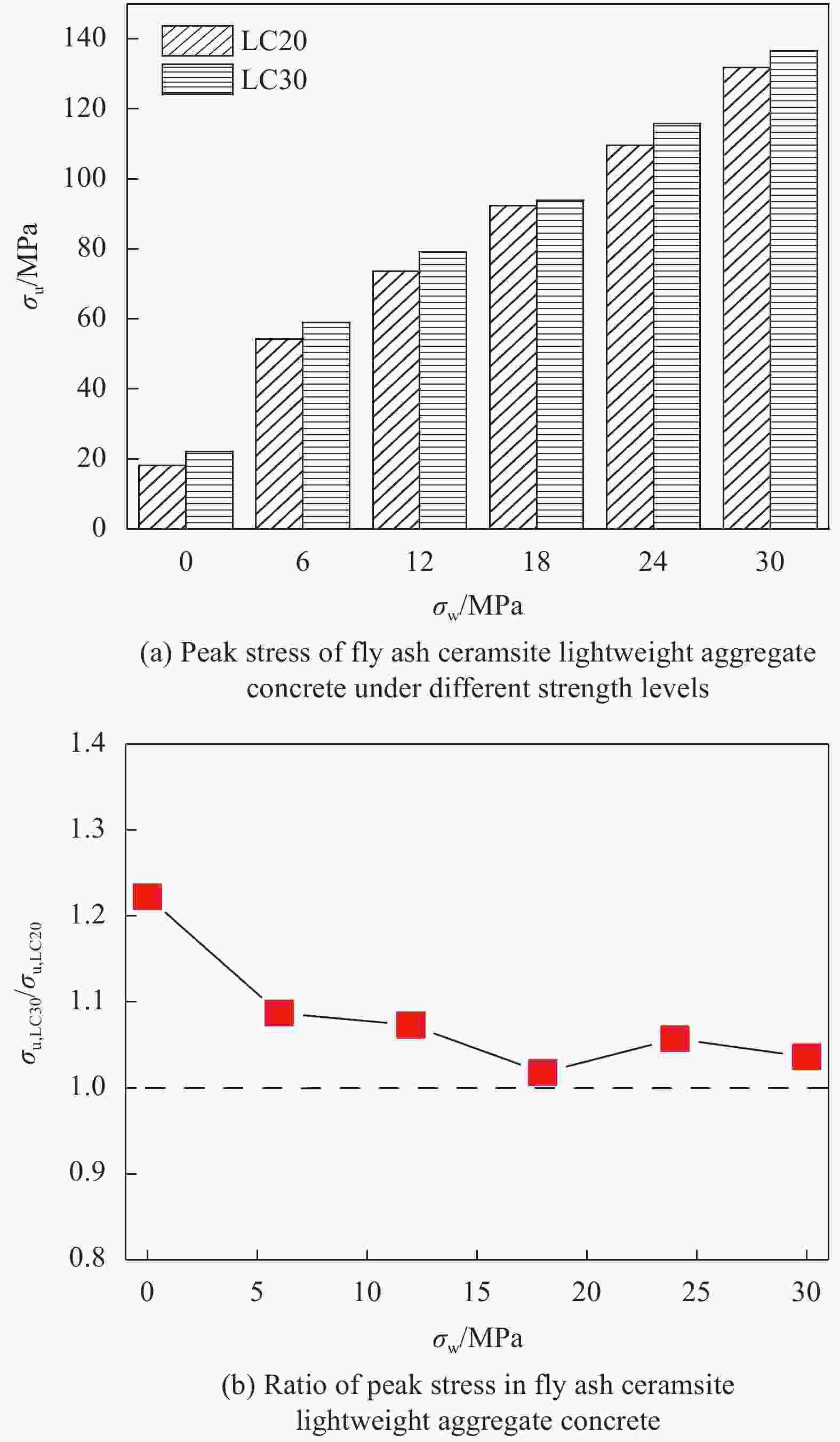

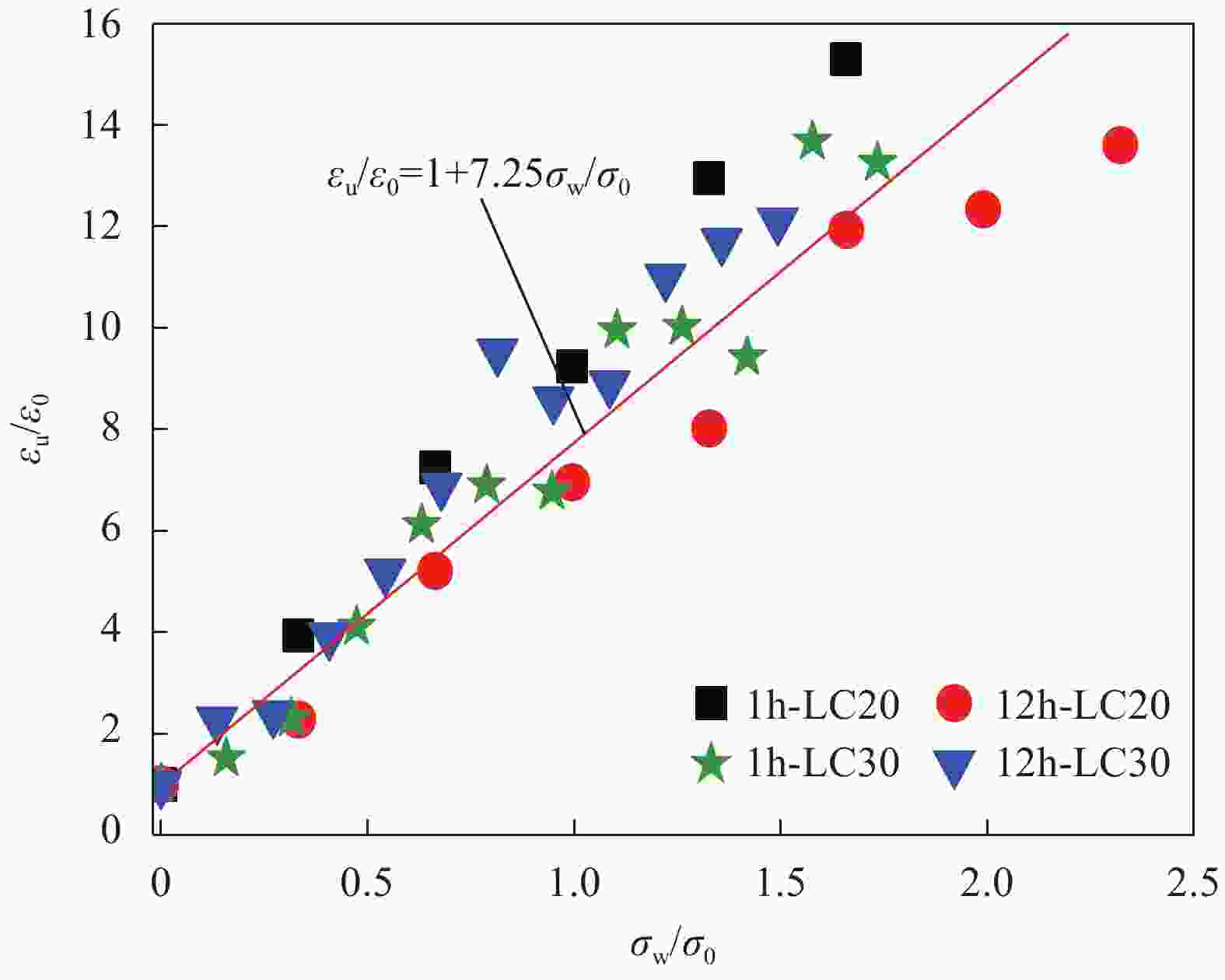

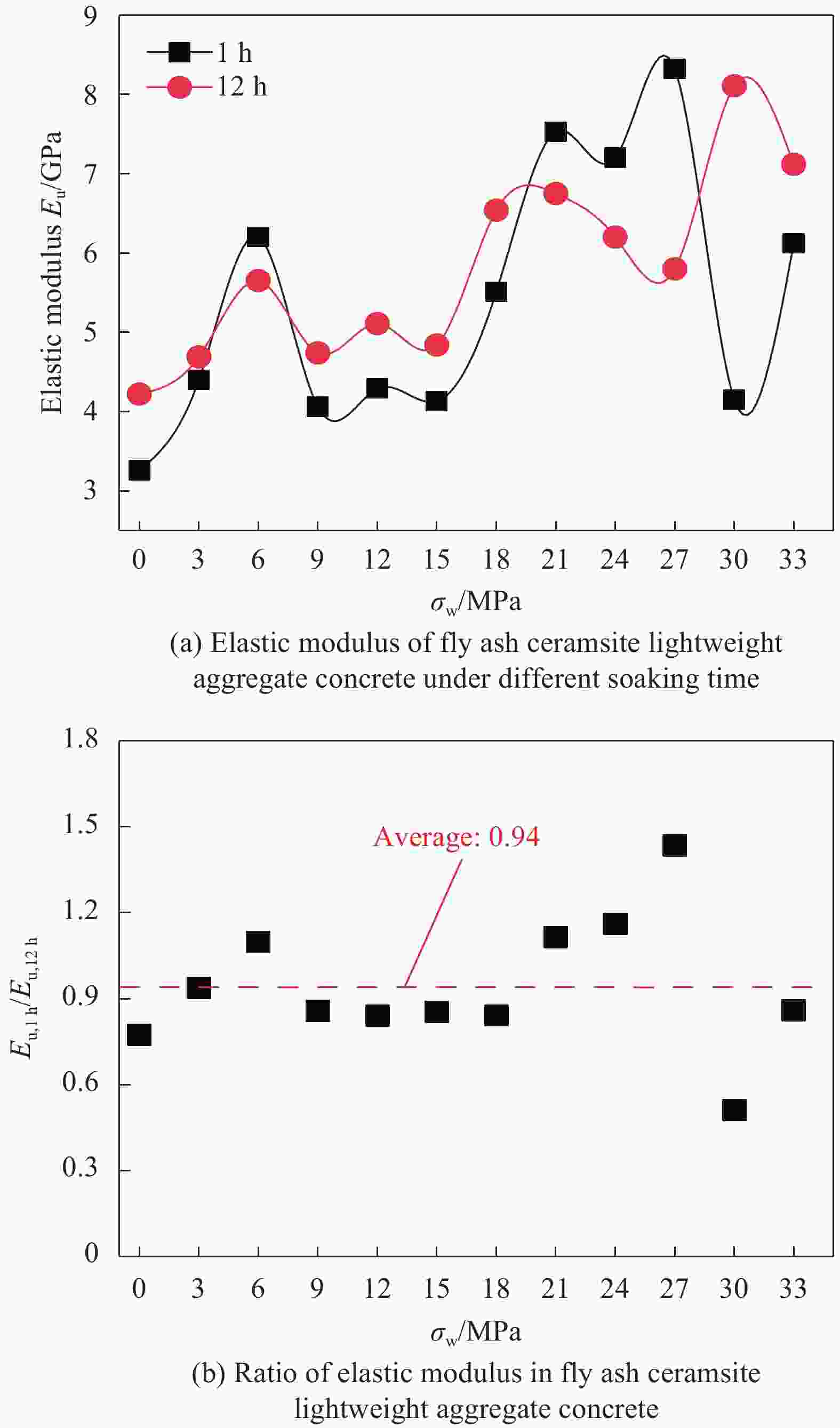

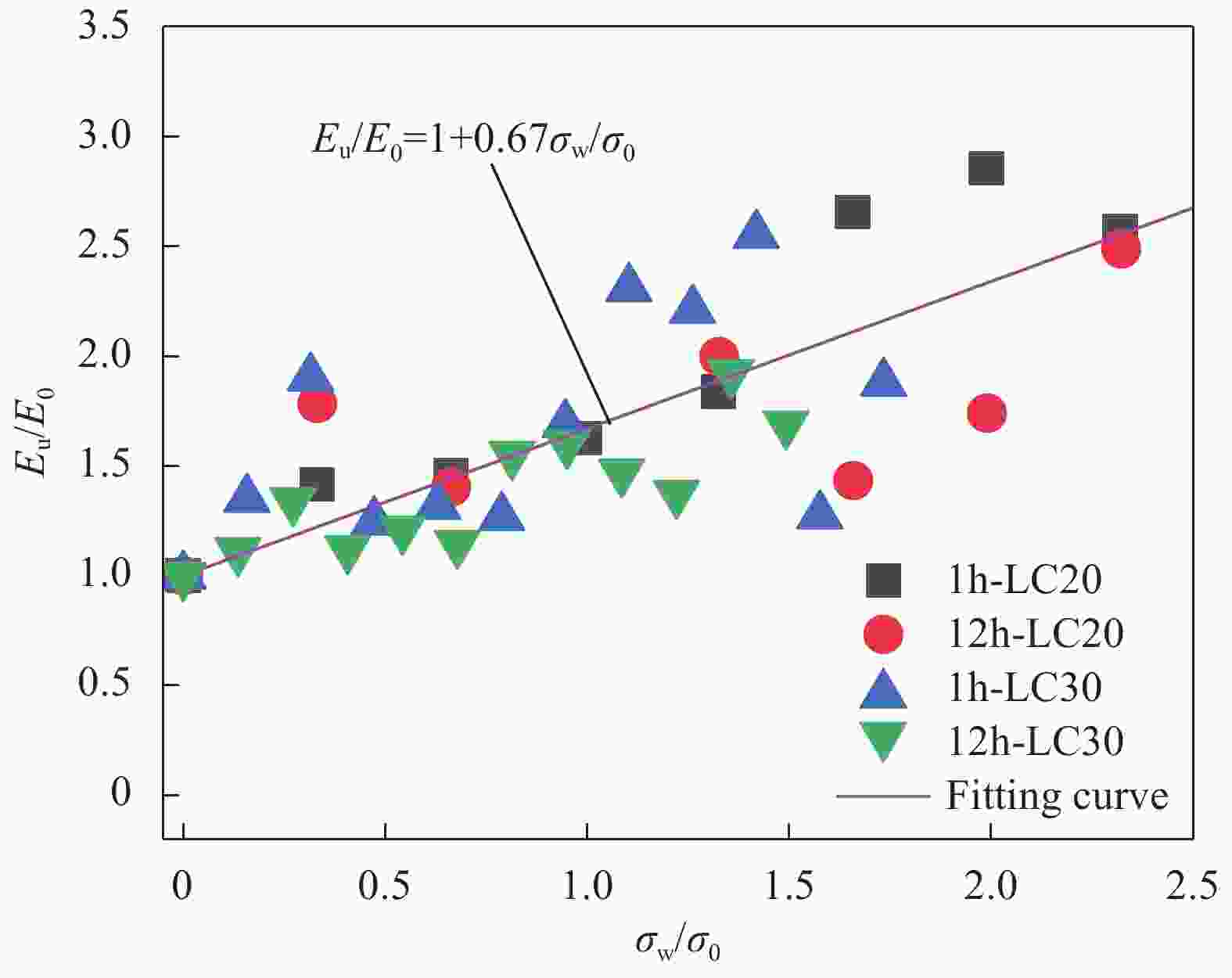

摘要: 以粉煤灰陶粒轻骨料浸泡时间、强度等级、侧向围压为变化参数,共设计120个粉煤灰陶粒轻骨料混凝土试件进行常规三轴受压试验,研究其在三轴应力状态下的力学性能。试验观察了轻骨料混凝土的破坏过程及破坏形态,获取了三轴受力状态下的应力-应变全过程曲线,分析了各变化参数对其三轴受压力学性能的影响规律。研究结果表明:随着围压值的增大,试件破坏由竖向劈裂破坏变为斜向剪切破坏,当围压值大于12 MPa时,试件则表现为外表无明显裂缝的鼓起破坏;应力-应变曲线受围压值影响较大,受骨料浸泡时间和强度等级的影响较小,围压值大于12 MPa后,曲线不再出现下降段;峰值应力随骨料浸泡时间、强度等级、侧向围压的增大而增大;峰值应变受陶粒浸泡时间的影响不大,随强度等级的增大而减小,随围压值的增大而增大;弹性模量随强度等级和围压值的增大而增大,受骨料浸泡时间的影响不显著。Abstract: A total of 120 specimens of fly ash ceramsite lightweight aggregate concrete were designed for conventional triaxial compression tests in order to reveal the mechanical properties and behavior under complex stress conditions with ceramsite soaking time, strength level and lateral confining pressure as the changing parameters. The failure process and final failure behavior of fly ash ceramsite lightweight aggregate concrete under triaxial compression were observed, the stress-strain curves of specimens were obtained, and the influence of changing parameters on the mechanical performances was analyzed. The experimental results show that with the increase of the confining pressure, the failure behavior of fly ash ceramsite lightweight aggregate concrete changes from vertical splitting failure to oblique shear failure. When the confining pressure value is greater than 12 MPa, the specimen shows bulging failure without obvious cracks. The stress-strain curve is greatly affected by the value of confining pressure, but less affected by the immersion time and strength grade of the concrete. And after the confining pressure is greater than 12 MPa, the curve no longer has a descending section. The peak stress increases with the increase of ceramsite immersion time, strength grade and lateral confining pressure. The peak strain is not greatly affected by the soaking time of the ceramsite, it decreases with the increase of the strength grade, and increases with the increase of the confining pressure value. The elastic modulus increases with the increase of the strength grade and the confining pressure value, and is not significantly affected by the soaking time of the ceramsite.

-

表 1 粉煤灰高强陶粒的物理性能

Table 1. Physical performance of ceramsite

Fly ash content/wt% Bulk density/(kg·m−3) Cylinder compressive strength/MPa Water absorption for

1 h/%Water absorption for

12 h/%Saturated water absorption/% 80 650 7.2 14.96 16.12 17.22 表 2 粉煤灰主要化学成分

Table 2. Main chemical composition of fly ash

Compound type SiO2 Fe2O3 Al2O3 CaO MgO SO3 Content/wt% 44.84 16.81 23.43 3.09 1.32 1.41 表 3 粉煤灰陶粒轻骨料混凝土配合比(kg/m3)

Table 3. Mix proportion of fly ash ceramsite lightweight aggregate concrete (kg/m3)

Strength level Cement Fly ash ceramsite Sand Fly ash Water Water-binder ratio LC20 350 420.3 667.4 75.0 170 0.40 LC30 400 407.7 634.3 47.4 170 0.38 表 4 粉煤灰陶粒轻骨料混凝土的特征点参数

Table 4. Characteristic point parameters of fly ash ceramsite lightweight aggregate concrete

Specimen Eu/GPa σu/MPa εu/10−3 1h-LC20-0MPa 3.03 18.10 5.60 1h-LC20-6MPa 4.29 54.30 22.02 1h-LC20-12MPa 4.42 75.92 40.54 1h-LC20-18MPa 4.93 101.93 51.79 1h-LC20-24MPa 5.57 115.61 72.54 1h-LC20-30MPa 8.05 133.65 85.62 1h-LC20-36MPa 8.66 151.90 102.79 1h-LC20-42MPa 7.79 167.17 107.20 12h-LC20-0MPa 3.51 18.09 8.86 12h-LC20-6MPa 5.43 54.29 20.17 12h-LC20-12MPa 4.28 73.64 46.14 12h-LC20-18MPa 6.20 92.25 61.61 12h-LC20-24MPa 6.11 109.49 71.04 12h-LC20-30MPa 4.66 131.77 105.74 12h-LC20-36MPa 6.32 145.72 109.34 12h-LC20-42MPa 7.18 162.35 120.56 1h-LC30-0MPa 3.26 19.03 7.23 1h-LC30-3MPa 4.40 44.43 10.97 1h-LC30-6MPa 6.20 56.01 16.66 1h-LC30-9MPa 4.06 64.34 29.73 1h-LC30-12MPa 4.29 77.45 44.24 1h-LC30-15MPa 4.13 87.76 49.88 1h-LC30-18MPa 5.51 93.79 48.95 1h-LC30-21MPa 7.53 100.36 71.99 1h-LC30-24MPa 7.20 114.11 72.47 1h-LC30-27MPa 8.32 115.75 68.10 1h-LC30-30MPa 4.15 130.57 98.88 1h-LC30-33MPa 6.12 138.43 95.86 12h-LC30-0MPa 4.22 22.11 6.98 12h-LC30-3MPa 4.69 46.83 15.84 12h-LC30-6MPa 5.65 59.02 16.68 12h-LC30-9MPa 4.74 71.25 27.43 12h-LC30-12MPa 5.11 79.02 36.21 12h-LC30-15MPa 4.84 88.91 48.05 12h-LC30-18MPa 6.54 93.88 66.50 12h-LC30-21MPa 6.75 108.49 59.92 12h-LC30-24MPa 6.20 115.76 62.10 12h-LC30-27MPa 5.80 126.55 76.79 12h-LC30-30MPa 8.11 136.52 81.71 12h-LC30-33MPa 7.12 140.43 84.55 Notes: Eu—Elastic modulus; σu—Peak stress; εu—Peak strain. -

[1] 刘喜, 吴涛, 魏慧, 等. 箍筋约束轻骨料混凝土轴心受压应力-应变曲线研究[J]. 建筑结构学报, 2021, 42(3):134-143. doi: 10.14006/j.jzjgxb.2018.0642LIU Xi, WU Tao, WEI Hui, et al. Axial compressive stress-strain relationship of confined lightweight aggregate concrete with stirrups[J]. Journal of Building Structures,2021,42(3):134-143(in Chinese). doi: 10.14006/j.jzjgxb.2018.0642 [2] 余振鹏, 黄侨, 赵志青, 等. 自密实轻骨料混凝土压-剪复合受力力学性能[J]. 复合材料学报, 2019, 36(8):1984-1994. doi: 10.13801/j.cnki.fhclxb.20181030.002YU Zhenpeng, HUANG Qiao, ZHAO Zhiqing, et al. Mechanical property of self-compacting lightweight aggregate concrete under combined compression-shear stress[J]. Acta Materiae Compositae Sinica,2019,36(8):1984-1994(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181030.002 [3] 梁圣, 崔宏志, 徐丹玥. 纳米SiO2改性轻骨料混凝土性能[J]. 复合材料学报, 2019, 36(2):498-505. doi: 10.13801/j.cnki.fhclxb.20180330.001LIANG Sheng, CUI Hongzhi, XU Danyue. Properties of nano-SiO2 modified lightweight aggregate concrete[J]. Acta Materiae Compositae Sinica,2019,36(2):498-505(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180330.001 [4] American Concrete Institute. Building code requirements for structural concrete and commentary on building code requirements for structural concrete: ACI 318-14[S]. Farmington Hills: American Concrete Institute Publisher, 2014. [5] 中华人民共和国住房和城乡建设部. 轻骨料混凝土结构技术规程: JGJ/T 12—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Construction of the People's Republic of China. Technical specification for lightweight aggregate concrete structures: JGJ/T 12—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [6] SANTHA K G, MISHRA A K. Influence of granite fine powder on the performance of cellular Light weight concrete[J]. Journal of Building Engineering,2021,40(11):102707. doi: /10.1016/j.jobe.2021.102707 [7] 王万祯, 郭鸣鸣, 吴晓聪. 主方支圆钢管轻骨料混凝土K型节点承载力[J]. 华中科技大学学报(自然科学版), 2020, 48(5):61-67. doi: 10.13245/j.hust.200512WANG Wanzhen, GUO Mingming, WU Xiaocong. Bearing capacity of K-joint of light-aggregate concrete steel tube with main square branch[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2020,48(5):61-67(in Chinese). doi: 10.13245/j.hust.200512 [8] 王万祯, 李华, 吴晓聪. 方钢管轻骨料混凝土加劲TY型节点承载力研究[J]. 华中科技大学学报(自然科学版), 2020, 48(8):33-38. doi: 10.13245/j.hust.200806WANG Wanzhen, LI Hua, WU Xiaocong. Study on the bearing capacity of TY-type joints reinforced with square steel tube lightweight aggregate concrete[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2020,48(8):33-38(in Chinese). doi: 10.13245/j.hust.200806 [9] FEDEROWICZ K, TECHMAN M, SANYTSKY M, et al. Modification of lightweight aggregate concretes with silica nanoparticles-A review[J]. Materials,2021,14(15):4242. doi: 10.3390/ma14154242 [10] 吴涛, 魏慧, 刘喜, 等. 箍筋约束高强轻骨料混凝土柱轴压性能试验研究[J]. 工程力学, 2018, 35(2):203-213.WU Tao, WEI Hui, LIU Xi, et al. Experimental study on axial compression performance of high-strength lightweight aggregate concrete columns confined by stirrups[J]. Engineering Mechanics,2018,35(2):203-213(in Chinese). [11] 吴涛, 杨雪, 刘喜. 钢-聚丙烯混杂纤维自密实轻骨料混凝土性能[J]. 建筑材料学报, 2021, 24(2):268-275, 282. doi: 10.3969/j.issn.1007-9629.2021.02.006WU Tao, YANG Xue, LIU Xi. Properties of self-compacting lightweight concrete reinforced with hybrid steel and polypropylene fibers[J]. Journal of Building Materials,2021,24(2):268-275, 282(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.02.006 [12] 王新堂, 周明, 王万祯, 等. 轻骨料钢管混凝土短柱受火后力学性能的试验研究[J]. 土木工程学报, 2011, 44(12):34-41. doi: 10.15951/j.tmgcxb.2011.12.013WANG Xintang, ZHOU Ming, WANG Wanzhen, et al. Experimental study on mechanical properties of lightweight aggregate concrete-filled steel tube short columns after exposure to fire[J]. China Civil Engineering Journal,2011,44(12):34-41(in Chinese). doi: 10.15951/j.tmgcxb.2011.12.013 [13] 任鹏飞, 王新堂, 梧松. 轻骨料混凝土-薄壁钢梁组合楼板受火后承载性能试验研究[J]. 建筑结构学报, 2019, 40(4):56-63. doi: 10.14006/j.jzjgxb.2019.04.006REN Pengfei, WANG Xintang, WU Song. Experimental study on post-fire bearing capacity of composite floor of lightweight aggregate concrete-thin walled steel beam[J]. Journal of Building Structures,2019,40(4):56-63(in Chinese). doi: 10.14006/j.jzjgxb.2019.04.006 [14] 叶艳霞, 王宗彬, 谢夫林, 等. 钢纤维增强高强轻骨料混凝土的力学性能[J]. 建筑材料学报, 2021, 24(1):63-70. doi: 10.3969/j.issn.1007-9629.2021.01.009YE Yanxia, WANG Zongbin, XIE Fulin, et al. Mechanical properties of steel fiber reinforced high-strength lightweight aggregate concrete[J]. Journal of Building Materials,2021,24(1):63-70(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.01.009 [15] 叶艳霞, 王宗彬, 彭琼, 等. 微细钢纤维高强轻骨料混凝土静力试验研究[J]. 建筑材料学报, 2020, 23(4):955-962. doi: 10.3969/j.issn.1007-9629.2020.04.031YE Yanxia, WANG Zongbin, PENG Qiong, et al. Static test of micro streel fiber high-strength lightweight aggregate concrete[J]. Journal of Building Materials,2020,23(4):955-962(in Chinese). doi: 10.3969/j.issn.1007-9629.2020.04.031 [16] 苏洁, 池寅, 孟宽. 钢-聚丙烯混杂纤维混凝土的真三轴强度试验研究[J]. 武汉大学学报(工学版), 2018, 51(1):40-46, 59. doi: 10.14188/j.1671-8844.2018-01-006SU Jie, CHI Yin, MENG Kuan. Experimental study of strength of steel-polypropylene hybrid fiber reinforced concrete subjected to true triaxial compression[J]. Engi-neering Journal of Wuhan University,2018,51(1):40-46, 59(in Chinese). doi: 10.14188/j.1671-8844.2018-01-006 [17] 余振鹏, 黄侨, 谢兴华. 普通混凝土和轻骨料混凝土双轴加载试验研究[J]. 建筑材料学报, 2019, 22(3):371-377. doi: 10.3969/j.issn.1007-9629.2019.03.007YU Zhenpeng, HUANG Qiao, XIE Xinghua. Experimental study on mechanical properties of ordinary concrete and lightweight aggregate concrete based on biaxial loading[J]. Journal of Building Materials,2019,22(3):371-377(in Chinese). doi: 10.3969/j.issn.1007-9629.2019.03.007 [18] 赵东拂, 高海静, 杨健辉. 混凝土双轴拉压、三轴拉压压变幅疲劳性能研究[J]. 工程力学, 2017, 34(8):154-160.ZHAO Dongfu, GAO Haijing, YANG Jianhui. Research on variable amplitude fatigue performance of concrete in biaxial tension and compression and triaxial tension and compression[J]. Engineering Mechanics,2017,34(8):154-160(in Chinese). [19] 王四巍, 孙逢涛, 吴华. 三轴应力下再生粗骨料塑性混凝土的力学性能和破坏准则[J]. 建筑材料学报, 2020, 23(2):454-459.WANG Siwei, SUN Fengtao, WU Hua. Mechanical properties and failure criteria of recycled coarse aggregate plastic concrete under triaxial stress[J]. Journal of Building Materials,2020,23(2):454-459(in Chinese). [20] CHEN Y L, CHEN Z P, XU J J, et al. Performance evaluation of recycled aggregate concrete under multiaxial compression[J]. Construction and Building Materials,2019,229:116935. doi: 10.1016/j.conbuildmat.2019.116935 [21] XU J J, CHEN Y L, XIE T Y, et al. Prediction of triaxial behavior of recycled aggregate concrete using multivariable regression and artificial neural network techniques[J]. Construction and Building Materials,2019,226:534-554. doi: 10.1016/j.conbuildmat.2019.07.155 [22] DENG Z H, WANG Y M, SHENG J, et al. Strength and deformation of recycled aggregate concrete under triaxial compression[J]. Construction and Building Materials,2017,156:1043-1052. doi: 10.1016/j.conbuildmat.2017.08.189 [23] 周甲佳, 潘金龙, 姚少科, 等. 高强高性能混凝土三轴拉压压力学性能试验研究[J]. 工程力学, 2018, 35(4):144-150.ZHOU Jiajia, PAN Jinlong, YAO Shaoke, et al. Experimental study on triaxial compression and tension properties of high strength and high performance concrete[J]. Engineering Mechanics,2018,35(4):144-150(in Chinese). [24] 李毅, 程桦, 张亮亮. 不同围压下C60混凝土三轴压缩过程能量分析[J]. 应用力学学报, 2020, 37(5):2086-2093, 2326.LI Yi, CHENG Hua, ZHANG Liangliang. Energy analysis of C60 concrete under triaxial compression under different confining pressures[J]. Chinese Journal of Applied Mechanics,2020,37(5):2086-2093, 2326(in Chinese). [25] 陈宗平, 陈宇良, 姚侃. 再生混凝土三轴受压力学性能试验及其影响因素[J]. 建筑结构学报, 2014, 35(12):72-81. doi: 10.14006/j.jzjgxb.2014.12.010CHEN Zongping, CHEN Yuliang, YAO Kan. Experimental research on mechanical behavior and influence factor of recycled coarse aggregate concretes under triaxial compression[J]. Journal of Building Structures,2014,35(12):72-81(in Chinese). doi: 10.14006/j.jzjgxb.2014.12.010 -

下载:

下载: