Research on interlayer properties of short fiber intercalated carbon fiber/epoxy composites

-

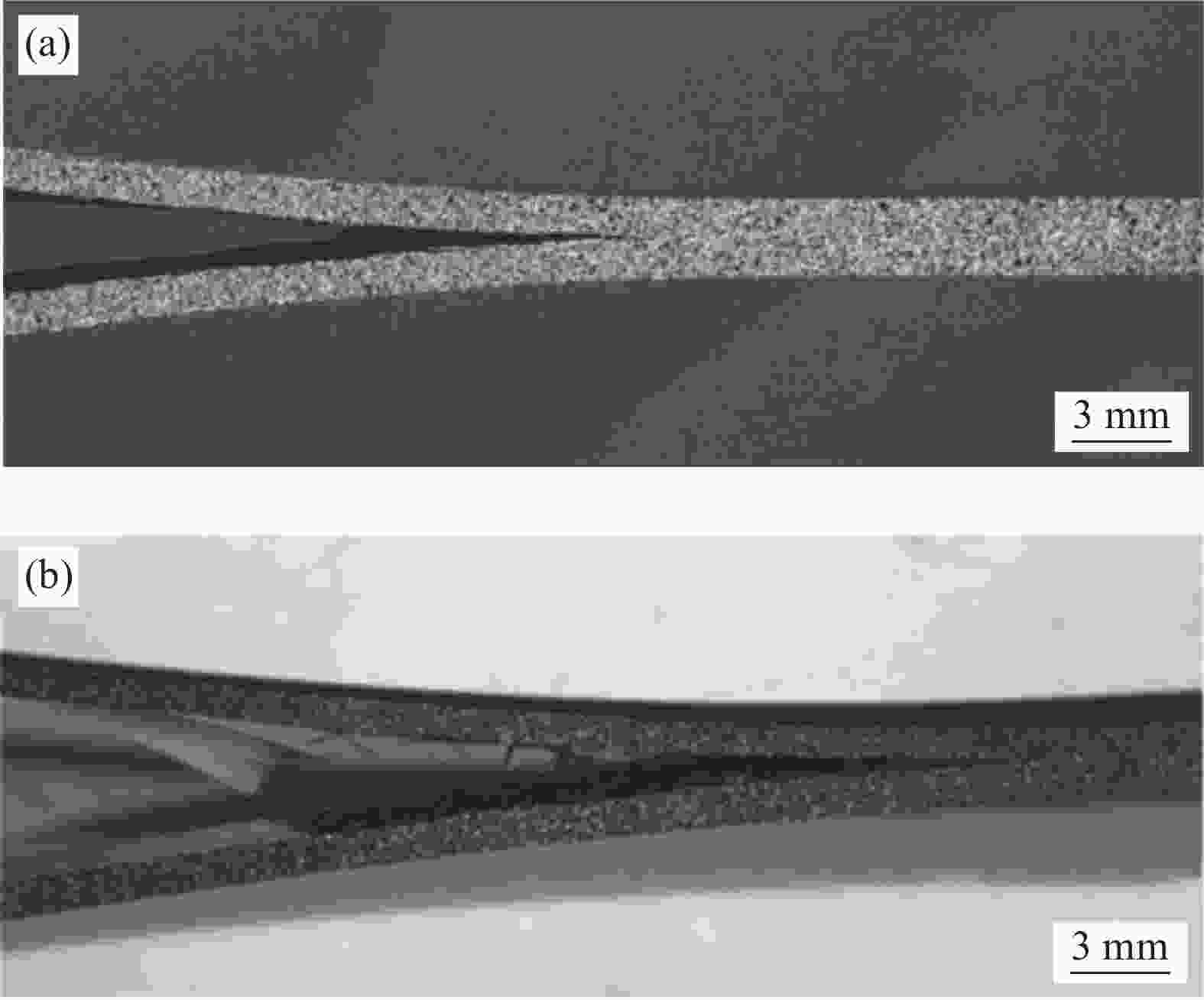

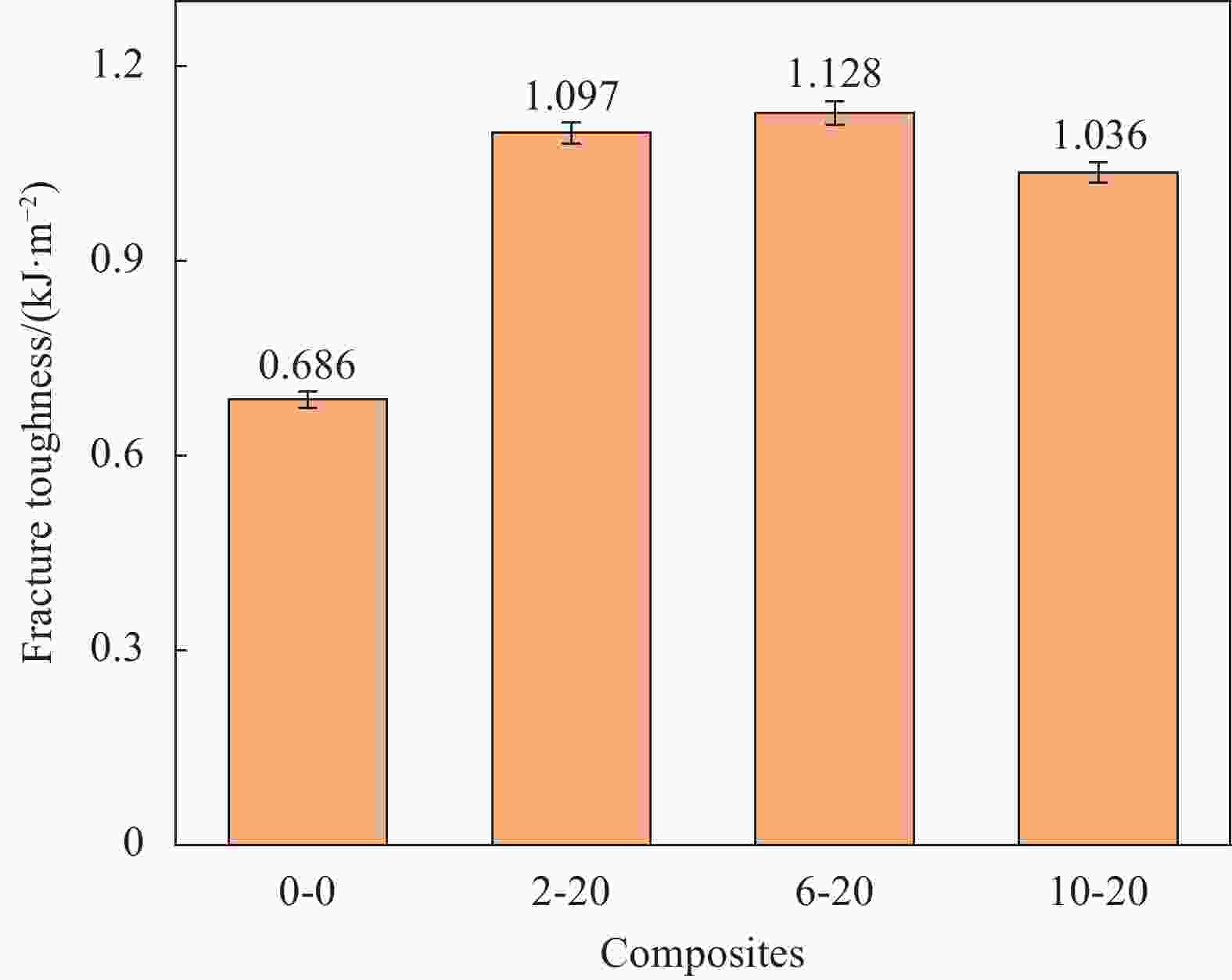

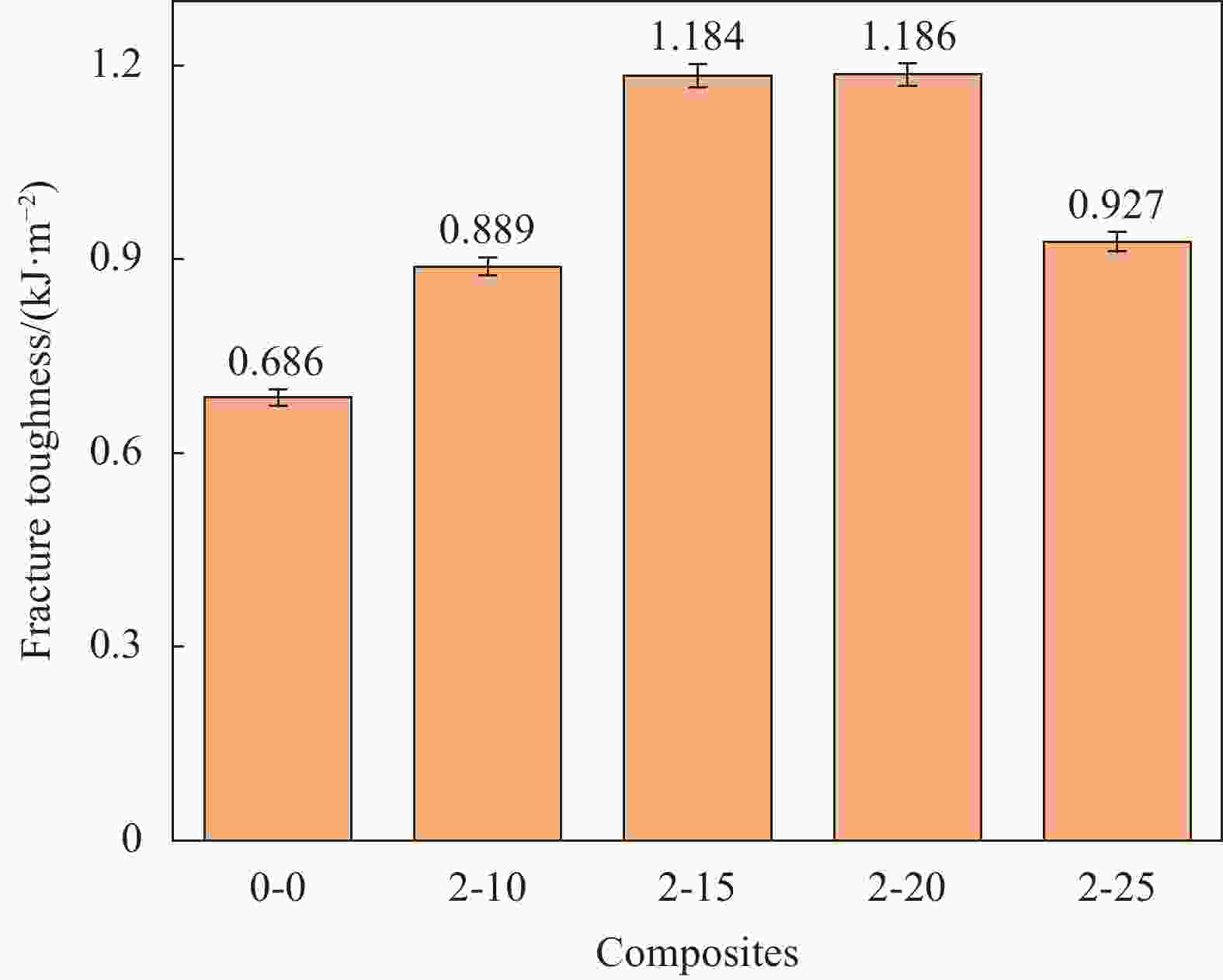

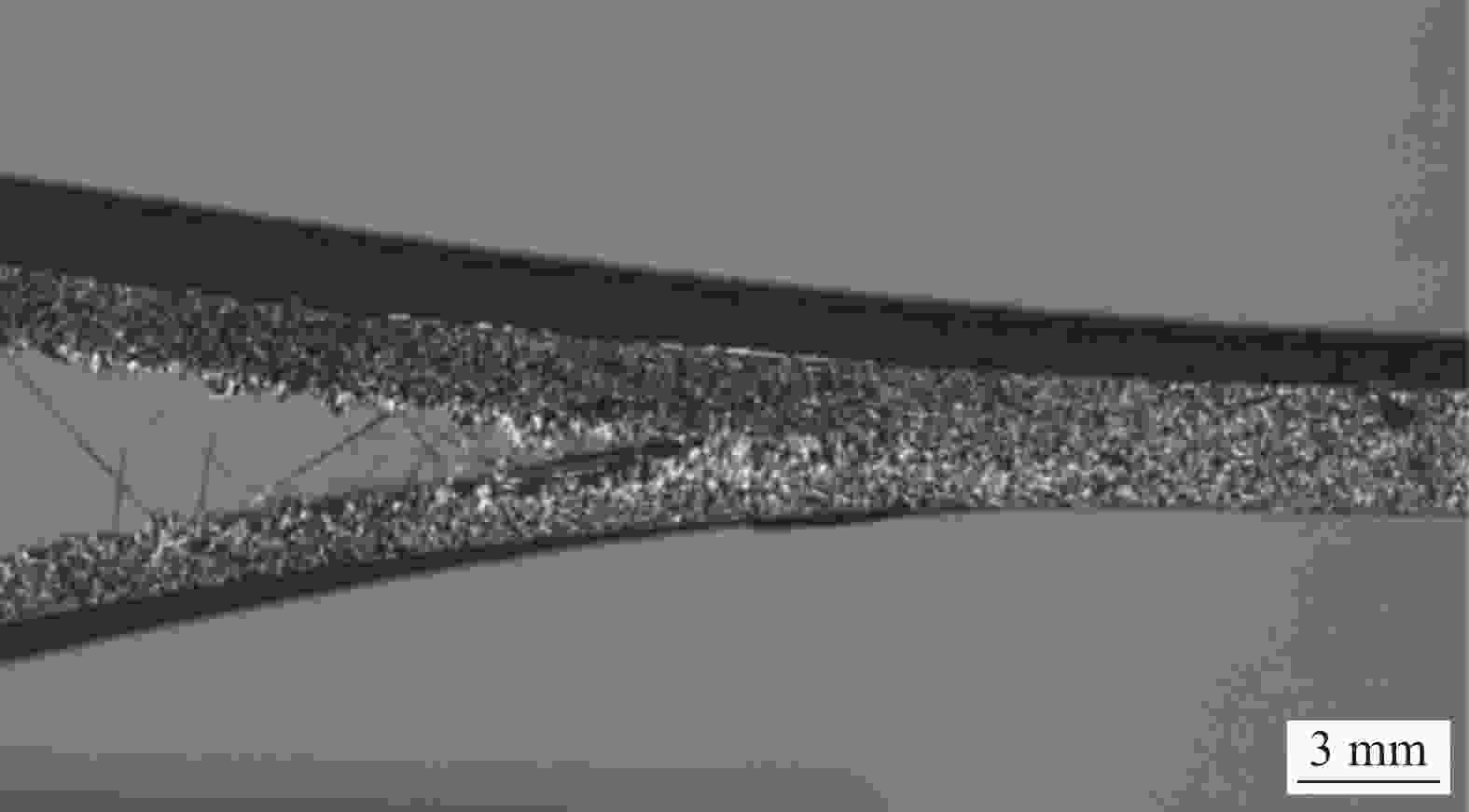

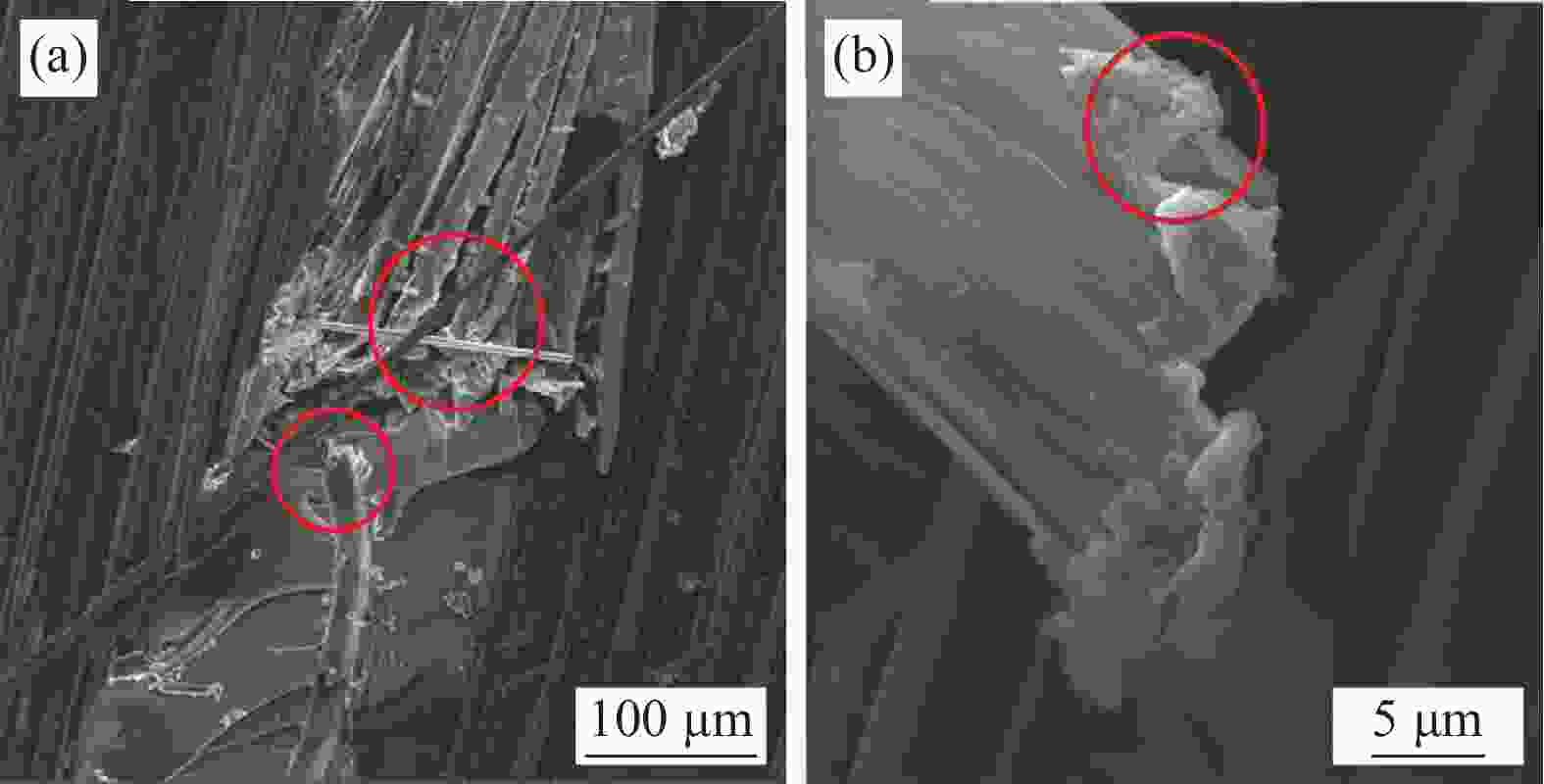

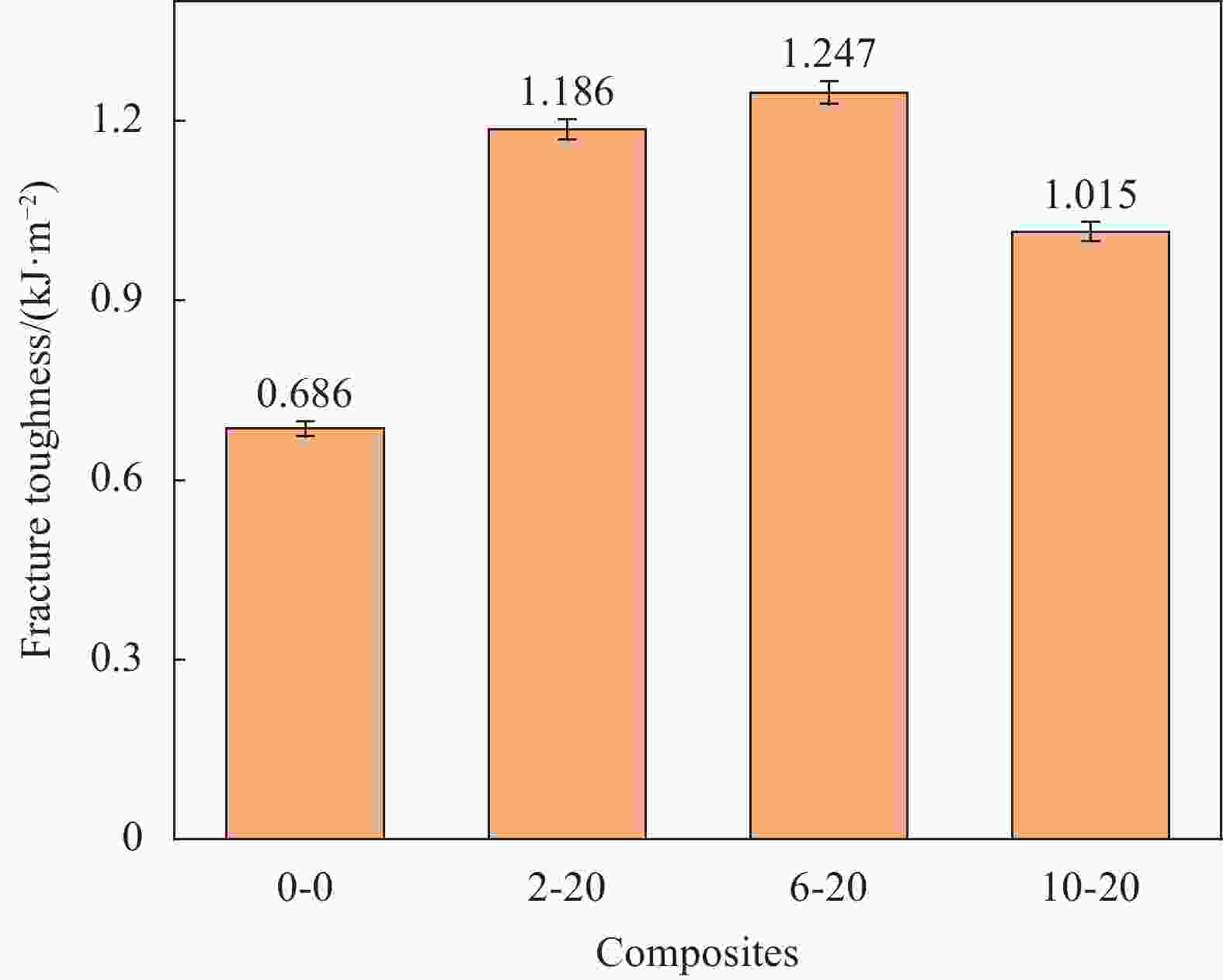

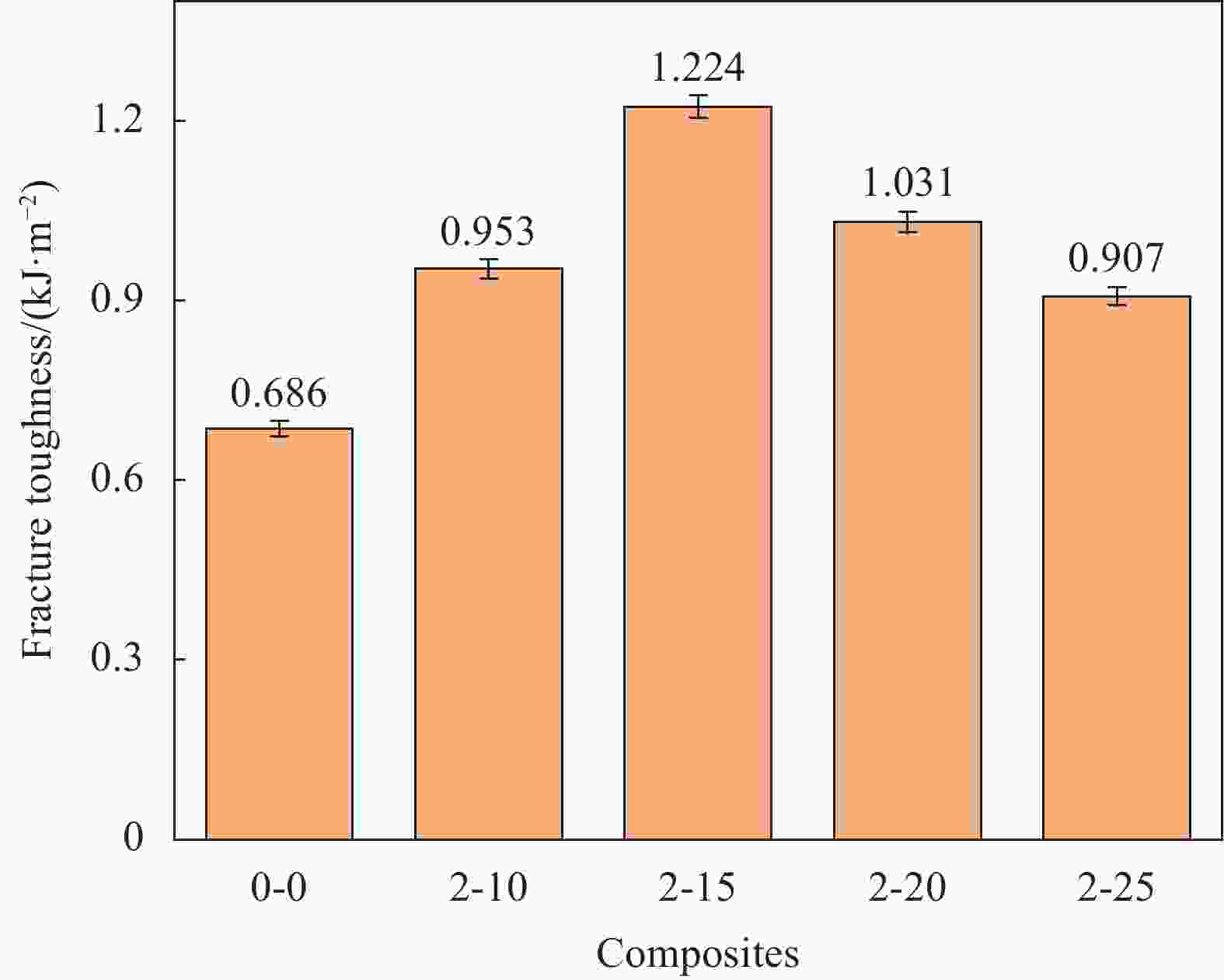

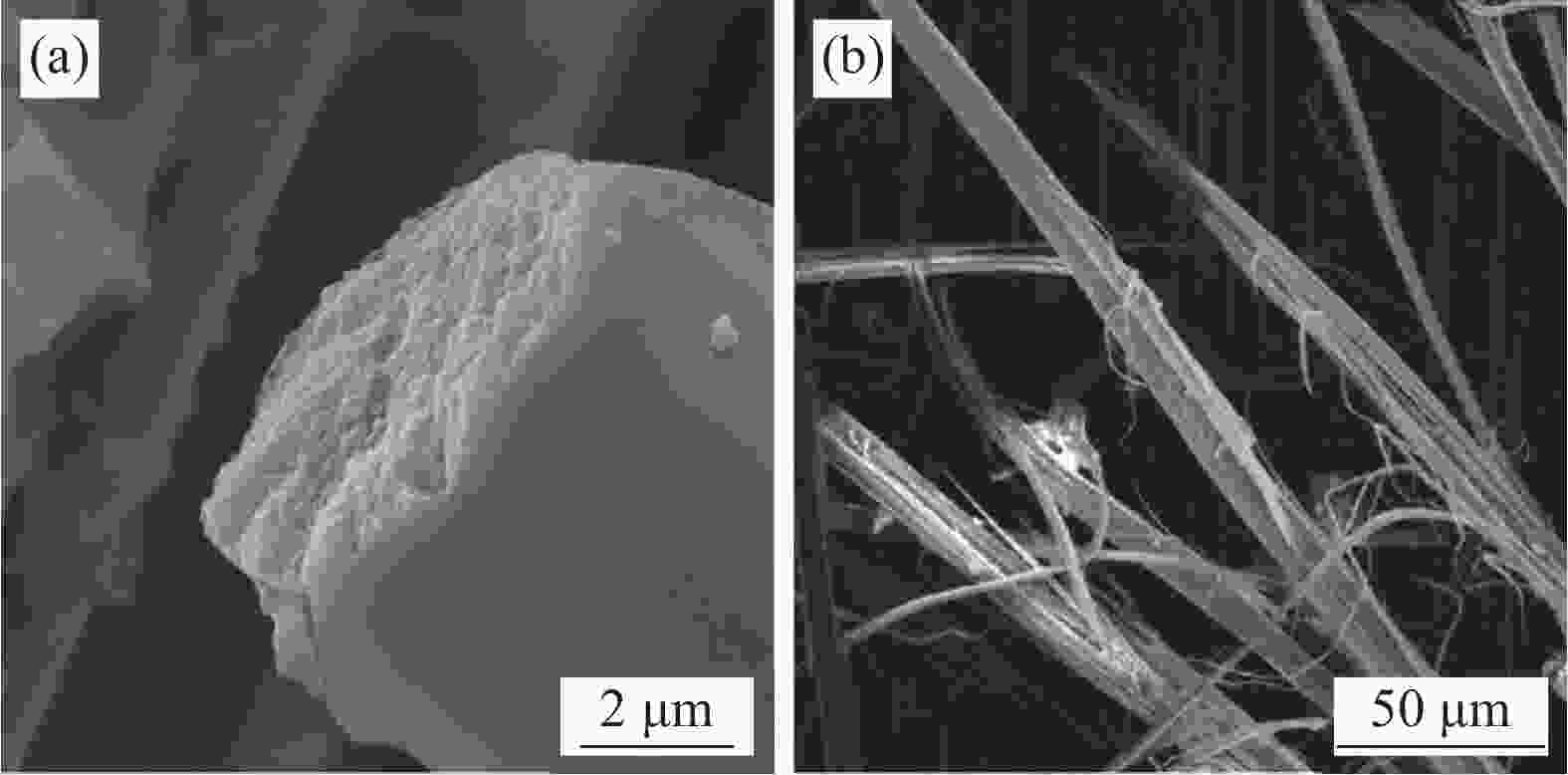

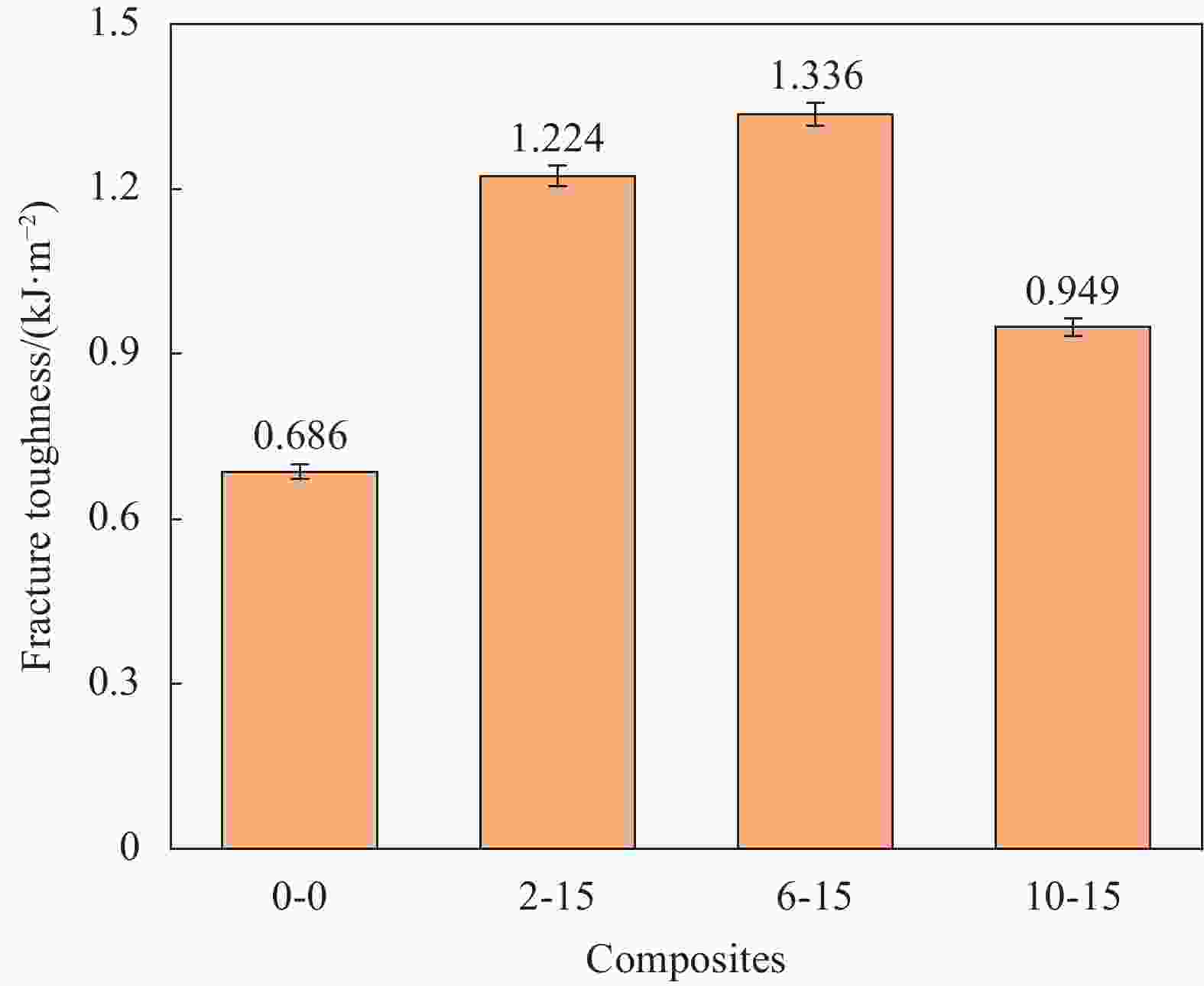

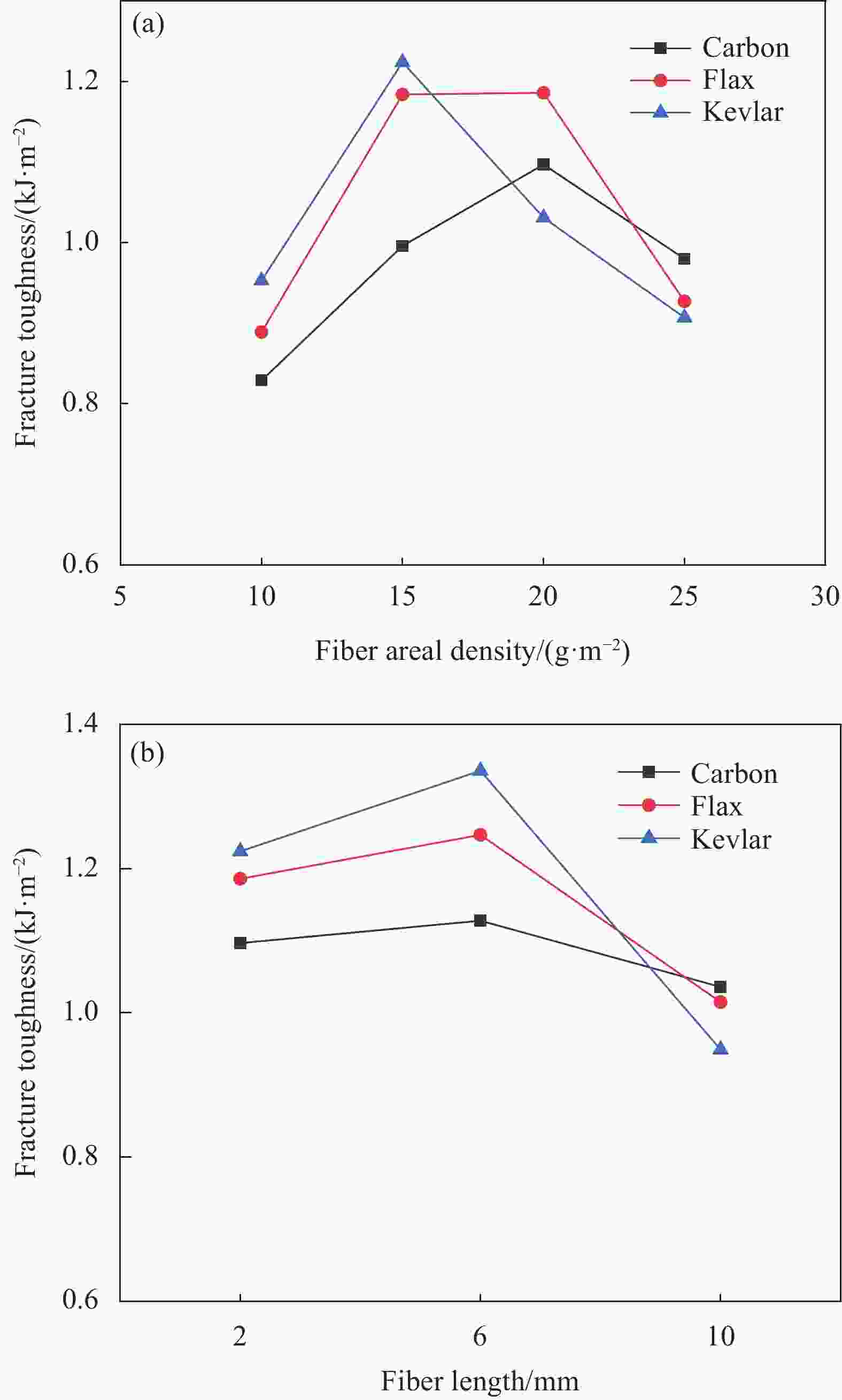

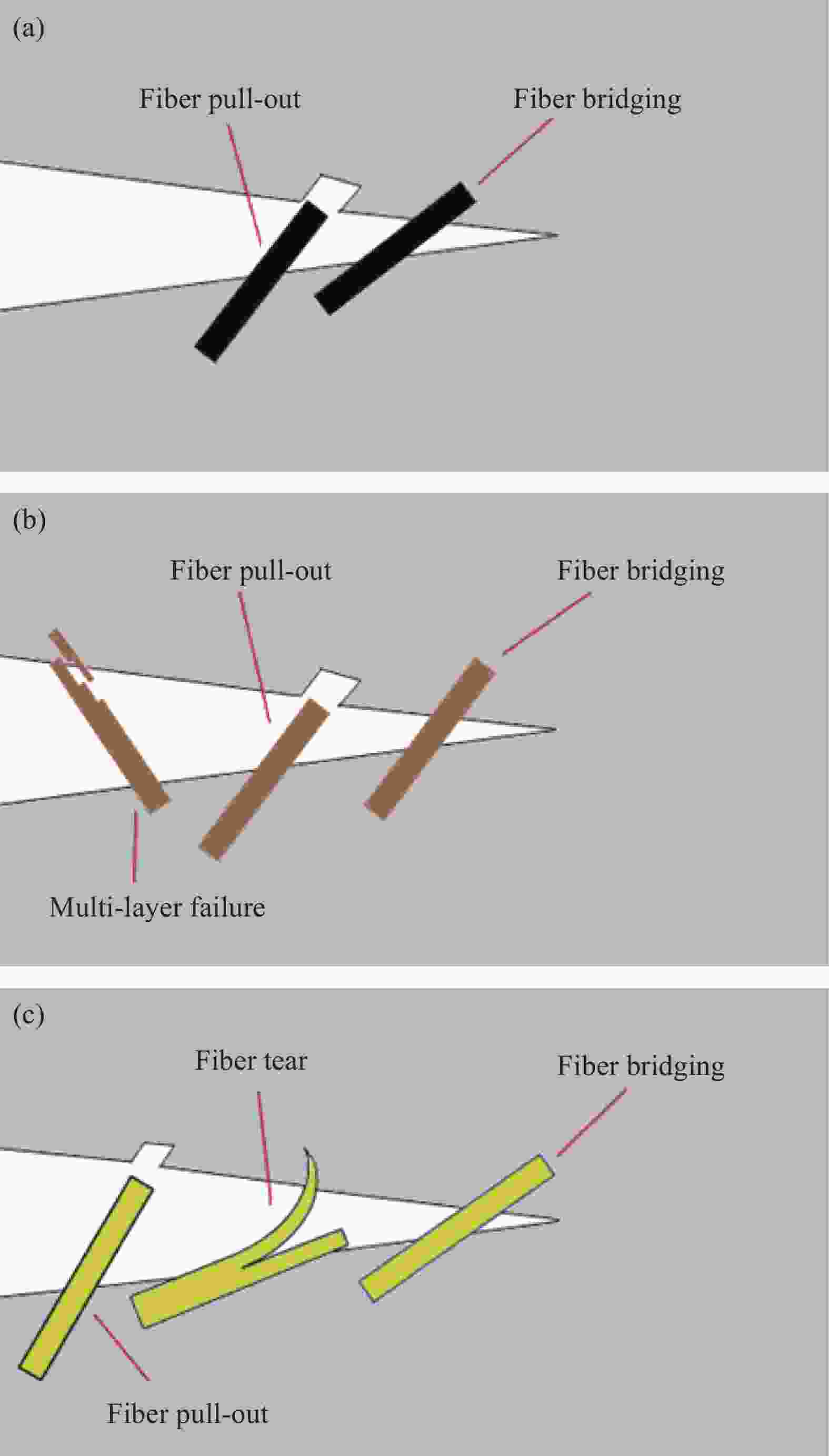

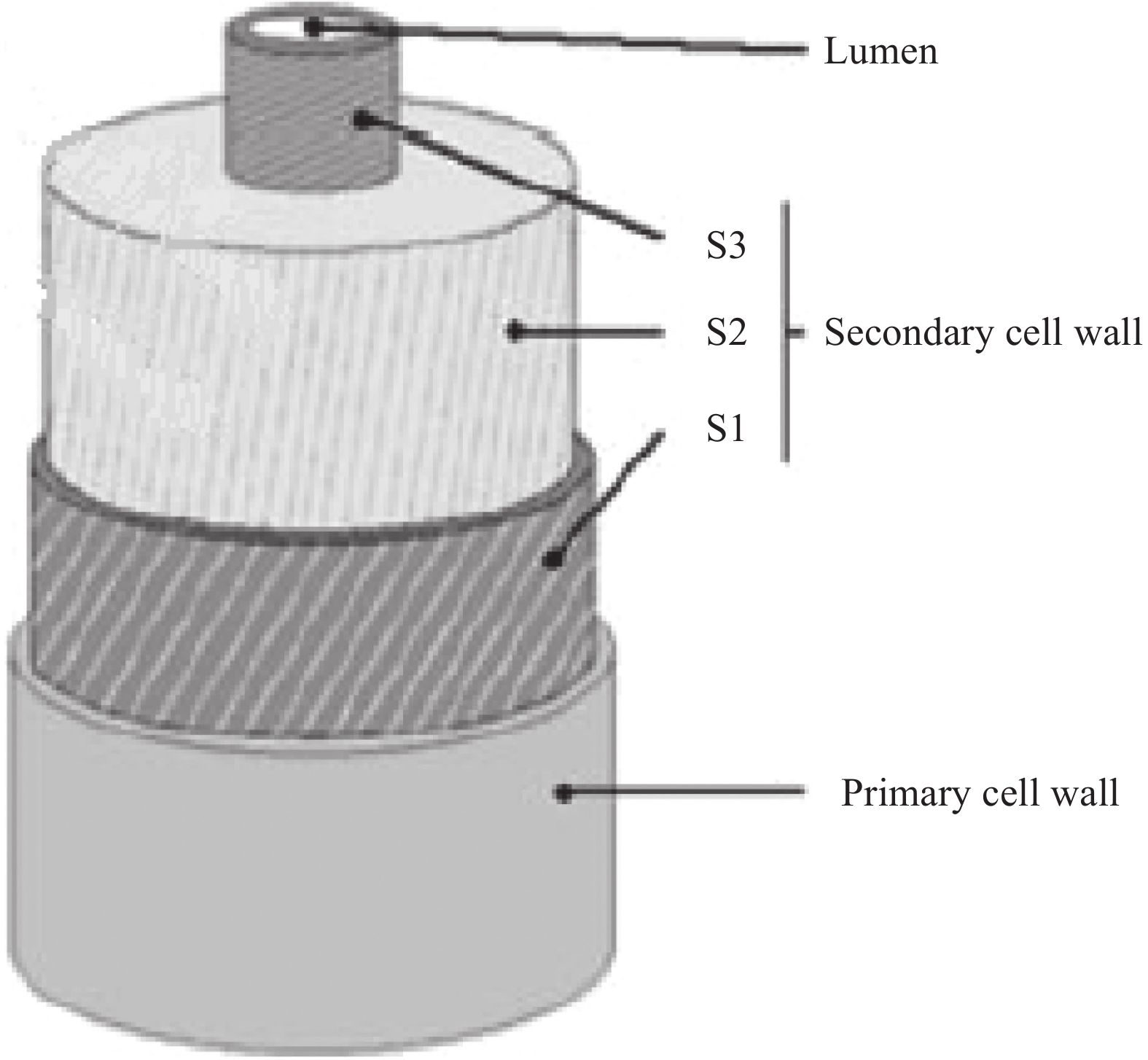

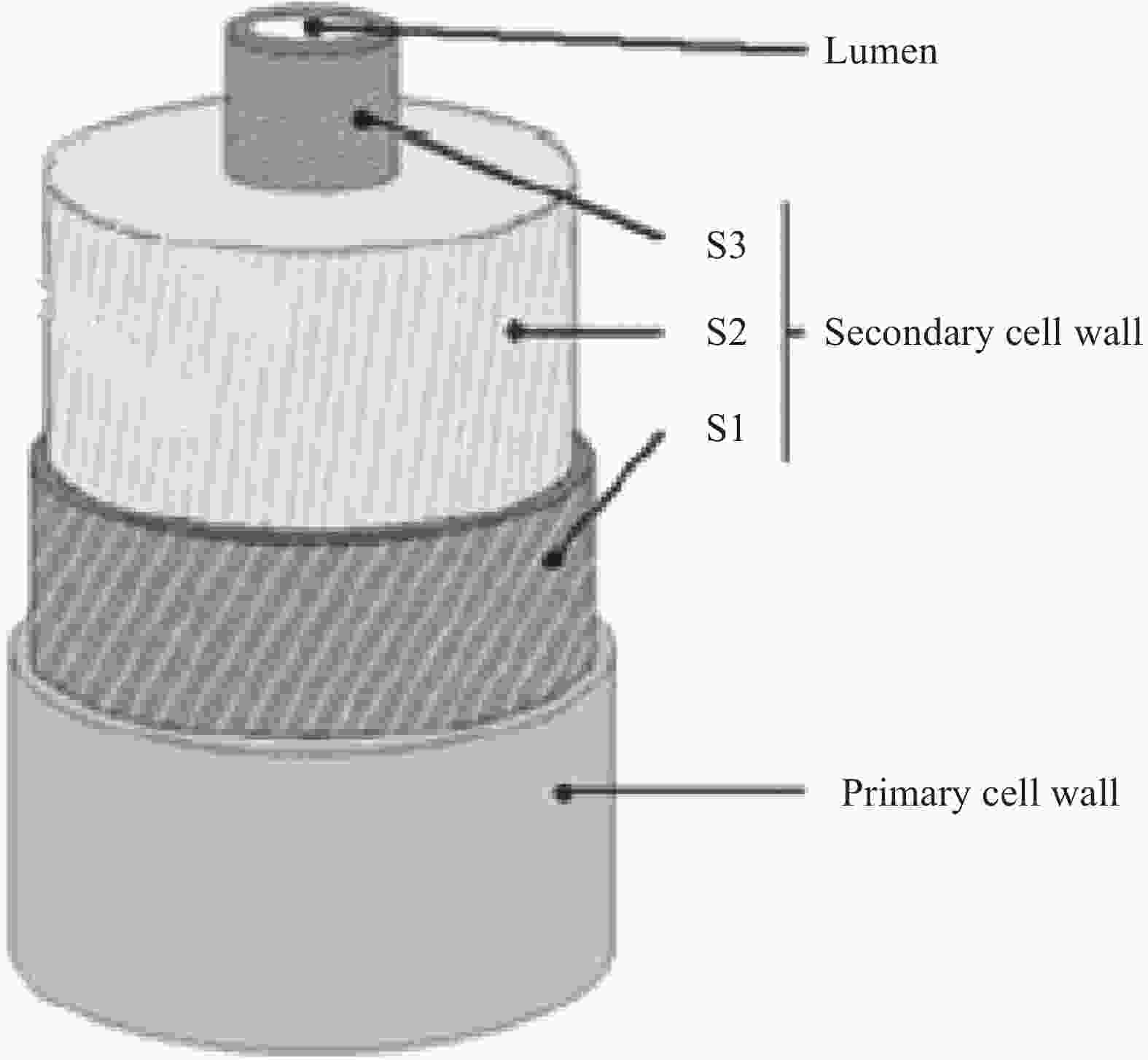

摘要: 碳纤维/环氧树脂复合材料因具有高的比强度、比模量、抗疲劳性好等优点,已在航空航天、轨道交通、汽车等领域得到越来越广泛的应用。然而作为碳纤维/环氧树脂复合材料的主要结构形式之一的层合板结构,由于厚度方向没有纤维,导致层间性能最弱,极易发生分层破坏,影响结构的承载性能。短纤维层间插层增韧是改善碳纤维/环氧树脂复合材料层间性能的有效手段,近年来,国内外学者开展了大量的相关研究工作,但仍缺乏短纤维层间插层增韧的系统研究。本论文选用碳纤维、亚麻纤维及Kevlar纤维作为插层短纤维,系统地分析和讨论了短纤维种类、插层面密度和纤维长度对碳纤维/环氧树脂复合材料层间增韧效果的影响。结果表明,对于不同的短纤维插层,均存在着随着短纤维长度和插层面密度的增加,复合材料层间断裂韧性先上升后下降的趋势。在此基础上揭示了不同种类纤维的增韧机制,纤维桥联、裂纹扩展路径改变、纤维多层级破坏及纵向撕裂等均有助于复合材料层间断裂韧性的提高,研究结果为短纤维插层增韧复合材料的结构设计奠定了基础。Abstract: Carbon fiber/epoxy composites had been widely used in aerospace, rail transit, automobile and other fields because of their high specific strength, specific modulus and good fatigue resistance. However, as one of the main structural forms of carbon fiber/epoxy composites, the laminate structure had the weakest interlayer performance due to the lack of fiber in the thickness direction, which was prone to delamination failure and affects the bearing performance of the structure. Short fiber intercalation toughening was an effective means to improve the interlaminar properties of carbon fiber/epoxy composites. In recent years, scholars at home and abroad had carried out a lot of relevant research work, but there was still a lack of systematic research on short fiber intercalation toughening. In this work, carbon fiber, flax fiber and Kevlar fiber were selected as intercalated short fibers. The effects of short fiber types, intercalation layer density and fiber length on the interlaminar toughening effect of carbon fiber/epoxy composites were systematically analyzed and discussed. The results show that for different short fiber intercalations, the interlaminar fracture toughness of composites increases first and then decreases with the increase of short fiber length and intercalation layer density. On this basis, the toughening mechanisms of different kinds of fibers are revealed. Fiber bridging, change of crack propagation path, multi-layer failure and longitudinal tearing of fibers are helpful to improve the interlaminar fracture toughness of composites. The research results lay a foundation for the structural design of short fiber intercalated toughened composites.

-

表 1 短纤维插层与短纤维参数对应表

Table 1. Corresponding table of short fiber intercalation and short fiber parameters

Short fiber intercalation Short fiber length/mm Short fiber intercalation density/(g·m−2) 0-0 — — 2-10 2 10 2-15 2 15 2-20 2 20 2-25 2 25 6-15 6 15 6-20 6 20 10-15 10 15 10-20 10 20 Notes: x-y—Laminates with short fibers at the length of x mm and the areal density of y g/m2; 0-0—There was no interlayer short fibers involved in the composites, which was the control group. 表 2 短纤维插层碳纤维/环氧树脂复合材料的拉伸和弯曲试验结果

Table 2. Tensile and flexural test results of short fiber intercalated carbon fiber/epoxy composites

Short fiber intercalation Tensile strength/MPa Tensile modulus/GPa Flexural strength/MPa Flexural modulus/GPa 0-0 1704.4±102.3 103.6±7.2 670.8±21.7 143.9±4.4 Carbon fiber 6-20 1772.1±114.1 106.7±6.4 663.8±19.7 146.1±4.5 Flax fiber 6-20 1738.2±96.9 107.4±7.9 666.3±23.3 142.6±4.3 Kevlar fiber 6-15 1792.5±123.6 105.8±6.3 686.1±20.6 154.4±5.2 -

[1] CHOI N S, KINLOCH A J, WILLIAMS J G. Delamination fracture of multidirectional carbon-fiber/epoxy composites under mode I, mode II and mixed-mode I/II loading[J]. Journal of Composite Materials,1999,33(1):73-100. [2] 矫桂琼, 宁荣昌, 卢智先, 等. 层间增韧复合材料研究[J]. 宇航材料工艺, 2001,31(4):36-39. doi: 10.3969/j.issn.1007-2330.2001.04.008JIAO Guiqiong, NING Rongchang, LU Zhixian, et al. Study on interlaminar toughened composites[J]. Aerospace Materials & Technology,2001,31(4):36-39(in Chinese). doi: 10.3969/j.issn.1007-2330.2001.04.008 [3] 张静静, 谷锦, 陈勇, 等. 环氧树脂增韧改性研究进展[J]. 材料开发与应用, 2012, 27(6):111-116.ZHANG Jingjing, GU Jin, CHEN Yong, et al. Research progress on toughening and modification of epoxy resin[J]. Development and Application of Materials,2012,27(6):111-116(in Chinese). [4] DADFAR M R, GHADAMI F. Effect of rubber modification on fracture toughness properties of glass reinforced hot cured epoxy composites[J]. Materials and Design,2013,47:16-20. doi: 10.1016/j.matdes.2012.12.035 [5] GARG A C, MAI Y W. Failure mechanisms in toughened epoxy resins-A review[J]. Composites Science and Tech-nology,1988,31(3):179-223. doi: 10.1016/0266-3538(88)90009-7 [6] ZHOU Y, PERVIN F, LEWIS L, et al. Fabrication and characterization of carbon/epoxy composites mixed with multi-walled carbon nanotubes[J]. Materials Science and Engineering A,2008,475(1/2):157-165. doi: 10.1016/j.msea.2007.04.043 [7] HUBERT P, ASHRAFI B, ADHIKARI K, et al. Synthesis and characterization of carbon nanotubere inforced epoxy: Correlation between viscosity and elastic modulus[J]. Composites Science and Technology,2009,69(14):2274-2280. doi: 10.1016/j.compscitech.2009.04.023 [8] SHAY H, HERMAN L, ANTHONY G, et al. Mode I and mode II fracture energy of MWCNT reinforced nanofibrilmats interleaved carbon/epoxy laminates[J]. Composites Science and Technology,2014,90:48-56. doi: 10.1016/j.compscitech.2013.10.013 [9] 徐亚娟, 刘少兵. 热塑性树脂增韧环氧树脂研究进展[J]. 热固性树脂, 2010, 25(6):43-47.XU Yajuan, LIU Shaobin. Research progress of epoxy resin toughened by thermoplastic resin[J]. Thermosetting Resin,2010,25(6):43-47(in Chinese). [10] LEE L, RUDOV-CLARK S, MOURITZ A P, et al. Effect of weaving damage on the tensile properties of three-dimensional woven composites[J]. Composite Structures,2002,57(1/4):405-413. doi: 10.1016/S0263-8223(02)00108-3 [11] DRANSFIELD K A, JAIN L K, MAI Y W. On the effects of stitching in CFRPs—I:Mode I delamination toughness[J]. Composites Science and Technology,1998,58(6):815-827. doi: 10.1016/S0266-3538(97)00229-7 [12] 陈静, 王海雷. 复合材料缝合技术的研究及应用进展[J]. 新材料产业, 2018, 95(6):38-41.CHEN Jing, WANG Hailei. Research and application progress of composite suture technology[J]. Advanced Mater-ials Industry,2018,95(6):38-41(in Chinese). [13] MOURITZ A. Review of Z-pinned composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2007,38:2383-2397. doi: 10.1016/j.compositesa.2007.08.016 [14] GARCIA E J, WARDLE B L, HART A J. Joining prepreg composite interfaces with aligned carbon nanotubes[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1065-1070. doi: 10.1016/j.compositesa.2008.03.011 [15] KHAN S U, KIM J K. Improved interlaminar shear properties of multiscale carbon fiber composites with bucky paper interleaves made from carbon nanofibers[J]. Carbon,2012,50(14):5265-5277. doi: 10.1016/j.carbon.2012.07.011 [16] LI B, LIU D, LI G, et al. Multifold interface and multilevel crack propagation mechanisms of graphene oxide/polyurethane/epoxy membranes interlaminar-toughened carbon fiber-reinforced polymer composites[J]. Journal of Materials Science,2018,53(23):15939-15951. doi: 10.1007/s10853-018-2753-y [17] 姚佳伟, 刘梦瑶, 牛一凡. PEK-C膜层间增韧碳纤维/环氧树脂复合材料的力学性能[J]. 复合材料学报, 2019, 36(5):1083-1091.YAO Jiawei, LIU Mengyao, NIU Yifan. Mechanical properties of PEK-C interlayer toughened carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2019,36(5):1083-1091(in Chinese). [18] SOHN M S, HU X. Processing of carbon-fibre/epoxy composites with cost-effective interlaminar reinforcement[J]. Composites Science and Technology,1998,58:211-220. doi: 10.1016/S0266-3538(97)00114-0 [19] PARK B Y, KIM S C. A study of the interlaminar fracture toughness of a carbon-fiber/epoxy composite containing surface-modified short Kevlar fibers[J]. Composites Science and Technology,1998,58(10):1599-1606. doi: 10.1016/S0266-3538(97)00224-8 [20] WALKER L, HU X. Comparison of carbon fibre/epoxy composites reinforced by short aramid and carbon fibres[J]. Scripta Materialia,1999,41(6):575-582. doi: 10.1016/S1359-6462(99)00193-1 [21] 刘浩洋, 吕超雨, 石姗姗, 等. 芳纶纤维增韧碳纤维增强环氧树脂复合材料-铝蜂窝夹芯结构界面性能和增韧机制[J]. 复合材料学报, 2022, 39(2): 559-567.LIU Haoyang, LV Chaoyu, SHI Shanshan, et al. Interfacial properties and toughening mechanism of aramid fiber toughened carbon fiber reinforced epoxy resin composite aluminum honeycomb sandwich structure[J]. Acta Mater-iae Compositae Sinica, 2022, 39(2): 559-567(in Chinese). [22] YASAEE M, BOND I P, TRASK R S, et al. Mode I interfacial toughening through discontinuous interleaves for damage suppression and control[J]. Composites Part A: Applied Science and Manufacturing,2012,43:198-207. doi: 10.1016/j.compositesa.2011.10.009 [23] DOMENGES B, CHARLET K. Direct insights on flax fiber structure by focused ion beam microscopy[J]. Microscopy and Microanalysis,2010,16(2):175-182. doi: 10.1017/S1431927609991292 [24] American Society for Testing Materials International. Test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528[S]. West Conshohocken: American Society for Testing Materials International, 2013. [25] American Society for Testing Materials International. Test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M[S]. West Conshohocken: American Society for Testing Materials International, 2017. [26] American Society for Testing Materials International. Test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: ASTM D790[S]. West Conshohocken: American Society for Testing Materials International, 2017. [27] LI Y, WANG D, MA H. Improving interlaminar fracture toughness of flax fiber/epoxy composites with chopped flax yarn interleaving[J]. Science China Technological Sciences,2015,58(10):1745-1752. doi: 10.1007/s11431-015-5911-3 [28] 莫正才, 胡程耀, 霍冀川, 等. 苎麻短纤维层间增韧碳纤维/环氧树脂复合材料[J]. 复合材料学报, 2017, 34(6):1237-1244.MO Zhengcai, HU Chengyao, HUO Jichuan, et al. Interlayer-toughening carbon fiber/epoxy composites with short ramie fiber[J]. Acta Materiae Compositae Sinica,2017,34(6):1237-1244(in Chinese). -

下载:

下载: