Mechanism of rubber particles inhibit heat damage of steam-curing concrete

-

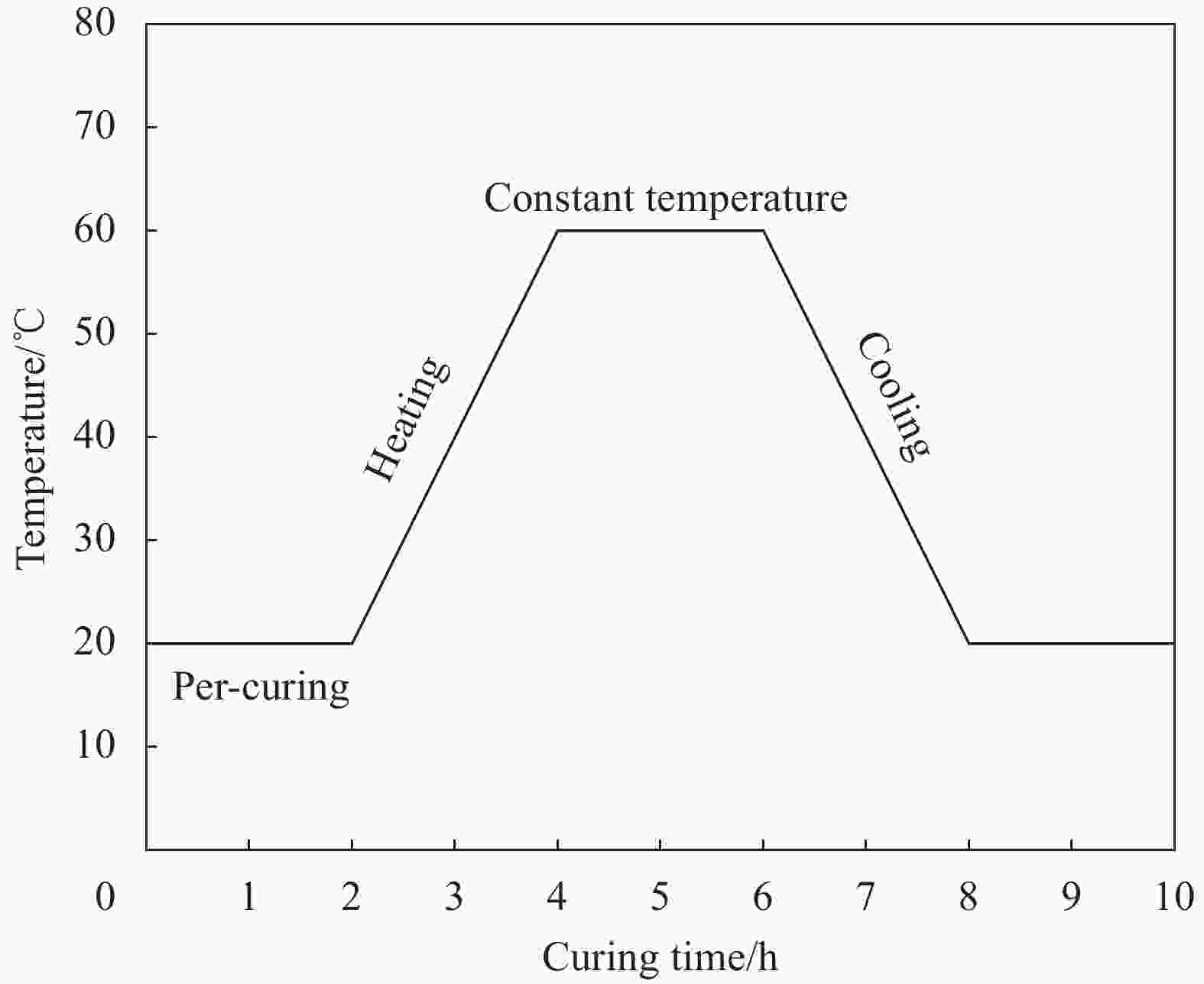

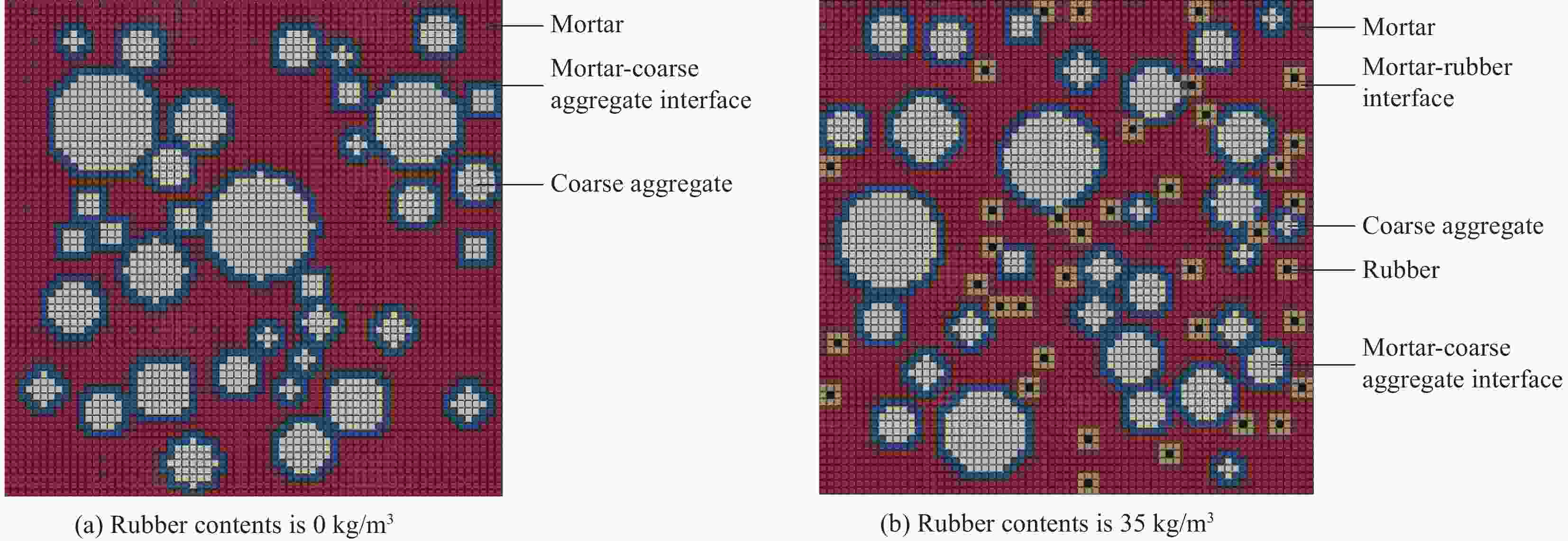

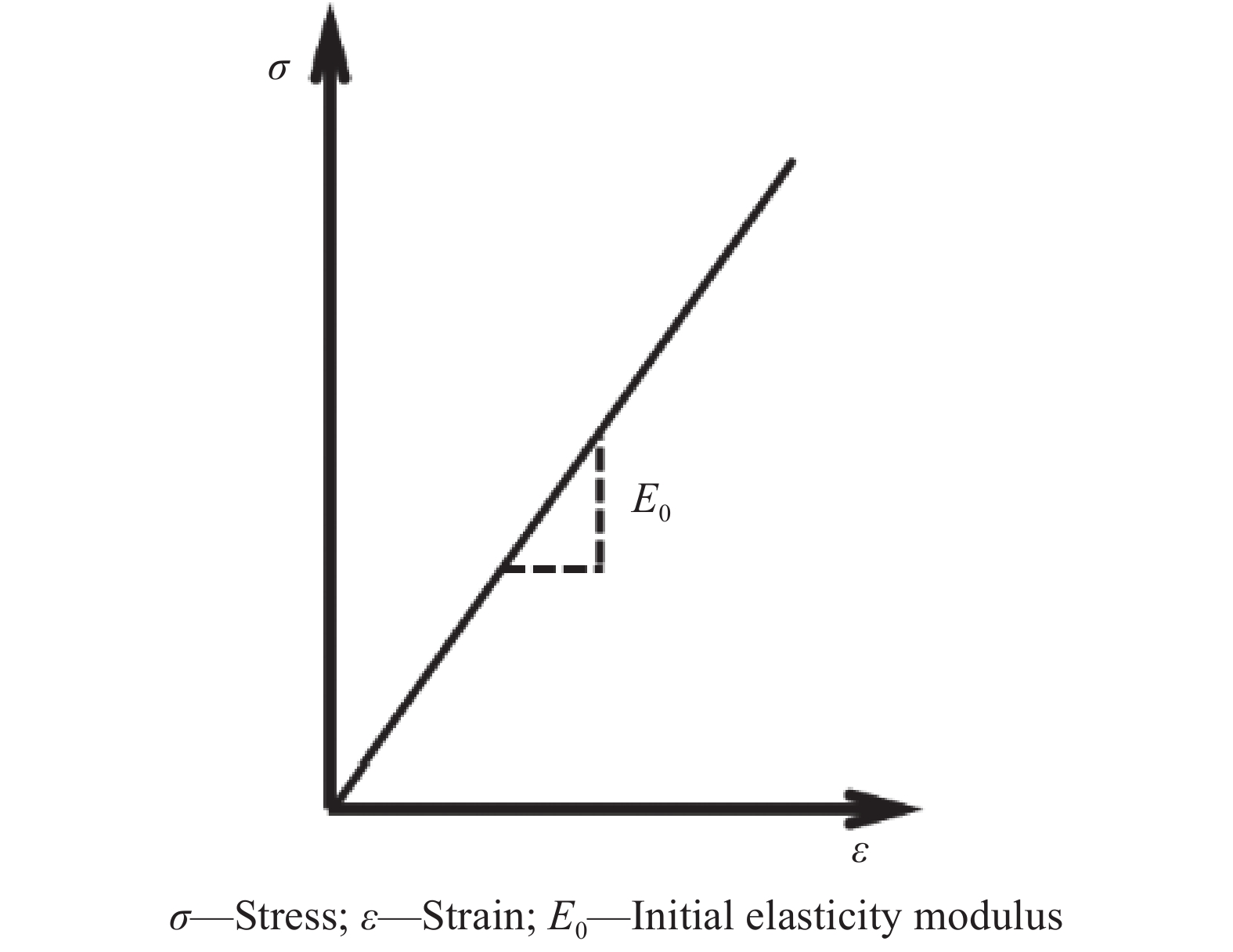

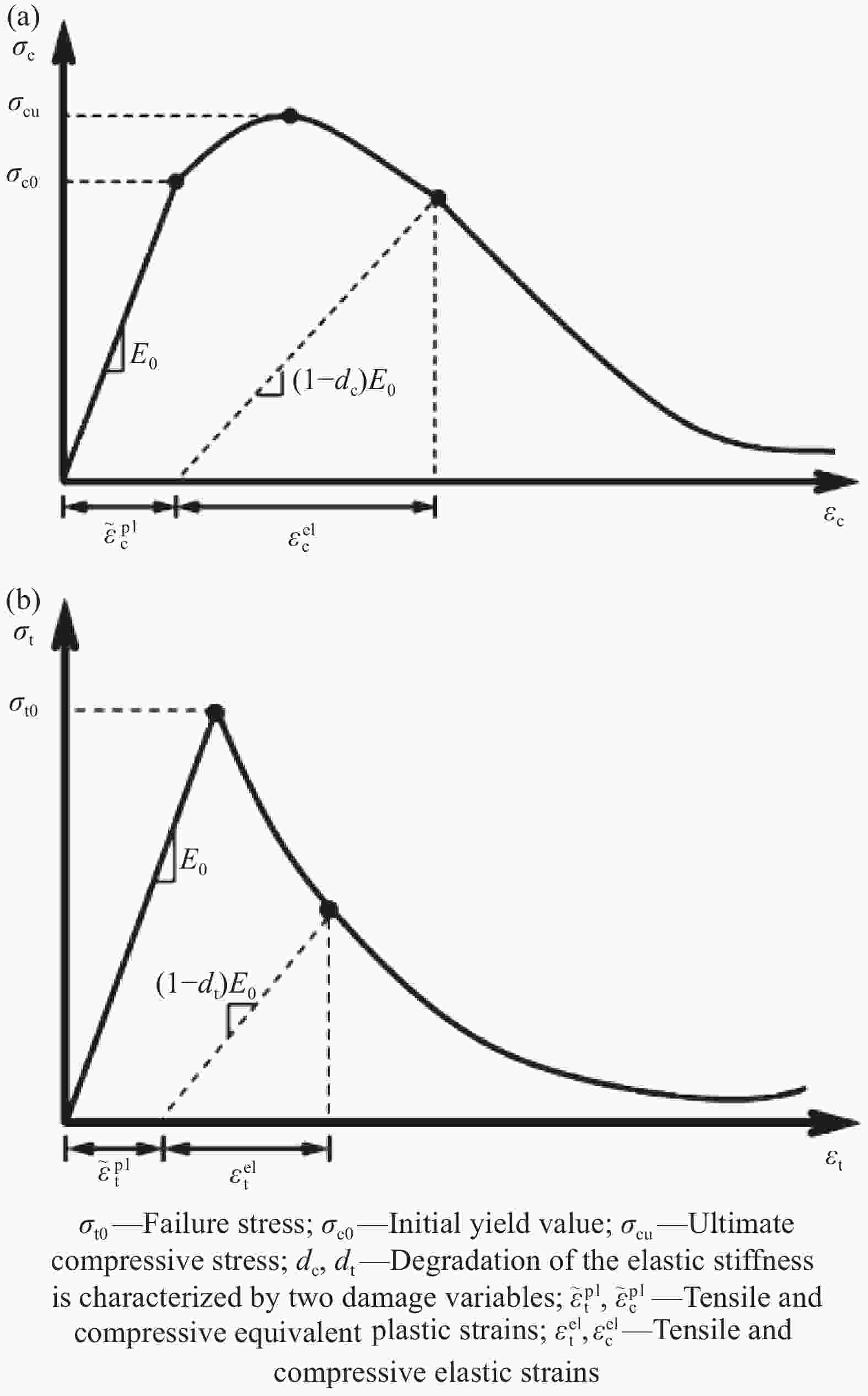

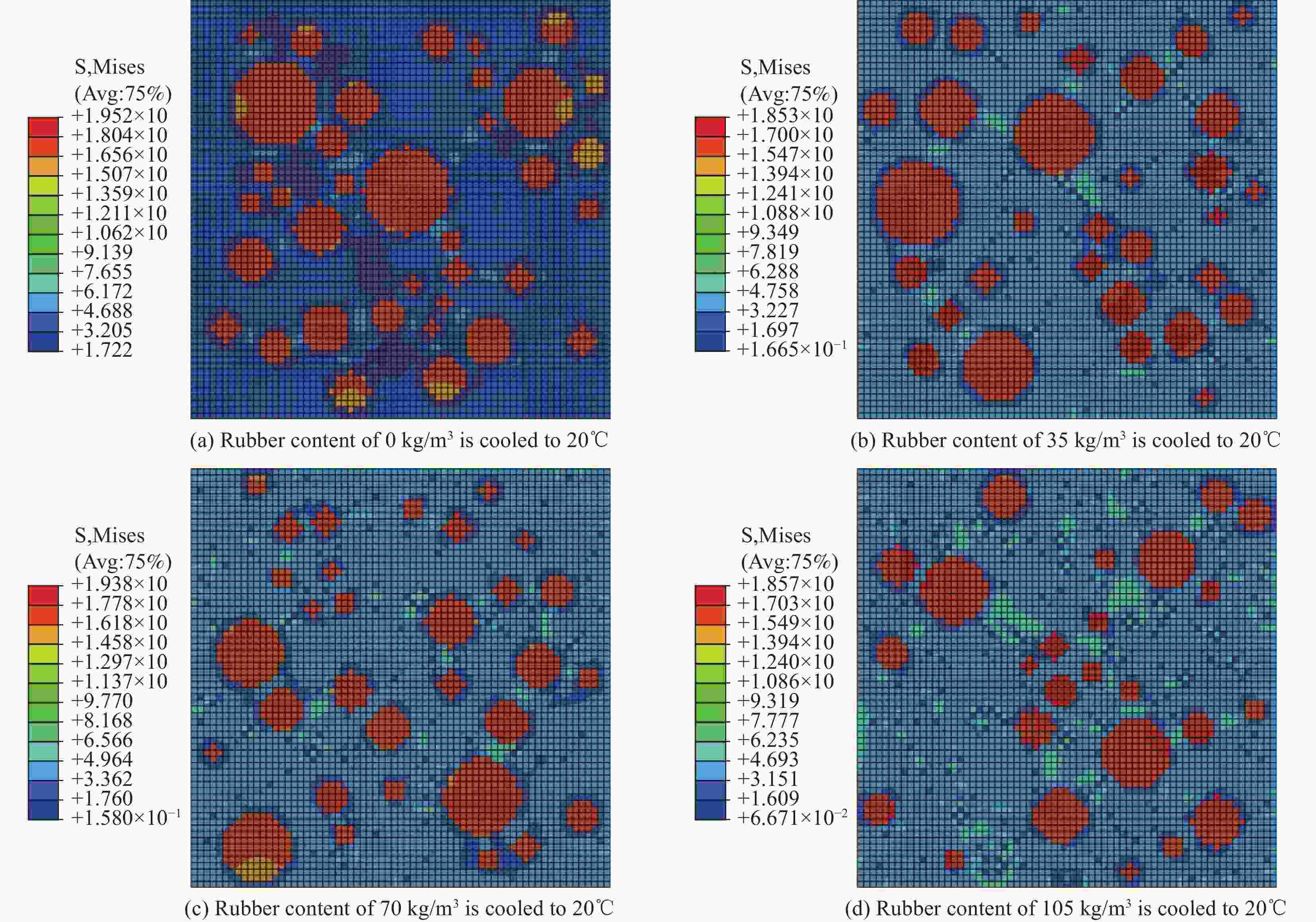

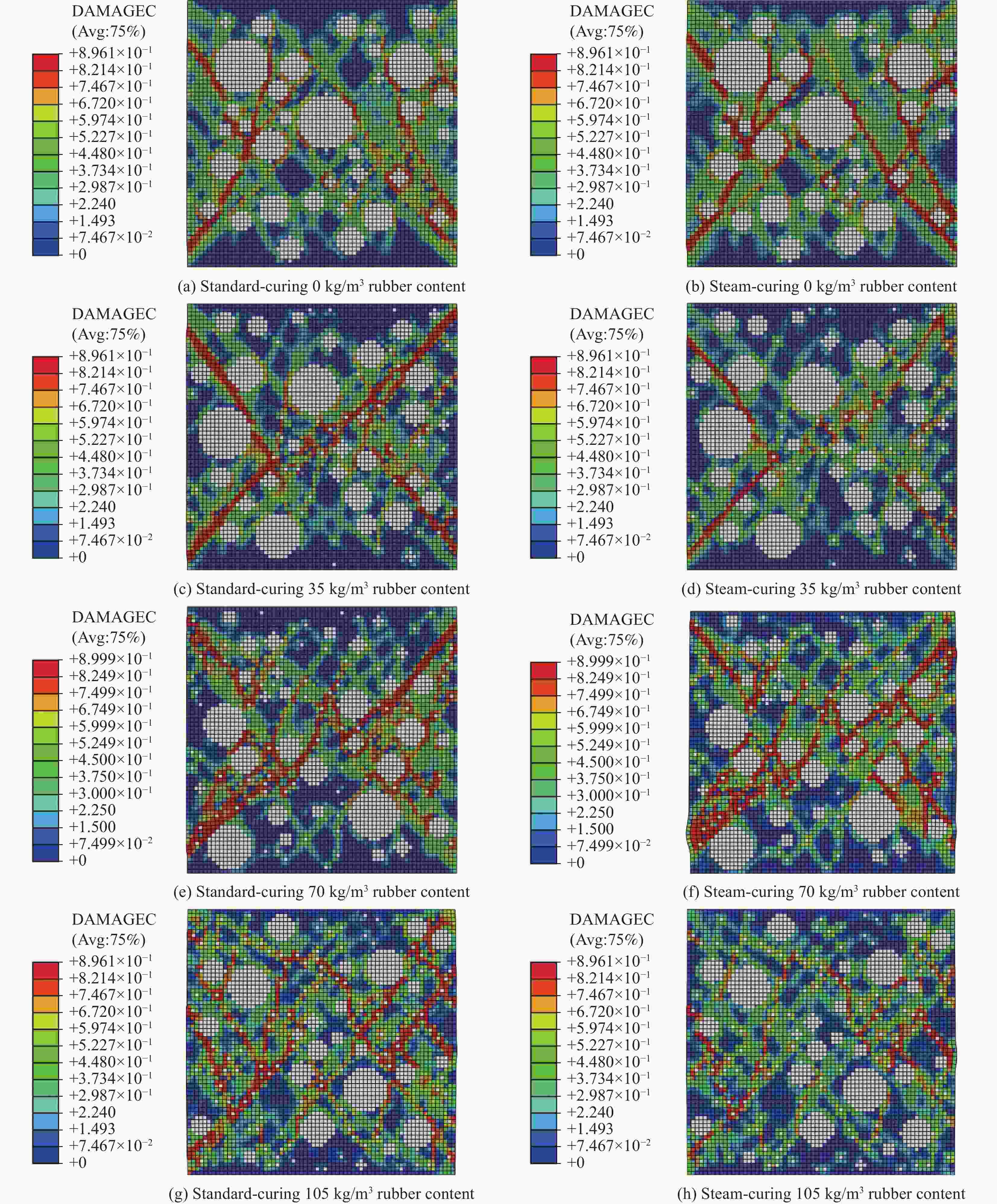

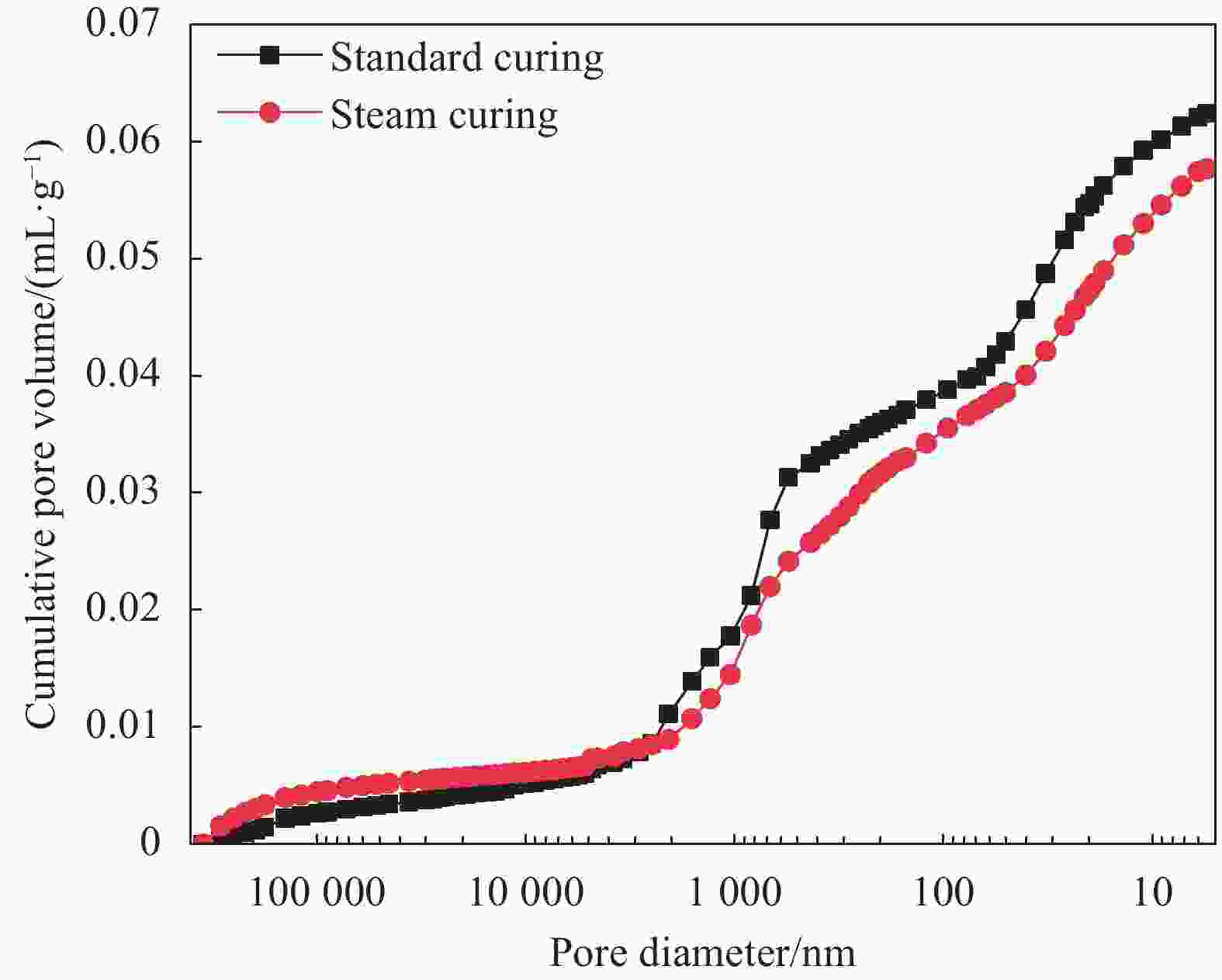

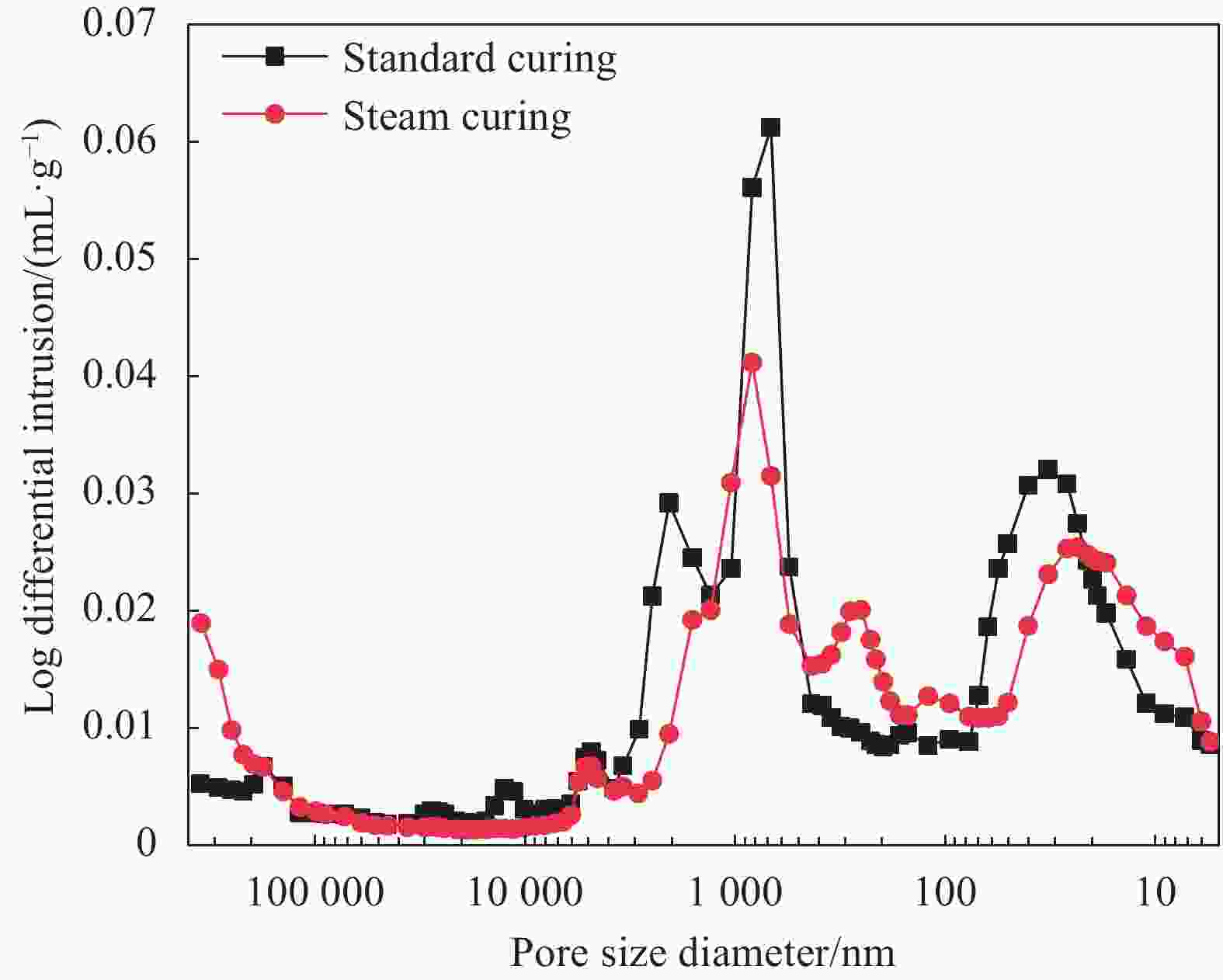

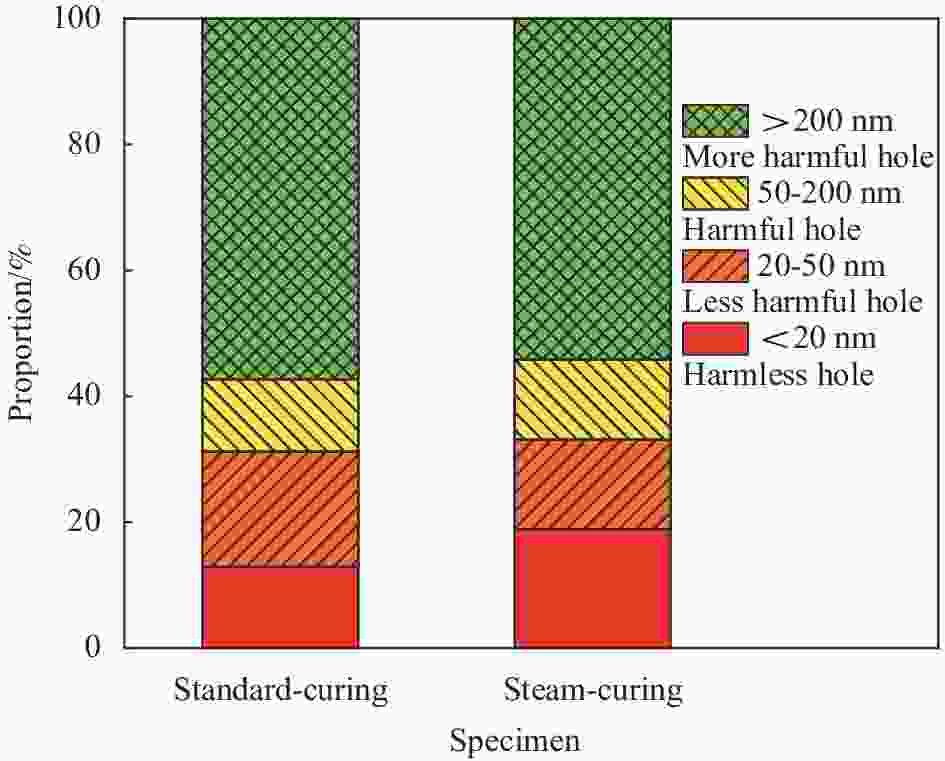

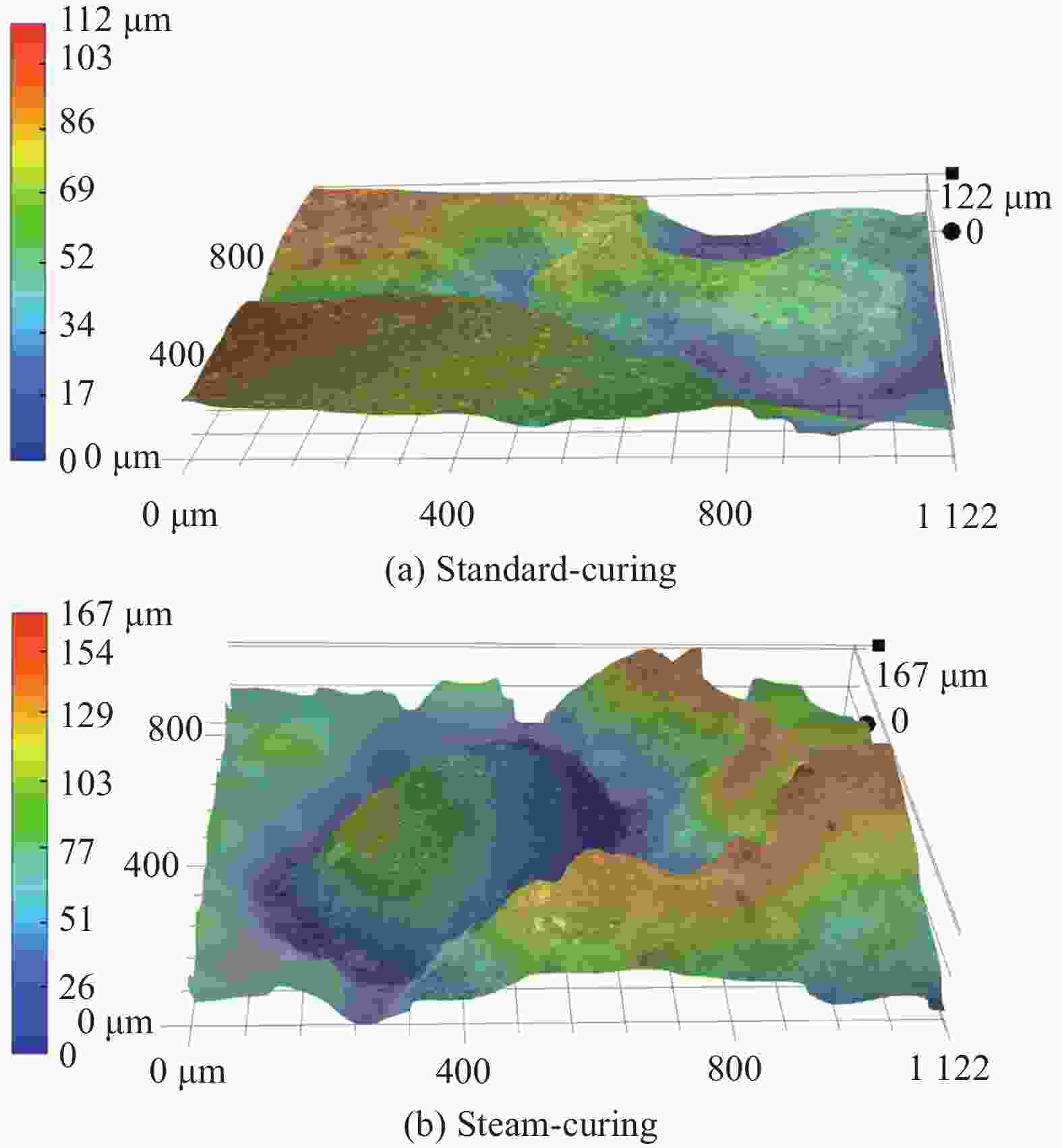

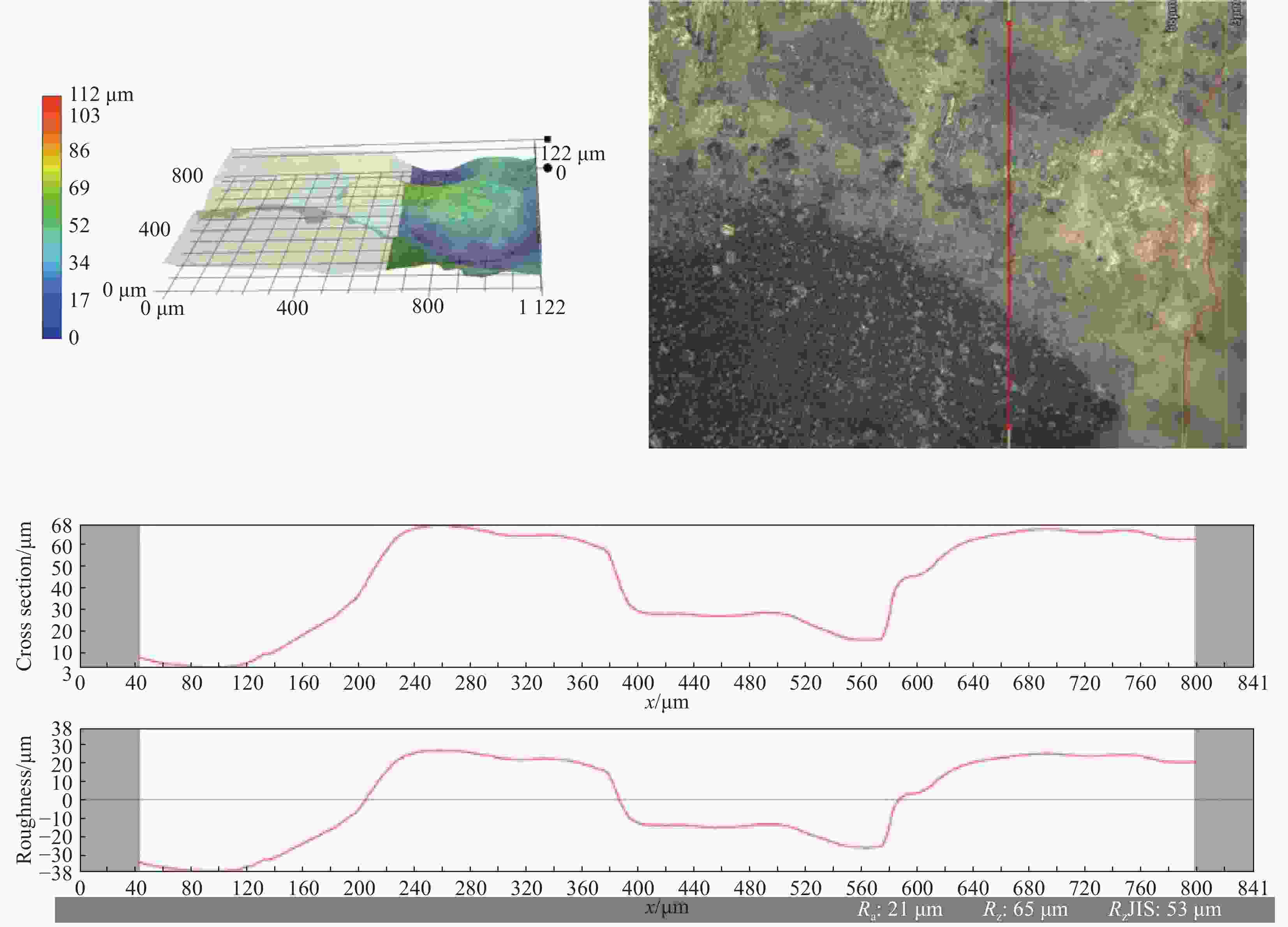

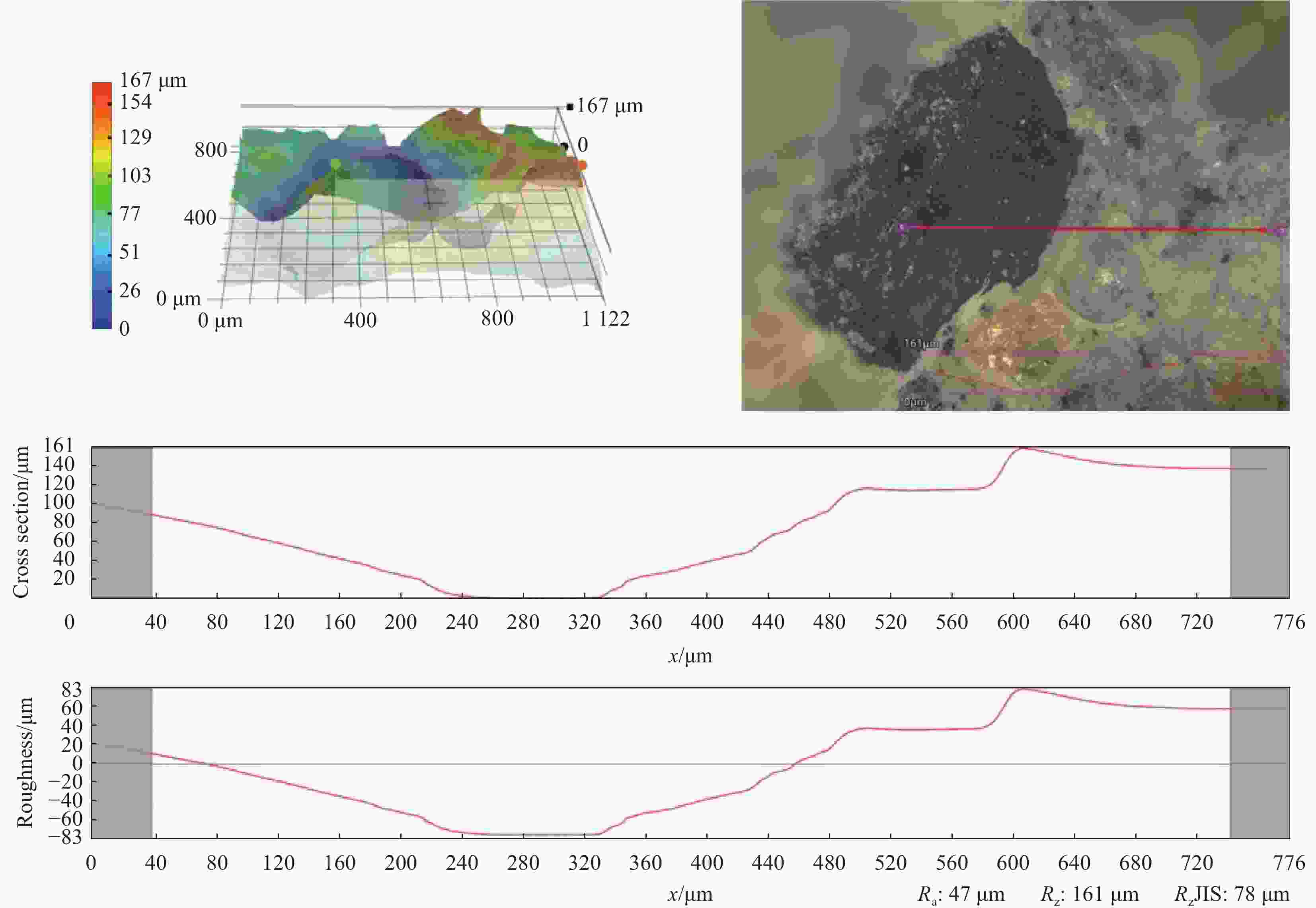

摘要: 通过向蒸养混凝土中掺入橡胶颗粒制备蒸养橡胶混凝土来抑制蒸养过程中混凝土产生的热损伤。通过试验测试了蒸养橡胶混凝土的抗压强度;建立了考虑界面过渡区的橡胶混凝土随机骨料模型,基于ABAQUS,模拟研究了橡胶颗粒对降温阶段混凝土温度损伤应力的影响,从细观角度研究橡胶颗粒抑制蒸养混凝土中微裂纹发展规律,并将温度损伤应力作为初始缺陷,模拟了橡胶混凝土的抗压性能,验证了模拟结果的可靠性;通过压汞(Mercury intrusion porosimetry,MIP)测试研究了橡胶颗粒对蒸养混凝土孔结构的影响;通过超景深显微镜研究了橡胶与水泥石之间的结合情况。研究结果表明:橡胶颗粒掺入可以抑制蒸养混凝土的热损伤,减少强度损失。橡胶颗粒可以有效降低蒸养混凝土试件的总孔隙率,蒸养橡胶混凝土试件有害孔径较未掺加橡胶颗粒的普通蒸养混凝土下降了3.1%,同时改善了橡胶和水泥基体的粘结状况。Abstract: The heat damage of steam-curing concrete was restrained by adding rubber particles into steam-curing concrete to prepare steam-curing rubber concrete. The compressive strength of steam-curing rubber concrete was tested through experiments. A random aggregate model of rubber concrete considering interface transition zone was established based on ABAQUS simulation. The influence of rubber particles on the temperature damage stress of concrete in the cooling stage was studied. The influence of rubber particles on the temperature damage stress of concrete at the cooling stage was studied. The development of microcracks in steam-curing concrete inhibited by rubber particles was studied from a microscopical point of view, and taking the temperature damage stress as the initial defect, the compressive property of rubber concrete was studied, and the reliability of the simulation results was verified. The effect of rubber particles on the pore structure of steam-curing concrete was studied by mercury intrusion porosimetry (MIP) test. The bond between rubber and cement was studied by an ultra-depth-of-field microscope. The results show that the addition of rubber particles can restrain heat damage and reduce the strength loss of steam-curing concrete. Rubber particles can effectively reduce the total porosity of steam-curing concrete specimens, and the harmful pore size of steam-curing rubber concrete decreases by 3.1% compared with that ordi-nary steam-curing concrete without adding rubber particles. Meanwhile, the bond between rubber and cement matrix is improved.

-

表 1 水泥的化学成分

Table 1. Chemical compositions of cement

wt% SiO2 Al2O3 Fe2O3 CaO MgO SO3 17.07 5.32 3.26 66.52 2.99 2.91 表 2 橡胶粉化学成分

Table 2. Chemical ingredients of crumb rubber

wt% Rubber hydrocarbon Carbon black Acetone extract Isoprene Water Ash content Fiber content Metal content Others 45.2 25.8 14.2 12.1 0.8 0.9 0.5 0.08 0.42 表 3 混凝土配合比设计

Table 3. Mix proportions of concretes

kg/m3 Specimen Cement Stone Water Sand Rubber RC0 520 810 195 835 0 RC35 520 810 195 747 35 RC70 520 810 195 696 70 RC105 520 810 195 571 105 表 4 不同养护制度不同橡胶掺量的混凝土抗压强度

Table 4. Compressive strength of concrete with different curing systems and different rubber contents

MPa Specimen Curing regime Standard-curing Steam-curing RC0 60.2 57.2 RC35 44.0 45.0 RC70 38.3 41.6 RC105 34.6 29.6 表 5 材料参数

Table 5. Material parameters

Material Elastic modulus/MPa Poisson's ratio Coarse aggregate 80000 0.20 Rubber 70 0.49 表 6 水灰比为0.375时公式计算砂浆的材料参数

Table 6. Formula calculates the material parameters of mortar when the water-cement ratio is 0.375

Water-cement ratio Elastic modulus/MPa Poisson's ratio Compressive strength/MPa Tensile strength/MPa 0.375 24000 0.2 46.1 3.7 表 7 不同养护制度和橡胶掺量的混凝土模拟结果与实验结果对比

Table 7. Simulation results of concrete with different curing systems and rubber contents compared with the experimental results

Specimen Rubber content/(kg·m−3) Compressive strength/MPa Relative error/% Experimental value Simulation value RC0-1 0 60.2 57.7 4.15 RC35-1 35 44.0 40.8 7.30 RC70-1 70 38.3 41.2 7.01 RC105-1 105 34.6 33.9 2.02 RC0-2 0 57.2 56.5 1.28 RC35-2 35 45.0 40.4 10.00 RC70-2 70 41.6 39.8 4.25 RC105-2 105 29.6 33.5 11.54 Notes: RC0-1 represents the standard-curing for group RC0 specimens; RC0-2 represents the steam-curing for group RC0 specimens. 表 8 不同橡胶掺量的混凝土损伤单元的比例

Table 8. Proportion of damaged elements of concrete with different rubber contents

% Specimen Curing regime Standard-curing Steam-curing RC0 49.79 53.05 RC35 45.62 45.26 RC70 45.21 45.90 RC105 50.58 52.42 表 9 RM70的孔隙率和中值孔径

Table 9. Porosity and median pore size of RM70

Rubber content/(kg·m−3) Porosity/% Median pore diameter/nm Standard-curing Steam-curing Standard-curing Steam-curing 70 12.56 11.66 560.87 283 -

[1] BI L P, LONG G C, MA C, et al. Effect of phase change composites on hydration characteristics of steam-cured cement paste[J]. Construction and Building Materials,2021,274:122030. doi: 10.1016/j.conbuildmat.2020.122030 [2] ZOU C, LONG G C, ZENG X H, et al. Water evolution and hydration kinetics of cement paste under steam-curing condition based on low-field NMR method[J]. Construction and Building Materials,2020,271:121583. [3] SHI J Y, LIU B J, WU X, et al. Evolution of mechanical pro-perties and permeability of concrete during steam curing process[J]. Journal of Building Engineering,2020,32:101796. doi: 10.1016/j.jobe.2020.101796 [4] YAN X C, JIANG L H, GUO M Z, et al. Evaluation of sulfate resistance of slag contained concrete under steam curing[J]. Construction and Building Materials,2019,195:231-237. doi: 10.1016/j.conbuildmat.2018.11.073 [5] ANDREU G C, MIREN E, CHI S P. Influence of steam curing on the pore structures and mechanical properties of fly-ash high performance concrete prepared with recycled aggregates[J]. Cement and Concrete Composites,2016,71:77-84. doi: 10.1016/j.cemconcomp.2016.05.010 [6] SHI J Y, LIU B J, WU X, et al. Effect of steam curing on surface permeability of concrete: Multiple transmission media[J]. Journal of Building Engineering,2020,32:101475. doi: 10.1016/j.jobe.2020.101475 [7] ZOU C, LONG G C, ZENG X H, et al. Hydration and multiscale pore structure characterization of steam-cured cement paste investigated by X-ray CT[J]. Construction and Building Materials,2021,282:122629. doi: 10.1016/j.conbuildmat.2021.122629 [8] 贺智敏, 龙广成, 谢友均, 等. 蒸养混凝土的表层伤损效应[J]. 建筑材料学报, 2014, 17(6):994-1000, 1008. doi: 10.3969/j.issn.1007-9629.2014.06.010HE Zhimin, LONG Guangcheng, XIE Youjun, et al. Surface layer degradation effect of steam-cured concrete[J]. Jour-nal of Building Materials,2014,17(6):994-1000, 1008(in Chinese). doi: 10.3969/j.issn.1007-9629.2014.06.010 [9] WANG M, XIE Y J, LONG G C, et al. The impact mechanical characteristics of steam-cured concrete under different curing temperature conditions[J]. Construction and Building Materials,2020,241:118042. doi: 10.1016/j.conbuildmat.2020.118042 [10] UTSI S, JONASSON J E. Estimation of the risk for early thermal cracking for SCC containing fly ash[J]. Materials and Structures,2012,45(1-2):153-169. doi: 10.1617/s11527-011-9757-2 [11] 李霖皓, 龙广成, 刘芳萍, 等. 混凝土在蒸养过程中的变形性能[J]. 材料导报, 2019, 33(8):1322-1327. doi: 10.11896/cldb.17120058LI Linhao, LONG Guangcheng, LIU Fangping, et al. Deformation behavior of concrete during steam curing[J]. Materials Reports,2019,33(8):1322-1327(in Chinese). doi: 10.11896/cldb.17120058 [12] 贺炯煌, 马昆林, 龙广成, 等. 蒸汽养护过程中混凝土力学性能的演变[J]. 硅酸盐学报, 2018, 46(11):1584-1592.HE Jionghuang, MA Kunlin, LONG Guangcheng, et al. Mechanical properties evolution of concrete in steam-curing process[J]. Journal of the Chinese Ceramic Society,2018,46(11):1584-1592(in Chinese). [13] 姚志昕. 混凝土蒸养过程中的应力应变场及其对开裂的影响[D]. 广州: 华南理工大学, 2019.YAO Zhixin. Stress and strain field and its effect on stress and strain field of concrete during steam curing and its effect on cracking[D]. Guangzhou: South China University of Technology, 2019(in Chinese). [14] 钱荷雯, 王燕谋. 湿热处理混凝土过程中预养期的物理化学作用[J]. 硅酸盐学报, 1964, 3(3):217-222.QIAN Hewen, WANG Yanmou. Physicochemical action during preconditioning period of concrete treated by moisture and heat[J]. Journal of the Chinese Ceramic Society,1964,3(3):217-222(in Chinese). [15] OROSZ K, HEDLUND H, CWIRZEN A. Effects of variable curing temperatures on autogenous deformation of blended cement concretes[J]. Construction and Building Materials,2017,149:474-480. doi: 10.1016/j.conbuildmat.2017.05.143 [16] SHI J Y, LIU B J, ZHOU F, et al. Effect of steam curing regimes on temperature and humidity gradient, permeabi-lity and microstructure of concrete[J]. Construction and Building Materials,2021,281:122562. doi: 10.1016/j.conbuildmat.2021.122562 [17] YU Y, JIN Z Q, SHAO S S, et al. Evolution of temperature stress and tensile properties of concrete during steam-curing process[J]. Construction and Building Materials,2021,305:124691. doi: 10.1016/j.conbuildmat.2021.124691 [18] XIANG Y, XIE Y J, LONG G C, et al. Hydration phase and pore structure evolution of hardened cement paste at elevated temperature[J]. Journal of Central South University,2021,28(6):1665-1678. doi: 10.1007/s11771-021-4725-7 [19] 赵秋红, 董硕, 朱涵, 等. 钢纤维橡胶混凝土循环受压应力-应变关系[J]. 建筑材料学报, 2022, 25(8): 789-797.ZHAO Qiuhong, DONG Shuo, ZHU Han, et al. Stress-strain relations steel fiber reinforced rubberized concrete under uniaxial cyclic compression[J]. Journal of Building Materials, 2022, 25(8): 789-797(in Chinese). [20] 赵秋红, 刘凯, 王菲, 等. GFRP筋橡胶集料混凝土梁受弯性能[J]. 复合材料学报, 2021, 38(5):1611-1622.ZHAO Qiuhong, LIU Kai, WANG Fei, et al. Analyses on flexural behavior of GFRP-reinforced crumb rubber concrete beams[J]. Acta Materiae Compositae Sinica,2021,38(5):1611-1622(in Chinese). [21] BALA A, GUPTA S. Thermal resistivity, sound absorption and vibration damping of concrete composite doped with waste tire rubber: A review[J]. Construction and Building Materials,2021,299:123939. doi: 10.1016/j.conbuildmat.2021.123939 [22] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [23] 史鑫宇, 姚燕, 王玲, 等. 基于单轴拉压模拟的CDP模型参数影响[J]. 建筑结构, 2021, 51(S2): 999-1007.SHI Xinyu, YAO Yan, WANG Ling, et al. The influence of CDP model parameters based on the numerical simulation of uniaxial loading test[J]. Building Structure, 2021, 51(S2): 999-1007(in Chinese). [24] 刘诚, 聂鑫, 汪家继, 等. 混凝土宏观本构模型研究进展[J]. 建筑结构学报, 2022, 43(1):29-41. doi: 10.14006/j.jzjgxb.2019.0842LIU Cheng, NIE Xin, WANG Jiaji, et al. State-of-the-art of macroscopic constitutive models of concrete[J]. Journal of Building Structures,2022,43(1):29-41(in Chinese). doi: 10.14006/j.jzjgxb.2019.0842 [25] DU X L, JIN L. Meso-scale numerical investigation on cracking of cover concrete induced by corrosion of reinforcing steel[J]. Engineering Failure Analysis,2014,39:21-33. doi: 10.1016/j.engfailanal.2014.01.011 [26] JIN L, JIANG X A, DU X L. Novel size-effect law for shear strength of CFRP-strengthened lightweight concrete deep beams without stirrups[J]. Journal of Composites for Construction,2022,26(1):04021065. doi: 10.1061/(ASCE)CC.1943-5614.0001172 [27] WRIGGERS P, MOFTAH S O. Mesoscale models for concrete: Homogenisation and damage behavior[J]. Finite Elements in Analysis and Design,2006,42(7):623-636. doi: 10.1016/j.finel.2005.11.008 [28] 杜修力, 金浏, 张仁波. 压缩荷载作用下混凝土中氯离子扩散行为细观模拟[J]. 建筑材料学报, 2016, 19(1):65-71. doi: 10.3969/j.issn.1007-9629.2016.01.011DU Xiuli, JIN Liu, ZHANG Renbo. Meso-scale simulation of chloride diffusivity in concrete subjected to compressive stress[J]. Journal of Building Materials,2016,19(1):65-71(in Chinese). doi: 10.3969/j.issn.1007-9629.2016.01.011 [29] 汪奔, 王弘, 张志强, 等. 基于网格生成的随机凹凸型混凝土骨料细观建模方法[J]. 计算力学学报, 2017, 34(5):591-596.WANG Ben, WANG Hong, ZHANG Zhiqiang, et al. Mesoscopic modeling method of concrete aggregates with arbitrary shapes based on mesh generation[J]. Chinese Journal of Computational Mechanics,2017,34(5):591-596(in Chinese). [30] WALRAVEN J C. Theory and experiments on the mechanical behavior of cracks in plain and reinforced concrete subjected to shear loading[J]. Heron,1981,26(1A):26-35. [31] NAGAI K, SATO Y, UEDA T. Mesoscopic simulation of failure of mortar and concrete by 2D RBSM[J]. Journal of Advanced Concrete Technology,2004,2(3):359-374. doi: 10.3151/jact.2.359 [32] 陈惠苏, 孙伟, STROEVEN P. 水泥基复合材料界面对材料宏观性能的影响[J]. 建筑材料学报, 2005, 8(1):51-62. doi: 10.3969/j.issn.1007-9629.2005.01.010CHEN Huisu, SUN Wei, STROEVEN P. Review on the study of effect of ITZ on the macro properties of cementitious composites[J]. Journal of Building Materials,2005,8(1):51-62(in Chinese). doi: 10.3969/j.issn.1007-9629.2005.01.010 [33] 薛刚, 孙立所, 许胜, 等. 橡胶混凝土抗压性能及细观破坏机理研究[J]. 沈阳建筑大学学报(自然科学版), 2020, 36(6):1082-1090.XUE Gang, SUN Lisuo, XU Sheng, et al. Study on compres-sive properties and meso failure mechanism of rubber concrete[J]. Journal of Shenyang Jianzhu University (Natural Science),2020,36(6):1082-1090(in Chinese). [34] 水中和, 曹蓓蓓. 水泥混凝土材料热膨胀性能研究[C]//第九届全国水泥和混凝土化学及应用技术会议论文汇编(上卷). 广州: 第九届全国水泥和混凝土化学及应用技术年会, 2005: 449-455.SHUI Zhonghe, CAO Beibei. Study on thermal expansion properties of cement concrete materials[C]//The 9th National Conference on Chemistry and Applied Technology of Cement and Concrete (Vol. 1). Guangzhou: The 9th National Annual Conference of Cement and Concrete Che-mistry and Applied Technology, 2005: 449-455(in Chinese). [35] 金浏, 杨旺贤, 余文轩, 等. 骨料粒径对混凝土动态拉伸强度及尺寸效应影响分析[J]. 振动与冲击, 2020, 39(9):24-34. doi: 10.13465/j.cnki.jvs.2020.09.004JIN Liu, YANG Wangxian, YU Wenxuan, et al. Influence of aggregate size on the dynamic tensile strength and size effect of concrete[J]. Journal of Vibration and Shock,2020,39(9):24-34(in Chinese). doi: 10.13465/j.cnki.jvs.2020.09.004 [36] LIU W D, GAO Y, HUANG X M. Effects of aggregate size and specimen scale on asphalt mixture cracking using a micromechanical simulation approach[J]. Journal of Wuhan University of Technology,2017,32(6):1503-1510. doi: 10.1007/s11595-017-1775-7 [37] 贺智敏. 蒸养混凝土的热损伤效应及其改善措施研究[D]. 长沙: 中南大学, 2012.HE Zhimin. Heat damage effects of steam curing on concrete and corresponding improvement measures[D]. Changsha: Central South University, 2012(in Chinese). [38] 吴中伟. 混凝土科学技术近期发展方向的探讨[J]. 硅酸盐学报, 1979, 7(3):262-270. doi: 10.14062/j.issn.0454-5648.1979.03.010WU Zhongwei. An approach to the recent trends of concrete science and technology[J]. Journal of the Chinese Ceramic Society,1979,7(3):262-270(in Chinese). doi: 10.14062/j.issn.0454-5648.1979.03.010 -

下载:

下载: