Influence of mold temperature on hydration heat of cement under continuous negative temperature and its prediction model

-

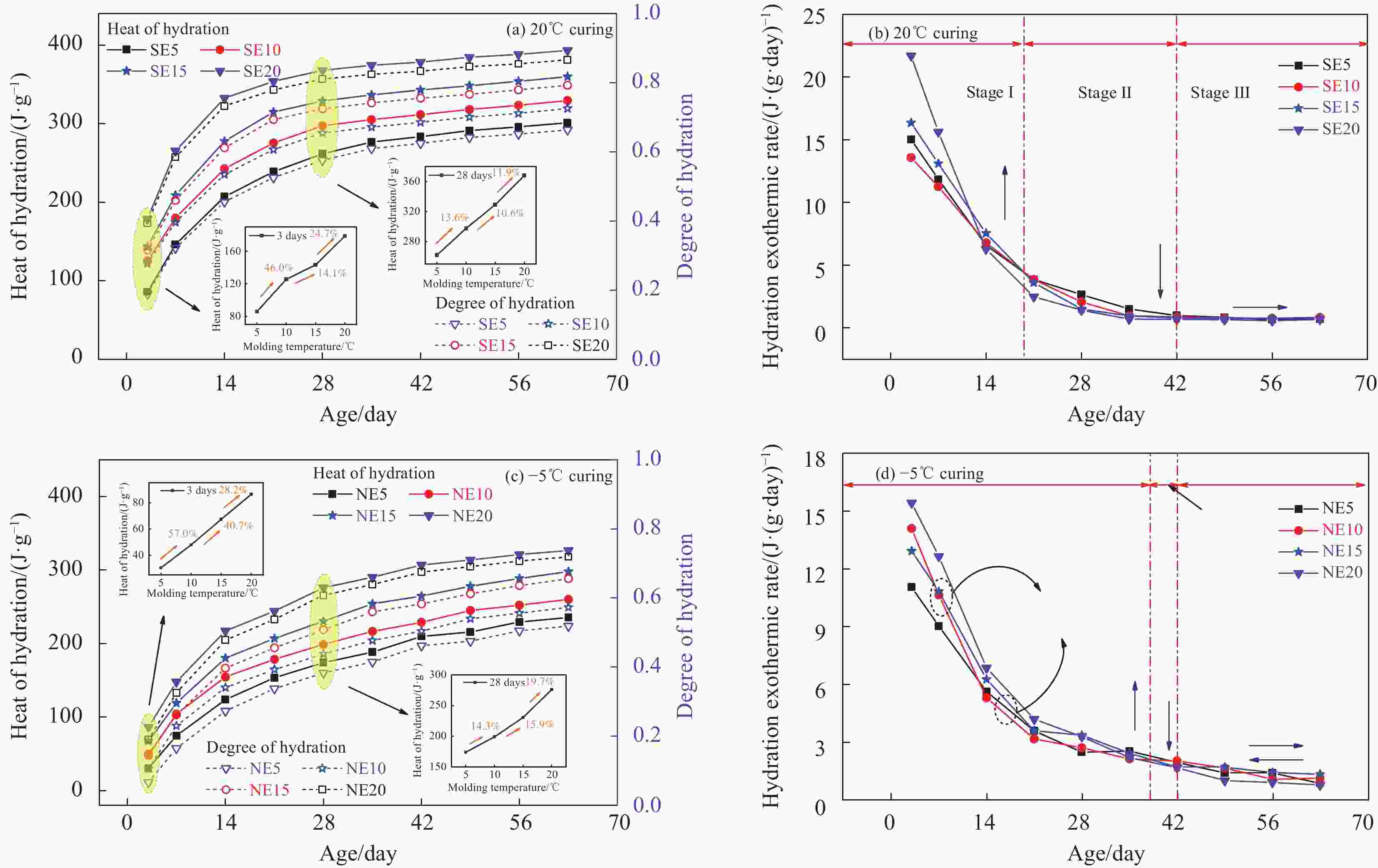

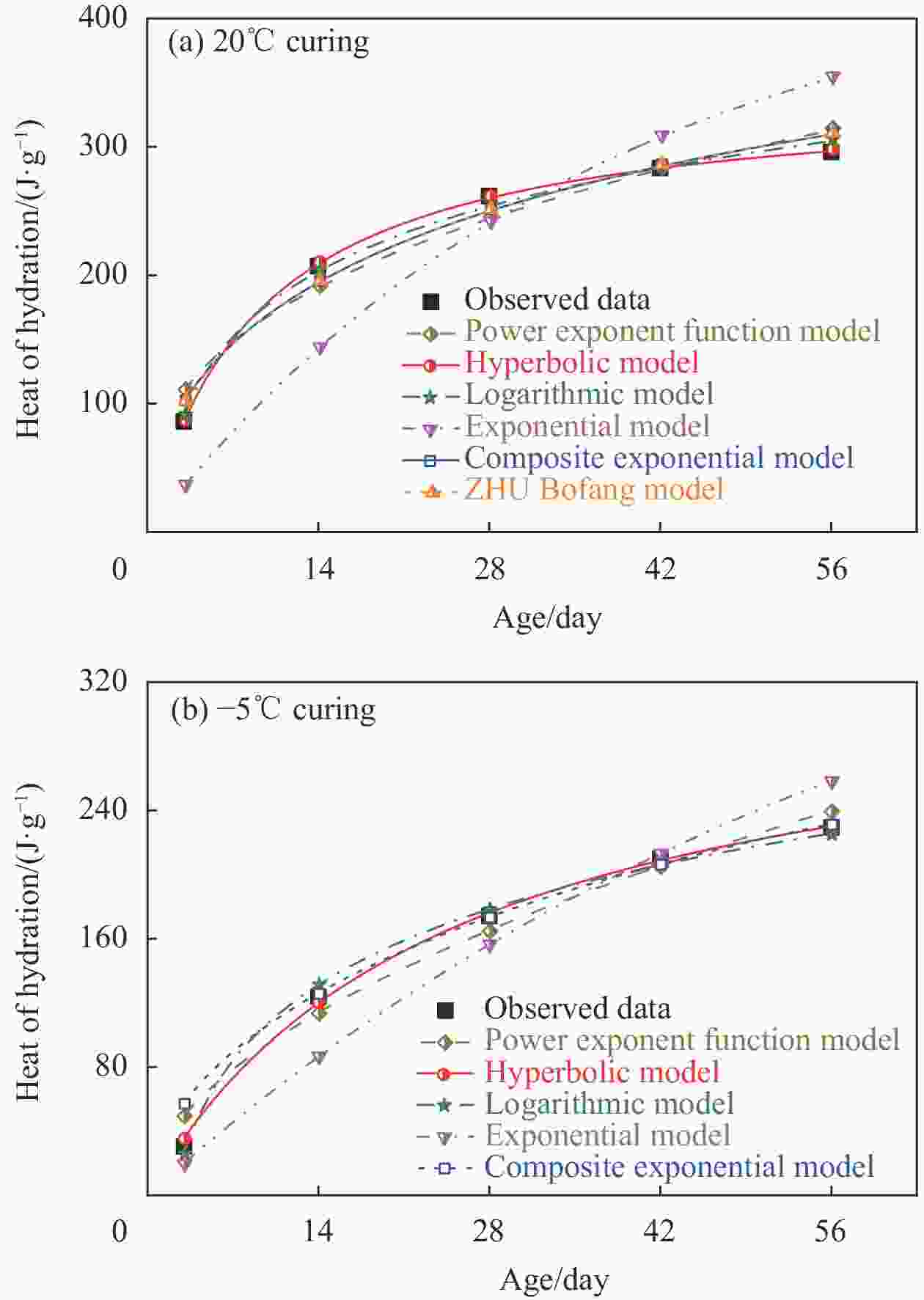

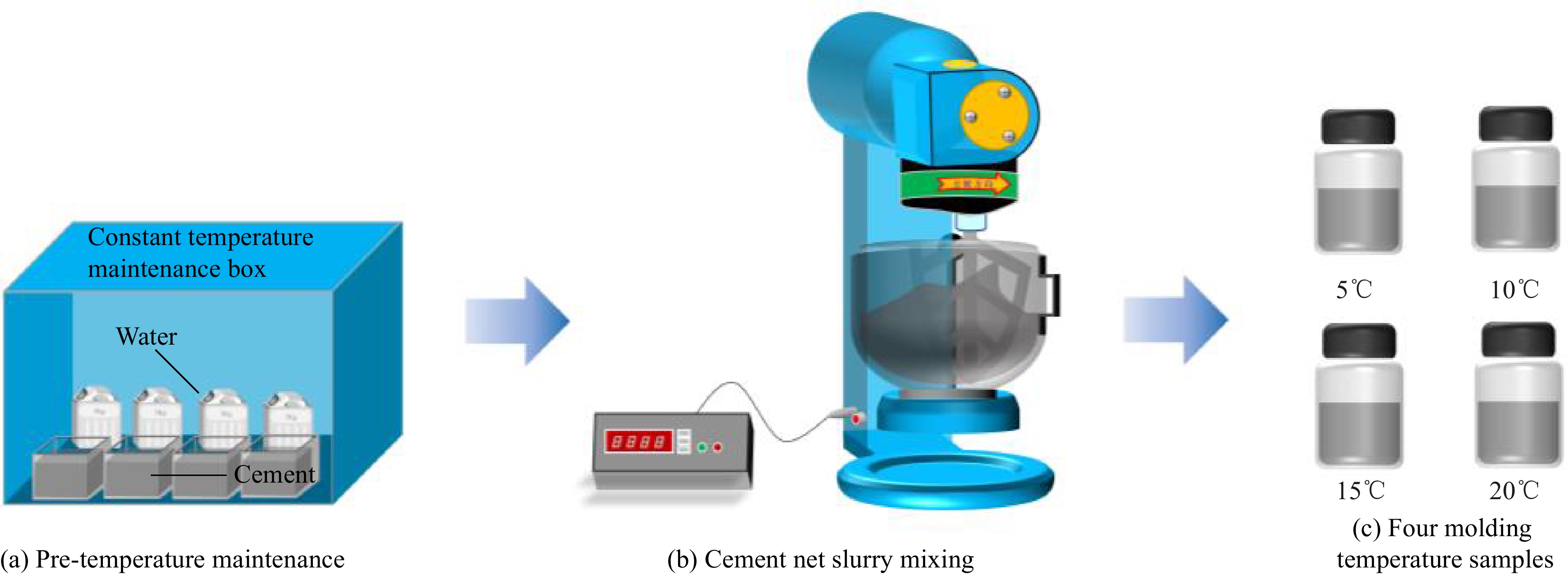

摘要: 为了研究持续−5℃与20℃养护环境下,不同入模温度的水泥水化发展规律,开展了两种养护制度下,入模温度分别为5℃、10℃、15℃、20℃水泥净浆水化热试验,分析养护制度与入模温度对水泥净浆水化热作用机制,探究了负温下水泥内部自由水相变作用对其性能影响,建立了两种养护制度下考虑入模温度(5~20℃)的水化热预测模型。研究结果表明:养护制度一定时,随着龄期与入模温度增长,水泥净浆水化热与水化程度均逐渐增大;入模温度会使20℃养护与持续−5℃养护的水化热差值峰值与水化速率等值龄期发生提前;负温与低入模温度均会使水化进程出现龄期“滞后”现象,通过分析二者共同作用的水化热发展规律及其对水泥净浆微观作用机制,建议在负温环境下,可在合理范围内适当提高入模温度,以优化混凝土宏-微观性能。Abstract: In order to study the hydration development law of cement with different molding temperatures under continuous −5°C and 20°C curing environment, the hydration heat tests of cement paste with different molding temperatures of 5°C, 10°C, 15°C and 20°C were carried out under two curing systems. The hydration heat mechanism of cement paste with different curing systems and molding temperatures was analyzed. The effect of free water phase transformation on the performance of cement under negative temperature was explored. The hydration heat prediction model considering molding temperature ( 5~20°C ) under two curing systems was established. The results show that when the curing system is fixed, the hydration heat and hydration degree of cement paste increase gradually with the increase of curing age and mold temperature. The peak value of hydration heat difference and the equivalent age of hydration rate of 20°C curing and continuous −5°C curing are advanced by the molding temperature. Both negative temperature and low molding temperature will cause the age ' lag ' phenomenon in the hydration process. By analyzing the development law of hydration heat and its microscopic mechanism of action on cement paste, it is suggested that the molding temperature can be appropriately increased within a reasonable range to optimize the macro-micro performance of concrete under the negative temperature environment.

-

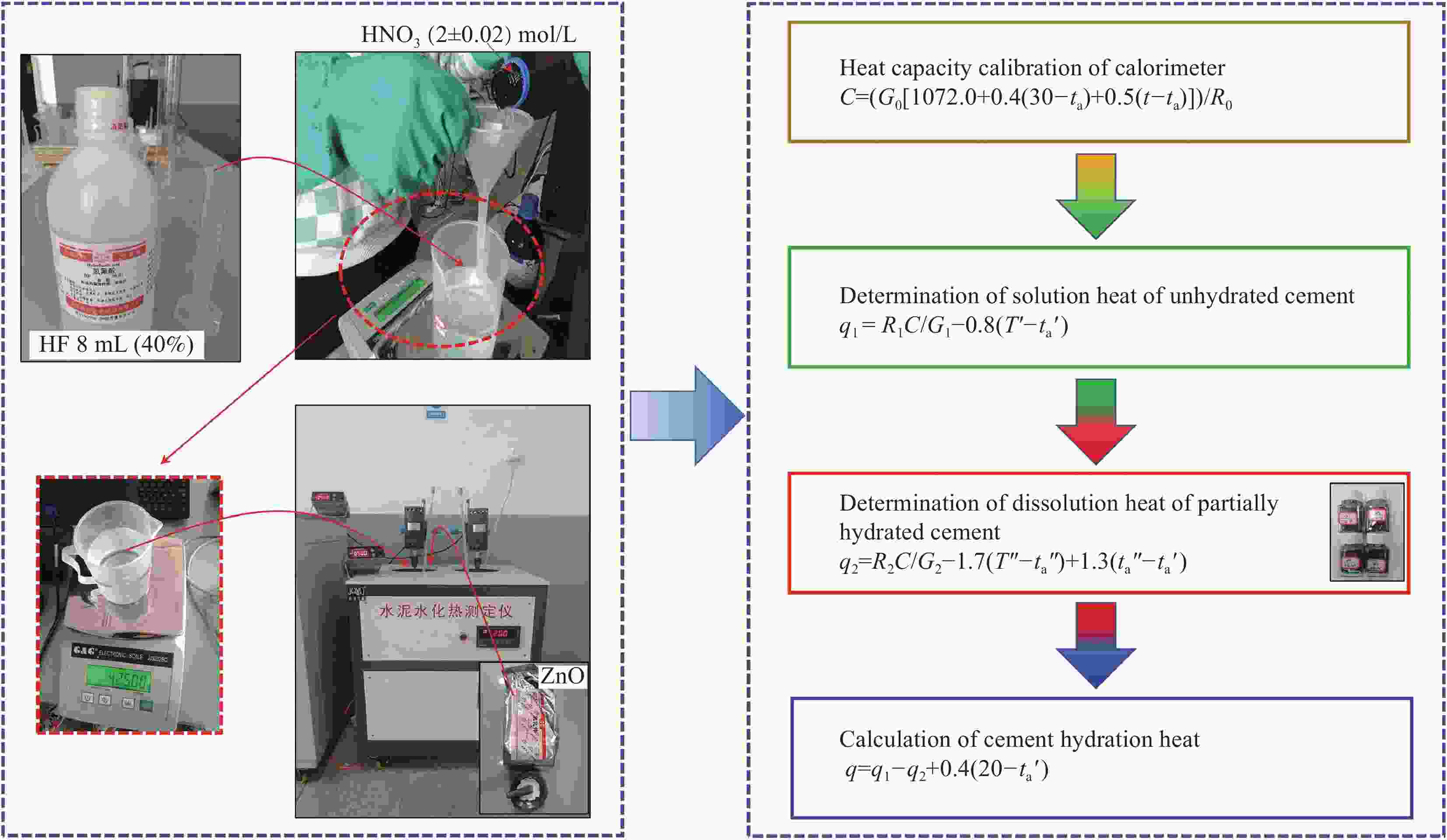

图 2 溶解热法测定水泥净浆水化热

Figure 2. Determination of hydration heat of cement paste by dissolution heat method

C—Calorimeter heat capacity (J/℃); G0—Weight of zinc oxide (g); t—Room temperature when zinc oxide is added into the calorimeter (℃); ta—Sum of the first measured reading in the dissolution period and the corresponding centigrade temperature at 0℃ of the Beckmann thermometer (℃); R0—Revised temperature rise (℃); q1—Heat of dissolution of unhydrated cement samples (J/g); G1—Quality of unhydrated cement samples after burning (g); T′—Room temperature of unhydrated cement sample filled with calorimeter (℃); ta′—Sum of the first measured reading of the unhydrated cement sample during the dissolution period and the corresponding centigrade temperature at 0℃ of the Beckmann thermometer (℃); R1—Revised temperature rise (℃); q2—Dissolution heat of hydrated cement sample after hydration for a certain age (J/g); G2—Quality of hydrated cement sample at a certain age after burning (g); T′′—Room temperature at which the hydrated cement sample is loaded into the calorimeter (℃); ta′′—Sum of the first measured reading of the hydration cement sample during the dissolution period and the corresponding centigrade temperature at 0℃ of the Beckmann thermometer (℃); R2—Revised temperature rise (℃)

表 1 P·O42.5普通硅酸盐水泥物理力学指标

Table 1. Physical and mechanical indexes of ordinary portland cement for P·O42.5

Testing

indexLoss on ignition/

wt%Water requirement of normal consistency of cement/wt% Specific surface area/(m2·kg−1) SO3/

wt%MgO/

wt%Cl−/

wt%Stability Setting time/min Mechanical property/MPa Flexural strength Compressive strength Initial

setFinal

set3 days 28 days 3 days 28 days Measured value 3.05 27.4 349 2.56 2.04 0.023 Qualification 95 140 5.5 8.9 23.4 46.6 表 2 试验用水检测指标

Table 2. Test water detection indexes

Testing

itemspH Intolerance content/

(mg·L−1)Soluble content/

(mg·L−1)SO42−/

(mg·L−1)Cl−/

(mg·L−1)Mixing conveyor water 8.02 168 112 76.6 20.3 表 3 水泥净浆配合比

Table 3. Proportion of cement paste

Serial

numberWater/

gCement/

gCuring temperature/

℃Molding temperature/

℃SE5 190 500 20 5 SE10 190 500 20 10 SE15 190 500 20 15 SE20 190 500 20 20 NE5 190 500 −5 5 NE10 190 500 −5 10 NE15 190 500 −5 15 NE20 190 500 −5 20 Notes: SE—Curing at 20°C; NE—Curing at continuous −5°C; Numbers after SE and NE—Corresponding molding temperature under two curing methods. 表 4 20℃养护水泥净浆水化热模型验证对比

Table 4. Verification and comparison of hydration heat models of cement paste for curing at 20℃

J/g Fitting model Age/day R2 7 21 35 49 63 +∞ $ {Q_t} = 73.82{t^{0.36}} $ 148.73(1.73) 220.89(−7.54) 265.48(4.01) 299.67(2.87) 328.05(8.88) +∞ 0.95125 $ {Q_t} = \dfrac{{345.07t}}{{9.15 + t}} $ 149.57(2.30) 240.35(0.61) 273.55(1.17) 290.77(0.18) 301.31(0.002) 345.07 0.99979 $ {Q_t} = 73.31\ln t + 9.39 $ 152.04(4.00) 232.58(−2.64) 270.03(2.45) 294.70(1.17) 313.12(3.92) +∞ 0.99423 $ {Q_t} = 454(1 - {{\rm{e}}^{ - 0.02695t}}) $ 78.05(46.61) 196.21(17.87) 277.23(0.16) 332.79(14.24) 370.88(23.09) 454 0.62376 $ {Q_t} = 454(1 - {{\rm{e}}^{ - {{(0.02321t)}^{0.5184}}}}) $ 146.56(0.25) 226.05(−5.38) 269.02(−2.81) 298.11(2.34) 319.66(6.09) 454 0.97585 $ {Q_t} = 454(1 - {{\rm{e}}^{ - 0.09677 \times {5^{0.23826}}{t^{0.5187}}}}) $ 146.50(0.20) 226.02(−5.39) 269.01(−2.81) 298.12(2.34) 319.68(6.10) 454 0.97585 Validation data 146.2 238.9 276.8 291.3 301.3 454 − Notes: Qt—Cumulative hydration heat of cement paste; t—Age; Qmax—Theoretical hydration heat; R2—Coefficient of determination; Relative error between verification data and calculation model in parentheses (%). 表 5 持续−5℃养护水泥净浆水化热模型验证对比

Table 5. Verification and comparison of hydration heat model of cement paste for continuous −5℃ maintenance

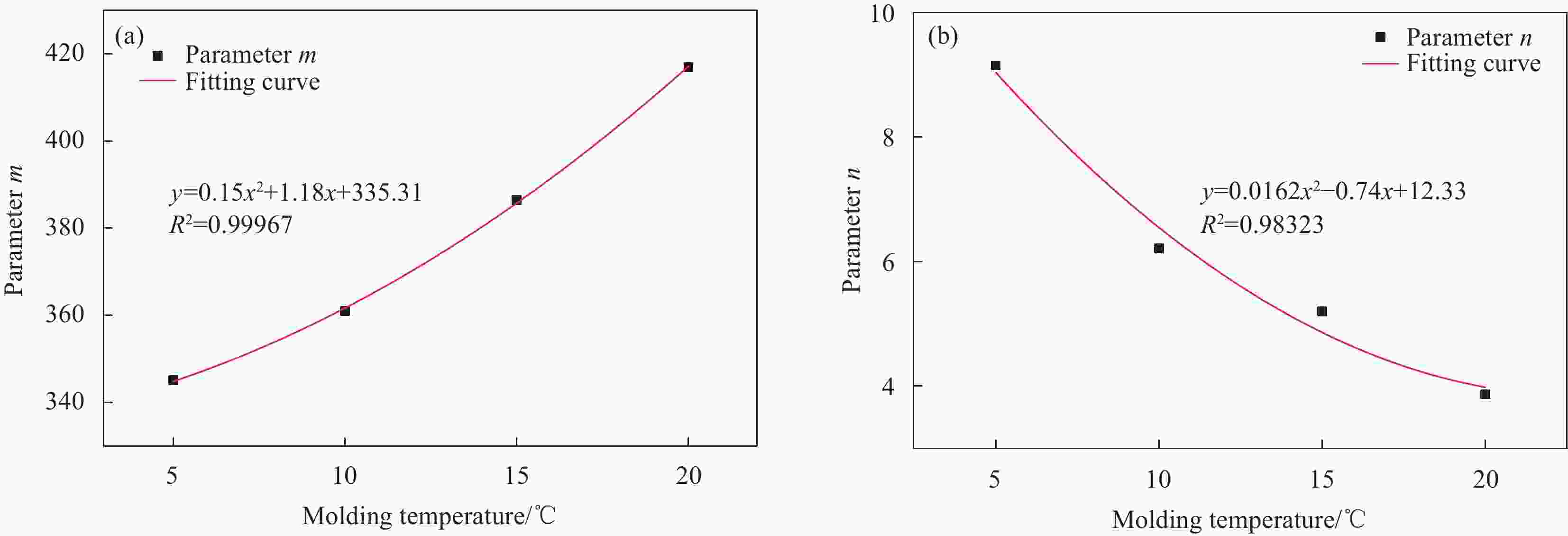

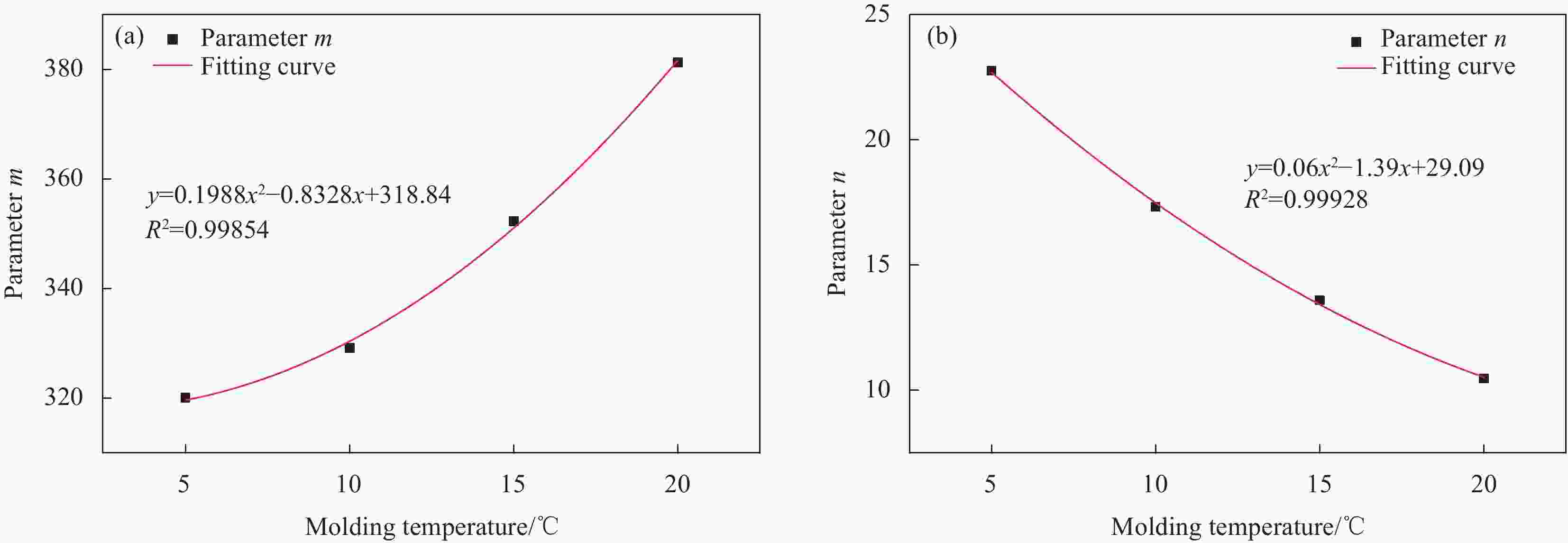

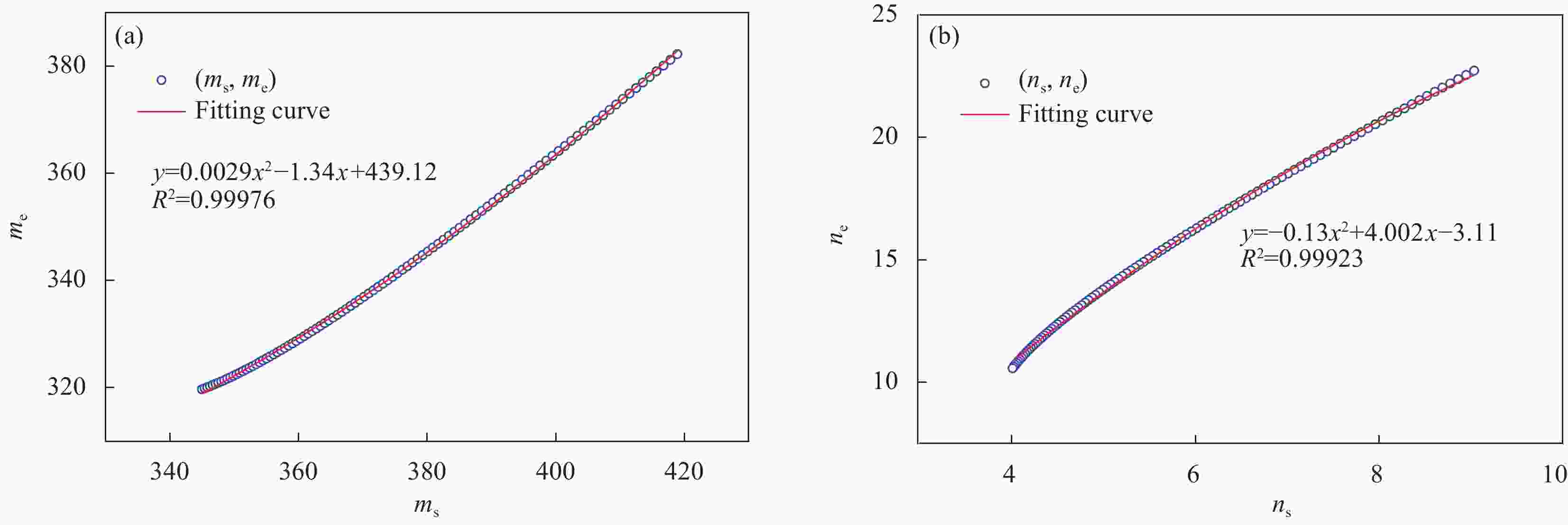

J/g Fitting model Age/day R2 7 21 35 49 63 +∞ $ {Q_t} = 27.64{t^{0.54}} $ 79.05(5.82) 143.07(−6.86) 188.51(0.06) 226.07(4.76) 258.93(9.95) +∞ 0.97339 $ {Q_t} = \dfrac{{320.05t}}{{22.76 + t}} $ 75.28(0.78) 153.59(0.00) 193.94(2.94) 218.54(1.27) 235.11(0.17) 331.51 0.99750 $ {Q_t} = 68.07\ln t - 48.44 $ 84.02(12.47) 158.80(3.39) 193.57(2.75) 216.48(0.31) 233.58(−0.81) +∞ 0.99531 $ {Q_t} = 454(1 - {{\rm{e}}^{ - 0.01508t}}) $ 45.48(−39.11) 123.23(−19.77) 186.18(−1.18) 237.16(9.90) 278.43(18.23) 454 0.89346 $ {Q_t} = 454(1 - {{\rm{e}}^{ - {{(0.00985t)}^{0.5669}}}}) $ 89.50(19.81) 152.49(−0.72) 191.22(1.50) 219.74(1.83) 242.32(2.90) 454 0.99984 $ {Q_t} = {Q_{\max }}(1 - {{\rm{e}}^{ - a{T^b}{t^c}}}) $ − − − − − − No converge Validation data 74.7 153.6 188.4 215.8 235.5 454 − 表 6 不同环境方式下水泥净浆双曲线模型拟合参数及决定系数

Table 6. Fitting parameters and determination coefficients of hyperbolic model of cement paste under different maintenance modes

Curing

temperature/℃Molding

temperature/℃m n R2 20 5 345.07 9.15 0.99979 10 361.01 6.21 0.99502 15 386.44 5.20 0.9987 20 416.95 3.87 0.99717 −5 5 320.05 22.76 0.9975 10 329.18 17.32 0.99641 15 352.29 13.59 0.99622 20 381.30 10.47 0.9997 表 7 两种养护方式下式(17)计算模型水泥净浆水化热验证对比

Table 7. Formula (17) verification and comparison of calculation model of hydration heat of cement paste under two maintenance modes

J/g Curing temperature

/℃Molding temperature

/℃Age/day 7 21 35 49 63 20 10 187.34

(4.08)276.22

(0.22)305.17

(−0.01)319.53

(0.42)328.10

(−0.45)15 228.85

(9.60)314.44

(−0.15)339.86

(0.94)352.06

(1.05)359.22

(−0.19)20 268.29

(1.05)352.87

(−0.32)376.62

(0.57)387.81

(0.81)394.31

(0.23)−5 10 95.55

(−8.39)182.36

(2.10)222.85

(2.89)246.29

(0.49)261.57

(0.53)15 122.96

(3.24)217.83

(5.28)257.58

(1.37)279.43

(0.52)293.25

(1.59)20 153.71

(3.79)256.90

(5.20)296.74

(2.21)317.86

(1.29)330.95

(1.33)Note: Relative error between verification data and calculation model in parentheses (%). -

[1] 周幼吾, 郭东信, 邱国庆, 等. 中国冻土 [M]. 北京: 科学出版社, 2000.ZHOU Youwu, GUO Dongxin, QIU Guoqing, et al. Geocryology in China[M]. Beijing: Science Press, 2000(in Chinese). [2] YU Q H, ZHANG Z Q, WANG G S, et al. Analysis of tower foundation stability along the Qinghai-tibet power transmission line and impact of the route on the permafrost[J]. Cold Regions Science and Technology,2016,121:205-213. doi: 10.1016/j.coldregions.2015.06.015 [3] 刘雨. 多年冻土地区单桩承载特性研究 [D]. 南京: 东南大学, 2005.LIU Yu. Research on the load bearing property of bored single pile in permafrost areas[D]. Nanjing: Southeast University, 2005(in Chinese). [4] 马巍, 王大雁. 冻土力学 [M]. 北京: 科学出版社, 2014.MA Wei, WANG Dayan. Mechanics of frozen soil[M]. Bejing: Science Press, 2014(in Chinese). [5] 王起才, 陈川, 张戎令, 等. 考虑持续低温影响的水泥水化放热计算模型[J]. 建筑材料学报, 2017, 20(2):186-190. doi: 10.3969/j.issn.1007-9629.2017.02.005WANG Qicai, CHEN Chuan, ZHANG Rongling, et al. Computing model for the hydration heat of cement paste considering the effect of sustained low temperature[J]. Journal of Building Materials,2017,20(2):186-190(in Chinese). doi: 10.3969/j.issn.1007-9629.2017.02.005 [6] 符进, 姜宇, 彭惠, 等. 多年冻土区大直径钻孔灌注桩早期回冻规律[J]. 交通运输工程学报, 2016, 16(4):104-111. doi: 10.3969/j.issn.1671-1637.2016.04.011FU Jin, JIANG Yu, PENG Hui, et al. Early refreezing law of large diameter cast in place piles in permafrost regions[J]. Journal of Traffic and Transportation Engineering,2016,16(4):104-111(in Chinese). doi: 10.3969/j.issn.1671-1637.2016.04.011 [7] 吴亚平, 苏强, 郭春香, 等. 冻土区桥梁群桩基础地基回冻过程的非线性分析[J]. 土木工程学报, 2006, 39(2):78-84. doi: 10.3321/j.issn:1000-131X.2006.02.015WU Yaping, SU Qiang, GUO Chunxiang, et al. Nonlinear analysis of ground refreezing process for pile group bridge foundation in permafrost[J]. China Civil Engineering Journal,2006,39(2):78-84(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.02.015 [8] 王旭, 蒋代军, 刘德仁, 等. 低温多年冻土地基大直径钻孔灌注桩未回冻状态承载性质试验研究[J]. 岩石力学与工程学报, 2013, 32(9): 1807-1812.WANG Xu, JIANG Daijun, LIU Deren, et al. Experimental study of bearing characteristics of large-diameter cast-in-place bored pile under non-refreezing condition in low temperature permafrost ground[J]. Chinese Journal of Rock Mechanics and Engineering. 2013, 32(9): 1807-1812(in Chinese). [9] BRONFENBRENER L. The modelling of the freezing process in fine-grained porous media: Application to the frost heave estimation[J]. Cold Regions Science and Technology,2008,56(2-3):120-134. doi: 10.1016/j.coldregions.2008.11.004 [10] 陈坤, 俞祁浩, 郭磊, 等. 基于灌注桩试验的多年冻土区桩–土传热过程分析[J]. 岩石力学与工程学报, 2020, 39(7):1483-1492.CHEN Kun, YU Qihao, GUO Lei, et al. Analysis of pile-soil heat transfer process based on field test in permafrost regions[J]. Chinese Journal of Rock Mechanics and Engineering,2020,39(7):1483-1492(in Chinese). [11] 方金城, 孔纲强, 陈斌, 等. 混凝土水化作用对群桩热力学特性影响现场试验[J]. 岩土力学, 2019, 40(8):2997-3003.FANG Jincheng, KONG Gangqiang, CHEN Bin, et al. Field test on thermo-mechanical properties of pile group influenced by concrete hydration[J]. Rock and Soil Mechanics,2019,40(8):2997-3003(in Chinese). [12] 商允虎, 牛富俊, 吴旭阳, 等. 多年冻土区钻孔灌注桩施工过程热力特性研究[J]. 铁道学报, 2020, 42(5):127-135. doi: 10.3969/j.issn.1001-8360.2020.05.017SHANG Yunhu, NIU Fujun, WU Xuyang, et al. Study on ground thermal regime and bearing capacity of a cast-in- place pile in permafrost regions[J]. Journal of the China Railway Society,2020,42(5):127-135(in Chinese). doi: 10.3969/j.issn.1001-8360.2020.05.017 [13] GAO Q, WEN Z, MING F, et al. Applicability evaluation of cast-in-place bored pile in permafrost regions based on a temperature-tracking concrete hydration model[J]. Applied Thermal Engineering,2019,149:484-491. doi: 10.1016/j.applthermaleng.2018.12.097 [14] LI G, YU Q, MA W, et al. Freeze-thaw properties and long-term thermal stability of the unprotected tower foundation soils in permafrost regions along the Qinghai-tibet power transmission line[J]. Cold Regions Science and Technology,2016,121:258-274. doi: 10.1016/j.coldregions.2015.05.004 [15] 李小和, 杨永平, 魏庆朝. 多年冻土地区不同入模温度下桩基温度场数值分析[J]. 北京交通大学学报, 2005, 29(1):9-13. doi: 10.3969/j.issn.1673-0291.2005.01.003LI Xiaohe, YANG Yongping, WEI Qingchao. Numerical simulation of pile foundation conduction at different molding temperature in permafrost regions[J]. Journal of Beijing Jiaotong University,2005,29(1):9-13(in Chinese). doi: 10.3969/j.issn.1673-0291.2005.01.003 [16] 贾艳敏, 梁东伟, 马云峰. 冻土地区CFG群桩模型温度数值分析[J]. 工程力学, 2014, 31(S1):161-165.JIA Yanmin, LIANG Dongwei, MA Yunfeng. Numerical analysis for temperature of CFG pile group model in permafrost region[J]. Engineering Mechanics,2014,31(S1):161-165(in Chinese). [17] 尹建. 养护制度对负温混凝土温度场及微观性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2017.YIN Jian . Effects of curing conditions on temperature field and microscopic properties of negative temperature concrete [D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [18] 中华人民共和国住房和城乡建设部. 混凝土结构工程施工规范: GB 50666—2011[S]. 北京: 中国建筑工业出版社, 2011.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for construction of concrete structures: GB 50666—2011[S]. Beijing: China Architecture & Building Press, 2011(in Chinese). [19] 中华人民共和国住房和城乡建设部. 建筑工程冬期施工规程: JGJ/T 104—2011[S]. 北京: 中国建筑工业出版社, 2011.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Specification for winter construction of building engineering: JGJ/T 104—2011[S]. Beijing: China Architecture & Building Press, 2011(in Chinese). [20] 中国国家标准化管理委员会. 水泥水化热测定方法: GB/T 12959—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Test methods for heat of hydration of cement: GB/T 12959—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [21] YANG K H, JUNG Y B, CHO M S, et al. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete[J]. Journal of Cleaner Production,2015,103:774-783. doi: 10.1016/j.jclepro.2014.03.018 [22] 危鼎, 戴耀军, 王桂玲. 胶凝材料水化热计算问题探讨[J]. 水泥, 2009(3):15-17. doi: 10.3969/j.issn.1002-9877.2009.03.005WEI Ding, DAI Yaojun, WANG Guiling. Discussion on the calculation of hydration heat of cementitious materials[J]. Cement,2009(3):15-17(in Chinese). doi: 10.3969/j.issn.1002-9877.2009.03.005 [23] 孔祥明, 卢子臣, 张朝阳. 水泥水化机理及聚合物外加剂对水泥水化影响的研究进展[J]. 硅酸盐学报, 2017, 45(2):274-281.KONG Xiangming, LU Zichen, ZHANG Chaoyang. Recent development on understanding cement hydration mechanism and effects of chemical admixtures on cement hydration[J]. Journal of the Chinese Ceramic Society,2017,45(2):274-281(in Chinese). [24] BULLARD J W, JENNINGS H M, LIVINGSTON R A, et al. Mechanisms of cement hydration[J]. Cement and Concrete Research,2011,41(12):1208-1223. doi: 10.1016/j.cemconres.2010.09.011 [25] SCRIVENER K L, JUILLAND P, MONTEIRO P J M. Advances in understanding hydration of portland cement[J]. Cement and Concrete Research,2015,78(Part A):38-56. doi: 10.1016/j.cemconres.2015.05.025 [26] 李瑶. 硅酸盐水泥-硅灰复合胶凝材料低温水化特征研究[D]. 大连: 大连理工大学, 2016.LI Yao. Research on hydration characteristics of portland cement-silica fume composite cementitious material at lower temperatures[D]. Dalian: Dalian University of Technology, 2016(in Chinese). [27] 谢超, 王起才, 于本田, 等. 负温下混凝土孔结构及抗氯离子渗透性发展规律[J]. 哈尔滨工程大学学报, 2020, 41(11):1703-1709.XIE Chao, WANG Qicai, YU Bentian, et al. The developing law of pore structure and resistance to chloride ion permeability of concrete at negative temperature[J]. Journal of Harbin Engineering University,2020,41(11):1703-1709(in Chinese). [28] JIANG Z, ZHANG C, DENG Z, et al. Thermal strain of cement-based materials under cryogenic temperatures and its freeze-thaw cycles using fibre Bragg grating sensor[J]. Cryogenics,2019,100:1-10. doi: 10.1016/j.cryogenics.2019.03.005 [29] HAYDEN F. Water movement and loss under frozen soil conditions[J]. Soil Science Society of America Journal,1964,28(5):700-703. doi: 10.2136/sssaj1964.03615995002800050034x [30] MEHTA P K, MONTEIRO P J M. Concrete microstructure, properties and materials[M]. New York: McGraw-Hill, 2008. [31] 刘军, 徐长伟. 低温混凝土的水化与性能[M]. 北京: 中国建筑工业出版社, 2018.LIU Jun, XU Changwei. Hydration and performance of low temperature concrete[M]. Beijing: China Architecture & Building Press, 2018(in Chinese). [32] 朱伯芳. 大体积混凝土温度应力与温度控制[M]. 北京: 中国电力出版社, 1999.ZHU Bofang. Thermal stresses and temperature control of mass concrete[M]. Beijing: China Electric Power Press, 1999(in Chinese). [33] 朱伯芳. 考虑温度影响的混凝土绝热温升表达式[J]. 水力发电学报, 2003(2):69-73. doi: 10.3969/j.issn.1003-1243.2003.02.010ZHU Bofang. A method for computing the adiabatic temperature rise of concrete considering the effect of the temperature of concrete[J]. Journal of Hydroelectric Engineering,2003(2):69-73(in Chinese). doi: 10.3969/j.issn.1003-1243.2003.02.010 -

下载:

下载: