Effects of fiber addition on the mechanical and thermal properties of jute fiber reinforced resin composites

-

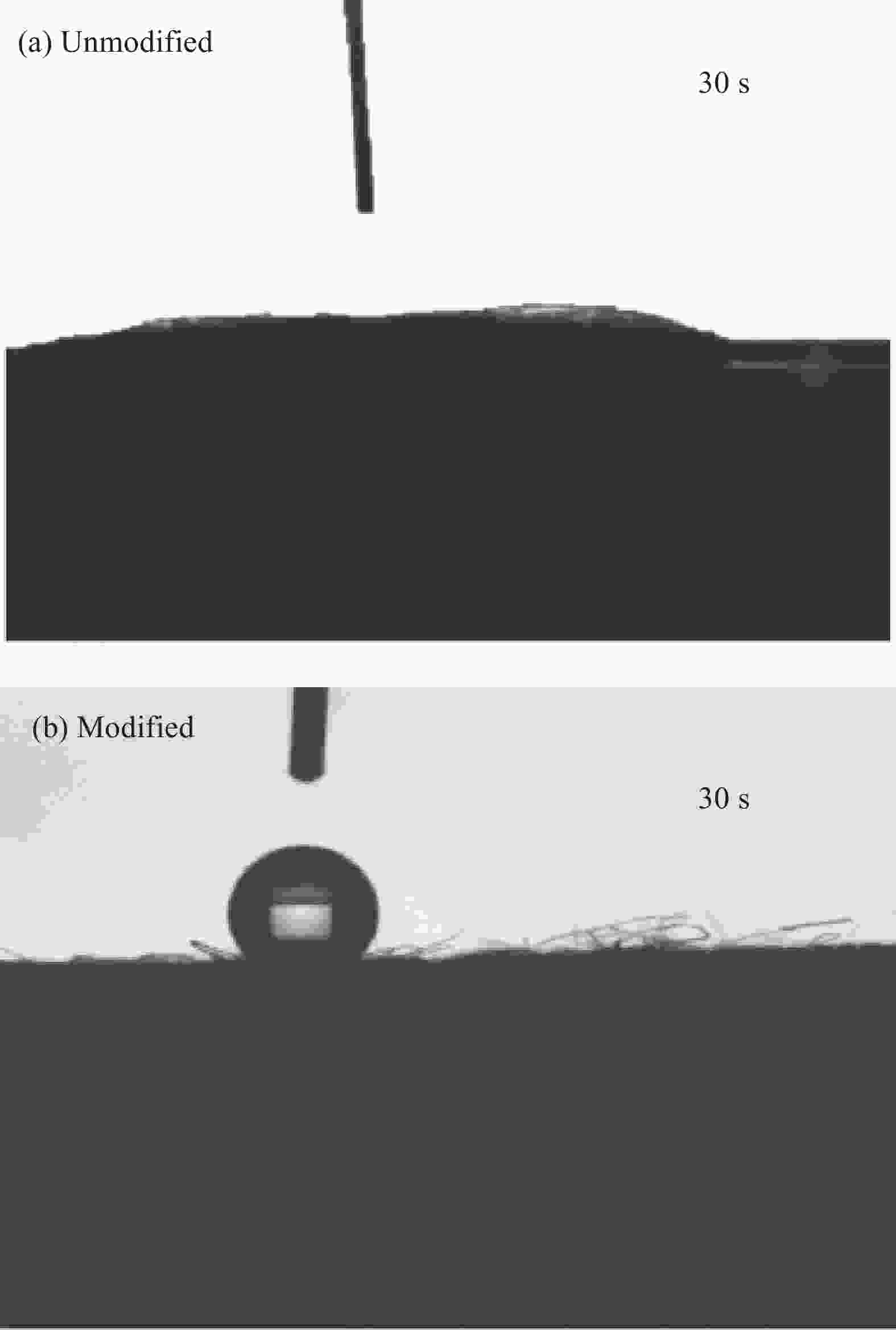

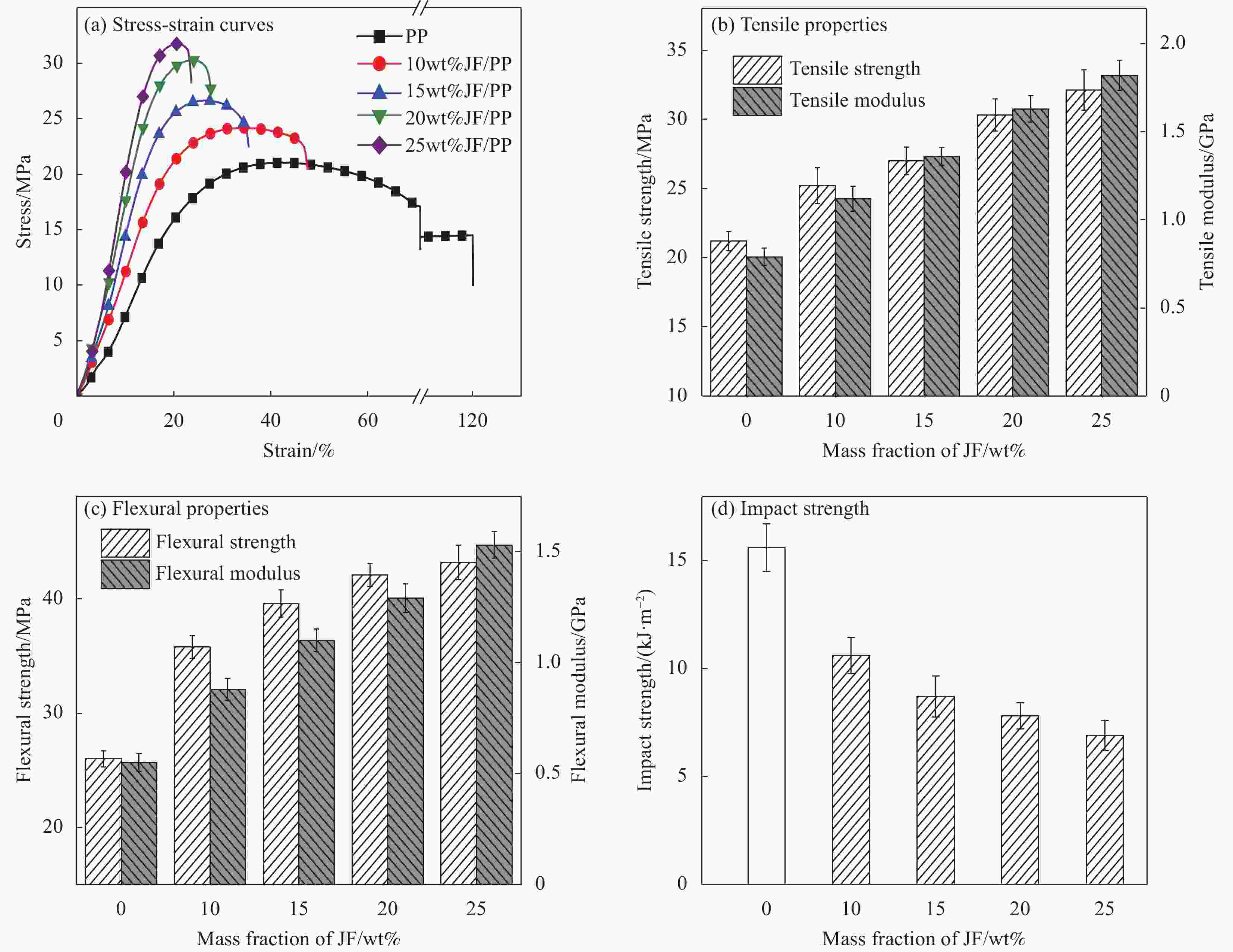

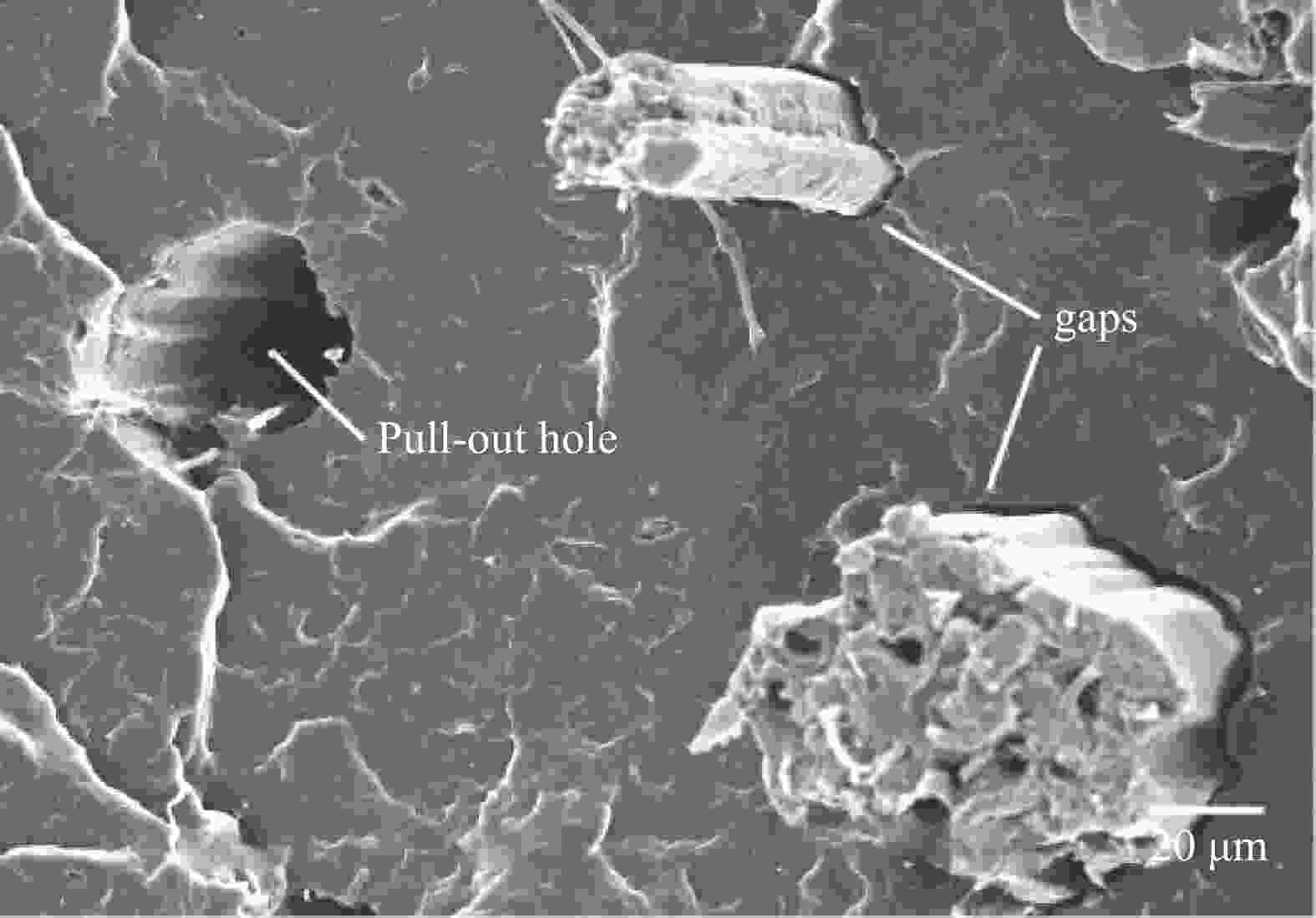

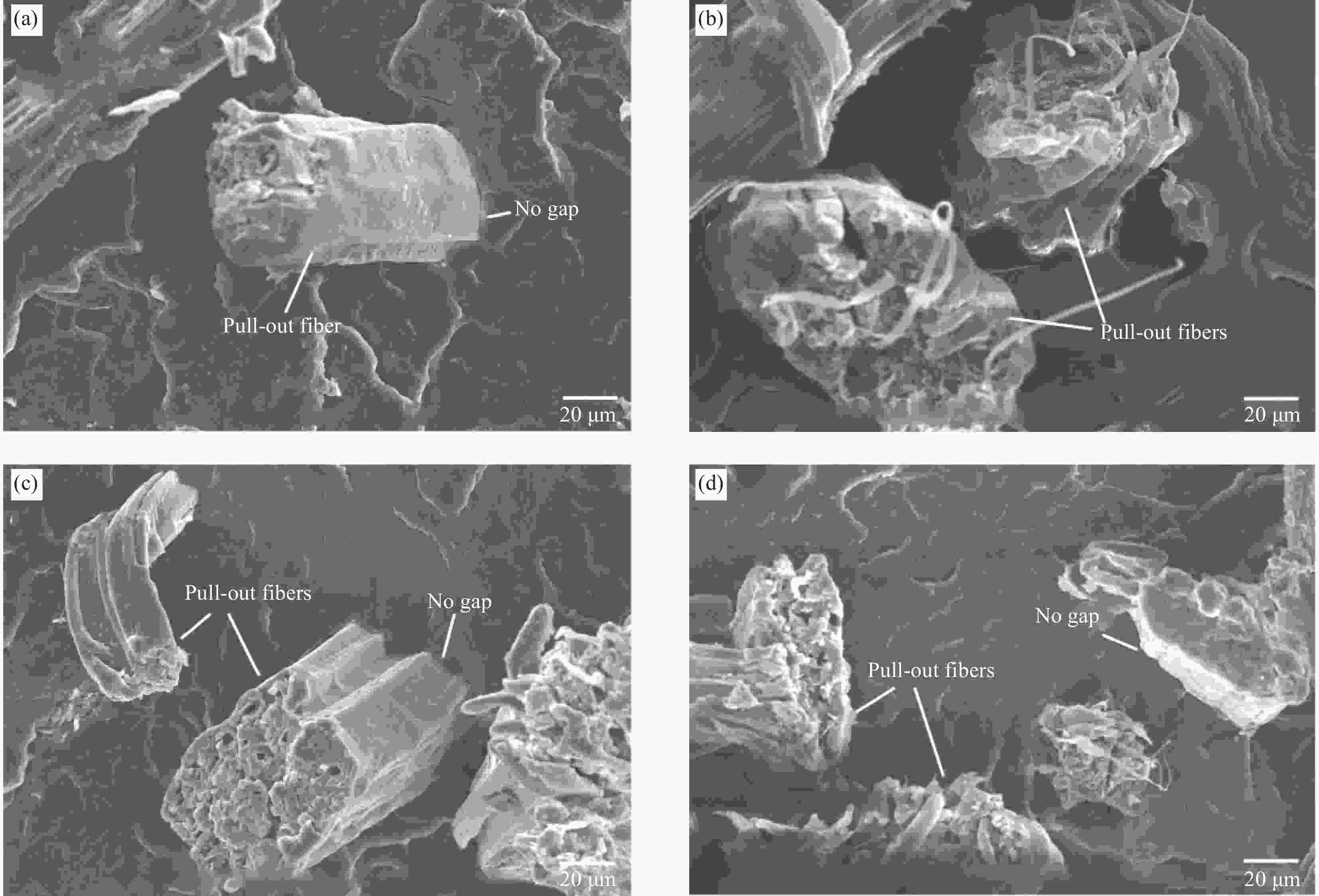

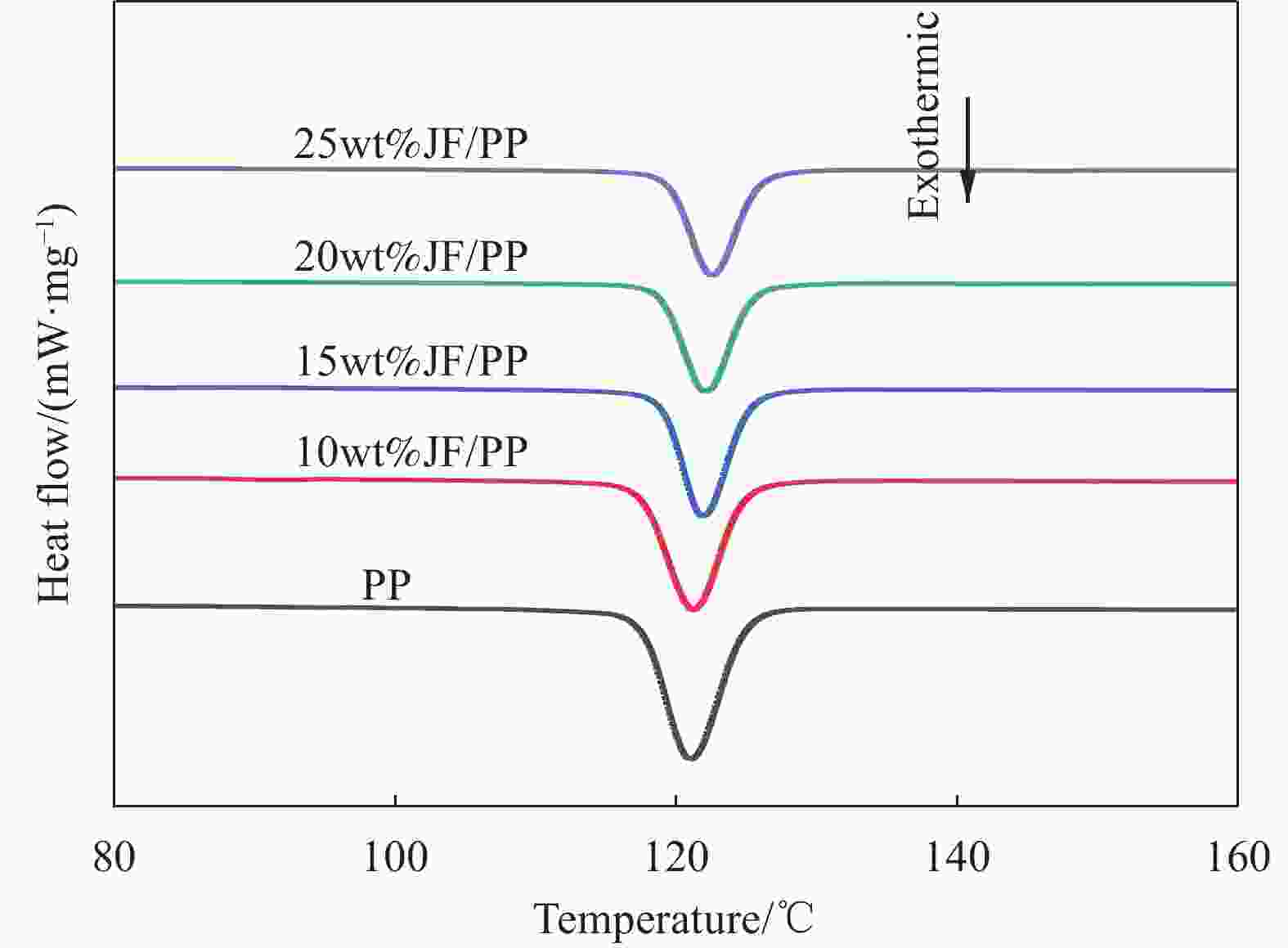

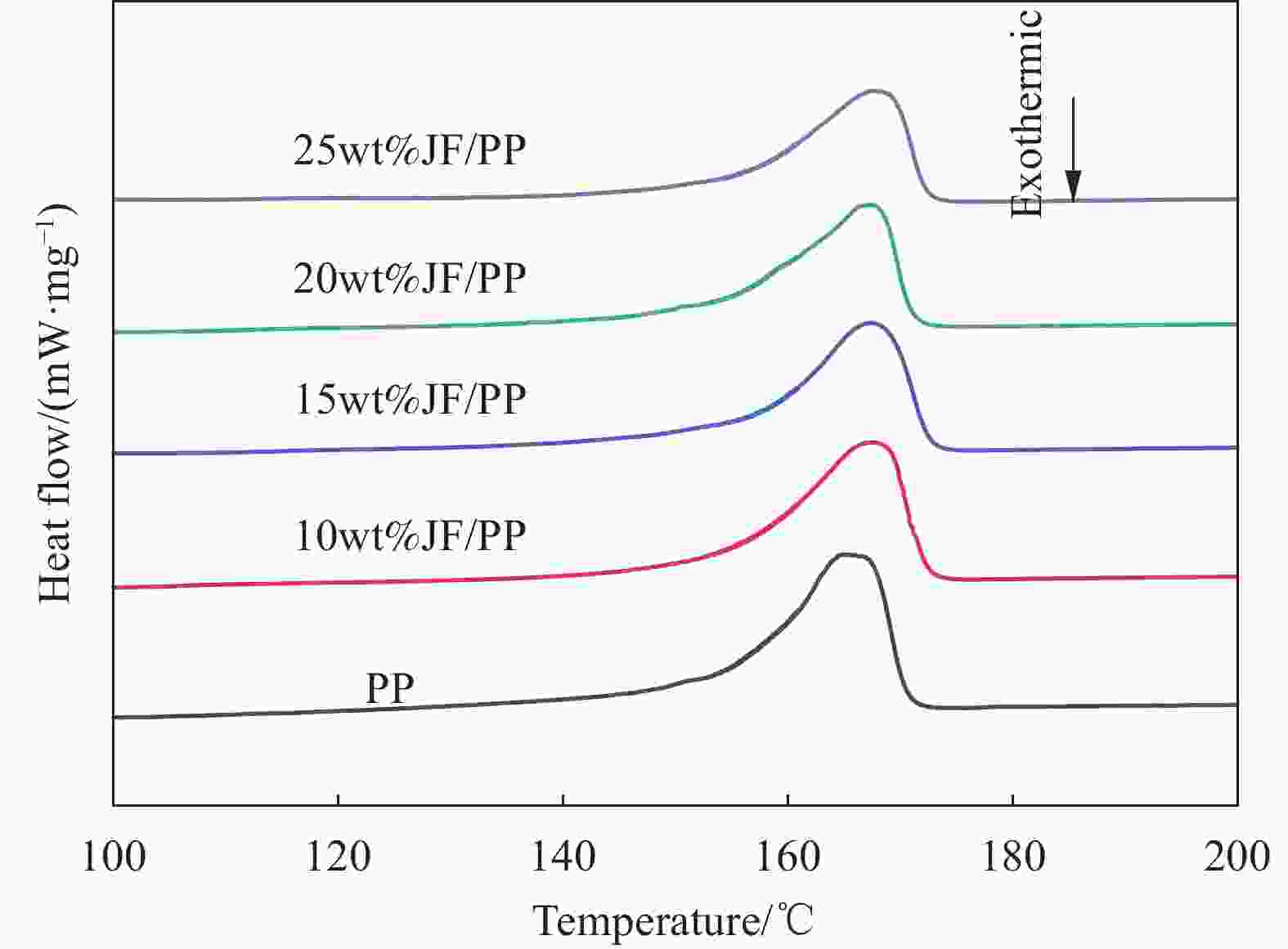

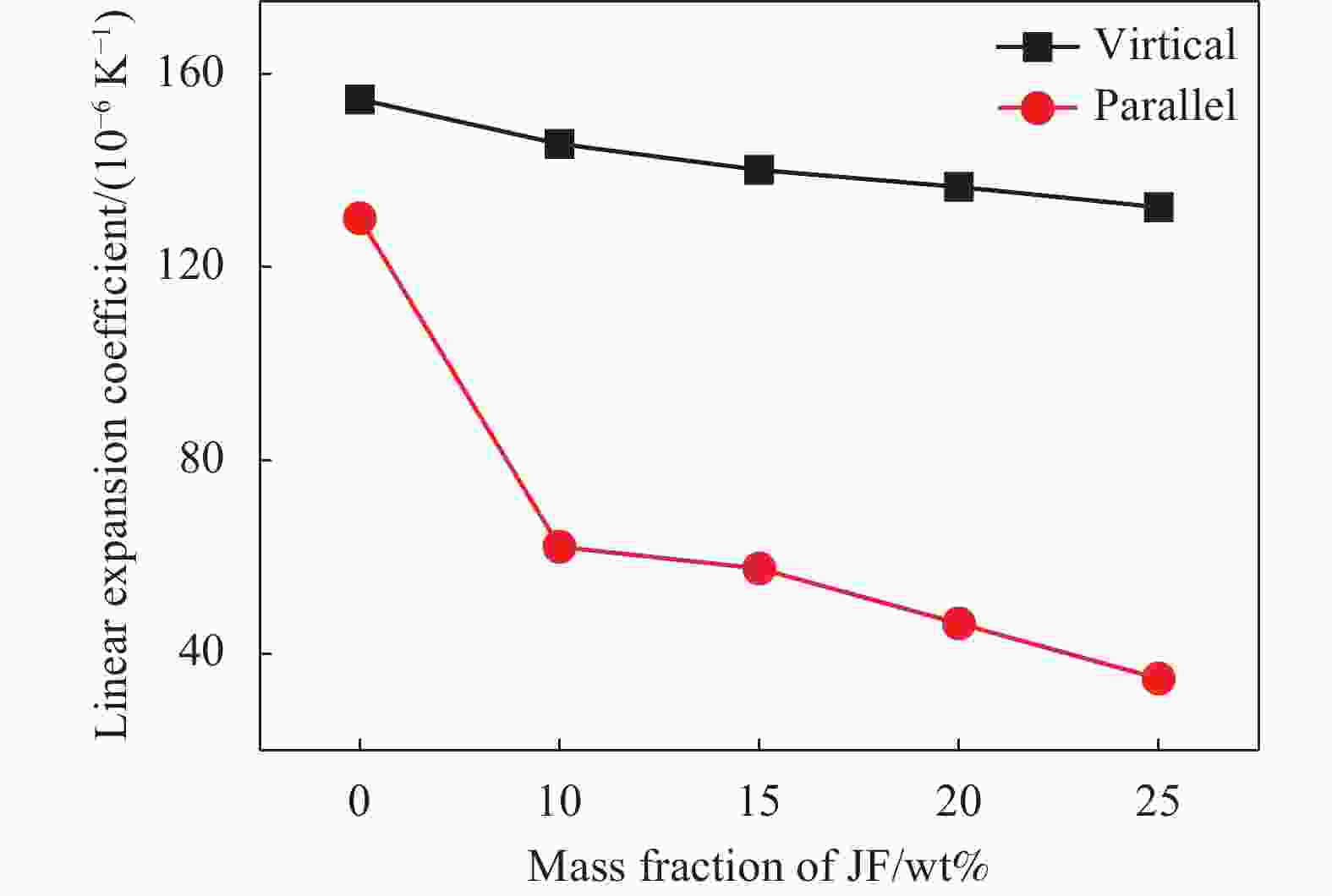

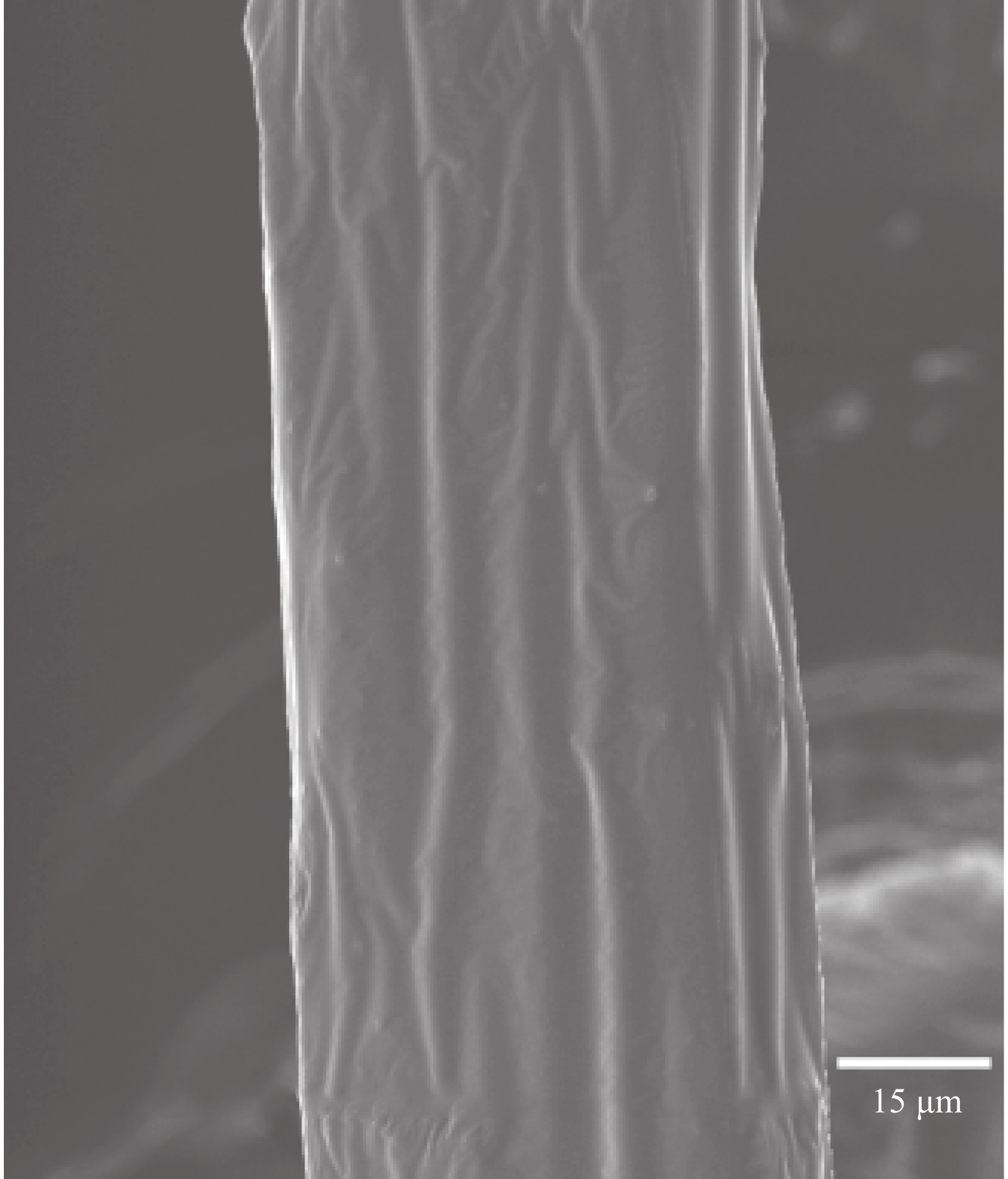

摘要: 为研发低碳、节能、性能优异的麻纤维增强树脂绿色复合材料并扩展其应用领域,本文采用团队发明的氨基硅油乳液对黄麻纤维(JF)进行表面改性,运用开炼-注塑成型复合工艺研制了纤维含量为10wt%~25wt%的改性黄麻纤维增强聚丙烯(JF/PP)新型复合材料,系统全面地研究了改性麻纤维含量对JF/PP复合材料力学性能、结晶行为、耐热性能(热变形温度)及热尺寸稳定性(线膨胀系数)的影响规律及相关作用机制,并采用接触角测试分析与SEM技术分析了复合材料界面相容性与结合状态。结果表明:氨基硅油乳液改性JF,增强了JF与PP基体的界面结合力。随着纤维含量的增加,JF/PP复合材料的拉伸和弯曲强度逐渐增加,而冲击强度则有所降低。DSC、热变形温度和线膨胀系数测试分析表明,添加改性JF能够促进PP异相成核,并限制PP分子链的运动能力,从而提高JF/PP复合材料的耐热性能,且随着纤维含量增加,耐热性能呈不断上升趋势。当改性JF含量为25wt%时,JF/PP复合材料的热变形温度为142.5℃,较纯PP提高了53.5%。同时,复合材料平均线膨胀系数随纤维含量增加而明显降低,表明复合材料的热尺寸稳定性显著提高。相比纯PP,含量为25wt%时的复合材料的平均线膨胀系数在平行流道方向下降了73.2%,垂直流道方向则下降了14.4%,存在各向异性。纤维含量为15wt%和20wt%时,改性JF/PP综合力学和热性能相对更优。Abstract: In order to develop green bast fiber reinforced resin composites with low carbon, energy saving and excellent mechanical and thermal properties and widen their applications, a new kind of modified jute fiber reinforced polypropylene composites (modified JF/PP) with fiber content in range of 10wt%-25wt% was fabricated by a hybrid technique of mill mixing and injection molding process, in which the jute fiber was modified with amino silicone oil invented by our research group in the present work. The effects of modified bast fiber content on the mechanical properties, crystallization behavior, heat resistance (heat deflection temperature) and thermal dimensional stability (linear expansion coefficient) of JF/PP composites were systematically and comprehensively studied. The compatibility and interfacial bonding strength in between the modified and non-modified fiber and PP matrix were analyzed by contact angle test and SEM images. The results indicate that the tensile and flexural strength of JF/PP composites increase with the increase of modified jute fiber content, while the impact strength decreases because the interfacial adhesion between jute fiber and polypropylene matrix is enhanced by modifying jute fiber with amino silicone oil. It is also found from the analyses of DSC, heat deflection temperature and linear expansion coefficient that the addition of modified JF can promote the heterogeneous nucleation of PP and hindered the mobility of PP molecular chain, which lead to the enhancement of the heat resistance property of modified JF/PP composites. The higher the fiber content, the higher heat resistance property of the modified JF/PP will be. When the content of modified JF is 25wt%, the heat deflection temperature of the modified JF/PP is 142.5 ℃, which is 53.5% higher than that of pure PP. Meanwhile, the linear expansion coefficient (CLE) of the modified JF/PP composites decrease significantly with the increase of fiber addition, which suggests that the fiber addition can significantly improve the thermal dimensional stability of the modified JF/PP composites. The linear expansion coefficients of pure PP and the modified JF/PP composites present anisotropic feature. Compared with pure PP, when the fiber addition is 25wt%, the linear expansion coefficientsof the composites decrease by 73.2% in the parallel flow direction and 14.4% in the vertical flow direction. The better mechanical and thermal properties of the modified JF/PP composites will achieve when the fiber addition is in range of 15wt%-20wt%.

-

表 1 PP及改性JF/PP复合材料的DSC测试结果

Table 1. DSC test results of PP and the modified JF/PP composites

Terms Mass fraction of JF/wt% 0 10 15 20 25 Tm/℃ 165.86±0.26 166.88±0.42 167.37±0.17 167.54±0.19 167.79±0.30 Tc/℃ 121.15±0.14 121.28±0.09 121.65±0.23 122.29±0.16 122.37±0.25 ΔHm/(J·g−1) 87.99±0.44 78.78±0.35 73.74±0.56 68.89±0.37 63.32±0.41 Xc/% 42.10±0.21 41.83±0.18 41.45±0.31 41.14±0.22 40.34±0.26 Notes: Tm—Melting temperature; Tc—Cold crystallization temperature; ΔHm—Melting enthalpy; Xc—Crystallinity; Data are tested mean value ± standard deviation. 表 2 JF/PP复合材料在平行与垂直流道方向的CLE对比

Table 2. Comparing the CLE results of the modified JF/PP composites in the parallel and vertical flow directions

CLE/(10−6 K−1) Mass fraction of JF/wt% 0 10 15 20 25 Vertical direction 154.7±3.2 145.5±2.6 140.1±2.4 136.6±1.0 132.4±1.9 Parallel direction 130.2±2.1 62.1±1.1 57.6±1.8 46.2±2.5 34.8±1.3 Difference between vertical to parallel directions 24.5±5.3 83.4±3.8 82.5±4.2 90.4±3.6 97.6±3.2 -

[1] WANG J, WU Q, LIU J, et al. Vehicle emission and atmospheric pollution in China: Problems, progress, and prospects[J]. PeerJ,2019,7:e6932-e6953. doi: 10.7717/peerj.6932 [2] SANTOS J, GOUVEIA R M, SILVA F. Designing a new sustainable approach to the change for lightweight materials in structural components used in truck industry[J]. Journal of Cleaner Production,2017,164(15):115-123. [3] SELLITTO A, RICCIO A, MAGNO G, et al. Feasibility study on the redesign of a metallic car hood by using composite materials[J]. International Journal of Automotive Technology,2020,21(2):471-479. doi: 10.1007/s12239-020-0044-5 [4] SHA H A J S, PATIL P P. A review on natural fiber composites[J]. Journal of Xidian University,2020,14(6):2844-2849. doi: 10.37896/jxu14.6/332 [5] 王春红, 鹿超, 贾瑞婷, 等. 洋麻纤维-棉纤维混纺织物/环氧树脂复合材料力学及吸湿性能[J]. 复合材料学报, 2020, 37(7):1581-1589. doi: 10.13801/j.cnki.fhclxb.20191226.002WANG Chunhong, LU Chao, JIA Ruiting, et al. Moisture absorption and mechanical properties of kenaf fiber-cotton fiber blended fabric/epoxy composite[J]. Acta Materiae Compositae Sinica,2020,37(7):1581-1589(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191226.002 [6] HE L, LI W, CHEN D, et al. Effects of amino silicone oil modification on properties of ramie fiber and ramie fiber/polypropylene composites[J]. Materials & Design,2015,77(15):142-148. [7] AGARWAL J, SAHOO S, MOHANTY S, et al. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review[J]. Journal of Thermoplastic Composite Materials,2020,33(7):978-1013. doi: 10.1177/0892705718815530 [8] HE L, XIA F, WANG Y, et al. Mechanical and dynamic mechanical properties of the amino silicone oil emulsion modified ramie fiber reinforced composites[J]. Polymers,2021,13(23):4083-4098. doi: 10.3390/polym13234083 [9] 孙宏雨, 吕兴聪, 袁纳新, 等. 基于响应曲面法的木塑复合材料强度分析及挤出工艺优化[J]. 复合材料学报, 2021, 38(6):1838-1846. doi: 10.13801/j.cnki.fhclxb.20200810.001SUN Hongyu, LV Xingcong, YUAN Naxin, et al. Strength analysis and extrusion process optimization of wood-plastic composite by response surface method[J]. Acta Materiae Compositae Sinica,2021,38(6):1838-1846(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200810.001 [10] KUMAR R, SUBRAMANINAN H S. Experimental and microstructural evaluation on mechanical properties of sisal fiber reinforced biocomposites[J]. Steel and Composite Structures,2019,33(2):299-306. [11] HE L, LI W, CHEN D, et al. Microscopic mechanism of amino silicone oil modification and modification effect with different amino group contents based on molecular dynamics simulation[J]. Applied Surface Science,2018,440:331-340. doi: 10.1016/j.apsusc.2018.01.101 [12] 那景新, 高原, 慕文龙, 等. 高温老化对玄武岩纤维增强树脂复合材料-铝合金单搭接接头失效的影响[J]. 复合材料学报, 2020, 37(1):140-146.NA Jingxin, GAO Yuan, MU Wenlong, et al. Effect of high temperature exposure on adhesively bonded basalt fiber reinforced polymer composite-aluminum alloy single lap joints[J]. Acta Materiae Compositae Sinica,2020,37(1):140-146(in Chinese). [13] 吴国峰, 雷亮, 杨波, 等. 车用聚丙烯材料线性膨胀系数的影响因素分析[J]. 工程塑料应用, 2017, 45(3):134-137. doi: 10.3969/j.issn.1001-3539.2017.03.030WU Guofeng, LEI Liang, YANG Bo, et al. Analysis on influence factors of linear expansion coefficient of automotive polypropylene materials[J]. Engineering Plastics Application,2017,45(3):134-137(in Chinese). doi: 10.3969/j.issn.1001-3539.2017.03.030 [14] 徐俊杰, 郝笑龙, 周海洋, 等. 超高填充聚丙烯基木塑复合材料高低温性能[J]. 复合材料学报, 2021, 38(12):4106-4122. doi: 10.13801/j.cnki.fhclxb.20210317.002XU Junjie, HAO Xiaolong, ZHOU Haiyang, et al. High- and low-temperature performance of ultra-highly filled polypropylene-based wood plastic composite[J]. Acta Materiae Compositae Sinica,2021,38(12):4106-4122(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210317.002 [15] GUILLOU J, LAVADIYA D N, MUNRO T, et al. From lignocellulose to biocomposite: Multi-level modelling and experimental investigation of the thermal properties of kenaf fiber reinforced composites based on constituent materials[J]. Applied Thermal Engineering,2018,128:1372-1381. doi: 10.1016/j.applthermaleng.2017.09.095 [16] SILVA T, PHPMD S, RIBEIRO M P, et al. Thermal and chemical characterization of kenaf fiber (Hibiscus cannabinus) reinforced epoxy matrix composites[J]. Polymers,2021,13(12):2016. doi: 10.3390/polym13122016 [17] GHANBARI A, SADAT JALILI N, HADDADI S A, et al. Mechanical properties of extruded glass fiber reinforced thermoplastic polyolefin composites[J]. Polymer Composites,2020,41(9):3748-3757. doi: 10.1002/pc.25672 [18] 韩松芬, 李阳, 何敏, 等. 聚乳酸基复合材料耐热改性研究进展[J]. 工程塑料应用, 2019, 47(6):143-147. doi: 10.3969/j.issn.1001-3539.2019.06.027HAN Songfen, LI Yang, HE Min, et al. Research progress on heat resistant modification of PLA matrix composites[J]. Engineering Plastics Application,2019,47(6):143-147(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.06.027 [19] ORUE A, ANAKABE J, ZALDUA-HUICI A M, et al. Preparation and characterization of composites based on poly(lacticacid)/poly(methyl methacrylate) matrix and sisal fiber bundles: The effect of annealing process[J]. Journal of Thermoplastic Composite Materials,2022,35(8):1132-1153. doi: 10.1177/0892705720930780 [20] CHEN X, REN J, LI J B, et al. Effects of heat treatment on the thermal and mechanical properties of ramie fabric-reinforced poly(lactic acid) bio-composites[J]. Journal of Reinforced Plastics and Composites,2015,34(1):28-36. doi: 10.1177/0731684414562222 [21] 展江湖, 王迎宵, 杨志浩, 等. 苎麻纤维增强聚乳酸复合材料性能研究[J]. 工程科学学报, 2021, 43(7):952-959.ZHAN Jianghu, WANG Yingxiao, YANG Zhihao, et al. Effect of fiber content on the properties of ramie fiber reinforced poly(lacticacid) composites[J]. Chinese Journal of Engineering,2021,43(7):952-959(in Chinese). [22] 陈明思, 李文军, 何莉萍. 一种生物质纤维处理剂及其制备方法: 中国, 201611053293.5[P]. 2019-1-29.CHEN Mingsi, LI Wenjun, HE Liping. A kind of biomass fiber treatment agent and its preparation method: China, 201611053293.5[P]. 2019-1-29(in Chinese). [23] 中国国家标准化管理委员会. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for tensile properties of fiber reinforced plastics: GB/T 1447—2005[S]. Beijing: China Standards Press, 2005 (in Chinese). [24] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for bending properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [25] 中国国家标准化管理委员会. 纤维增强塑料冲击性能试验方法: GB/T 1451—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for impact properties of fiber reinforced plastics: GB/T 1451—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [26] 李浩, 宋永明, 王海刚, 等. 滑石粉对微孔发泡木粉/聚丙烯复合材料结晶行为及泡孔结构的影响[J]. 复合材料学报, 2017, 34(8):1636-1644.LI Hao, SONG Yongming, WANG Haigang, et al. Influence of talc on crystallization behavior and cellular structure of microcellular foamed wood flour/PP composites[J]. Acta Materiae Compositae Sinica,2017,34(8):1636-1644(in Chinese). [27] 中国国家标准化管理委员会. 塑料 负荷变形温度的测定 第1部分: 通用试验方法: GB/T 1634.1—2019 [S]. 北京: 中国标准出版社, 2019.Standardization Administration of the People’s Republic of China. Plastics—Determination of temperature of deflection under load—Part 1: General test method: GB/T 1634.1—2019[S]. Beijing: China Standards Press, 2019 (in Chinese). [28] 中国国家标准化管理委员会. 纤维增强塑料平均线膨胀系数试验方法: GB/T 2572—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastics composites—Determination for mean coefficient of linear expansion: GB/T 2572—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [29] ALI A, SHAKER K, NAWAB Y, et al. Hydrop-hobic treatment of natural fibers and their composites-A review[J]. Journal of Industrial Textiles,2018,47(8):2153-2183. doi: 10.1177/1528083716654468 [30] LI G, YUE J, GUO C, et al. Influences of modified nanoparticles on hydrophobicity of concrete with organic film coating[J]. Construction and Building Materials,2018,169:1-7. doi: 10.1016/j.conbuildmat.2018.02.191 [31] ASIM M, JAWAID M, FOUAD H, et al. Effect of surface modified date palm fibre loading on mechanical, thermal properties of date palm reinforced phnolic composites[J]. Composite Structures,2021,267(2):113913. [32] 刘运学, 田鑫, 范兆荣, 等. 聚丙烯/剑麻纤维复合材料的制备与性能研究[J]. 塑料科技, 2018, 46(5):49-52. doi: 10.15925/j.cnki.issn1005-3360.2018.05.007LIU Yunxue, TIAN Xin, FAN Zhaorong, et al. Preparation and properties of sisal fiber/polypropylene composites[J]. Plastics Science and Technology,2018,46(5):49-52(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2018.05.007 [33] LOPATTANANON N, PAYAE Y, SEADAN M. Influence of fiber modification on interfacial adhesion and mechanical properties of pineapple leaf fiber-epoxy composites[J]. Journal of Applied Polymer Science,2008,110(1):433-443. doi: 10.1002/app.28496 [34] PENGFEI N, XIAOJUN W, BAOYING L, et al. Melting and nonisothermal crystallization behavior of polypropylene/hemp fiber composites[J]. Journal of Composite Materials,2012,46(2):203-210. doi: 10.1177/0021998311410494 [35] 刘一楠, 刘珊杉, 郭文静. 木纤维尺寸对聚乳酸结晶特性的影响[J]. 西南林业大学学报(自然科学), 2017, 37(2):184-191.LIU Yi'nan, LIU Shanshan, GUO Wenjing. Effects of wood fibre size on crystallization morphology of poly(lactic acid)[J]. Journal of Southwest Forestry University (Natural Science),2017,37(2):184-191(in Chinese). [36] ZHANG A, ZHAO G, CHAI J, et al. Crystallization and mechanical properties of glass fiber reinforced polypropylene composites molded by rapid heat cycle molding[J]. Fibers and Polymers,2020,21(12):2915-2926. doi: 10.1007/s12221-020-1284-8 [37] LUO H, ZHANG C, XIONG G, et al. Effects of alkali and alkali/silane treatments of corn fibers on mechanical and thermal properties of its composites with polylactic acid[J]. Polymer Composites,2016,37(12):3499-3507. doi: 10.1002/pc.23549 [38] 王经武. 塑料改性技术[M]. 北京: 化学工业出版社, 2004: 798-823.WANG Jingwu. Plastic modification technology[M]. Beijing: Chemical Industry Press, 2004: 798-823. [39] MONROE J A, GEHRING D, KARAMAN I, et al. Tailored thermal expansion alloys[J]. Acta Materialia,2016,102:333-341. doi: 10.1016/j.actamat.2015.09.012 [40] 付鹏, 崔吉吉, 于艺博, 等. 硅灰石填充改性尼龙1212复合材料的制备[J]. 高分子材料科学与工程, 2014, 30(4):154-157. doi: 10.16865/j.cnki.1000-7555.2014.04.032FU Peng, CUI Jiji, YU Yibo, et al. Preparation of nylon1212/wollastonite composites[J]. Polymer Materials Science and Engineering,2014,30(4):154-157(in Chinese). doi: 10.16865/j.cnki.1000-7555.2014.04.032 [41] XIE Y, XIAO Z, MILITZ H, et al. Silane coupling agents used in natural fiber/plastic composites[J]. Handbook of Composites from Renewable Materials, Functionalization,2017,4(407):1219-1228. [42] LI F, QU C B, HUA Y, et al. Largely improved dimensional stability of short carbon fiber reinforced polyether sulfone composites by graphene oxide coating at a low content[J]. Carbon,2017,119:339-349. doi: 10.1016/j.carbon.2017.04.056 -

下载:

下载: