Continuous fabrication of flexible, thermally conductive aluminum nitride/aramid nanofiber composite films

-

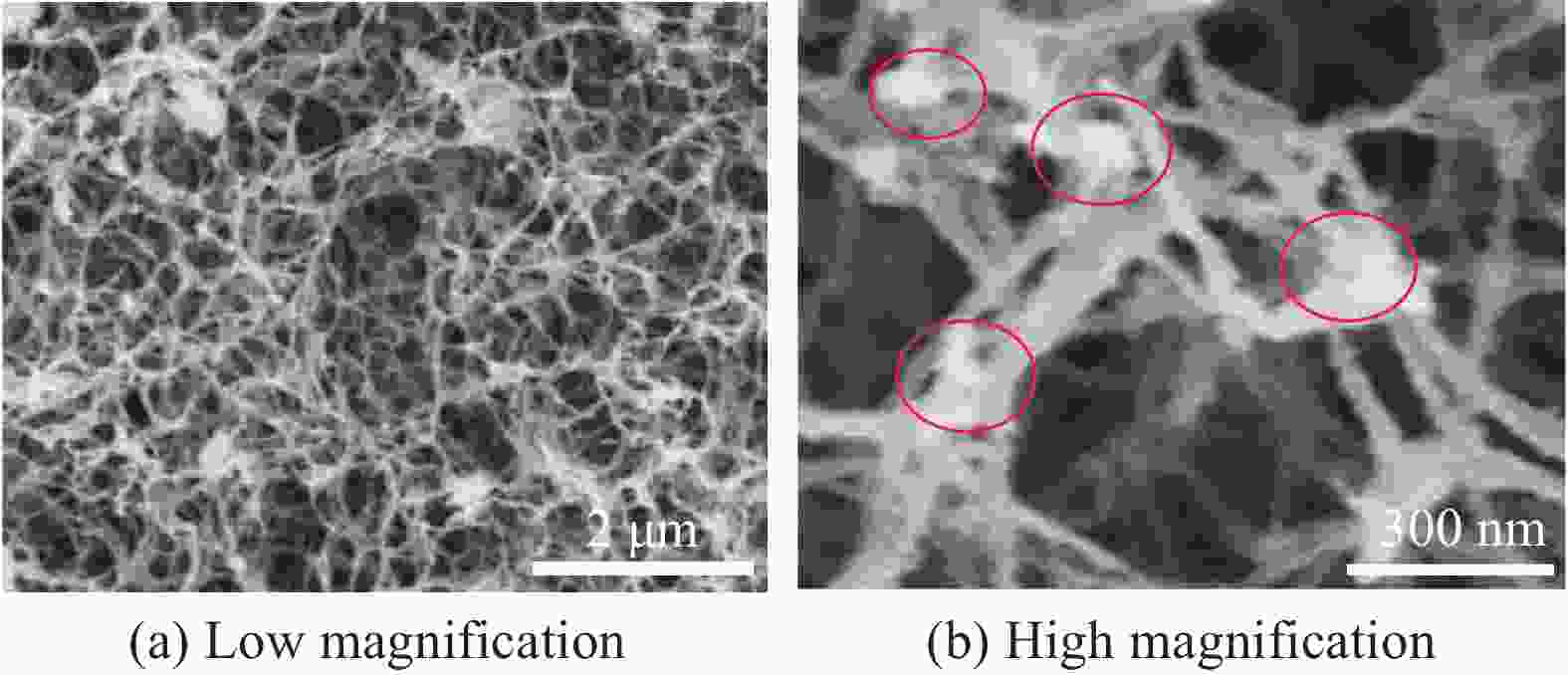

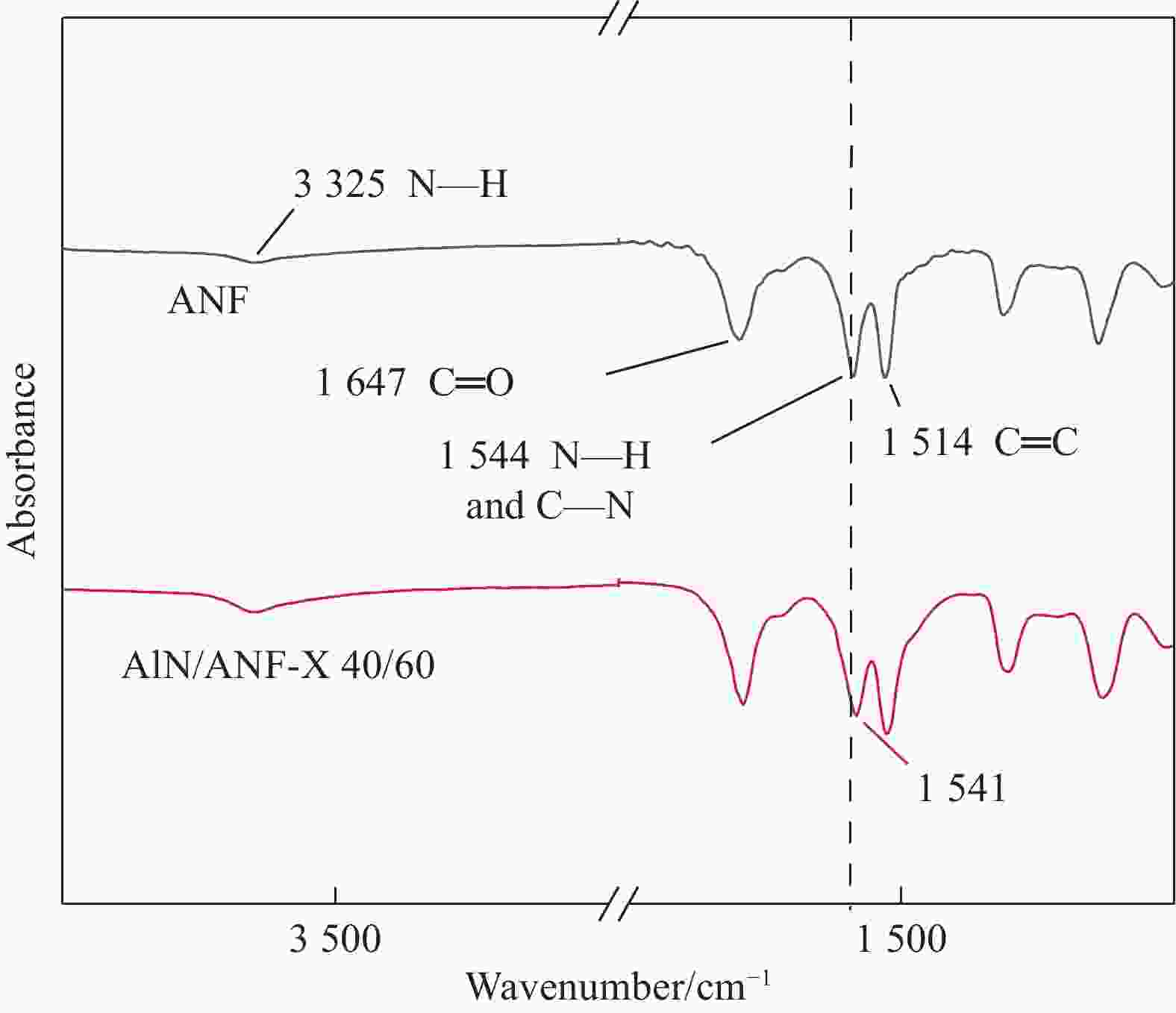

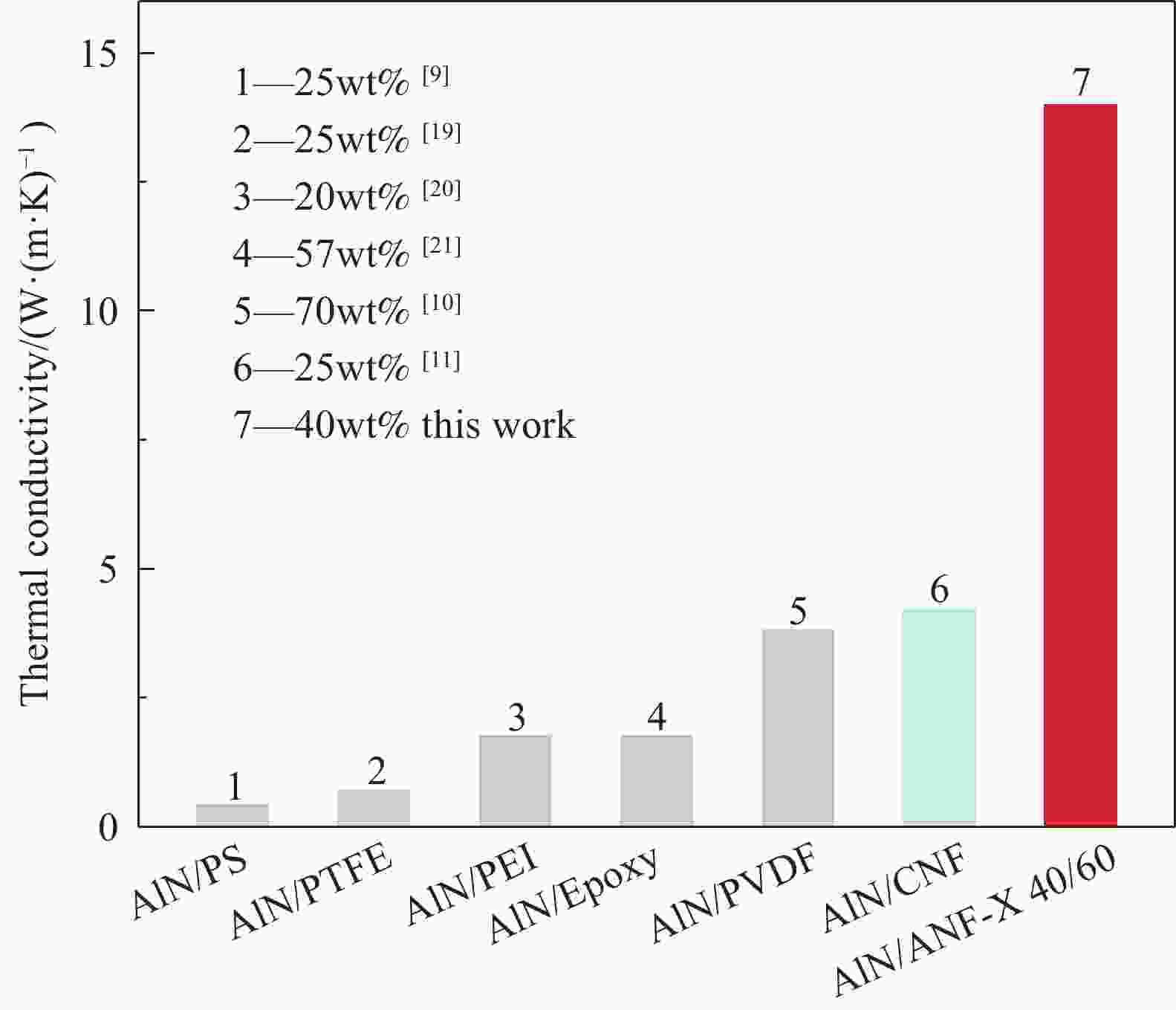

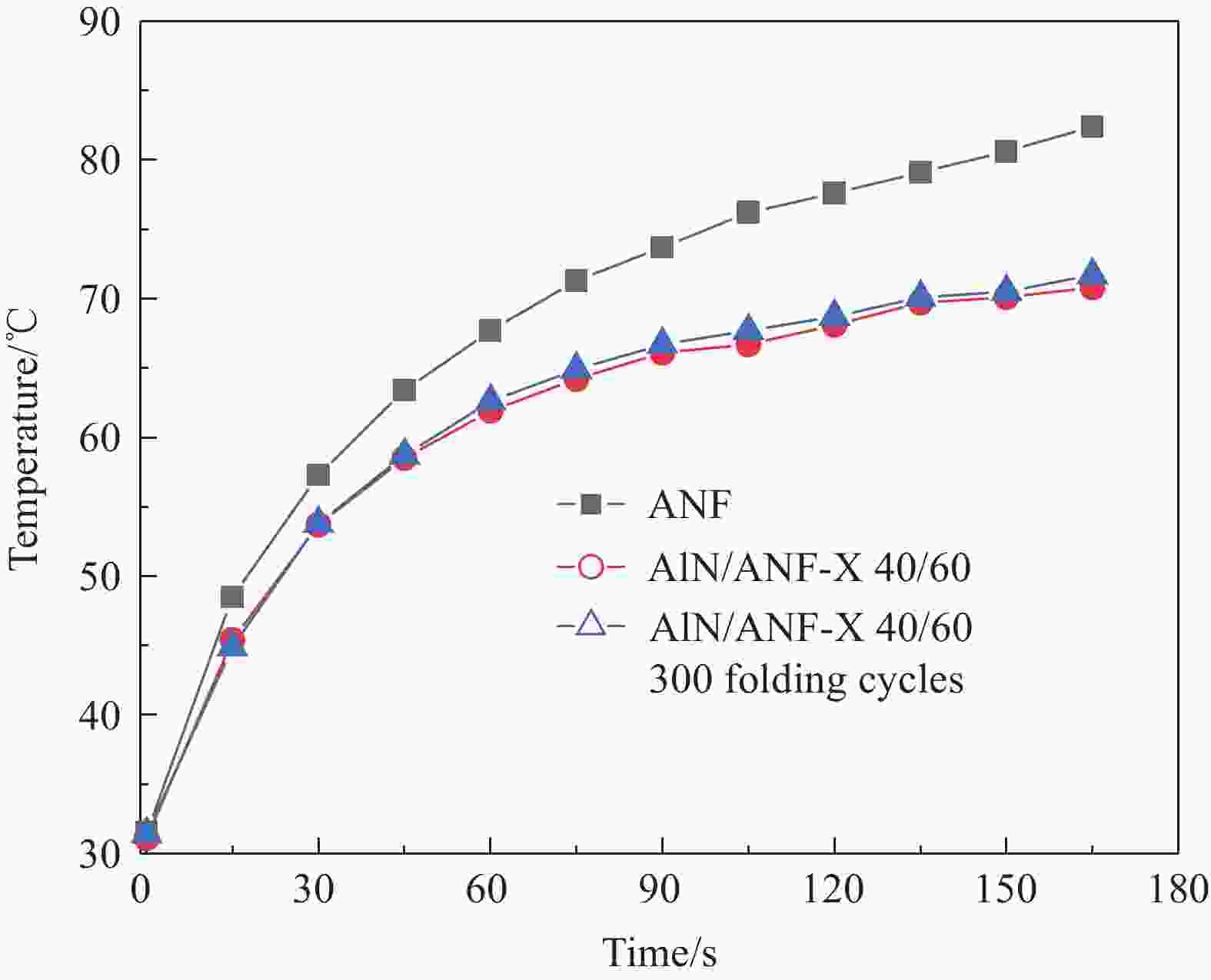

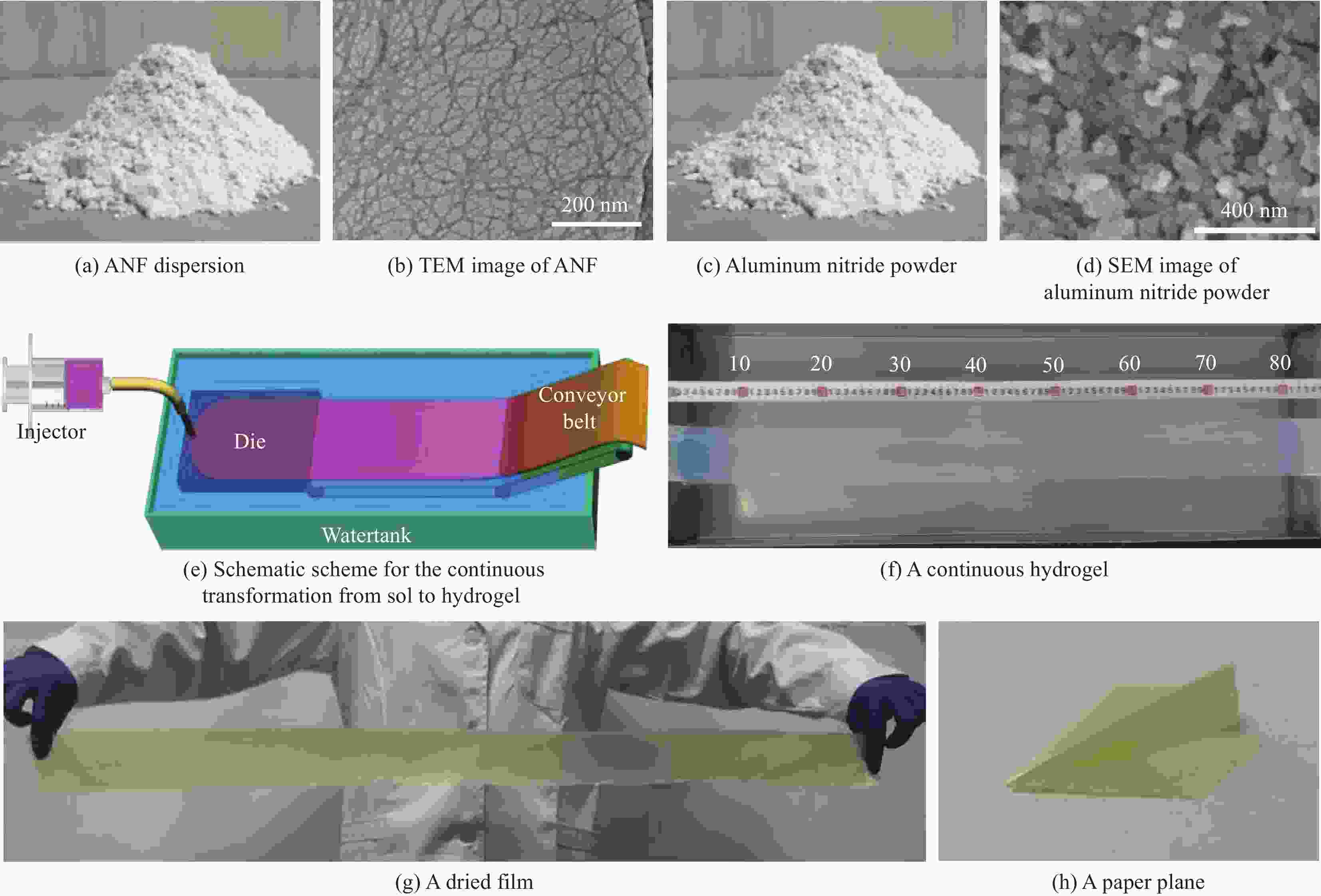

摘要: 设计制备柔性导热材料对柔性电子器件的热管理具有重要意义。本文基于溶剂剥离的芳纶纳米纤维和氮化铝(AlN)纳米颗粒,采用溶胶-凝胶-薄膜转换方法,连续制备了柔性导热的AlN/芳纶纳米纤维复合薄膜材料。其中,芳纶纳米纤维形成了三维连通的网络结构,提供力学支撑作用;AlN颗粒填充在该网络结构中,赋予复合材料良好的导热性能。结果显示,该复合材料的拉伸强度为65.5 MPa,断裂应变为12%,反复折叠300次后其拉伸强度和断裂应变保持率在90%以上,导热率为13.98 W·(m·K)−1。此外,该复合薄膜显示出良好的绝缘性能和耐热性能,体积电阻率为1.85×1015 Ω·cm、起始热分解温度为524℃。最后,演示该高性能的AlN/芳纶纳米纤维复合薄膜作为柔性基底材料,可用于冷却电子器件。Abstract: Designing and preparing flexible thermally conductive materials is important for thermal management of flexible electronic devices. Based on exfoliated aramid nanofiber and aluminum nitride (AlN) nanoparticle, flexible and thermally conductive composite films were fabricated by a sol-gel-film transformation approach. In the composite films, aramid nanofibers forms three-dimensional connective network for providing mechanical support. AlN nanoparticles are filled in the network of aramid nanofiber to impart the composite films with good thermal conduction performance. As a result, the tensile strength and strain at break are 65.5 MPa and 12%, respectively. After folding for 300 cycles, the composite films retain more than 90% of original tensile strength and strain at break. The thermal conductivity is up to 13.98 W·(m·K)−1. Moreover, the composite films show good electrically insulating property and thermal stability. The volume electrical resistivity and initial thermal decomposition temperature are 1.85×1015 Ω·cm and 524℃. Finally, we demonstrate that the high-performance AlN/aramid nanofiber composite films can be act as flexible substrate for cooling electronics.

-

Key words:

- aramid nanofiber /

- aluminum nitride /

- composite film /

- mechanical property /

- thermal conductivity

-

表 1 氮化铝/芳纶纳米纤维三维网络(AlN/ANF-X)复合材料配比

Table 1. Proportion of aluminum nitride/aramid nanofiber 3D network (AlN/ANF-X) composites

Material AlN/wt% ANF/wt% Pure ANF 0 100 AlN/ANF-X 20/80 20 80 AlN/ANF-X 40/60 40 60 表 2 纯ANF薄膜和AlN/ANF-X复合薄膜的热扩散系数、比热容、密度和导热系数

Table 2. Thermal diffusivity, specific heat capacity, density and thermal conductivity of pure ANF film and AlN/ANF-X composite films

Material α/(mm2·s−1) Cp/(J·(g·℃)−1) ρ/(g·cm−3) K/(W·(m·K)−1) ANF 5.320 1.249 1.131 7.51 AlN/ANF-X 20/80 7.516 1.069 1.114 8.94 AlN/ANF-X 40/60 11.725 1.196 0.997 13.98 Notes: K—Thermal conductivity; α—Thermal diffusivity coefficient; Cp—Heat capacity; ρ—Density. -

[1] BALANDIN A A. Thermal properties of graphene and nanostructured carbon materials[J]. Nature Materials,2011,10(8):569-581. doi: 10.1038/nmat3064 [2] SONG W L, WANG W, VECA L M, et al. Polymer/carbon nanocomposites for enhanced thermal transport properties-carbon nanotubes versus graphene sheets as nanoscale fillers[J]. Journal of Materials Chemistry,2012,22(33):17133-17139. doi: 10.1039/c2jm32469e [3] CHEN J, HUANG X, SUN B, et al. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability[J]. ACS Nano,2019,13(1):337-345. doi: 10.1021/acsnano.8b06290 [4] SLACK G A, TANZILLI R A, POHL R O, et al. The intrinsic thermal conductivity of AIN[J]. Journal of Physics & Chemistry of Solids,1987,48(7):641-647. [5] YU S, HING P, HU X. Thermal conductivity of polystyrene-aluminum nitride composite[J]. Composites Part A: Applied Science and Manufacturing,2002,33(2):289-292. doi: 10.1016/S1359-835X(01)00107-5 [6] CAO Y, IRWIN P C, YOUNSI K. The future of nanodielectrics in the electrical power industry[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2004,11(5):797-807. doi: 10.1109/TDEI.2004.1349785 [7] CHOY C L. Thermal conductivity of polymers[J]. Polymer,1977,18(10):984-1004. doi: 10.1016/0032-3861(77)90002-7 [8] CHEN H, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science,2016,59:41-85. doi: 10.1016/j.progpolymsci.2016.03.001 [9] WU G, WANG Y, WANG K, et al. The effect of modified AlN on the thermal conductivity, mechanical and thermal properties of AlN/polystyrene composites[J]. RSC Advances,2016,6(104):102542-102548. doi: 10.1039/C6RA22794E [10] KIM K, YOO M, AHN K, et al. Thermal and mechanical properties of AlN/BN-filled PVDF composite for solar cell backsheet application[J]. Ceramics International,2015,41(1):179-187. doi: 10.1016/j.ceramint.2014.08.056 [11] ZHANG K, PENG T, ZHANG Y H, et al. Highly thermal conductivity of CNF/AlN hybrid films for thermal management of flexible energy storage devices[J]. Carbohydrate Polymers,2019,213:228-235. doi: 10.1016/j.carbpol.2019.02.087 [12] GARCÍA J M, GARCÍA F C, SERNA F, et al. High-performance aromatic polyamides[J]. Progress in Polymer Science,2010,35(5):623-686. doi: 10.1016/j.progpolymsci.2009.09.002 [13] CHATZI E G, KOENIG J L. Morphology and structure of kevlar fibers: a review[J]. Polymer-Plastics Technology and Engineering,1987,26:229-270. doi: 10.1080/03602558708071938 [14] YANG M, CAO K, SUI L, et al. Dispersions of aramid nanofibers: A new nanoscale building block[J]. ACS Nano,2011,5(9):6945-6954. doi: 10.1021/nn2014003 [15] KUANG Q, ZHANG D, YU J C, et al. Toward record-high stiffness in polyurethane nanocomposites using aramid nanofibers[J]. The Journal of Physical Chemistry C,2015,119(49):27467-27477. doi: 10.1021/acs.jpcc.5b08856 [16] ZHU J, YANG M, EMRE A, et al. Branched aramid nanofibers[J]. Angewandte Chemie International Edition,2017,56(39):11744-11748. doi: 10.1002/anie.201703766 [17] TSAGAROPOULOS G, EISENBERG A. Dynamic mechanical study of the factors affecting the two glass transition behavior of filled polymers: Similarities and differences with random ionomers[J]. Macromolecules,1995,28(18):6067-6077. doi: 10.1021/ma00122a011 [18] PAN C, KOU K, WU G, et al. Fabrication and characterization of AlN/PTFE composites with low dielectric constant and high thermal stability for electronic packaging[J]. Journal of Materials Science: Materials in Electronics,2016,27(1):286-292. doi: 10.1007/s10854-015-3752-2 [19] CHEN P, KOU K C, ZHANG Y, et al. Enhanced through-plane thermal conductivity of PTFE composites with hybrid fillers of hexagonal boron nitride platelets and aluminum nitride particles[J]. Composites Part B: Engineering,2018,153:1-8. doi: 10.1016/j.compositesb.2018.07.019 [20] WU S Y, HUANG Y L, MA C C M, et al. Mechanical, thermal and electrical properties of aluminum nitride/polyetherimide composites[J]. Composites Part A: Applied Science and Manufacturing,2011,42(11):1573-1583. doi: 10.1016/j.compositesa.2011.06.009 [21] KIM K, KIM J. Magnetic aligned AlN/epoxy composite for thermal conductivity enhancement at low filler content[J]. Composites Part B: Engineering,2016,93:67-74. doi: 10.1016/j.compositesb.2016.02.052 [22] ZHANG T, WU X, LUO T. Polymer nanofibers with outstanding thermal conductivity and thermal stability: Fundamental linkage between molecular characteristics and macroscopic thermal properties[J]. The Journal of Physical Chemistry C,2014,118(36):21148-21159. doi: 10.1021/jp5051639 -

下载:

下载: