Effect of graphene nanosheets on the properties of Ni-W-ZrO2 composite coating

-

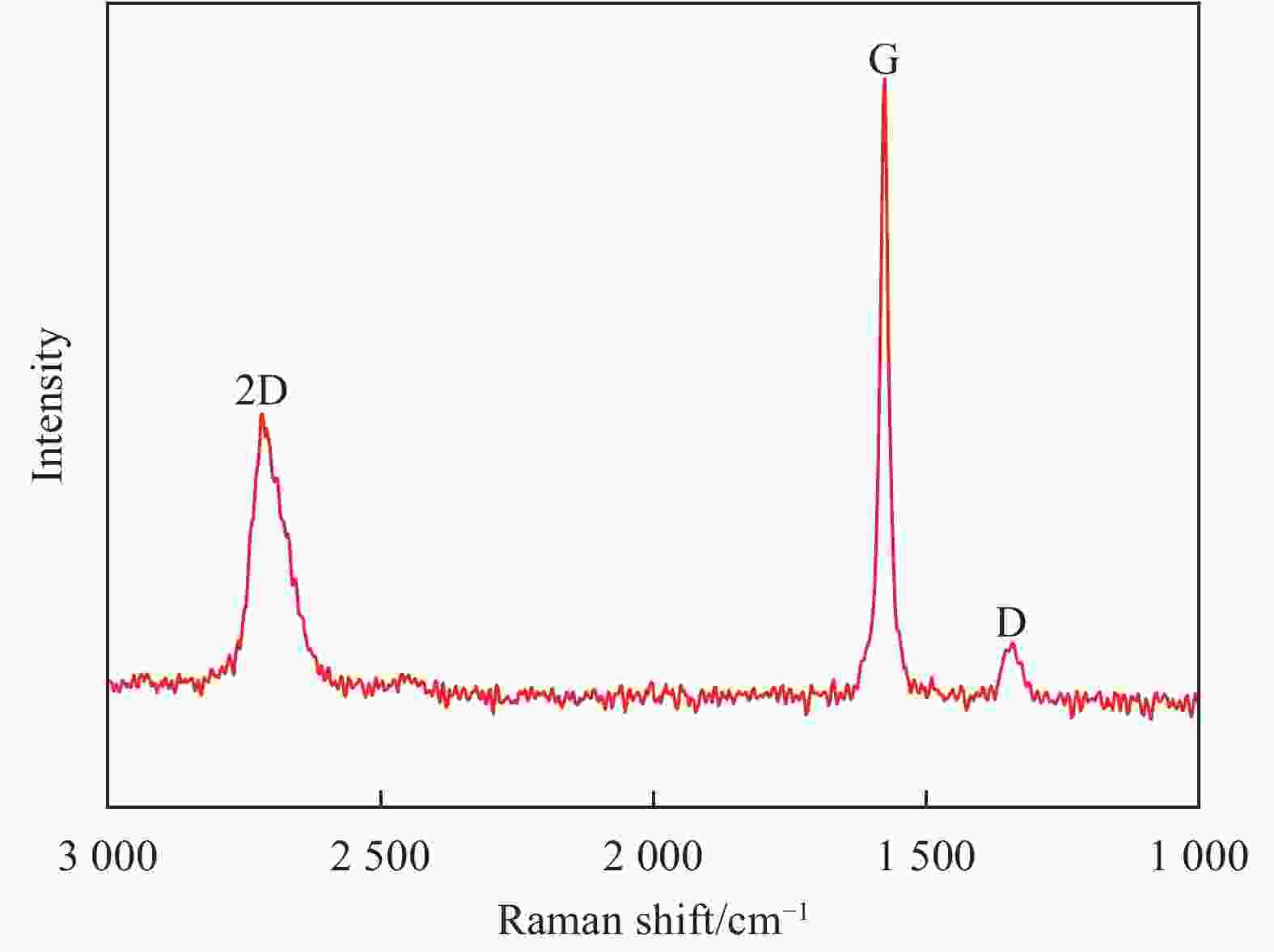

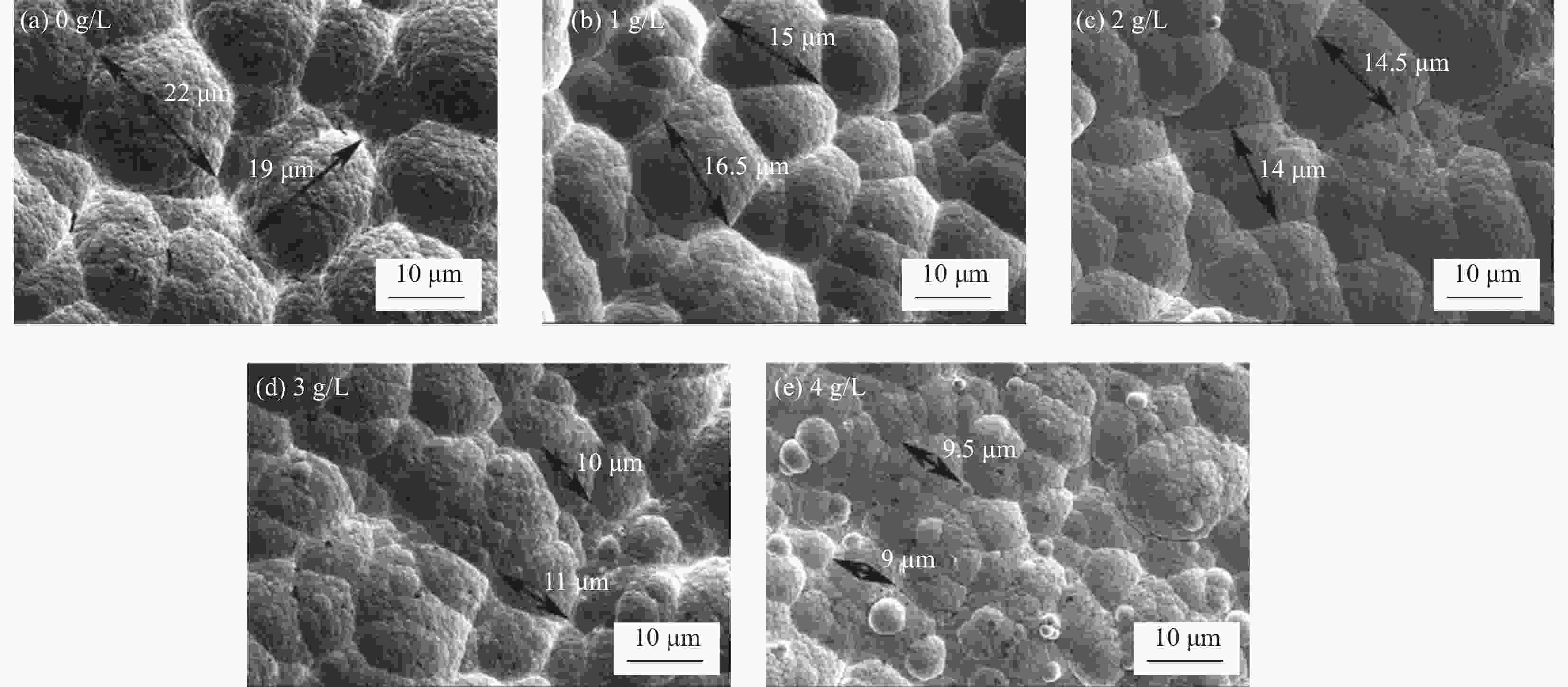

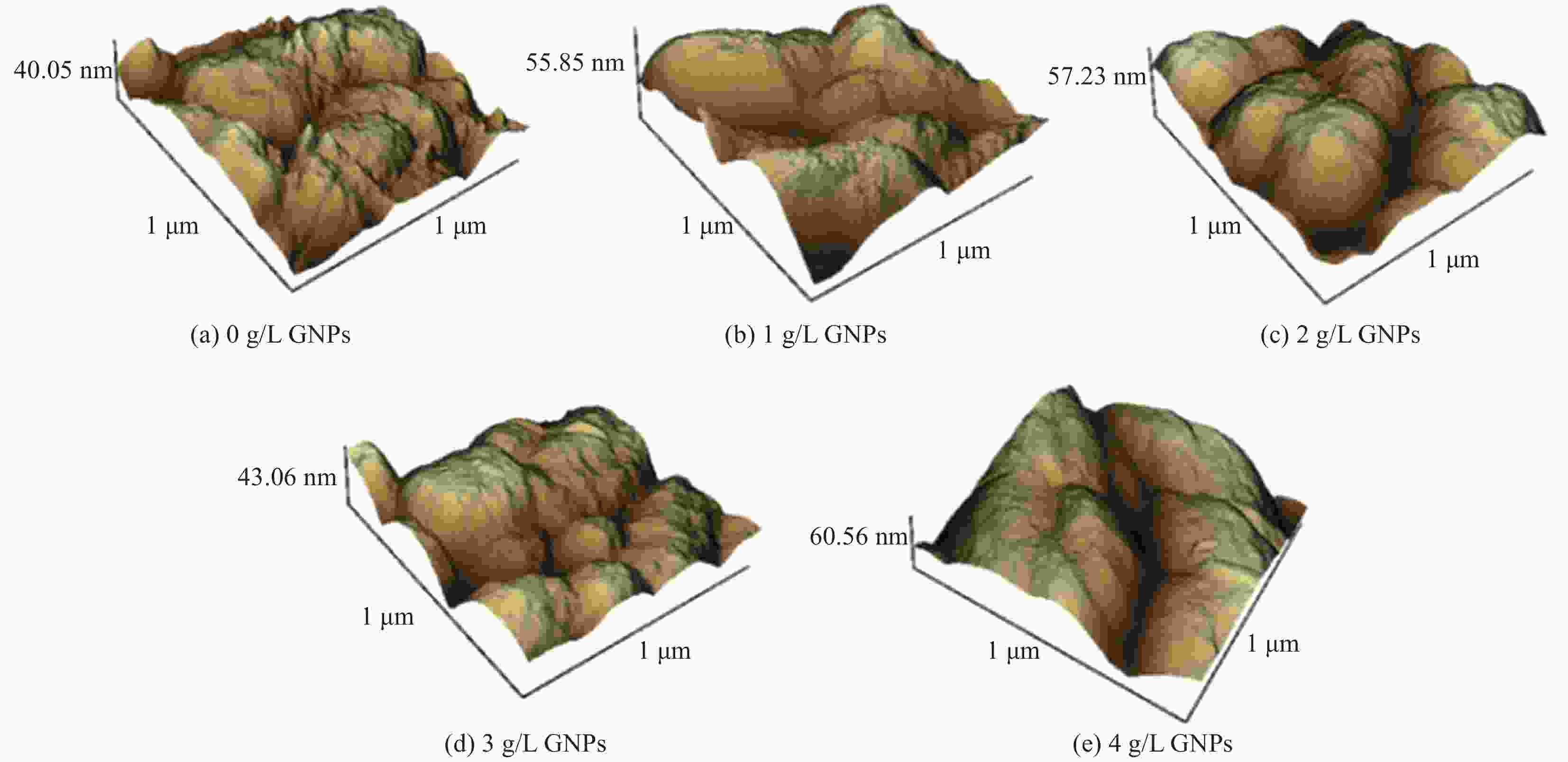

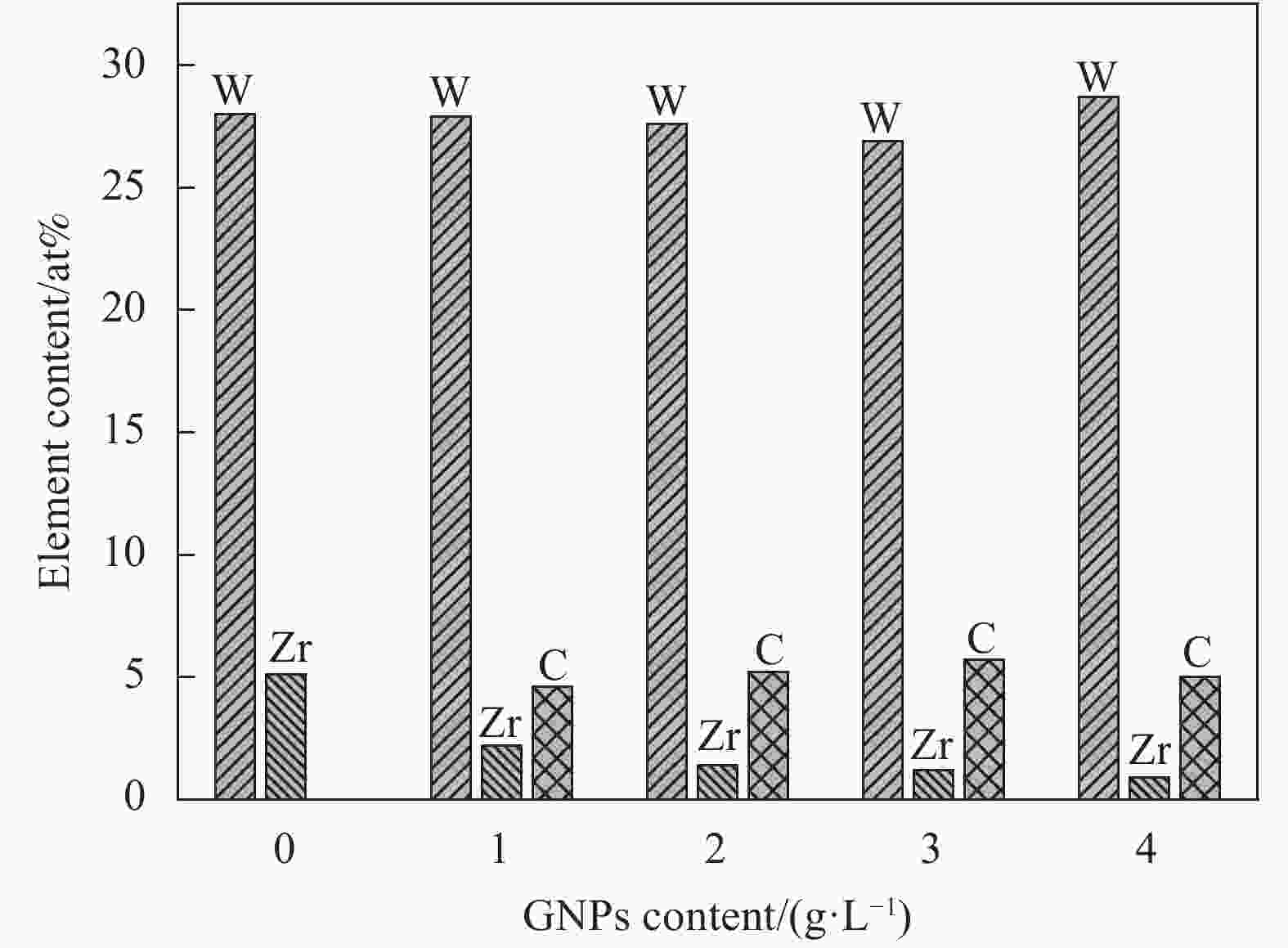

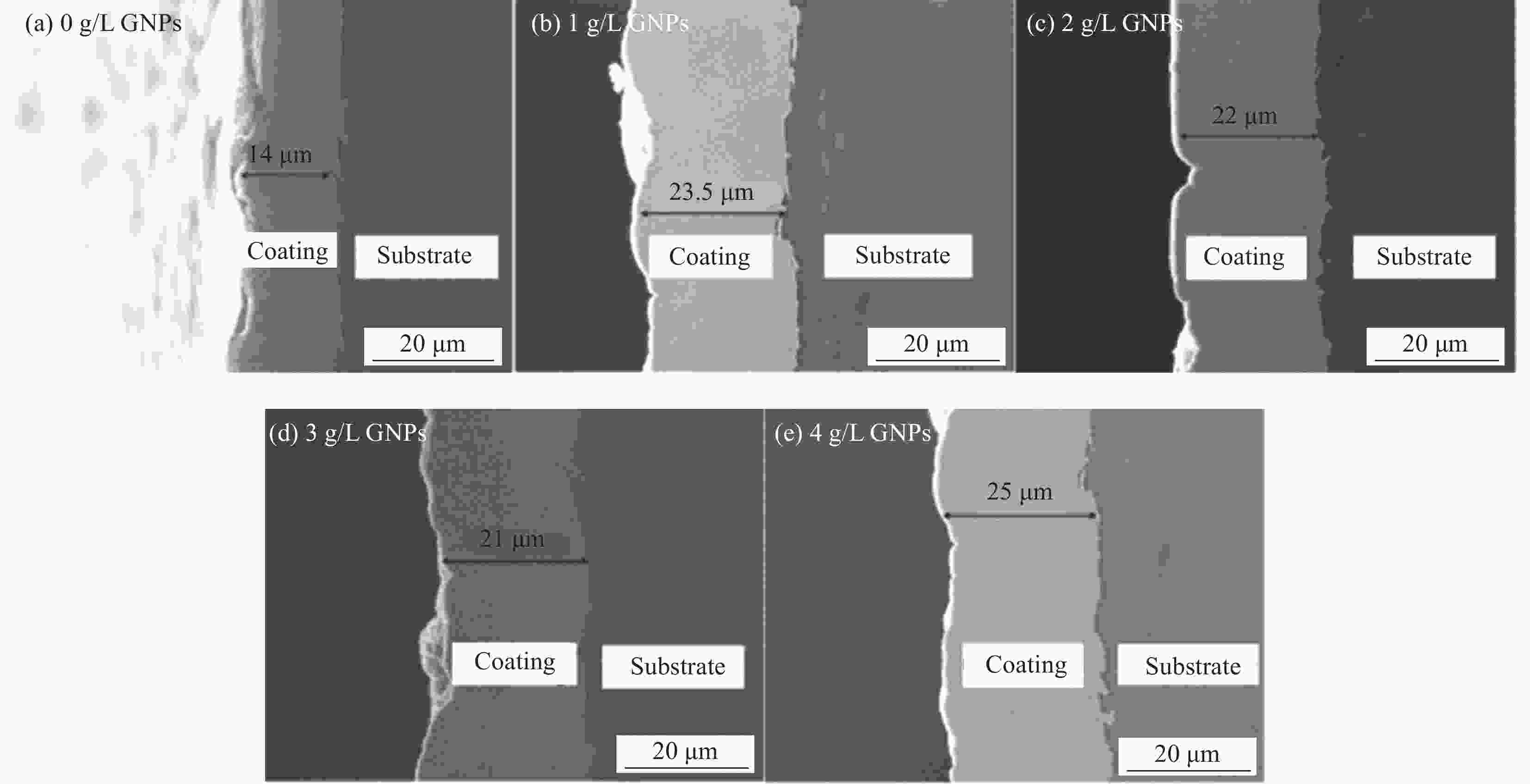

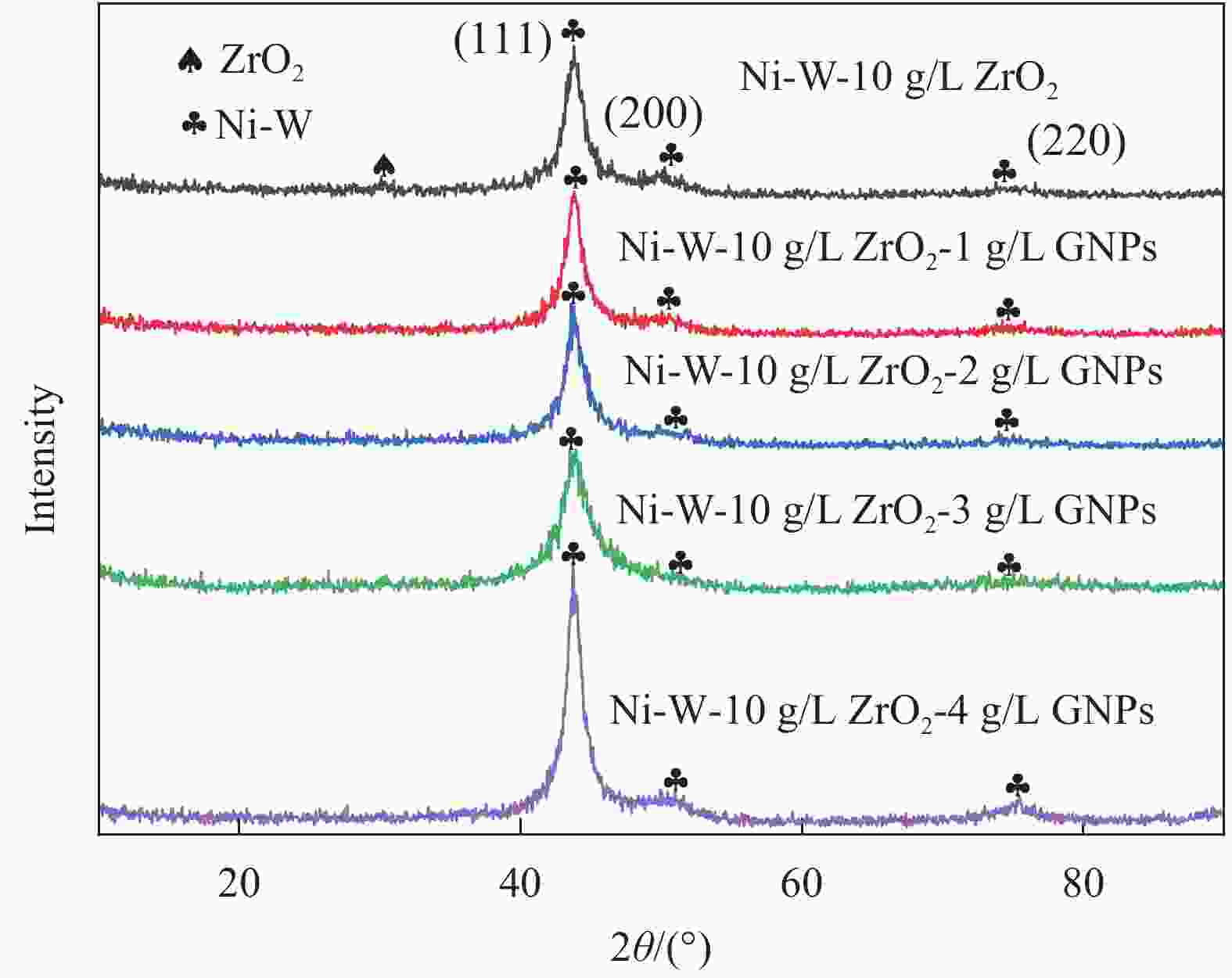

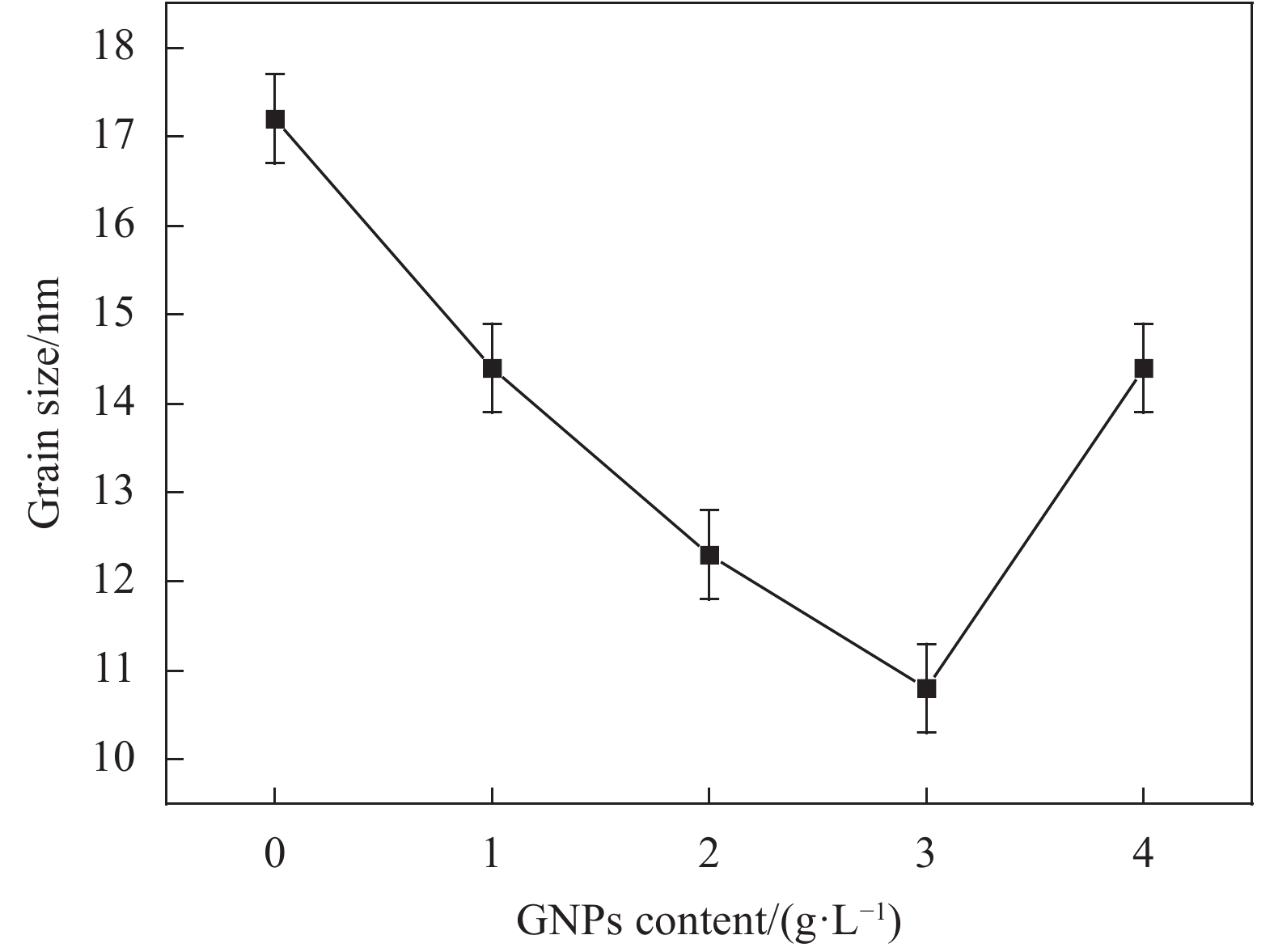

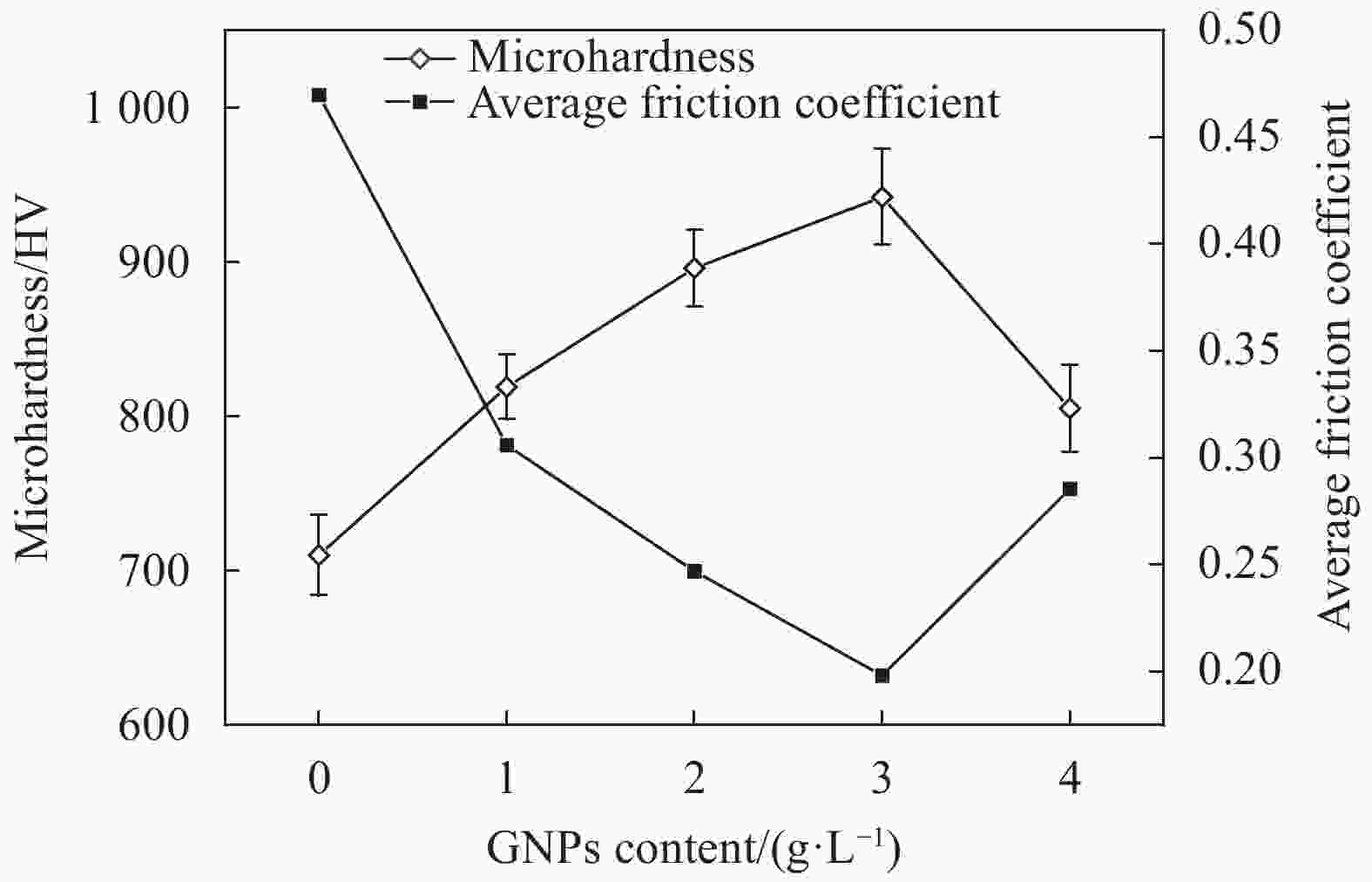

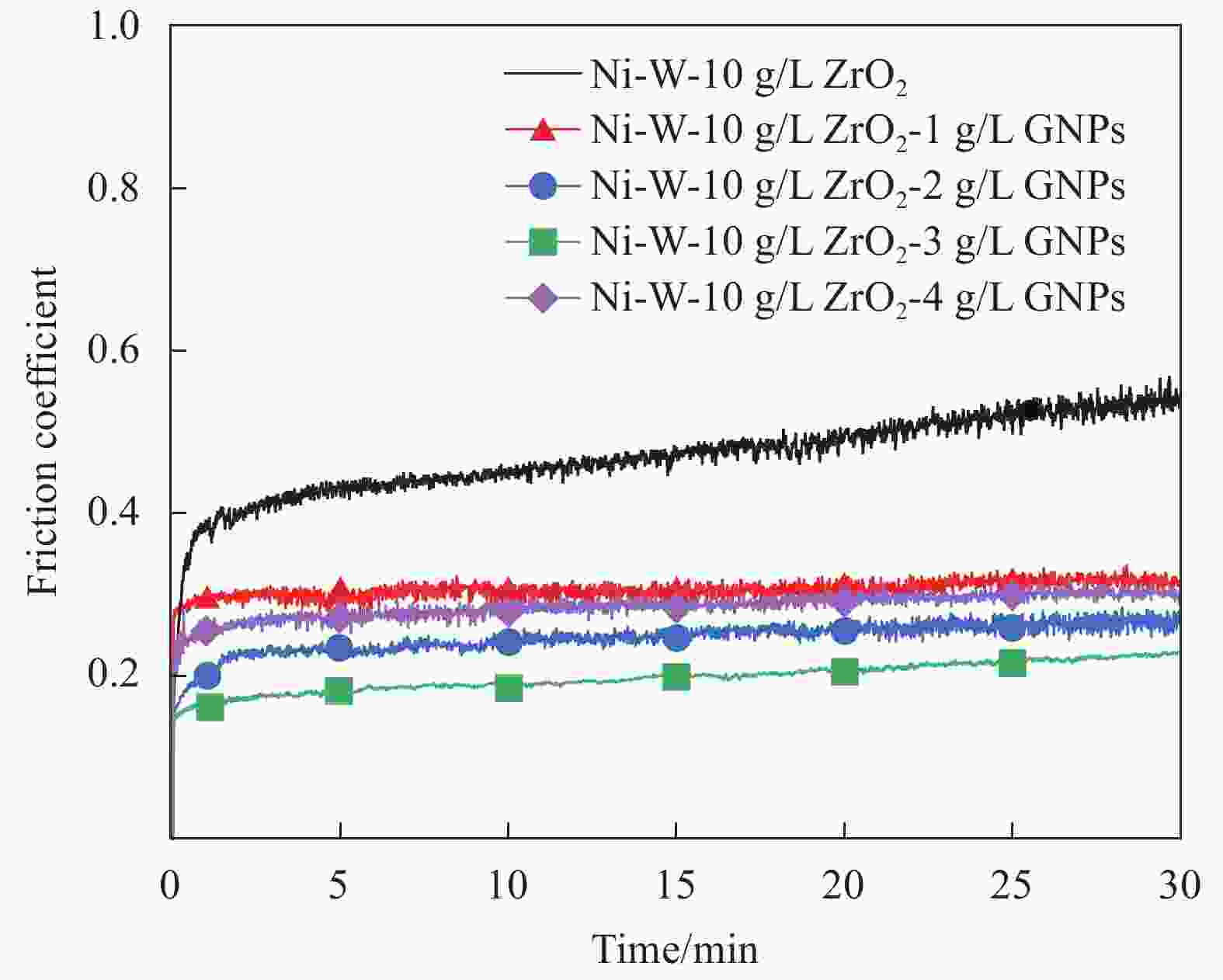

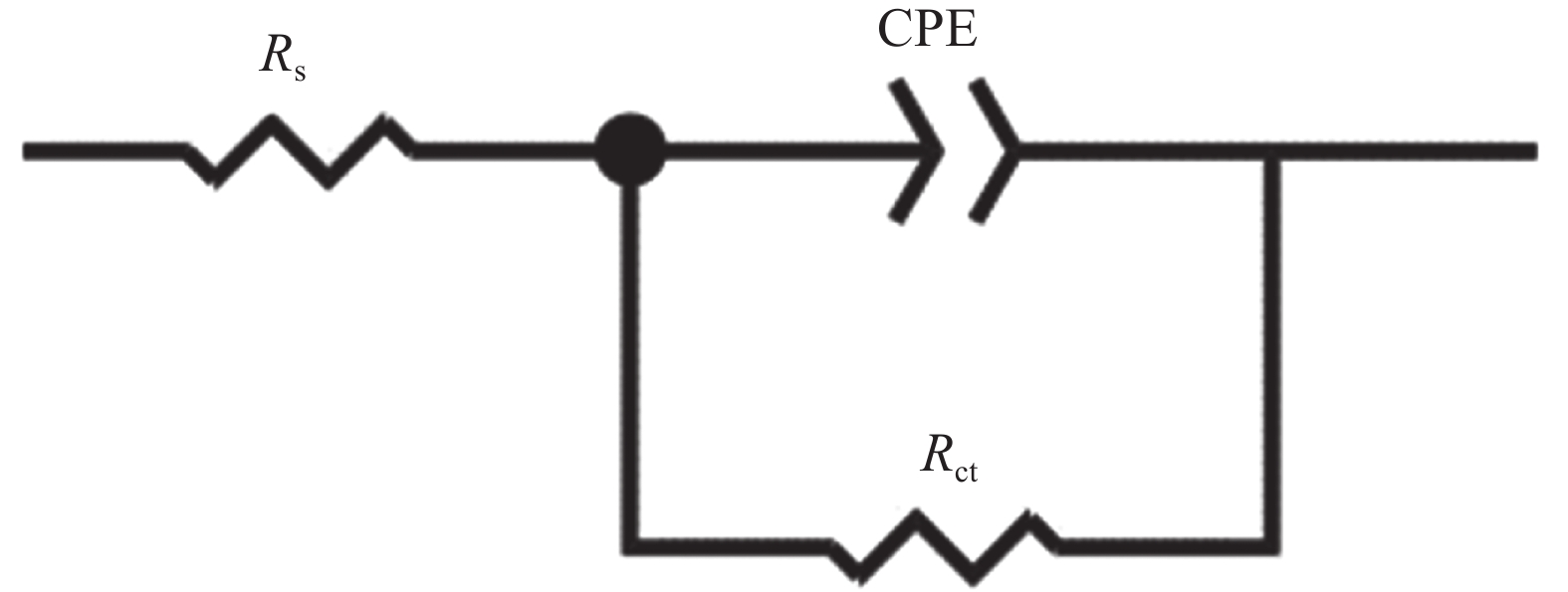

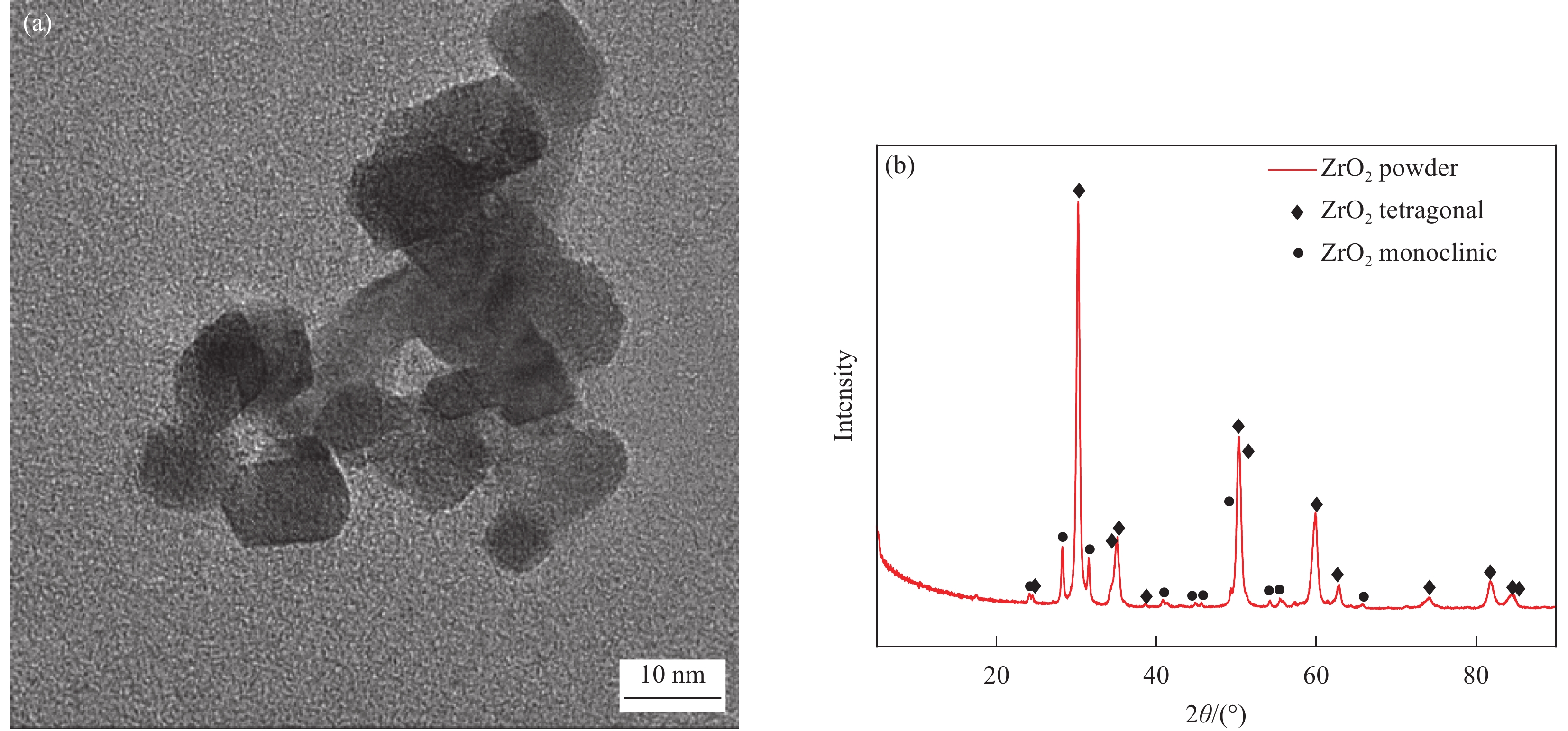

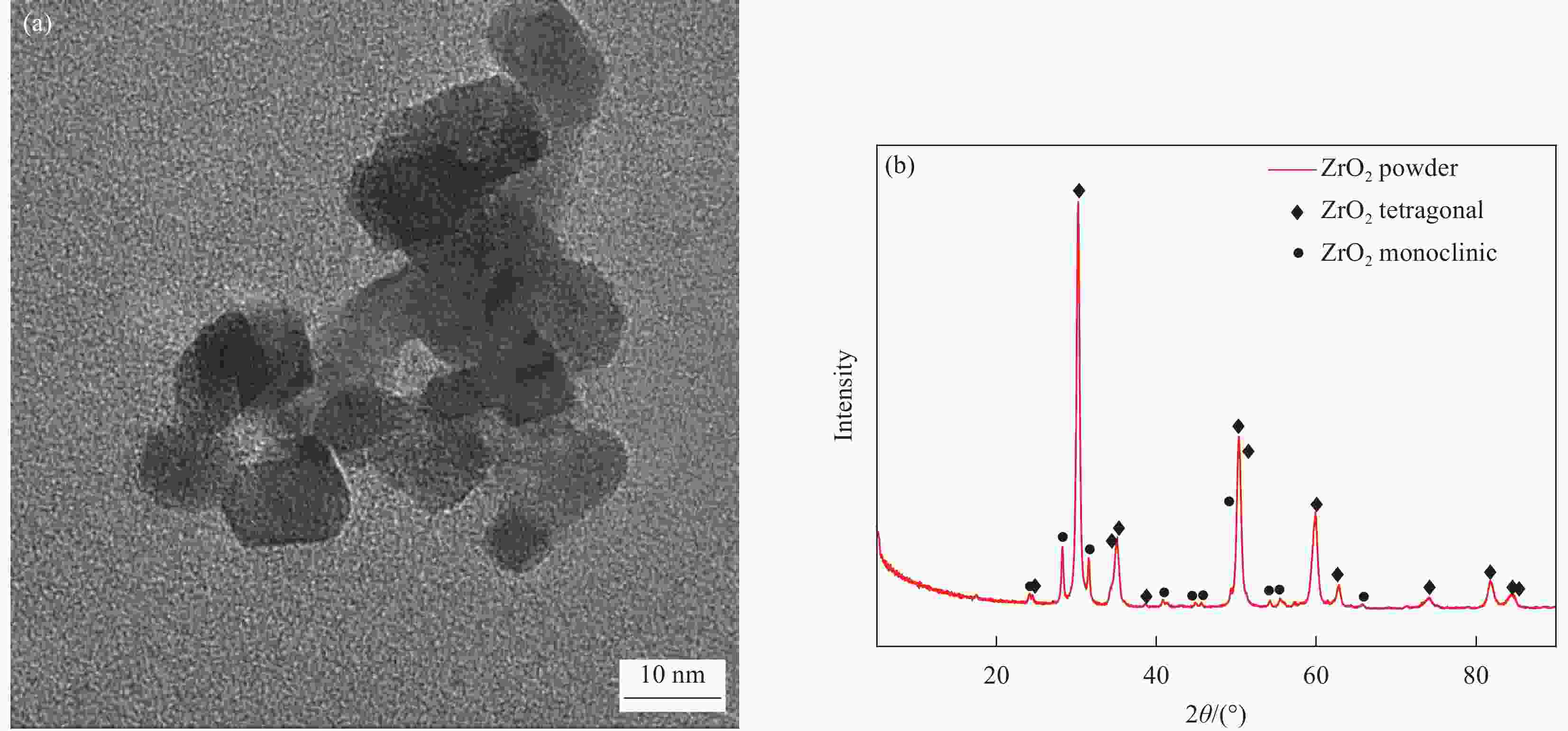

摘要: 为提高Ni-W-ZrO2复合镀层的显微硬度和耐蚀性,通过电沉积方法在7075铝合金上制备Ni-W-ZrO2-石墨烯纳米片(GNPs)复合镀层,利用GNPs来改善Ni-W-ZrO2复合镀层表面性能不足的问题。利用正交试验对实验工艺条件进行优选:电流密度为10 A/dm2,搅拌速度为250 r/min,温度为60℃。在优选工艺条件下,ZrO2纳米颗粒保持10 g/L,改变GNPs的含量(1、2、3、4 g/L),寻求最佳GNPs添加量的Ni-W-10 g/L ZrO2-GNPs复合镀层。通过显微硬度计及旋转摩擦试验仪,研究显微硬度和耐磨性,通过SEM、EDS、XRD和AFM进行微观表征。通过电化学方法研究Ni-W-ZrO2-GNPs复合镀层在质量分数为3.5wt%NaCl溶液中的耐蚀性。结果表明:GNPs和ZrO2纳米颗粒均匀共沉积在镍钨镀层中,GNPs的掺入对Ni-W-ZrO2复合镀层微观形貌、晶粒大小、显微硬度、摩擦性能及耐蚀性均有显著影响,当GNPs添加量为3 g/L时,镍(钨)基体的晶粒尺寸最小,显微硬度(HV 942)最高,平均摩擦系数(0.1981)最小;当GNPs添加量为2 g/L时,Ni-W-ZrO2-GNPs复合镀层的耐蚀性(电荷转移电阻Rct:9532 Ω·cm2)相较Ni-W-ZrO2复合镀层的耐蚀性(Rct:1766 Ω·cm2)改善明显。Abstract: In order to improve the microhardness and corrosion resistance of Ni-W-ZrO2 composite coating, Ni-W-ZrO2-graphene nanosheets (GNPs) composite coating was prepared on 7075 aluminum alloy by electrodeposition method, and GNPs was used to improve the surface performance of Ni-W-ZrO2 composite coating. Orthogonal experiment was used to optimize the experimental process conditions: the current density was 10 A/dm2, the stirring speed was 250 r/min, and the temperature was 60℃. Under the optimal process conditions, ZrO2 nanoparticles maintain 10 g/L, change the content of GNPs (1, 2, 3, 4 g/L), and seek the best GNPs addition amount of Ni-W-10 g/L ZrO2-GNPs composite coating. The microhardness and abrasion resistance were studied by the microhardness tester and the rotating friction tester, and the microscopic characterization was carried out by SEM, EDS, XRD and AFM. The corrosion resistance of Ni-W-ZrO2-GNPs composite coating in 3.5wt%NaCl solution was studied by electrochemical method. The results show that GNPs and ZrO2 nanoparticles are uniformly co-deposited in the nickel-tungsten coating, and the incorporation of GNPs has a significant effect on the microscopic morphology, grain size, microhardness, friction performance and corrosion resistance of the Ni-W-ZrO2 composite coating. When the amount of GNPs added is 3 g/L, the grain size of the Ni (W) matrix is the smallest, the microhardness (HV 942) is the highest, and the average friction coefficient (0.1981) is the smallest. When the amount of GNPs is 2 g/L, the corrosion resistance of Ni-W-ZrO2-GNPs composite coating (Charge transfer resistance Rct: 9532 Ω·cm2) is significantly improved compared to Ni-W-ZrO2 composite coating (Rct: 1766 Ω·cm2).

-

表 1 Ni-W-ZrO2-GNPs复合镀层正交试验结果

Table 1. Orthogonal experimental results of Ni-W-ZrO2-GNPs composite plating

Number Content of GNPs/

(g·L−1)Current density/

(A·dm−2)Temperature/

℃Stirring speed/

(r·min−1)Microhardness Average friction

coefficient1 0 6 40 150 659 0.5721 2 0 8 50 200 684 0.5437 3 0 10 60 250 710 0.4697 4 0 12 70 300 723 0.5042 5 1 6 50 250 734 0.3181 6 1 8 40 300 702 0.3469 7 1 10 70 150 746 0.2731 8 1 12 60 200 893 0.2661 9 2 6 60 300 801 0.2504 10 2 8 70 250 757 0.2573 11 2 10 40 200 785 0.2326 12 2 12 50 150 745 0.3006 13 3 6 70 200 768 0.2724 14 3 8 60 150 831 0.2520 15 3 10 50 300 821 0.2227 16 3 12 40 250 819 0.2533 表 2 Ni-W-ZrO2-GNPs复合镀层直接分析结果

Table 2. Direct analysis results of Ni-W-ZrO2-GNPs composite plating

Number Content of

GNPs/(g·L−1)Current density/

(A·dm−2)Temperature/

℃Stirring speed/

(r·min−1)Microhardness Average friction

coefficient1 3 12 60 200 876 0.2454 2 3 10 60 250 942 0.1981 3 3 10 50 300 821 0.2227 表 3 Ni-W-ZrO2-GNPs复合镀层电化学阻抗数据

Table 3. Electrochemical impedance data of Ni-W-ZrO2-GNPs composite coating

Sample Rs/(Ω·cm2) Rct/(Ω·cm2) CPE-T/(Ω−1·cm−2·s−n) CPE-P/(Ω−1·cm−2·s−n) Ni-W-10 g/L ZrO2 8.254 1766 0.000104 0.81017 Ni-W-10 g/L ZrO2-1 g/L GNPs 7.411 3051 0.000136 0.82018 Ni-W-10 g/L ZrO2-2 g/L GNPs 8.877 9532 0.000042 0.92166 Ni-W-10 g/L ZrO2-3 g/L GNPs 7.672 7448 0.000068 0.85591 Ni-W-10 g/L ZrO2-4 g/L GNPs 9.783 2606 0.000111 0.83356 Note: CPE-T, CPE-P—Two parameters of CPE. -

[1] 任秀秀, 赵省向, 韩仲熙, 等. 纳米复合含能材料的制备方法、复合体系及其性能的研究进展[J]. 材料导报, 2019, 33(23):91-100.REN Xiuxiu, ZHAO Shengxiang, HAN Zhongxi, et al. Research progress on preparation methods, composite system and its property of nanocomposite energetic materials[J]. Materials Review,2019,33(23):91-100(in Chinese). [2] 武高辉. 金属基复合材料发展的挑战与机遇[J]. 复合材料学报, 2014, 31(5):1228-1237.WU Gaohui. Development challenge and opportunity of metal matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(5):1228-1237(in Chinese). [3] 王慧远, 李超, 李志刚, 等. 纳米增强体强化轻合金复合材料制备及构型设计研究进展与展望[J]. 金属学报, 2019, 55(6):683-691.WANG Huiyuan, LI Chao, LI Zhigang, et al. Current research and future prospect on the preparation and architecture design of nanomaterials reinforced light metal matrix composites[J]. Acta Metallurgica Sinica,2019,55(6):683-691(in Chinese). [4] TORABINEJAD V, ALIOFKHAZRAEI M, ROUHAGHDAM A S, et al. Mechanical properties of multilayer Ni-Fe and Ni-Fe-Al2O3 nanocomposite coating[J]. Materials Science & Engineering A,2017,700:448-456. [5] ZHOU Y R, ZHANG S, NIE L L, et al. Electrodeposition and corrosion resistance of Ni-P-TiN composite coating on AZ91D magnesium alloy[J]. Transactions of Nonferrous Metals Society of China,2016,26(11):2976-2987. doi: 10.1016/S1003-6326(16)64428-X [6] ALLAHYARZADEH M H, ALIOFKHAZRAEI M, REZVANIAN A R, et al. Ni-W electrodeposited coatings: Characterization, properties and applications[J]. Surface and Coatings Technology,2016, 307:978-1010. [7] COSTA J M, NETO A. Electrodeposition of nickel-tungsten alloys under ultrasonic waves: Impact of ultrasound inten-sity on the anticorrosive properties[J]. Ultrasonics Sonochemistry,2021,73:105495. doi: 10.1016/j.ultsonch.2021.105495 [8] LEE H B. Synergy between corrosion and wear of electrodeposited Ni-W coating[J]. Tribology Letters,2013,50(3):407-419. [9] BELTOWSKA-LEHMAN E, BIGOS A, SZCZERBA M J, et al. Heat treatment of ultrasonic electrodeposited Ni-W/ZrO2 nanocomposites[J]. Surface and Coatings Technology,2020,393:125779. doi: 10.1016/j.surfcoat.2020.125779 [10] LIU X J, WAN C, DONG Y R, et al. Preparation and property of gradient Ni-W-ZrO2 composite coating on LY12 alloy[J]. Transactions of the Indian Institute of Metals,2019,72(5):1187-1199. doi: 10.1007/s12666-019-01606-2 [11] 舒霞, 李云, 吴玉程, 等. Ni-W-ZrO2复合镀层的制备及耐腐蚀性能[J]. 复合材料学报, 2007, 24(6):116-120.SHU Xia, LI Yun, WU Yucheng, et al. Preparation and corrosion resistance of Ni-W-ZrO2 composite coatings by electrodeposition[J]. Acta Materiae Compositae Sinica,2007,24(6):116-120(in Chinese). [12] LI B S, LI D D, ZHANG J, et al. Preparation of Ni-W nanocrystalline composite films reinforced by embedded zirconia ceramic nanoparticles[J]. Materials Research Bulletin,2019,114:138-147. doi: 10.1016/j.materresbull.2019.03.004 [13] ZHANG W W, JI C C, LI B S. Synthesis and properties of Ni-W/ZrO2 nanocomposite coating fabricated by pulse electrodeposition[J]. Results in Physics,2019,13:102242. [14] 苏峰华, 张欣博, 孙建芳. 功能化石墨烯及石墨烯基纳米复合材料润滑添加剂的研究进展[J]. 表面技术, 2021, 50(4):1-17.SU Fenghua, ZHANG Xinbo, SUN Jianfang. Research progress of functionalized graphene and graphene-based nanocomposites lubricating additives[J]. Surface Technology,2021,50(4):1-17(in Chinese). [15] 王剑桥, 雷卫宁, 薛子明, 等. 石墨烯增强金属基复合材料的制备及应用研究进展[J]. 材料工程, 2018, 46(12):18-27.WANG Jianqiao, LEI Weining, XUE Ziming, et al. Research progress on synthesis and application of graphene reinforced metal matrix composites[J]. Journal of Materials Engineering,2018,46(12):18-27(in Chinese). [16] 王娟, 张法明, 商彩云, 等. 石墨烯/钛基复合材料的界面反应控制、微观组织和压缩性能[J]. 复合材料学报, 2020, 37(12):3137-3148.WANG Juan, ZHANG Faming, SHANG Caiyun, et al. Tailoring of interface reaction, microstructure and compressive properties of graphene reinforced titanium alloy matrix composites[J]. Acta Materiae Compositae Sinica,2020,37(12):3137-3148(in Chinese). [17] YI F, YI H, LUO P Y, et al. Pulse current electrodeposition and properties of Ni-W-GO composite coatings[J]. Jour-nal of the Electrochemical Society,2016,163(3):68-73. [18] UYSAL M, ALGÜL H, DURU E, et al. Tribological properties of Ni-W-TiO2-GO composites produced by ultrasonically-assisted pulse electro co-deposition[J]. Surface and Coatings Technology,2021,410:126942. doi: 10.1016/j.surfcoat.2021.126942 [19] 田水昌, 崔洪芝, 张国松, 等. Ni-W-GO-Al2O3复合镀层的制备及其耐磨耐蚀性能[J]. 材料热处理学报, 2019, 40(2):140-147.TIAN Shuichang, CUI Hongzhi, ZHANG Guosong, et al. Preparation of Ni-W-GO-Al2O3 composite coatings and its wear and corrosion resistance[J]. Transactions of Mater-ials and Heat Treatment,2019,40(2):140-147(in Chinese). [20] 冯彦寒, 方建华, 吴江, 等. 等离子喷涂制备石墨烯/Al2O3+13%TiO2自润滑涂层及其性能研究[J]. 表面技术, 2019, 48(12):201-207.FENG Yanhan, FANG Jianhua, WU Jiang, et al. Preparation and property research of graphene/Al2O3+13%TiO2 self-lubricating coatings fabricated by plasma spray[J]. Surface Technology,2019,48(12):201-207(in Chinese). [21] 丁建涛, 孟凡涛, 隋江, 等. 石墨烯分散方法研究进展[J]. 应用化工, 2018, 315(5):202-206.DING Jiantao, MENG Fantao, SUI Jiang, et al. A review of graphene dispersion method[J]. Applied Chemical Industry,2018,315(5):202-206(in Chinese). [22] ZHAO C M, YAO Y W, HE L. Electrodeposition and characterization of Ni-W/ZrO2 nanocomposite coatings[J]. Bulletin of Materials Science,2014,37(5):1053-1058. doi: 10.1007/s12034-014-0044-z [23] BELTOWSKA-LEHMAN E, INDYKA P, BIGOS A, et al. Ni-W/ZrO2 nanocomposites obtained by ultrasonic DC electrodeposition[J]. Materials & Design,2015,80:1-11. [24] ELIAS L, HEGDE A C. Electrodeposition of laminar coatings of Ni-W alloy and their corrosion behaviour[J]. Surface & Coatings Technology,2015,283:61-69. [25] LI H, HE Y, HE T, et al. The influence of pulse plating parameters on microstructure and properties of Ni-W-Si3N4 nanocomposite coatings[J]. Ceramics International,2016,42(16):18380-18392. doi: 10.1016/j.ceramint.2016.08.171 [26] CORDERO Z C, KNIGHT B E, SCHUH C A. Six decades of the Hall-Petch effect-A survey of grain-size strengthening studies on pure metals[J]. International Materials Reviews,2016,61(8):495-512. [27] LI B S, LI D D, ZHANG J, et al. Electrodeposition of Ni-W/TiN-Y2O3 nanocrystalline coating and investigation of its surface properties and corrosion resistance[J]. Journal of Alloys and Compounds,2019,787:952-962. doi: 10.1016/j.jallcom.2019.02.168 [28] ZHANG R Y, LI Z L, YU X, et al. Characterisation and pro-perties of Ni-W-Y2O3-ZrO2 nanocomposite coating[J]. Surface Engineering,2019,35(7):578-587. doi: 10.1080/02670844.2018.1547246 -

下载:

下载: