Microstructure and mechanical properties of heterogeneous layered titanium alloy components fabricated via additive manufacturing

-

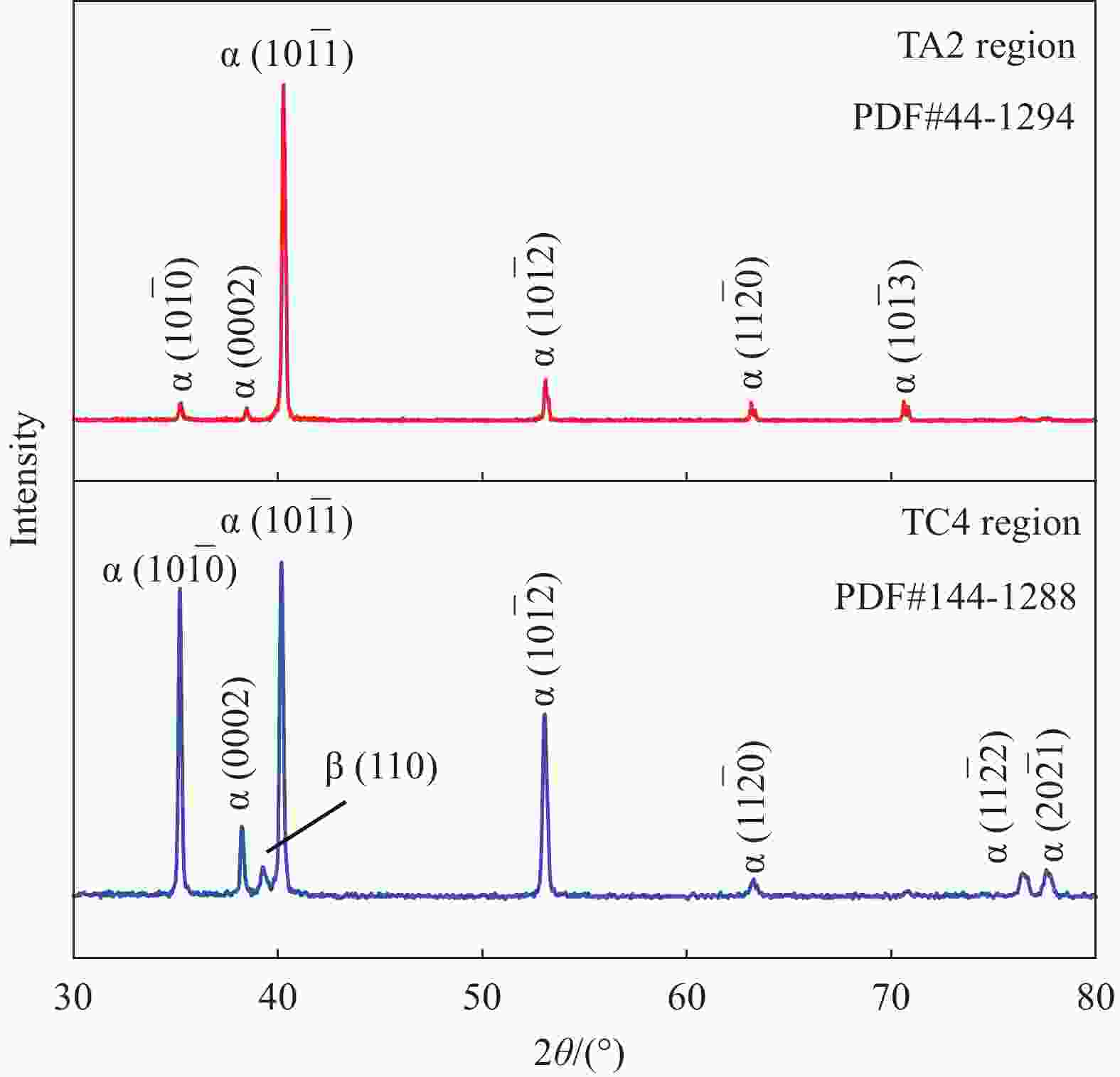

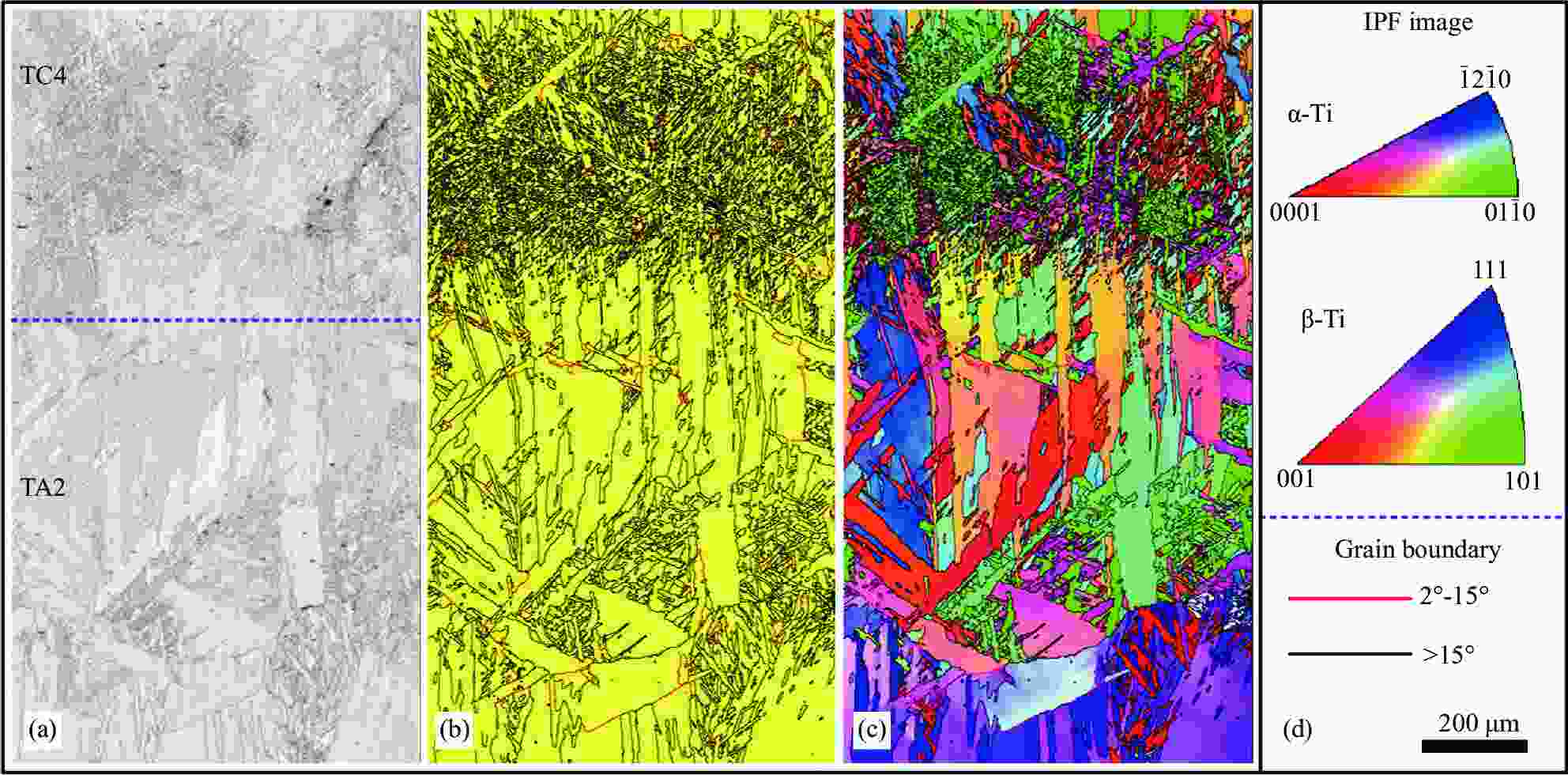

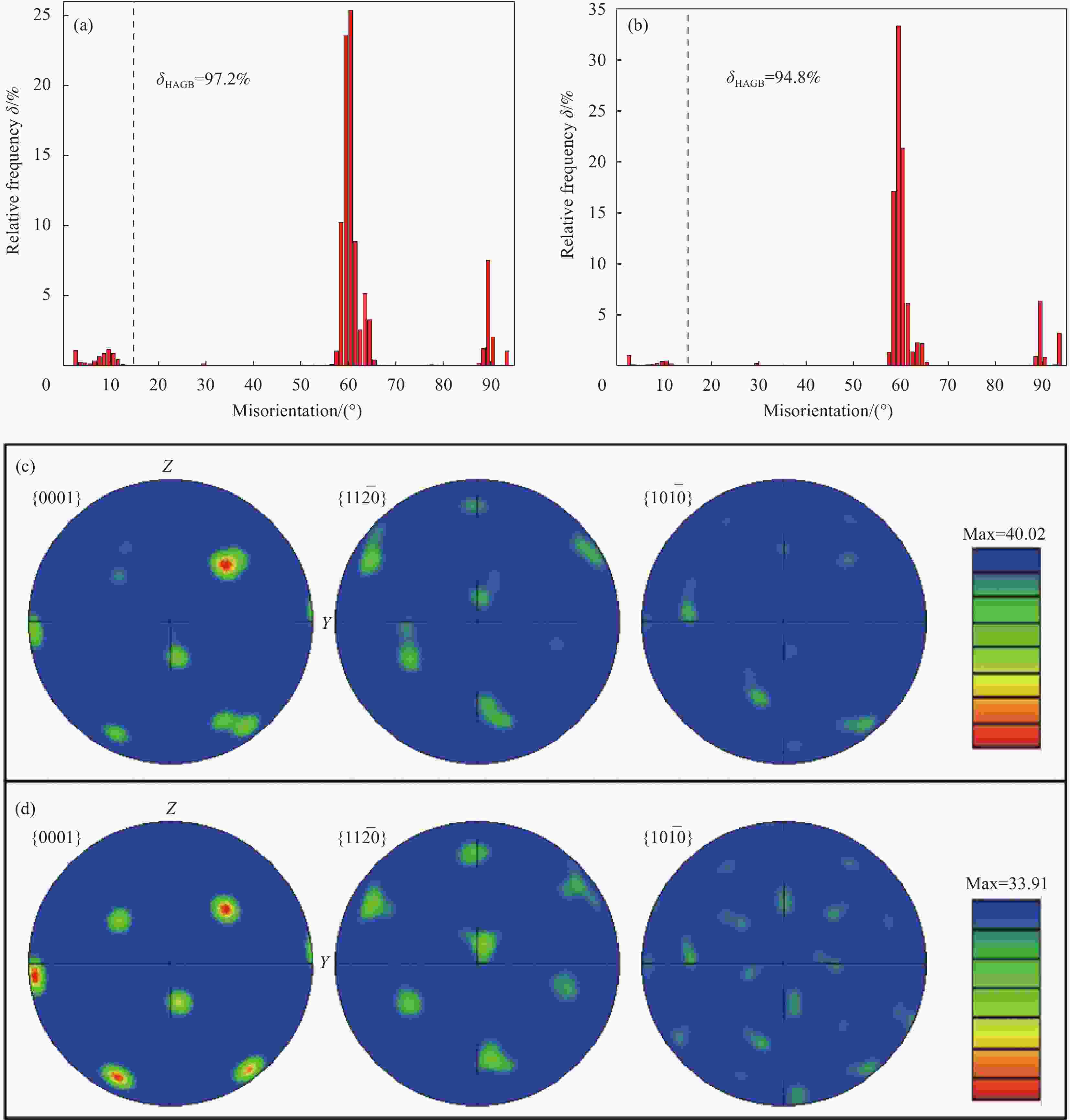

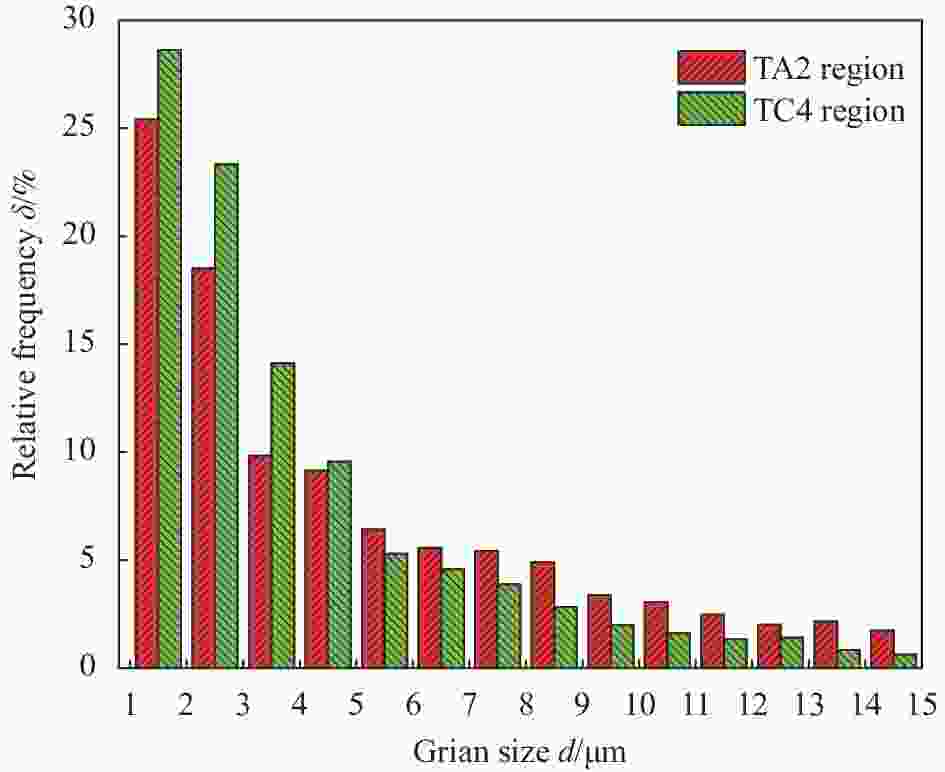

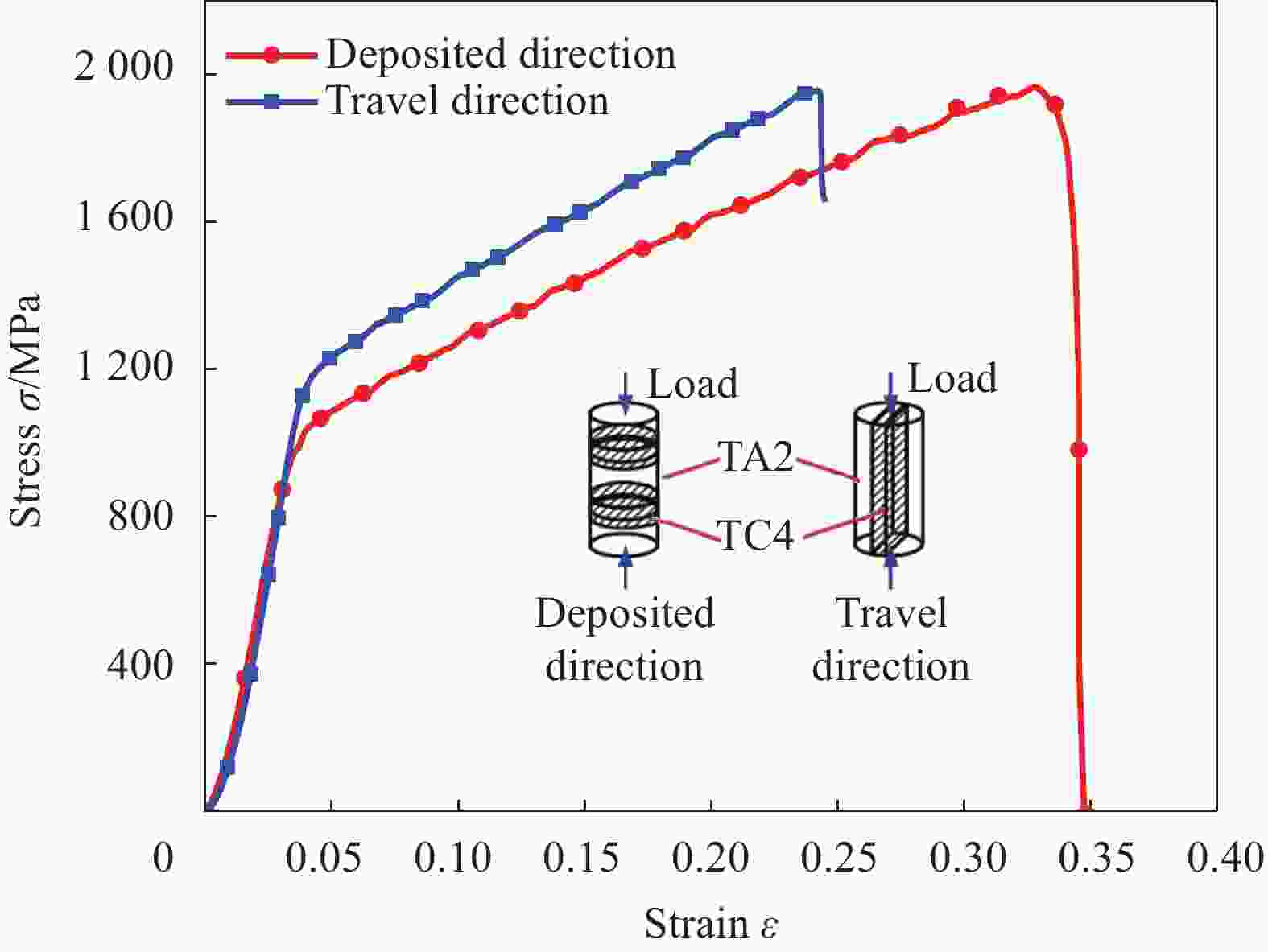

摘要: 采用双丝等离子实现了TC4与TA2交替沉积的异质层状钛合金构件的增材制造,构件具有良好的沉积形貌及力学性能。采用了OM、SEM、背散射电子衍射技术(EBSD)、XRD等方法对构件进行了微观组织表征,并结合显微硬度和压缩性能测试了其力学性能。研究结果表明:TA2和TC4区域主要组织分别是由片层α相和α+β的网篮组织/集束组织组成。各区域晶粒沿着热流反方向凝固生长,TC4区域与TA2区域的晶界特征和晶体取向具有相似规律,但由于异质材料相生长差异,层与层之间β相晶粒生长方向发生改变,TC4区域的原始β相会沿着已沉积TA2区域晶粒某一择优取向生长,进而限制了β相连续生长为粗大柱状晶。层状结构中TC4区域的硬度明显高于TA2区域,并沿着沉积方向硬度呈现增加的趋势。增材构件沿着不同方向具有接近的抗压强度,近2.0 GPa,但是TC4和TA2交替形成的层状特殊结构,其沿着沉积方向具有高的断裂应变(0.33),沿着扫描方向具有高的屈服强度(1133 MPa)。Abstract: The additive manufacturing of heterogeneous layered titanium alloy is realized by the alternating deposition of TC4 and TA2 using a double wire plasma system. The components have good deposition morphology and mechanical properties. OM, SEM, backscattered electron diffraction technique (EBSD), XRD etc. were used to analyze the microstructure, mechanical properties were tested with microhardness and compression properties. The results show that TA2 and TC4 regions are mainly composed of lamellae α phase and α+β phase of basketweave and colonies structure. The grains in each region grow in the opposite direction of heat flow. The grain boundary characteristics and crystal orientation of TC4 region and TA2 region have similar laws, but due to the differences of phase growth of heterogeneous materials, the growth direction of β phase has changed between different layers, and the original β phase growth direction of TC4 region will grow along a preferred orientation of the deposited TA2 region, which limits the phenomenon of continuous growth of β phase into coarsened columnar crystal. In the layered structure, the hardness of TC4 region is significantly higher than that of TA2 region, and the hardness increases along the deposited direction. The component has close compressive strength along different directions, nearly 2.0 GPa, but the special layered structure formed alternately by TC4 and TA2 has high fracture strain (0.33) along the deposited direction and high yield strength (1133 MPa) along the travel direction.

-

表 1 基板及焊丝化学成分

Table 1. Chemical compositions of base plate and wires

wt% Element N O H Fe Al V Ti Base plate 0.03 0.10 0.01 0.21 6.42 4.30 Bal. Wire of TC4 0.02 0.12 0.01 0.19 6.09 3.94 Bal. Wire of TA2 0.02 0.13 0.01 0.13 — — Bal. Note: Bal.—Banlance. 表 2 增材过程工艺参数

Table 2. Parameters of additive manufacturing

Parameters Current/A Deposition velocity/

(m·min−1)Shield gas

flux/(L·min−1)Plasma gas flow

rate/(L·min−1)Wire feeding speed

of TC4/(m·min−1)Wire feeding speed

of TA2/(m·min−1)130 0.3 20 0.8 0.8 0.8 表 3 层状TC4-TA2钛合金与单一材料TA2和TC4压缩性能公开报告与本研究对比

Table 3. Compressive properties of layered TC4-TA2 titanium alloy compared to that of single material of TA2 and TC4 published in the literatures

Material Direction

(test)σCY/MPa σUCS/MPa εf/% Percent change in σCY/% Percent change in εf/% CP-Ti [19-20] Z 530 820 60.0 83.4 −45.0 CP-Ti SLM [21] Z 620 1100 51.0 56.8 −35.3 X 620 1050 51.0 82.7 −52.9 CP-Ti LENS [19, 22] Z 395±10 880±15 50.0±2.0 146.1 −34.0 TC4SPS [23] Z 1354 1735 10.0 −28.2 230 TC4SLM [24] Z 1400±10 1699±17 18.6±4.9 −30.6 77.4 X 1375±20 1741±18.7 23.3±0.8 −17.6 3.0 TC4WAAM [25] Z 960±12 1 918±18 13.8±1.0 1.3 139.1 X 971±10 1 891±112 19.5±1.0 16.7 23.1 Notes: σCY—Compressive yield strength; σUCS—Ultimate compressive strength; εf—Fracture strain; CP-Ti—Commercially pure titanium; SLM—Selective laser melting; LENS—Laser engineered net shaping; SPS—Spark plasma sintering; WAAM—Wire and arc additive manufacturing. -

[1] ZHENG J, CHEN S, JIANG L, et al. Effect of carbon content on the microstructure and mechanical properties of NiCrFe-7 A alloys synthesized by wire arc additive manufacturing[J]. Materials Science and Engineering: A,2022,842:142925. doi: 10.1016/j.msea.2022.142925 [2] NG C H, BERMINGHAM M J, YUAN L, et al. Towards β-fleck defect free additively manufactured titanium alloys by promoting the columnar to equiaxed transition and grain refinement[J]. Acta Materialia,2022,224:117511. doi: 10.1016/j.actamat.2021.117511 [3] CHAO Q, MATETI S, ANNASAMY M, et al. Nanoparticle-mediated ultra grain refinement and reinforcement in additively manufactured titanium alloys[J]. Additive Manufacturing,2021,46:102173. doi: 10.1016/j.addma.2021.102173 [4] WANG C, SUDER W, DING J, et al. Wire based plasma arc and laser hybrid additive manufacture of Ti-6Al-4V[J]. Journal of Materials Processing Technology,2021,293:117080. doi: 10.1016/j.jmatprotec.2021.117080 [5] WANG L, ZHANG Y, HUA X, et al. Fabrication of γ-TiAl intermetallic alloy using the twin-wire plasma arc additive manufacturing process: microstructure evolution and mechanical properties[J]. Materials Science and Engineering: A,2021,812:141056. doi: 10.1016/j.msea.2021.141056 [6] WANG K, LIU Y, SUN Z, et al. Microstructural evolution and mechanical properties of Inconel 718 superalloy thin wall fabricated by pulsed plasma arc additive manufacturing[J]. Journal of Alloys and Compounds,2020,819:152936. doi: 10.1016/j.jallcom.2019.152936 [7] LIN J, LV Y, LIU Y, et al. Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment[J]. Journal of the Mechanical Behavior of Biomedical Materials,2017,69:19-29. doi: 10.1016/j.jmbbm.2016.12.015 [8] MOGHIMIAN P, POIRIE T, HABIBNEJAD-KORAYEM M, et al. Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys[J]. Additive Manufacturing,2021,43:102017. doi: 10.1016/j.addma.2021.102017 [9] 李长富, 郑鉴深, 周思雨, 等. CMT电弧增材制造TC4钛合金的显微组织与力学性能[J]. 中国有色金属学报, 2022, 32(9): 2609-2619.LI Changfu, ZHENG Jianshen, ZHOU Siyu, et al. Microstructure and mechanical properties analysis of CMT wire arc additive manufactured Ti-6Al-4V titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(9): 2609-2619(in Chinese). [10] 魏志祥, 李国选, 汪月勇, 等. TIG电弧增材制造TC4钛合金的组织与性能[J]. 有色金属工程, 2021, 11(10):14-19. doi: 10.3969/j.issn.2095-1744.2021.10.003WEI Zhixiang, LI Guoxuan, WANG Yueyong, et al. Microstructure and properties of TC4 titanium alloy produced by TIG arc additive manufacturing[J]. Nonferrous Metal Engineering,2021,11(10):14-19(in Chinese). doi: 10.3969/j.issn.2095-1744.2021.10.003 [11] GU G X, TAKAFFOLI M, HSIEH A J, et al. Biomimetic additive manufactured polymer composites for improved impact resistance[J]. Extreme Mechanics Letters,2016,9:317-323. doi: 10.1016/j.eml.2016.09.006 [12] 邵浩彬, 朱军, 周琦, 等. 三角帆蚌贝壳的微结构及尺寸变化特征[J]. 复合材料学报, 2019, 36(10):2398-2406. doi: 10.13801/j.cnki.fhclxb.20190301.001SHAO Haobin, ZHU Jun, ZHOU Qi, et al. Characteristics of microstructure and size change of the shell of Hyriopsis cumingii[J]. Acta Materiae Compositae Sinica,2019,36(10):2398-2406(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190301.001 [13] 徐俊强, 彭勇, 周琦, 等. 异种钛合金协同送丝等离子增材制造试验[J]. 焊接学报, 2019, 40(9):59-64, 163-164.XU Junqiang, PENG Yong, ZHOU Qi, et al. Study on plasma wire and arc additive manufacturing process of titanium alloys with twin-wire feeding[J]. Transactions of the China Welding Institution,2019,40(9):59-64, 163-164(in Chinese). [14] XU J, ZHU J, FAN J, et al. Microstructure and mechanical properties of Ti-6Al-4V alloy fabricated using electron beam freeform fabrication[J]. Vacuum,2019,167:364-373. doi: 10.1016/j.vacuum.2019.06.030 [15] LIM S C V, YANG K V, YANG Y, et al. Tracking microstructure, texture and boundary misorientation evolution of hot deformed and post-deformation annealed Ti-6Al-4V alloy[J]. Materials Science and Engineering: A,2016,651:524-534. doi: 10.1016/j.msea.2015.09.060 [16] BELADI H, CHAO Q, ROHRER G S. Variant selection and intervariant crystallographic planes distribution in martensite in a Ti-6Al-4V alloy[J]. Acta Materialia,2014,80:478-489. doi: 10.1016/j.actamat.2014.06.064 [17] BAYKASOGLU C, AKYILDIZ O, TUNAY M, et al. A process-microstructure finite element simulation framework for predicting phase transformations and microhardness for directed energy deposition of Ti-6Al-4V[J]. Additive Manufacturing,2020,35:101252. doi: 10.1016/j.addma.2020.101252 [18] 李雷, 于治水, 张培磊, 等. TC4钛合金电弧增材制造叠层组织特征[J]. 焊接学报, 2018, 39(12):37-43. doi: 10.12073/j.hjxb.2018390294LI Lei, YU Zhishui, ZHANG Peilei, et al. Microstructural characteristics of wire and arc additive layer manufacturing of TC4 components[J]. Transactions of the China Welding Institution,2018,39(12):37-43(in Chinese). doi: 10.12073/j.hjxb.2018390294 [19] AYYAR H, EHTEMAM-HAGHIGHI S, KENT D, et al. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes[J]. Materials Science and Engineering: A,2017,705:385-393. doi: 10.1016/j.msea.2017.08.103 [20] LONG F W, JIAGN Q W, XIAO L, et al. Compressive defor-mation behaviors of coarse-and ultrafine-grained pure titanium at different temperatures: A comparative study[J]. Materials Transactions,2011,52(8):1617-1622. doi: 10.2320/matertrans.M2011041 [21] LI X P, VAN H J, KRUTH J P. Selective laser melting of weak-textured commercially pure titanium with high strength and ductility: A study from laser power perspective[J]. Materials & Design,2017,116:352-358. [22] BANDYOPADHYAY A, DITTRICK S, GUALTIERI T, et al. Calcium phosphate-titanium composites for articulating surfaces of load-bearing implants[J]. Journal of the Mechanical Behavior of Biomedical Materials,2016,57:280-288. doi: 10.1016/j.jmbbm.2015.11.022 [23] LONG Y, ZHANG H, WANG T, et al. High-strength Ti-6Al-4V with ultrafine-grained structure fabricated by high energy ball milling and spark plasma sintering[J]. Materials Science and Engineering: A,2013,585:408-414. doi: 10.1016/j.msea.2013.07.078 [24] SUI Q, LI P, WANG K, et al. Effect of build orientation on the corrosion behavior and mechanical properties of selective laser melted Ti-6Al-4V[J]. Metals,2019,9(9):976. doi: 10.3390/met9090976 [25] ABBASZADEH M, VENTZKE V, NETO L, et al. Compression behaviour of wire + arc additive manufactured structures[J]. Metals,2021,11(6):877. doi: 10.3390/met11060877 [26] 齐田宇, 杨建军, 赵佳伟, 等. 基于多材料3D打印和约束牺牲层连续功能梯度材料-结构一体化制造与性能[J]. 复合材料学报, 2022, 39(3):1055-1067.QI Tianyu, YANG Jianjun, ZHAO Jiawei, et al. Integrated manufacturing and performance study of continuous functionally graded materials structures based on multi-material 3D printing and constraint sacrifice layer[J]. Acta Materiae Compositae Sinica,2022,39(3):1055-1067(in Chinese). [27] 常海, 徐超, 胡小石. 累积叠轧纯Mg/ZK60镁合金层状金属复合材料的组织与性能[J]. 复合材料学报, 2019, 36(1):178-185. doi: 10.13801/j.cnki.fhclxb.20180606.001CHANG Hai, XU Chao, HU Xiaoshi. Microstructure evolution and mechanical properties of Mg/ZK60 laminated composite fabricated by accumulated roll-bonding[J]. Acta Materiae Compositae Sinica,2019,36(1):178-185(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180606.001 -

下载:

下载: