3D printing magnetic soft gripper

-

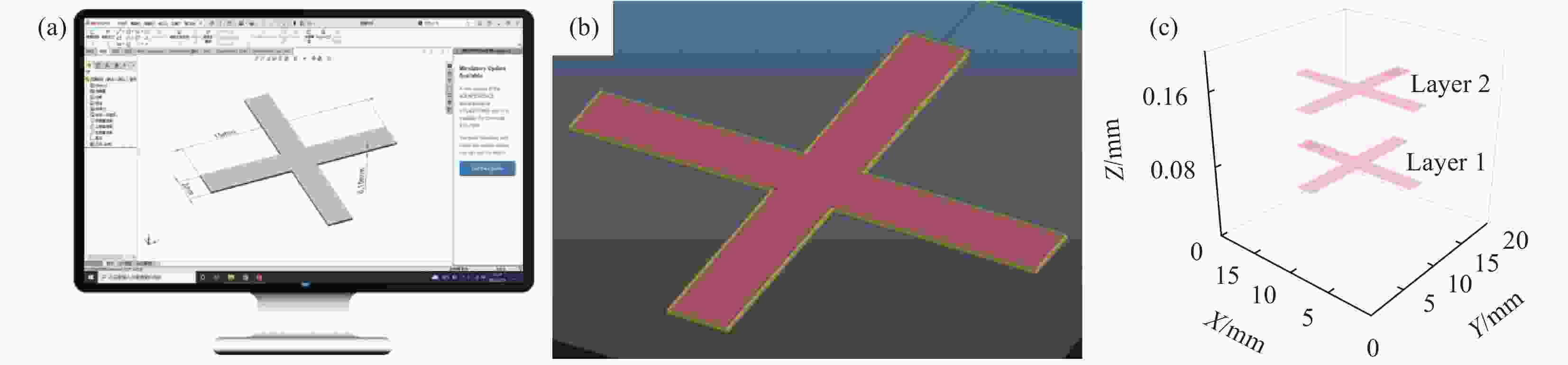

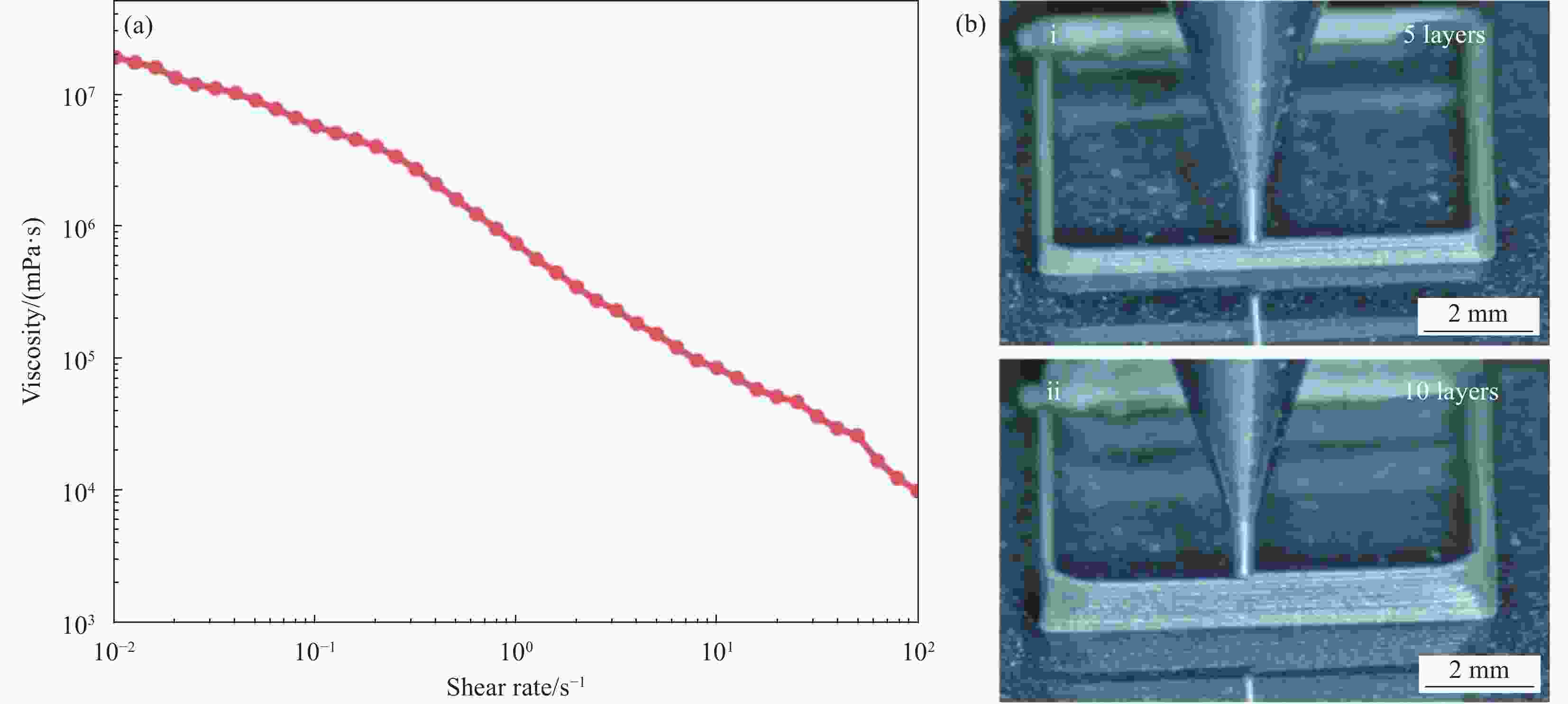

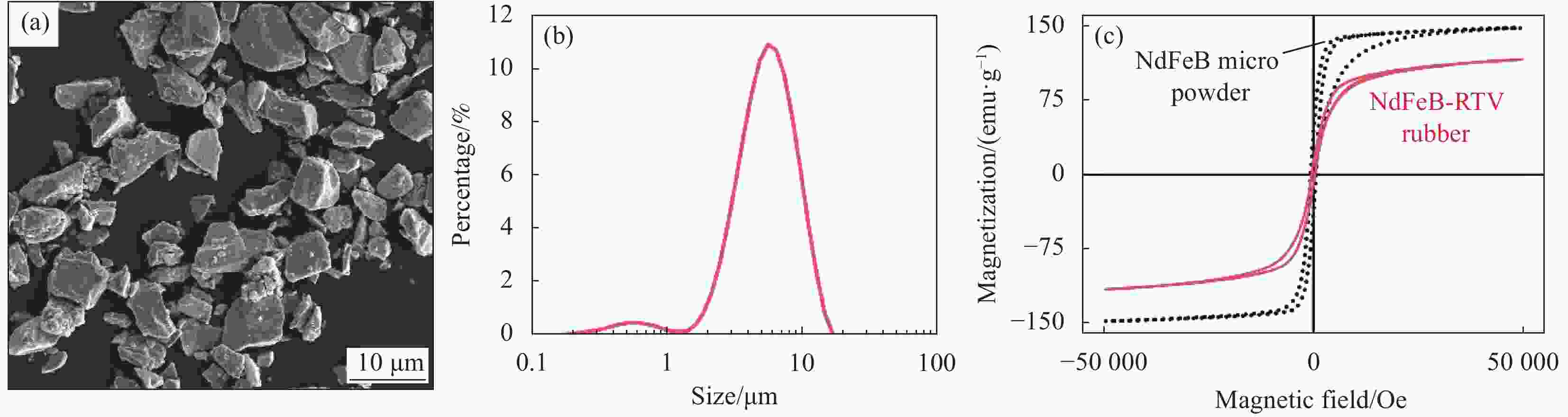

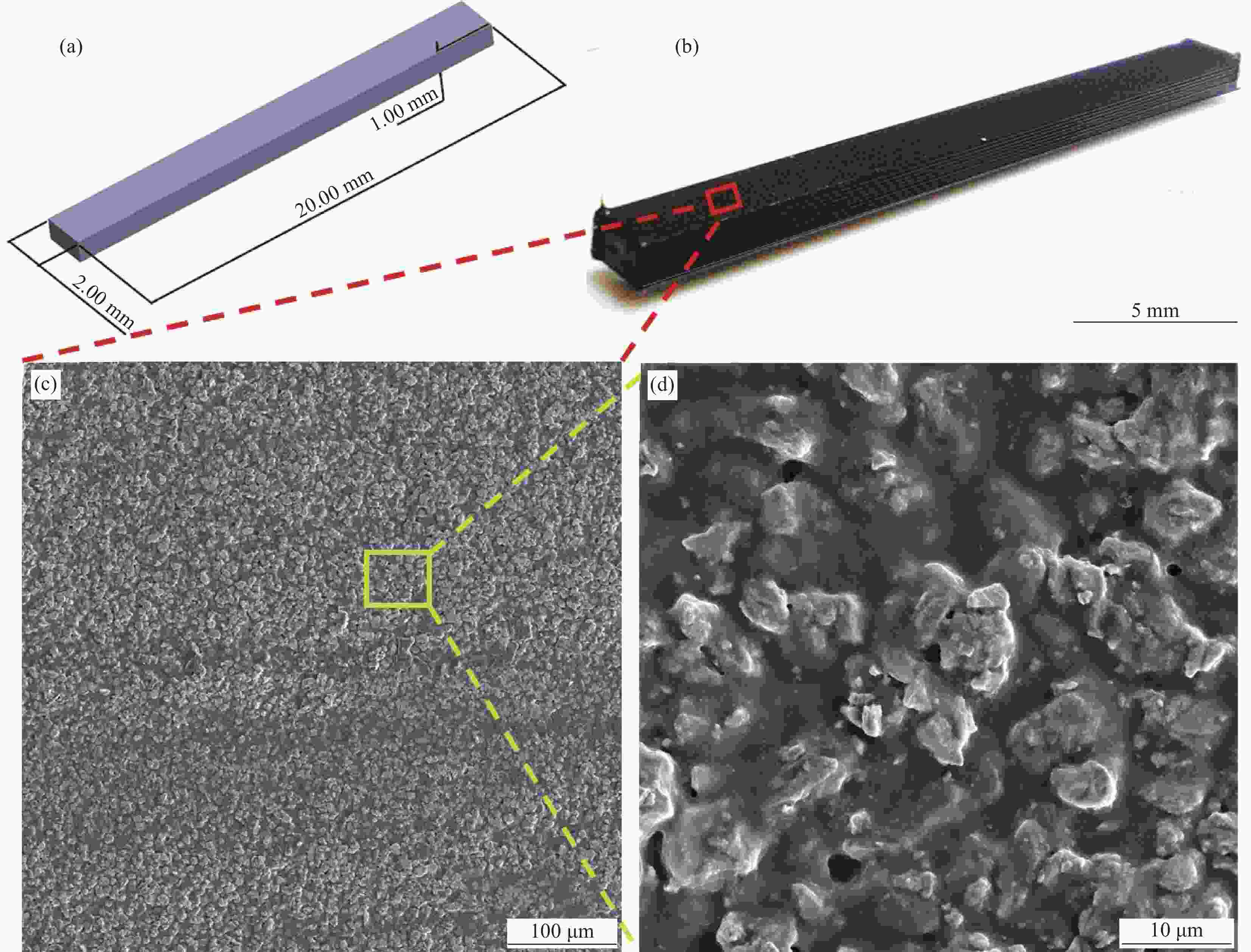

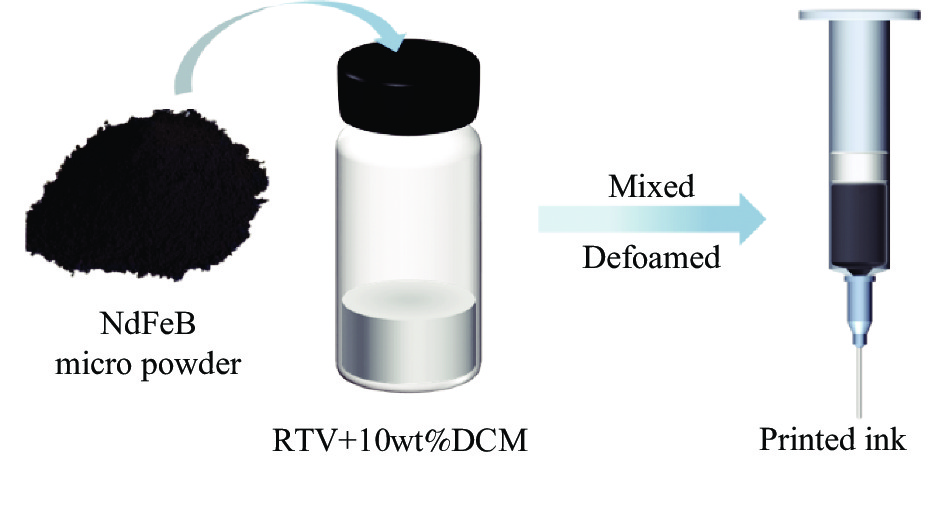

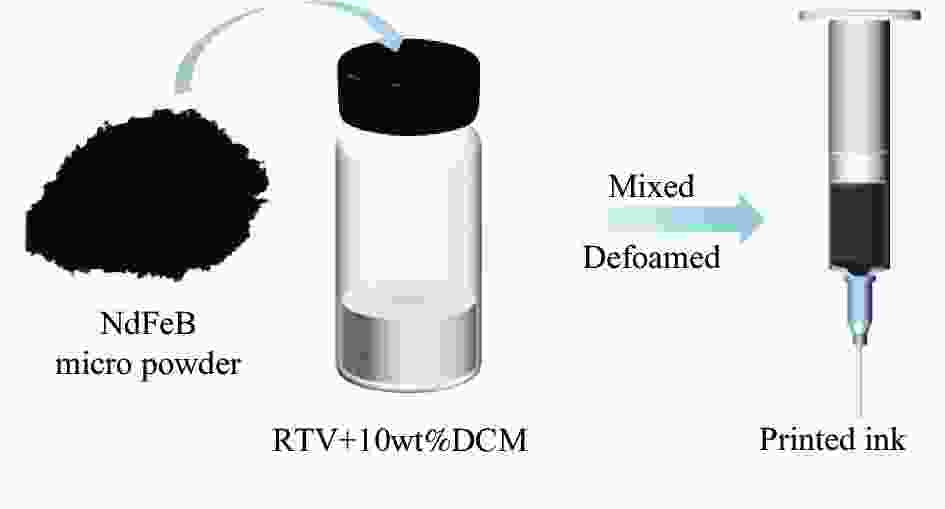

摘要: 柔性抓手能够在外部刺激下发生形变,在货物运输等领域有较好的应用。然而,目前使用的柔性抓手响应速度慢,对货物的形态和质量都有着较高要求,无法像人手一样适配绝大多数场景,因此有必要开发一种响应速度快、适配各种货物的柔性抓手。本文将硬磁材料——钕铁硼粉末(NdFeB)与硅橡胶(Room temperature vulcanized rubber,RTV橡胶)进行共混复合,形成了一种可打印的磁响应NdFeB-RTV橡胶复合材料。通过对墨水直写3D打印技术的制造工艺参数的探索和优化,将NdFeB-RTV橡胶复合材料的前驱体墨水打印成型。该材料固化后呈现出优异的力学性能—断裂伸长率接近300%,抗拉强度为1.03 MPa,拉伸杨氏模量为1.27 MPa,弯曲强度为78.06 MPa,弯曲模量为160.96 MPa。最后,本文采用墨水直写3D打印技术,设计制造了磁响应的四臂抓手机器人。利用机器人的磁致动与柔韧特性,实现了灵活变形、快速抓取、平稳运输等功能。Abstract: The soft gripper can deform under external stimuli, and has a good application in the fields of cargo transportation. However, the current soft gripper has a slow response speed, and cannot adapt to most scenarios like a human hand to move the cargoes with various shapes and weights. Therefore, it is necessary to develop a soft gripper with fast response speed and adaptation for various cargoes. In this work, a hard magnetic material—Neodymium-Iron-Boron powder (NdFeB) was blended with a room temperature vulcanized rubber (RTV rubber) to form a printable magnetically responsive NdFeB-RTV rubber composite. Through the exploration and optimization of the manufacturing process-related parameters of the direct ink writing technology, the precursor ink of the NdFeB-RTV rubber composite could be accurately printed into various shapes. The material exhibits excellent mechanical properties after curing: The elongation at break is close to 300%, the tensile strength is 1.03 MPa, the tensile Young's modulus is 1.27 MPa, the flexural strength is 78.06 MPa, and the flexural modulus is 160.96 MPa. Finally, the direct ink writing technology was used to design and manufacture a magnetically responsive four-arm gripper robot. Using the magnetic actuation and flexibility characteristics of the robot, functions such as soft deformation, fast grasping, and smooth transportation are realized.

-

Key words:

- magnetic responsive material /

- direct ink write 3D printing /

- soft gripper /

- elastomer /

- actuator

-

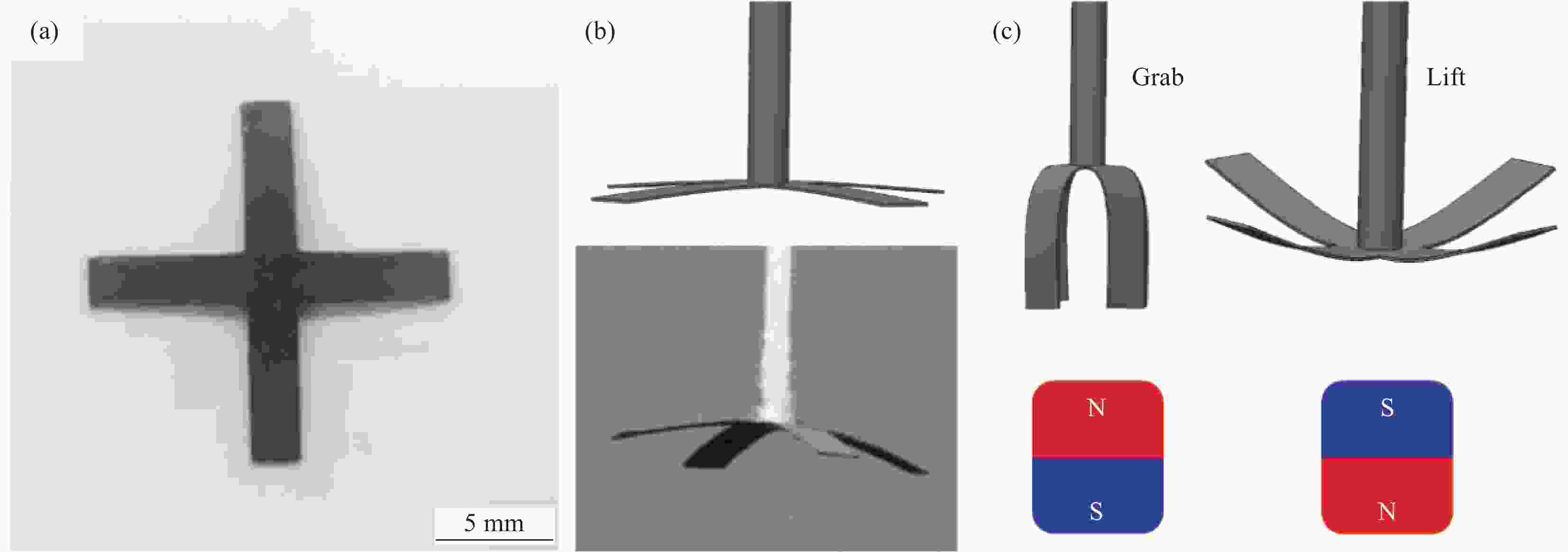

图 5 (a)墨水直写3D打印过程示意图;在1100 kPa的分配气压下不同打印速度下打印的墨水线宽(b)和实物图(c)

p—Pressure; D—Diameter; V—Printing speed; h—Height

Figure 5. (a) Schematic diagram of direct ink write 3D printing; Printing ink line width (b) and optical image (c) printed at different printing speeds with distribution pressure is 1100 kPa

图 7 (a)单轴拉伸测试示意图;(b)三点弯曲测试示意图;NdFeB-RTV橡胶复合材料的单轴拉伸测试数据图(c)和三点弯曲测试数据图(d)

F—Pull

Figure 7. (a) Schematic diagram of uniaxial tensile test; (b) Schematic diagram of three-point bending test; Uniaxial tensile test data diagram (c) and three-point bending test data diagram (d) of NdFeB-RTV rubber composite

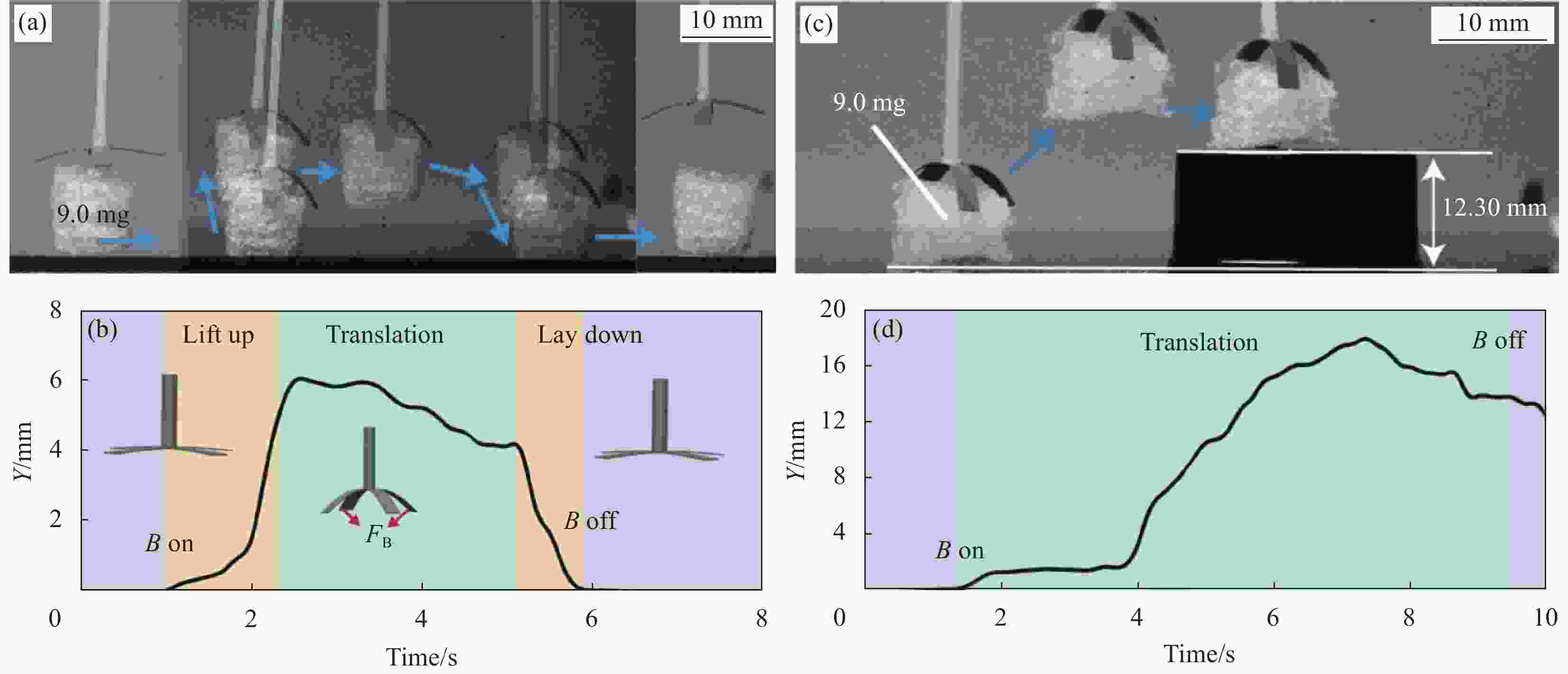

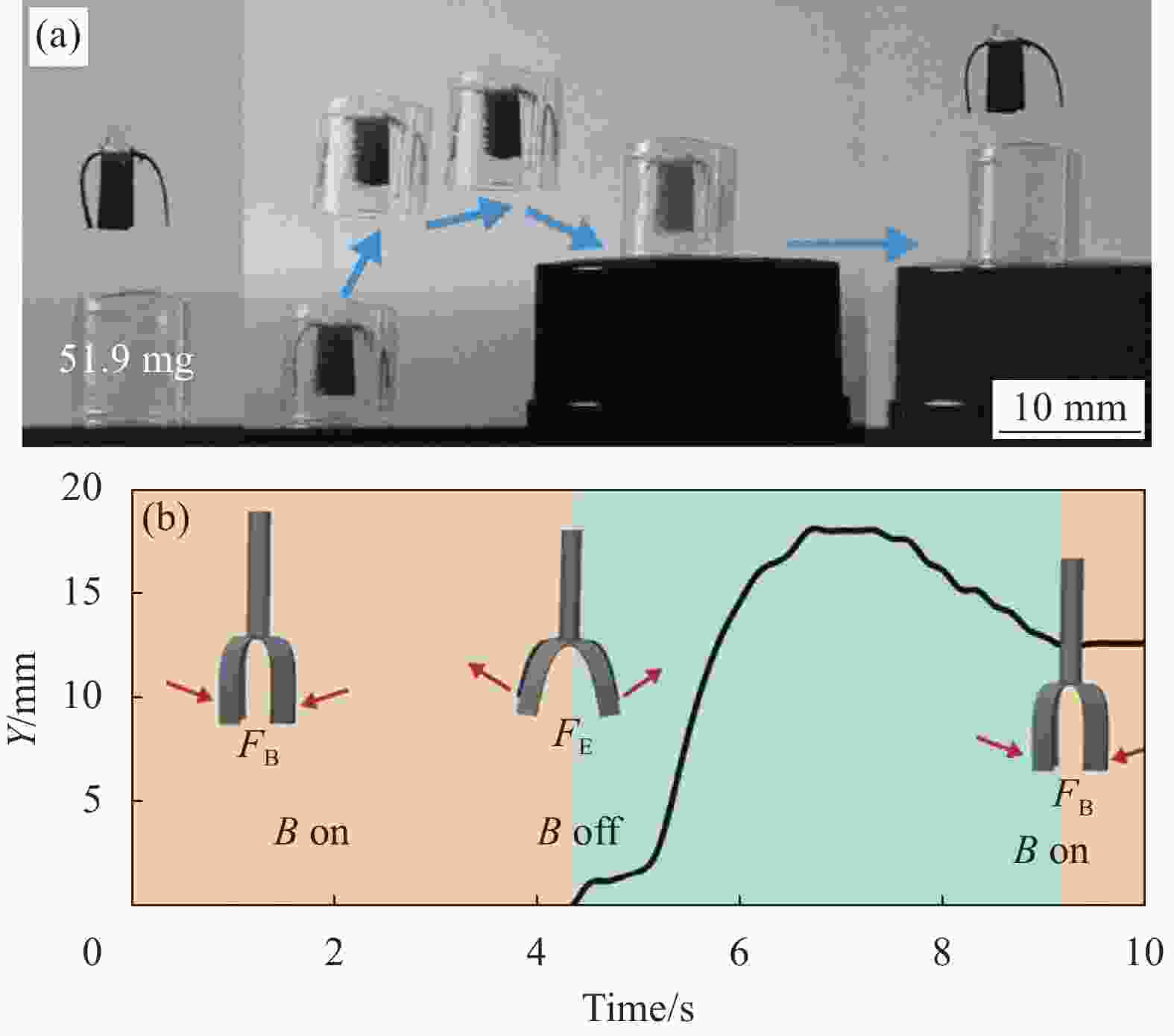

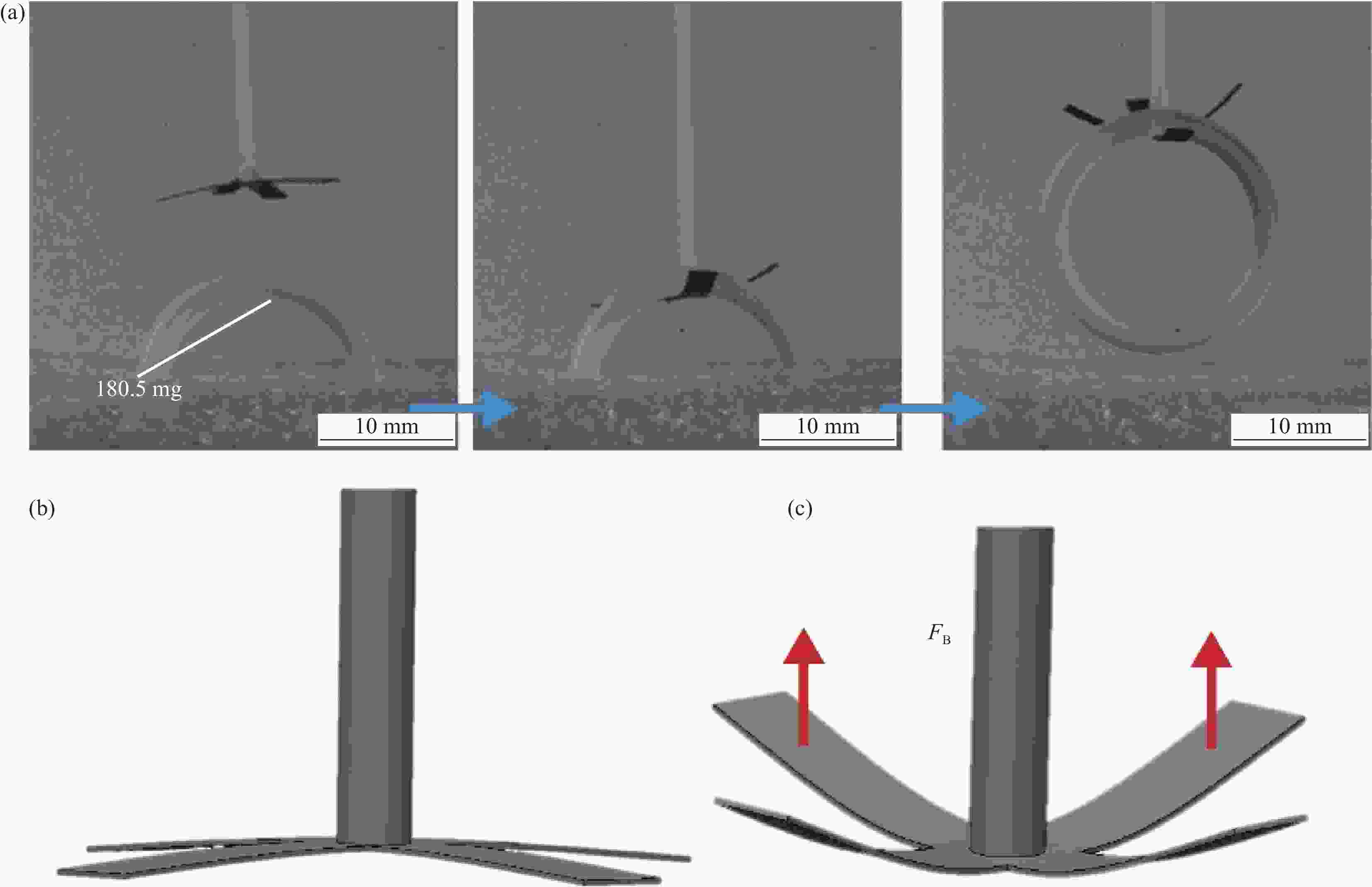

图 9 四臂抓手机器人完成任务1的过程及运动轨迹分析:(a)泡沫货物平地转移过程;(b)泡沫货物平地转移的运动轨迹分析;(c)泡沫货物抬高转移过程;(d)泡沫货物抬高转移的运动轨迹分析

B—Magnetic field; FB—Magnetic force

Figure 9. Process and motion trajectory analysis of the four-arm gripper robot completing task 1: (a) Process of transferring the foam cargo to the ground; (b) Trajectory analysis of the transfer of the foam cargo on the ground; (c) Lifting transfer process of the foam cargo; (d) Movement trajectory analysis of foam cargo lift and transfer

表 1 NdFeB粉末的物理性能

Table 1. Physical properties of NdFeB powder

Particle size Br/kOe Hcj/kOe HcB/kOe BHmax/MGOe ~5 μm 14.43 14.70 13.40 49.50 Notes: Br—Remanence; Hcj—Intrinsic coercivity; HcB—Coercivity; BHmax—Maximum magnetic energy product. -

[1] HINES L, PETERSEN K, LUM G Z, et al. Soft actuators for small-scale robotics[J]. Advanced Materials,2016,29(13):1603483. [2] 汪培义, 郭盛, 王向阳, 等. 基于柔性并联连续体的灵巧操作手的设计及分析[J]. 机械工程学报, 2020, 56(19):122-131. doi: 10.3901/JME.2020.19.122WANG Peiyi, GUO Sheng, WANG Xiangyang, et al. Design and analysis of a dexterous gripper based on soft parallel continuum manipulator[J]. Journal of Mechanical Engi-neering,2020,56(19):122-131(in Chinese). doi: 10.3901/JME.2020.19.122 [3] MONTGOMERY S M, WU S, KUANG X, et al. Magneto-mechanical metamaterials with widely tunable mechanical properties and acoustic bandgaps[J]. Advanced Functional Materials,2020,31(3):2005319. [4] REN Z, HU W, DONG X, et al. Multi-functional soft-bodied jellyfish-like swimming[J]. Nature Communications,2019,10(1):2703. doi: 10.1038/s41467-019-10549-7 [5] WANG T, REN Z, HU W, et al. Effect of body stiffness distribution on larval fish-like efficient undulatory swimming[J]. Science Advances,2021,7(19):eabf7364. doi: 10.1126/sciadv.abf7364 [6] MA C, WU S, ZE Q, et al. Magnetic multimaterial printing for multimodal shape transformation with tunable properties and shiftable mechanical behaviors[J]. ACS Applied Materials & Interfaces,2021,13(11):12639-12648. [7] LIU J A C, GILLEN J H, MISHRA S R, et al. Photothermally and magnetically controlled reconfiguration of polymer composites for soft robotics[J]. Science Advances,2019,5(8):eaaw2897. doi: 10.1126/sciadv.aaw2897 [8] CEYLAN H, YASA I C, YASA O, et al. 3D-printed biodegradable microswimmer for theranostic cargo delivery and release[J]. ACS Nano,2019,13(3):3353-3362. doi: 10.1021/acsnano.8b09233 [9] BOZUYUK U, YASA O, YASA I C, et al. Light-triggered drug release from 3D-printed magnetic chitosan microswimmers[J]. ACS Nano,2018,12(9):9617-9625. doi: 10.1021/acsnano.8b05997 [10] YASA I C, TABAK A F, YASA O, et al. 3D-printed microrobotic transporters with recapitulated stem cell niche for programmable and active cell delivery[J]. Advanced Functional Materials,2019,29(17):1808992. doi: 10.1002/adfm.201808992 [11] DONG Y, WANG J, GUO X, et al. Multi-stimuli-responsive programmable biomimetic actuator[J]. Nature Communications,2019,10(1):4087. doi: 10.1038/s41467-019-12044-5 [12] GOUDU S R, YASA I C, HU X, et al. Biodegradable untethered magnetic hydrogel milli-grippers[J]. Advanced Functional Materials,2020,30(50):2004975. doi: 10.1002/adfm.202004975 [13] LI G, CHEN X, ZHOU F, et al. Self-powered soft robot in the mariana trench[J]. Nature,2021,591(7848):66-71. doi: 10.1038/s41586-020-03153-z [14] 顾莉莉, 熊克, 卞侃, 等. 制备温度对Ag-IPMC拉伸及致动性能的影响[J]. 复合材料学报, 2013, 30(5):34-40. doi: 10.3969/j.issn.1000-3851.2013.05.006GU Lili, XIONG Ke, BIAN Kan, et al. Performance of tensile and actuating of IPMC with silver as electrodes under different manufacturing temperatures[J]. Acta Materiae Compositae Sinica,2013,30(5):34-40(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.05.006 [15] ZHANG Y, ZHANG N, HINGORANI H, et al. Fast-response, stiffness-tunable soft actuator by hybrid multimaterial 3D printing[J]. Advanced Functional Materials,2019,29(15):1806698. doi: 10.1002/adfm.201806698 [16] SAED M O, AMBULO C P, KIM H, et al. Molecularly-engi-neered, 4D-printed liquid crystal elastomer actuators[J]. Advanced Functional Materials,2019,29(3):1806412. doi: 10.1002/adfm.201806412 [17] TRUBY R L, WEHNER M, GROSSKOPF A K, et al. Soft somatosensitive actuators via embedded 3D printing[J]. Advanced Materials,2018,30(15):1706383. doi: 10.1002/adma.201706383 [18] KENETH E S, KAMYSHNY A, TOTARO M, et al. 3D printing materials for soft robotics[J]. Advanced Materials,2021,33(19):2003387. doi: 10.1002/adma.202003387 [19] 罗斌, 李小兰, 徐雪杰, 等. PVC凝胶驱动及CNT/PDMS传感一体化柔性抓手的研究[J]. 西安交通大学学报, 2020, 54(12):30-36.LUO Bin, LI Xiaolan, XU Xuejie, et al. Integrated polyvinyl chloride (PVC) gel actuating and CNT/PDMS sensing structure for soft gripper[J]. Journal of Xi'an Jiaotong University,2020,54(12):30-36(in Chinese). [20] 朱德举, 张超慧, 刘鹏. 天然和仿生柔性生物结构的设计[J]. 复合材料学报, 2018, 35(6):1636-1645. doi: 10.13801/j.cnki.fhclxb.20170920.001ZHU Deju, ZHANG Chaohui, LIU Peng. Study on the design of natural and biomimetic soft biological structures[J]. Acta Materiae Compositae Sinica,2018,35(6):1636-1645(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170920.001 [21] TANG Y, CHI Y, SUN J, et al. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots[J]. Science Advances,2020,6(19):eaaz6912. doi: 10.1126/sciadv.aaz6912 [22] BAKER R D, MONTENEGRO-JOHNSON T, SEDIAKO A D, et al. Shape-programmed 3D printed swimming microtori for the transport of passive and active agents[J]. Nature Communications,2019,10(1):4932. doi: 10.1038/s41467-019-12904-0 [23] WALLIN T J, PIKUL J, SHEPHERD R F. 3D printing of soft robotic systems[J]. Nature Reviews Materials,2018,3(6):84-100. doi: 10.1038/s41578-018-0002-2 [24] GUL J Z, SAJID M, REHMAN M M, et al. 3D printing for soft robotics—A review[J]. Science and Technology of Advanced Materials,2018,19(1):243-262. doi: 10.1080/14686996.2018.1431862 [25] 齐田宇, 杨建军, 赵佳伟, 等. 基于多材料3D打印和约束牺牲层连续功能梯度材料-结构一体化制造与性能[J]. 复合材料学报, 2022, 39(3):1055-1067.QI Tianyu, YANG Jianjun, ZHAO Jiawei, et al. Integrated manufacturing and performance study of continuous functionally graded materials-structures based on multi-material 3D printing and constraint sacrifice layer[J]. Acta Materiae Compositae Sinica,2022,39(3):1055-1067(in Chinese). [26] 李西敏, 杨韬, 彭必友, 等. 二氧化钛陶瓷浆料的制备及其直写成型3D打印[J]. 复合材料学报, 2022, 39(7):3510-3517.LI Ximin, YANG Tao, PENG Biyou, et al. Preparation of titanium dioxide ceramic slurry and its 3D printing for direct-ink-writing[J]. Acta Materiae Compositae Sinica,2022,39(7):3510-3517(in Chinese). -

下载:

下载: