Compression properties of three-dimensional woven double spacer composites

-

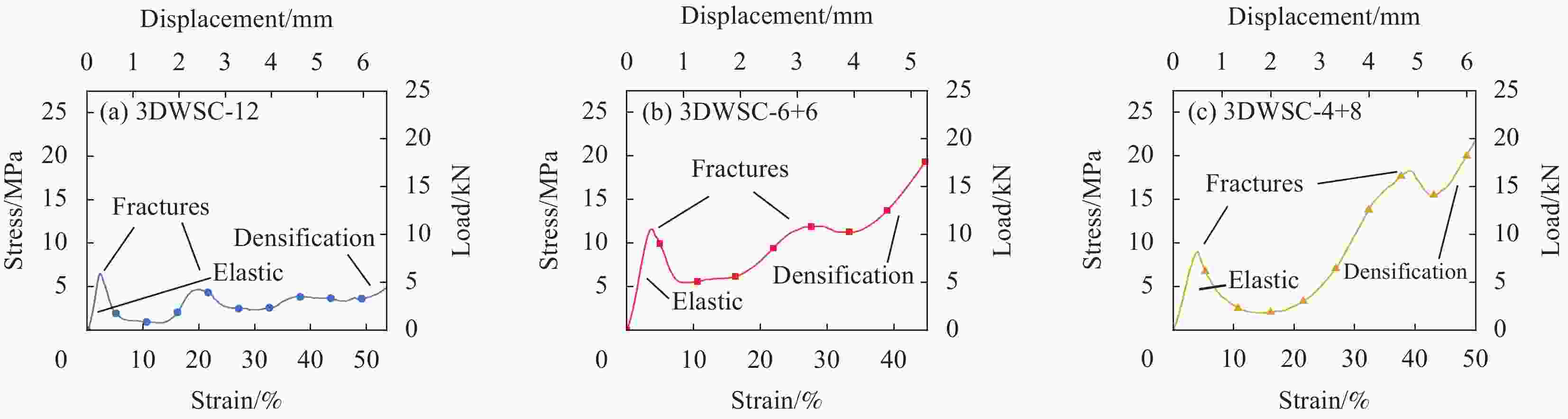

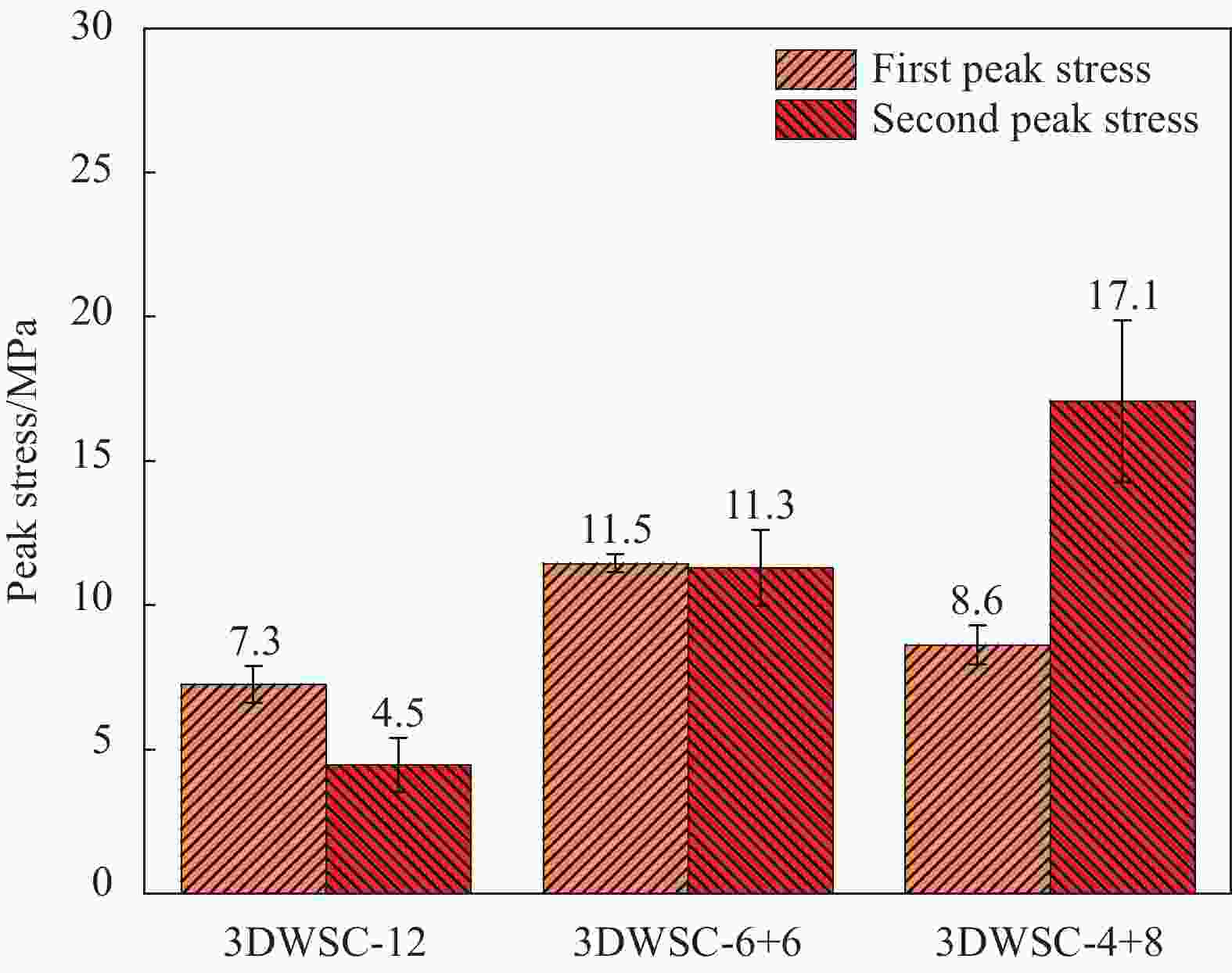

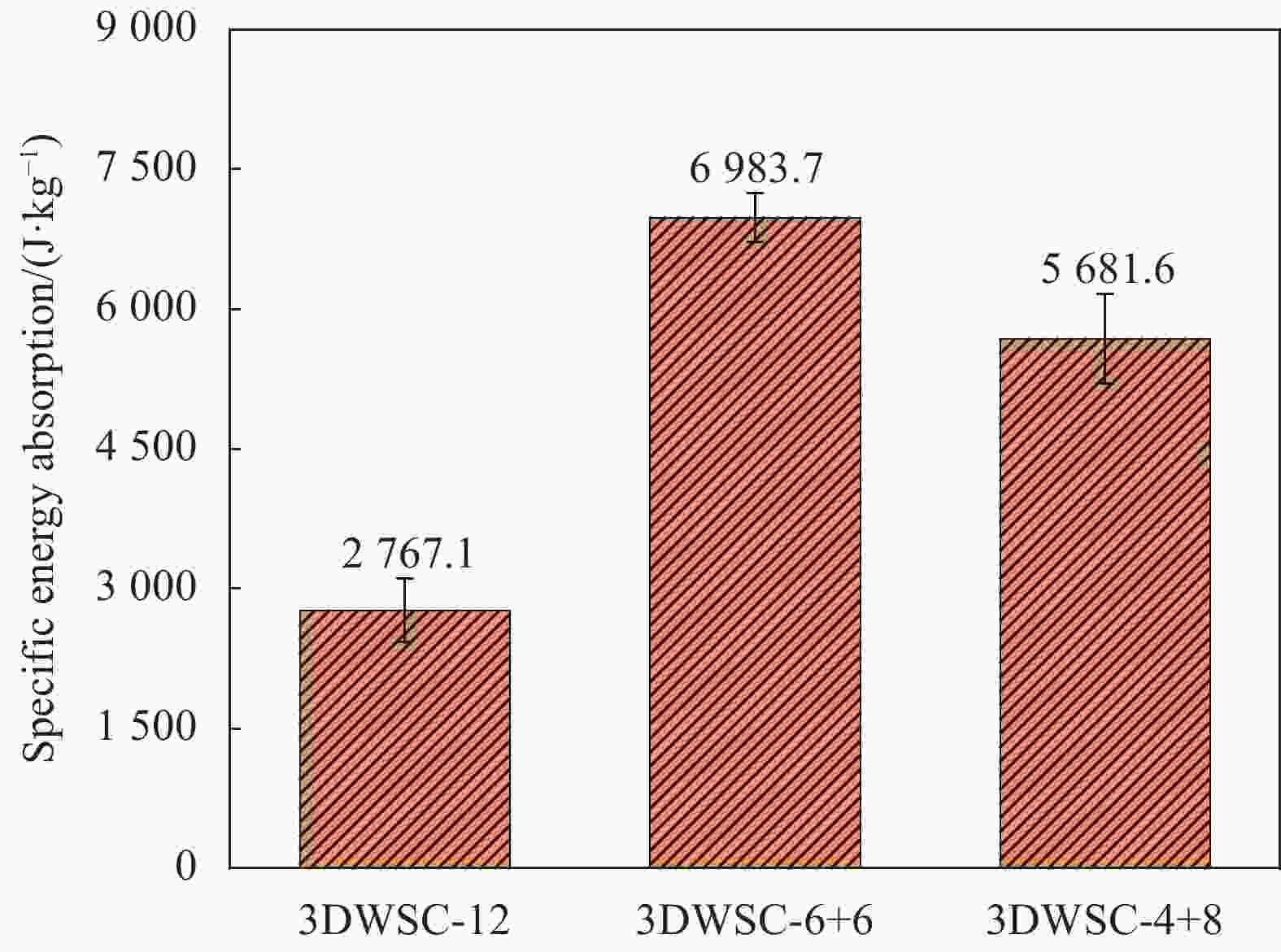

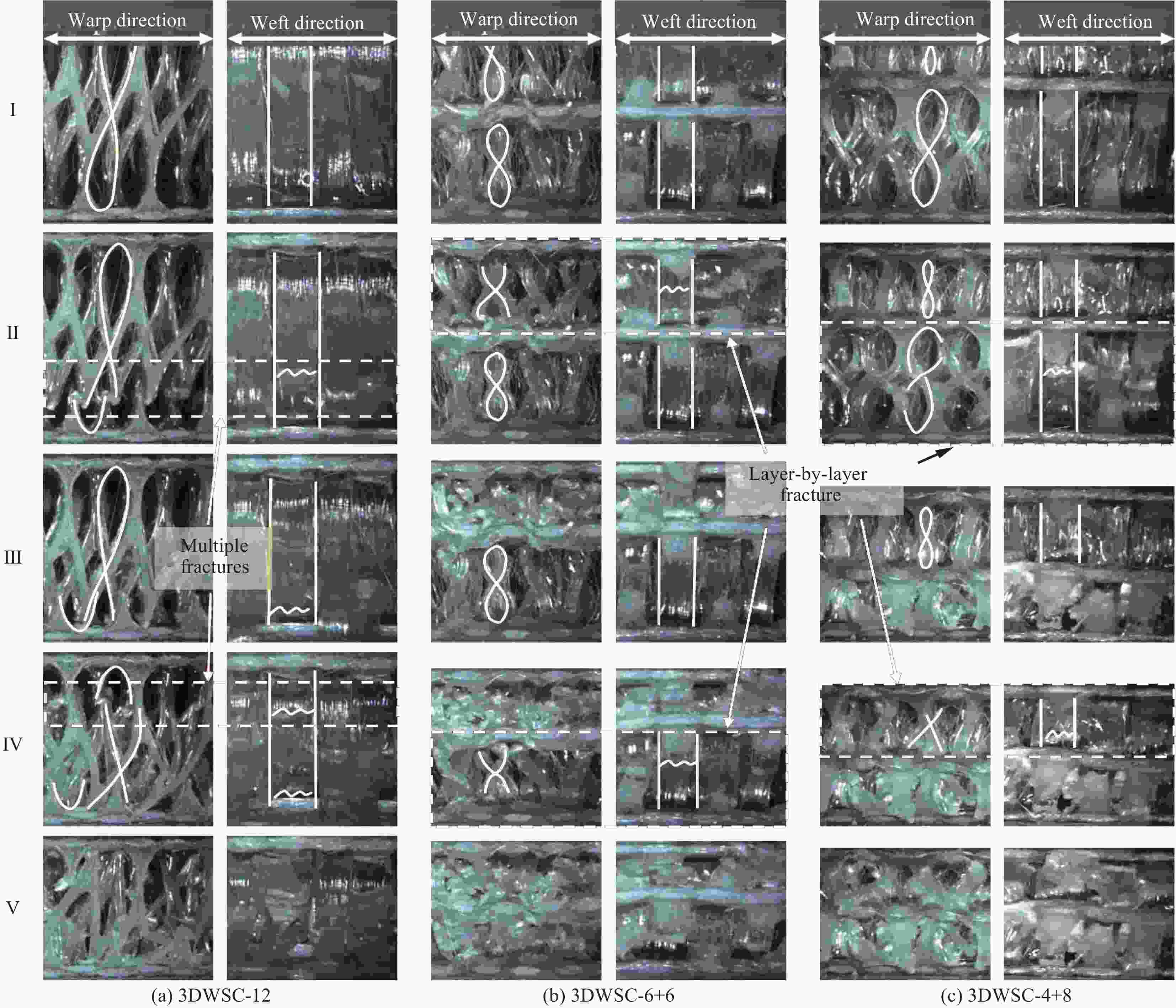

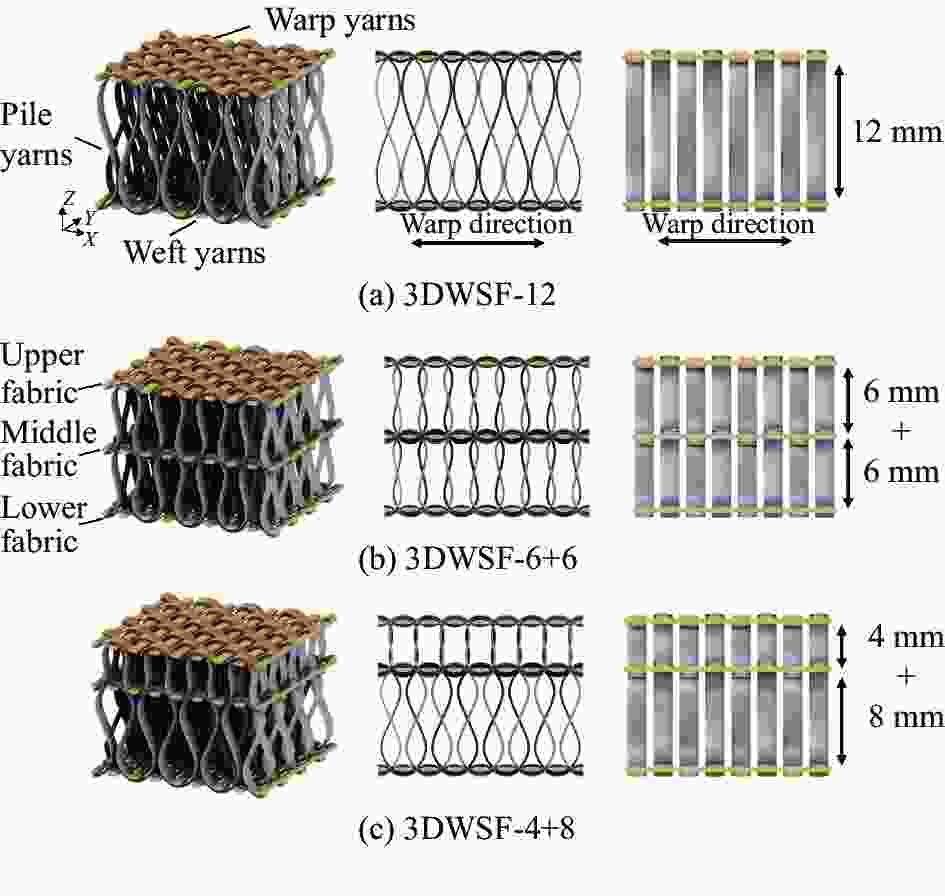

摘要: 为了增强三维机织间隔复合材料的压缩强度及提高其压缩能量吸收能力,受多层夹芯结构的设计理念启发,本论文设计并制备了柱纱高度为(6+6) mm及(4+8) mm的三维机织双层间隔复合材料。通过与柱纱高度为12 mm的单层间隔复合材料进行对比,研究了复合材料的平压、侧压性能及其破坏模式。结果表明,两种双层间隔复合材料的平压强度、侧压强度及能量吸收值相较于单层间隔复合材料都显著提高,其中柱纱高度为(6+6) mm的双层间隔复合材料的平压强度 (11.5 MPa) 提高了57.5%,平压比吸能值 (6983.7 J/kg) 提高了152.4%;此外,双层间隔复合材料的平压破坏模式为柱纱的逐层断裂,侧压破坏模式为面板裂纹扩展,表现出更大的吸能特性。双层间隔结构设计不仅显著增强了间隔复合材料的平压和侧压性能,而且改善了其破坏模式,提高了其在实际应用中的安全性,并为较高柱纱高度以及多层间隔复合材料的结构设计提供了新的思路。

-

关键词:

- 三维机织间隔复合材料 /

- 双层间隔结构 /

- 压缩性能 /

- 吸能结构 /

- 破坏模式

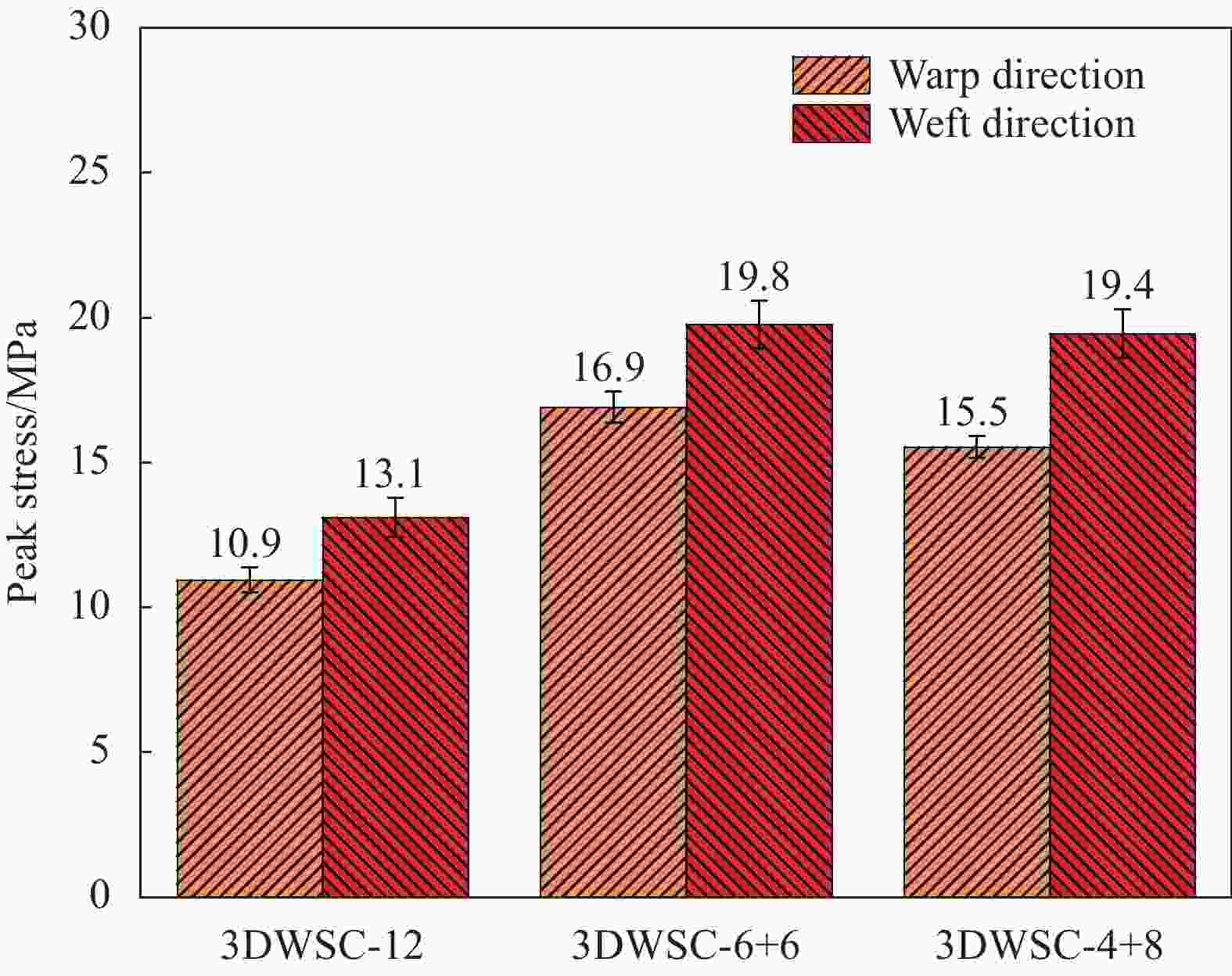

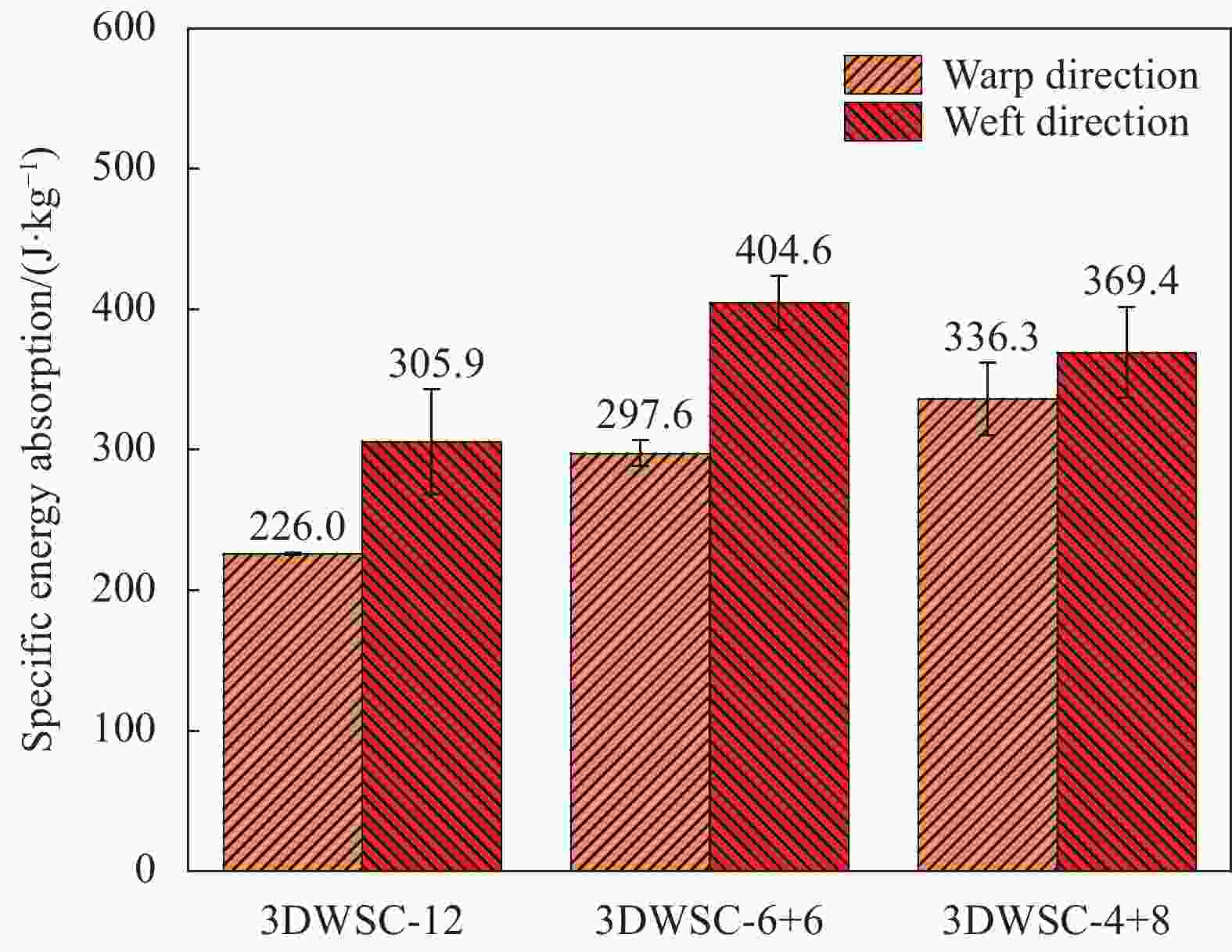

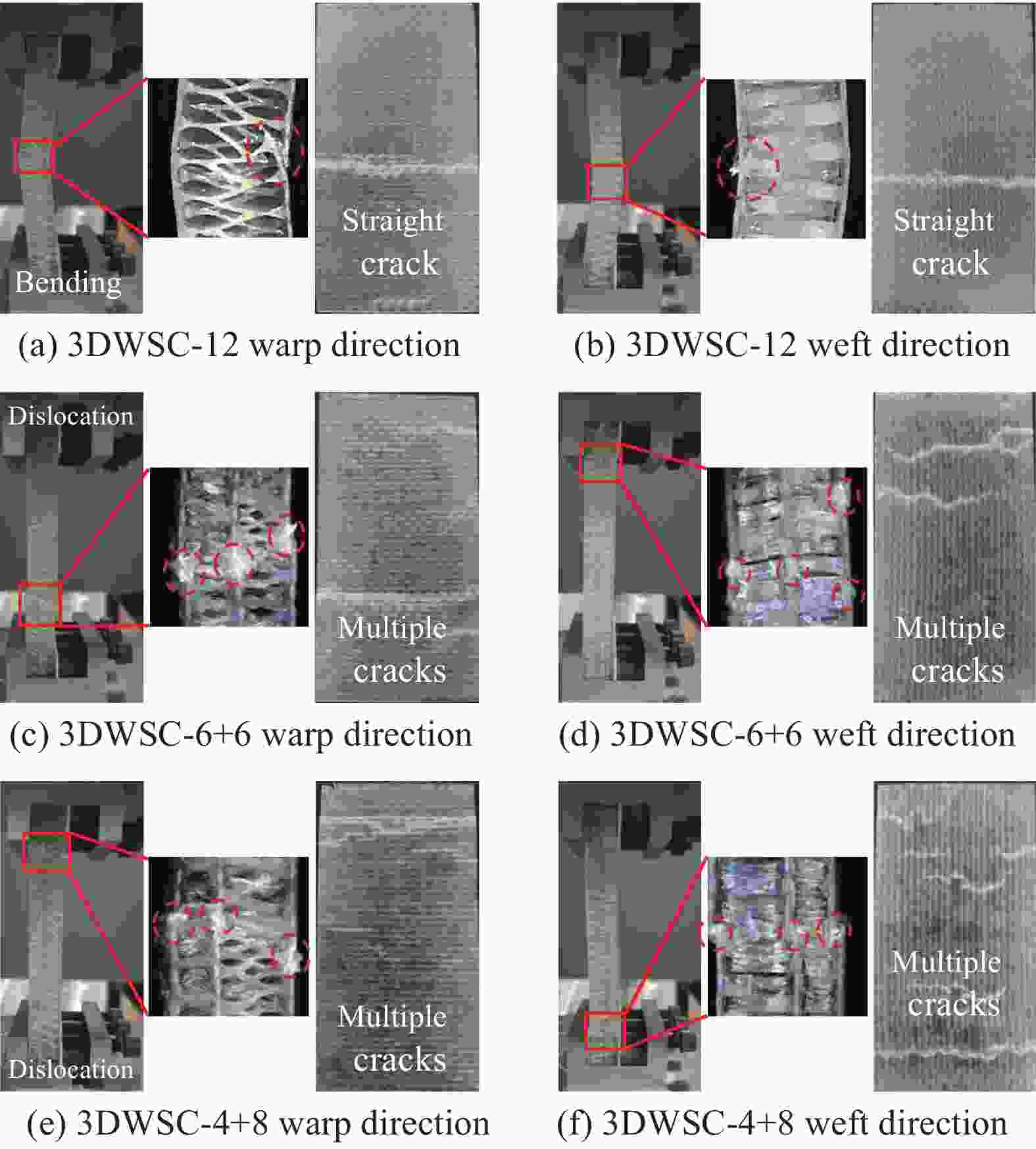

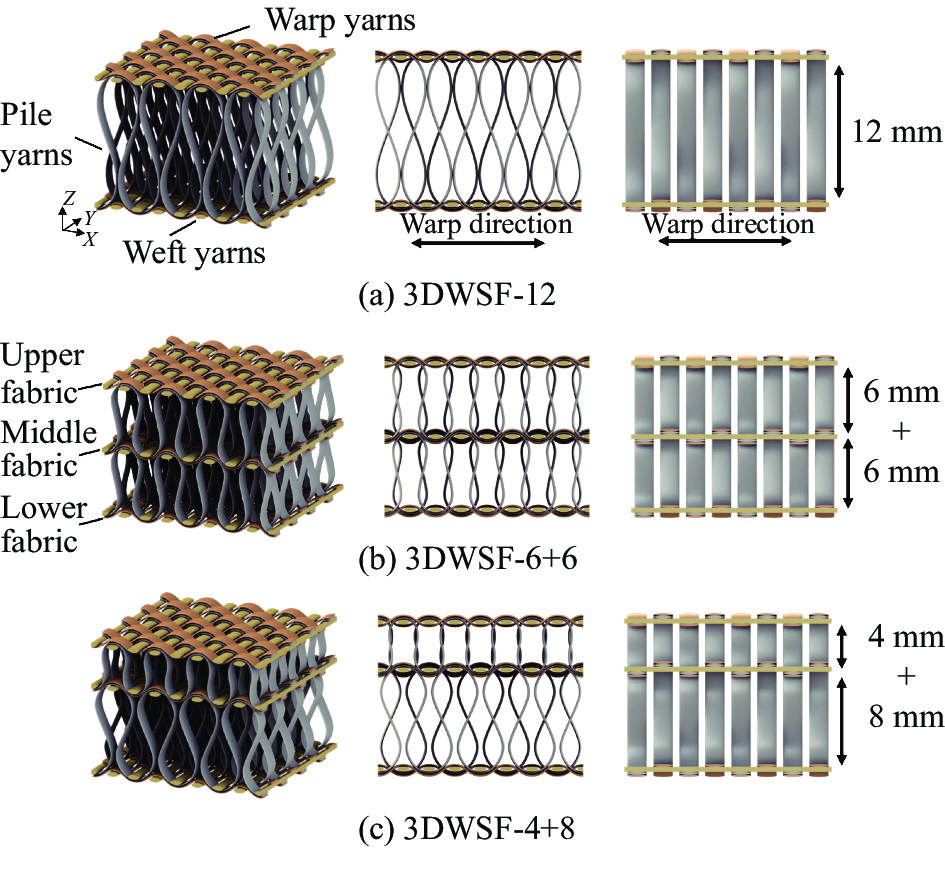

Abstract: In order to enhance the compression strength of three-dimensional woven spacer composites and improve its compression energy absorption, inspired by the design concept of multi-layer sandwich structure, three-dimensional woven double spacer composites with pile height of (6+6) mm and (4+8) mm were designed and fabricated. The flatwise compression and edgewise compression properties and failure modes of the double spacer composites were investigated by comparing with the single spacer composites with the pile height of 12 mm. The results show that the flatwise compressive strength, edgewise compression strength and energy absorption of the two double spacer composites are improved significantly compared with that of single spacer composites. Among them, the flatwise compression strength (11.5 MPa) and specific energy absorption value (6983.7 J/kg) of the double spacer composites with pile height of (6+6) mm are increased by 57.5% and 152.4%, respectively. In addition, the flatwise compression failure mode of the double spacer composites is the fractures of the pile yarns layer by layer, and the edgewise compression failure mode is crack propagation of panel, which show greater energy absorption characteristic. The design of double spacer structure not only enhances the flatwise compression and edgewise compression properties of three-dimensional woven spacer composites, but also optimizes its failure modes, which improves the safety of spacer composites in practical application, and provides a new idea for the structural design of spacer composites with higher pile height or multilayer. -

表 1 三维机织单/双层间隔织物的具体织造参数

Table 1. Specific weaving parameters of 3D woven single/double spacer fabrics

Specimen Yarn linear density/(10−6 kg·m−1) Fabric density/(ends·cm−1) Pile height/mm Warp Weft Pile Warp Weft Pile 3DWSF-12 300 600 300 5.1 5.5 5.1 12 3DWSF-6+6 5.1 5.3 5.1 6+6 3DWSF-4+8 5.1 5.3 5.1 4+8 表 2 三维机织单/双层间隔复合材料试样的参数信息

Table 2. Details of parameters of 3D woven single/double spacer composites

Specimen Compression direction L/mm W/mm H/mm Density/(g·cm−3) Fiber mass fraction/wt% 3DWSC-12 Flat 29.89 29.98 12.13 0.38 47.27 Warp 99.55 52.07 Weft 100.62 52.04 3DWSC-6+6 Flat 30.19 30.43 11.78 0.55 44.47 Warp 99.85 51.96 Weft 100.15 52.19 3DWSC-4+8 Flat 29.86 30.02 12.23 0.52 42.42 Warp 100.20 51.47 Weft 100.30 51.59 Notes: L—Length of the specimen; W—Width of the specimen; H—Thickness of the specimen. -

[1] MIHAILOVIC T V, ASANOVIC K A, CEROVIC D D. Structural design of face fabrics and the core as a premise for compression behavior of 3D woven sandwich fabric[J]. Journal of Sandwich Structures & Materials,2016,20(6):718-734. [2] VAN VUURE A W, IVENS J A, VERPOEST I. Mechanical properties of composite panels based on woven sandwich-fabric preforms[J]. Composites Part A: Applied Science and Manufacturing,2000,31(7):671-680. doi: 10.1016/S1359-835X(00)00017-8 [3] WANG L Y, LIU X H, SALEEMI S, et al. Bending properties and failure mechanisms of three-dimensional hybrid woven spacer composites with glass and carbon fibers[J]. Textile Research Journal,2019,89(21-22):4502-4511. doi: 10.1177/0040517519837730 [4] ZHANG M, WANG X, LIU S, et al. Effects of face sheet structure on mechanical properties of 3D integrated woven spacer composites[J]. Fibers and Polymers,2020,21(7):1594-1604. doi: 10.1007/s12221-020-9908-6 [5] XU F J, ZHANG K, QIU Y P. Light-weight, high-gain three-dimensional textile structural composite antenna[J]. Composites Part B: Engineering, 2020, 185: 107781. [6] GEERINCK R, DE BAERE I, DE CLERCQ G, et al. One-shot production of large-scale 3D woven fabrics with integrated prismatic shaped cavities and their applications[J]. Mater-ials & Design, 2019, 165: 107578. [7] WANG L Y, ZHANG K, FARHA F I, et al. Compressive strength and thermal insulation properties of the 3D woven spacer composites with connected spacer yarn structure[J]. Journal of Materials Science,2020,55(6):2380-2388. doi: 10.1007/s10853-019-04197-x [8] 张艳红, 耿杰, 匡宁, 等. 三维中空复合材料在天线罩上的应用研究[J]. 玻璃纤维, 2015(3):20-23. doi: 10.3969/j.issn.1005-6262.2015.03.005ZHANG Yanhong, GENG Jie, KUANG Ning, et al. Application of 3D hollow sandwich composite in radome[J]. Fiber Glass,2015(3):20-23(in Chinese). doi: 10.3969/j.issn.1005-6262.2015.03.005 [9] LI M, WANG S K, ZHANG Z G, et al. Effect of structure on the mechanical behaviors of three-dimensional spacer fabric composites[J]. Applied Composite Materials,2009,16(1):1-14. doi: 10.1007/s10443-008-9072-4 [10] MIRDEHGHAN A, NOSRATY H, SHOKRIEH M M, et al. Micromechanical modelling of the compression strength of three-dimensional integrated woven sandwich composites[J]. Journal of Industrial Textiles,2018,48(9):1399-1419. [11] FAN H L, ZHAO L, CHEN H L, et al. Dynamic compression failure mechanisms and dynamic effects of integrated woven sandwich composites[J]. Journal of Composite Materials,2014,48(4):427-438. doi: 10.1177/0021998312473859 [12] 高爱君, 李敏, 王绍凯, 等. 三维间隔连体织物复合材料力学性能[J]. 复合材料学报, 2008, 25(2):87-93. doi: 10.3321/j.issn:1000-3851.2008.02.016GAO Aijun, LI Min, WANG Shaokai, et al. Experimental study on the mechanical characteristics of 3D spacer fabric composites[J]. Acta Materiae Compositae Sinica,2008,25(2):87-93(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.016 [13] 周光明, 薄晓莉, 匡宁. 整体中空夹层复合材料的弹性性能分析[J]. 复合材料学报, 2010, 27(1):185-189.ZHOU Guangming, BO Xiaoli, KUANG Ning. Analysis of elastic property for hollow integrated sandwich compo-sites[J]. Acta Materiae Compositae Sinica,2010,27(1):185-189(in Chinese). [14] UMAIR M, HAMDANI S T A, NAWAB Y, et al. Effect of pile height on the mechanical properties of 3D woven spacer composites[J]. Fibers and Polymers,2019,20(6):1258-1265. doi: 10.1007/s12221-019-8761-y [15] SADIGHI M, HOSSEINI S A. Finite element simulation and experimental study on mechanical behavior of 3D woven glass fiber composite sandwich panels[J]. Composites Part B: Engineering,2013,55:158-166. doi: 10.1016/j.compositesb.2013.06.030 [16] ZHAO C Q, LI D S, GE T Q, et al. Experimental study on the compression properties and failure mechanism of 3D integrated woven spacer composites[J]. Materials & Design,2014,56:50-59. [17] FAN H L, ZHOU Q, YANG W, et al. An experiment study on the failure mechanisms of woven textile sandwich panels under quasi-static loading[J]. Composites Part B: En-gineering,2010,41(8):686-692. doi: 10.1016/j.compositesb.2010.07.004 [18] REN C X, HU Z F, YAO C, et al. Experimental study on the quasi-static compression behavior of multilayer aluminum foam sandwich structure[J]. Journal of Alloys and Compounds, 2019, 810: 151860. [19] XIE S, WANG H, YANG C, et al. Mechanical properties of combined structures of stacked multilayer Nomex® honeycombs[J]. Thin-Walled Structures, 2020, 151: 106729. [20] WANG Z G, LIU J F, LU Z J, et al. Mechanical behavior of composited structure filled with tandem honeycombs[J]. Composites Part B: Engineering,2017,114:128-138. doi: 10.1016/j.compositesb.2017.01.018 [21] XIONG J, VAZIRI A, MA L, et al. Compression and impact testing of two-layer composite pyramidal-core sandwich panels[J]. Composite Structures,2012,94(2):793-801. doi: 10.1016/j.compstruct.2011.09.018 [22] WANG Z W, E Y P. Energy absorption properties of multi-layered corrugated paperboard in various ambient humidities[J]. Materials & Design,2011,32(6):3476-3485. [23] FAN H, YANG W, ZHOU Q. Experimental research of compressive responses of multi-layered woven textile sandwich panels under quasi-static loading[J]. Composites Part B: Engineering,2011,42(5):1151-1156. doi: 10.1016/j.compositesb.2011.03.008 [24] 中国国家标准化管理委员会. 夹层结构或芯子平压性能试验方法: GB/T 1453—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for flatwise compression of sandwich constructions or cores: GB/T 1453—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [25] 中国国家标准化管理委员会. 夹层结构侧压性能试验方法: GB/T 1454—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for edgewise compressive properties of sandwich constructions: GB/T 1454—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [26] 中国国家标准化管理委员会. 玻璃纤维增强塑料树脂含量试验方法: GB/T 2577—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Reublic of China. Test method for resin content of glass fiber reinforced plastics: GB/T 2577—2005[S]. Beijing: China Standards Press, 2005(in Chinese). -

下载:

下载: