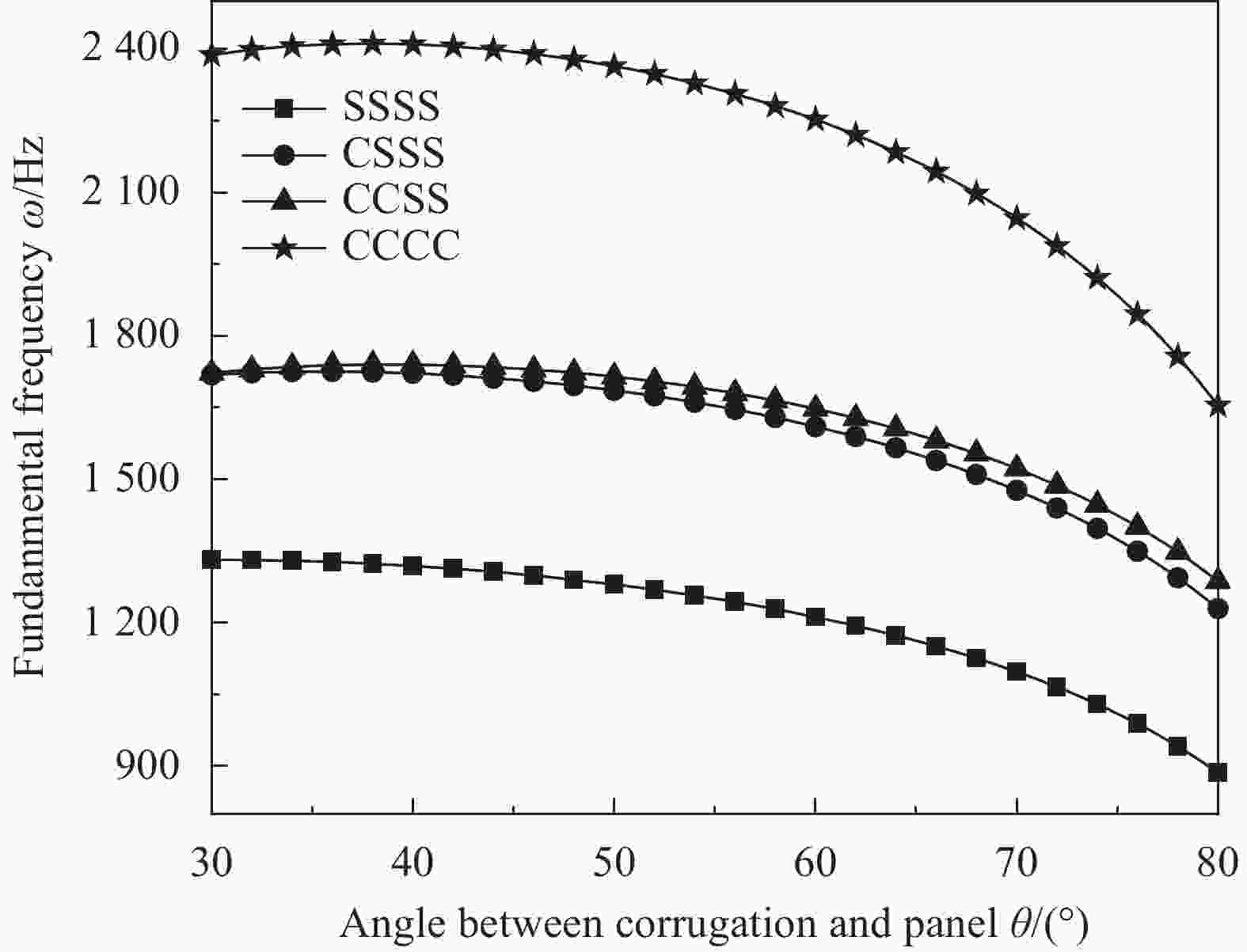

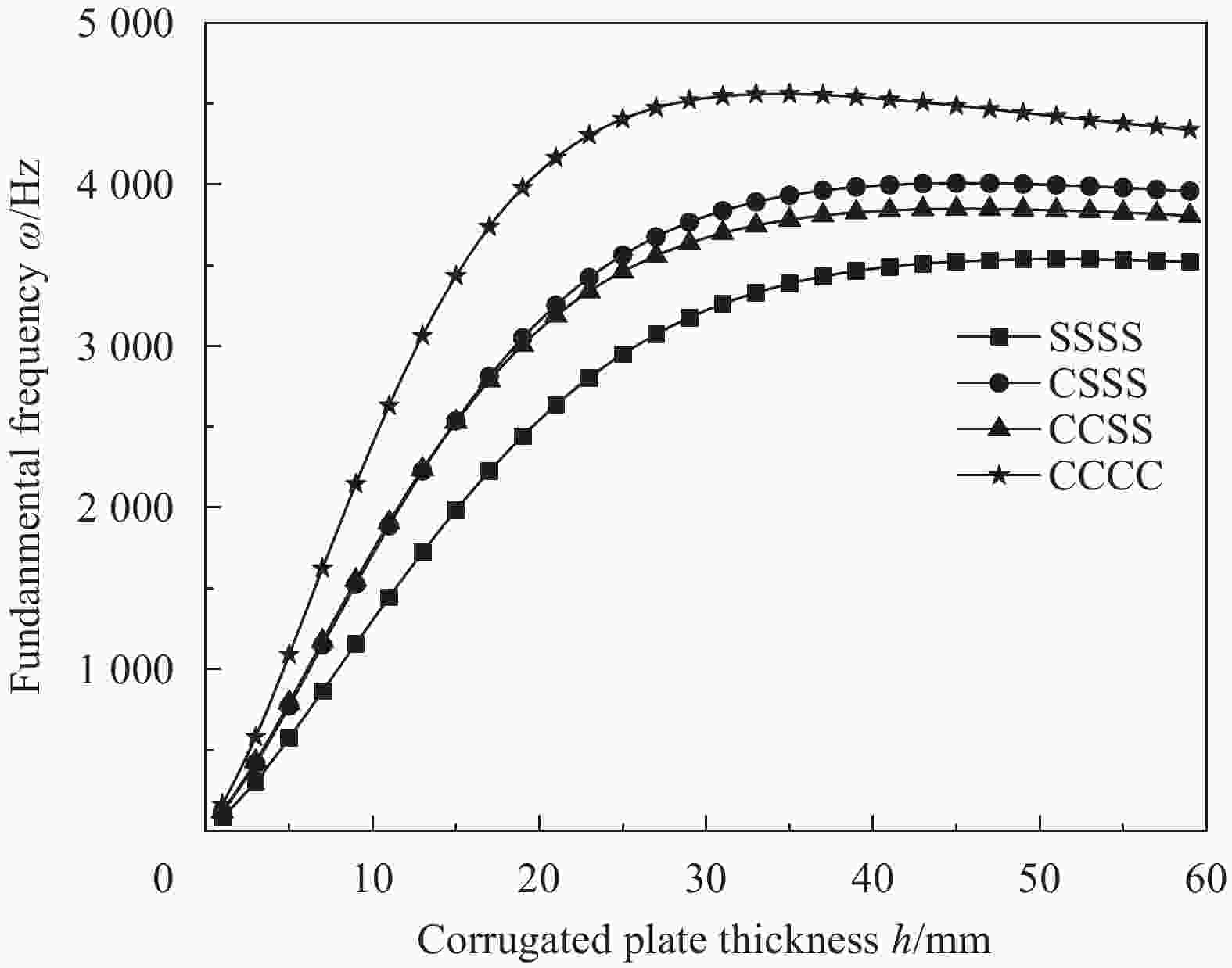

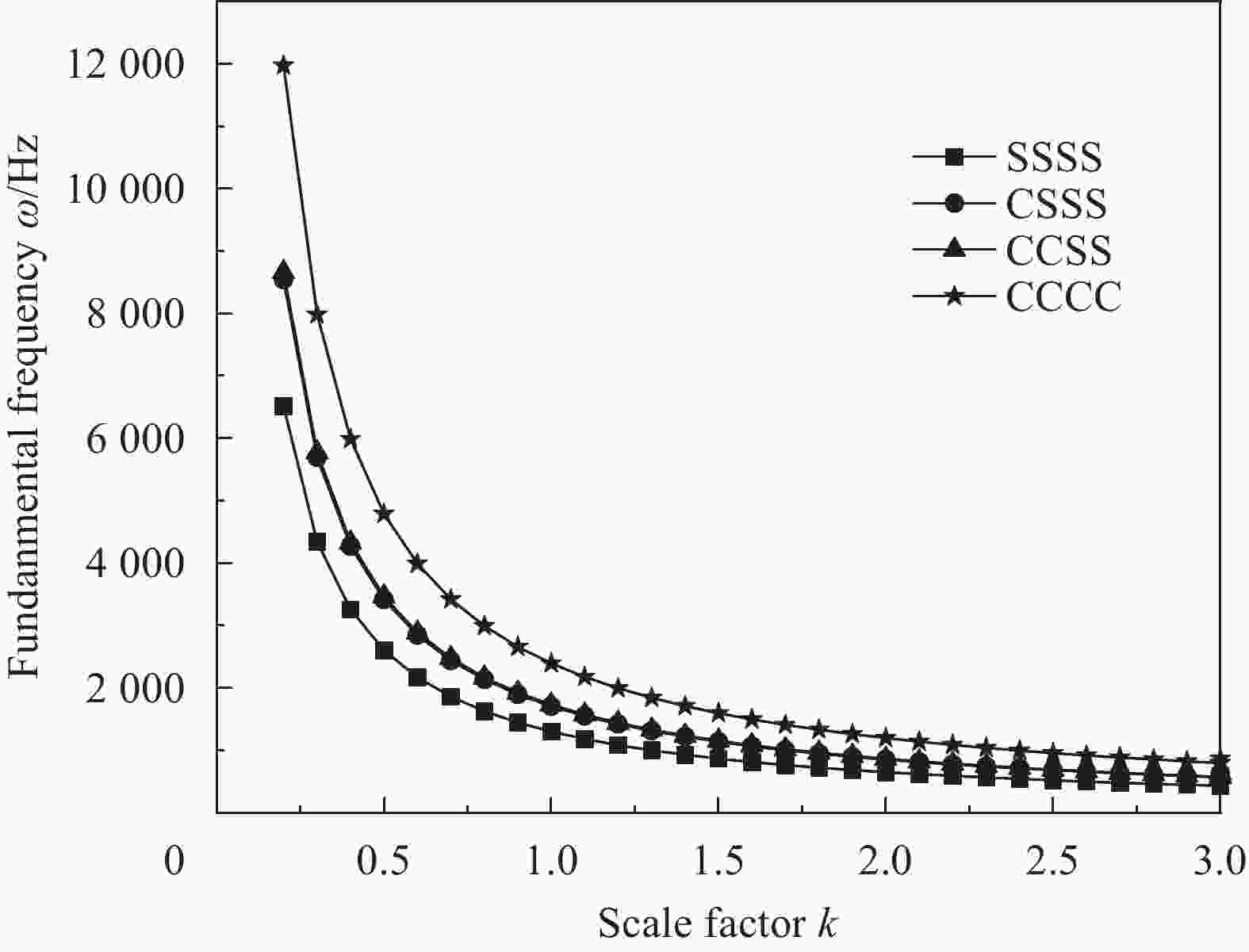

Free vibration characteristics of corrugated sandwich plates under different boundary conditions

-

摘要: 波纹夹芯板作为一种特殊的复合材料结构,边界条件对其振动特性有重要影响。根据不同剪切方式下的剪切变形理论和基尔霍夫经典板理论(CLPT),利用Hamilton原理建立波纹夹芯板的动力学方程。其中,波纹芯层等效成各向异性均质体。根据四边简支、四边固支、对边简支和固支、一边固支三边简支的边界条件,推导出位移形式的偏微分动力学方程。求解得到波纹夹芯板在不同边界条件下自由振动的固有频率,与有限元仿真结果进行对比,验证了理论结果的正确性。在此基础上,基于指数剪切变形理论(ESDT),分析了不同边界条件下波纹夹芯板的基频随材料参数和结构几何参数的变化规律。结果表明,材料和几何参数对不同边界条件下波纹夹芯板的振动特性有重要影响。相关研究结果将对波纹夹芯板在工程应用中的减振设计及优化分析提供一定的理论依据。Abstract: As a special composite structure, the vibration characteristics of corrugated sandwich panel are greatly influenced by the boundary conditions. According to the shear deformation theory of different shear modes and Kirchhoff's classical plate theory(CLPT), the dynamic equation of corrugated sandwich plates was established by Hamilton principle. Among them, the corrugated core layer was equivalent to an anisotropic homogeneous body. According to the boundary conditions of four sides simply supported, four sides clamped, opposite sides simply supported and clamped, one side fixed and three edges clamped, the partial differential dynamic equation relative to the displacements was derived. By solving the equation, the natural frequencies of the corrugated sandwich plates under different boundary conditions were obtained. Compared with the finite element simulation results, the correctness of the theoretical results was verified. On this basis, based on the exponential shear deformation theory(ESDT), the variation of fundamental frequency of the corrugated sandwich plate with material parameters and structural geometric parameters under different boundary conditions was analyzed. The results show that the material and structural geometric parameters have an important influence on the vibration characteristics of the corrugated sandwich plates under different boundary conditions. Relevant research results will provide a theoretical basis for the vibration reduction design and optimization analysis of corrugated sandwich plates in engineering application.

-

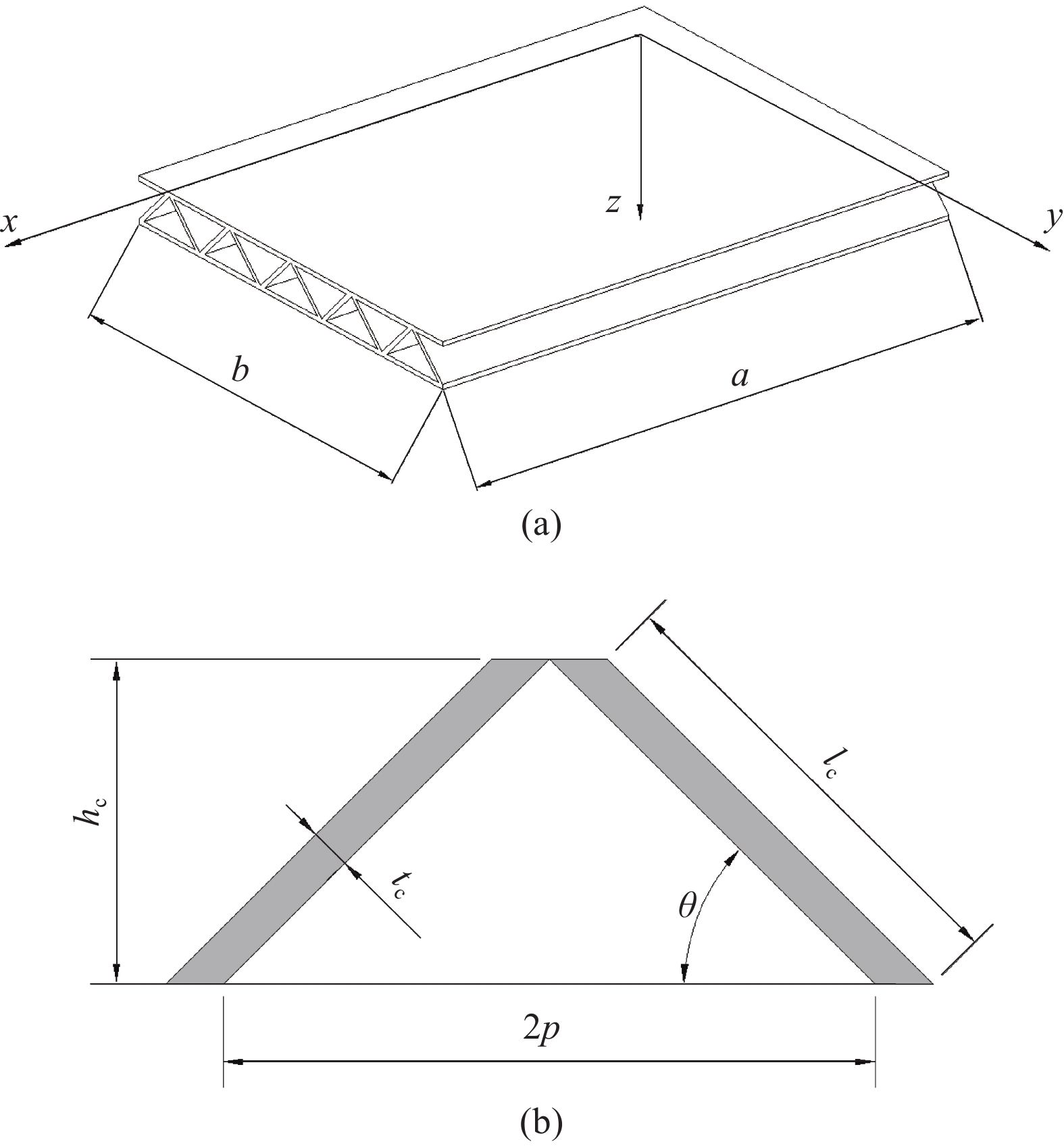

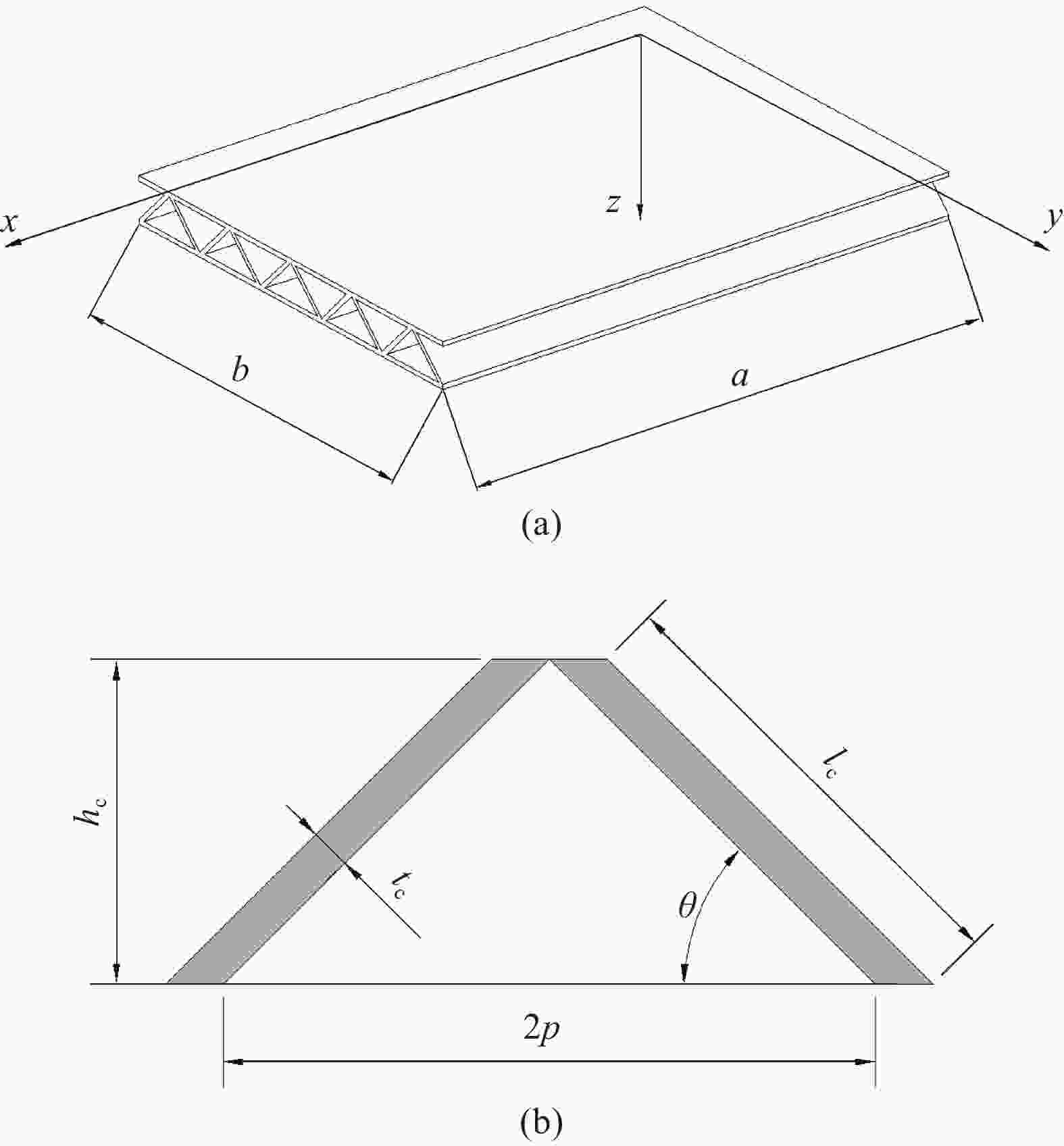

图 1 波纹夹芯板的模型(a)和波纹单胞示意图(b)

Figure 1. Model diagrams of corrugated sandwich panel (a) and corrugated cell (b)

a—Length of corrugated sandwich panel; b—Width of corrugated sandwich panel; lc—Length of the hypotenuse; hc—Height of core layer; tc—Wall thickness; θ—Corrugation angle; p—Length of bottom side

表 1 不同板理论对应的剪切形状函数

Table 1. Shear shape functions corresponding to different plate theories

Shear theory Function f (${\textit{z}} $) CLPT $f({\textit{z}}) = 0$ FSDT $f({\textit{z} }) = {\textit{z}}$ SSDT $f({\textit{z}}) = \dfrac{h}{{\text{π}}}\sin \left(\dfrac{{{\text{π}}{\textit{z}}} }{h}\right)$ TSDT $f({\textit{z}}) = {\textit{z}}\left[1 - \dfrac{4}{3}{\left(\dfrac{{\textit{z}}}{h}\right)^2}\right]$ ESDT $f({\textit{z}}) = {\textit{z}}{ {\rm{e} }^{ - 2{ {\left( {\dfrac{{\textit{z}}}{h} } \right)}^2} } }$ Notes: CLPT—Classical plate theory; FSDT—First-order shear plate theory; SSDT—Sinusoidal shear deformation theory; TSDT—Third-order shear deformation theory; ESDT—Exponential shear deformation theory. 表 2 不同边界条件下的函数Xm(x) 和 Yn(y)

Table 2. Functions Xm(x) and Yn(y) for different boundary conditions

Boundary conditions Function Xm(x) Function Yn(y) SSSS $\sin \alpha x$ $\sin \beta x$ CCCC $1 - \cos 2\alpha x$ $1 - \cos 2\beta x$ CCSS $1 - \cos 2\alpha x$ $\sin \beta x$ CSSS $\sin \alpha x(\cos \alpha x - 1)$ $\sin \beta x$ Notes: SSSS—Four sides simply supported; CCCC—Four sides clamped; CCSS—Opposite sides simply supported and clamped; CSSS—One side fixed and three edges clamped; ${ {\alpha = m{\text{π}}} / a}$; ${ {\beta = n{\text{π}} } / b}$; m, n—Half-wave numbers in two orthogonal coordinate directions respectively. 表 3 四边简支波纹夹芯板在不同理论下的固有频率理论解与有限元仿真结果

Table 3. Theoretical solutions and finite element simulation results of natural frequency of simply supported corrugated sandwich plates using different theories

Mode ABAQUS CLPT FSDT SSDT TSDT ESDT Result Error/% Result Error/% Result Error/% Result Error/% Result Error/% (1,1) 31.18 31.72 1.75 31.41 0.77 31.00 −0.57 31.01 −0.54 30.99 −0.58 (2,1) 65.39 69.52 6.32 68.09 4.13 65.82 0.66 65.88 0.75 65.79 0.61 (1,2) 86.48 88.51 2.36 86.23 −0.29 83.74 −3.16 83.78 −3.12 83.74 −3.17 (2,2) 116.13 125.70 8.24 121.21 4.38 115.60 −0.45 115.72 −0.35 115.57 −0.48 (3,1) 118.46 132.06 11.48 127.11 7.30 119.24 0.66 119.45 0.84 119.12 0.56 表 4 不同边界条件和板理论下波纹夹芯板的基频理论解与有限元仿真结果

Table 4. Theoretical solutions and finite element simulation results of fundamental frequency of corrugated sandwich plates with different boundary conditions and plate theories

Boundary conditons ABAQUS CLPT FSDT SSDT TSDT ESDT Result Error/% Result Error/% Result Error/% Result Error/% Result Error/% SSSS 31.18 31.72 1.75 31.41 0.77 31.00 −0.57 31.01 −0.54 30.99 −0.58 CCCC 56.42 60.46 7.17 58.90 4.40 56.99 1.01 57.03 1.08 56.98 0.99 CCSS 40.47 43.19 6.71 42.44 4.87 41.23 1.88 41.26 1.96 41.22 1.84 CSSS 39.50 42.14 6.70 41.56 5.22 40.66 2.94 40.68 2.99 40.65 2.91 表 5 不同材料组合下波纹夹芯板的基频

Table 5. Fundamental frequencies of corrugated sandwich panels with different material combinations

Boundary conditon Al-Al-Al Ti-Ti-Ti Al-Ti-Al Ti-Al-Ti SSSS 30.99 38.72 29.07 40.53 CCCC 56.98 71.16 54.31 71.99 CCSS 41.22 51.46 39.96 52.38 CSSS 40.65 50.76 39.03 52.17 -

[1] 岳灿甫, 吴始栋. 国外船用激光焊接波纹夹芯板的开发与应用[J]. 鱼雷技术, 2007, 15(4):1-5.YUE C F, WU S D. Introduction to development and applications of marine laser welded lightweight sandwich panel in the US navy and european countries[J]. Torpedo Technology,2007,15(4):1-5(in Chinese). [2] 贺梦豪, 吴昊, 程远胜. 波纹夹芯杂交夹层板入水砰击动力响应特性研究[J]. 舰船科学技术, 2016, 38(8):11-17.HE M H, WU H, CHENG Y S. Dynamic response analysis of hybrid sandwich plate with corrugated-cores subjected to slam-ming impact[J]. Ship Science and Technology,2016,38(8):11-17(in Chinese). [3] 孙小曼. 车用波纹夹芯板弯曲性能研究[D]. 大连: 大连理工大学, 2013.SUN X M. Analysis of bending performance of vehicle corrugated core sandwich structure[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [4] KUJALA P, KLANAC A. Steel sandwich panels in marine applications[J]. Brodogradnja,2005,56(4):305-314. [5] PENG L X, LIEW K M, KITIPORNCHAI S. Analysis of stiffened corrugated plates based on the FSDT via the mesh-free method[J]. International Journal of Mechanical Sciences,2006,49(3):364-378. [6] SEMENYUK N P, NESKHODOVSKAYA N A. On design models in stability problems for corrugated cylindrical shells[J]. International Applied Mechanics,2002,38(10):1245-1252. doi: 10.1023/A:1022214630581 [7] BRIASSOULIS D. Equivalent orthotropic properties of corrugated sheets[J]. Computers & Structures,1986,23(2):129-138. [8] SOHRAB K, DAN Z. Corrugated all-composite sandwich structures. Part 2: Failure mechanisms and experimental programme[J]. Composites Science and Technology,2009,69(7):920-925. [9] TIAN Y S, LU T J. Optimal design of compression corrugated panels[J]. Thin-Walled Structures,2005,43(3):477-498. doi: 10.1016/j.tws.2004.07.014 [10] SAMANTA A, MUKHOPADHYAY M. Finite element static and dynamic analyses of folded plates[J]. Engineering Structures,1999,21(3):277-287. doi: 10.1016/S0141-0296(97)90172-3 [11] XIA Y, FRISWELL M I, FLORES E I S. Equivalent models of corrugated panels[J]. International Journal of Solids and Structures,2012,49(13):1453-1462. doi: 10.1016/j.ijsolstr.2012.02.023 [12] LI X, WANG Z, ZHU F, et al. Response of aluminium corrugated sandwich panels under air blast loadings: Experiment and numerical simulation[J]. International Journal of Impact Engineering,2014,65:79-88. doi: 10.1016/j.ijimpeng.2013.11.002 [13] 王红霞, 王德禹, 李喆. 三角形夹芯板夹心层的等效弹性常数[J]. 固体力学学报, 2007, 28(2):178-182. doi: 10.3969/j.issn.0254-7805.2007.02.011WANG H X, WANG D Y. LI Z. Equivalent elastic constants of truss-core sandwich plates[J]. Acta Mechanica Solida Sinica,2007,28(2):178-182(in Chinese). doi: 10.3969/j.issn.0254-7805.2007.02.011 [14] 王青伟, 赵才其. 三角形桁架夹芯层等效弹性常数研究和夹芯板参数优化设计[J]. 特种结构, 2010, 27(5):61-66. doi: 10.3969/j.issn.1001-3598.2010.05.015WANG Q W, ZHAO C Q. Research of equivalent elastic constants of triangle truss-core sandwich panels and optimization design of constants of core sandwich panels[J]. Special Structures,2010,27(5):61-66(in Chinese). doi: 10.3969/j.issn.1001-3598.2010.05.015 [15] 吴建均, 王永静, 谢敬尧, 等. 泡沫波纹复合夹心梁等效弹性常数的推导及其振动特性研究[J]. 西安交通大学学报, 2018, 52(11):73-80.WU J J, WANG Y J, XIE J Y, et al. Derivation of equivalent elastic constant and vibration analysis of foam-corrugated composite sandwich beam[J]. Journal of Xi'an Jiaotong University,2018,52(11):73-80(in Chinese). [16] 崔岸, 刘芳芳, 张晗, 等. 车身泡沫填充铝合金波纹夹芯板结构性能分析与优化[J]. 汽车工程, 2019, 41(10):1221-1227.CUI A, LIU F F, ZHANG H, et al. Performance analysis and optimization of foam-filled aluminum-alloy corrugated sandwich panel structure for vehicle body[J]. Automotive Engineering,2019,41(10):1221-1227(in Chinese). [17] 李静雯, 张博明, 孙义亮, 等. 不同铺层方式下连续玻璃纤维/聚丙烯复合材料波纹夹芯板的力学性能[J]. 复合材料学报, 2019, 36(5):1074-1082.LI J W, ZHANG B M, SUN Y L, et al. Mechanical properties of continuous glass fiber/polypropylene corrugated sandwich boards under different laminates[J]. Acta Materiae Compositae Sinica,2019,36(5):1074-1082(in Chinese). [18] 刘昆, 王哲, 王自力. 波纹夹层板冲击响应理论计算方法研究[J]. 振动与冲击, 2019, 38(2):90-97.LIU K, WANG Z, WANG Z L. Theoretical calculation method for the impact responses of corrugated sandwich panels[J]. Journal of Vibration and Shock,2019,38(2):90-97(in Chinese). [19] REDDY J N. Mechanics of laminated composite plates and shells: Theory and analysis[M]. New York: CRC Press, 2004. [20] CROCE L D, VENINI P. Finite elements for functionally graded Reissner-Mindlin plates[J]. Computer Methods in Applied Mechanics and Engineering,2004,193(9–11):705-725. [21] MATSUNAGA H. Free vibration and stability of functionally graded plates according to a 2-D higher-order deformation theory[J]. Composite Structures,2008,82(4):499-512. doi: 10.1016/j.compstruct.2007.01.030 [22] TALHA M, SINGH B N. Static response and free vibration analysis of FGM plates using higher order shear deformation theory[J]. Applied Mathematical Modelling,2010,34(12):3991-4011. doi: 10.1016/j.apm.2010.03.034 [23] WU C P, LI H Y. An RMVT-based third-order shear deformation theory of multilayered functionally graded material plates[J]. Composite Structures,2010,92:2591-2605. doi: 10.1016/j.compstruct.2010.01.022 [24] THAI H T, VO T P. A new sinusoidal shear deformation theory for bending, buckling, and vibration of functionally graded plates[J]. Applied Mathematical Modelling,2013,37:3269-3281. doi: 10.1016/j.apm.2012.08.008 [25] 曹源, 雷剑. 基于正弦剪切变形理论的功能梯度材料三明治微梁的静动态特性[J]. 复合材料学报, 2020, 37(1):223-235.CAO Y, LEI J. Static and dynamic properties of functionally graded materials sandwich microbeams based on sinusoidal shear deformation theory[J]. Acta Materiae Compositae Sinica,2020,37(1):223-235(in Chinese). [26] KARAMA M, AFAQ K S, MISTOU S. Mechanical behaviour of laminated composite beam by the new multi-layered laminated composite structures model with transverse shear stress continuity[J]. International Journal of Solids and Structures,2003,40(6):1525-1546. doi: 10.1016/S0020-7683(02)00647-9 [27] REDDY J N. Energy principles and variational methods in applied mechanics[M]. New York: John Wiley & Sons Inc, 2002. -

下载:

下载: