Moisture absorption and mechanical properties of kenaf fiber-cotton fiber blended fabric/epoxy composite

-

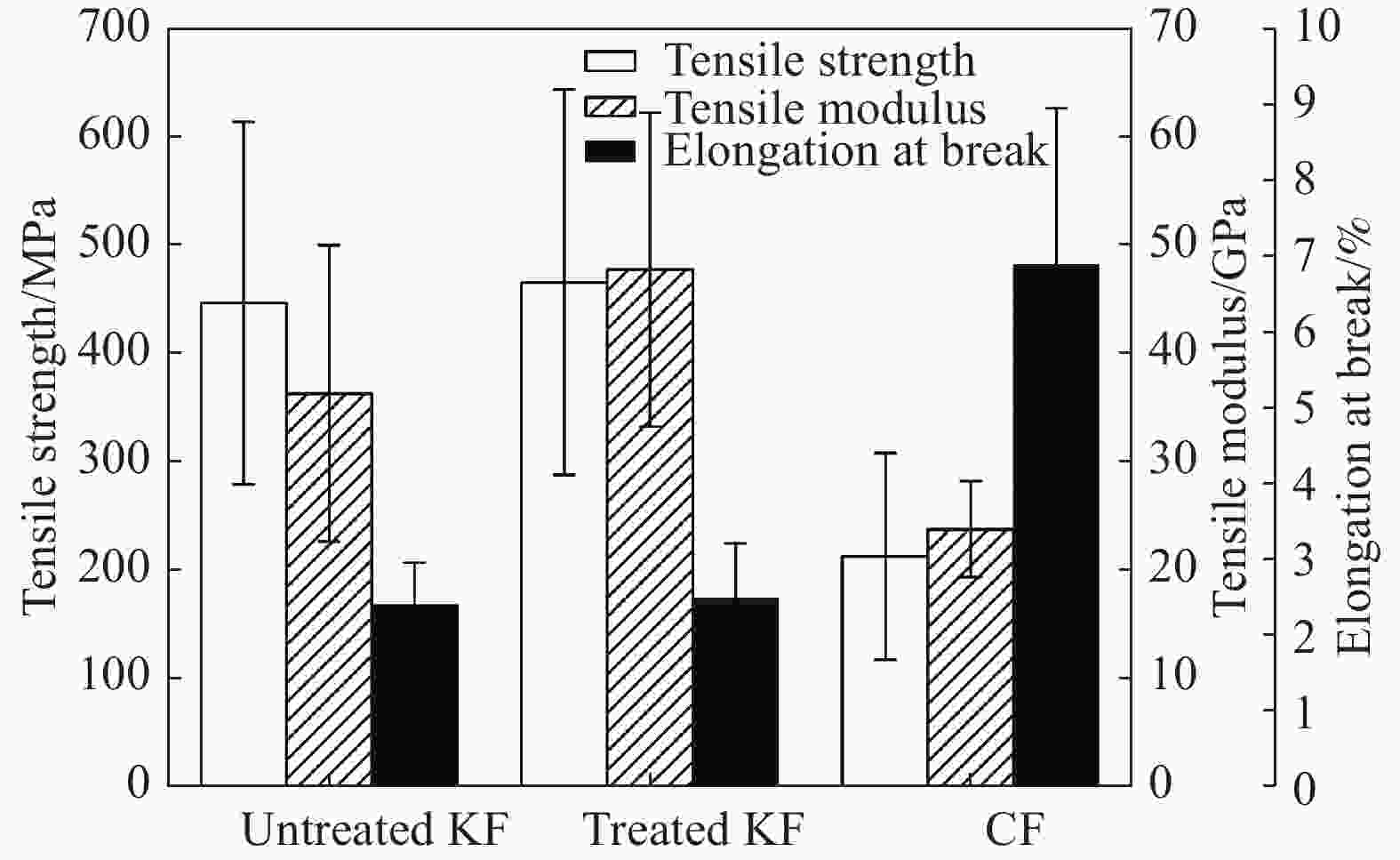

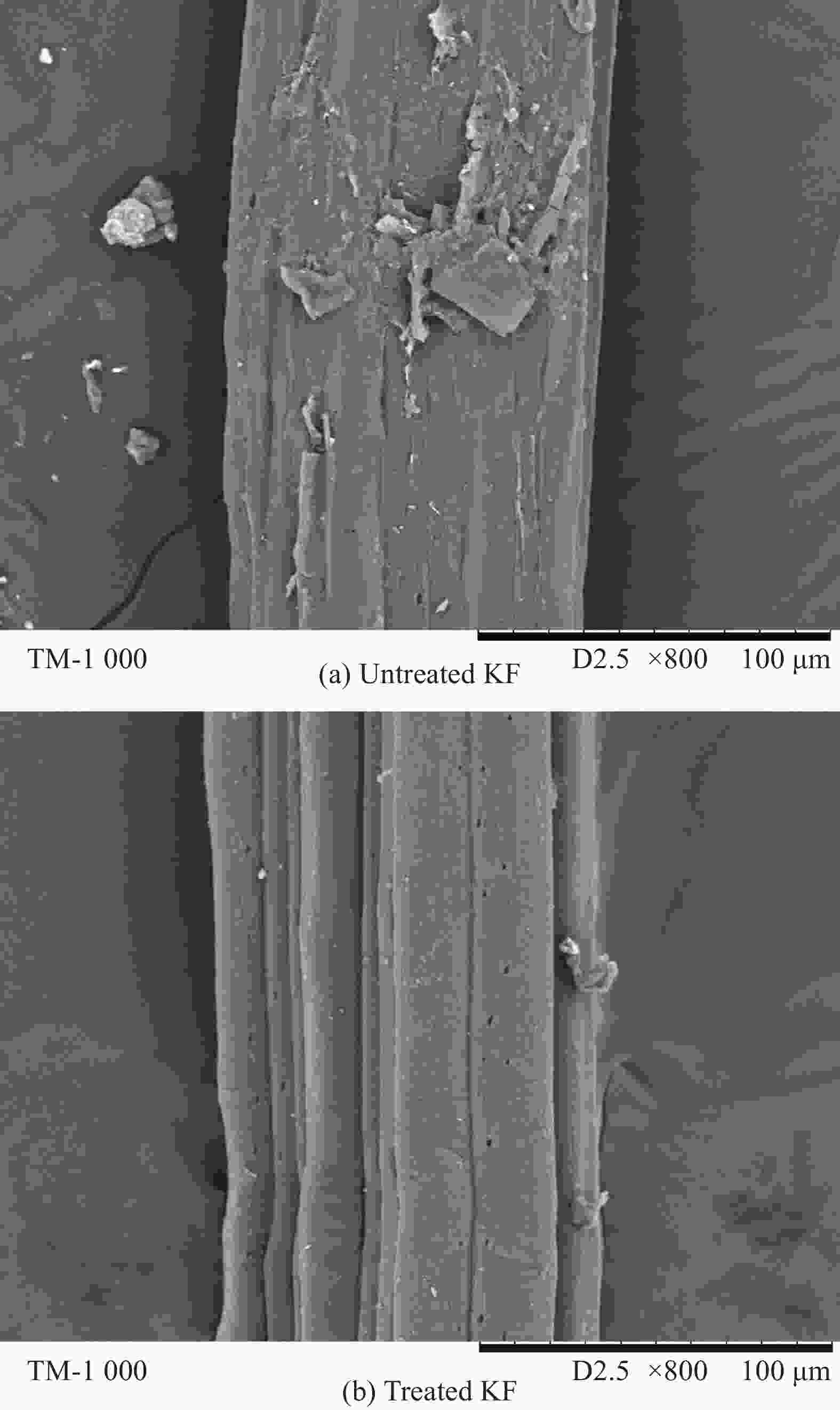

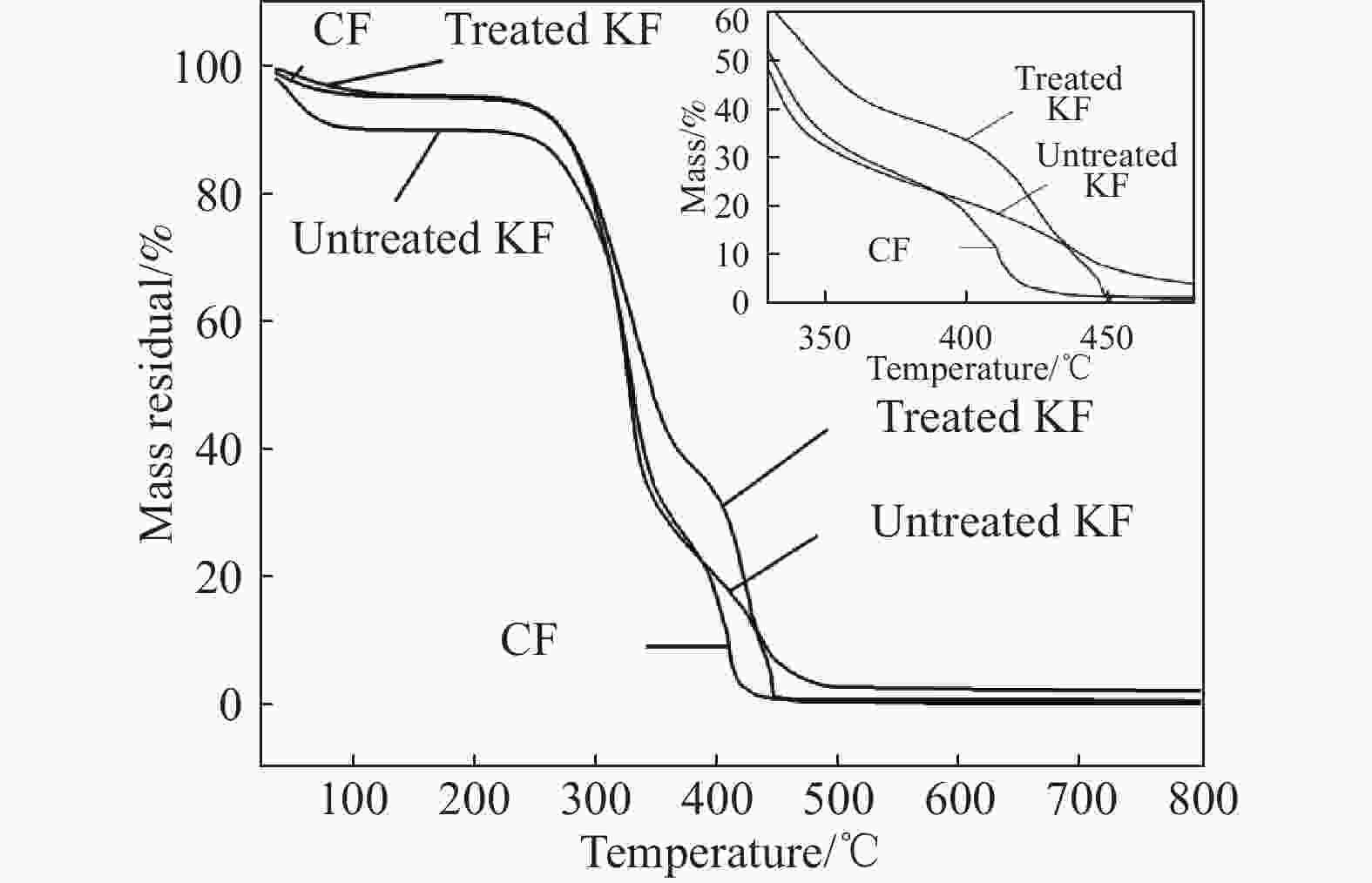

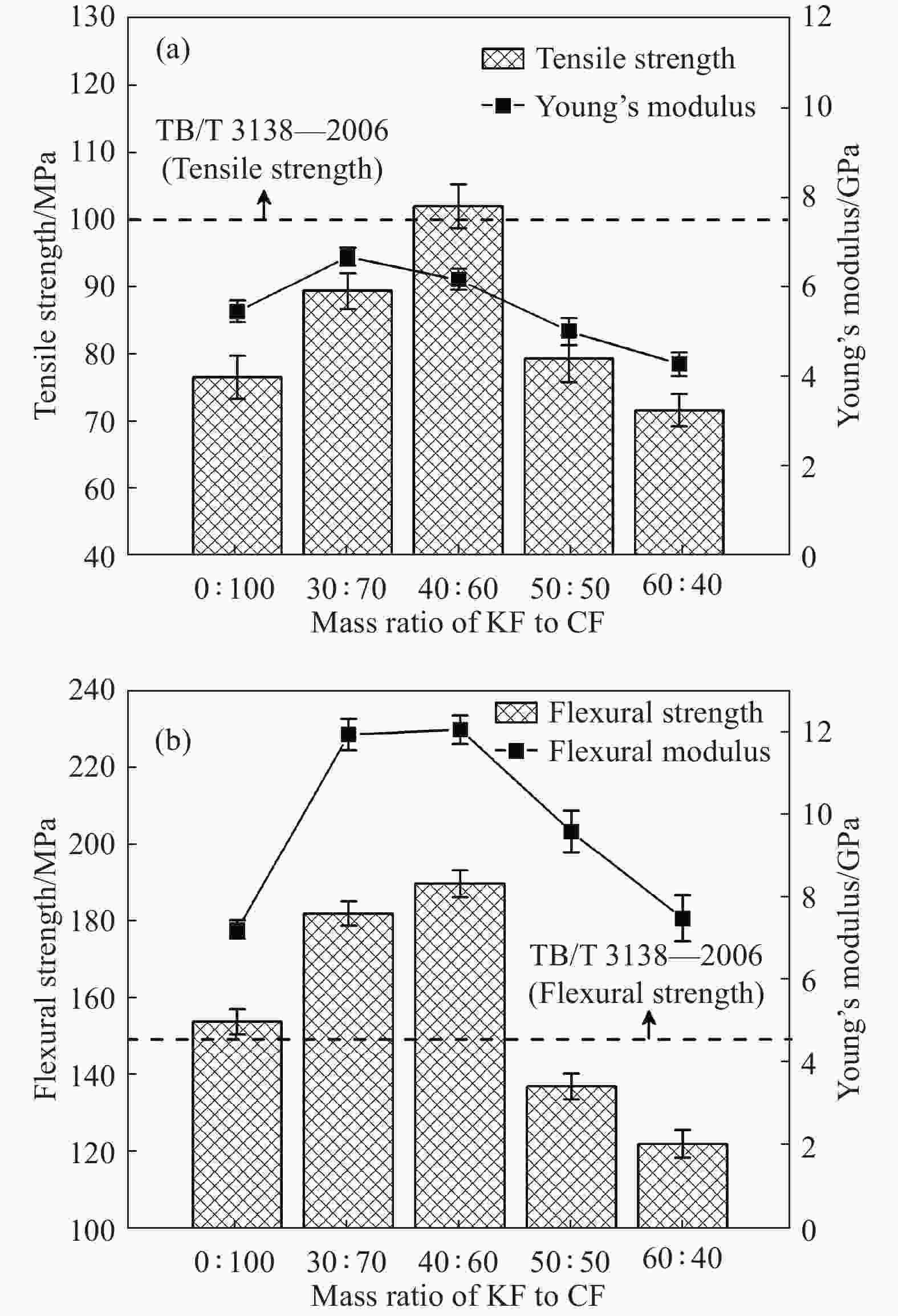

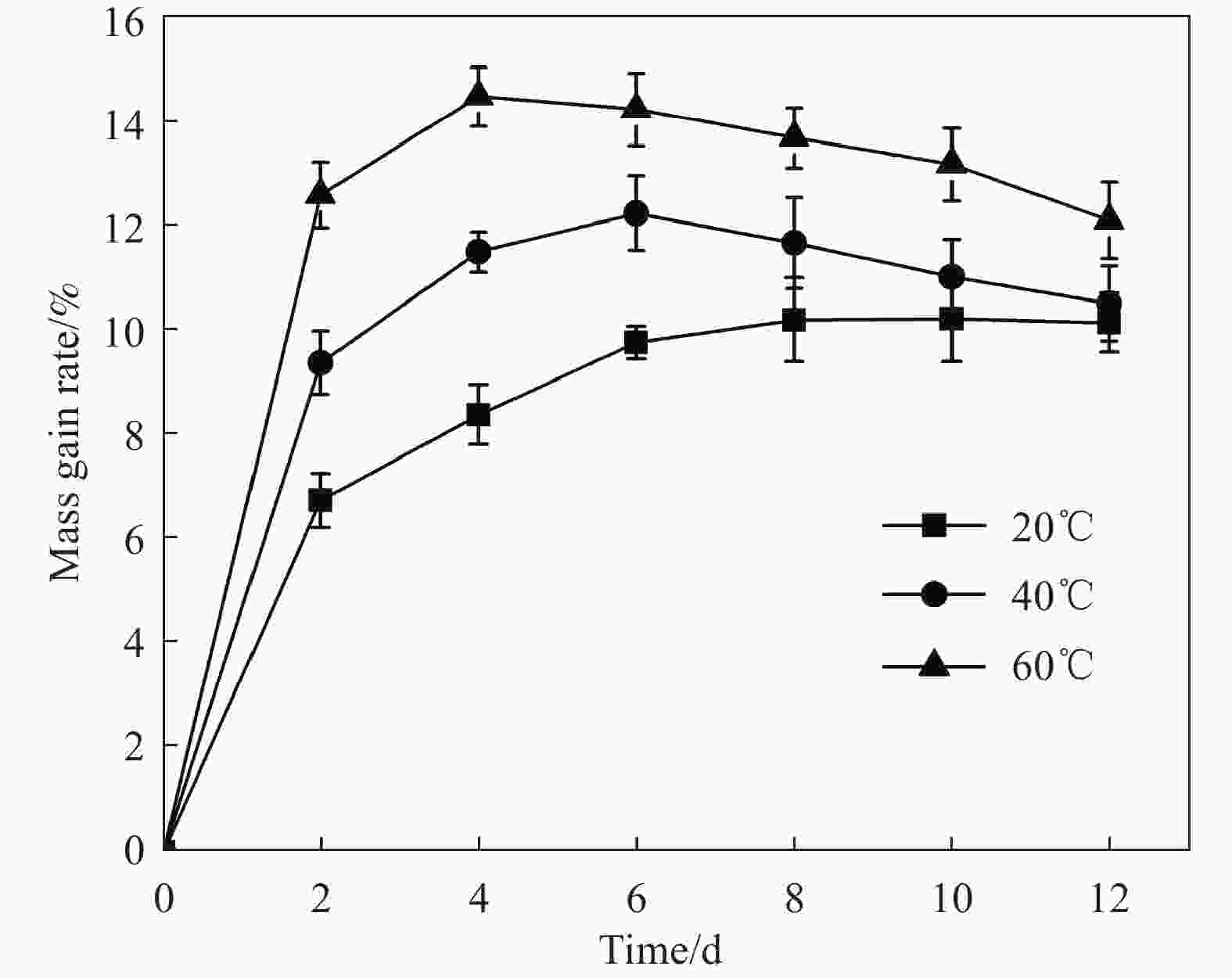

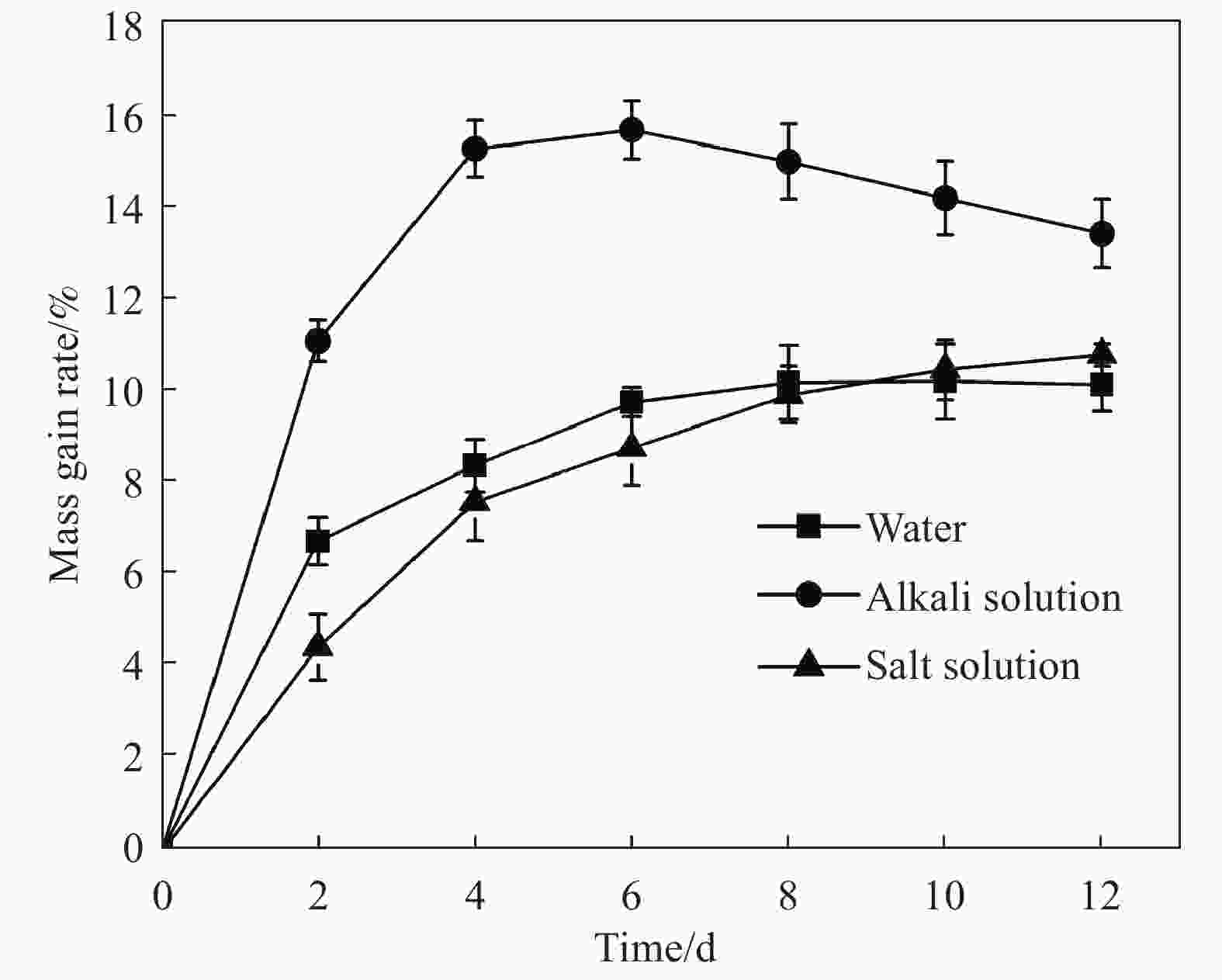

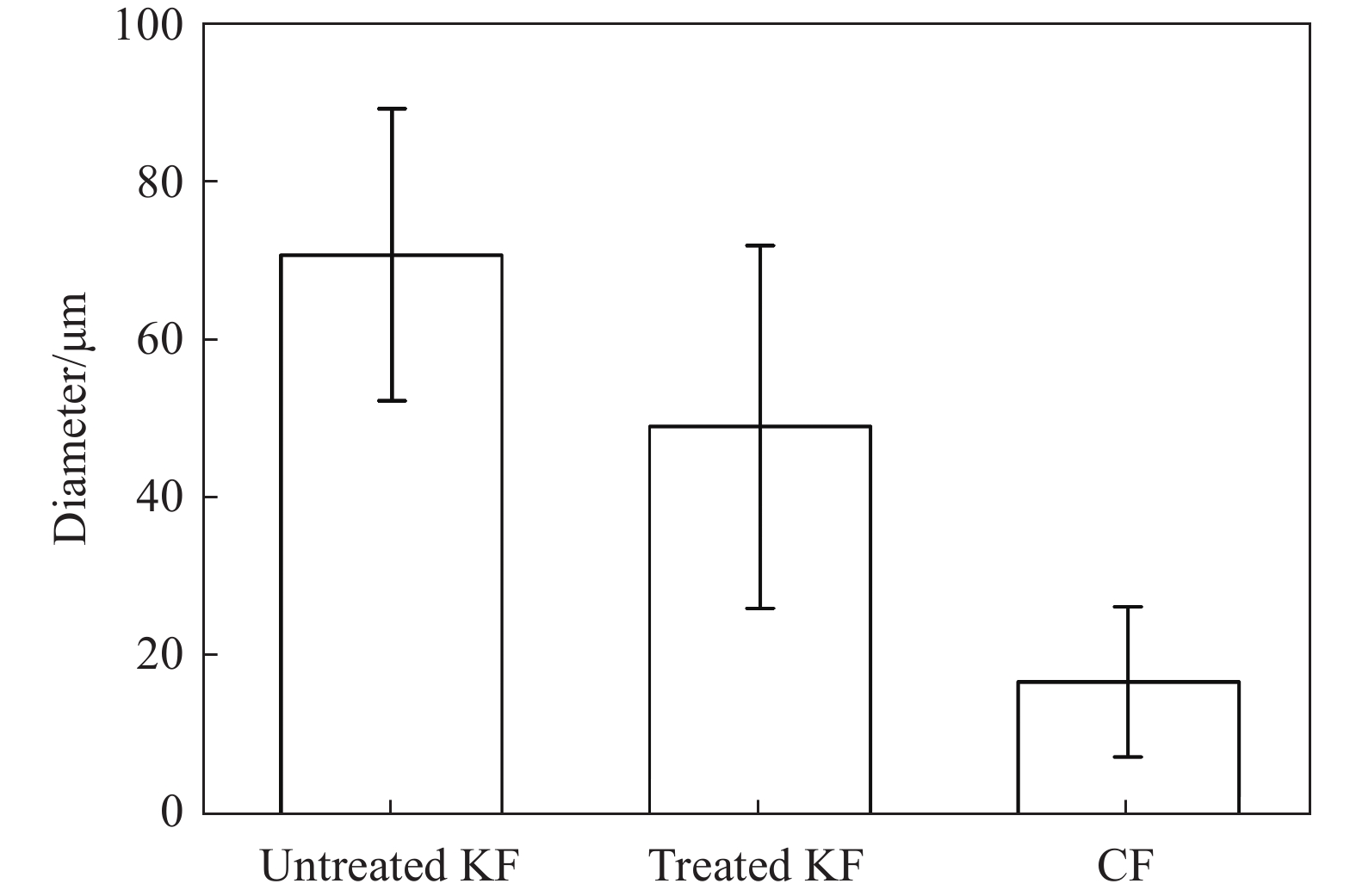

摘要: 采用碱氧一浴法对洋麻纤维(KF)进行精细化处理,并制备了不同混纺质量比的精细化处理KF-棉纤维(KF-CF)混纺织物及KF-CF/环氧树脂(EP)复合材料。通过纤维强度、细度测试和FTIR、TG、SEM研究了精细化处理对KF性能的影响,通过对KF-CF/EP复合材料力学性能分析得到最佳混纺质量比,探究了最佳混纺质量比KF-CF/EP复合材料在湿热及化学环境下的吸湿性能。结果表明:精细化处理后的KF直径降低了30.66%,拉伸模量提高了31.24%,柔软度提高了13.20%,热稳定性得到提高;当KF与CF混纺质量比为40∶60时,KF-CF/EP复合材料力学性能最优,拉伸强度为101.90 MPa,弯曲强度为189.64 MPa;在湿热环境下,时间越长,温度越高,KF-CF/EP复合材料的吸水率越高,碱性环境会导致KF-CF/EP复合材料吸水率提高。Abstract: The kenaf fiber(KF) was modified with the alkali peroxide in the aqueous solution. The refined KF-cotton fiber(KF-CF) blended fabrics with different blending mass ratios and KF-CF/epoxy(EP) composites were prepared. The single fiber tester, microscope, FTIR, TG and SEM were used to study the effect of fine treatment on the properties of KF. The best blending mass ratio was obtained by analyzing the mechanical properties of KF-CF/EP composites. The hygroscopicity of KF-CF/EP composites under hydrothermal and chemical conditions was investigated at the optimum blending ratio. The results show that the diameter of KF decreases by 30.66%, the Young’s modulus increases by 31.24%, the softness increases by 13.20%, and the thermal stability improves after refinement treatment. The KF-CF/EP composite with mass ratio of 40∶60 has the best mechanical properties with tensile strength of 101.90 MPa and flexural strength of 189.64 MPa. In the humid and hot environment, the longer the time and the higher the temperature, the higher the water absorption rate of the KF-CF/EP composite, and the alkaline environment leads the water absorption rate of the KF-CF/EP composite to increase.

-

Key words:

- kenaf fiber /

- fine treatment /

- composites /

- mechanical property /

- moisture absorption

-

表 1 精细化处理前后KF的断裂捻回数

Table 1. Twist numbers at fracture of KF before and after refinement treatment

Fibers Twist number at fracture/(T(10 cm)−1) Untreated KF 15.2±2.7 Treated KF 19.7±2.4 -

[1] PREMNATH A A. Impact of surface treatment on the mechanical properties of sisal and jute reinforced with epoxy resin natural fiber hybrid composites[J]. Journal of Natural Fibers,2019,16(5):718-728. doi: 10.1080/15440478.2018.1432002 [2] LEE M S, SEO H Y, KANG C G. Comparative study on mechanical properties of CR340/CFRP composites through three point bending test by using theoretical and experimental methods[J]. International Journal of Precision Engineering and Manufacturing: Green Technology,2016,3(4):359-365. doi: 10.1007/s40684-016-0045-z [3] 李文略, 金关荣, 骆霞虹, 等. 不同红麻品种的土壤重金属污染修复潜力对比研究[J]. 农业环境科学学报, 2018, 37(10):2150-2158. doi: 10.11654/jaes.2018-0381LI Wenlue, JIN Guanrong, LUO Xiahong, et al. Comparative study on the potential of a kenaf (Hibiscus cannabinus) variety for remediating heavy metal contaminated soils[J]. Journal of Agro Environment Science,2018,37(10):2150-2158(in Chinese). doi: 10.11654/jaes.2018-0381 [4] 曹勇, 吴义强, 合田公一. 洋麻增强复合材料的开发和应用[J]. 高分子材料科学与工程, 2008, 24(7):11-15. doi: 10.3321/j.issn:1000-7555.2008.07.003CAO Yong, WU Yiqiang, GODA Koichi. Development and application of composites reinforced with kenaf[J]. Polymer Materials Science and Engineering,2008,24(7):11-15(in Chinese). doi: 10.3321/j.issn:1000-7555.2008.07.003 [5] FISCHER S, 洪枚青. 洋麻: 造纸用原料[J]. 国际造纸, 1983(2):7-8.FISCHER S, HONG M Q. Kenaf: Raw material for paper making[J]. World Pulp and Paper,1983(2):7-8(in Chinese). [6] 何顺辉, 王春红, 吴美雅. 洋麻纤维精细化处理及性能测试[J]. 天津工业大学学报, 2013, 32(6):28-31. doi: 10.3969/j.issn.1671-024X.2013.06.007HE Shunhui, WANG Chunhong, WU Meiya. Fine treatment and performance test of kenaf fiber[J]. Journal of Tianjin Polytechnic University,2013,32(6):28-31(in Chinese). doi: 10.3969/j.issn.1671-024X.2013.06.007 [7] 王春红, 何顺辉, 吴美雅, 等. 纺纱方法对洋麻/芳纶长丝混纺纱性能的影响[J]. 上海纺织科技, 2014, 42(2):17-20.WANG Chunhong, HE Shunhui, WU Meiya, et al. The effect of spinning method on the performance of kenaf/aramid filament blended yarn[J]. Shanghai Tixtile Science and Technology,2014,42(2):17-20(in Chinese). [8] 王春红, 贾瑞婷, 何顺辉, 等. 洋麻纤维碱氧-浴一步柔软法精细化工艺优化[J]. 天津工业大学学报, 2015, 34(3):16-19, 23. doi: 10.3969/j.issn.1671-024x.2015.03.004WANG Chunhong, JIA Ruiting, HE Shunhui, et al. Optimization for softing refining process of kenaf fiber with alkali and hydrogen peroxide in one step[J]. Journal of Tianjin Polytechnic University,2015,34(3):16-19, 23(in Chinese). doi: 10.3969/j.issn.1671-024x.2015.03.004 [9] GOUTIANOS S, PEIJS T, NYSTROM B, et al. Development of flax fibre based textile reinforcements for composite applications[J]. Applied Composite Materials,2006,13(4):199-215. doi: 10.1007/s10443-006-9010-2 [10] 曾竟成, 肖加余, 梁重云, 等. 黄麻纤维增强聚合物复合材料工艺与性能研究[J]. 玻璃钢/复合材料, 2001(2):30-33. doi: 10.3969/j.issn.1003-0999.2001.02.009ZENG Jingcheng, XIAO Jiayu, LIANG Chongyun, et al. Study on technology and properties of jute fiber reinforced polymer composites[J]. Fiber Reinforced Plastics/Composites,2001(2):30-33(in Chinese). doi: 10.3969/j.issn.1003-0999.2001.02.009 [11] 王新玲, 苏真. 苎麻织物表面改性对其增强环氧树脂复合材料力学性能的影响[J]. 山东纺织科技, 2017, 58(2):1-4. doi: 10.3969/j.issn.1009-3028.2017.02.002WANG Xinling, SU Zhen. Effect of surface modification on mechanical properties of ramie fabrics reinforced epoxy resin composites[J]. Shandong Textile Science & Technology,2017,58(2):1-4(in Chinese). doi: 10.3969/j.issn.1009-3028.2017.02.002 [12] 赵文杰, 胡求学, 闫雯玲, 等. 改性亚麻布/不饱和聚酯复合材料的吸湿及力学性能[J]. 复合材料学报, 2018, 35(1):35-43.ZHAO Wenjie, HU Qiuxue, YAN Wenling, et al. Moisture absorption and mechanical property of modified linen/unsaturated polyester composites[J]. Acta Materiae Compositae Sinica,2018,35(1):35-43(in Chinese). [13] 张永励, 李岩, 孙震. 织物形式对苎麻纤维渗透率及其复合材料力学性能的影响[J]. 复合材料学报, 2013, 30(2):195-200.ZHANG Yongli, LI Yan, SUN Zhen. Influence of fabric woven styles on the permeability and mechanical properties of ramie fiber reinforced composites[J]. Acta Materiae Compositae Sinica,2013,30(2):195-200(in Chinese). [14] EL-SHEKEIL Y A, SAPUAN S M, JAWAID M, et al. Influence of fiber content on mechanical, morphological and thermal properties of kenaf fibers reinforced poly(vinyl chloride)/thermoplastic polyurethane poly-blend composites[J]. Materials and Design,2014,58:130-135. doi: 10.1016/j.matdes.2014.01.047 [15] 王春红, 贾瑞婷, 白肃跃, 等. 洋麻/芳纶混纺织物增强复合材料的力学性能研究[J]. 玻璃钢/复合材料, 2015(3):15-19.WANG Chunhong, JIA Ruiting, BAI Suyue, et al. Mechanical properties of kenaf/aramid blended fabric reinforced composites[J]. Fiber Reinforced Plastics/Composites,2015(3):15-19(in Chinese). [16] 中国国家标准化管理委员会. 纺织原料细度实验方法(直径)显微镜投影仪法: SN/T 2672—2010[S]. 北京: 中国标准出版社, 2011.Standardization Administration of the People’s Republic of China. Textile raw materials fineness testing method(diameter): Micro projection: SN/T 2672—2010[S]. Beijing: China Standards Press, 2011(in Chinese). [17] ASTM International. Standard test method for tensile properties of single textile fibers: ASTM D3822M—14[S]. West Conshohocken: ASTM International, 2020. [18] 中国国家标准化管理委员会. 黄、洋(红)麻纤维柔软度试验方法-捻度计试验法: GB/T 12411.4—1990[S]. 北京: 中国标准出版社, 1991.Standardization Administration of the People’s Republic of China. Test method for softness of jute and kenaf fibres: Twist tester method: GB/T 12411.4—1990[S]. Beijing: China Standards Press, 1991(in Chinese). [19] ASTM International. Standard test method for tensile properties of plastic: ASTM D638—10[S]. West Conshohocken: ASTM International, 2010. [20] ASTM International. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: ASTM D790—17[S]. West Conshohocken: ASTM International, 2017. [21] ASTM International. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229M—20[S]. West Conshohocken: ASTM International, 2020. [22] 林天扬, 王春红, YOUSFANI S H S, 等. 碱处理提取竹黄纤维的响应曲面优化[J]. 复合材料学报, 2018, 35(4):876-884.LIN T Y, WANG C H, YOUSFANI S H S, et al. Study on extraction technology of bamboo fiber by response surface[J]. Acta Material Compositae Sinica,2018,35(4):876-884(in Chinese). [23] 王金霞, 刘温霞. 纤维素的化学改性[J]. 纸和造纸, 2011, 30(8):31-37.WANG Jinxia, LIU Wenxia. Chemical modification of cellulose[J]. Paper and Paper Making,2011,30(8):31-37(in Chinese). [24] 王伟, 左小彪, 李杰, 等. 阻燃增韧环氧树脂及其复合材料性能研究[J]. 宇航材料工艺, 2011, 41(1):42-45. doi: 10.3969/j.issn.1007-2330.2011.01.010WANG Wei, ZUO Xiaobiao, LI Jie, et al. Properties of flame retardant and toughening epoxy resin and composite[J]. Aerospace Materials & Technology,2011,41(1):42-45(in Chinese). doi: 10.3969/j.issn.1007-2330.2011.01.010 [25] 窦艳丽, 李雪菲, 张天琪, 等. β-环糊精/聚磷酸铵对黄麻/聚丙烯复合材料阻燃性能的影响[J]. 复合材料学报, 2019, 36(11):2568-2578.DOU Yanli, LI Xuefei, ZHANG Tianqi, et al. Effect of β-cyclodextrin and ammonium polyphosphate on flame retardancy of jute/polypropylene composites[J]. Acta Materiae Compositae Sinica,2019,36(11):2568-2578(in Chinese). [26] 胡晓兰, 兰茜, 代少伟, 等. 黄麻纤维/聚酯纤维复合材料的阻燃改性[J]. 复合材料学报, 2017, 34(4):694-703.HU Xiaolan, LAN Qian, DAI Shaowei, et al. Flame retarded modification of jute fiber/polyester fiber composites[J]. Acta Materiae Compositae Sinica,2017,34(4):694-703(in Chinese). [27] 杨卿, 武书彬. 麦草的热失重特性及动力学[J]. 农业工程学报, 2009, 25(3):193-197.YANG Qing, WU Shubin. Thermal weightlessness characteristics and kinetics of wheat straw[J]. Transactions of The Chinese Society of Agricultural Engineering,2009,25(3):193-197(in Chinese). [28] 中国国家标准化管理委员会. 机车车辆阻燃材料技术条件: TB/T 3138—2006[S]. 北京: 中国标准出版社, 2007.Standardization Administration of the People’s Republic of China. Technical specification of flame retardant materials for railway locomotive and vehicle: TB/T 3138—2006[S]. Beijing: China Standards Press, 2007(in Chinese). [29] 李岩, 罗业. 天然纤维增强复合材料力学性能及其应用[J]. 固体力学学报, 2010, 31(6):613-630.LI Yan, LUO Ye. Mechanical properties and applications of natural fiber reinforced composites[J]. Chinese Journal of Solid Mechanics,2010,31(6):613-630(in Chinese). [30] 高坤, 史汉桥, 孙宝岗, 等. 湿热老化对玻璃纤维/环氧树脂复合材料性能的影响[J]. 复合材料学报, 2016, 33(6):1147-1152.GAO Kun, SHI Hanqiao, SUN Baogang, et al. Effects of hydro-thermal aging on properties of glass fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2016,33(6):1147-1152(in Chinese). [31] 谢荣斌, 薛静, 陈实, 等. 环氧树脂的湿热老化特性研究[J]. 绝缘材料, 2019, 52(6):21-29.XIE Rongbin, XUE Jing, CHEN Shi, et al. Study on hygrothermal aging characteristics of epoxy resin[J]. Insulating Materials,2019,52(6):21-29(in Chinese). [32] 张晖, 阳建红, 李海斌, 等. 湿热老化环境对环氧树脂性能影响研究[J]. 兵器材料科学与工程, 2010, 33(3):41-43. doi: 10.3969/j.issn.1004-244X.2010.03.013ZHAGN Hui, YANG Jianhong, LI Haibin, et al. Effects of hydrothermal aging on properties of epoxy resin[J]. Ordnance Material Science and Engineering,2010,33(3):41-43(in Chinese). doi: 10.3969/j.issn.1004-244X.2010.03.013 -

下载:

下载: