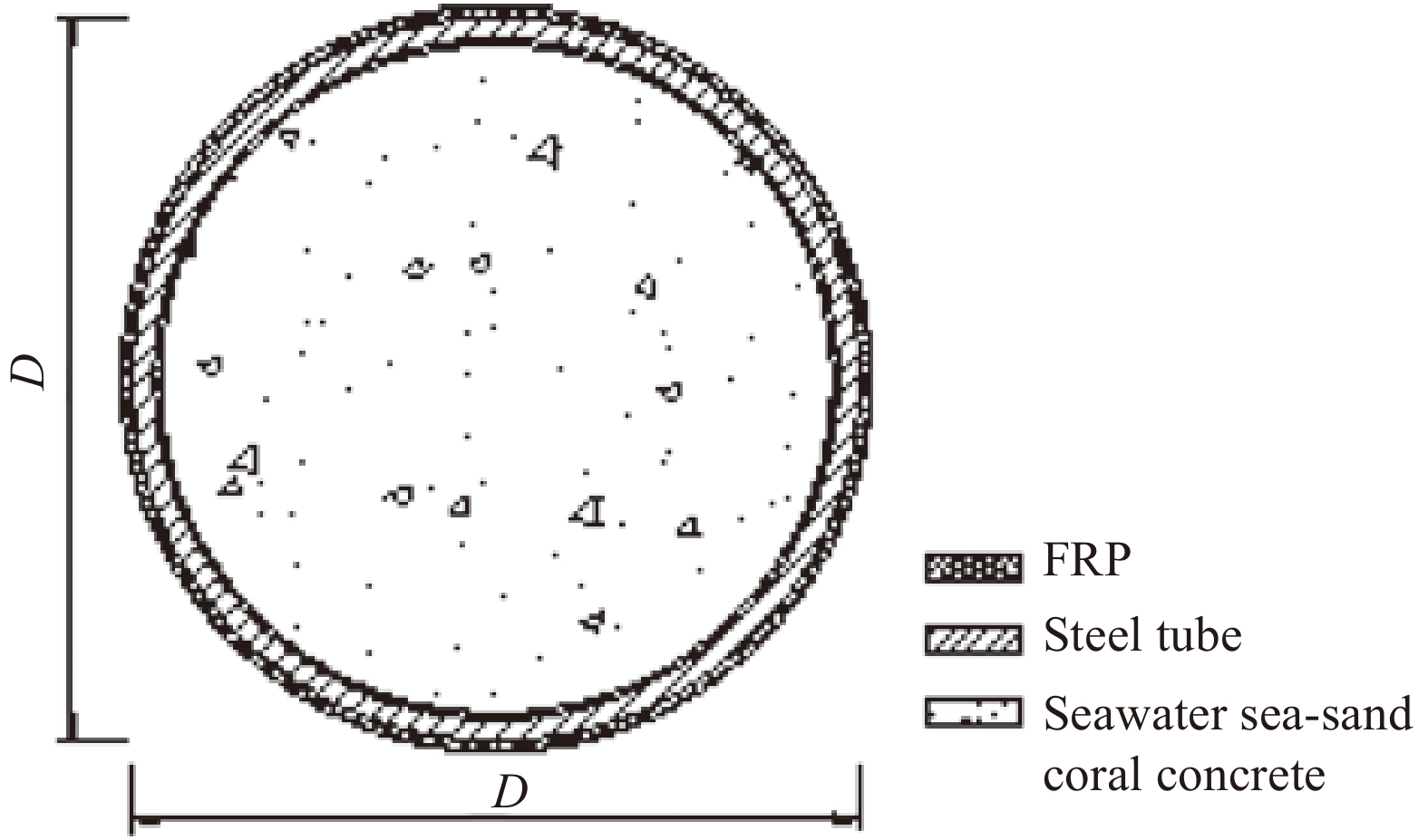

Experimental study on axial compression performance of CFRP-steel composite tube filled circular seawater sea-sand coral concrete columns

-

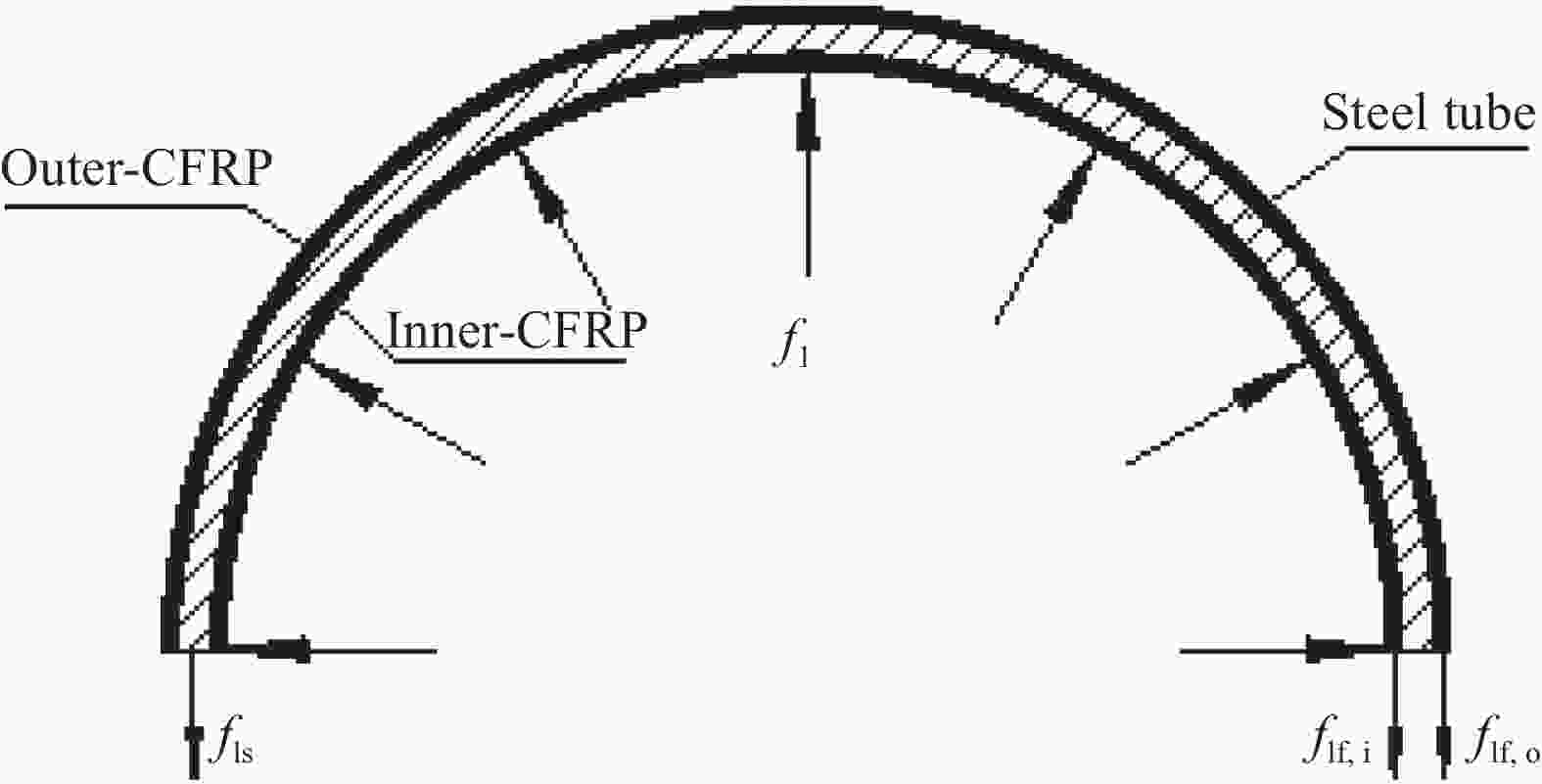

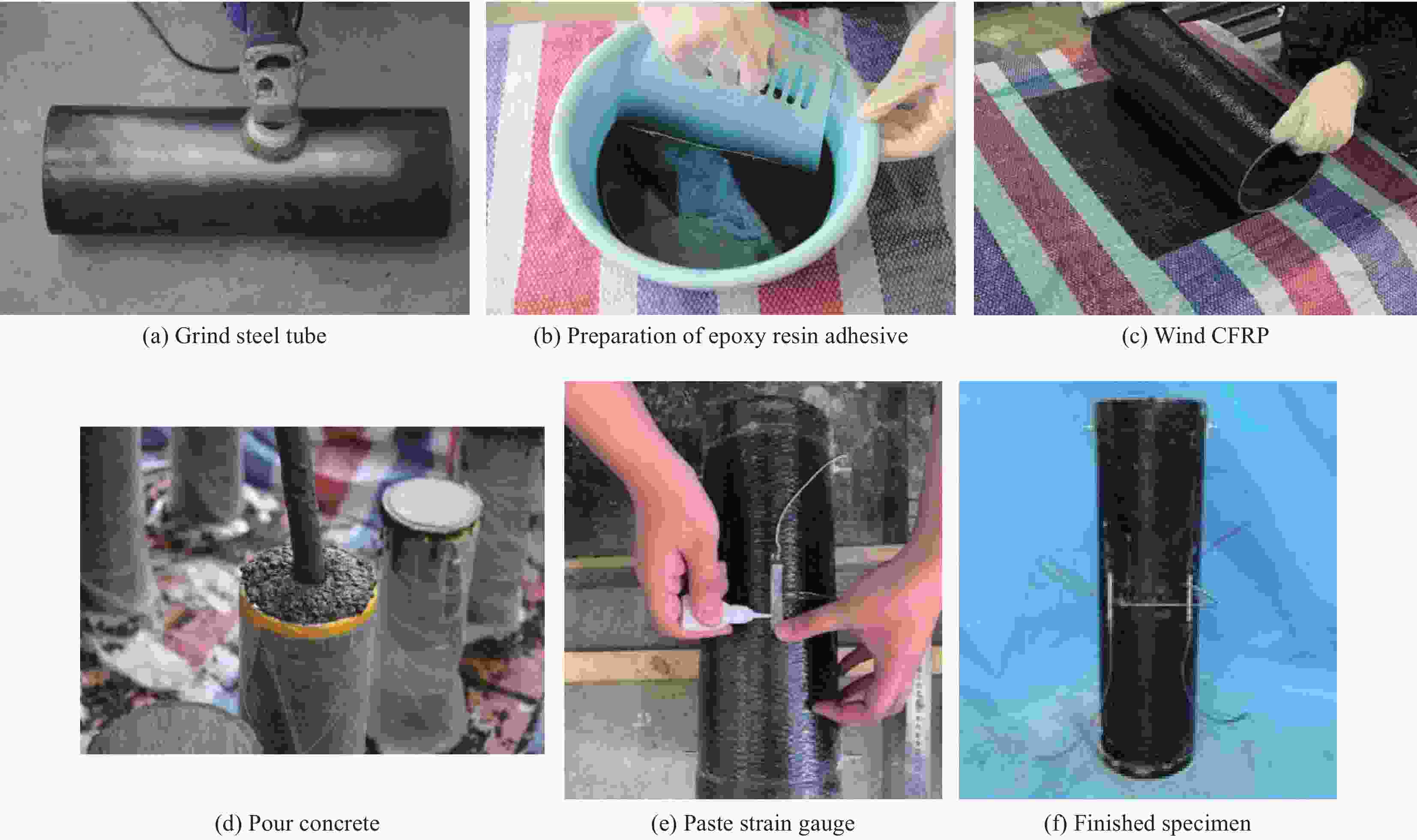

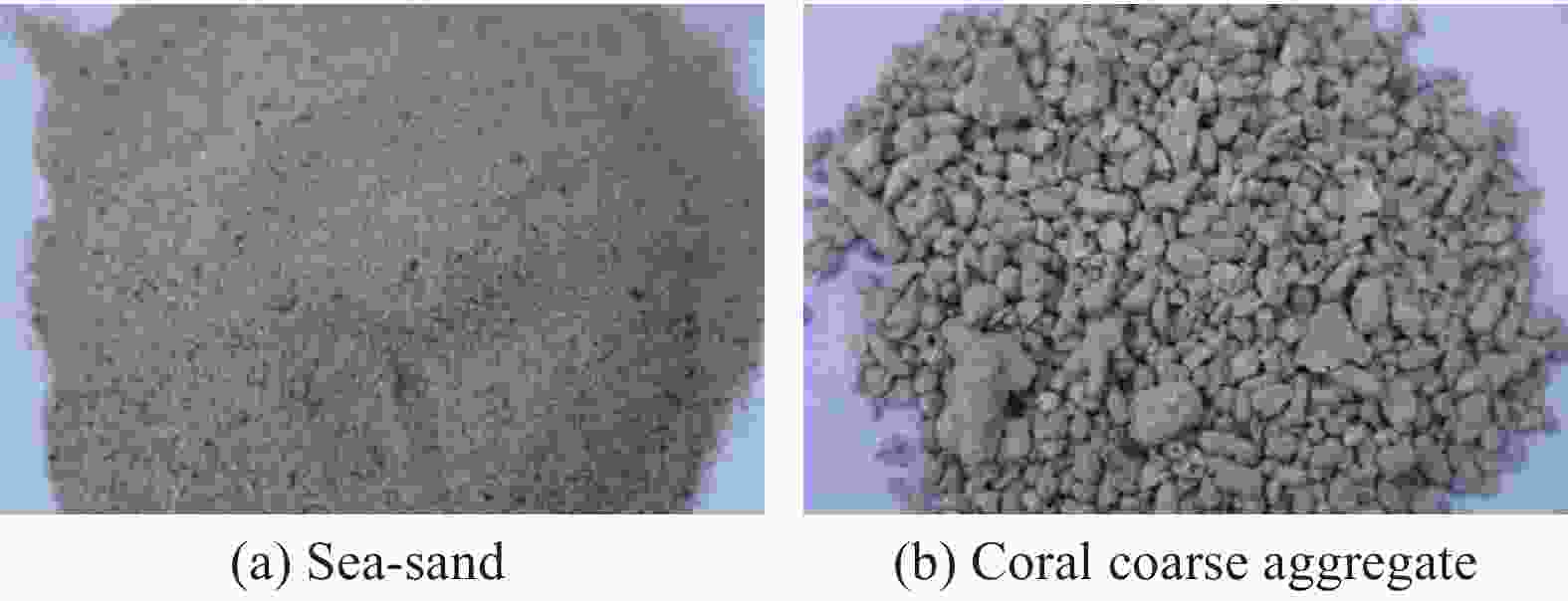

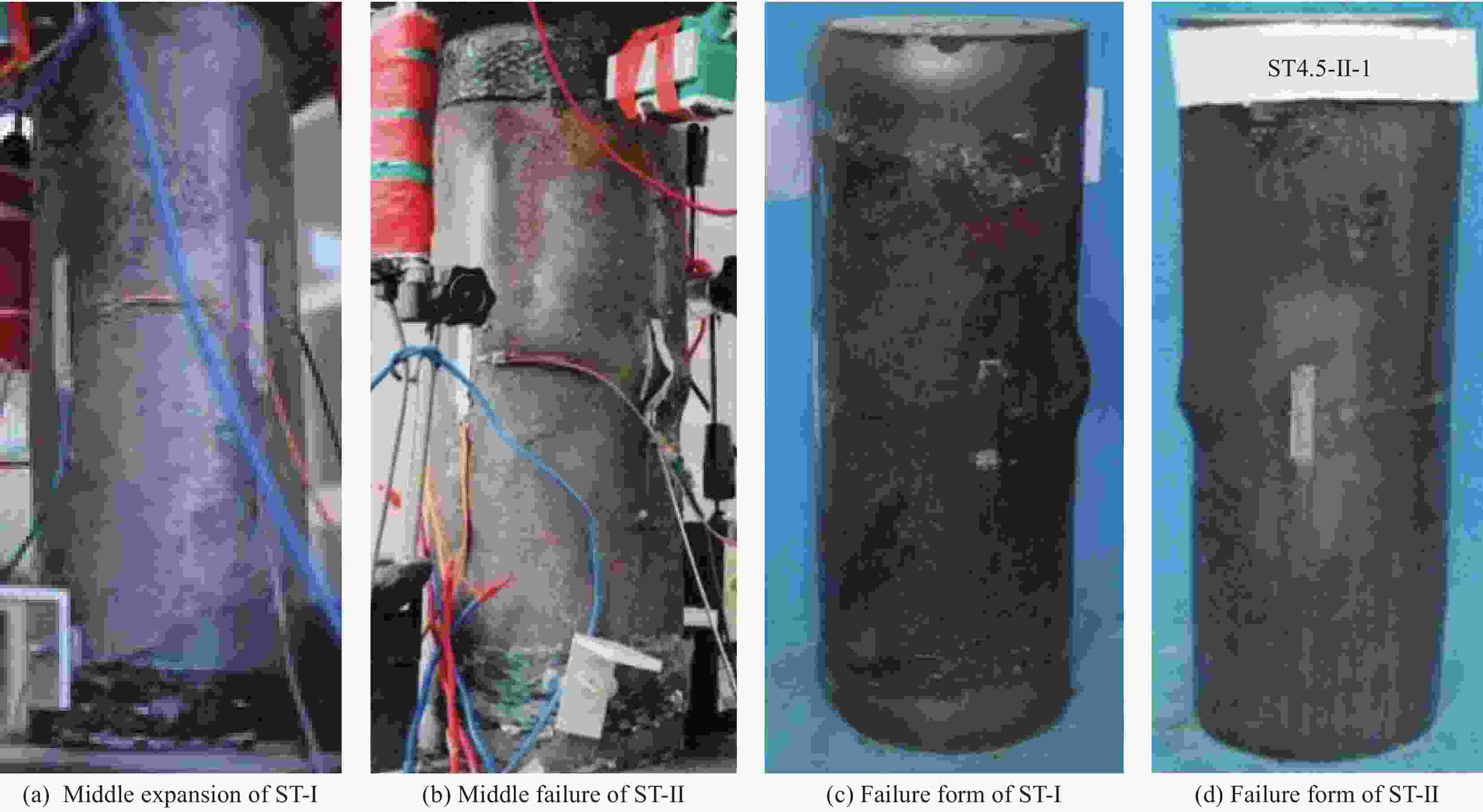

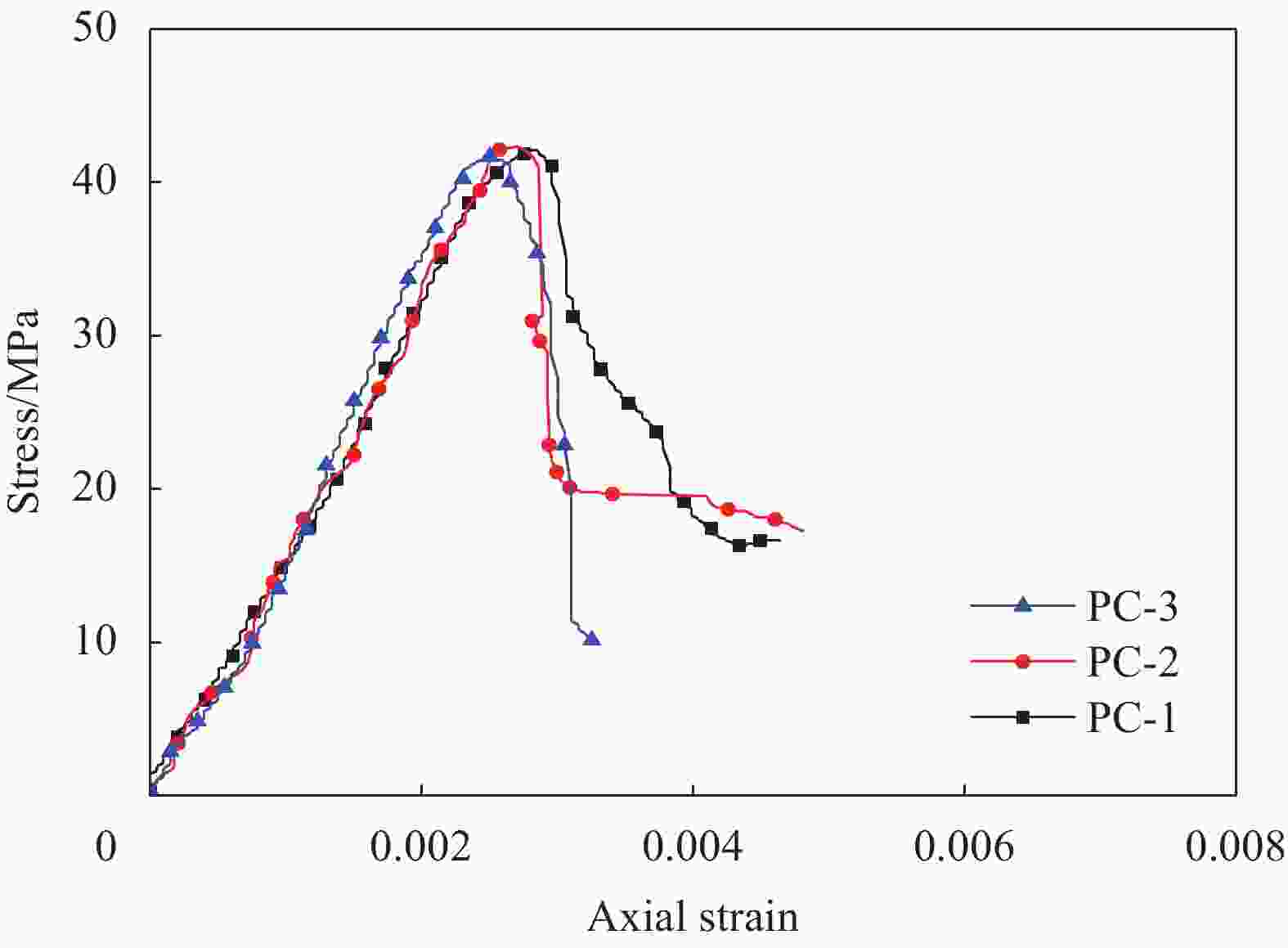

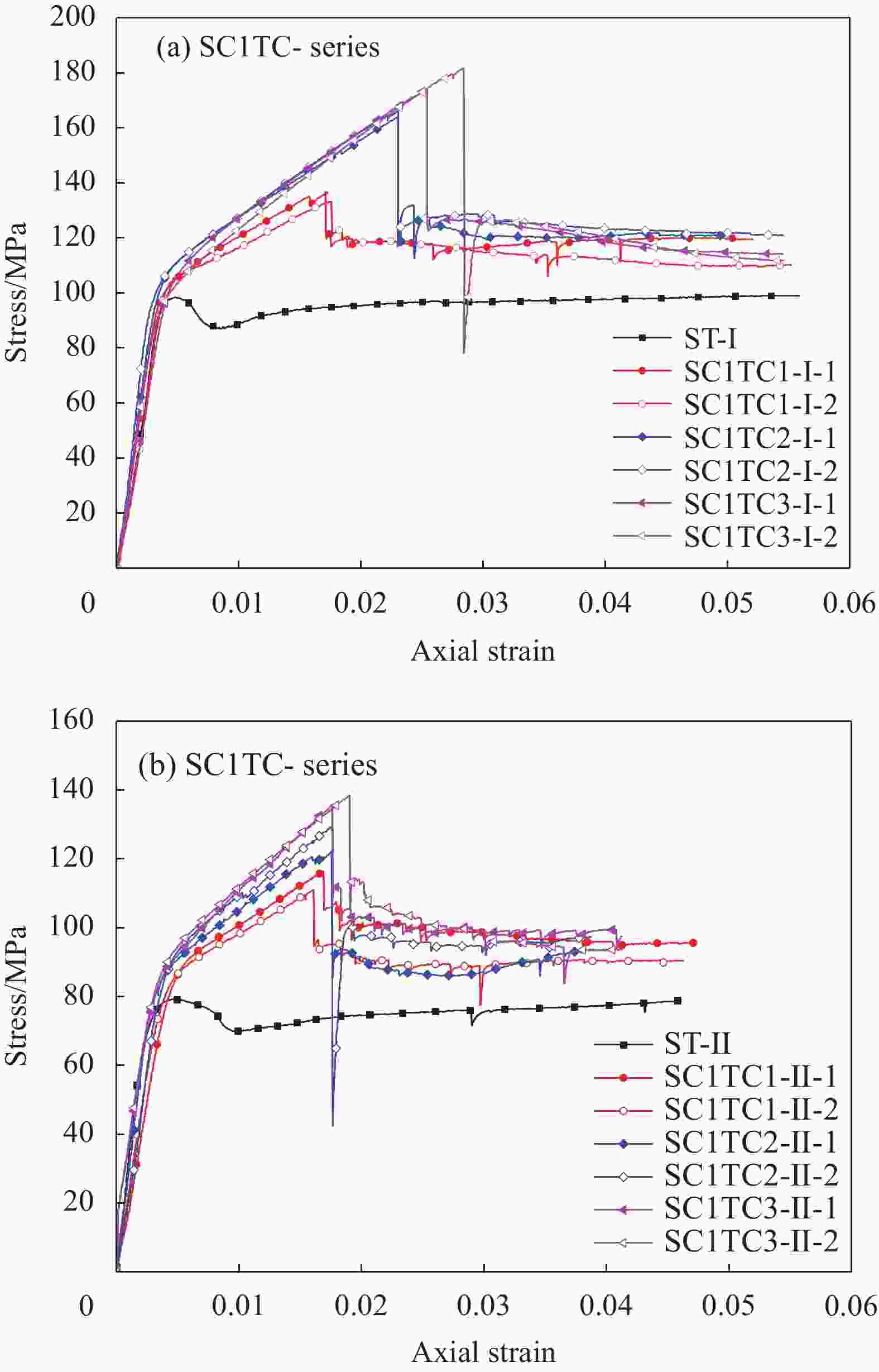

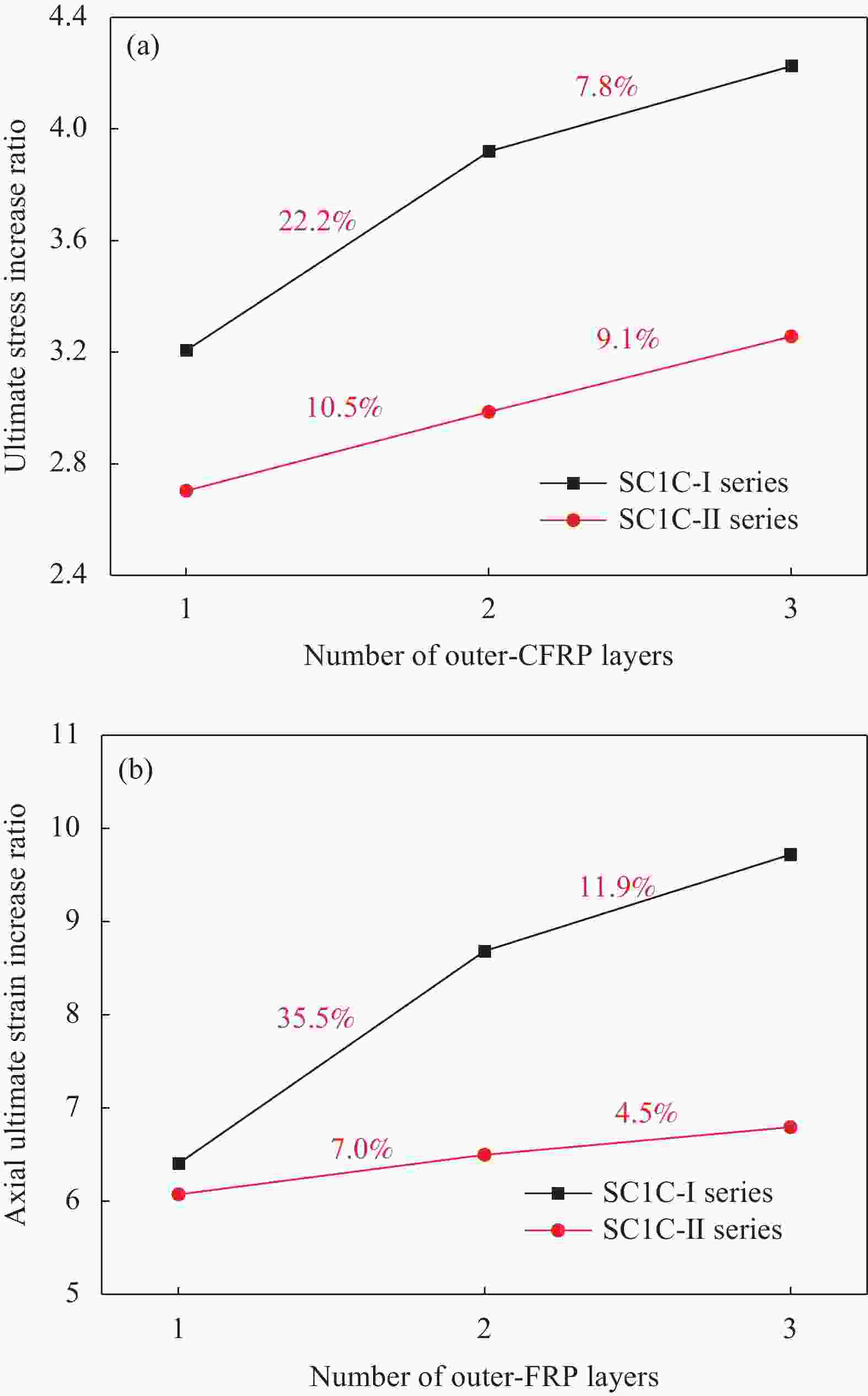

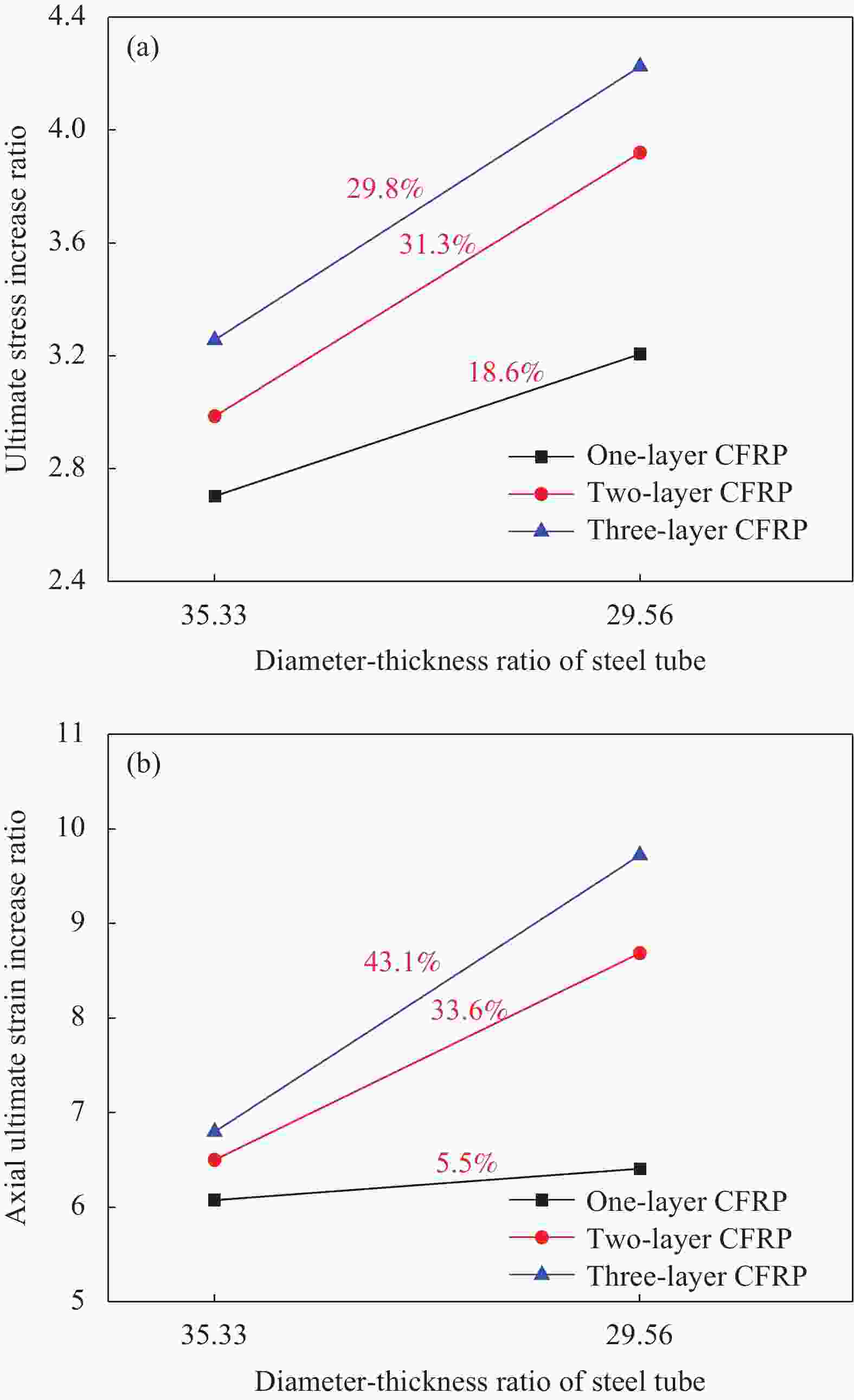

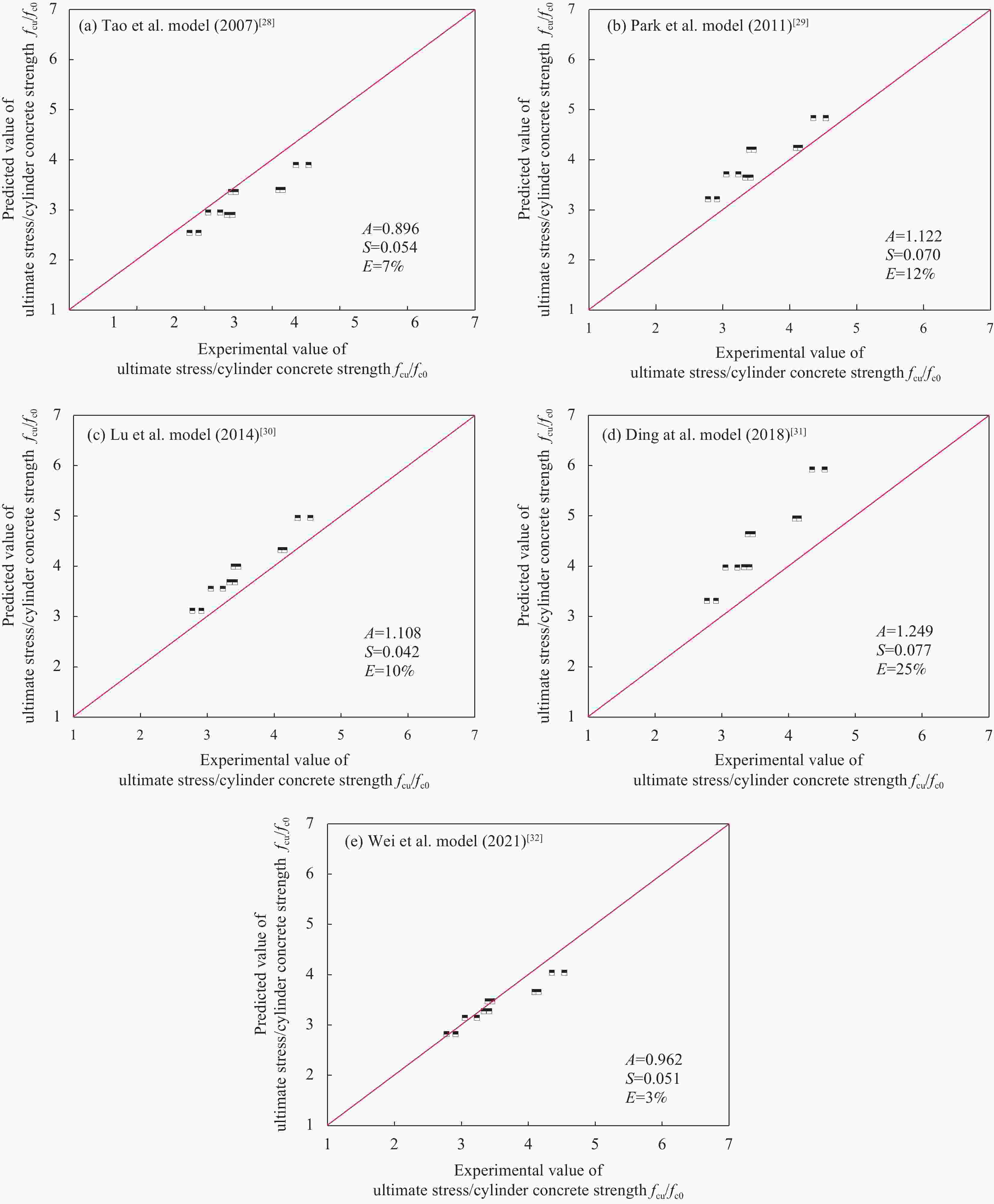

摘要: 为了将原状海水海砂珊瑚混凝土更好地直接应用于海洋工程,对12根碳纤维增强树脂复合材料(CFRP)-钢复合管约束海水海砂珊瑚混凝土柱和2根纯钢管约束海水海砂珊瑚混凝土柱进行了单调轴压试验,主要研究参数为钢管径厚比、CFRP层数,得到了试件的轴向应力-应变关系曲线。试验结果表明,试件在轴压作用下,最终呈现柱身有明显剪切滑移线的剪切破坏形式;CFRP的约束作用对试件初始截面刚度影响不明显,对试件线性强化阶段刚度影响显著;随着CFRP层数的增加,试件的极限应力和极限应变均显著提高;随着钢管径厚比的减小,试件的力学性能也相应地提高;结合试验数据对已有FRP-钢复合管约束混凝土强度计算模型进行评估。Abstract: In order to better directly apply the undisturbed seawater sea-sand coral concrete to marine engineering, this paper performed a monotonous study on 12 carbon fiber reinforced plastics (CFRP)-steel composite tube filled circular seawater sea-sand coral concrete columns and 2 pure steel tube confined seawater sea-sand coral concrete columns. In the axial compression test, the main research parameters are the diameter-thickness ratio of the steel tube and the number of CFRP layers. The test has obtained the axial stress-strain relationship curve of the specimen. The results show that the specimen is in the form of shear failure with obvious shear slip line at the end of the column under axial pressure. The constraint effect of CFRP has no obvious effect on the initial section stiffness of the specimen, but has a significant effect on the stiffness of the specimen in the linear strengthening stage. With the increase of the number of CFRP layers, the ultimate stress and strain of the specimens are significantly increased. With the decrease of the diameter-thickness ratio of the steel tube, the mechanical properties of the specimens increase correspondingly. Combined with the test data, the existing FRP steel composite pipe confined concrete strength calculation model was evaluated.

-

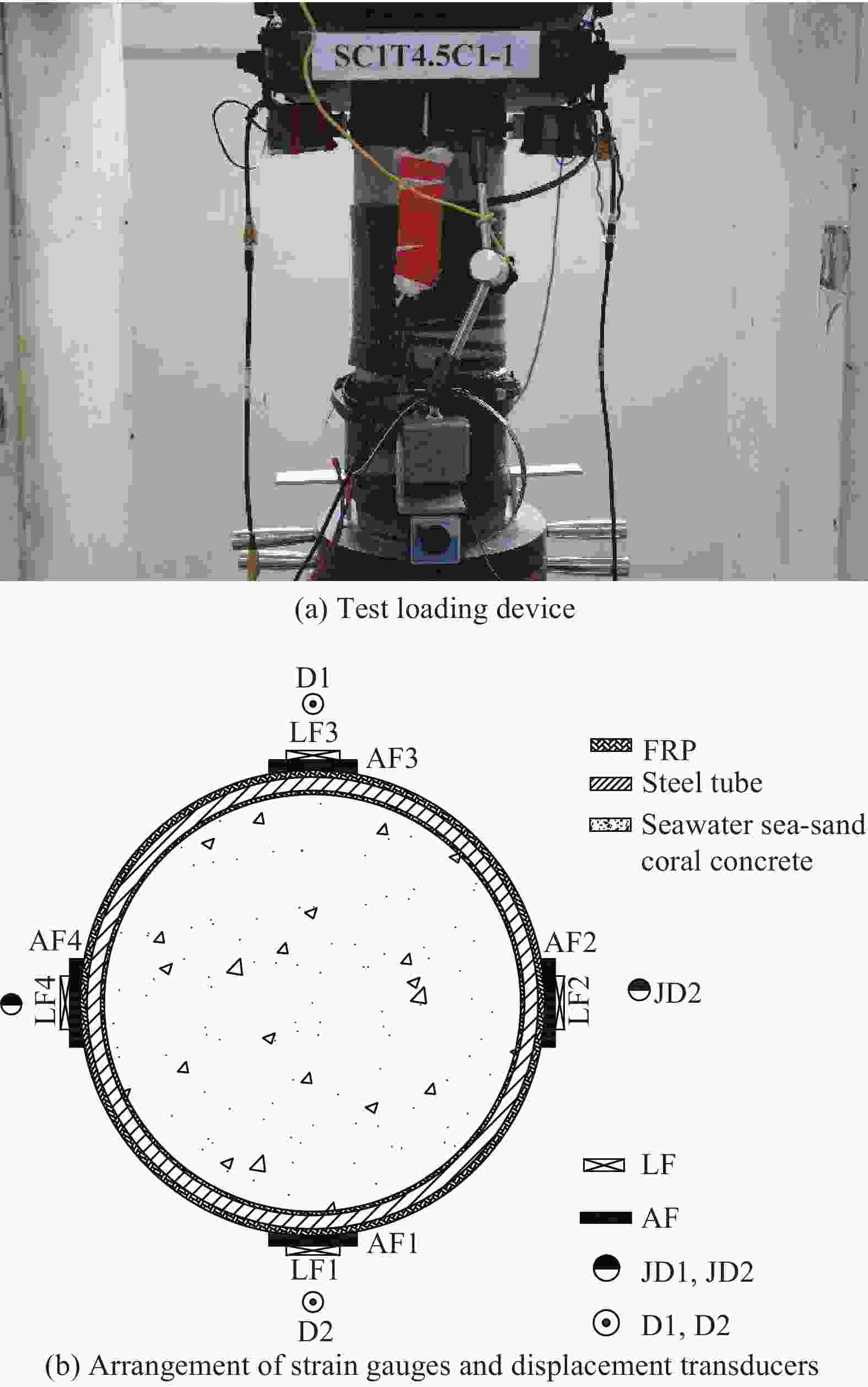

图 5 圆形CFRP-钢复合管约束海水海砂珊瑚混凝土柱轴压试验加载及测量装置

Figure 5. Axial compression test loading and measuring device of CFRP-steel composite tube filled circular sea-water sea-sand coral concrete columns

LF—Transverse strain gauges; AF—Axial strain gauges; JD1, JD2—Laser displacement meters; D1, D2—Linear variable displacement transducers

表 1 圆形CFRP-钢复合管海水海砂珊瑚混凝土柱试件轴压试验结果

Table 1. Test results of CFRP-steel composite tube filled circular seawater sea-sand coral concrete columns under axial compression

Specimen

numberHeight

H/mmDiameter D/mm Steel thickness ts/mm D/ts Inner-CFRP

layersOuter-CFRP

layersUltimate

stress fcu/MPaUltimate

strain εcuST-I 400 133 4.5 29.56 – – – – SC1TC1-I-1 400 133 4.5 29.56 1 1 136.6 0.0171 SC1TC1-I-2 400 133 4.5 29.56 1 1 133.3 0.0175 SC1TC2-I-1 400 133 4.5 29.56 1 2 163.8 0.0240 SC1TC2-I-2 400 133 4.5 29.56 1 2 166.2 0.0229 SC1TC3-I-1 400 133 4.5 29.56 1 3 174.1 0.0253 SC1TC3-I-2 400 133 4.5 29.56 1 3 181.6 0.0272 ST-II 477 133 4.5 35.33 – – – – SC1TC1-II-1 477 159 4.5 35.33 1 1 116.5 0.0168 SC1TC1-II-2 477 159 4.5 35.33 1 1 111.1 0.0160 SC1TC2-II-1 477 159 4.5 35.33 1 2 122.1 0.0175 SC1TC2-II-2 477 159 4.5 35.33 1 2 129.3 0.0176 SC1TC3-II-1 477 159 4.5 35.33 1 3 135.7 0.0176 SC1TC3-II-2 477 159 4.5 35.33 1 3 138.5 0.0191 Notes: Specimens were numbered according to the different parameters of the specimens. Two specimens with the same parameters were prepared, and they were distinguished by "-1" and "-2". The "S" represents the seawater sea-sand coral concrete; the "C" and the number after it represent the inner CFRP layer; the "T" represents the steel tube; the "C" and the number after it represent the outer CFRP layer. "I" is added after the number of the specimen with a diameter-to-thickness ratio of 29.56 and "II" is added after the number of the specimen with a diameter-to-thickness ratio of 35.33. ST-I—Steel tube filled circular seawater sea-sand coral concrete column with diameter thickness ratio of 29.56; ST-II—Steel tube filled circular seawater sea-sand coral concrete column with diameter thickness ratio of 35.33; SC1TC2-I-1—CFRP-steel composite tube filled circular seawater sea-sand coral concrete column with diameter thickness ratio of 29.56 and one-layer inner-CFRP and two-layers outer-CFRP; SC1TC2-II-1—CFRP-steel composite tube filled circular seawater sea-sand coral concrete column with diameter thickness ratio of 35.33 and one-layer inner-CFRP and two-layers outer-CFRP. 表 2 普通FRP-钢复合管约束混凝土承载力计算模型

Table 2. Calculation model of bearing capacity of ordinary FRP-steel composite tube filled concrete

Model source Calculation formula Tao et al. (2007)[28] ${N_{\text{u}}} = \left( {1 + 1.02{\xi _{\text{s}}}} \right){f_{{\text{c}}0}}{A_{{\text{sc}}}} + 1.15{\xi _{\text{f}}}{f_{{\text{c}}0}}{A_{\text{c}}}$ Park et al. (2011)[29] $ \dfrac{{{f_{{\text{cu}}}}}}{{{f_{{\text{c}}0}}}} = 1 + {\text{5}}{\text{.72}}\dfrac{{\left( {{t_{\text{s}}}{f_{\text{y}}} + {t_{\text{f}}}{f_{\text{f}}}} \right)}}{{D{f_{{\text{c}}0}}}} $ Lu et al. (2014)[30] ${N_{\text{u}}} = \left( {1 + 1.8{\xi _{\text{s}}} + 1.15{\xi _{\text{f}}}} \right){A_{\text{c}}}{f_{{\text{c}}0}}$ Ding at al. (2018)[31] ${N_{\text{u}}} = \left( {1 + 1.7{\xi _{\text{s}}} + 1.7{\xi _{\text{f}}}} \right){f_{{\text{c}}0}}{A_{\text{c}}}$ Wei et al. (2021)[32] $ \dfrac{{{f_{{\text{cu}}}}}}{{{f_{{\text{c}}0}}}} = 1 + 1.27{\xi _{\text{s}}} + 1.28\left( {{\xi _{{\text{f,i}}}} + {\xi _{{\text{f,o}}}}} \right) $ Notes:fcu—Ultimate stress of specimen; fc0—Cylinder concrete strength; fy—Yield stress of steel tube; ff—Ultimate strength of FRP; ts—Thickness of steel tube; tf—Thickness of FRP; ξs—Steel tube confinement index; ξf—FRP confinement index; ξf,o—Confinement index provided by the outer FRP; ξf,i—Confinement index provided by the inner FRP;Nu—Axial compressive bearing capacity; As—Area of the steel tube section; Ac—Area of the core concrete; Asc—Cross-sectional area of the column. -

[1] 李林. 珊瑚混凝土的基本特性研究[D]. 南宁: 广西大学, 2012: 1-8.LI L. Research on basic characteristics of coral concrete[D]. Nanning: Guangxi University, 2012: 1-8(in Chinese). [2] SAFI B, SAIDI M, DAOUI A, et al. The use of seashells as a fine aggregate (by sand substitution) in self-compacting mortar (SCM)[J]. Construction and Building Materials,2015,78:430-438. doi: 10.1016/j.conbuildmat.2015.01.009 [3] ZHANG Q, XIAO J, ZHANG P, et al. Mechanical behaviour of seawater sea-sand recycled coarse aggregate concrete columns under axial compressive loading[J]. Construction and Building Materials,2019,229:117050. doi: 10.1016/j.conbuildmat.2019.117050 [4] DA B, YU H, MA H, et al. Experimental investigation of whole stress-strain curves of coral concrete[J]. Construction and Building Materials,2016,122:81-89. doi: 10.1016/j.conbuildmat.2016.06.064 [5] LIU J, OU Z, MO J, et al. Effectiveness of saturated coral aggregate and shrinkage reducing admixture on the autogenous shrinkage of ultrahigh performance concrete[J]. Advances in Materials Science and Engineering,2017(4):1-11. [6] 王磊, 赵艳林, 吕海波. 珊瑚骨料混凝土的基础性能及研究应用前景[J]. 混凝土, 2012(2):99-100. doi: 10.3969/j.issn.1002-3550.2012.02.031WANG L, ZHAO Y L, LV H B. Prospect on the properties and application situation of coral aggregate concrete[J]. Concrete,2012(2):99-100(in Chinese). doi: 10.3969/j.issn.1002-3550.2012.02.031 [7] 余红发, 达波, 麻海燕, 等. 全珊瑚海水混凝土及其梁柱构件的力学性能与耐久性[J]. 建筑材料学报, 2019, 22(6):993-998. doi: 10.3969/j.issn.1007-9629.2019.06.023YU H F, DA B, MA H Y, et al. Mechanical behavior and durability of coral aggregate seawater concrete and its beam-column member[J]. Journal of Building Materials,2019,22(6):993-998(in Chinese). doi: 10.3969/j.issn.1007-9629.2019.06.023 [8] 达波, 余红发, 麻海燕, 等. 全珊瑚海水混凝土单轴受压应力-应变全曲线试验研究[J]. 建筑结构学报, 2017, 38(1):144-151.DA B, YU H F, MA H Y, et al. Experimental research on whole stress-strain curves of coral aggregate seawater concrete under uniaxial compression[J]. Journal of Building Materials,2017,38(1):144-151(in Chinese). [9] HUANG Y, HE X, SUN H, et al. Effects of coral, recycled and natural coarse aggregates on the mechanical properties of concrete[J]. Construction and Building Materials,2018,192:330-347. doi: 10.1016/j.conbuildmat.2018.10.111 [10] 王磊, 王国旭, 邓雪莲. 不同掺量碳纤维珊瑚混凝土力学性能试验研究[J]. 中国农村水利水电, 2014(9):148-151. doi: 10.3969/j.issn.1007-2284.2014.09.038WANG L, WANG G X, DENG X L. Research on the mecha-nical properties of different content carbon fiber coral concrete[J]. China Rural Water and Hydropower,2014(9):148-151(in Chinese). doi: 10.3969/j.issn.1007-2284.2014.09.038 [11] 鲁于, 黄一杰, 王海超, 等. 改性海水海砂珊瑚混凝土力学性能试验研究[J]. 混凝土, 2019(4):150-154. doi: 10.3969/j.issn.1002-3550.2019.04.035LU Y, HUANG Y J, WANG H C, et al. Experimental study on the mechanical properties of modified sea water sea sand coral concrete[J]. Concrete,2019(4):150-154(in Chinese). doi: 10.3969/j.issn.1002-3550.2019.04.035 [12] DONG C X, KWAN A K H, HO J C M. Axial and lateral stress-strain model for concrete-filled steel tubes with FRP jackets[J]. Engineering Structures,2016,126:365-378. doi: 10.1016/j.engstruct.2016.07.059 [13] GUO M, HU B, XING F, et al. Characterization of the mecha-nical properties of eco-friendly concrete made with untreated sea-sand and seawater based on statistical analysis[J]. Construction and Building Materials,2020,234:117339. doi: 10.1016/j.conbuildmat.2019.117339 [14] LI Y L, TENG J G, ZHAO X L, et al. Theoretical model for seawater and sea-sand concrete-filled circular FRP tubular stub columns under axial compression[J]. Engineering Structures,2018,160:71-84. doi: 10.1016/j.engstruct.2018.01.017 [15] LIANG H J, LI S, LU Y Y, et al. Electrochemical perfor-mance of corroded reinforced concrete columns strengthened with fiber reinforced polymer[J]. Composite Structures,2019,207:576-588. doi: 10.1016/j.compstruct.2018.09.028 [16] WU Z S, YANG C Q, IWASHITA K, et al. Development of damage-controlled latter cast FRP–RC hybrid girders[J]. Compo-sites Part B: Engineering,2011,42(6):1770-1777. doi: 10.1016/j.compositesb.2011.01.019 [17] WANG J, FENG P, HAO T, et al. Axial compressive behavior of seawater coral aggregate concrete-filled FRP tubes[J]. Construction and Building Materials,2017,147:272-285. doi: 10.1016/j.conbuildmat.2017.04.169 [18] ZHANG T, NIU D, RONG C. GFRP-confined coral aggre-gate concrete cylinders: The experimental and theoretical analysis[J]. Construction and Building Materials,2019,218:206-213. doi: 10.1016/j.conbuildmat.2019.05.052 [19] WEI Y, ZHANG X, WU G, et al. Behaviour of concrete confined by both steel spirals and fiber-reinforced polymer under axial load[J]. Composite Structures,2018,192:577-591. doi: 10.1016/j.compstruct.2018.03.041 [20] 郭莹, 刘界鹏, 苗亚军, 等. 圆CFRP-钢复合管约束混凝土短柱轴压试验研究[J]. 工程力学, 2017, 34(6):41-50.GUO Y, LIU J P, MIAO Y J, et al. Experimental study on axial behavior of circular CFRP-steel composite tube confined concrete stube columns[J]. Engineering Mechanics,2017,34(6):41-50(in Chinese). [21] HUANG L, YU T, ZHANG S, et al. FRP-confined concrete-encased cross-shaped steel columns: Concept and behaviour[J]. Engineering Structures,2017,152:348-358. doi: 10.1016/j.engstruct.2017.09.011 [22] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Y R, WEI Y, BAI J W, et al. Models for predicting axial compression behavior fiber reinforced polymber-steel composite circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese). [23] LI Y L, ZHAO X L, SINGH R K R, et al. Experimental study on seawater and sea-sand concrete filled GFRP and stainless steel tubular stub columns[J]. Thin-Walled Structures,2016,106:390-406. doi: 10.1016/j.tws.2016.05.014 [24] LI Y L, ZHAO X L, RAMAN S R K, et al. Tests on seawater and sea-sand concrete-filled CFRP, BFRP and stainless steel tubular stub columns[J]. Thin-Walled Structures,2016,108:163-184. doi: 10.1016/j.tws.2016.08.016 [25] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报, 2021, 38(9):3084-3093.BAI J W, WEI Y, ZHANG Y R, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica,2021,38(9):3084-3093(in Chinese). [26] 中国国家标准化管理委员会. 金属材料拉伸试验: 第一部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of China. Metallic mater-ials—Tensile testing—Part 1: Method of test at room temperature: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [27] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [28] TAO Z, HAN L, ZHUANG J. Axial loading behavior of CFRP strengthened concrete-filled steel tubular stub columns[J]. Advances in Structural Engineering,2007,10(1):37-46. doi: 10.1260/136943307780150814 [29] PARK J W, HONG Y K, HONG G S, et al. Design formulas of concrete filled circular steel tubes reinforced by carbon fiber reinforced plastic sheets[J]. Procedia Engineering,2011,14:2916-2922. doi: 10.1016/j.proeng.2011.07.367 [30] LU Y, LI N, LI S. Behavior of FRP-confined concrete-filled steel tube columns[J]. Polymers,2014,6(5):1333-1349. doi: 10.3390/polym6051333 [31] DING F, LU D, BAI Y, et al. Behaviour of CFRP-confined concrete-filled circular steel tube stub columns under axial loading[J]. Thin-Walled Structures,2018,125:107-118. doi: 10.1016/j.tws.2018.01.015 [32] WEI Y, BAI J, ZHANG Y, et al. Compressive performance of high-strength seawater and sea-sand concrete-filled circular FRP-steel composite tube columns[J]. Engineering Structures,2021,240:112357. doi: 10.1016/j.engstruct.2021.112357 -

下载:

下载: