Tunable mechanical and acoustic properties of anisotropic magnetic polyurethane foams with different carbonyl iron powder magnetic particle contents

-

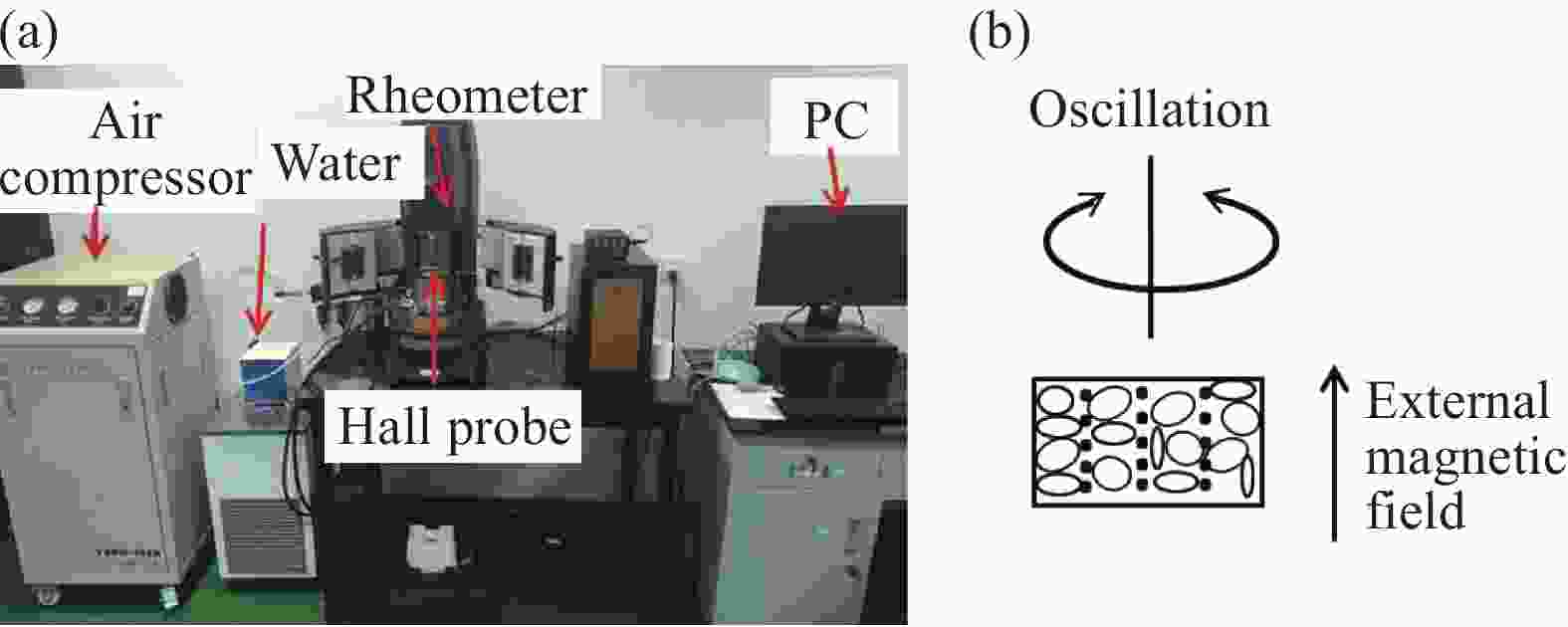

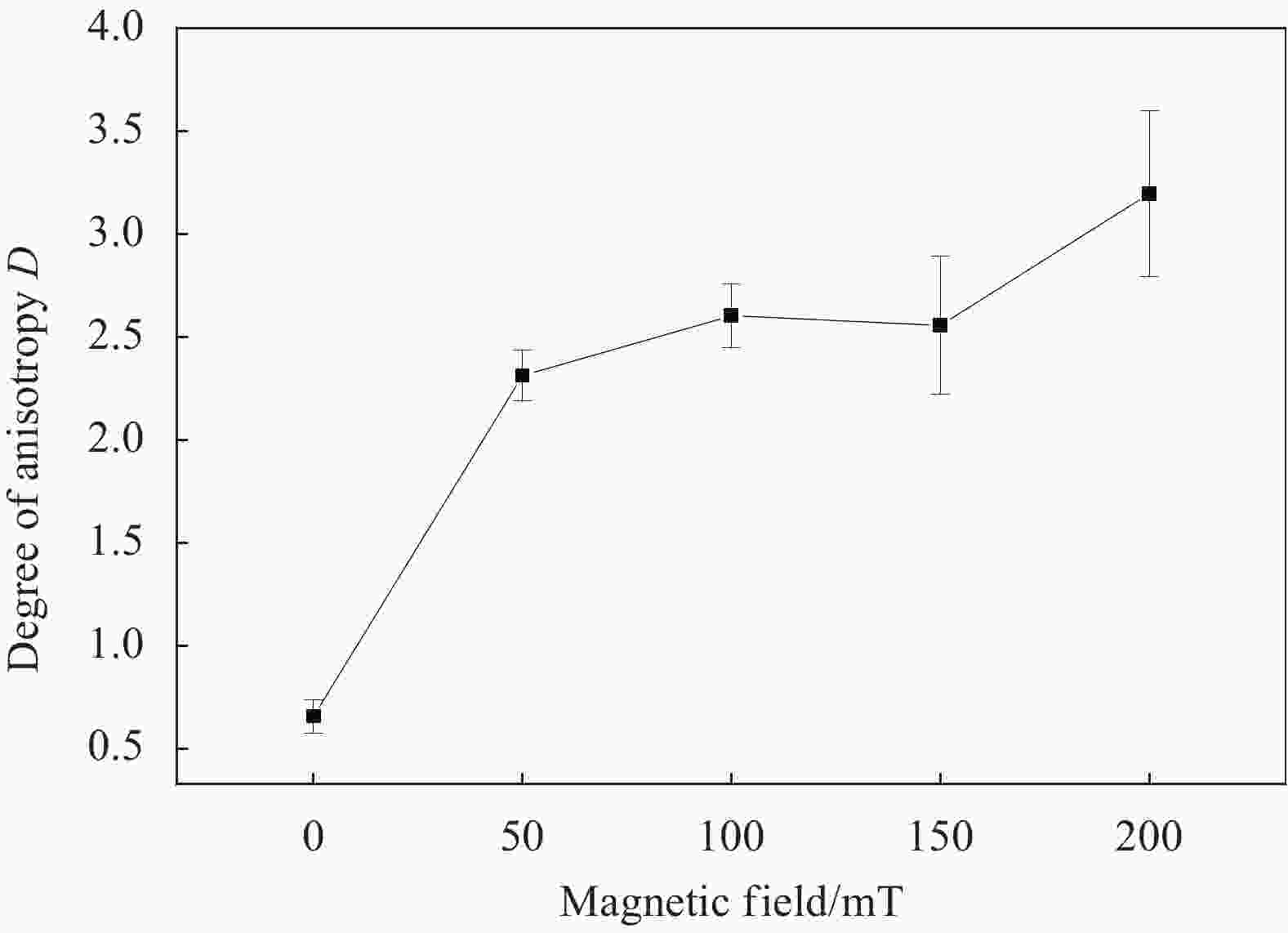

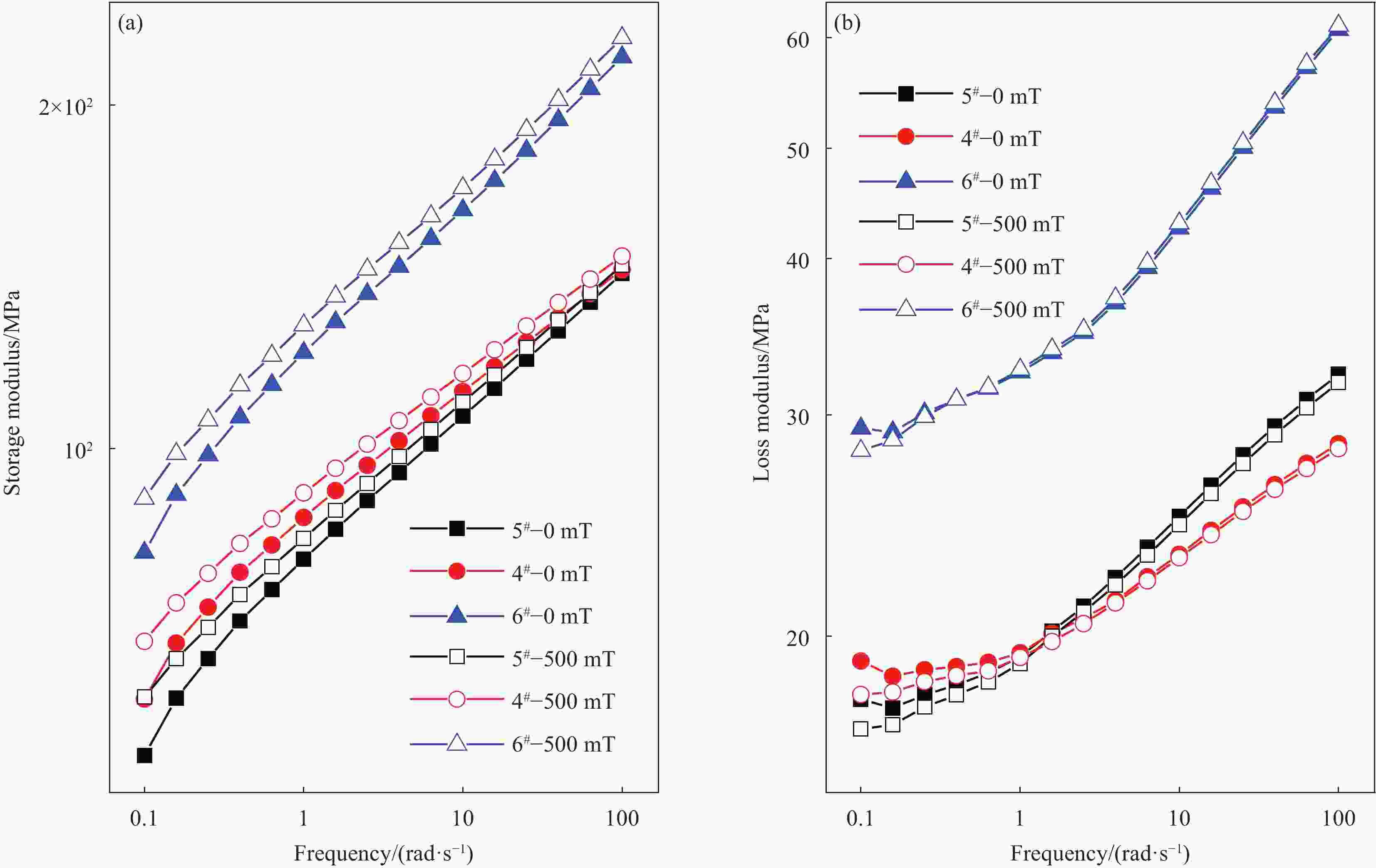

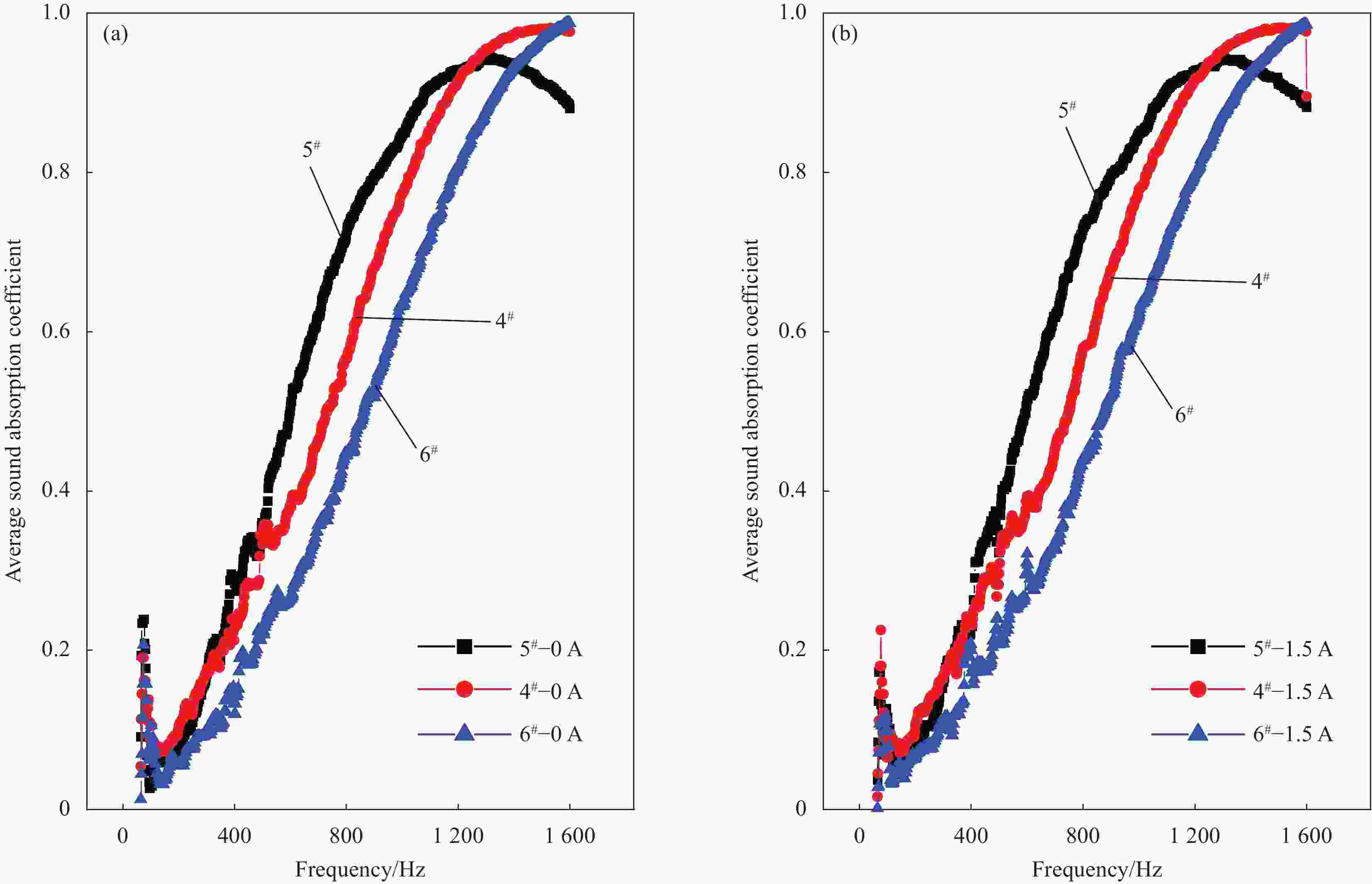

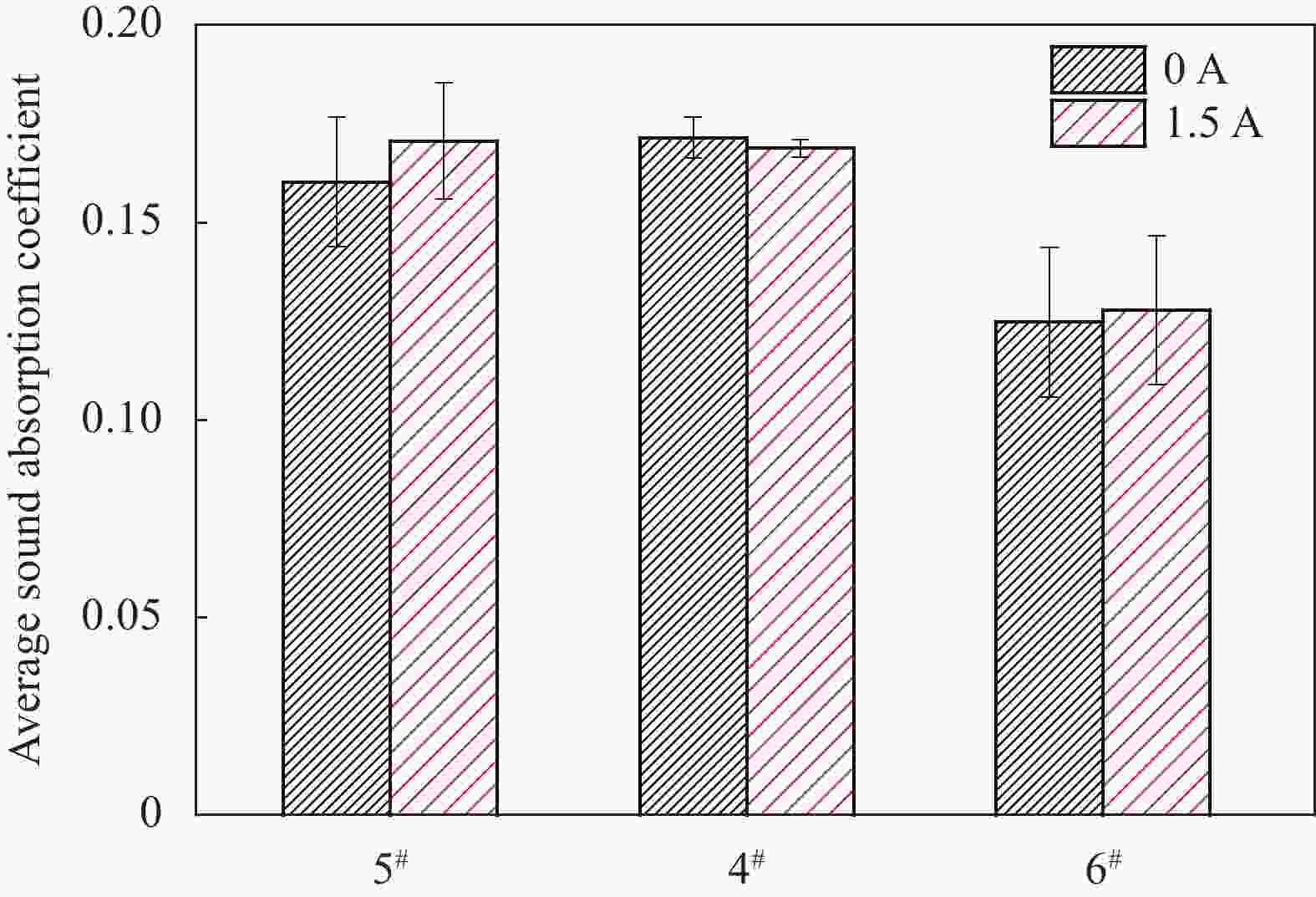

摘要: 聚氨酯泡沫(PUFs)被广泛应用于飞机、车辆和许多其他设施中的噪声控制。本文研究的磁性聚氨酯泡沫(MPUFs)是一种新型智能泡沫,其力学和声学特性可通过磁场控制。采用一步全水法制备了添加羟基铁粉颗粒的磁性聚氨酯泡沫(CIPs/MPUFs),在发泡过程中施加一定强度的磁场,磁颗粒沿着外加磁场方向排列成链状有序结构,得到各向异性磁性泡沫。在外加磁场作用下,CIPs/MPUFs内部磁性颗粒发生迁移,材料的力学和声学性能发生改变。实验研究了外加磁场对CIPs/MPUFs力学性能和吸声性能的影响。实验结果表明:在外加磁场条件下,CIPs/MPUFs的储能模量和损耗模量随磁性颗粒含量的增加而增加;CIPs/MPUFs的平均吸声系数变化幅度在1%~7%之间,当颗粒含量为5wt%、制备磁场为200 mT、测试施加1.5 A电流时,CIPs/MPUFs的平均吸声系数增加幅度最大,为6.5%。Abstract: Polyurethane foams (PUFs) have been widely used in aircrafts, vehicles and many other facilities for noise control. Magnetic polyurethane foams (MPUFs) are a new kind of smart foams whose mechanical and acoustic properties can be controlled by magnetic fields. In this paper, the anisotropic MPUFs was studied which were prepared by one-step full water foaming method with carbonyl iron powders (CIPs) magnetic particles. During the foaming process, the magnetic field was applied, and the CIPs were arrayed into a chain-like structure along the direction of the magnetic field. The movement of CIPs inside MPUFs under the magnetic field induces a change towards the mechanical and sound absorption properties. The influence of the external magnetic field on the mechanical properties and sound absorption properties of CIPs/MPUFs was investigated by experiments. The results show that under the magnetic field, the storage modulus and loss modulus of CIPs/MPUFs increase with the increase of CIPs content. The variation of the average sound absorption coefficient is between 1% and 7%. For the sample with 5wt% CIPs foamed under 200 mT, the increment of its average sound absorption coefficient under 1.5 A is 6.5%, which is maximum.

-

图 7 CIPs/ MPUFs的应力-应变曲线(压缩速率为10 mm/min)

Figure 7. Stress-strain curves of CIPs/ MPUFs (Compression rate is 10 mm/min) ((a) Parallel to the particle chain direction of 5#, 4# and 6#; (b) Parallel to and perpendicular to the particle chain direction of 5# ; (c) Parallel to and perpendicular to the particle chain direction of 4# ; (d) Parallel to and perpendicular to the particle chain direction of 6#)

表 1 各向同性和各向异性羰基铁粉(CIPs)/MPUFs配方

Table 1. Formulations for the isotropic and anisotropic carbonyl iron powders (CIPs)/MPUFs

Sample Carbonyl iron particles/wt% Magnetic intensity/mT A component B component Polyether

polyol/gDeionized

water/gDBTDL/

gSilicone

oil/gCarbonyl iron

particles/gMDI/

g1# 15 50 25.000 0.750 0.075 0.500 6.570 17.500 2# 15 100 25.000 0.750 0.075 0.500 6.570 17.500 3# 15 150 25.000 0.750 0.075 0.500 6.570 17.500 4# 15 200 25.000 0.750 0.075 0.500 6.570 17.500 5# 5 200 25.000 0.750 0.075 0.500 2.190 17.500 6# 40 200 25.000 0.750 0.075 0.500 17.530 17.500 Note: DBTDL—Dibutyltin dilaurate. -

[1] ZHANG C, LI J, ZHEN H, et al. Correlation between the acoustic and porous cell morphology of polyurethane foam: Effect of interconnected porosity[J]. Materials & Design,2012,41(Complete):319-325. [2] 王永华. 多级仿生耦合材料吸声性能及机制研究[D]. 长春: 吉林大学, 2014.WANG Y H. Research on sound absorption properties and mechanisms of multi-level bionic coupling materials[D]. Changchun: Jilin University, 2014 (in Chinese). [3] SUNG G, KIM J H. Effect of high molecular weight isocyanate contents on manufacturing polyurethane foams for improved sound absorption coefficient[J]. Korean Journal of Chemical Engineering,2017,34(4):1-7. [4] SCHÜMANN M, GÜNTHER S, ODENBACH S. The effect of magnetic particles on pore size distribution in soft polyurethane foams[J]. Smart Materials & Structures,2014,23(7):697-707. [5] GONG Q C, WU J K, GONG X L, et al. Smart polyurethane foam with magnetic field controlled modulus and anisotropic compression property[J]. RSC Advances,2013,3(10):3241-3248. doi: 10.1039/c2ra22824f [6] SORRENTINOL, AURILIA M, FORTE G, et al. Anisotropic mechanical behavior of magnetically oriented iron particle reinforced foams[J]. Journal of Applied Polymer Science,2010,119(2):1239-1247. [7] D’AURIA M, DAVINO D, PANTANI R, et al. Polymeric foam-ferromagnet composites as smart lightweight materials[J]. Smart Materials and Structures,2016,25(5):055014. doi: 10.1088/0964-1726/25/5/055014 [8] DAVINO D, MEI P, SORRENTINO L, et al. Polymeric composite foams with properties controlled by the magnetic field[J]. IEEE Transactions on Magnetics,2012,48(11):3043-3046. doi: 10.1109/TMAG.2012.2198634 [9] SCARPA F, BULLOUGH W A, LUMLEY P. Trends in acoustic properties of iron particle seeded auxetic polyurethane foam[C]// 60th Annual Meeting of the Divison of Fluid Dynamics. American Physical Society, 2004: 241-244. [10] KIM B S, KWON S, JEONG S, et al. Semi-active control of smart porous structure for sound absorption enhancement[J/OL]. Journal of Intelligent Material Systems and Structures, 2019, https://doi.org/10.1177/1045389X19862371 [11] 王晓杰, 李彬. 一种智能磁性降噪聚氨酯泡沫的制备方法: 中国, 201410649702.2[P]. 2014-11-17.WANG Xiaojie, LI Bin. An intelligent magnetic noise reduction polyurethane foam: China, 201410649702.2[P]. 2014-11-17(in Chinese). [12] 中华人民共和国国家质量监督检验检疫总局. 声学阻抗管中吸声系数和声阻抗的测量第2部分: 传递函数法: GB/T18696.2—2002[S]. 北京: 中国标准出版社, 2002.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Acoustics–Determinatio of sound absorption coefficient and impedance in impedance tubes–Part 2: Transfer function method: GB/T18696.2—2002[S]. Beijing: China Standards Press, 2002 (in Chinese). [13] SOTO G, CASTRO A, VECHIATTI N, et al. Biobased porous acoustical absorbers made from polyurethane and waste tire particles[J]. Polymer Testing,2017,57:42-51. doi: 10.1016/j.polymertesting.2016.11.010 [14] 赵文强. 磁流变塑性体力学性能优化与机理研究[D]. 合肥: 中国科学技术大学, 2019.ZHAO Wenqiang. Study on magnetorheological plastomer: The optimization and mechanism of its mechanical properties[D]. Hefei: University of Science and Technology of China, 2019(in Chinese). [15] CHEN L, GONG X L, JIANG W Q, et al. Investigation on magnetorheological elastomers based on natural rubber[J]. Journal of Materials Science,2007,42(14):5483-5489. doi: 10.1007/s10853-006-0975-x [16] MUHAZELI N S, NORDIN N A, MAZLAN S A, et al. Characterization of morphological and rheological properties of rigid magnetorheological foams via in situ fabrication method[J]. Journal of Materials Science, 2019, 54(2): 13821. [17] 许阳光. 新型磁敏智能软材料(磁流变塑性体)的制备、表征及机理研究[D]. 合肥: 中国科学技术大学, 2014.XU Yangguang. Preparation, characterization and mechanism of a novel magneto-sensitive smart soft materials: Magnetorheological plastomers[D]. Hefei: University of science and technology of China, 2014(in Chinese). [18] SCHÜMANN, M, SEELIGN, ODENBACH S. The effect of external magnetic fields on the pore structure of polyurethane foams loaded with magnetic microparticles[J]. Smart Materials and Structures,2015,24(10):105028. doi: 10.1088/0964-1726/24/10/105028 [19] 王彩萍, 孙天宇, 王晓杰. 磁性聚氨酯泡沫的微观形貌及低频吸声性能[J]. 复合材料学报, 2018, 35(1):24-29.WANG Caiping, SUN Tianyu, WANG Xiaojie. Study on micro topography and low frequency sound absorption performance of magnetic polyurethane foam[J]. Acta Materiae Compositae Sinica,2018,35(1):24-29(in Chinese). [20] 钟祥璋. 建筑吸声材料与隔声材料[M]. 北京: 化学工业出版社, 2012.ZHONG X Z. Building sound-absorbing materials and insulation materials[M]. Beijing: Chemical Industry Press, 2012(in Chinese). -

下载:

下载: