Study on structure and performance control of carbon fiber reinforced poly(ether ketone ketone) molding composites

-

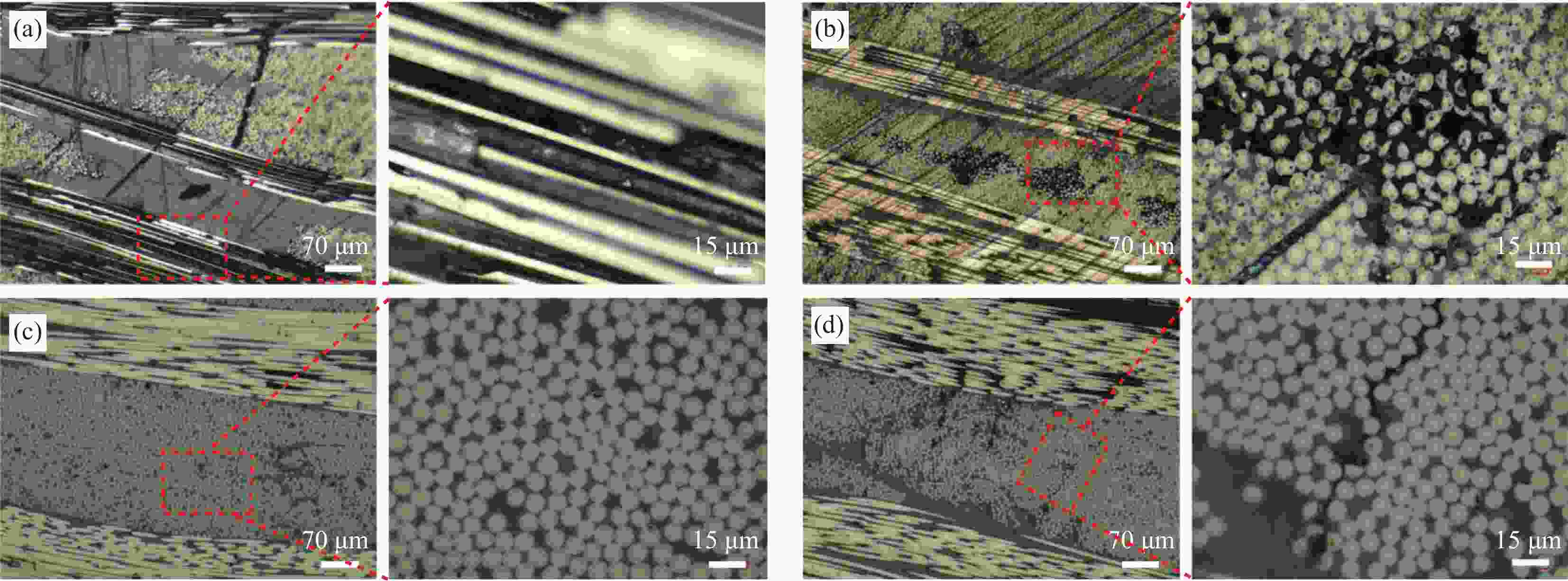

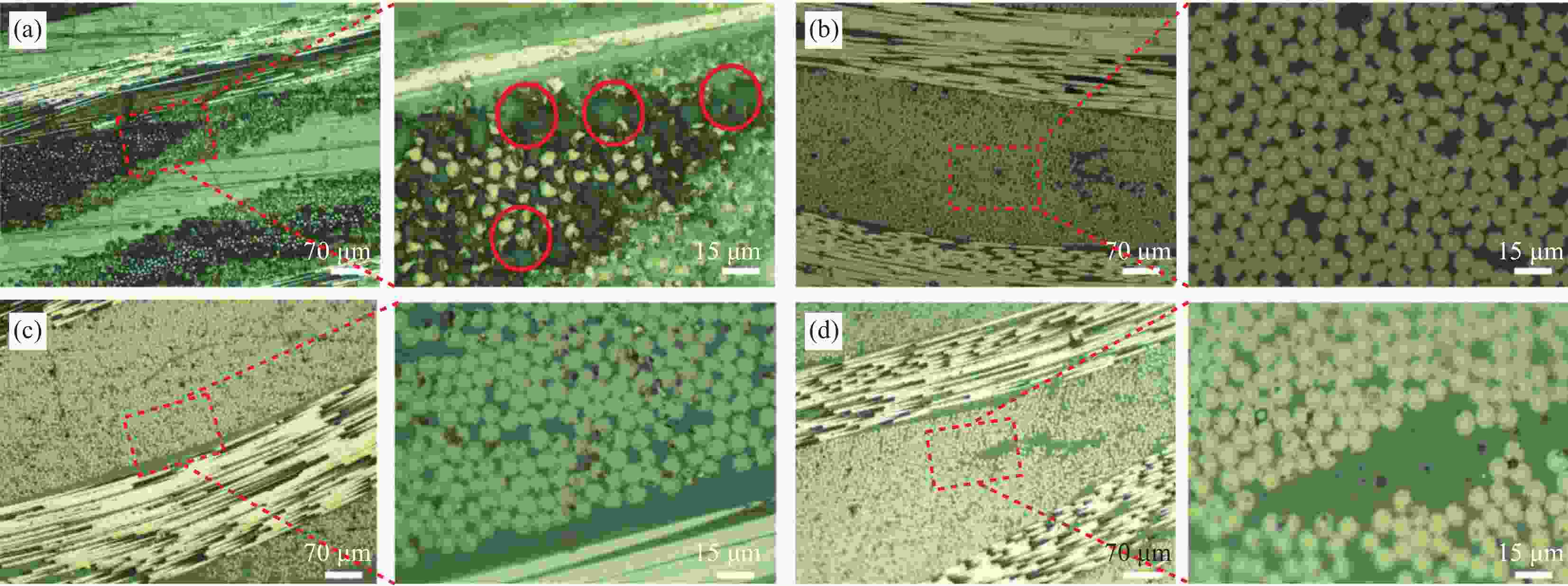

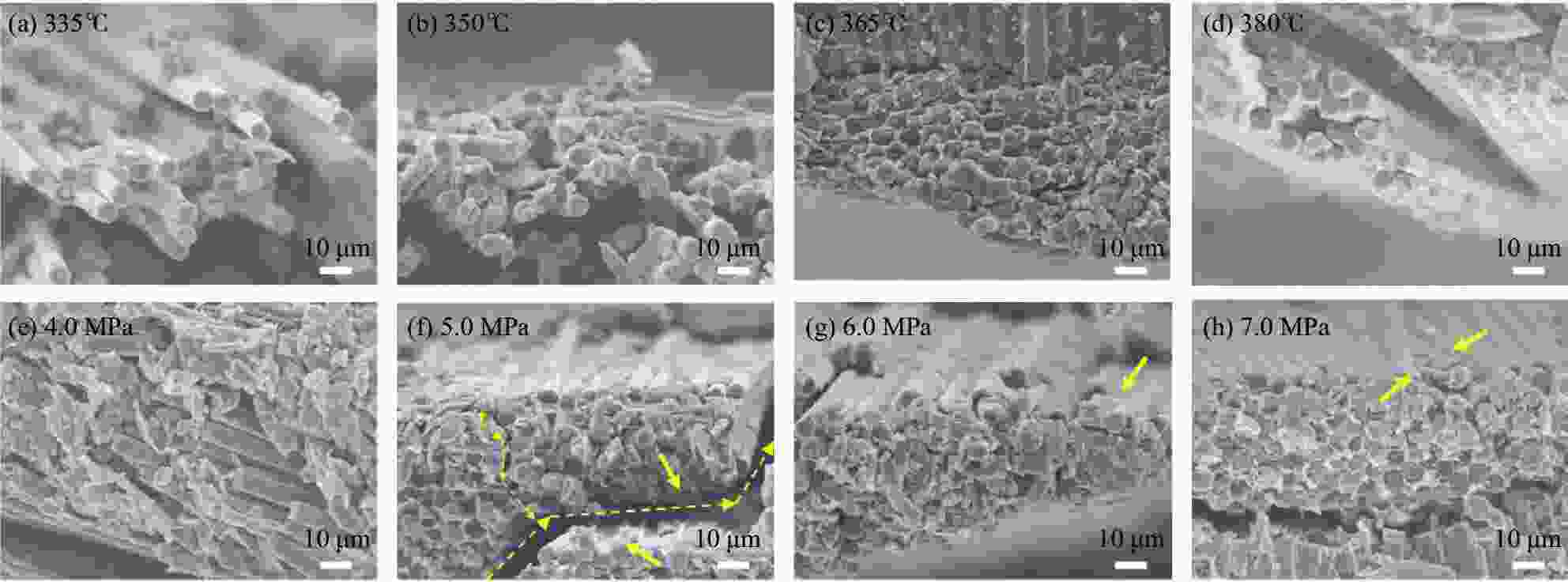

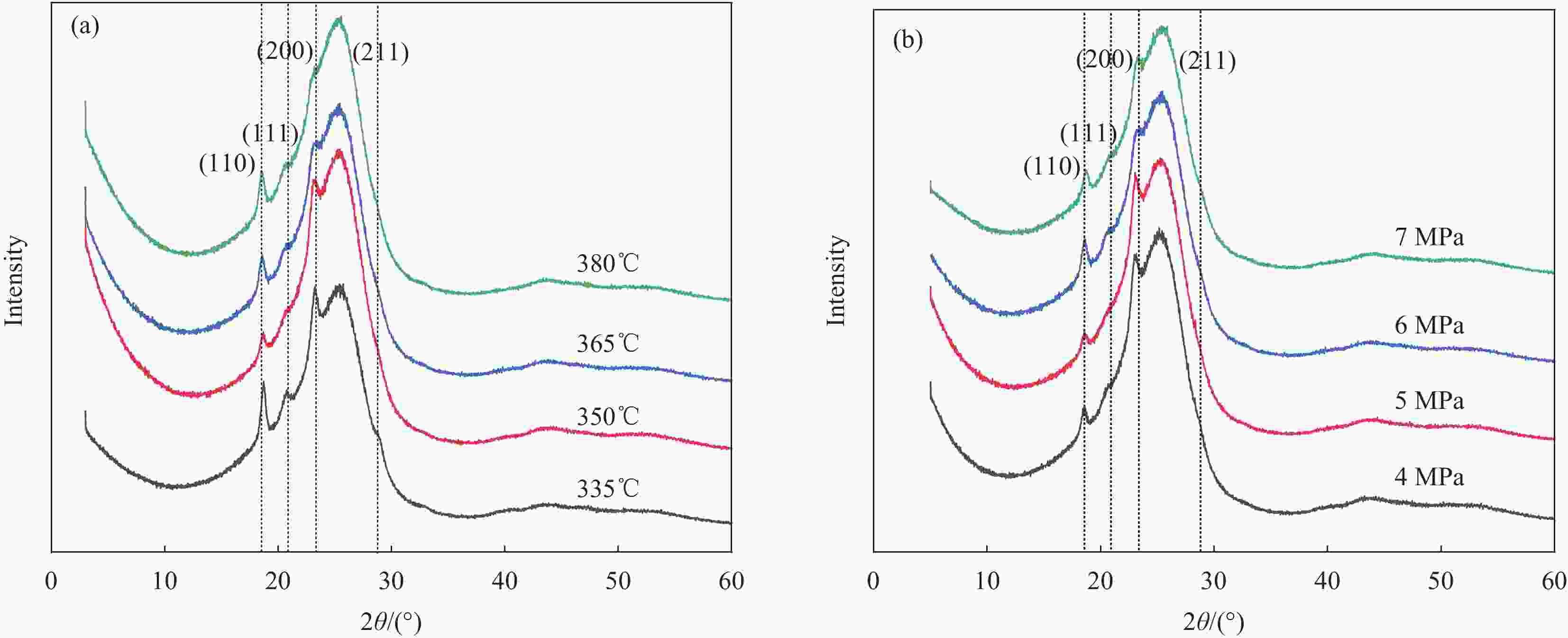

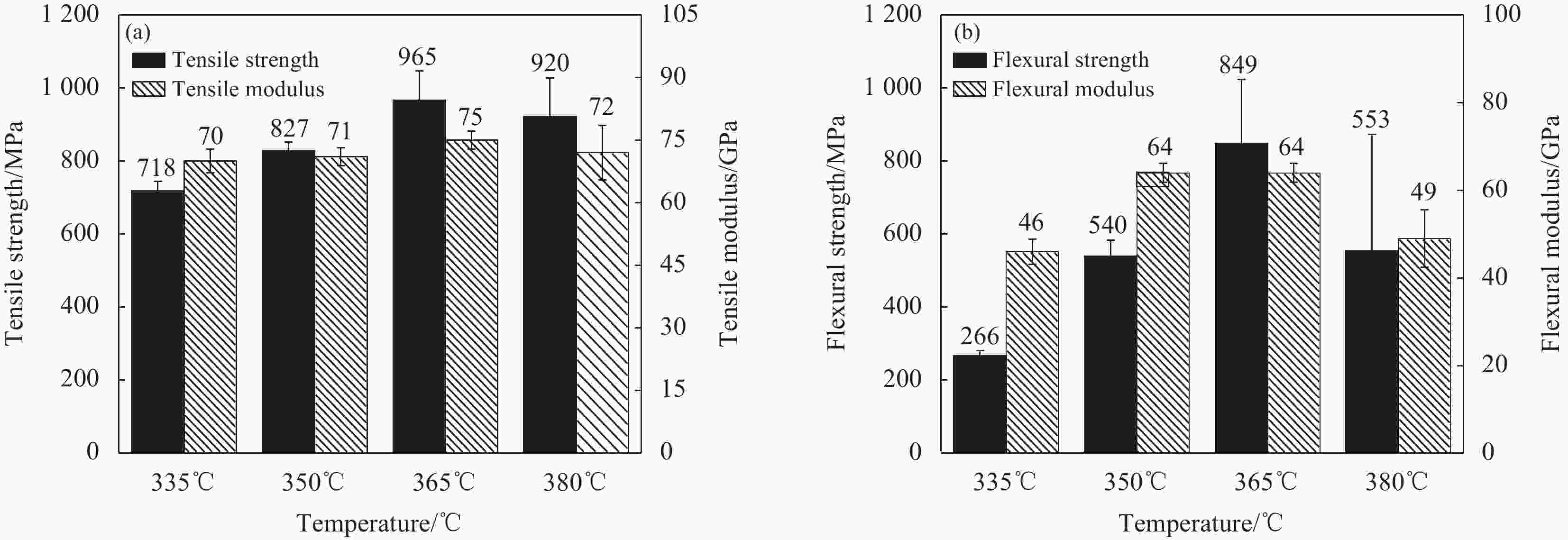

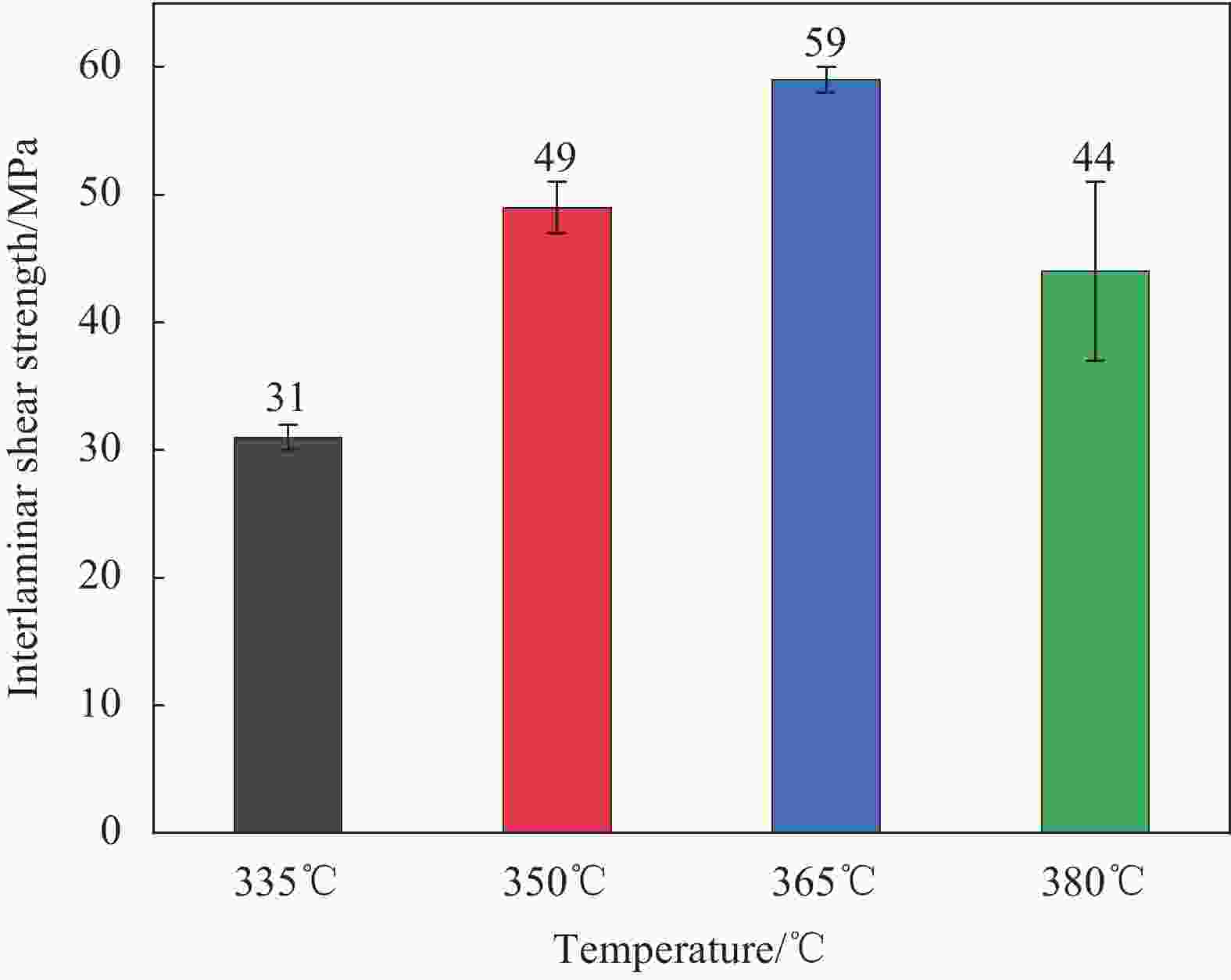

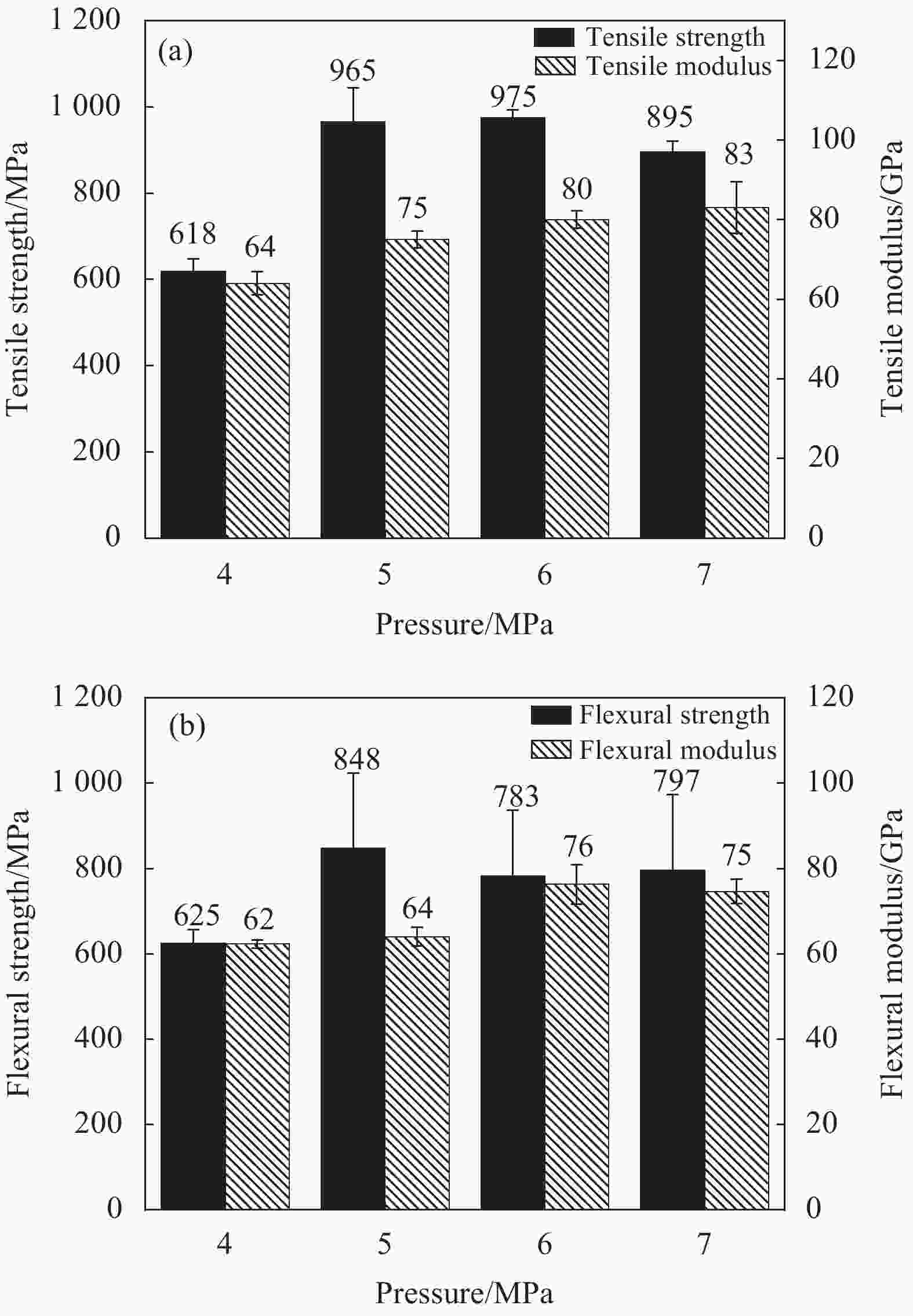

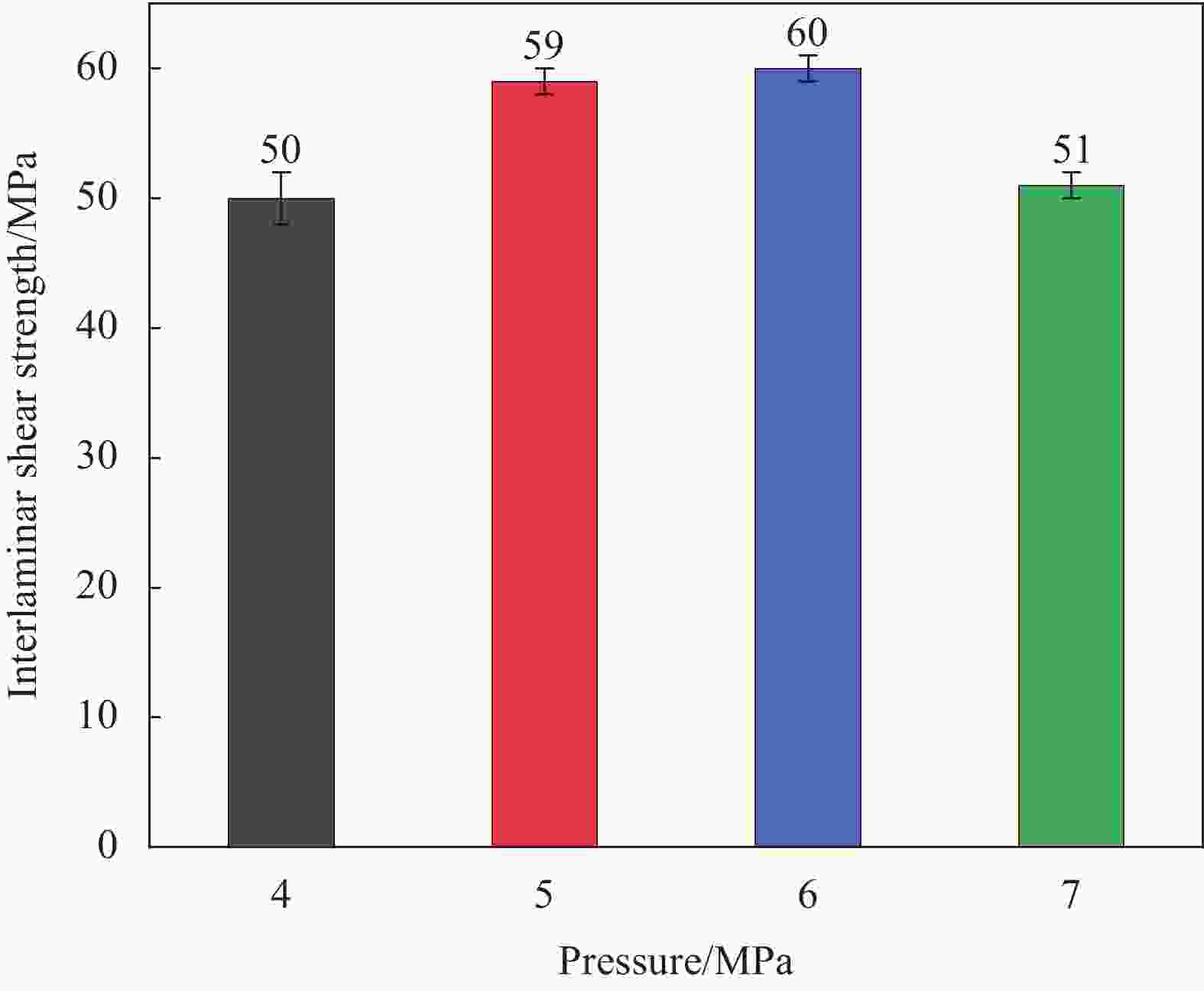

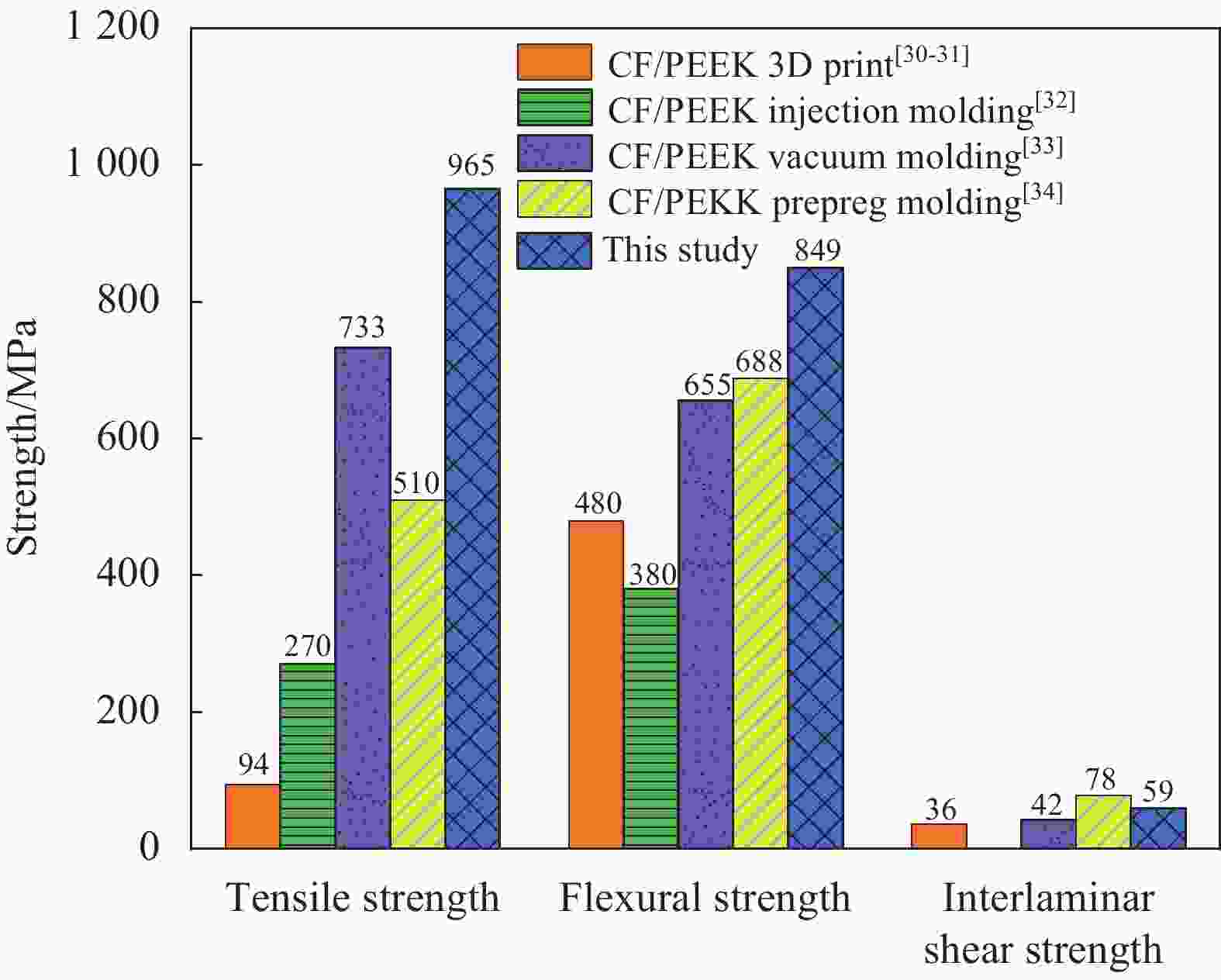

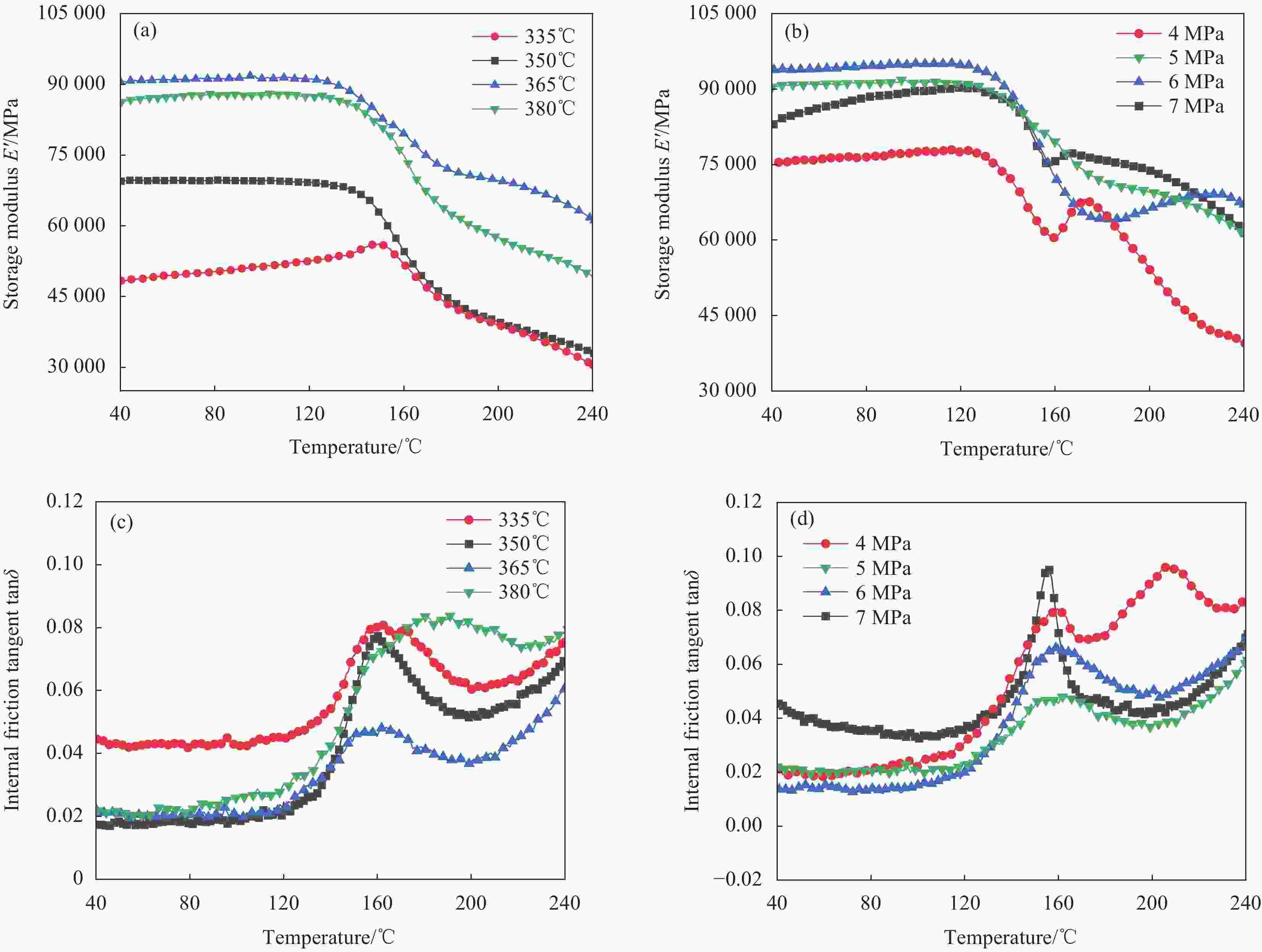

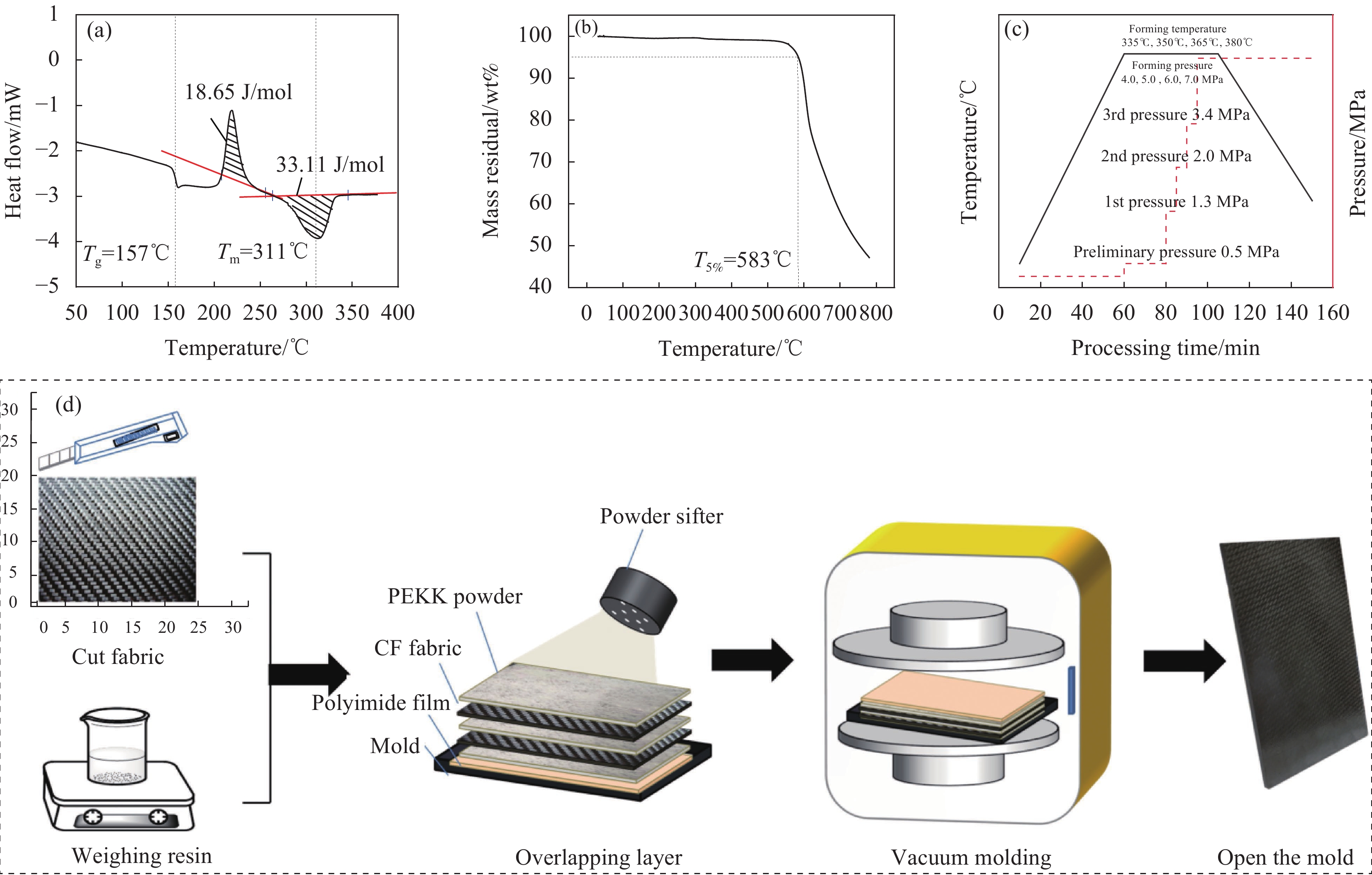

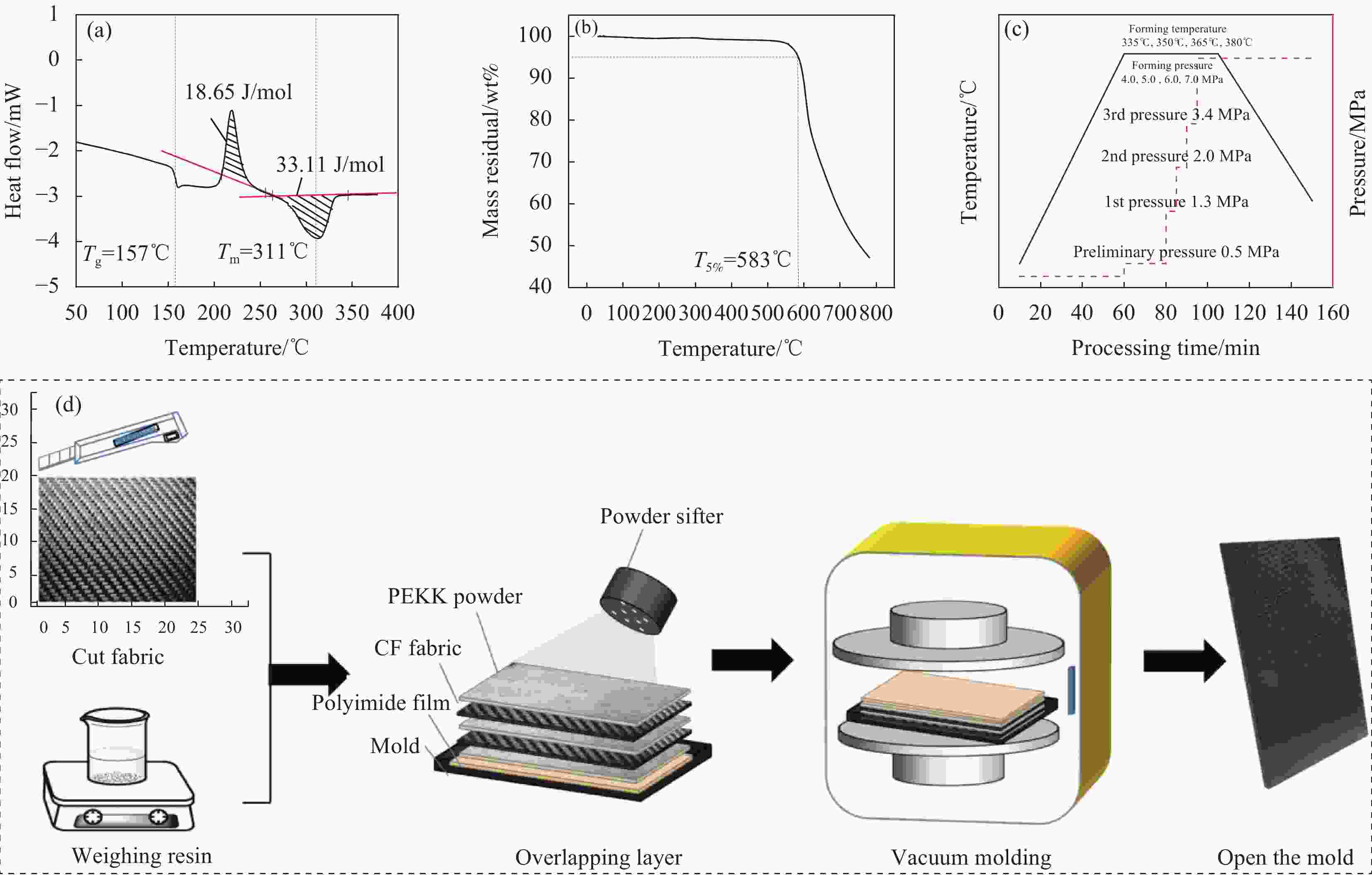

摘要: 为探究模压工艺参数对碳纤维增强聚醚酮酮复合材料(CF/PEKK)结构与性能的影响规律,采用真空模压工艺制备CF/PEKK复合材料层压板,系统讨论了模压温度和压力对树脂与纤维的界面结构、PEKK凝聚态结构及复合材料力学性能的影响,通过扫描电镜分析了复合材料的微观结构,讨论了复合材料的失效形式,采用X射线衍射观察了复合材料中PEKK的晶体结构,使用动态热机械分析研究了复合材料界面阻尼与模压成型工艺的关系。研究结果表明,在365℃的模压温度和5.0~6.0 MPa模压压力下,CF/PEKK复合材料的综合力学性能最优,其中拉伸强度达到965 MPa,弯曲强度849 MPa,层间剪切强度59 MPa,复合材料的断裂失效形式以树脂开裂与层间Z形断裂为主。

-

关键词:

- 碳纤维/聚醚酮酮复合材料 /

- 模压工艺 /

- 凝聚态结构 /

- 力学性能 /

- 失效形式

Abstract: In order to explore the effect of molding parameters on the structure and properties of carbon fiber reinforced poly(ether ketone ketone) composites (CF/PEKK), CF/PEKK composite laminates were prepared by vacuum molding in this paper. The effects of molding temperature and pressure on the interface structure between resin and fiber, the condensed structure of PEKK and the mechanical properties of the composites were discussed systematically. The microstructure and the failure modes of the composites was analyzed by scanning electron microscope. The crystal structure of PEKK in the composites was observed by X-ray diffraction. The relationship between interfacial damping and molding process of the composites was studied by dynamic mechanical analysis. The results show that under the molding temperature of 365℃ and molding pressure of 5.0-6.0 MPa, the comprehensive mechanical properties of CF/PEKK composites are the best, in which the tensile strength is 965 MPa, the bending strength is 849 MPa, and the inter-laminar shear strength is 59 MPa. The fracture failure modes of the composites are mainly zigzag cracking and resin breakage.-

Key words:

- CF/PEKK composites /

- molding process /

- condensed structure /

- mechanical properties /

- failure modes

-

图 1 聚醚酮酮(PEKK)树脂粉末的热力学性能:(a) DSC曲线;(b) TGA曲线;碳纤维(CF)/PEKK复合材料模压工艺流程 (c) 和CF/PEKK复合材料层压板制备过程 (d)

Figure 1. Thermal properties of poly(ether ketone ketone) (PEKK) resin powder: (a) DSC curve; (b) TGA curve; Molding process of carbon fiber (CF)/PEKK composites (c) and preparation process of CF/PEKK composite laminates (d)

Tg—Glass transition temperature; Tm—Melting temperature; T5%—Decomposition temperature

表 1 不同模压工艺参数对CF/PEKK复合材料结晶性影响

Table 1. Effect of different molding parameters on the crystallinity of CF/PEKK composites

335℃ 350℃ 365℃ 380℃ 4.0 MPa 5.0 MPa 6.0 MPa 7.0 MPa XS(110)/nm 16.9 18.7 23.2 22.3 22.6 23.2 20.4 19.4 XC/% 8.97 8.32 11.14 10.89 8.69 11.14 11.61 10.90 Notes: XS(110)—Grain size of PEKK (110) crystal plane; XC—XRD crystallinity of PEKK. -

[1] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017, 4(194):3-17.YANG Yang, JIAN Xuezhen, YUAN Xieyao, et al. Application and manufacturing technology of advanced thermoplastic composites in structural parts of large passenger aircraft[J]. Fiber Reinforced Plastics,2017,4(194):3-17(in Chinese). [2] 谌广昌, 姚佳楠, 张金栋, 等. 高性能热塑性复合材料在直升机结构上的应用与展望[J]. 航空材料学报, 2019, 39(5):24-33.CHEN Guangchang, YAO Jianan, ZHANG Jindong, et al. Application and prospect of high performance thermoplastic composites in helicopter structure[J]. Journal of Aeronautical Materials,2019,39(5):24-33(in Chinese). [3] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review[J]. Advanced Composites and Hybrid Materials,2019,2(2):214-233. doi: 10.1007/s42114-018-0072-z [4] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Opportunities and challenges for the development of carbon fiber and resin matrix composites industry[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). [5] Teijin Carbon. A350XWB-World’s first aircraft using CFRTP for primary structure parts, delivered to JAL in Tokyo[EB/OL]. (2019-06-20)[2021-08-01]. https://www.teijin.com/news/2019/20190620_2803.html. [6] MATHIJSEN D. Leading the way in thermoplastic composites[J]. Reinforced Plastics,2016,60(6):405-407. doi: 10.1016/j.repl.2015.08.067 [7] 邓德鹏, 康敬欣, 刘勇. 特种工程塑料聚醚酮酮的性能[J]. 工程塑料应用, 2016, 44(9):83-86.DENG Depeng, KANG Jingxin, LIU Yong. Properties of special engineering plastics polyether ketone[J]. Application of Engineering Plastics,2016,44(9):83-86(in Chinese). [8] 饶先花, 曹民, 代惊奇, 等. 国内外特种工程塑料聚芳醚酮的生产、应用及发展前景[J]. 塑料工业, 2012, 40(9):18-22.RAO Xianhua, CAO Min, DAI Jingqi, et al. Production, application and development prospect of special engineering plastics poly(aryl ether ketone)[J]. Plastics Industry,2012,40(9):18-22(in Chinese). [9] 肇研, 刘寒松. 连续纤维增强高性能热塑性树脂基复合材料的制备与应用[J]. 材料工程, 2020, 48(8):49-61.ZHAO Yan, LIU Hansong. Preparation and application of continuous fiber reinforced high performance thermoplastic resin matrix composites[J]. Materials Engineering,2020,48(8):49-61(in Chinese). [10] 张佳新, 梅启林. CF/PPS编织复合材料的制备及力学性能研究[J]. 复合材料科学与工程, 2020(1):76-81.ZHANG Jiaxin, MEI Qilin. Preparation and mechanical properties of CF/PPS braided composites[J]. Composite Science and Engineering,2020(1):76-81(in Chinese). [11] 宋清华, 肖军, 文立伟, 等. 模压工艺对玻璃纤维增强聚丙烯复合材料层合板力学性能的影响[J]. 复合材料学报, 2016, 33(12):2740-2748.SONG Qinghua, XIAO Jun, WEN Liwei, et al. Effect of molding process on mechanical properties of glass fiber reinforced polypropylene composite laminates[J]. Acta Materiae Compositae Sinica,2016,33(12):2740-2748(in Chinese). [12] 敖玉辉, 石飞, 尚垒, 等. 碳纤维增强聚醚醚酮复合材料的制备与性能[J]. 高分子材料科学与工程, 2014, 30(6):161-164.AO Yuhui, SHI Fei, SHANG Lei, et al. Preparation and properties of carbon fiber reinforced PEEK composites[J]. Polymer Materials Science and Engineering,2014,30(6):161-164(in Chinese). [13] 刘亚男, 刘晨晓, 朱明浩, 等. 模压CF/PEKK与自动铺丝CF/PEEK热塑性复合材料对比研究[J]. 航空制造技术, 2021, 4(11):50-57.LIU Ya'nan, LIU Chenxiao, ZHU Minghao, et al. Comparative study on molded CF/PEKK and automatic wire laying CF/PEEK thermoplastic composites[J]. Air Manufacturing Technology,2021,4(11):50-57(in Chinese). [14] DAI G, ZHAN L, GUAN C, et al. Optimization of molding process parameters for CF/PEEK composites based on Taguchi method[J]. Composites and Advanced Materials, 2021, 30(14): 713-715. [15] 王洋, 熊平, 周利庄, 等. 模压工艺对聚酰亚胺树脂力学性能的影响[J]. 塑料科技, 2018, 46(7):73-75.WANG Yang, XIONG Ping, ZHOU Lizhuang, et al. Effect of molding process on mechanical properties of polyimide resin[J]. Plastics Science and Technology,2018,46(7):73-75(in Chinese). [16] CHEN J, WANG K, DONG A, et al. A comprehensive study on controlling the porosity of CCF300/PEEK composites by optimizing the impregnation parameters[J]. Polymer Composites,2018,39(10):3765-3779. doi: 10.1002/pc.24407 [17] 张照. 碳纤维织物增强聚醚醚酮基(CFF/PEEK)航空复合材料的制备及其界面改性[D]. 上海: 东华大学, 2017.ZHANG Zhao. Preparation and interface modification of carbon fiber fabric reinforced polyetheretherketone (CFF/PEEK) aviation composites[D]. Shanghai: Donghua University, 2017(in Chinese). [18] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for tensile properties of fiber reinforced plastics: GB/T 1447—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [19] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for flexural properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [20] 中华人民共和国国家质量监督检验检疫总局. 聚合物基复合材料短梁剪切强度试验方法: GB/T 30969—2014[S]. 北京: 中国标准出版社, 2014.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for shear strength of short beams of polymer matrix composites: GB/T 30969—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [21] CHEN J, WANG K, ZHAO Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface[J]. Composites Science and Technology,2018,154:175-186. doi: 10.1016/j.compscitech.2017.11.005 [22] HASSAN E A M, YANG L, ELAGIB T H H, et al. Synergistic effect of hydrogen bonding and π-π stacking in interface of CF/PEEK composites[J]. Composites Part B: Engineering,2019,171:70-77. doi: 10.1016/j.compositesb.2019.04.015 [23] 许并社. 材料科学概论[M]. 北京: 北京工业大学出版社, 2002.XU Bingshe. Introduction to materials science[M]. Beijing: Beijing University of Technology Press, 2002(in Chinese). [24] CHOUPIN T, FAYOLLE B, REGNIER G, et al. Isothermal crystallization kinetic modeling of poly(etherketoneketone) (PEKK) copolymer[J]. Polymer,2017,111:73-82. doi: 10.1016/j.polymer.2017.01.033 [25] 王维, 吴选征, 漆宗能. 聚醚醚酮/碳纤维复合材料的界面结构以及结晶形态的研究[J]. 高分子学报, 1989(5): 544-551.WANG Wei, WU Xuanzheng, QI Zongneng. Study on interfacial structure and crystalline morphology of PEEK/CF composites[J]. Acta Polymer Sinica, 1989(5): 544-551(in Chinese). [26] 席代坤. 聚醚醚酮及聚醚醚酮/碳富勒烯复合体系在高压下结晶行为的研究[D]. 成都: 西南交通大学, 2012.XI Daikun. Study on crystallization behavior of PEEK and PEEK/c-fullerene composites under high pressure[D]. Chengdu: Southwest Jiaotong University, 2012(in Chinese). [27] ALI R, IANNACE S, NICOLAIS L. Effects of processing conditions on the impregnation of glass fibre mat in extrusion/calendering and film stacking operations[J]. Composites Science & Technology,2003,63(15):2217-2222. [28] 李洪峰, 曲春艳, 王德志, 等. 短切玻纤增强PEKK与BDM/DABPA共混体系固化反应动力学及断裂韧性[J]. 材料导报, 2018, 32(6):971-976. doi: 10.11896/j.issn.1005-023X.2018.06.022LI Hongfeng, QU Chunyan, WANG Dezhi, et al. Curing reaction kinetics and fracture toughness of chopped glass fiber reinforced PEKK and BDM/DABPA blends[J]. Mater-ials Guide,2018,32(6):971-976(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.06.022 [29] REN F, YU Y, YANG J, et al. A mathematical model for continuous fiber reinforced thermoplastic composite in melt impregnation[J]. Applied Composite Materials, 2016, 24(3): 1-16. [30] WANG P, ZOU B, DING S, et al. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK[J]. Chinese Journal of Aeronautics, 2021, 34(9): 236-246. [31] LUO M A, TIAN X A, SHANG J A, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A: Applied Science and Manufacturing,2019,121:130-138. doi: 10.1016/j.compositesa.2019.03.020 [32] VICTREX. Victrex peek 150CA30[EB/OL]. (2021-08-27)[2021-08-01].https://www.victrex.com/zh-Hans/datasheets. [33] 冯明祥. CF/PEEK复合材料制备及SPEEK改性CF研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.FENG Mingxiang. Preparation of CF/PEEK composites and study on SPEEK modified CF[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [34] 王杰. 连续碳纤维增强聚醚酮酮板材的研究[D]. 淄博: 山东理工大学, 2019.WANG Jie. Study on continuous carbon fiber reinforced polyether ketone sheet[D]. Zibo: Shandong University of Technology, 2019(in Chinese). [35] ALEXANDRE M A, DANTRAS E, LACABANNE C, et al. Effect of PEKK oligomers sizing on the dynamic mechanical behavior of poly(ether ketone ketone)/carbon fiber composites[J]. Journal of Applied Polymer Science,2019,137(24):48818. -

下载:

下载: