Mechanical properties and fracture mechanisms of low-density fiber preforms reinforced phenolic aerogel composites

-

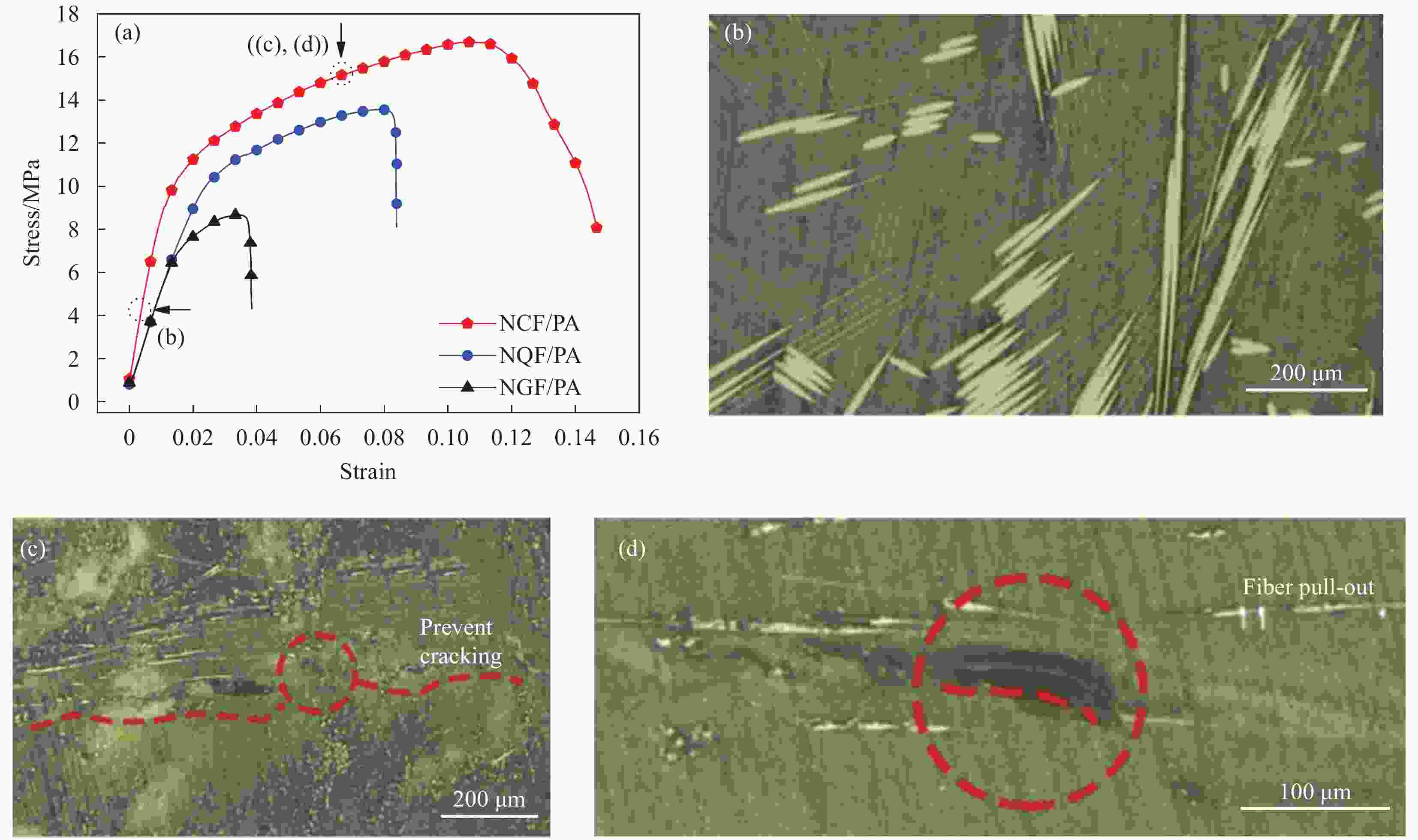

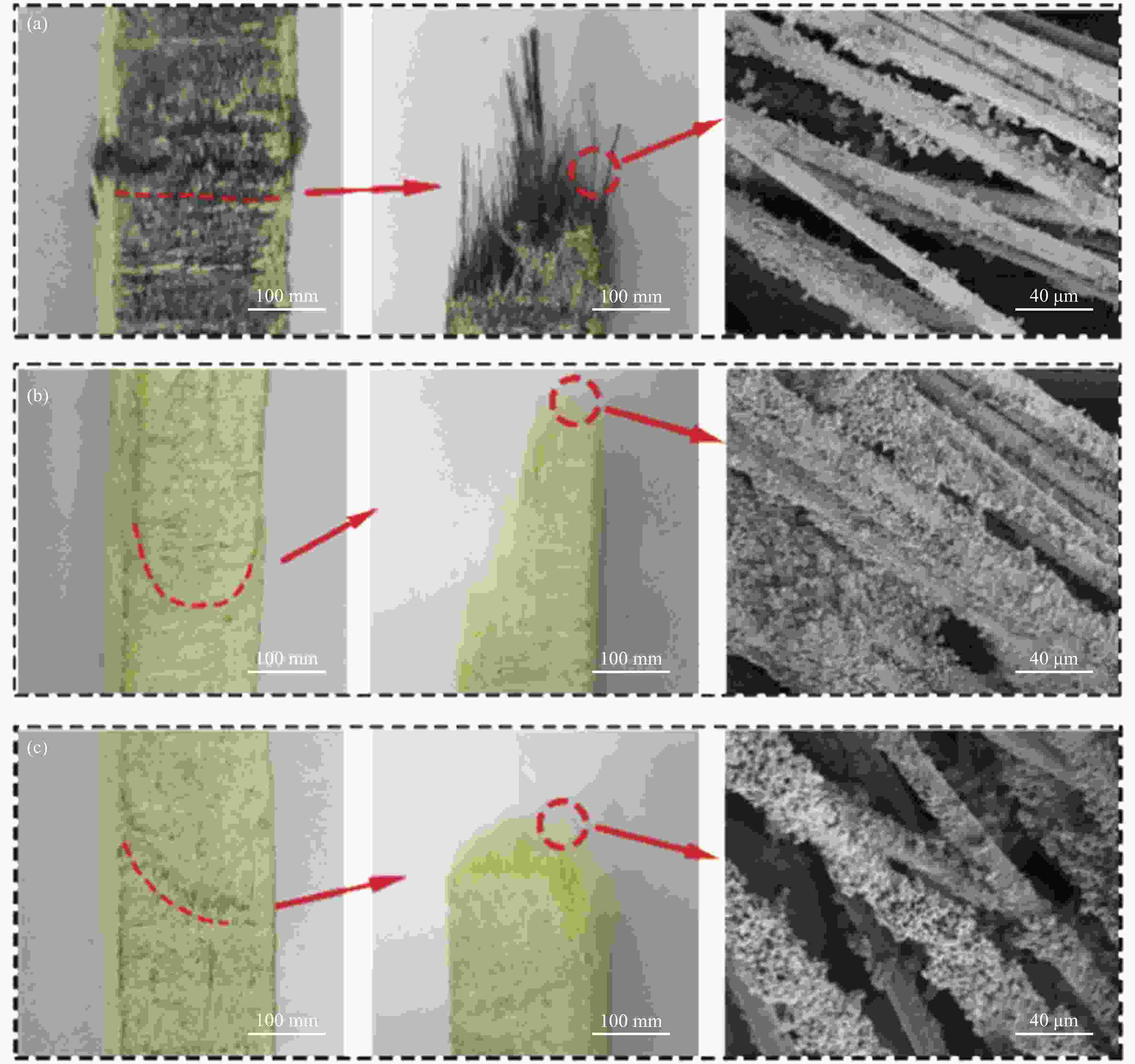

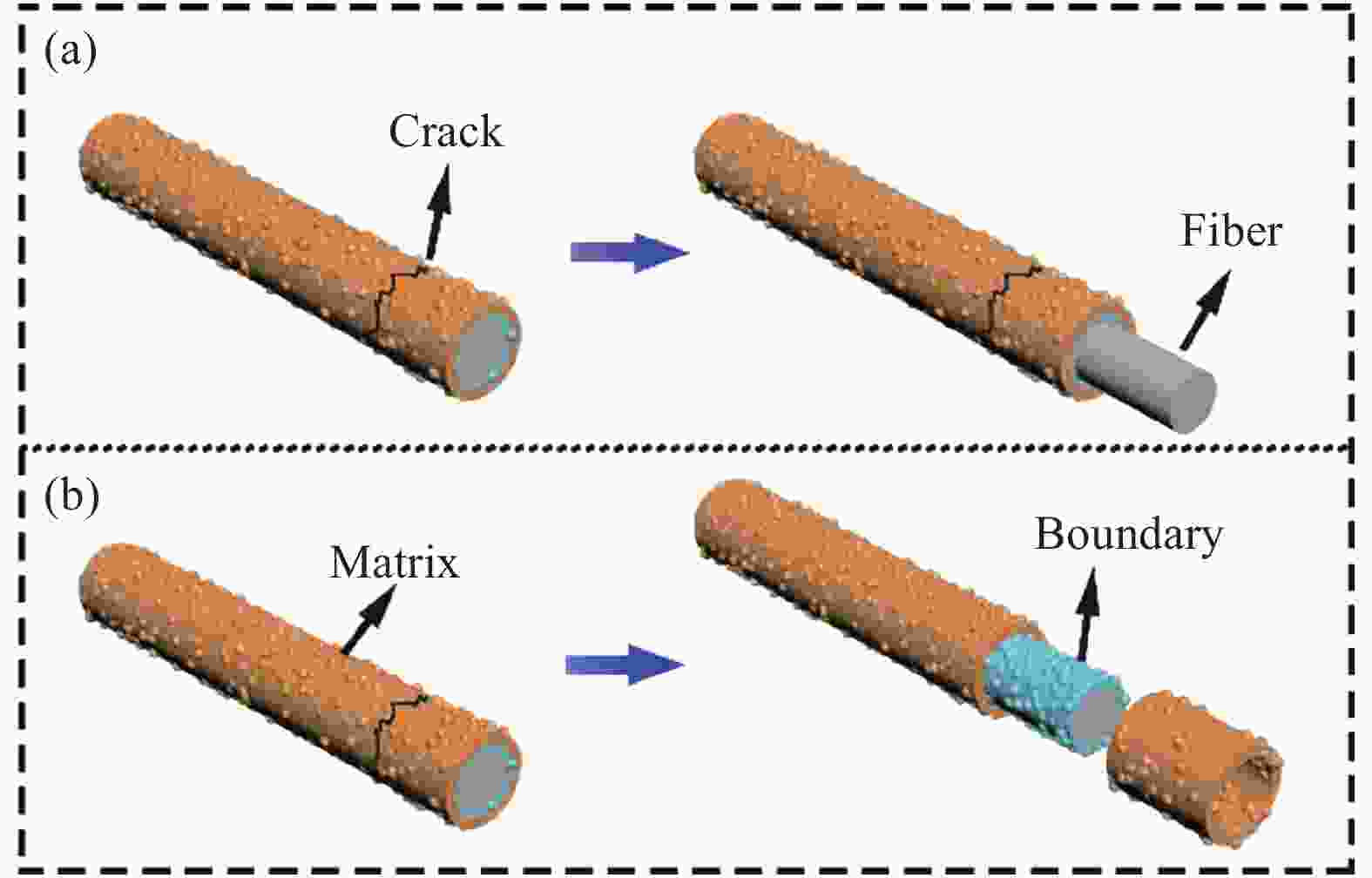

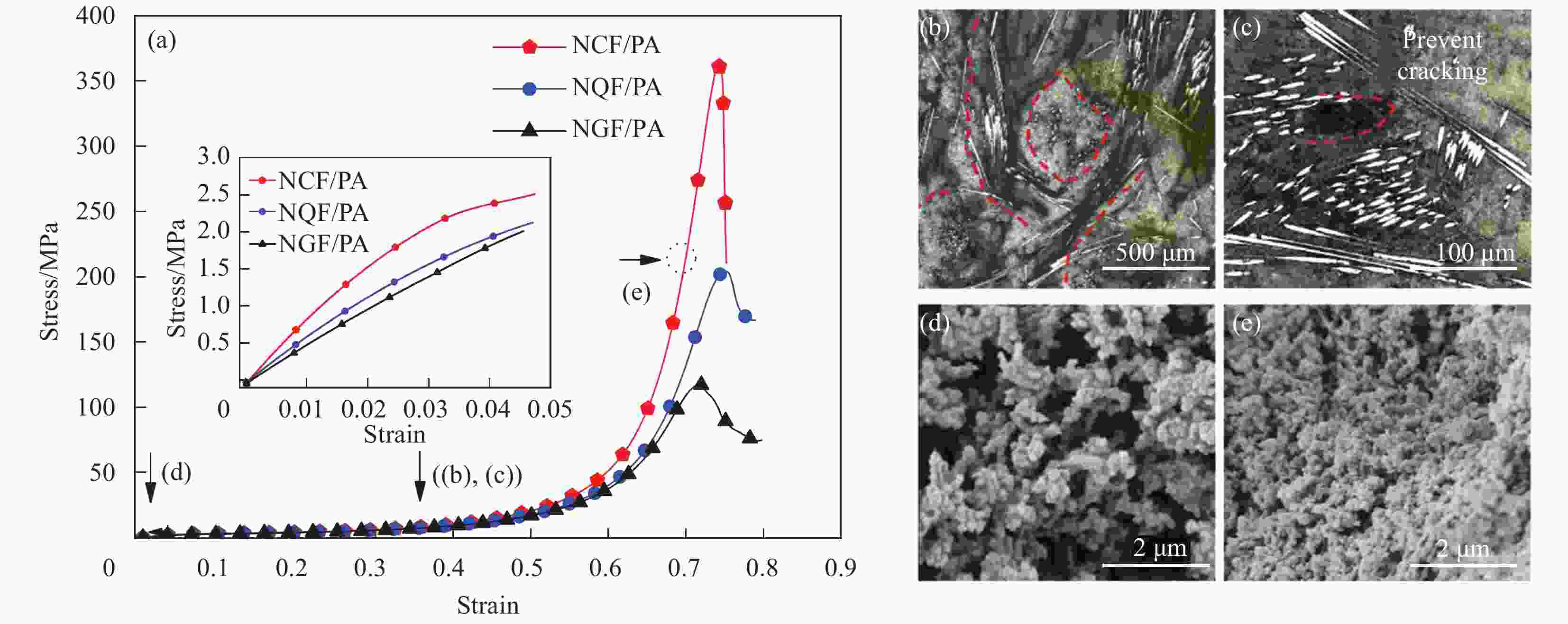

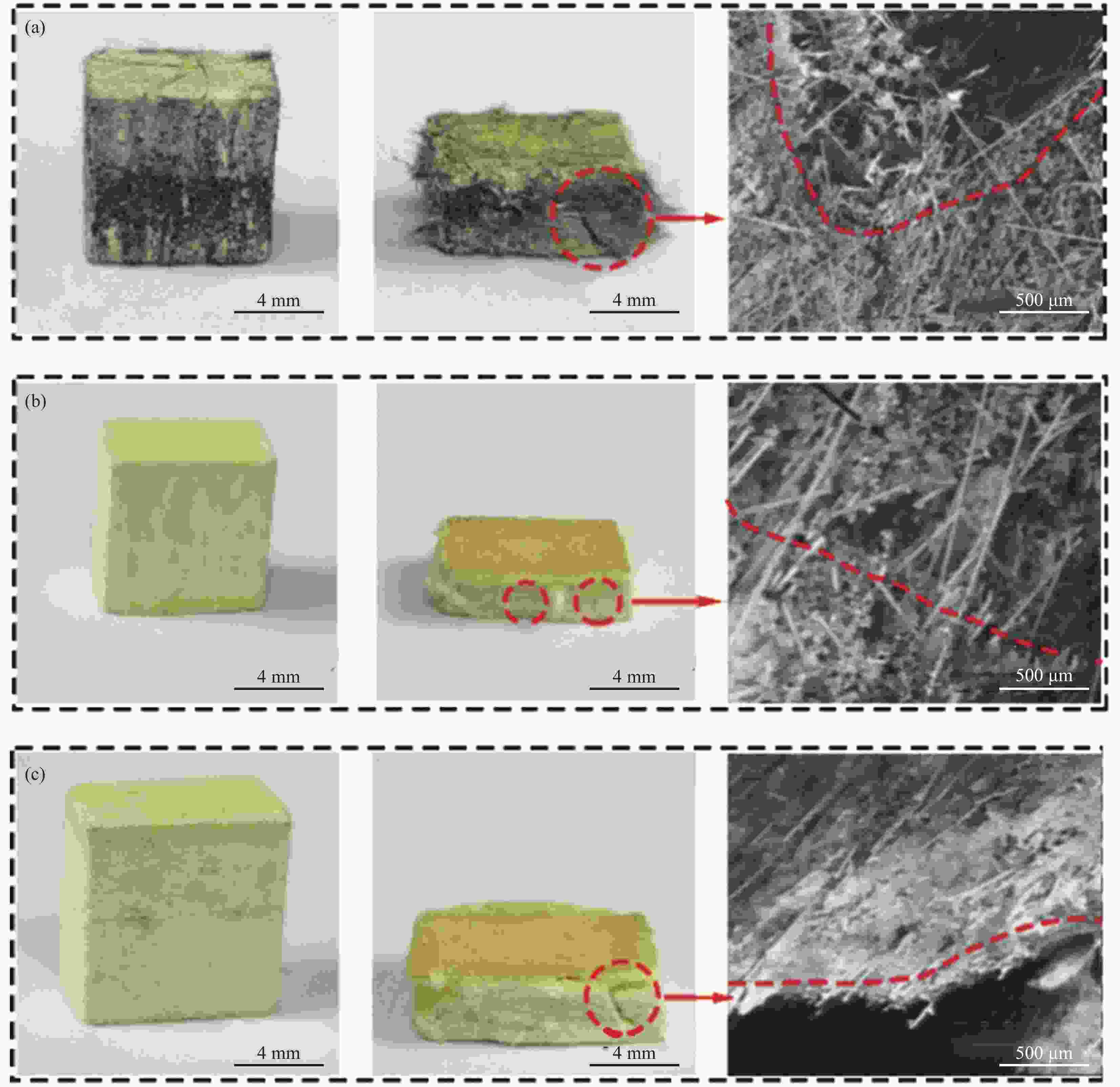

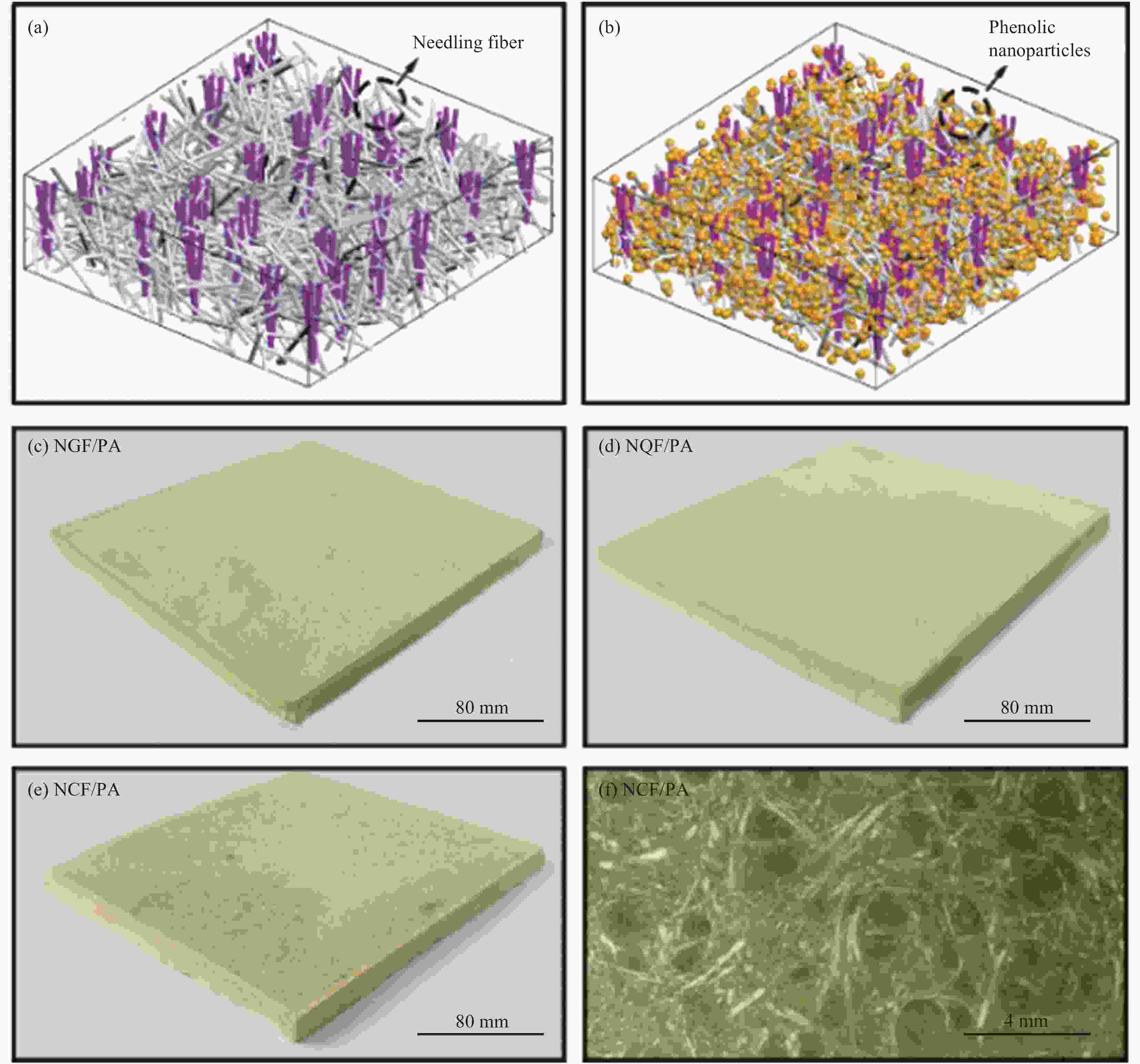

摘要: 分别以低密度玻璃纤维、石英纤维、碳纤维针刺预制体为增强体,制备出不同的纤维针刺预制体增强酚醛气凝胶复合材料(NF/PA),研究了纤维种类对材料力学性能及断裂行为的影响。结果表明:酚醛气凝胶与纤维预制体形成良好的界面结构,微观上呈现“珠串”状三维开孔网络结构特征,因而复合材料具有较低的密度(0.45 g/cm3)和室温热导率(0.046~0.067 W/(m·K))。在拉伸与压缩过程中,基于NF/PA明显的塑性形变现象,分析了裂纹扩展过程中材料所吸收的能量,发现纤维种类会显著影响界面特性进而影响材料断裂和失效机制。其中,碳纤维的界面结合强度小于酚醛气凝胶极限剪切应力,在断裂过程中纤维先与酚醛气凝胶脱粘,表现为“滑脱界面”;玻璃纤维与石英纤维界面结合强度大于酚醛气凝胶极限剪切应力,在断裂过程中酚醛气凝胶先被破坏,表现为“粘性界面”。相较于玻璃纤维、石英纤维,碳纤维对NF/PA增韧、补强效果较优。Abstract: Three kinds of needled fiber preforms reinforced phenolic aerogel composites (NF/PA) were prepared using lightweight needled preforms of glass fibers, carbon fibers and quartz fibers as reinforcements, respectively. The resultant fiber-dependent mechanical properties and fracture behavior were studied systematically. It is found that the NF/PA has a low density of ~0.45 g/cm3 and good insulation with room-temperature thermal conductivity as low as 0.046-0.067 W/(m·K). The phenolic aerogel has typical 3D porous structure with the overlapped and interconnected phenolic aerogel nanoparticles filling in fiber preforms, which has excellent interface structure with fiber. The NF/PA have obvious plastic deformation in the process of tension and compression. Furthermore, this work analyze the energy absorption of NF/PA during the crack propagate, and conclude that the type of fiber significantly affects the interface characteristics and thereby the fracture and failure mechanisms of composites. The interfacial bonding strength of carbon fiber is less than the ultimate shear stress of phenolic aerogel, and thereafter fibers are initially deboned with phenolic nanoparticles during the fracture process, responding to a “slip interface” feature. On the other hand, the bonding strengths of glass fiber and quartz fiber are both greater than the limit of shear stress of phenolic aerogel. Therefore, the phenolic aerogel is destroyed initially during the fracture process, which manifests as a “sticky interface” feature. Compared with glass fiber and quartz fiber, the carbon fiber shows more toughening and reinforcing effect on NF/PA.

-

图 1 纤维针刺预制体(NF) (a) 与纤维针刺预制体增强酚醛气凝胶复合材料(NF/PA) (b) 的结构示意图;玻璃纤维针刺预制体增强酚醛气凝胶复合材料(NGF/PA) (c)、石英纤维针刺预制体增强酚醛气凝胶复合材料(NQF/PA) (d)、碳纤维针刺预制体增强酚醛气凝胶复合材料(NCF/PA) (e) 的图像;NCF/PA的金相显微组织图像 (f)

Figure 1. Sketch of needled fiber preform (NF) (a) and NF reinforced phenolic aerogel composite (NF/PA) (b); Photographs of needled glass fiber preforms reinforced phenolic aerogel composites (NGF/PA) (c), needled quartz fiber preforms reinforced phenolic aerogel composites (NQF/PA) (d), and needled carbon fiber preforms reinforced phenolic aerogel composites (NCF/PA) (e); Metallographic image of NCF/PA (f)

图 6 (a) NF/PA压缩应力-应变曲线 (插图为NF/PA弹性段应力-应变曲线); ((b), (c)) 塑性段金相显微组织图像;((d), (e)) 初始阶段以及压实阶段酚醛气凝胶SEM图像

Figure 6. (a) Compressive stress-strain curves of NF/PA (Illustration is elastic segments stress-strain curves of NF/PA); ((b), (c)) Metallographic microstructure of the plastic section; ((d), (e)) SEM images of phenolic aerogel at initial and compaction stage

表 1 NF/PA的物理性能参数

Table 1. Physical parameters of NF/PA

Composites Density/

(g·cm−3)Thermal conductivity/

(W·(m·K)−1)Tensile strength/

MPaTensile modulus/

MPaCompressive

strength/MPaCompressive

modulus/MPaNCF/PA 0.45 0.067 16.6 2939 362 86 NQF/PA 0.45 0.046 13.5 1103 203 56 NGF/PA 0.45 0.045 8.8 1163 117 50 表 2 NF/PA的压缩性能

Table 2. Compression performance of NF/PA

Composite Compressive strength

(5%)/MPaCompressive strength

(10%)/MPaCompressive strength

(Elasticity)/MPaCompressive strength

(Plasticity)/MPaCompressive strength

(Densification)/MPaNCF/PA 2.57 3.21 1.03 4.35 362 NQF/PA 2.20 2.80 1.09 3.71 203 NGF/PA 2.19 2.91 1.20 3.96 117 -

[1] 喻成璋, 刘卫华. 高超声速飞行器气动热预测技术研究进展[J]. 航空科学技术, 2021, 32(2): 14-21.YU Chengzhang, LIU Weihua. Research status of aeroheating prediction technology for hypersonic aircraft[J]. Aeronautical Science and Technology, 2021, 32(2): 14-21(in Chinese). [2] ALLEN H J. Hypersonic flight and the reentry problem: The twenty-first wright brothers lecture[J]. Journal of the Aerospace Sciences,1958,25(4):217-227. doi: 10.2514/8.7600 [3] KARIMI M S, OBOODI M J. Investigation and recent deve-lopments in aero dynamic heating and drag reduction for hypersonic flows[J]. Heat and Mass Transfer, 2019, 55(2): 547-569. [4] 韩杰才, 洪长青, 张幸红, 等. 新型轻质热防护复合材料的研究进展[J]. 载人航天, 2015, 21(4): 315-321HAN Jiecai, HONG Changqing, ZHANG Xinghong, et al. Research progress of novel lightweight thermal protection composites[J]. Manned Spaceflight, 2015, 21(4): 315-321(in Chinese). [5] 薛华飞, 姚秀荣, 程海明, 等. 热防护用轻质烧蚀材料现状与发展[J]. 哈尔滨理工大学学报, 2017, 22(1):123-128.XUE Huafei, YAO Xiurong, CHENG Haiming, et al. Current status and development of light ablative materials for thermal protection[J]. Journal of Harbin University of Science and Technology,2017,22(1):123-128(in Chinese). [6] LACHAUD J, COZMUTA I, MANSOUR N N. Multiscale approach to ablation modeling of phenolic impregnated carbon ablators[J]. Journal of Spacecraft and Rockets,2010,47(6):910-921. doi: 10.2514/1.42681 [7] NATALI M, PURI I, KENNY J M, et al. Microstructure and ablation behavior of an affordable and reliable nanostructured phenolic impregnated carbon ablator (PICA)[J]. Polymer Degradation and Stability, 2017, 141: 84-96. [8] TRAN H K, RASKY D J, ESFAHANI L. Thermal response and ablation characteristics of lightweight ceramic ablators[J]. Journal of Spacecraft and Rockets,1994,31(6):993-998. doi: 10.2514/3.26549 [9] RIVIER M, LACHAUD J, CONGEDO P M. Ablative thermal protection system under uncertainties including pyrolysis gas composition[J]. Aerospace Science and Technology, 2019, 84: 1059-1069. [10] MEURISSE J B E, LACHAUD J, PANERAI F, et al. Multidimensional material response simulations of a full-scale tiled ablative heat shield[J]. Aerospace Science and Technology, 2018, 76: 497-511. [11] LIU X, SUN J, YUAN F, et al. Lightweight, flexible, and heat-insulated phenolic impregnated carbon ablator (PICA) with adjustable flexibility and high compressive resilience property[J]. Journal of Applied Polymer Science, 2022, 139(9): 51712. [12] ZHNG J, FANG G D, YANG L W, et al. Comparison of abla-tive and compressive mechanical behavior of several PICA-like ablative materials[J]. Science China Technological Sciences, 2020, 63(8): 1478-1486. [13] 程海明. 新型超轻质碳/酚醛烧蚀复合材料的制备与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.CHENG Haiming. Preparation and properties of novel ultra-lightweight carbon/phenolic ablation composites[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [14] WHITE S M. High-temperature spectrometer for thermal protection system radiation measurements[J]. Journal of Spacecraft and Rockets, 2010, 47(1): 21-28. [15] 刘建军, 李铁虎, 郝志彪, 等. 针刺炭布/网胎复合织物的组分形态及性能研究[J]. 固体火箭技术, 2005, 28(4):299-302. doi: 10.3969/j.issn.1006-2793.2005.04.016LIU Jianjun, LI Tiehu, HAO Zhibiao, et al. Study on composition morphology and properties of acupuncture carbon fabric/mesh pad composite fabric[J]. Solid Rocket Technology,2005, 28(4):299-302(in Chinese). doi: 10.3969/j.issn.1006-2793.2005.04.016 [16] 朱召贤, 董金鑫, 贾献峰, 等. 酚醛气凝胶/炭纤维复合材料的结构与烧蚀性能[J]. 新型炭材料, 2018, 33(4):370-376.ZHU Zhaoxian, DONG Jinxin, JIA Xianfeng, et al. Structure and ablation properties of phenolic aerogel/carbon fiber composites[J]. New Carbon Materials,2018,33(4):370-376(in Chinese). [17] 董金鑫, 朱召贤, 姚鸿俊, 等. 酚醛气凝胶/碳纤维复合材料的结构调控及性能研究[J]. 化工学报, 2018, 69(11):4896-4901.DONG Jinxin, ZHU Zhaoxian, YAO Hongjun, et al. Structure and properties of phenolic aerogel/carbon fiber composites[J]. Chinese Journal of Chemical Engineering and Technology,2018,69(11):4896-4901(in Chinese). [18] COX H L. The elasticity and strength of paper and other fibrous materials[J]. British Journal of Applied Physics,1952,3(3):72-79. doi: 10.1088/0508-3443/3/3/302 [19] FU S Y, LAUKE B. An analytical characterization of the anisotropy of the elastic modulus of misaligned short-fiber-reinforced polymers[J]. Composites Science and Tech-nology,1998,58(12):1961-1972. doi: 10.1016/S0266-3538(98)00033-5 [20] 唐国宏, 陈昌麒. 界面断裂[J]. 复合材料学报, 1994, 11(3):43-49.TANG Guohong, CHEN Changqi. Interfacial fracture[J]. Acta Materiae Compositae Sinica,1994,11(3):43-49(in Chinese). [21] NIE J, XU Y, ZHANG L, et al. Microstructure and tensile behavior of multiply needled C/SiC composite fabricated by chemical vapor infiltration[J]. Journal of Materials Processing Technology,2009,209(1):572-576. doi: 10.1016/j.jmatprotec.2008.02.035 [22] 方光武, 高希光, 陈晶, 等. 加载循环数对2D针刺C/SiC复合材料疲劳剩余强度的影响[J]. 复合材料学报, 2016, 33(1):149-154.FANG Guangwu, GAO Xiguang, CHEN Jing, et al. Effect of loading cycles on fatigue residual strength of 2D needle punched C/SiC composites[J]. Acta Materiae Compositae Sinica,2016,33(1):149-154(in Chinese). [23] 邢亚娟, 孙波, 高坤, 等. 航天飞行器热防护系统及防热材料研究现状[J]. 宇航材料工艺, 2018, 48(4):9-15.XING Yajuan, SUN Bo, GAO Kun, et al. Research status of thermal protection system and thermal protective materials for space vehicle[J]. Aerospace Materials & Technology,2018,48(4):9-15(in Chinese). [24] 中国国家标准化管理委员会. 纤维增强塑料 拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of tensile properties: GB/T 1447—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [25] 中国国家标准化管理委员会. 纤维增强塑料 压缩性能试验方法: GB/T 1448—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of compressive properties: GB/T 1448—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [26] 张冬梅, 叶金蕊, 刘奎, 等. 孔隙微观特征影响CFRP力学性能的细观综述[J]. 复合材料学报, 2013, 30(S1):118-123.ZHANG Dongmei, YE Jinrui, LIU Kui, et al. Microscopic review of influence of pore microstructure on mechanical properties of CFPR[J]. Acta Materiae Compositae Sinica,2013,30(S1):118-123(in Chinese). [27] 刘克杰, 朱华兰, 彭涛, 等. 无机特种纤维介绍(一)[J]. 合成纤维, 2013, 42(5):32-37.LIU Kejie, ZHU Hualan, PENG Tao, et al. The introduction of inorganic special fiber(I)[J]. Synthetic Fiber,2013,42(5):32-37(in Chinese). [28] 张焱, 祖群. 航空领域用特种高性能玻璃纤维材料[J]. 航空制造技术, 2014, 57(15): 130-131.ZHANG Yan, ZU Qun. Special high-performance glass fiber materials used in aviation field[J]. Aeronautical Manufacturing Technology, 2014, 57(15): 130-131(in Chinese). [29] AVESTON J, COOPER G A, KELLY A. The properties of fiber composites[C]//National Physical Laboratory Conference Proceeding. England: IPS Science & Technology Press, 1971: 1254-1262. [30] 张盼. 三维针刺C/C复合材料的微结构建模及力学性能预测[D]. 西安: 西北工业大学, 2016.ZHANG Pan. Microstructure modeling and mechanical properties prediction of three-dimensional needled C/C composites[D]. Xi’an: Northwestern Polytechnical University, 2016(in Chinese). -

下载:

下载: