Damage failure mechanism of unidirectional fiber reinforced SiCf/SiC composites under uniaxial tension

-

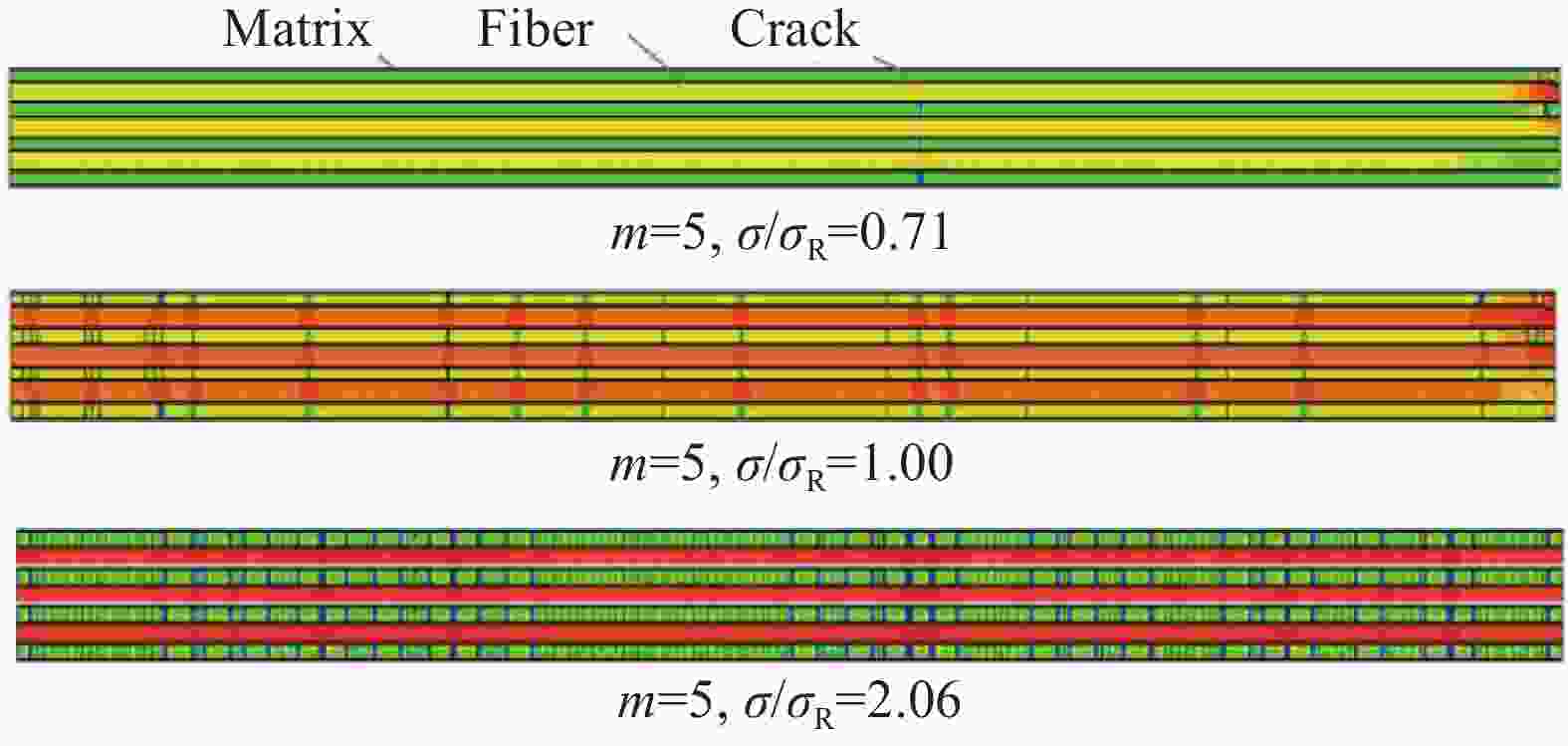

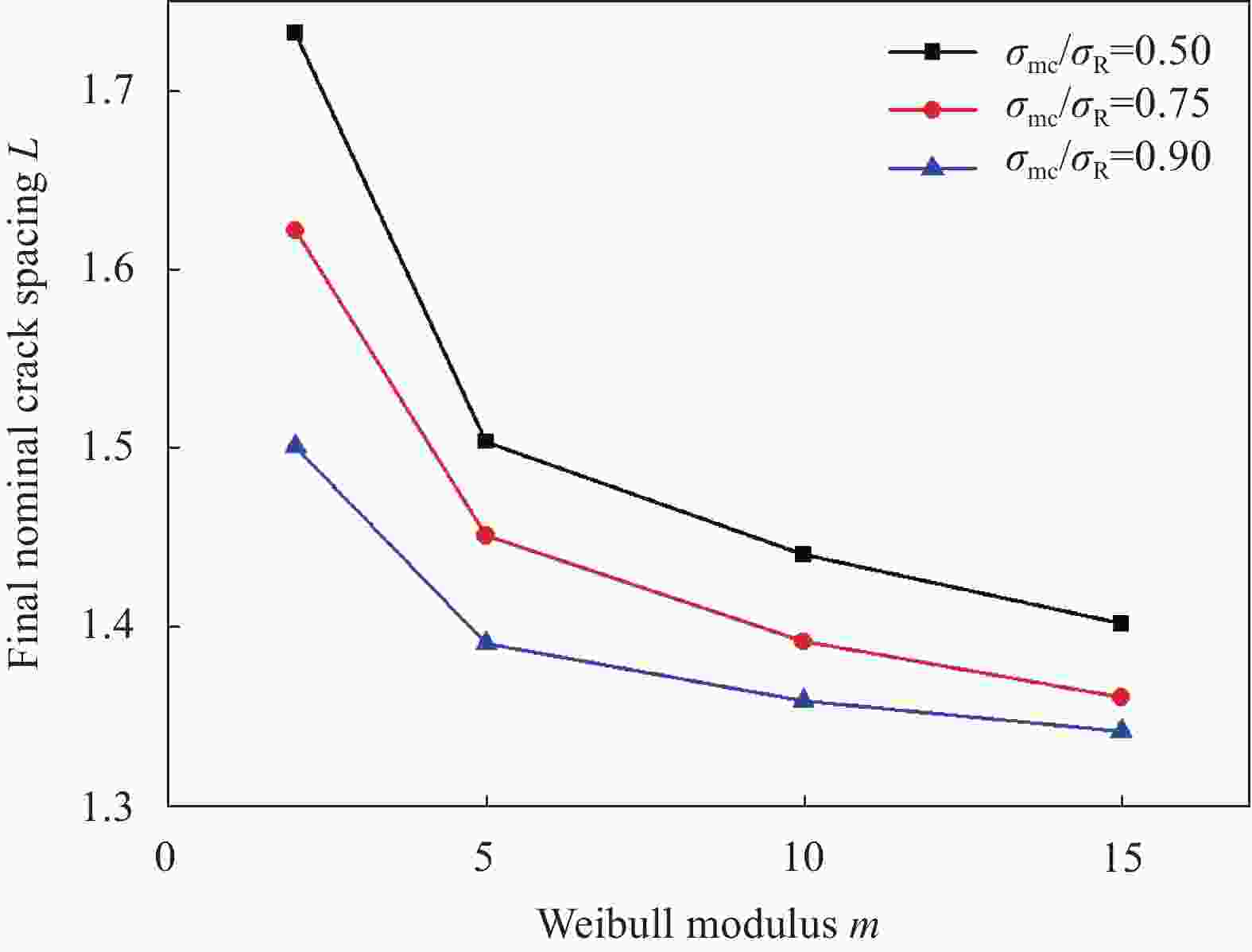

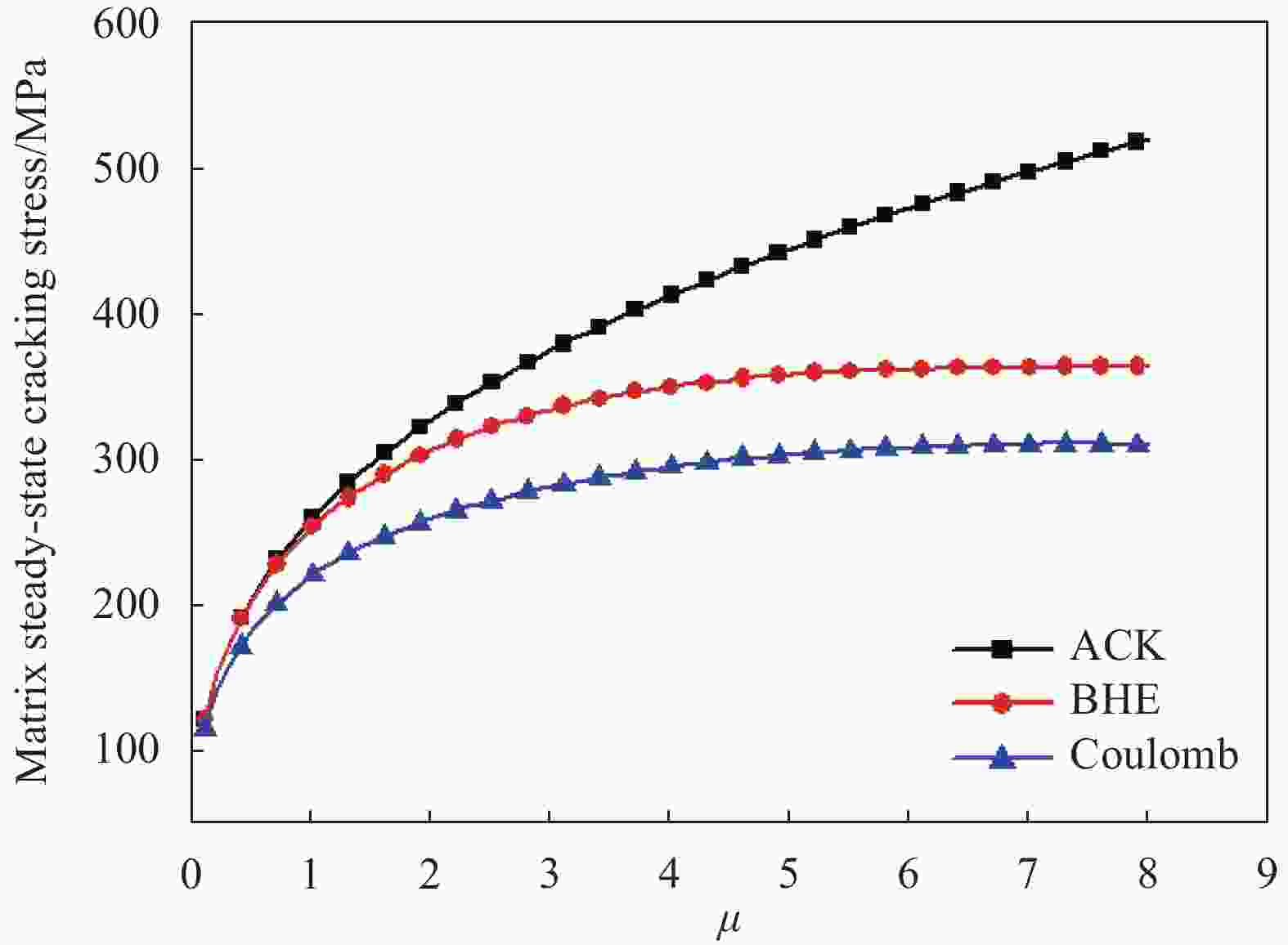

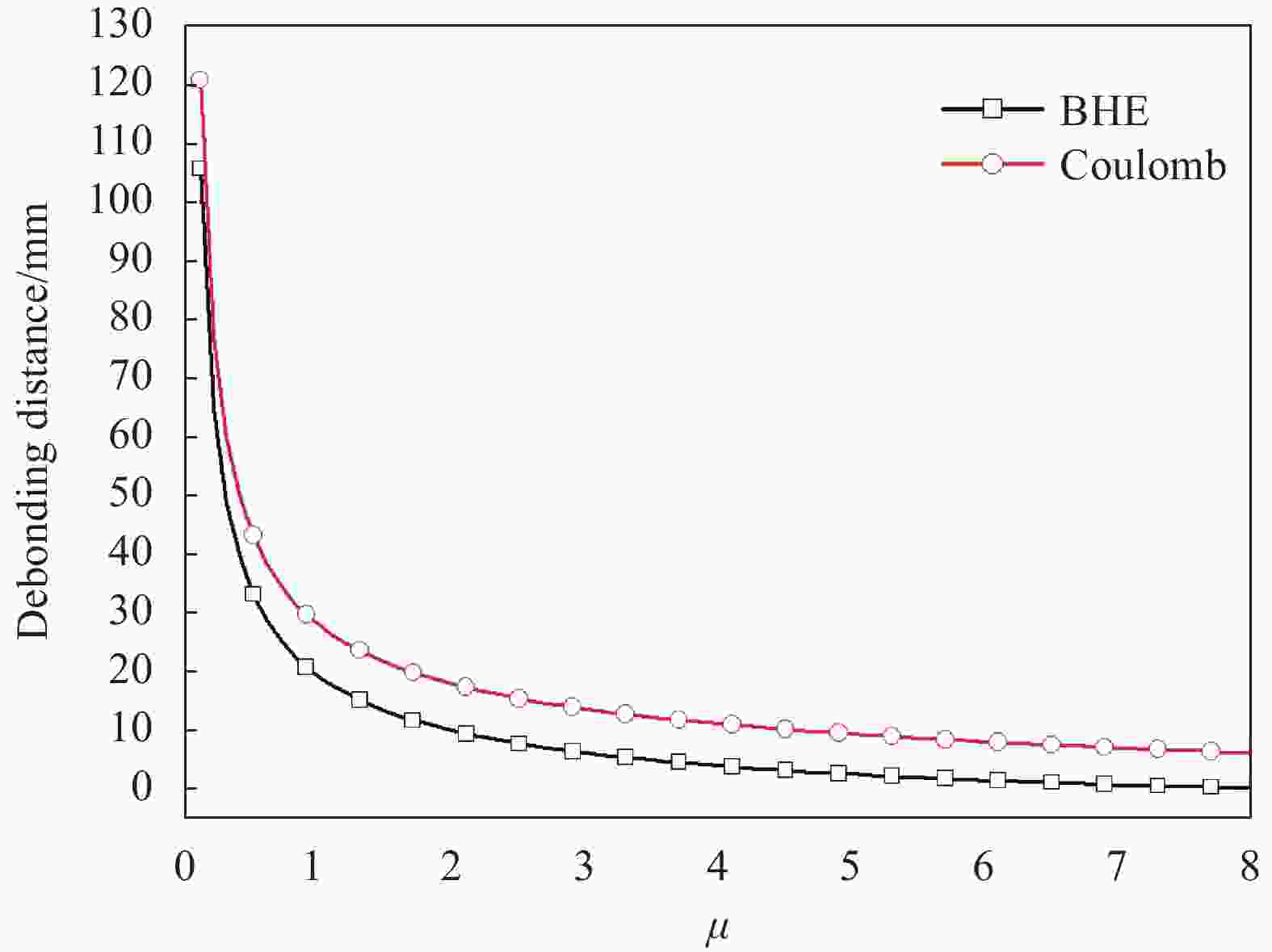

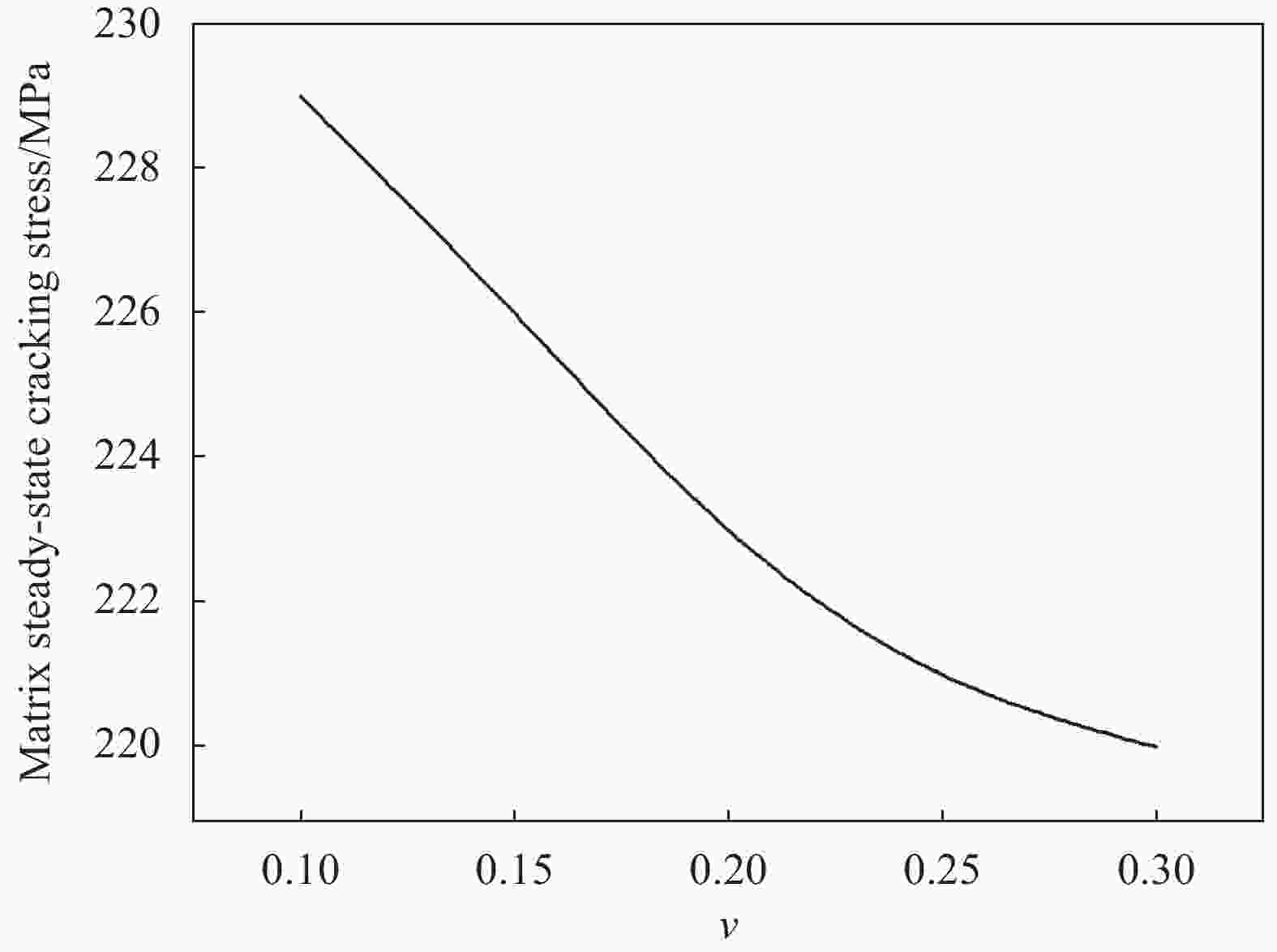

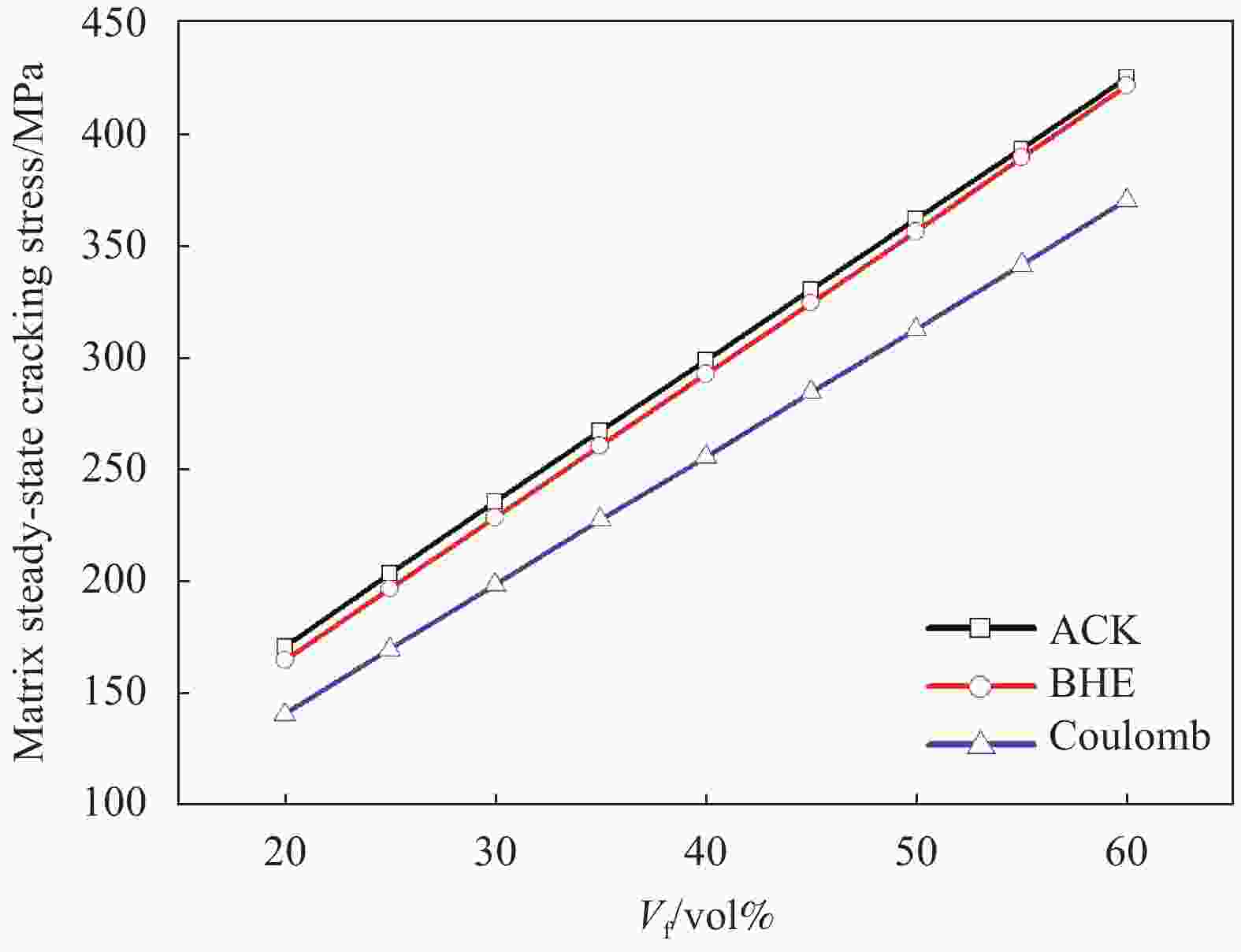

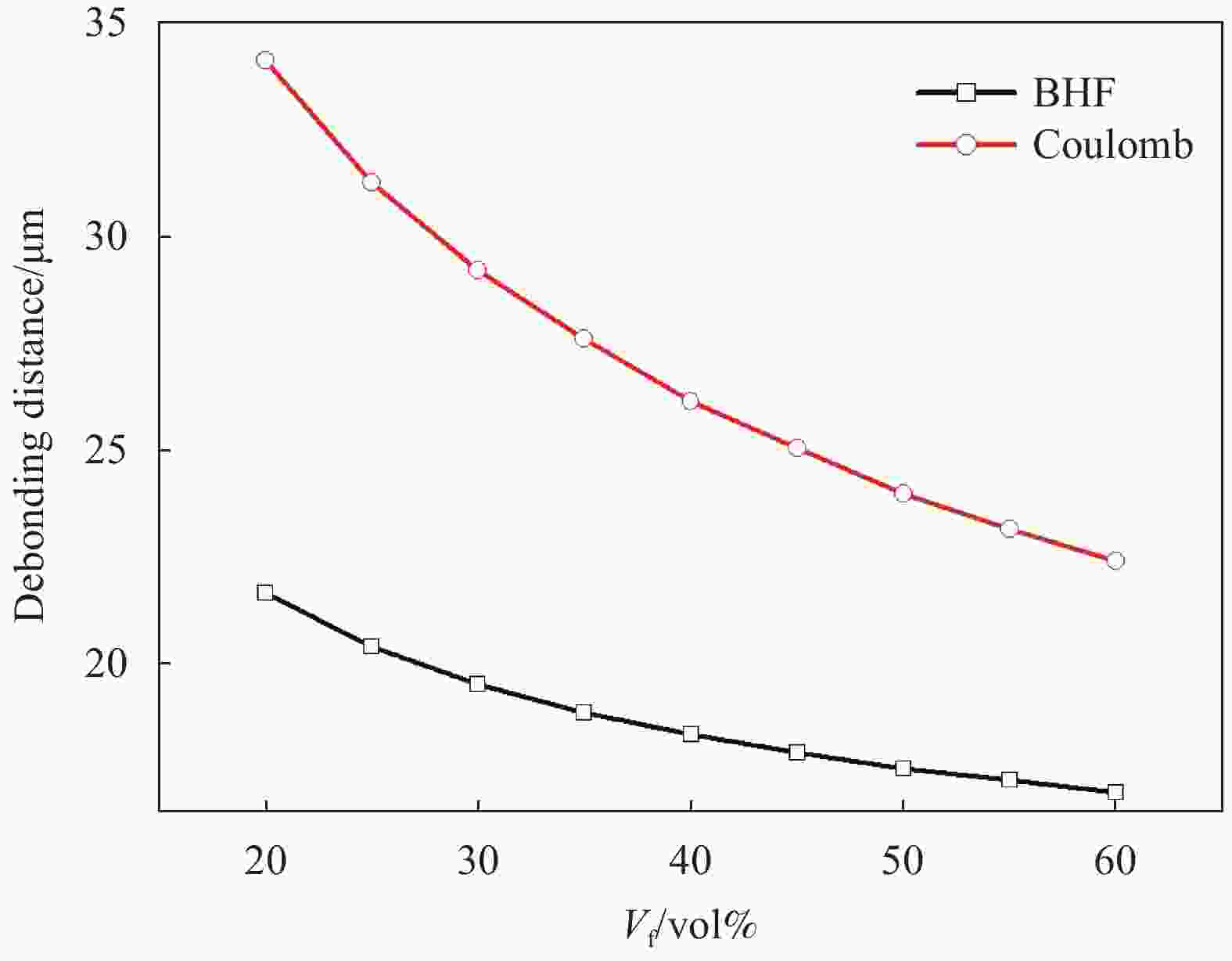

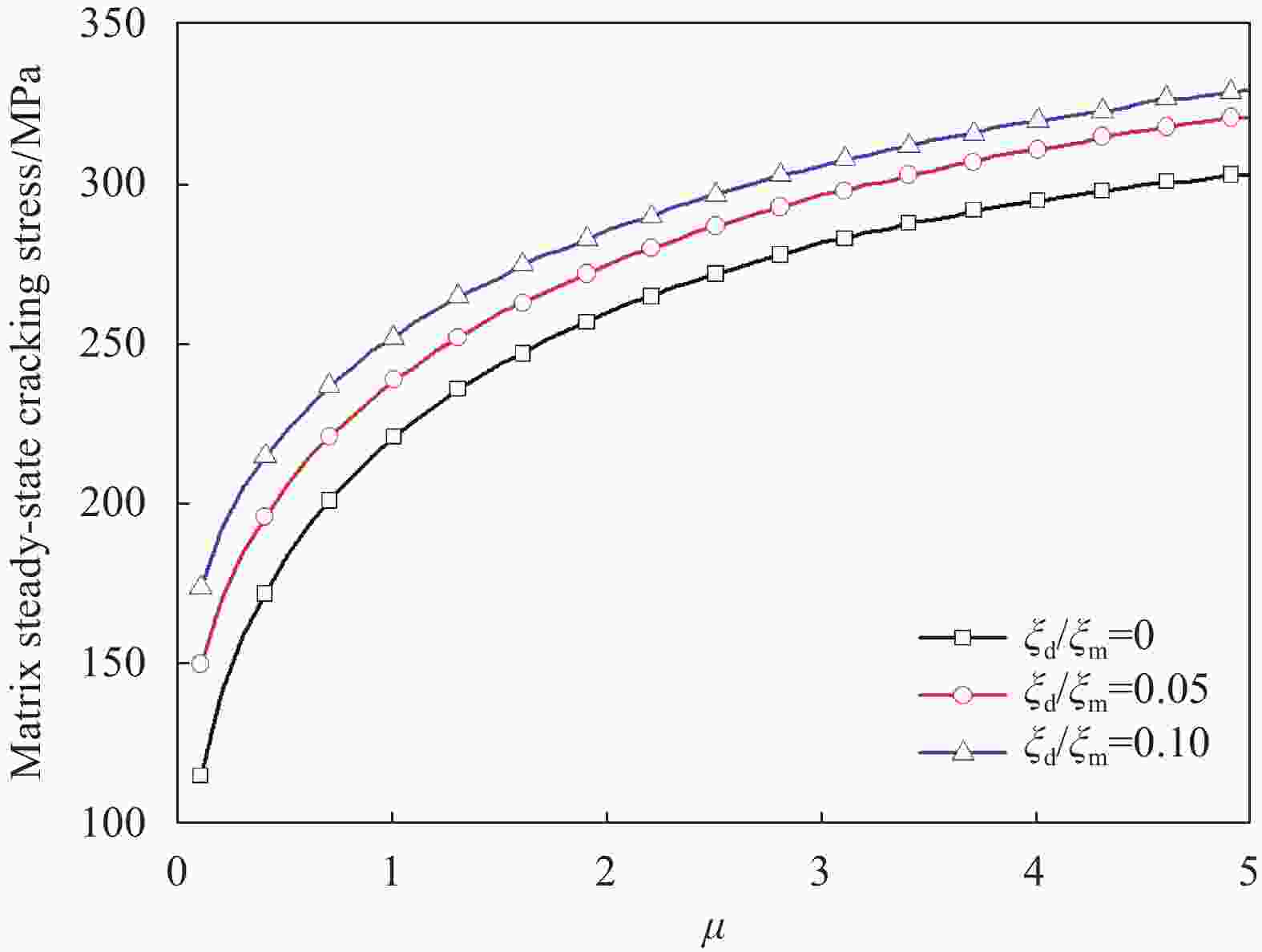

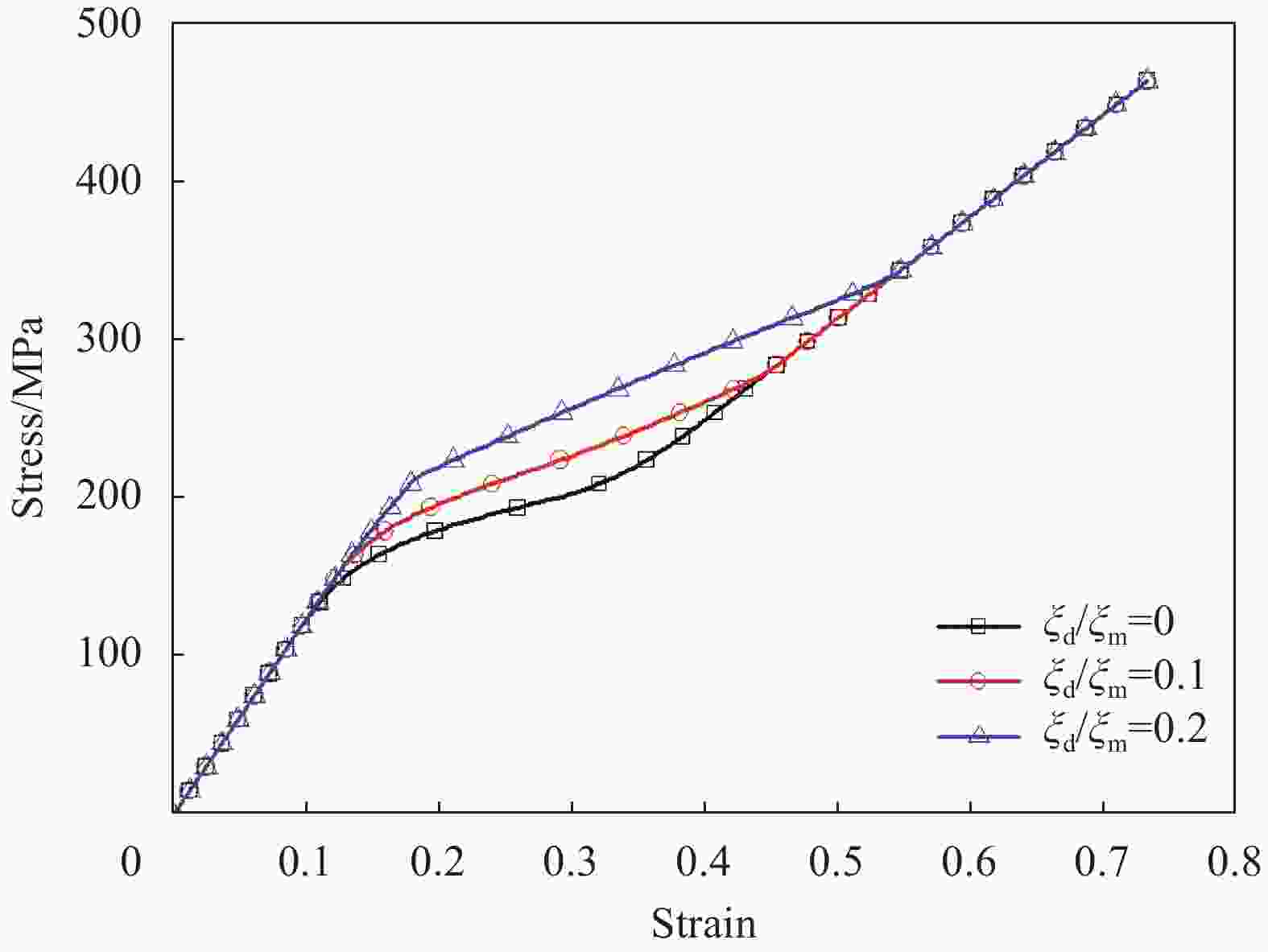

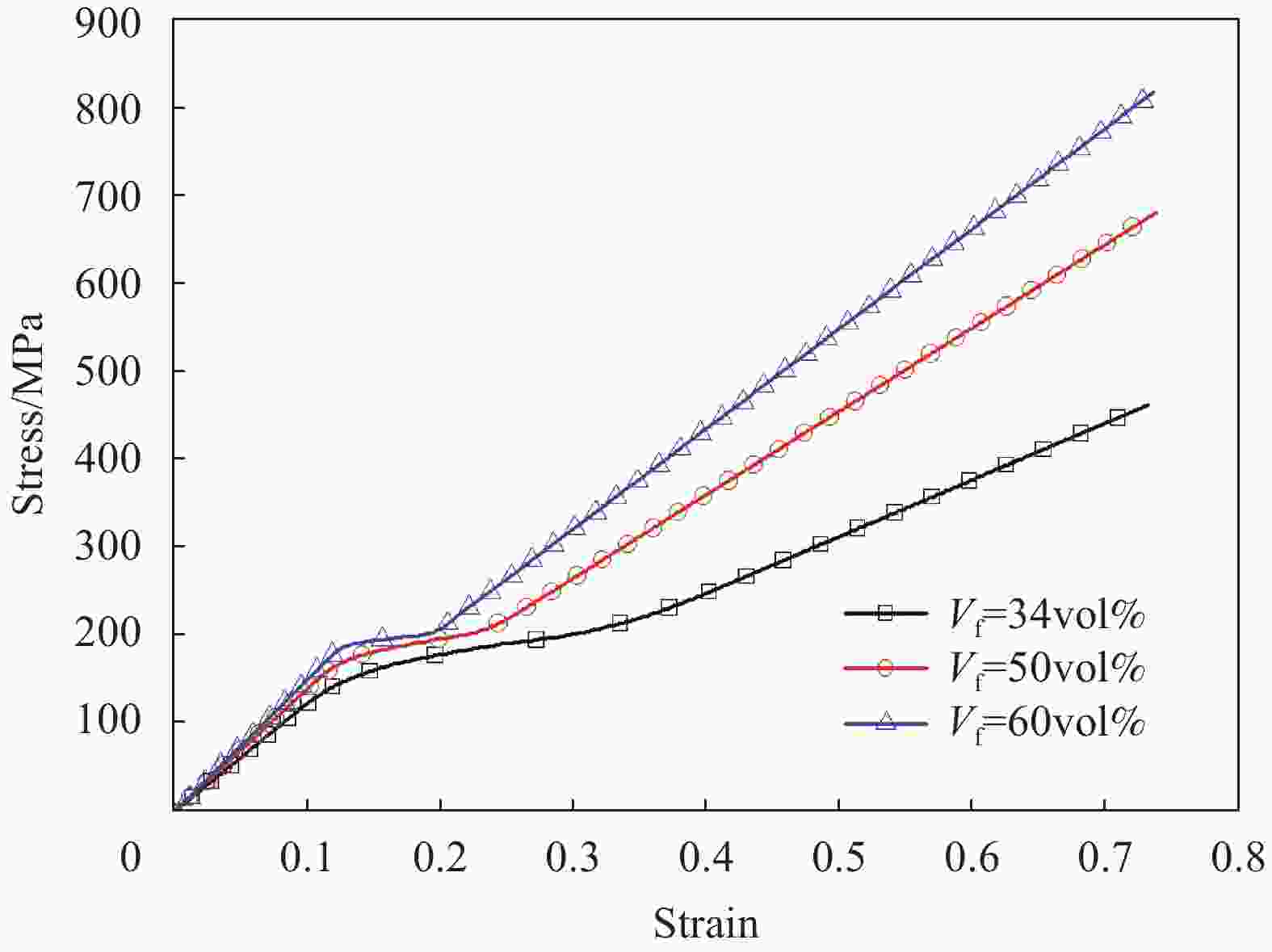

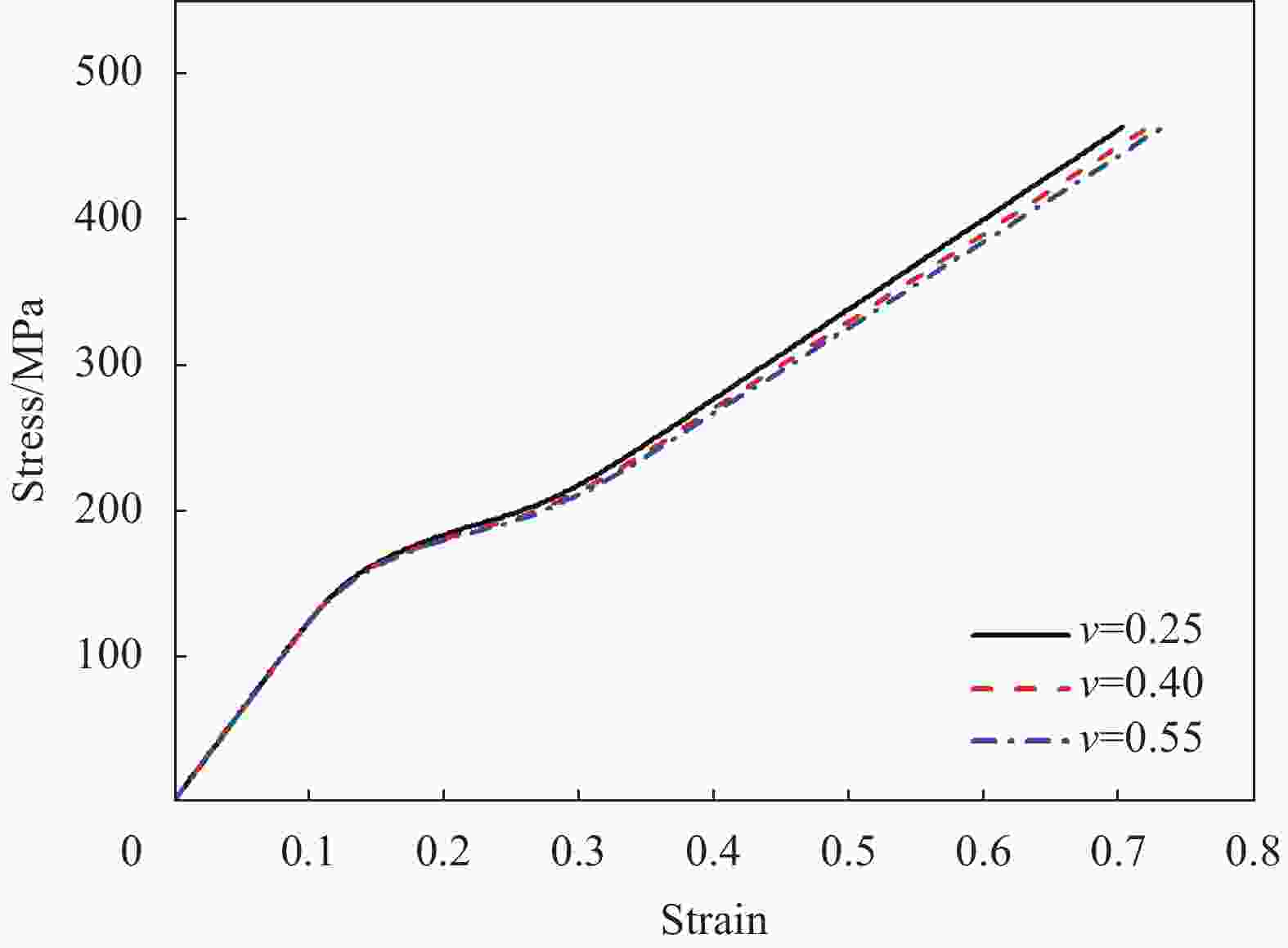

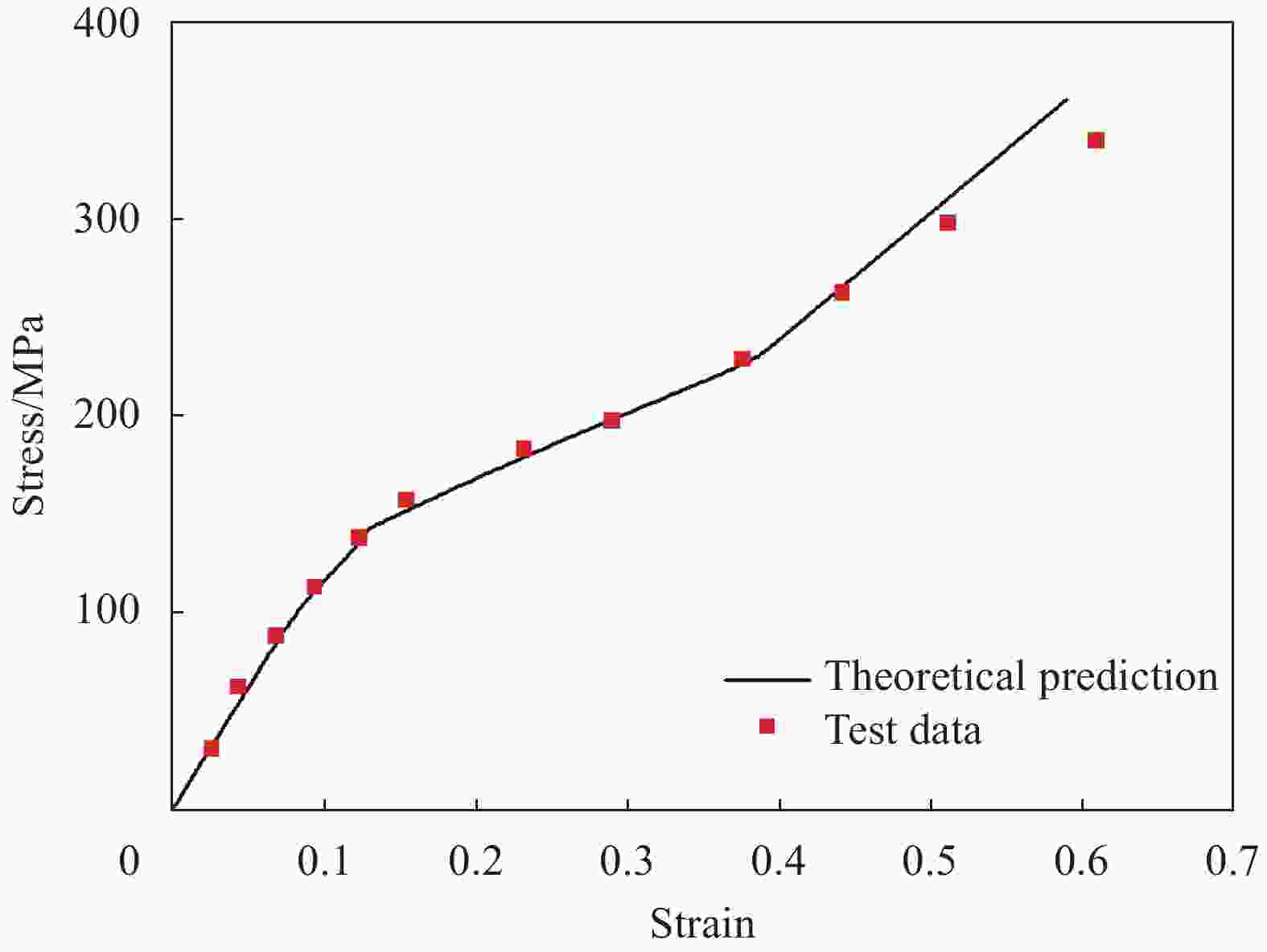

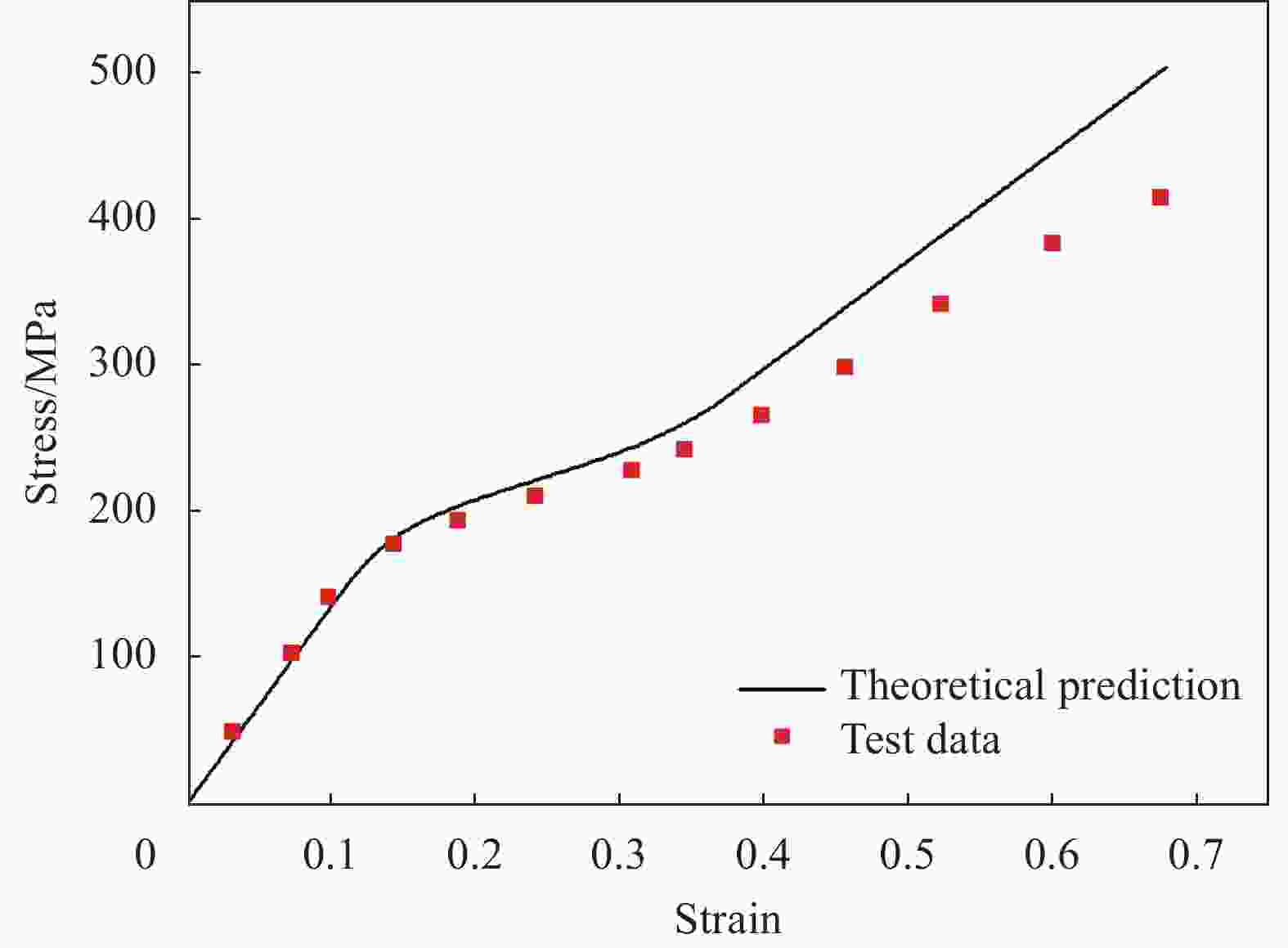

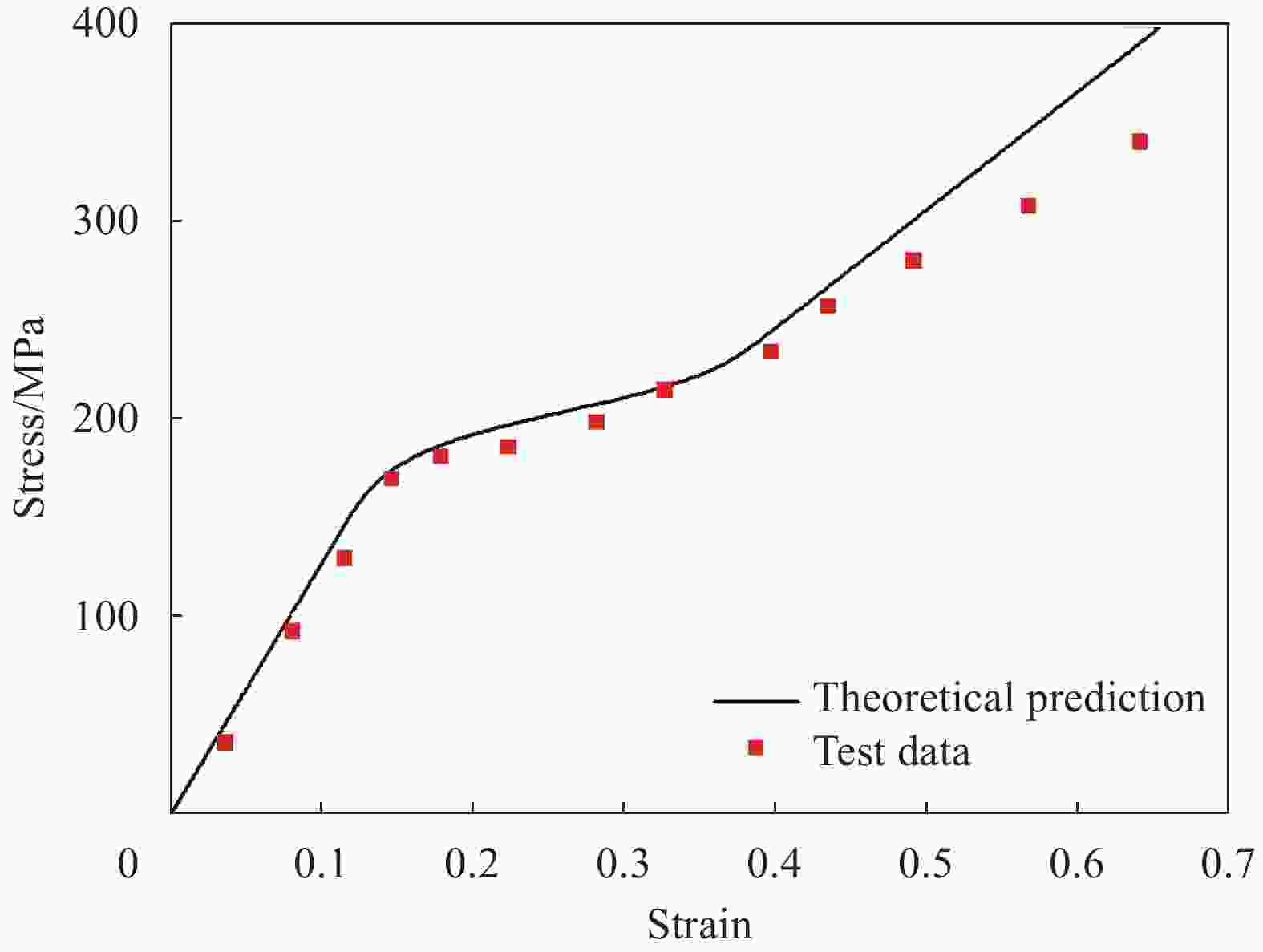

摘要: 本文对纤维增强陶瓷基复合材料在单向载荷下的损伤失效机制进行了研究。根据常规的剪滞模型,引入库仑定律描述界面剪应力,根据能量平衡方法和断裂力学脱粘准则,计算了基体的稳态开裂应力和界面的脱粘长度。分析了不同剪滞模型下基体稳态开裂应力的区别和适用范围,讨论了界面剪应力、界面摩擦系数、界面脱粘能、纤维体积分数等对基体稳态开裂应力的影响。采用剪滞模型描述纤维增强陶瓷基复合材料在损伤后的细观结构应力场,根据基体裂纹随机演化方法确定基体裂纹的间距,根据断裂力学脱粘准则描述界面的脱粘行为,将剪滞模型和损伤模型结合预测了单向纤维增强陶瓷基复合材料在单轴载荷下的应力-应变曲线,讨论了各因素对应力-应变曲线的影响。Abstract: This paper studied the damage failure mechanism of fiber-reinforced ceramic composites under unidirectional loading. According to the conventional shear-lag model, Coulomb’s law was introduced to describe the interfacial shear stress. According to the energy balance method and the debonding criterion of fracture mechanics, the steady-state cracking stress of the matrix and the debonding length of the interface were calculated. The difference and applicable range of the steady-state cracking stress of the matrix under different shear lag models were analyzed, and the effects of the interfacial shear stress, the interfacial friction coefficient, the interfacial debonding energy, and the fiber volume fraction on the steady-state cracking stress of the matrix were discussed. The shear lag model was used to describe the microstructure stress field of the fiber-reinforced ceramic composites after damage, the distance between the matrix cracks was determined according to the random evolution method of matrix cracks, and the debonding behavior of the interface was described according to the fracture mechanics debonding criterion. Combined with the damage model, the stress-strain curve of unidirectional fiber-reinforced ceramic composites under unidirectional load was predicted, and the influence of various factors on the stress-strain curve was discussed.

-

Key words:

- ceramic composites /

- continuous fiber reinforced /

- shear-lag model /

- fiber debonding /

- matrix cracking

-

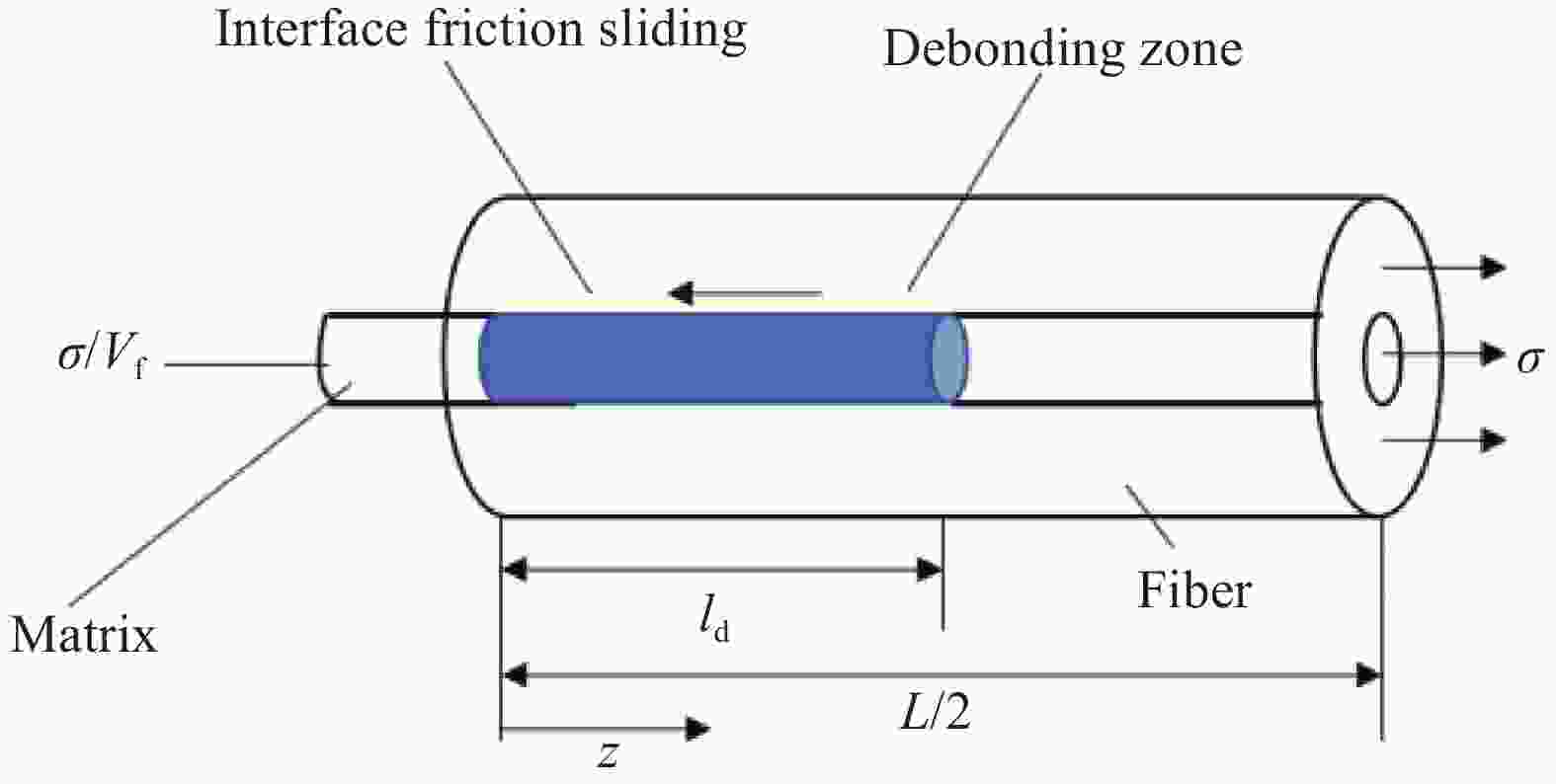

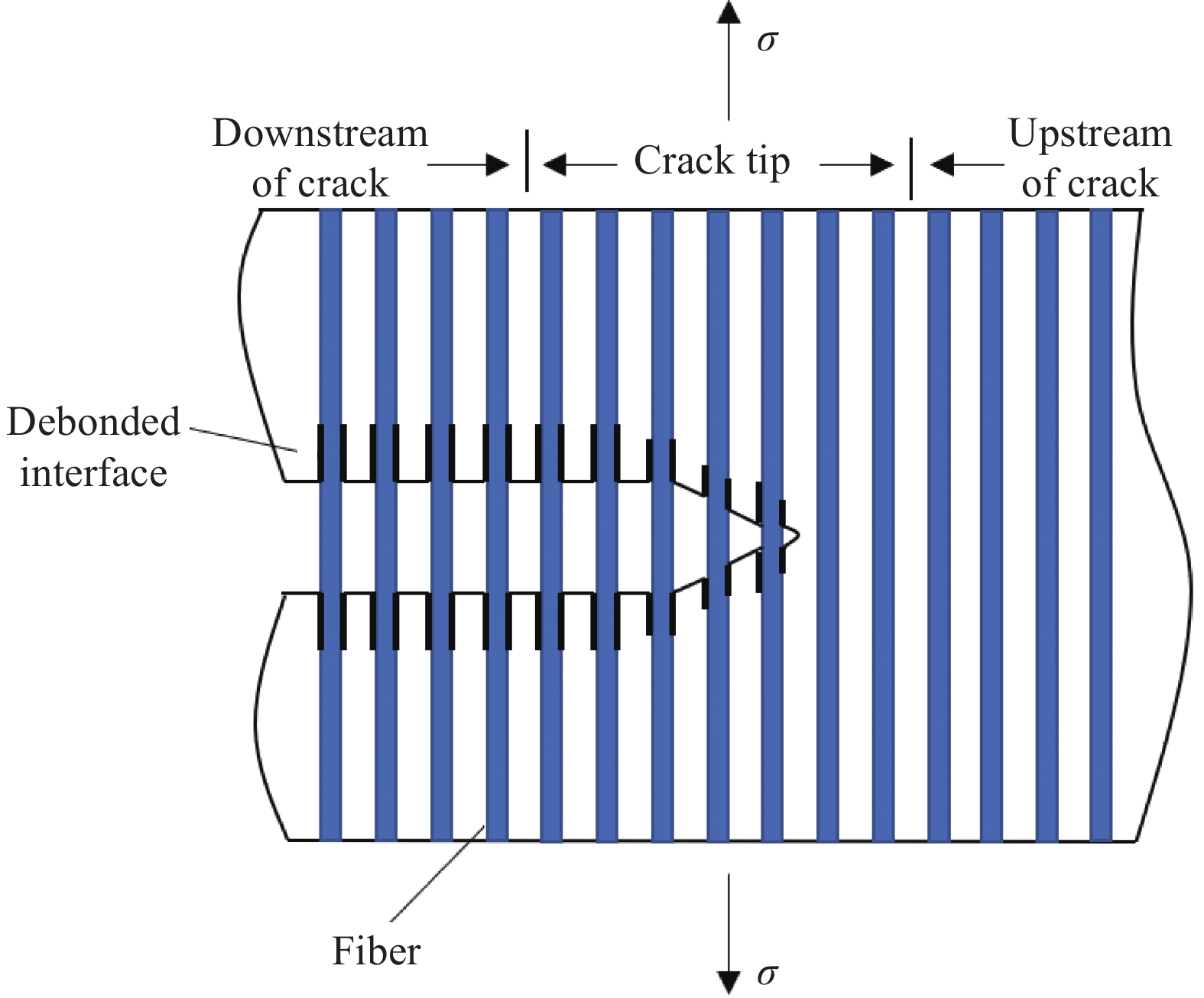

图 2 纤维增强陶瓷基复合材料裂纹尾迹桥连纤维等效体积单元示意图

Figure 2. Schematic diagram of representative volume element of fiber-reinforced ceramic composites with crack wake bridging fiber

Vf—Fiber volume fraction; v(0)—Relative displacement function; $\overline R$—Effective radius; r—Radial direction; θ—Tangents; z—Axial direction; ld—Debonding length; L—Matrix crack spacing; τi—Interfacial frictional shear stress

表 1 单向纤维增强陶瓷基复合材料(CMCs)各组分参数

Table 1. Parameters of constituents of unidirectional fiber reinforced ceramic matrix composites (CMCs)

SiC/CAS[24,38] SiC/CAS[24,39] SiC/CAS-II[24,40] Radius of the fiber a/μm 7.5 7.5 7.5 Fiber volume fraction Vf/vol% 34 37 30 Fibre elastic modulusEf /GPa 190 200 200 Elastic modulus of matrix Em/GPa 90 97 98 Fracture energy of matrix ξm/(J·m-2) 6 6 6 Debonding energy of interface ξd/(J·m-2) 0.8 0.4 0.4 Thermal expansion coefficient of fiber αf/℃−1 3.3×10−6 4×10−6 4×10−6 Thermal expansion coefficient of matrix αm/℃−1 4.6×10−6 5×10−6 5×10−6 Temperature difference between composite

preparation and working condition ΔT/℃−1000 −1000 −1000 Weibull modulus of matrix m 5 5 7 Constant frictional shear stress τs/MPa 10 15 20 Weibull modulus of fiber mf 3.6 3.6 3.0 Matrix characteristic strength σc/MPa 2.0 2.0 2.0 Final strength of composites σUTS/MPa

(Experiment)395 447 350 Final strength of composites σUTS/MPa

(Theory)464.76 505.77 399.63 Error/% 17.66 13.15 14.18 -

[1] 文生琼, 何爱杰. 陶瓷基复合材料在航空发动机热端部件上的应用[J]. 航空制造技术, 2009(S1):4-7. doi: 10.3969/j.issn.1671-833X.2009.z1.003WEN Shengqiong, HE Aijie. Application of ceramic matrix composites in aero-engine hot-end components[J]. Aviation Manufacturing Technology,2009(S1):4-7(in Chinese). doi: 10.3969/j.issn.1671-833X.2009.z1.003 [2] SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling[J]. Journal of Nuclear Materials,2007,371(1-3):329-377. doi: 10.1016/j.jnucmat.2007.05.016 [3] UDAYAKUMAR A, SRI GANESH A, RAJA S, et al. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI[J]. Journal of the European Ceramic Society,2011,31(6):1145-1153. doi: 10.1016/j.jeurceramsoc.2010.12.018 [4] MADAR R. Materials science: Silicon carbide in contention[J]. Nature,2004,430(7003):974-975. doi: 10.1038/430974a [5] EVANS A G. Perspective on the development of high-toughness ceramics[J]. Journal of the American Ceramic Society,1990,73(2):187-206. doi: 10.1111/j.1151-2916.1990.tb06493.x [6] 袁钦, 宋永才. 连续SiC纤维和SiCf/SiC复合材料的研究进展[J]. 无机材料学报, 2016, 31(11):1157-1165. doi: 10.15541/jim20160119YUAN Qin, SONG Yongcai. Research progress of continuous SiC fibers and SiCf/SiC composites[J]. Journal of Inorganic Materials,2016,31(11):1157-1165(in Chinese). doi: 10.15541/jim20160119 [7] BHEEMREDDY V, CHANDRASHEKHARA K, DHARANI L R, et al. Computational study of micromechanical damage behavior in continuous fiber-reinforced ceramic composites[J]. Journal of Materials Science,2016,51(18):8610-8624. doi: 10.1007/s10853-016-0120-4 [8] LI L. Fatigue life prediction of fiber-reinforced ceramic-matrix composites with different fiber preforms at room and elevated temperatures[J]. Materials,2016,9(3):207. doi: 10.3390/ma9030207 [9] DICARLO J A. Advances in SiC/SiC composites for aero-propulsion[M]//BANSAL N P, LAMON J. HOBOKEN. Ceramic matrix composites: Materials, modeling and technology, New York: John Wiley & Sons., Inc., 2014: 217-235. [10] 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007, 24(2):1-6. doi: 10.3321/j.issn:1000-3851.2007.02.001ZHANG Litong, CHENG Laifei. Discussion on sustainable development strategy of continuous fiber toughened ceramic matrix composites[J]. Acta Materiae Compositae Sinica,2007,24(2):1-6(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.02.001 [11] 胡海峰, 张玉娣, 邹世钦, 等. SiC/SiC复合材料及其在航空发动机上的应用[J]. 航空制造技术, 2010(6):90-91. doi: 10.3969/j.issn.1671-833X.2010.06.021HU Haifeng, ZHANG Yudi, ZOU Shiqin, et al. SiC/SiC composite material and its application in aero-engine[J]. Aviation Manufacturing Technology,2010(6):90-91(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.06.021 [12] 邹世钦, 张长瑞, 周新贵, 等. 碳纤维增强SiC陶瓷复合材料的研究进展[J]. 高科技纤维与应用, 2003(2):15-20. doi: 10.3969/j.issn.1007-9815.2003.02.004ZOU Shiqin, ZHANG Changrui, ZHOU Xingui, et al. Research progress of carbon fiber reinforced SiC ceramic composites[J]. High-tech Fibers and Applications,2003(2):15-20(in Chinese). doi: 10.3969/j.issn.1007-9815.2003.02.004 [13] 方光武, 高希光, 宋迎东. 单向纤维增强陶瓷基复合材料界面滑移规律[J]. 复合材料学报, 2013, 30(4):101-107. doi: 10.13801/j.cnki.fhclxb.2013.04.023FANG Guangwu, GAO Xiguang, SONG Yingdong. Interfacial slip law of unidirectional fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica,2013,30(4):101-107(in Chinese). doi: 10.13801/j.cnki.fhclxb.2013.04.023 [14] BRAGINSKY M, PRZYBYLA C P. Simulation of crack propagation/deflection in ceramic matrix continuous fiber reinforced composites with weak interphase via the extended finite element method[J]. Composite Structures,2016,136:538-545. [15] MEYER P, WAAS A M. Mesh-objective two-scale finite element analysis of damage and failure in ceramic matrix composites[J]. Integrating Materials and Manufacturing Innovation,2015,4(1):63-80. doi: 10.1186/s40192-015-0034-z [16] GAO X, FANG G, SONG Y. Hysteresis loop model of unidirectional carbon fiber-reinforced ceramic matrix composites under an arbitrary cyclic load[J]. Composites Part B: Engineering,2014,56:92-99. doi: 10.1016/j.compositesb.2013.08.063 [17] 方光武, 高希光, 宋迎东. 多层界面相陶瓷基复合材料裂纹偏转机制模拟[J]. 航空动力学报, 2019, 34(8):1805-1812. doi: 10.13224/j.cnki.jasp.2019.08.021FANG Guangwu, GAO Xiguang, SONG Yingdong. Simulation of crack deflection mechanism of multi-layer interface phase ceramic matrix composites[J]. Journal of Aerodynamics,2019,34(8):1805-1812(in Chinese). doi: 10.13224/j.cnki.jasp.2019.08.021 [18] 杨成鹏, 矫桂琼, 王波. 界面性能对陶瓷基复合材料拉伸强度的影响[J]. 无机材料学报, 2009, 24(5):919-923. doi: 10.3724/SP.J.1077.2009.00919YANG Chengpeng, JIAO Guiqiong, WANG Bo. Influence of interface properties on tensile strength of ceramic matrix composites[J]. Journal of Inorganic Materials,2009,24(5):919-923(in Chinese). doi: 10.3724/SP.J.1077.2009.00919 [19] EVANS A G. Overview No.125 design and life prediction issues for high-temperature engineering ceramics and their composites[J]. Acta Materialia,1997,45(1):23-40. doi: 10.1016/S1359-6454(96)00143-7 [20] OKABE T, TAKEDA N, KOMOTORI J, et al. A new fracture mechanics model for multiple matrix cracks of SiC fiber reinforced brittle-matrix composites[J]. Acta Materialia,1999,47(17):4299-4309. doi: 10.1016/S1359-6454(99)00309-2 [21] KIM R Y, PAGANO N J. Crack initiation in unidirectional brittle-matrix composites[J]. Journal of the American Ceramic Society,1991,74(5):1082-1090. doi: 10.1111/j.1151-2916.1991.tb04346.x [22] BENT F S, TALREJA R. Analysis of damage in a ceramic matrix composite[J]. International Journal of Damage Mechanics,1993,2(3):246-271. doi: 10.1177/105678959300200305 [23] HOLMES J W, SHULER S F. Temperature rise during fatigue of fibre-reinforced ceramics[J]. Journal of Materials Science Letters,1990,9(11):1290-1291. doi: 10.1007/BF00726522 [24] 李龙彪. 长纤维增强陶瓷基复合材料疲劳损伤模型与寿命预测[D]. 南京: 南京航空航天大学, 2010.LI Longbiao. Fatigue damage model and life prediction of long fiber reinforced ceramic matrix composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010(in Chinese). [25] LI L. Modelling matrix multi-cracking evolution of fibre-reinforced ceramic-matrix composites considering fibre fracture[J]. Ceramics Silikaty,2019,63(1):21-31. doi: 10.13168/cs.2018.0042 [26] CURTIN W A. Theory of mechanical properties of ceramic-matrix composites[J]. Journal of the American Ceramic Society,1991,74(11):2837-2845. doi: 10.1111/j.1151-2916.1991.tb06852.x [27] CURTIN W A, AHN B K, TAKEDA N. Modeling brittle and tough stress-strain behavior in unidirectional ceramic matrix composites[J]. Acta Materialia,1998,46(10):3409-3420. doi: 10.1016/S1359-6454(98)00041-X [28] AHN B K, CURTIN W A, PARTHASARATHY T A, et al. Criteria for crack deflection/penetration criteria for fiber-reinforced ceramic matrix composites[J]. Composites Science and Technology,1998,58(11):1775-1784. doi: 10.1016/S0266-3538(98)00043-8 [29] SØRENSEN B F, TALREJA R, SØRENSEN O T. Micromechanical analysis of damage mechanisms in ceramic-matrix composites during mechanical and thermal cycling[J]. Composites,1993,24(2):129-140. doi: 10.1016/0010-4361(93)90009-W [30] AVESTON J, KELLY A. Theory of multiple fracture of fibrous composites[J]. Journal of Materials Science,1973,8(3):352-362. doi: 10.1007/BF00550155 [31] BUDIANSKY B, HUTCHINSON J W, EVANS A G. Matrix fracture in fiber-reinforced ceramics[J]. Journal of the Mechanics and Physics of Solids,1986,34(2):167-189. doi: 10.1016/0022-5096(86)90035-9 [32] CHIANG Y. On fiber debonding and matrix cracking in fiber-reinforced ceramics[J]. Composites Science and Technology,2001,61(12):1743-1756. doi: 10.1016/S0266-3538(01)00078-1 [33] GAO Y C, MAI Y W, COTTERELL B. Fracture of fiber-reinforced materials[J]. Journal of Applied Mathematics and Physics,1988,39(4):550-572. [34] HUTCHINSON J W, JENSEN H M. Models of fiber debonding and pullout in brittle composites with friction[J]. Mechanics of Materials, 1990, 9(2): 139-163. [35] HSUEH C H. Interfacial debonding and fiber pull-out stresses of fiber-reinforced composites[J]. Materials Science and Engineering: A, 1990, 123(1): 1-11. [36] KUNTZ M, GRATHWOHL G. Coulomb friction controlled bridging stresses and crack resistance of ceramic matrix composites[J]. Materials Science and Engineering: A, 1998, 250: 313-319. [37] CHIANG Y. On a matrix cracking model using Coulomb’s friction law[J]. Engineering Fracture Mechanics,2007,74(10):1602-1616. doi: 10.1016/j.engfracmech.2006.09.006 [38] PRYCE A W, SMITH P A. Behaviour of unidirectional and crossply ceramic matrix composites under quasi-static tensile loading[J]. Journal of Materials Science,1992,27(10):2695-2704. doi: 10.1007/BF00540692 [39] BEYERLE D S, SPEARING S M, ZOK F W, et al. Damage and failure in unidirectional ceramic-matrix composites[J]. Journal of the American Ceramic Society,1992,75(10):2719-2725. doi: 10.1111/j.1151-2916.1992.tb05495.x [40] SØRENSEN B F, HOLMES J W. Effect of loading rate on the monotonic tensile behavior of a continuous-fiber-reinforced glass-ceramic matrix composite[J]. Journal of the American Ceramic Society,1996,79(2):313-320. doi: 10.1111/j.1151-2916.1996.tb08122.x -

下载:

下载: