Prediction of effective chloride diffusion coefficient of recycled aggregate concrete based on multiscale analysis

-

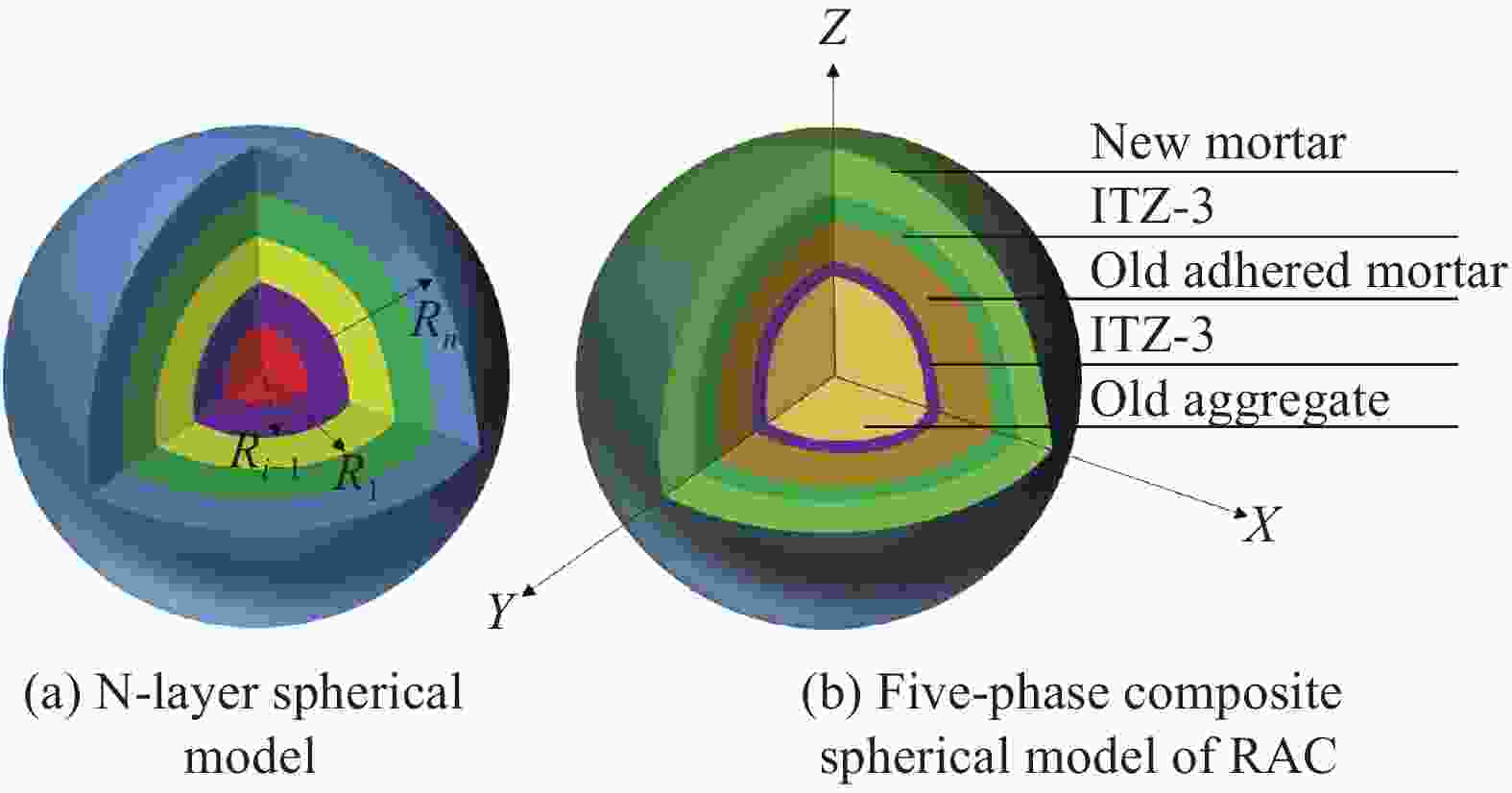

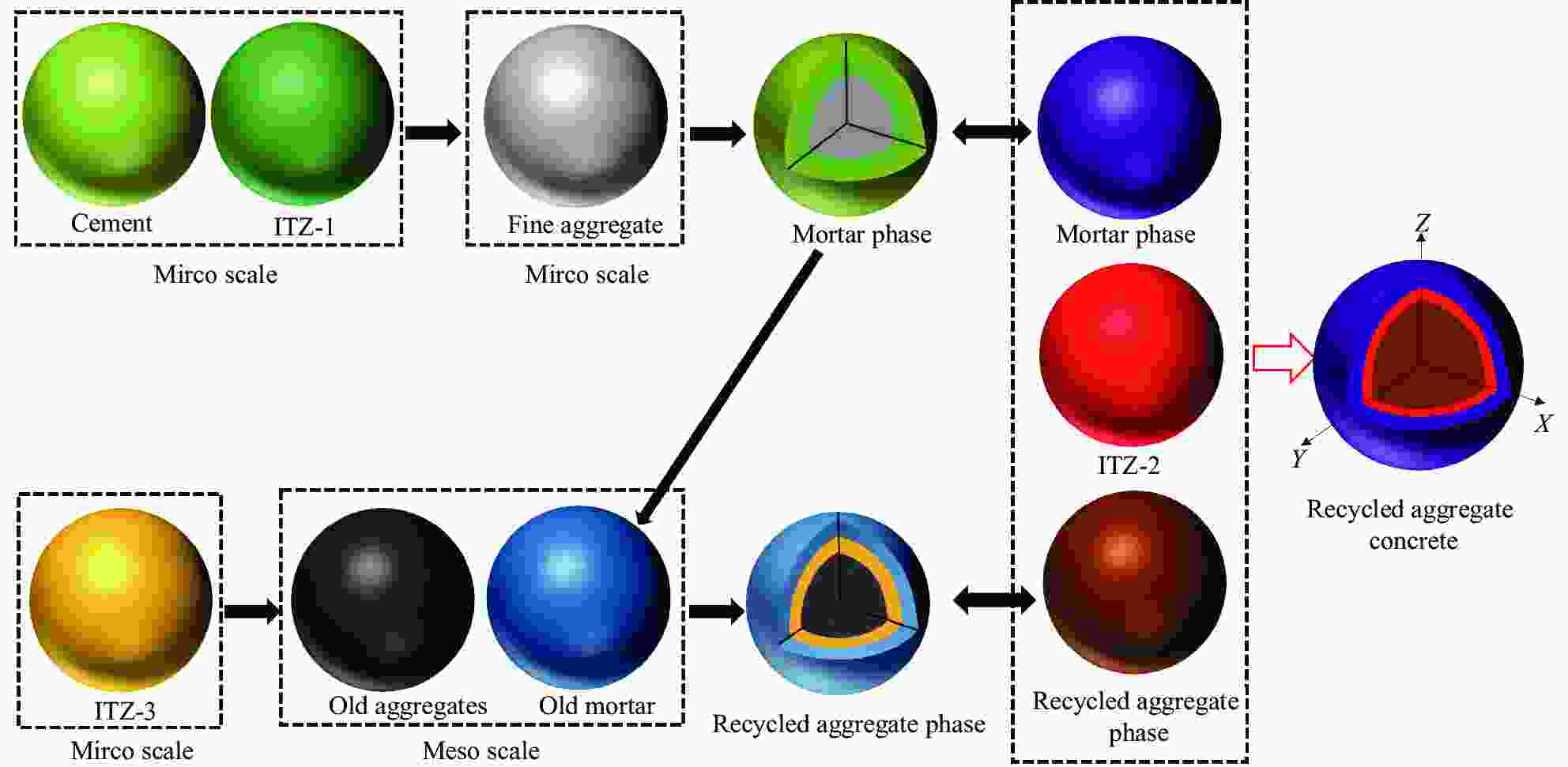

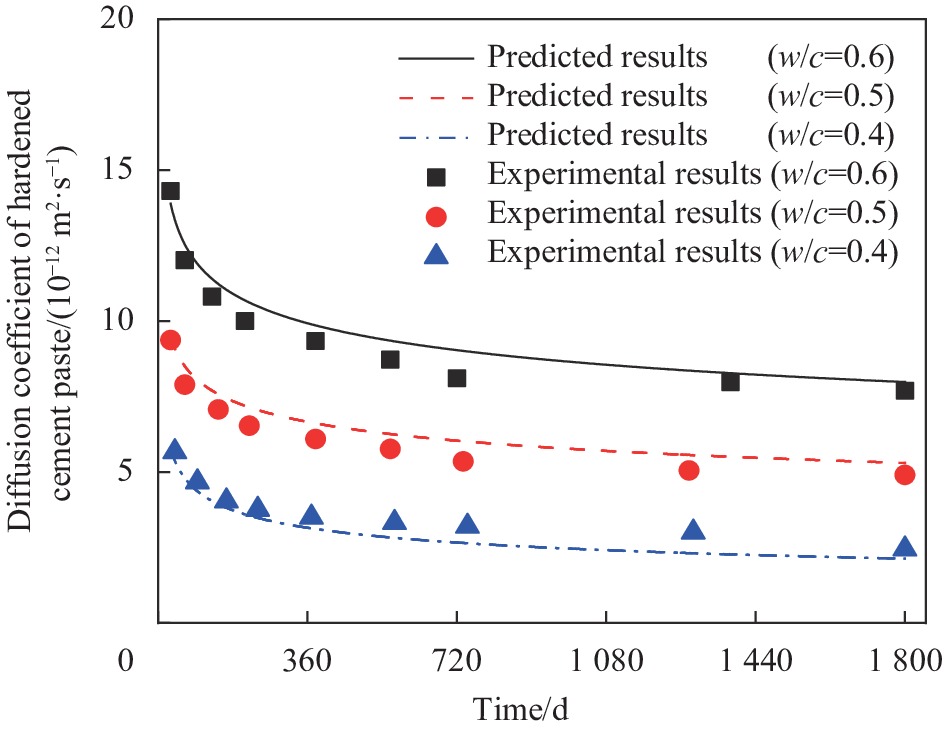

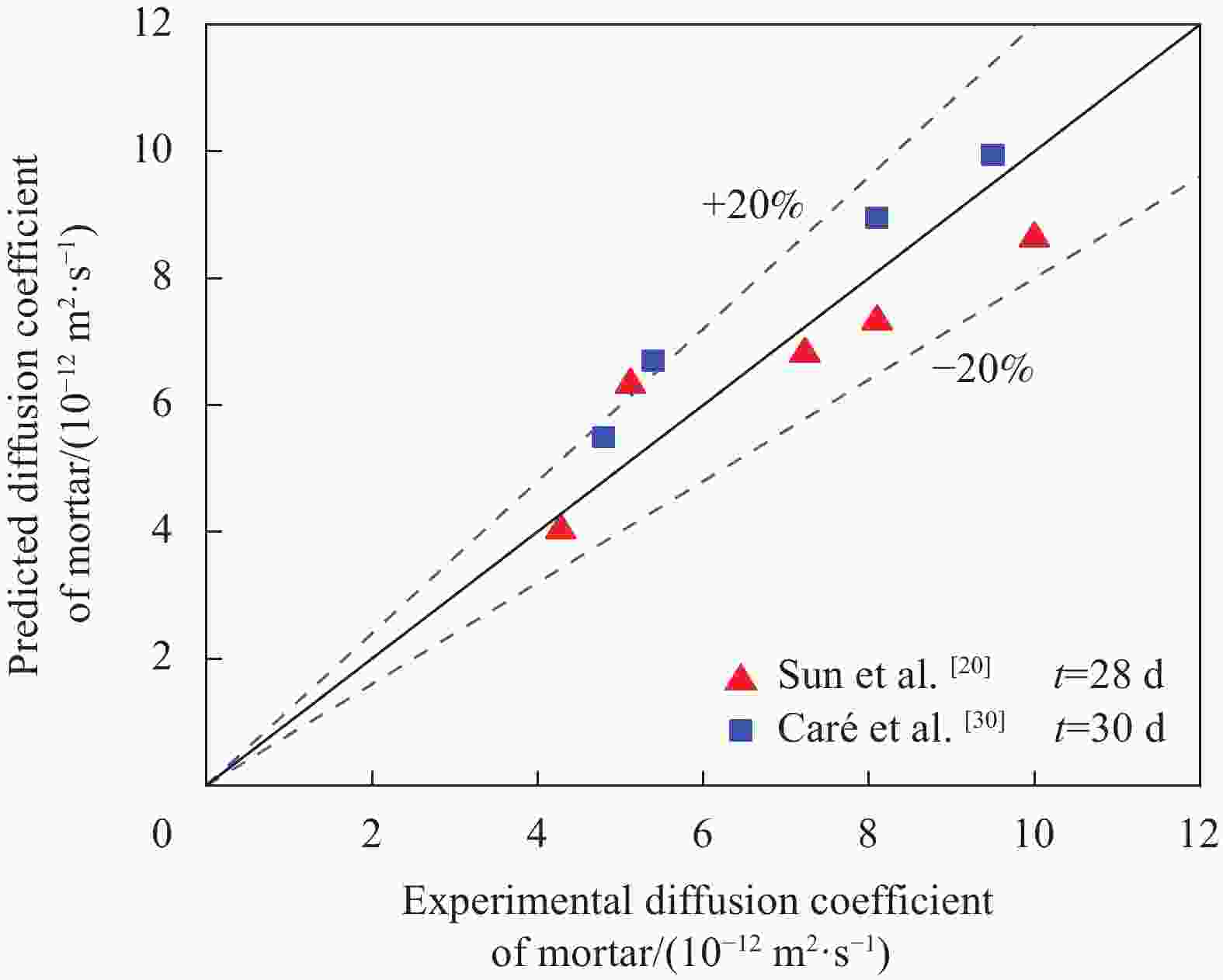

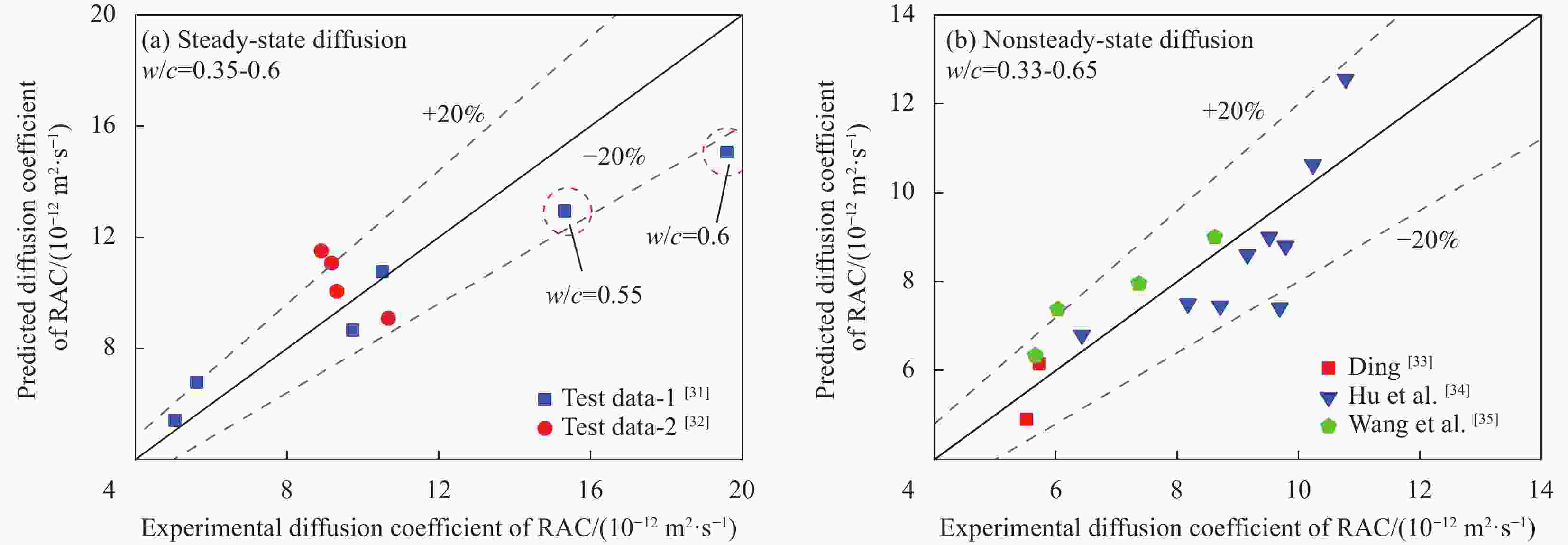

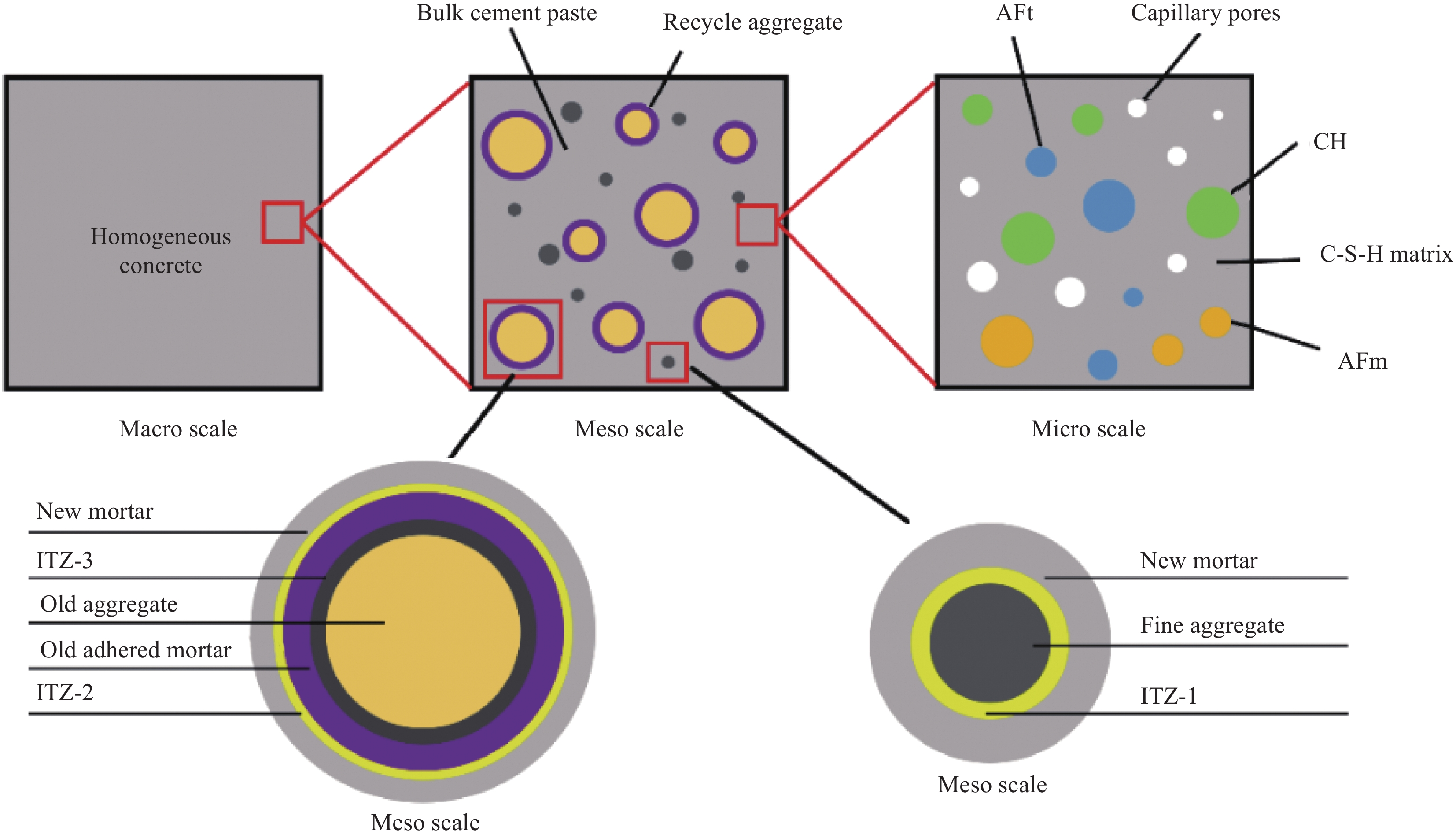

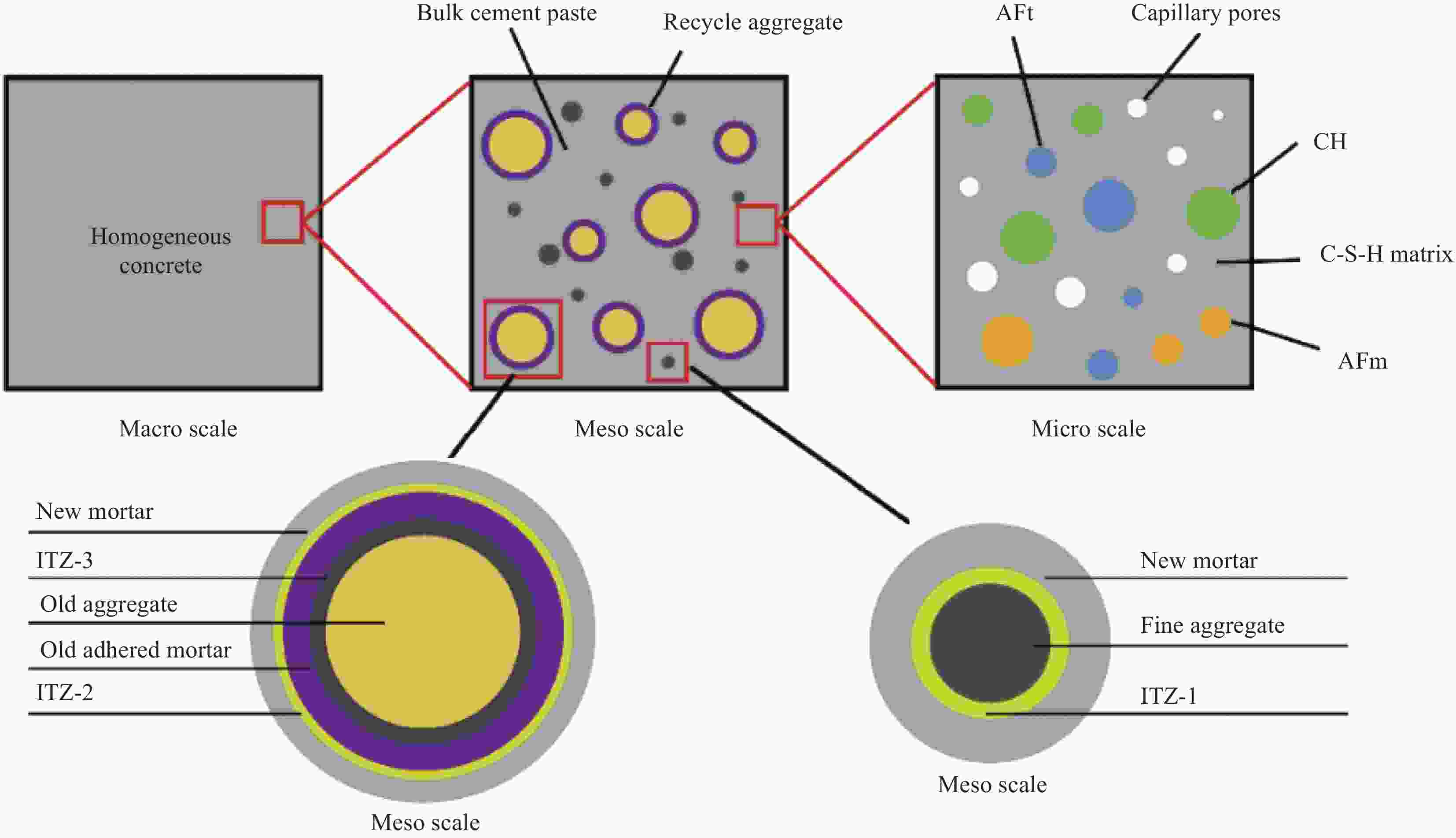

摘要: 将再生混凝土视为由砂浆相、再生骨料相和二者砂浆之间的界面过渡区相(ITZ-2)组成的非均质复合材料,其中砂浆相由细骨料、细骨料-新砂浆界面过渡区(ITZ-1)、硬化水泥浆体三相组成,而再生骨料相由旧骨料、附着砂浆及旧骨料与旧砂浆的界面(ITZ-3)三相组成。基于N层球夹杂理论,考虑微观相的影响,建立了再生混凝土有效氯离子扩散系数预测的五相多尺度模型,通过硬化水泥浆体、砂浆和再生混凝土的稳态扩散系数实测值与模型预测值对比分析,验证其模型的准确性和有效性;最后,进一步讨论了氯离子侵蚀时间、再生骨料体积分数和附着砂浆含量等关键参数对其有效扩散系数的影响。结果表明:有效扩散系数预测值与试验值吻合较好,说明模型对预测再生混凝土的有效氯离子扩散系数具有普适性,为氯盐环境下再生混凝土耐久性评估与寿命预测提供理论依据。Abstract: Recycled aggregate concrete is regarded as a kind of heterogeneous composite material composed of mortar matrix phase, recycled aggregate phase and the interfacial transition zone (ITZ-2) phase between new and old mortars. Among them, mortar matrix phase is composed of fine aggregate, hardened cement pastes and the interfacial transition zone (ITZ-1) between them, while the recycled aggregate phase is composed of old aggregate, attached old mortar, old interfacial transition zone (ITZ-3) between them. Based on the N-layer spherical inclusion theory with considering the influence of microscale phase, a five-phase multiscale model of effective chloride diffusion coefficient of recycled aggregate concrete was established. The accuracy and validity of the proposed model were verified by comparing between the experimental and predicted results of steady-state chloride diffusion coefficient of hardened cement paste, mortar and recycled aggregate concrete, respectively. Finally, the influence of the key parameters including the chloride ingress time, the volume fraction of recycled coarse aggregate and the attached mortar content on effective chloride diffusion coefficient was further discussed. The results show that the predicted effective diffusion coefficient agrees well with the experimental results obtained in the literature. It indicates that the proposed model can be universally used to predict the effective chloride diffusion coefficient of recycled aggregate concrete, which provides a theoretical basis for durability evaluation and service life prediction of recycled aggregate concrete exposed to chloride salt environment.

-

图 1 再生混凝土(RAC)多尺度模型结构示意图

AFt—Ettringite; AFm—Calcium sulfoaluminate; C-S-H—Hydrated silicate gel; CH—Calcium hydroxide; ITZ-1—Interfacial transition zone between new mortar and fine aggregate; ITZ-2—Interfacial transition zone between new mortar and old adhered mortar; ITZ-3—Interfacial transition zone between old adhered mortar and old aggregate

Figure 1. Schematic diagram of recycled aggregate concrete (RAC) multiscale model structure

图 8 侵蚀时间、再生骨料体积分数和附着砂浆含量对再生混凝土有效扩散系数的影响

w/c—Water cement ratio; R—Rate of adhered mortar; V—Volume fraction of RCA; t—Exposure time; RCA—Recylced coarse aggregate

Figure 8. Effect of exposure time, volume fraction of recycled aggregate and attached mortar content on effective diffusion coefficient of RAC

-

[1] MA M, TAM V W Y, LE K N, et al. Factors affecting the price of recycled concrete: A critical review[J]. Journal of Building Engineering,2022,46:103743. doi: 10.1016/j.jobe.2021.103743 [2] BAO J, LI S, ZHANG P, et al. Influence of the incorporation of recycled coarse aggregate on water absorption and chloride penetration into concrete[J]. Construction and Building Materials,2020,239:117845. doi: 10.1016/j.conbuildmat.2019.117845 [3] GUO H, SHI C, GUAN X, et al. Durability of recycled aggregate concrete—A review[J]. Cement and Concrete Composites,2018,89:251-259. doi: 10.1016/j.cemconcomp.2018.03.008 [4] XIAO J, YING J, SHEN L. FEM simulation of chloride diffusion in modeled recycled aggregate concrete[J]. Construction and Building Materials,2012,29:12-23. doi: 10.1016/j.conbuildmat.2011.08.073 [5] HU Z, MAO L, XIA J, et al. Five-phase modelling for effec-tive diffusion coefficient of chlorides in recycled concrete[J]. Magazine of Concrete Research,2018,70(11):583-594. doi: 10.1680/jmacr.17.00194 [6] JIN L, YU H, WANG Z, et al. Effect of crack and damaged zone on chloride penetration in recycled aggregate concrete: A seven-phase mesoscale numerical method[J]. Construction and Building Materials,2021,291:123383. doi: 10.1016/j.conbuildmat.2021.123383 [7] WU Y, XIAO J. Multiscale digital-image driven stochastic finite element modeling of chloride diffusion in recycled aggregate concrete[J]. Construction and Building Materials,2018,162:239-252. doi: 10.1016/j.conbuildmat.2017.12.024 [8] YU Y, LIN L. Modeling and predicting chloride diffusion in recycled aggregate concrete[J]. Construction and Building Materials,2020,264:120620. doi: 10.1016/j.conbuildmat.2020.120620 [9] HERVÉ E. Thermal and thermoelastic behaviour of multiply coated inclusion-reinforced composites[J]. International Journal of Solids and Structures,2002,39(4):1041-1058. doi: 10.1016/S0020-7683(01)00257-8 [10] TIAN Y, TIAN Z, JIN N, et al. A multiphase numerical simulation of chloride ions diffusion in concrete using electron microprobe analysis for characterizing properties of ITZ[J]. Construction and Building Materials,2018,178:432-444. doi: 10.1016/j.conbuildmat.2018.05.047 [11] YANG C, LIANG C. Determining the steady-state chloride migration coefficient of ITZ in mortar by using the accelerated chloride migration test[J]. Journal of the Chinese Institute of Engineers,2014,37(7):892-898. doi: 10.1080/02533839.2014.888813 [12] BOURDETTE B, RINGOT E, OLLIVIER J P. Modelling of the transition zone porosity[J]. Cement and Concrete Research,1995,25(4):741-751. doi: 10.1016/0008-8846(95)00064-J [13] XIAO J, LI W, SUN Z, et al. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation[J]. Cement and Concrete Composites,2013,37:276-292. doi: 10.1016/j.cemconcomp.2013.01.006 [14] OH B H, JANG S Y. Prediction of diffusivity of concrete based on simple analytic equations[J]. Cement and Concrete Research,2004,34(3):463-480. doi: 10.1016/j.cemconres.2003.08.026 [15] GUO Y, ZHANG T, DU J, et al. Evaluating the chloride diffusion coefficient of cement mortars based on the tortuosity of pore structurally-designed cement pastes[J]. Microporous and Mesoporous Materials,2021,317:111018. doi: 10.1016/j.micromeso.2021.111018 [16] XIE J, WANG J, LI M, et al. Estimation of chloride diffusion coefficient from water permeability test of cementitious materials[J]. Construction and Building Materials,2022,340:127816. doi: 10.1016/j.conbuildmat.2022.127816 [17] POWERS T C. Physical properties of cement paste[R]. Chicago: National Bureau of Standards Monograph, 1962. [18] NAKARAI K, ISHIDA T, MAEKAWA K. Multi-scale physicochemical modeling of soil-cementitious material interaction[J]. Soils and Foundations,2006,46(5):653-663. doi: 10.3208/sandf.46.653 [19] MAEKAWA K, ISHIDA T, KISHI T. Multi-scale modeling of concrete performance integrated material and structural mechanics[J]. Journal of Advanced Concrete Technology,2003,1(2):91-126. doi: 10.3151/jact.1.91 [20] SUN G, ZHANG Y, SUN W, et al. Multi-scale prediction of the effective chloride diffusion coefficient of concrete[J]. Construction and Building Materials,2011,25(10):3820-3831. doi: 10.1016/j.conbuildmat.2011.03.041 [21] STAMBAUGH N D, BERGMAN T L, SRUBAR III W V. Numerical service-life modeling of chloride-induced corrosion in recycled-aggregate concrete[J]. Construction and Building Materials,2018,161:236-245. doi: 10.1016/j.conbuildmat.2017.11.084 [22] KRSTULOVIĆ R, DABIĆ P. A conceptual model of the cement hydration process[J]. Cement and Concrete Research,2000,30(5):693-698. doi: 10.1016/S0008-8846(00)00231-3 [23] ZHENG J, ZHANG J, ZHOU X, et al. A three-step analytical scheme for estimating the steady-state chloride diffusion coefficient of mature cement paste[J]. Construction and Building Materials,2018,191:1004-1010. doi: 10.1016/j.conbuildmat.2018.10.070 [24] OZBAKKALOGLU T, GHOLAMPOUR A, XIE T. Mechanical and durability properties of recycled aggregate concrete: Effect of recycled aggregate properties and content[J]. Journal of Materials in Civil Engineering,2018,30(2):04017275. doi: 10.1061/(ASCE)MT.1943-5533.0002142 [25] YU S W, PAGE C L. Diffusion in cementitious materials: 1. Comparative study of chloride and oxygen diffusion in hydrated cement pastes[J]. Cement and Concrete Research,1991,21(4):581-588. doi: 10.1016/0008-8846(91)90109-U [26] NGALA V T, PAGE C L, PARROTT L J, et al. Diffusion in cementitious materials: II, further investigations of chloride and oxygen diffusion in well-cured OPC and OPC/30% PFA pastes[J]. Cement and Concrete Research,1995,25(4):819-826. doi: 10.1016/0008-8846(95)00072-K [27] NUMATA S, AMANO H, MINAMI K. Diffusion of tritiated water in cement materials[J]. Journal of Nuclear Materials,1990,171(2-3):373-380. doi: 10.1016/0022-3115(90)90383-X [28] MACDONALD K A, NORTHWOOD D O. Experimental measurements of chloride ion diffusion rates using a two-compartment diffusion cell: Effects of material and test variables[J]. Cement and Concrete Research,1995,25(7):1407-1416. doi: 10.1016/0008-8846(95)00135-Y [29] TANG L P, NILSSON L O. Rapid determination of the chloride diffusivity in concrete by applying an electric field[J]. Materials Journal,1993,89(1):49-53. [30] CARÉ S, HERVÉ E. Application of a n-phase model to the diffusion coefficient of chloride in mortar[J]. Transport in Porous Media,2004,56(2):119-135. doi: 10.1023/B:TIPM.0000021730.34756.40 [31] 罗伯光, 覃荷瑛. 利用NEL法研究再生混凝土抗氯离子渗透性能[J]. 混凝土, 2014(9):41-44. doi: 10.3969/j.issn.1002-3550.2014.09.010LUO Boguang, QIN Heying. Study on anti-chloride ion permeability of recycled aggregate concrete by NEL method[J]. Concrete,2014(9):41-44(in Chinese). doi: 10.3969/j.issn.1002-3550.2014.09.010 [32] 覃荷瑛, 唐慧. 粗骨料含量对再生混凝土抗氯离子渗透性能影响的试验研究[J]. 中外公路, 2015, 35(6):286-290. doi: 10.14048/j.issn.1671-2579.2015.06.065QIN Heying, TANG Hui. Experimental study on the influence of coarse aggregate content on chloride penetration resistance of recycled concrete[J]. Journal of China & Foreign Highway,2015,35(6):286-290(in Chinese). doi: 10.14048/j.issn.1671-2579.2015.06.065 [33] 丁小雅. 水分和氯离子在再生混凝土中的传输机理[D]. 青岛: 青岛理工大学, 2018.DING Xiaoya. The transport mechanism of moisture and chloride ions in recycled concrete[D]. Qingdao: Qingdao University of Technology, 2018. [34] 胡波, 柳炳康, 张李黎. 再生混凝土氯离子渗透性能测试与分析[J]. 合肥工业大学学报(自然科学版), 2009, 32(8):1240-1243.HU Bo, LIU Bingkang, ZHANG Lili. Chloride ion permeabi-lity test and analysis for recycled concrete[J]. Journal of Hefei University of Technology (Natural Science),2009,32(8):1240-1243(in Chinese). [35] WANG W, WU J, WANG Z, et al. Chloride diffusion coefficient of recycled aggregate concrete under compressive loading[J]. Materials and Structures,2016,49(11):4729-4736. doi: 10.1617/s11527-016-0820-x [36] 胡志, 毛丽璇, 刘清风. 再生骨料混凝土抗氯离子侵蚀的多相数值研究[J]. 硅酸盐通报, 2020, 39(8):2425-2432. doi: 10.16552/j.cnki.issn1001-1625.2020.08.009HU Zhi, MAO Lixuan, LIU Qingfeng. Multi-phase numeri-cal analysis of chloride resistance of recycled aggregate concrete[J]. Bulletin of the Chinese Ceramic Society,2020,39(8):2425-2432(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2020.08.009 -

下载:

下载: