Influence law of compound admixture on the mechanical properties of filling slurry before and after curing

-

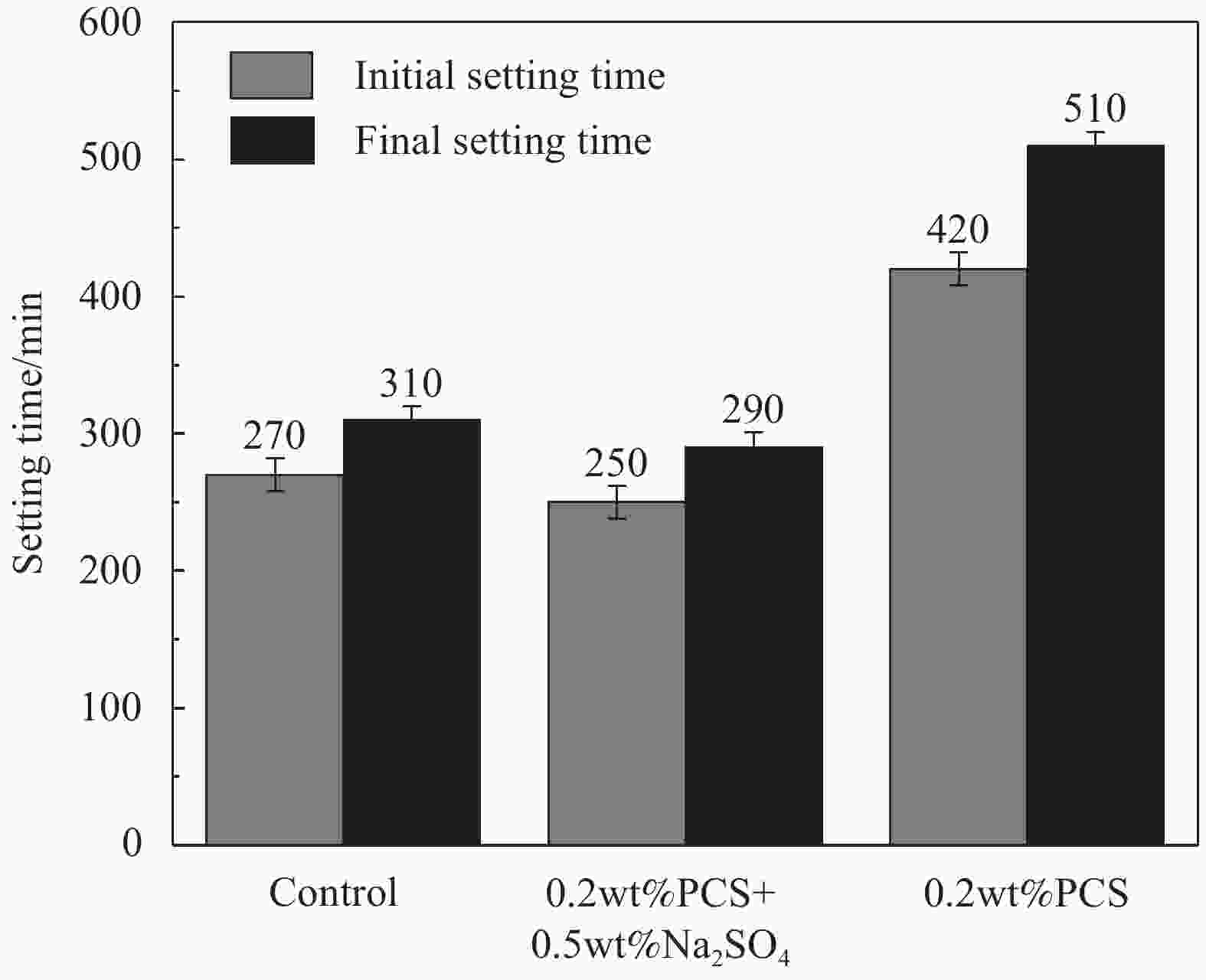

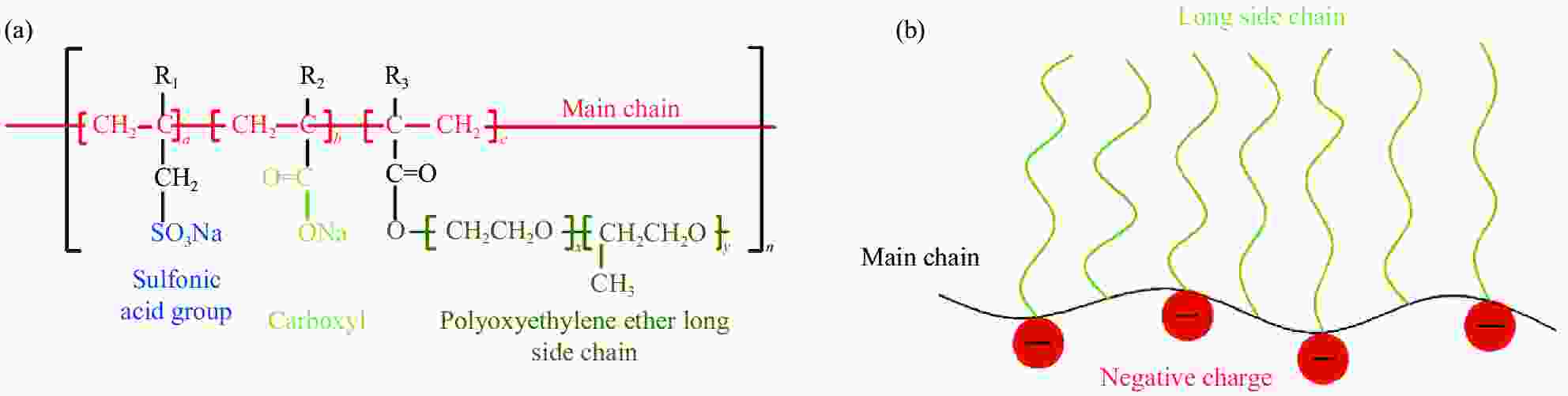

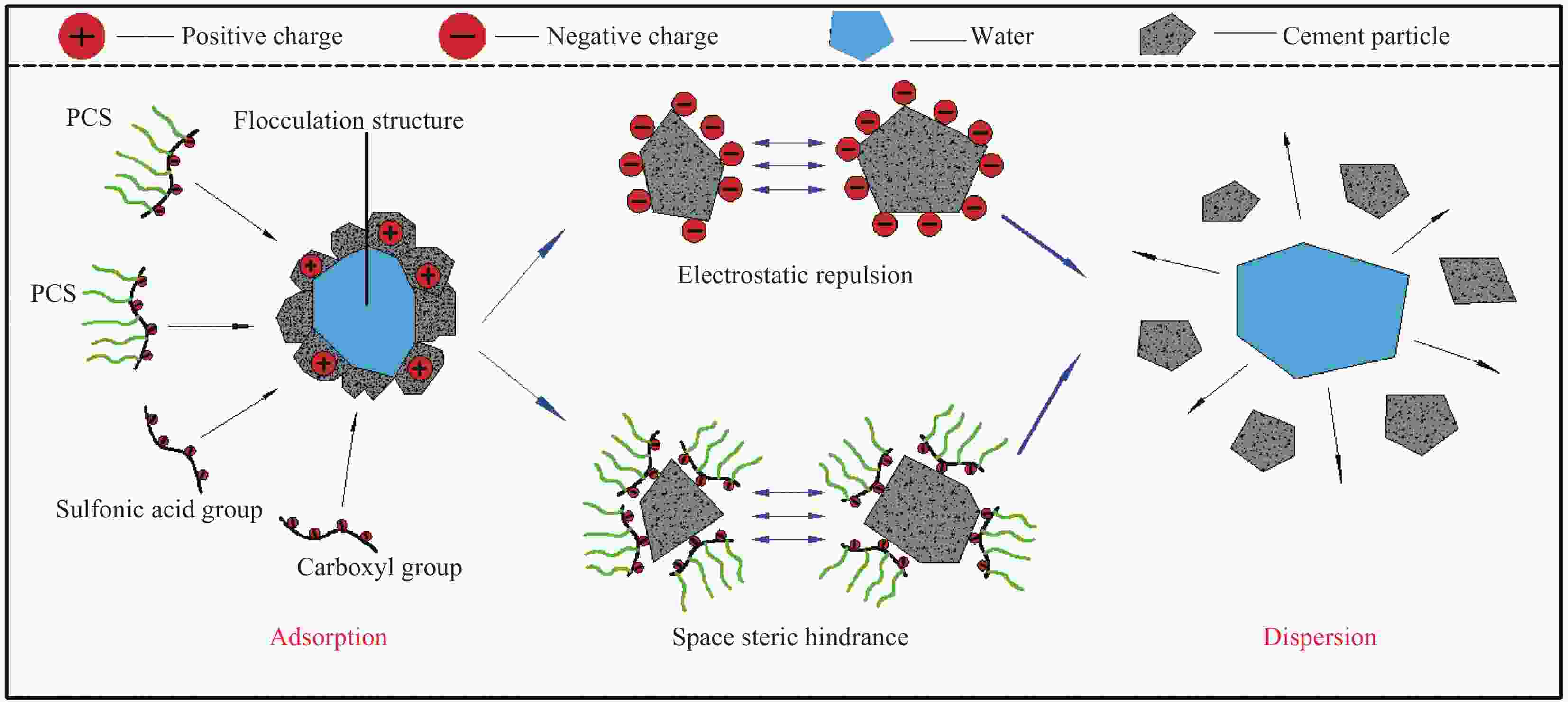

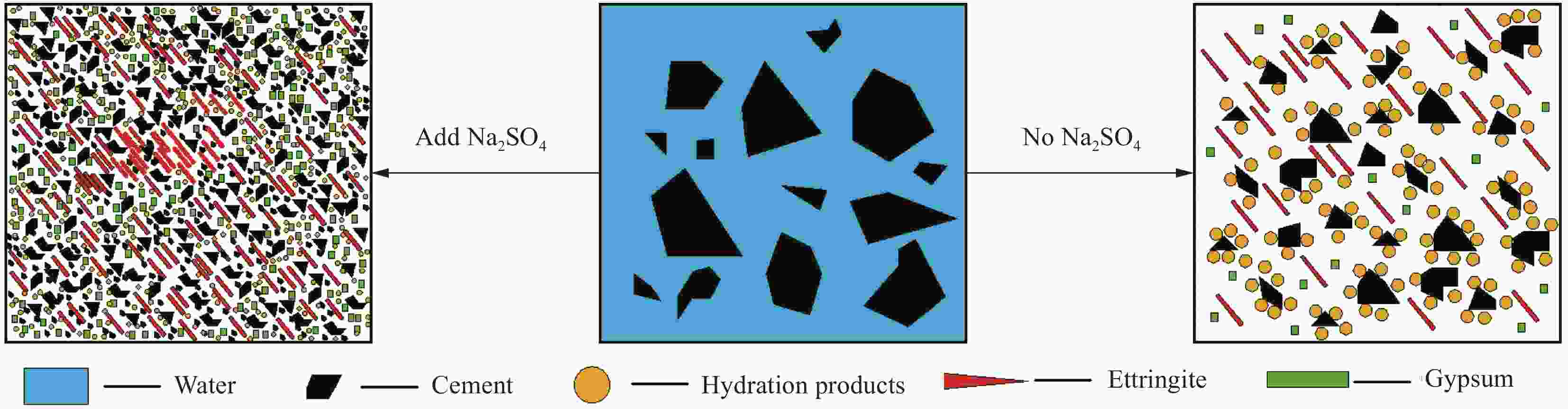

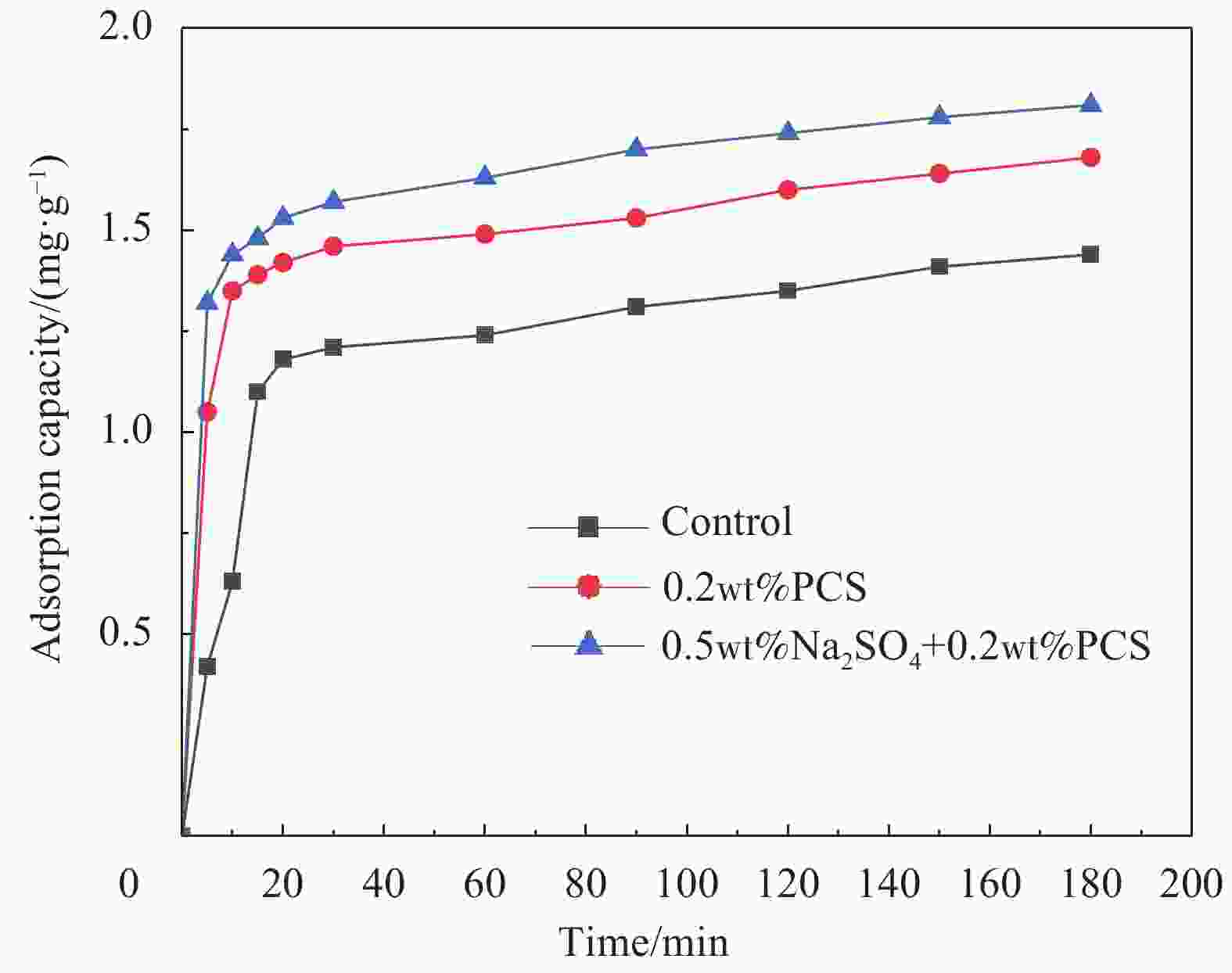

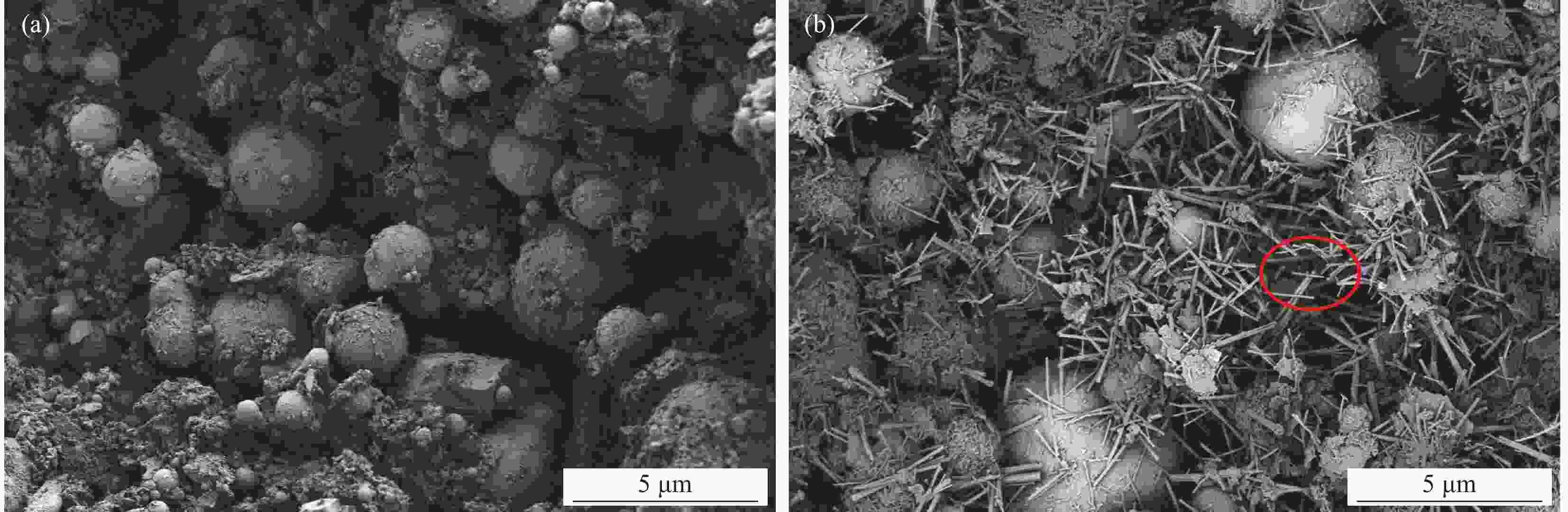

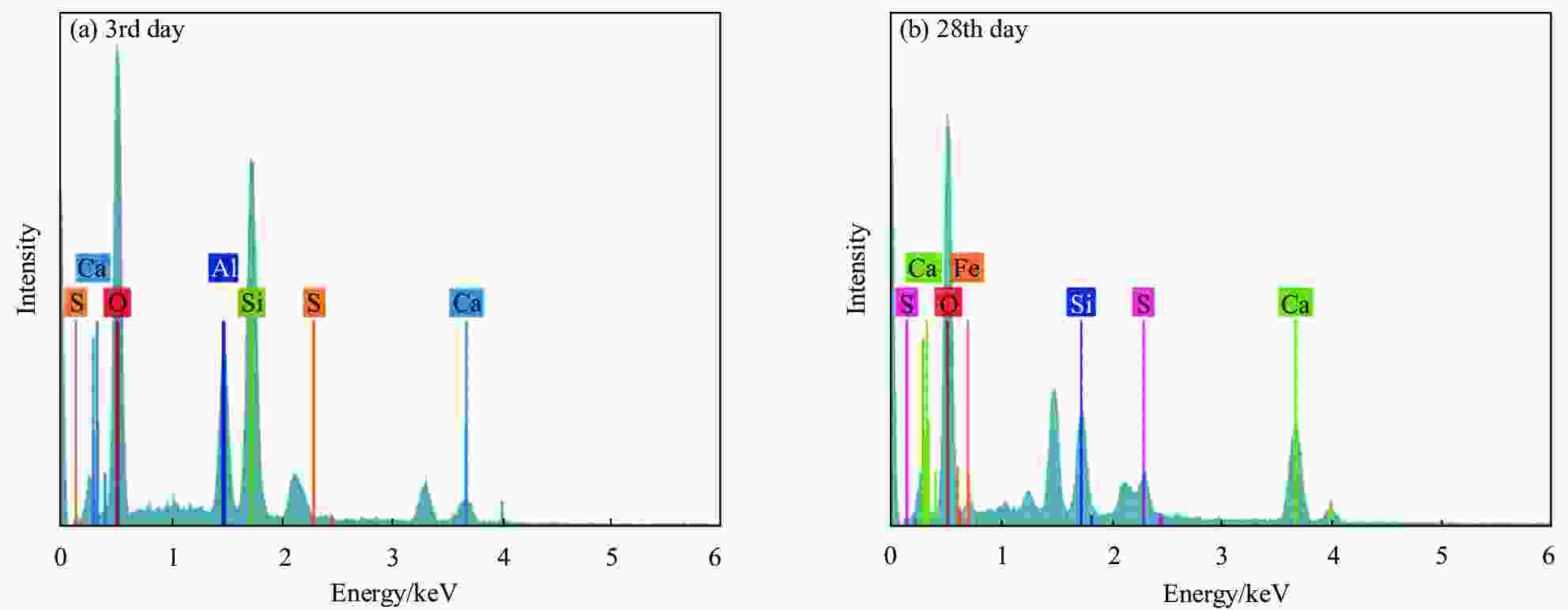

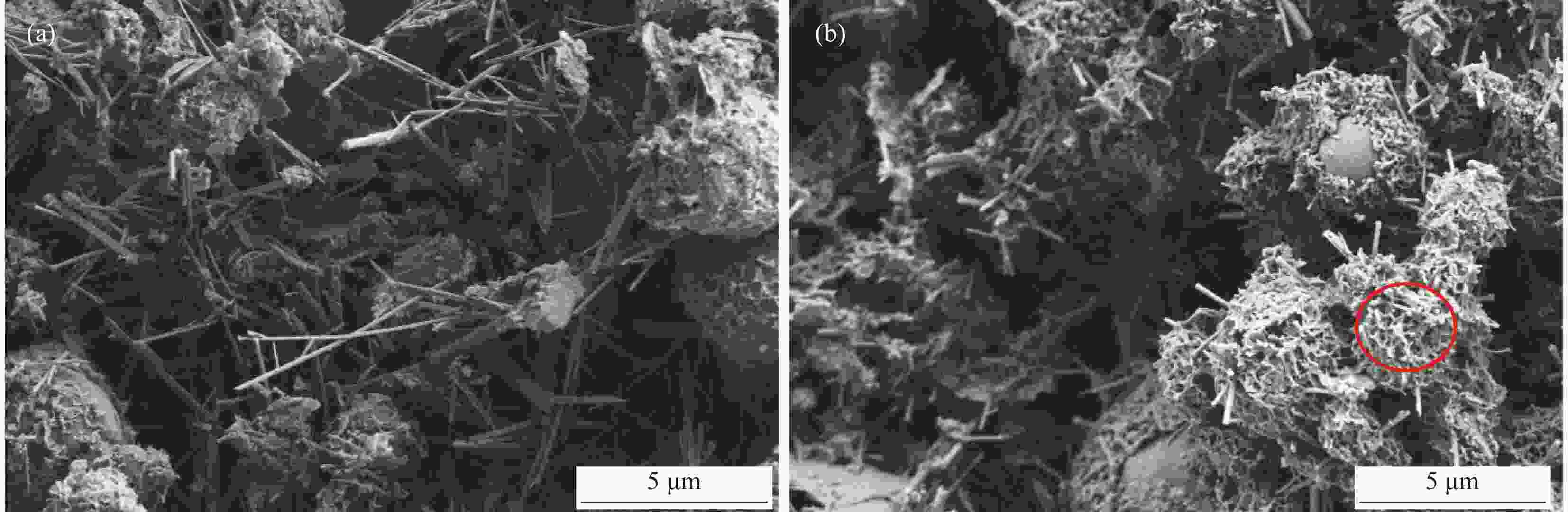

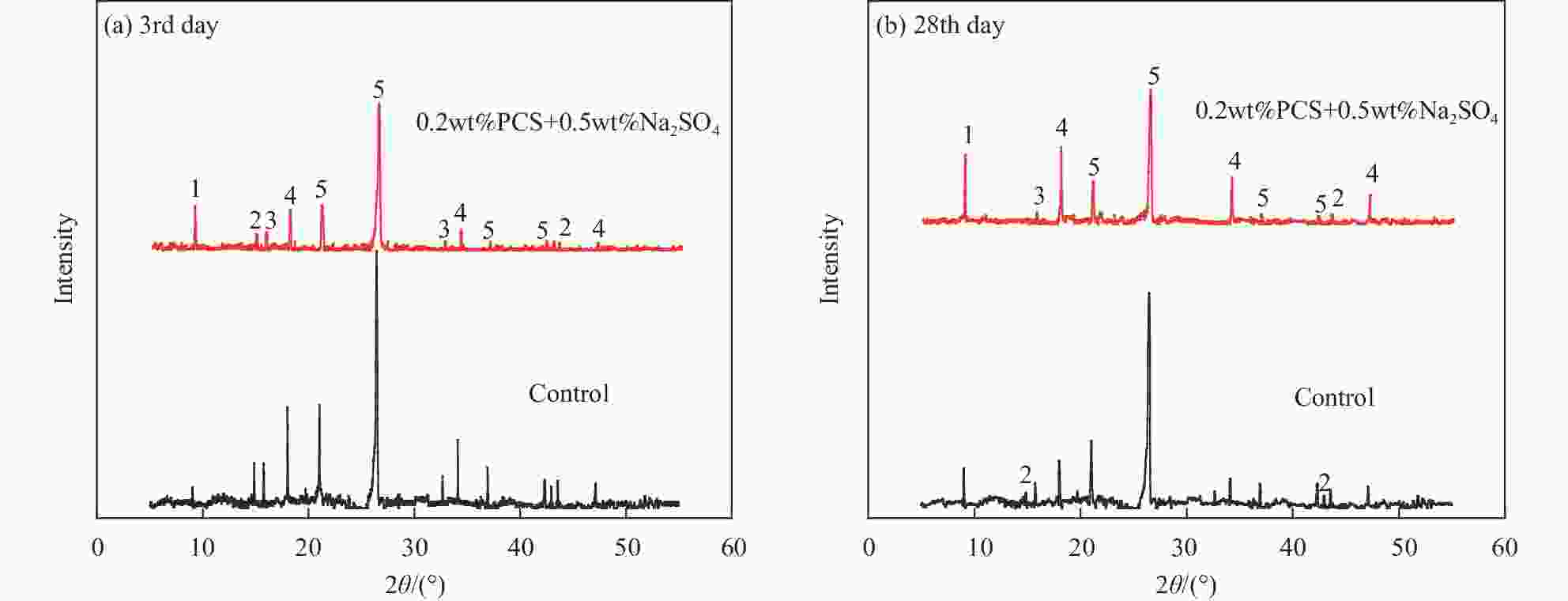

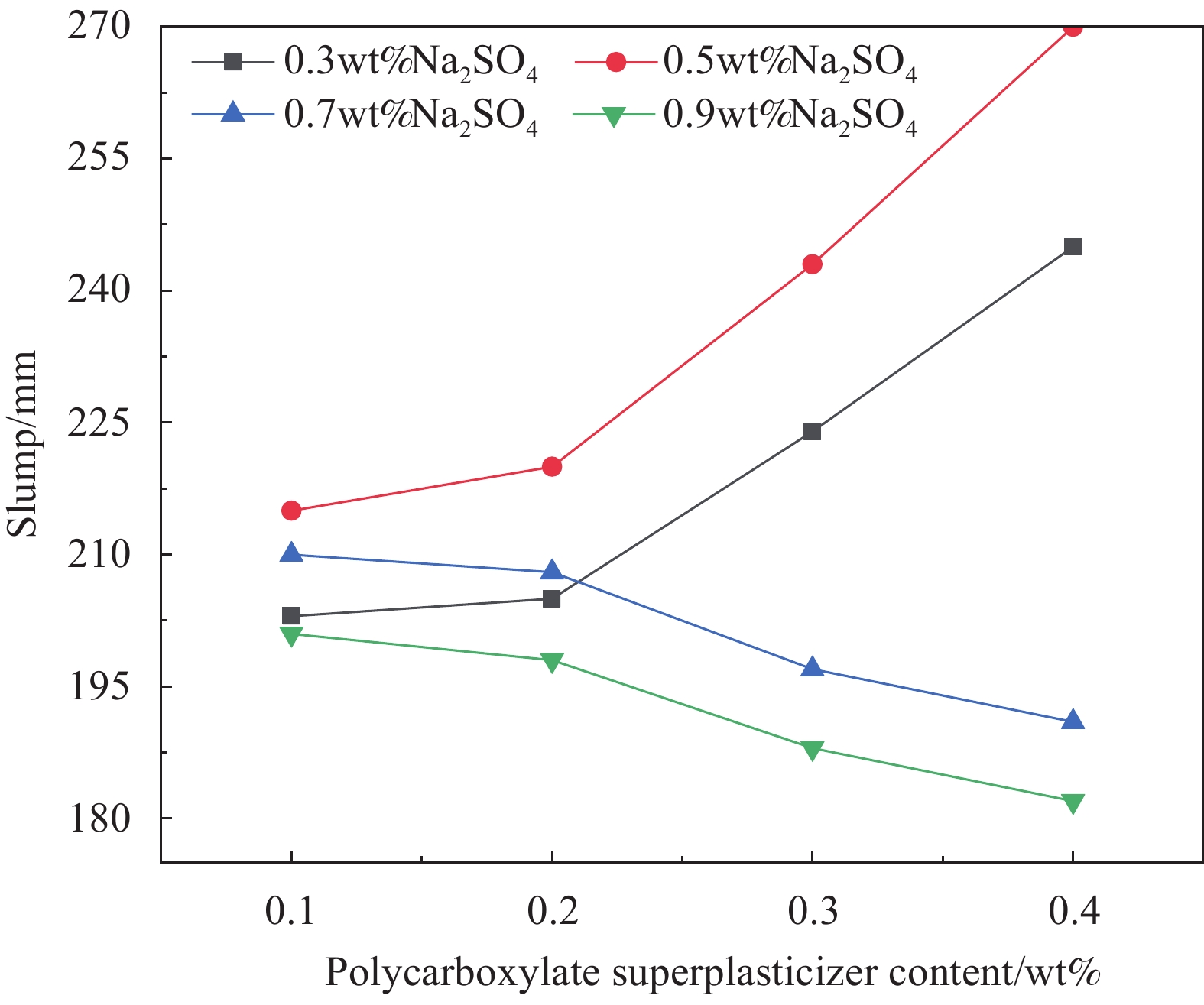

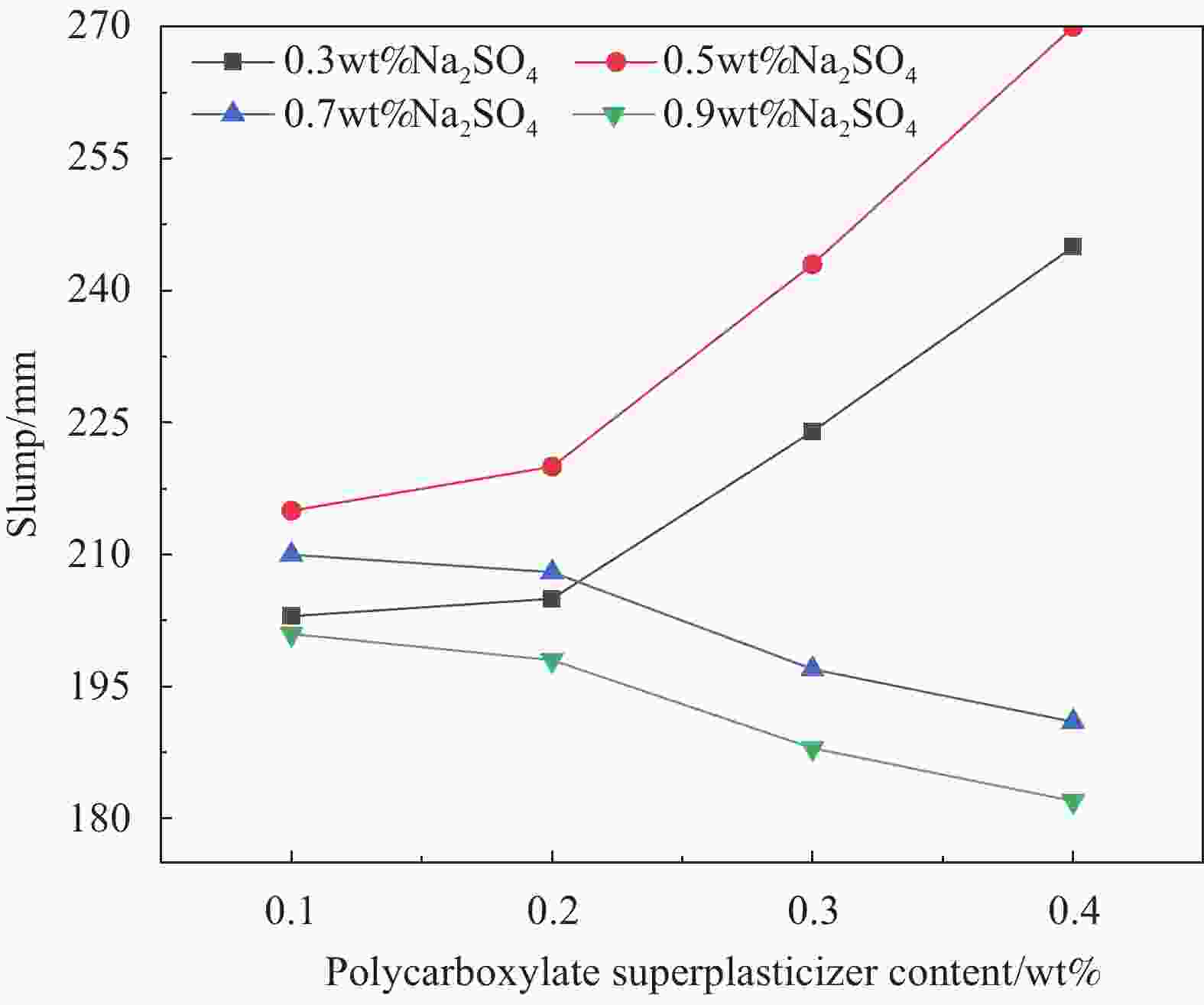

摘要: 为了提高煤矿充填浆体固化前后的性能,利用硫酸钠和聚羧酸减水剂复掺制备成复合外加剂,通过宏观实验探究其对充填浆体固化前后工作性能和力学性能的影响,并结合微观实验分析其影响机制。实验表明,0.5wt%硫酸钠与0.2wt%聚羧酸减水剂复掺的充填浆体,其水泥用量可减少2%,塌落度可增加4.1 cm,初凝时间和终凝时间可缩短20 min,减水率可提高7.7%,3天和28天单轴抗压强度最高可增加22%和42%。分析表明,硫酸钠的早强机制、聚羧酸减水剂的静电斥力作用和空间位阻作用及二者的互促作用是影响充填浆体固化前工作性能的主要原因,而针状性产物钙矾石和白色纤维状物质水化硅酸钙是影响充填浆体固化后力学性能的主要物质,二者的生成提高了充填膏体的单轴抗压强度。Abstract: In order to improve the performance of coal mine filling slurry before and after solidification, sodium sulfate and polycarboxylic acid water reducing agent were used to prepare a composite admixture, and the effect on the working performance and mechanical properties of the filling slurry before and after solidification was explored through indoor macroscopic experiments. Its influence mechanism was analyzed in combination with indoor microscopic experiments. Experiments show that the cement consumption of 0.5wt% sodium sulfate and 0.2wt% polycarboxylic acid water-reducing agent mixed filling slurry can be reduced by 2%, the slump can be increased by 4.1 cm, the initial and final setting time can be shortened by 20 min, and the water reduction rate can be increased by 7.7%, the 3rd day and 28th day uniaxial compressive strength can increase up to 22% and 42%. The analysis shows that the early strength mechanism of sodium sulfate, the electrostatic repulsion and steric hindrance of polycarboxylic acid water-reducing agent, and the mutual promotion of the two are the main reasons that affect the working performance of the filling slurry before curing. The needle-like product ettringite and the white fibrous substance calcium silicate hydrate are the main substances that affect the mechanical properties of the filling paste after solidification, and the formation of the two improves the uniaxial compressive strength of the filling paste.

-

Key words:

- filling slurry /

- compound admixture /

- ettringite /

- hydrated calcium silicate /

- influence mechanism

-

表 1 充填骨料化学成分(wt%)

Table 1. Chemical composition of filling aggregate (wt%)

Material SiO2 Al2O3 Fe2O3 CaO MgO K2O Others Cement 21.38 4.23 3.58 66.49 2.50 1.07 0.74 Fly ash 53.94 30.91 2.38 6.53 0.92 1.02 4.29 Coal gangue 59.10 18.90 4.30 2.36 1.41 1.89 12.03 表 2 充填浆体减水率测试结果

Table 2. Test results of water reduction rate of filling slurry

Group Cement/kg Fly ash/kg Coal

gangue/kgPCS/kg Na2SO4/kg Water

consumption/kgSlump/mm Water reduction

rate/%G-0 1 4 5 0 0 3.09 22 0 G-S 0 0.005 3.09 22 0 G-PCS 0.002 0 2.91 22 5.0 G-PCS-S 0.002 0.005 2.85 22 7.7 Notes: G-0—No adding Na2SO4 and PCS; G-PCS—Adding only PCS; G-S—Adding only Na2SO4; G-PCS-S—Adding PCS and Na2SO4 at the same time. 表 3 CPB的XRD图谱结果分析

Table 3. Analysis of XRD patterns results for CPB

2θ Name Chemical formula 8.98° Ettringite Ca6(Al(OH)6)2(SO4)3·26H2O 14.86°, 42.97°, 43.27° Tricalcium silicate C3S 15.57°, 32.66° Dicalcium silicate C2S 18.04°, 34.11°, 47.12° Calcium hydroxide Ca(OH)2 21.06°, 26.73°, 36.92°, 42.89° Quartz SiO2 -

[1] 钱鸣高, 许家林, 王家臣. 再论煤炭的科学开采[J]. 煤炭学报, 2018, 43(1):1-13.QIAN Minggao, XU Jialin, WANG Jiachen. Further on the sustainable mining of coal[J]. Journal of China Coal Society,2018,43(1):1-13(in Chinese). [2] 吴爱祥, 王勇, 王洪江. 膏体充填技术现状及趋势[J]. 金属矿山, 2016(7):1-9. doi: 10.3969/j.issn.1001-1250.2016.07.001WU Aixiang, WANG Yong, WANG Hongjiang. Status and prospects of the paste backfill technology[J]. Journal of China Metal Mine,2016(7):1-9(in Chinese). doi: 10.3969/j.issn.1001-1250.2016.07.001 [3] 温震江, 高谦, 陈得信, 等. 混合骨料级配对充填料浆离析的影响[J]. 中南大学学报(自然科学版), 2019, 50(9):2264-2272.WEN Zhenjiang, GAO Qian, CHEN Dexin, et al. The effect of mixed aggregate gradation on the separation of filler slurry[J]. Journal of Central South University (Natural Science Edition),2019,50(9):2264-2272(in Chinese). [4] BABAK K, AHMAD K, DARBAN A, et al. A comparison between the influence of superplasticizer and organosilanes on different properties of cemented paste backfill[J]. Construction and Building Materials,2018,173(10):180-188. [5] 吕生华, 丁怀东, 孙婷, 等. 萘系减水剂/氧化石墨烯复合材料对水泥石微观结构和性能的影响[J]. 陕西科技大学学报(自然科学版), 2014, 32(5): 42-47.LV Shenghua, DING Huaidong, SUN Ting, et al. Effect of naphthalene superplasticizer/graphene oxide composite on microstructure and mechanical properties of hardened cement paste[J]. Journal of Shaanxi University of Science and Technology, 2014, 32(5): 42-47(in Chinese). [6] 孙小巍, 李殿平, 礼航.不同缓凝剂与萘系减水剂相容性研究[J]. 江苏建材, 2011(4): 31-33.SUN Xiaowei, LI Dianping, LI Hang. Study on compatibi-lity of different retarders and naphthalene water reducers[J]. Jiangsu Building Materials, 2011(4): 31-33(in Chinese). [7] 丁斌, 欧阳利军, 房钰柯. 混凝土早强性能研究进展和展望[J]. 混凝土与水泥制品, 2020(9):24-29.DING Bin, OUYANG Lijun, FANG Yuke. Research progress and prospect of early strength performance of concrete[J]. Concrete and Cement Products,2020(9):24-29(in Chinese). [8] ERZENGIN S G, KAYA K, SABRIYE P, et al. The properties of cement systems superplasticized with methacrylic ester-based polycarboxylates[J]. Construction and Building Materials,2018,166(30):96-109. doi: 10.1016/j.conbuildmat.2018.01.088 [9] WU Y H, CHEN H, ZHANG P, et al. Effect of cationic monomer on early strength performance of polycarboxylate superplasticizer[J]. Journal of the Chinese Ceramic Society,2017,36(2):433-437. [10] HOUST Y F, BOWEN P, PERCHE F, et al. Design and function of novel superplasticizers for more durable high performance concrete[J]. Cement and Concrete Research,2008,38(10):1197-1209. doi: 10.1016/j.cemconres.2008.04.007 [11] LIU X, WANG Z M, ZHU J, et al. Synthesis, characterization and performance of a polycarboxylate superplasticizer with amide structure[J]. Colloids and Surfaces A Physicochemical and Engineering Aspects,2014,448(4):119-129. [12] KONG F R, PAN L S, WANG C M, et al. Effects of polycarboxylate superplasticizers with different molecular structure on the hydration behavior of cement paste[J]. Construction and Building Materials,2016,105:545-553. doi: 10.1016/j.conbuildmat.2015.12.178 [13] KAZUO Y, SHOICHI O, SHUNSUKE H. Controlling of the adsorption and dispersing force of polycarboxylate-type superplasticizer by sulfate ion concentration in aqueous phase[J]. Cement and Concrete Research,2001,31(3):375-383. doi: 10.1016/S0008-8846(00)00503-2 [14] KOOHESTANI B, BELEM T, KOUBAA A, et al. Experimental investigation into the compressive strength development of cemented paste backfill containing nano-silica[J]. Cement and Concrete Composites,2016,72:180-189. doi: 10.1016/j.cemconcomp.2016.06.016 [15] 中华人民共和国住房和城乡建设部. 普通混凝土拌合物性能试验方法标准: GB/T 50080—2016[S]. 北京: 中国标准出版社, 2017.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of ordinary concrete mixture performance: GB/T 50080—2016[S]. Beijing: China Standards Press, 2017(in Chinese) [16] 国家质量技术监督局. 混凝土外加剂匀质性试验方法: GB/T8077—2008[S]. 北京: 中国标准出版社, 2008.National Bureau of Quality and Technical Supervision. Test method for homogeneity of concrete admixtures: GB/T8077—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [17] 中华人民共和国国家质量监督检验检疫总局. 水泥标准稠度用水量、凝结时间、安定性检验方法: GB/T1346—2011[S]. 北京: 中国标准出版社, 2012.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Cement standard consistency water consumption, setting time, and stability test method: GB/T1346—2011[S]. Beijing: China Standard Press, 2012(in Chinese). [18] 中华人民共和国建设部. 普通混凝土力学性能试验方法标准标准: GB/T 50081—2002[S]. 北京: 中国标准出版社, 2003.Ministry of Construction of the People's Republic of China. Standards for test methods of ordinary concrete mechani-cal properties: GB/T 50081—2002[S]. Beijing: China Standards Press, 2003(in Chinese). [19] SHA S N, SHI C J, XIANG S C, et al. The state-of-the-art synthesis techniques of polycarboxylate superplasticizer (Review)[J]. Cailiao Daobao/Materials Review,2019,33(2):558-568. [20] MA B G, YANG H, TAN H B, et al. Adsorption characteris-tics of different superplasticizers on cement and clay minerals[J]. Journsl of the Chinese Ceramic Society,2013(3):328-333. [21] 倪琳. 聚羧酸减水剂的应用现状及存在的问题[J]. 辽宁化工, 2020, 49(12):1548-1549, 1554. doi: 10.3969/j.issn.1004-0935.2020.12.027NI Lin. The application status and existing problems of polycarboxylic acid water reducer[J]. Liaoning Chemical Industry,2020,49(12):1548-1549, 1554(in Chinese). doi: 10.3969/j.issn.1004-0935.2020.12.027 [22] 张艳荣. 水泥-化学外加剂-水分散体系早期微结构与流变性[D]. 北京: 清华大学, 2014.ZHANG Yanrong. Early microstructure and rheology of cement-chemical admixture-water dispersion system[D]. Beijing: Tsinghua University, 2014(in Chinese). [23] PUERTAS F, SANTOS H, PALACIOS M, et al. Polycarboxylate superplasticiser admixtures: Effect on hydration, microstructure and rheological behavior in cement pastes[J]. Advances in Cement Research,2005,17(2):77-89. doi: 10.1680/adcr.2005.17.2.77 [24] SAKAI E, KASUGA T, SUGIYAMA T, et al. Influence of superplasticizers on the hydration of cement and the pore structure of hardened cement[J]. Cement and Concrete Research,2006(36):2049-2053. [25] 汪杰. 聚羧酸减水剂分子结构及缓凝组分对C3A-石膏体系吸附行为及水化行为的影响[D]. 武汉: 武汉理工大学, 2014.WANG Jie. The influence of molecular structure and retarding components of polycarboxylic acid water reducer on the adsorption and hydration behavior of C3A-gypsum system[D]. Wuhan: Wuhan University of Technology, 2014(in Chinese). [26] LOTHENBACH B, WINNEFELD F. Thermodynamic modelling of the hydration of portland cement[J]. Cement and Concrete Research,2006(36):209-226. [27] PLANK J, DAI Z M, HELENA K, et al. Fundamental mecha-nisms for polycarboxylate intercalation into C3A hydrate phases and the role of sulfatepresent in cement[J]. Cement and Concrete Research,2010,40(1):45-57. doi: 10.1016/j.cemconres.2009.08.013 [28] YAMADA K, TAKAHASHI T, HANEHARA S, et al. Effects of the chemical structure on the properties of polycarboxylate-type superplasticizer[J]. Cement and Concrete Research,2000,30(2):197-207. doi: 10.1016/S0008-8846(99)00230-6 [29] 高原, 许金余, 张国喜. 矿渣碱激发胶凝材料早期性能的响应曲面研究[J]. 建筑材料学报, 2016, 19(2):209-213. doi: 10.3969/j.issn.1007-9629.2016.02.001GAO Yuan, XU Jinyu, ZHANG Guoxi. Response surface study on early performance of slag alkali excited cementitious materials[J]. Journal of Building Materials,2016,19(2):209-213(in Chinese). doi: 10.3969/j.issn.1007-9629.2016.02.001 [30] SNELLINGS R, SCHERER G. Surface chemistry of calcium aluminosilicate glasses[J]. Journal of the American Ceramic Society,2015,98(1):303-314. doi: 10.1111/jace.13263 -

下载:

下载: