Thermal conduction simulation and verification of TiB2/Cu composites with different particle sizes

-

摘要: 采用ANSYS对不同粒径TiB2/Cu复合材料热传导过程进行模拟。采用粉末冶金法制备了不同粒径TiB2增强的Cu复合材料,采用LINSEIS LFA1600激光导热仪测试了室温至280℃下的TiB2/Cu复合材料热传导性能变化,并与模拟结果进行对比。结果表明:热导率模拟结果与实验结果吻合较好。在50~200℃之间,复合材料热导率变化不大,在6%~9%范围内波动。200℃之后,模拟值与实验值均呈现出随温度升高而增大的趋势,且吻合度较高。这是由于温度低于200℃时,在模拟过程中未考虑材料界面处两相不同热膨胀系数的影响,导致模拟值与实验值有较大的差异。当温度高于200℃时,模拟值和实验值吻合程度趋于稳定。在200℃时,由于两相热膨胀系数的影响,复合材料内部界面处等效应力大于Cu基体屈服强度,使其发生塑性变形,从而引起热导率发生较大幅度变化。此外,热导率随着TiB2粒径的增大呈现出先提高后降低的趋势,在10 μm时达到最大。这是由于当颗粒直径小于临界平均直径时,颗粒直径的增大会减少界面数量,从而降低界面热阻。当颗粒直径大于临界平均直径时,平均自由程l的急剧增加导致热导率降低。

-

关键词:

- TiB2/Cu复合材料 /

- ANSYS有限元分析 /

- 不同粒径 /

- 热导率 /

- 热膨胀系数

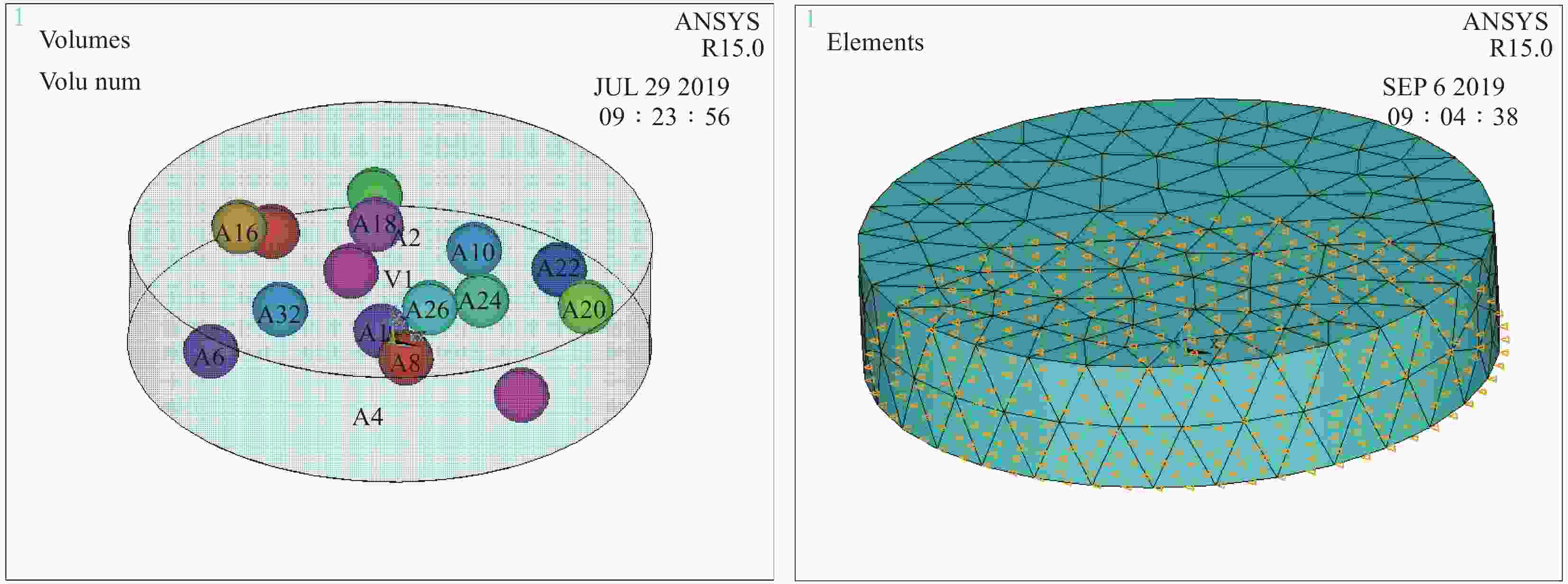

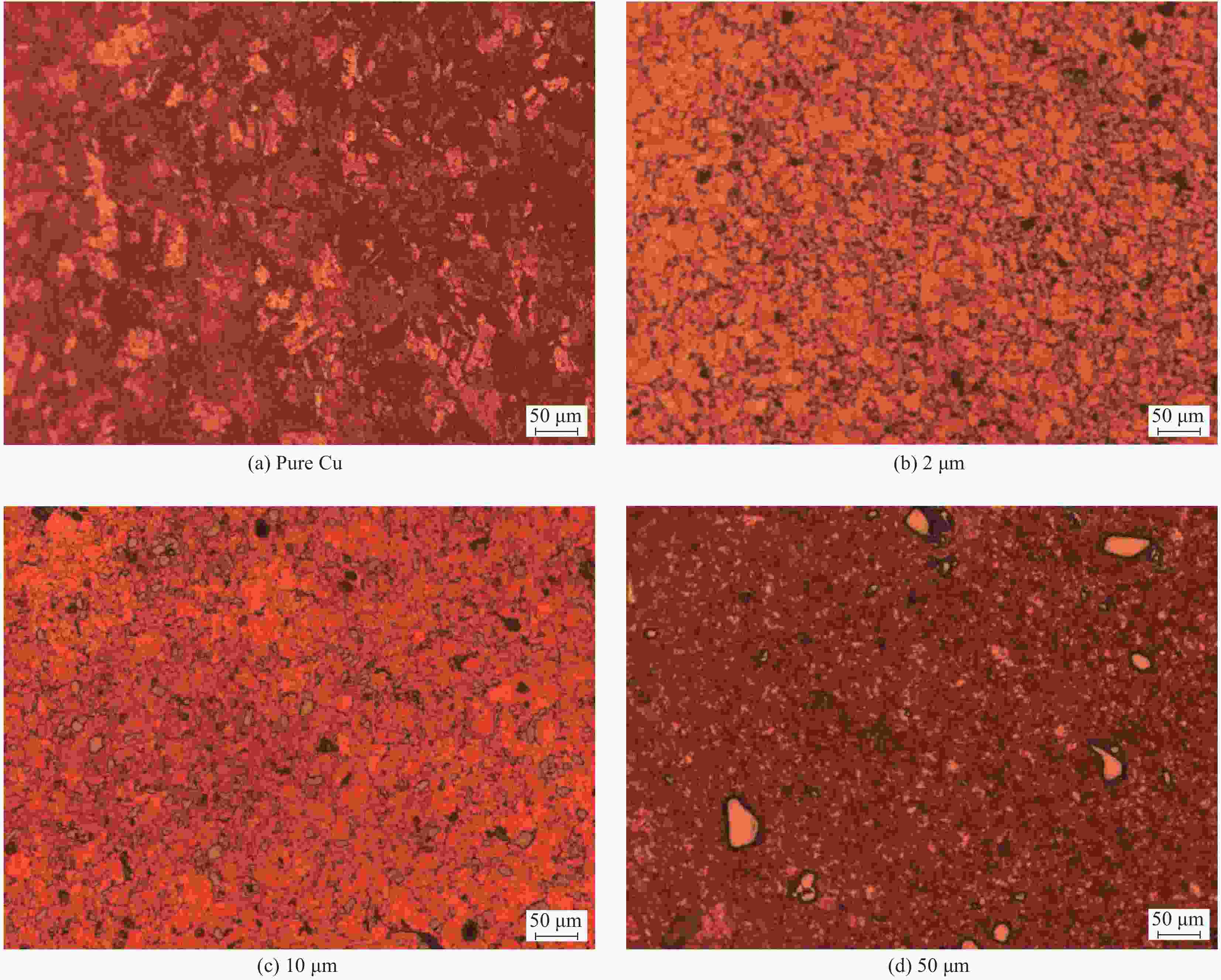

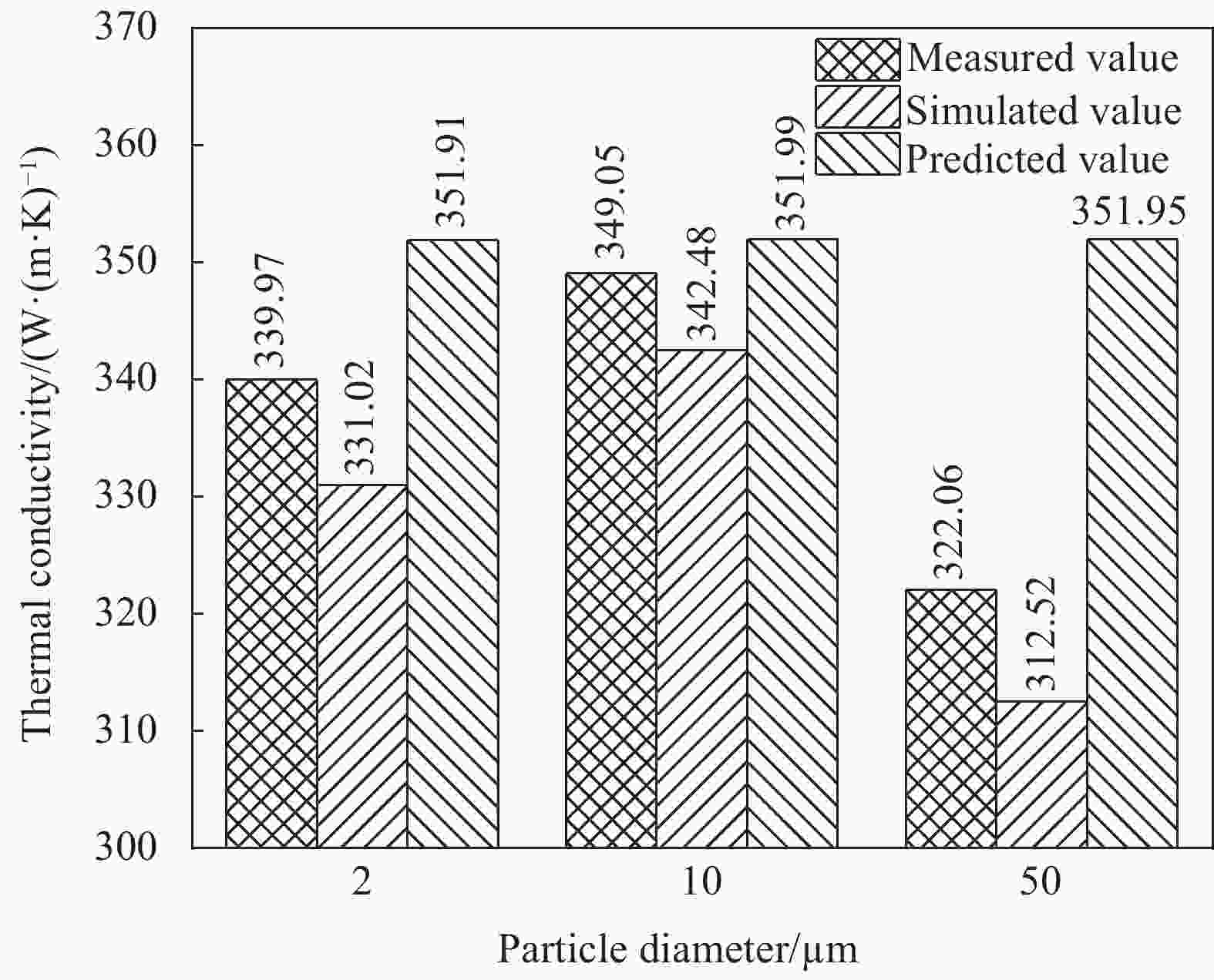

Abstract: ANSYS was used to simulate the thermal conduction process of TiB2/Cu composites with different TiB2 particle sizes. The TiB2/Cu composites with different TiB2 particle sizes were prepared by powder metallurgy. LINSEIS LFA1600 laser thermal conductivity instrument was used to determine the thermal conductivity of the TiB2/Cu composites ranging from room temperature to 280℃, and the measured values were compared with the simulation results. The simulation results are in good agreement with the measured values. In the range of 50-200℃, the thermal conductivities of the TiB2/Cu composites fluctuate in the range of 6%-9%. When the temperature is above 200℃, both the simulated results and the measured values increase with the increase of temperature, and they match well with each other. This is because the large difference of their thermal expansion coefficients in the interface between TiB2 and Cu below 200℃ is not considered in the simulation process. When the temperature is above 200℃, the simulation results have good accordance with the measured values. At 200℃, due to the influence of two-phase thermal expansion coefficients, the equivalent stress at the internal interface of the composite is larger than the yield strength of the Cu matrix, thus causing plastic deformation, which leads to a significant change in the thermal conductivity. In addition, the thermal conductivity increases and then decreases with the increase of particle size, and reaches its maximum value at 10 μm. This is because when the particle diameter is less than the critical average diameter, the increased particle diameter reduces the number of interfaces, thus reducing the interfacial thermal resistance. When the particle diameter is larger than the critical mean diameter, the mean free path l greatly increases and the thermal conductivity reduces. -

表 1 TiB2/Cu复合材料内部界面应力P与界面处等效应力σe的计算值

Table 1. Calculated stress P and equivalent stress σe at the interface in TiB2/Cu composites

Tempurature/℃ 50 100 150 200 250 280 Interfacial stress/MPa 20.7 62.1 103.5 144.9 186.3 211.1 σe/MPa 9.3 27.9 46.5 65.2 83.8 94.9 -

[1] WANG L, LI J, CHE Z, et al. Combining Cr precoating and Cr alloying to improve the thermal conductivity of diamond particles reinforced Cu matrix composites[J]. Journal of Alloys and Compounds,2018,749:1098-1105. doi: 10.1016/j.jallcom.2018.03.241 [2] CHEN J, NIU P, WEI T, et al. Fabrication and mechanical properties of AlCoNiCrFe high-entropy alloy particle reinforced Cu matrix composites[J]. Journal of Alloys and Compounds,2015,649:630-634. doi: 10.1016/j.jallcom.2015.07.125 [3] AHN B W, KIM J H, HAMAD K, et al. Microstructure and mechanical properties of a B4C particle-reinforced Cu matrix composite fabricated by friction stir welding[J]. Journal of Alloys and Compounds,2017,693:688-691. doi: 10.1016/j.jallcom.2016.08.304 [4] 李国辉, 刘勇, 国秀花, 等. TiB2/Cu复合材料的电弧侵蚀行为[J]. 复合材料学报, 2018, 35(3):616-622.LI Guohui, LIU Yong, GUO Xiuhua, et al. Arc erosion behavior of TiB2/Cu composites[J]. Acta Materiae Compositae Sinica,2018,35(3):616-622(in Chinese). [5] 张胜利, 国秀花, 宋克兴, 等. 多粒径TiB2颗粒增强铜基复合材料制备与载流摩擦磨损的特性[J]. 复合材料学报, 2019, 36(10):93-101.ZHANG Shengli, GUO Xiuhua, SONG Kexing, et al. Preparation and electrical wear characteristics of copper matrix composites reinforced with mixing sized TiB2 particle[J]. Acta Materiae Compositae Sinica,2019,36(10):93-101(in Chinese). [6] WANG P, ZHANG H, YIN J, et al. Wear and friction behaviours of copper mesh and flaky graphite-modified carbon/carbon composite for sliding contact material under electric current[J]. Wear,2017,380:59-65. [7] DINAHARAN I, SARAVANAKUMAR S, KALAISELVAN K, et al. Microstructure and sliding wear characterization of Cu/TiB2 copper matrix composites fabricated via friction stir processing[J]. Journal of Asian Ceramic Societies,2017,5(3):295-303. doi: 10.1016/j.jascer.2017.06.002 [8] 郭明星, 汪明朴, 李周, 等. TiB2/Cu金属基复合材料的研究[J]. 材料导报, 2004, 18(8):39-42. doi: 10.3321/j.issn:1005-023X.2004.08.012GUO Mingxing, WANG Mingpu, LI Zhou, et al. The studies of TiB2/Cu metal matrix composites[J]. Materials Review,2004,18(8):39-42(in Chinese). doi: 10.3321/j.issn:1005-023X.2004.08.012 [9] 王耐艳, 涂江平, 杨友志, 等. Cu-纳米TiB2原位复合材料的摩擦磨损性能[J]. 摩擦学学报, 2002, 22(6):414-418. doi: 10.3321/j.issn:1004-0595.2002.06.002WANG Naiyan, TU Jiangping, YANG Youzhi, et al. Dry sliding friction and wear behavior of Cu-nanosized TiB2 in-situ composites[J]. Tribology,2002,22(6):414-418(in Chinese). doi: 10.3321/j.issn:1004-0595.2002.06.002 [10] KIM P, SHI L, MAJUMDAR A, et al. Thermal transport measurements of individual multiwalled nanotubes[J]. Physical Review letters,2001,87(21):215502. doi: 10.1103/PhysRevLett.87.215502 [11] GUO J, WANG X, WANG T. Thermal characterization of microscale conductive and nonconductive wires using transient electrothermal technique[J]. Journal of Applied Physics,2007,101(6):063537. doi: 10.1063/1.2714679 [12] CHENG Z, LIU L, XU S, et al. Temperature dependence of electrical and thermal conduction in single silver nanowire[J]. Scientific Reports,2015,5:10718. doi: 10.1038/srep10718 [13] CORBINO O. Periodic resistance changes of fine metal threads which are brought together by alternating streams as well as deduction of their thermo characteristics at high temperatures[J]. Physikalische Zeitschrift,1911,12:292-295. [14] PARKER W, JENKINS R, BUTLER C, et al. Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity[J]. Journal of Applied Physics,1961,32(9):1679-1684. doi: 10.1063/1.1728417 [15] GOLI P, NING H, LI X, et al. Thermal properties of graphene-copper-graphene heterogeneous films[J]. Nano Letters,2014,14(3):1497-1503. doi: 10.1021/nl404719n [16] YU G C, WU L Z, FENG L J. Enhancing the thermal conductivity of carbon fiber reinforced polymer composite laminates by coating highly oriented graphite films[J]. Materials & Design,2015,88:1063-1070. [17] CAHILL D G. Analysis of heat flow in layered structures for time-domain thermoreflectance[J]. Review of Scientific Instruments,2004,75(12):5119-5122. doi: 10.1063/1.1819431 [18] RAMAN C V, KRISHNAN K S. A new type of secondary radiation[J]. Nature,1928,121(3048):501-502. [19] 徐辉. 高熔点高热导率铜合金组织与性能研究[D]. 南昌: 南昌航空大学, 2012.XU Hui. Study on microstructure and properties of high melting point and high thermal conductivity copper alloy[D]. Nanchang: Nanchang Hangkong University, 2012(in Chinese). [20] 冯薇薇. 粉末冶金法制备Cu/TiB2复合材料及其性能的研究[D]. 上海: 华东理工大学, 2014.FENG Weiwei. Study on preparation and properties of Cu/TiB2 composites by powder metallurgy[D]. Shanghai: East China University of Science and Technology, 2014(in Chinese). [21] HASSELMAN D, JOHNSON L F. Effective thermal conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composite Materials,1987,21(6):508-515. doi: 10.1177/002199838702100602 [22] 高晓霞. 金属基复合材料界面热传导性的研究[D]. 北京: 北京工业大学, 2000.GAO Xiaoxia. Study of the interfacial thermal conductivity of metal matrix composites[D]. Beijing: Beijing University of Technology, 2000(in Chinese). [23] 张胜利, 宋克兴, 国秀花, 等. TiB2颗粒混杂对TiB2/Cu复合材料微观组织和性能的影响[J]. 材料热处理学报, 2018, 39(8):7-13.ZHANG Shengli, SONG Kexing, GUO Xiuhua, et al. Effect of mixing TiB2 particles on microstructure and properties of TiB2/Cu composites[J]. Transactions of Materials and Heat Treatment,2018,39(8):7-13(in Chinese). [24] 杜洛金, 奚同庚, 王梅花. 固体热物理性质导论-理论和测量[M]. 北京: 中国计量出版社, 1987.DU Luojin, XI Tonggeng, WANG Meihua. Introduction to solid thermophysical properties-theory and measurement[M]. Beijing: China Metrology Publishing House, 1987(in Chinese). [25] GUO X, SONG K, LIANG S, et al. Effect of the thermal expansion characteristics of reinforcements on the electrical wear performance of copper matrix composite[J]. Tribology Transactions,2014,57(2):283-291. doi: 10.1080/10402004.2013.870271 [26] 郭源. 纳米线热导率的尺寸效应[D]. 湘潭: 湘潭大学, 2015.GUO Yuan. Size effect of nanowire thermal conductivity[D]. Xiangtan: Xiangtan University, 2015(in Chinese). [27] 马双彦, 王恩泽, 鲁伟员, 等. 金刚石/铜复合材料热导率研究[J]. 热加工工艺, 2008, 37(4):36-38. doi: 10.3969/j.issn.1001-3814.2008.04.011MA Shuangyan, WANG Enze, LU Weiyuan, et al. Research on thermal conductivity of diamond/copper composites[J]. Hot Working Technology,2008,37(4):36-38(in Chinese). doi: 10.3969/j.issn.1001-3814.2008.04.011 -

下载:

下载: