Experiment and failure mechanism of composite fuselage curved panel under circumferential bending load

-

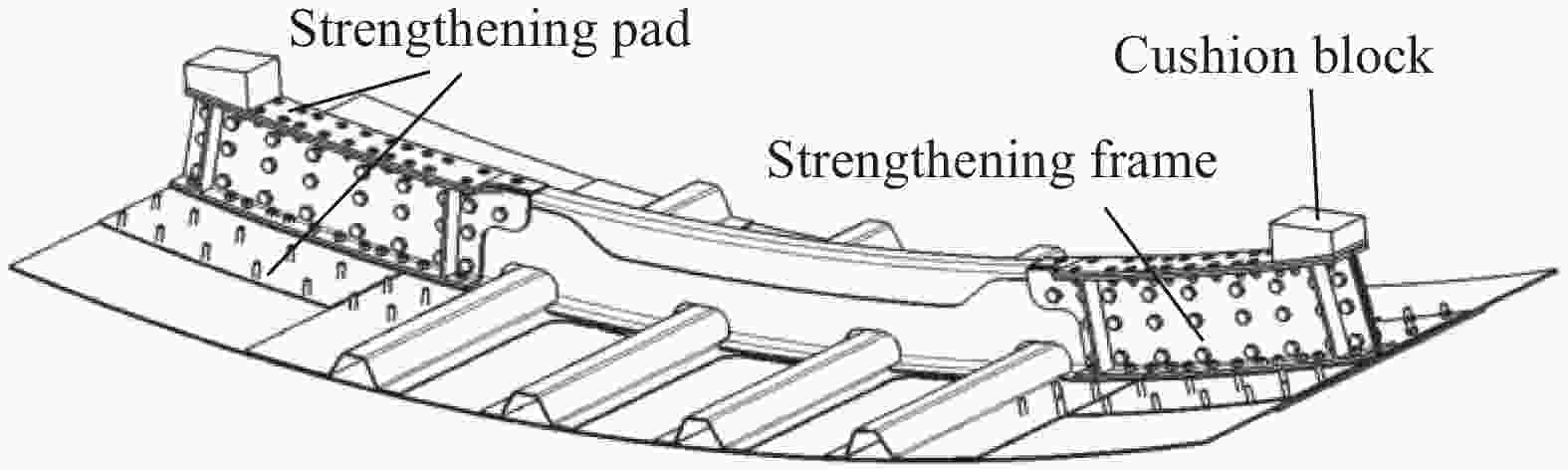

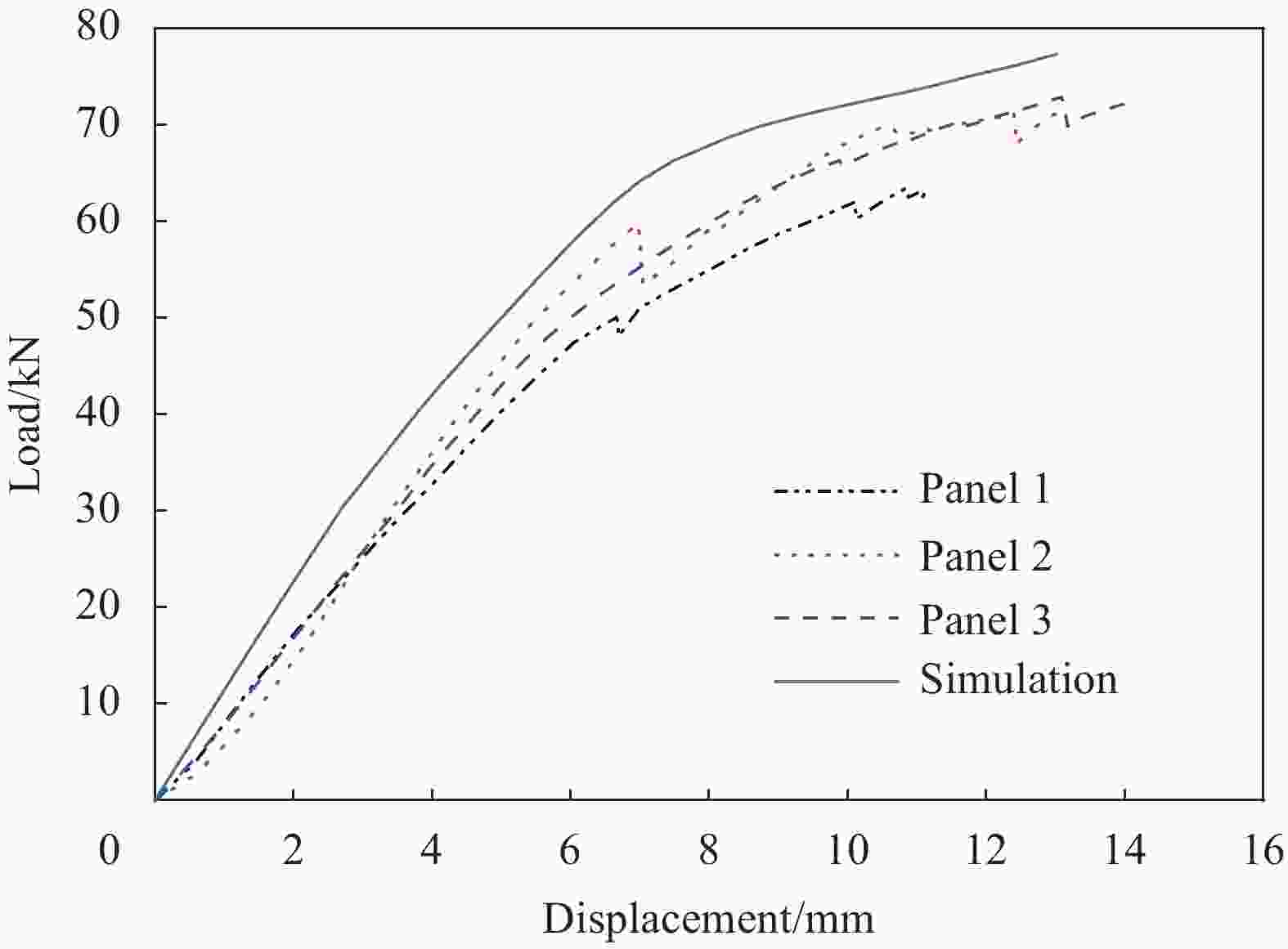

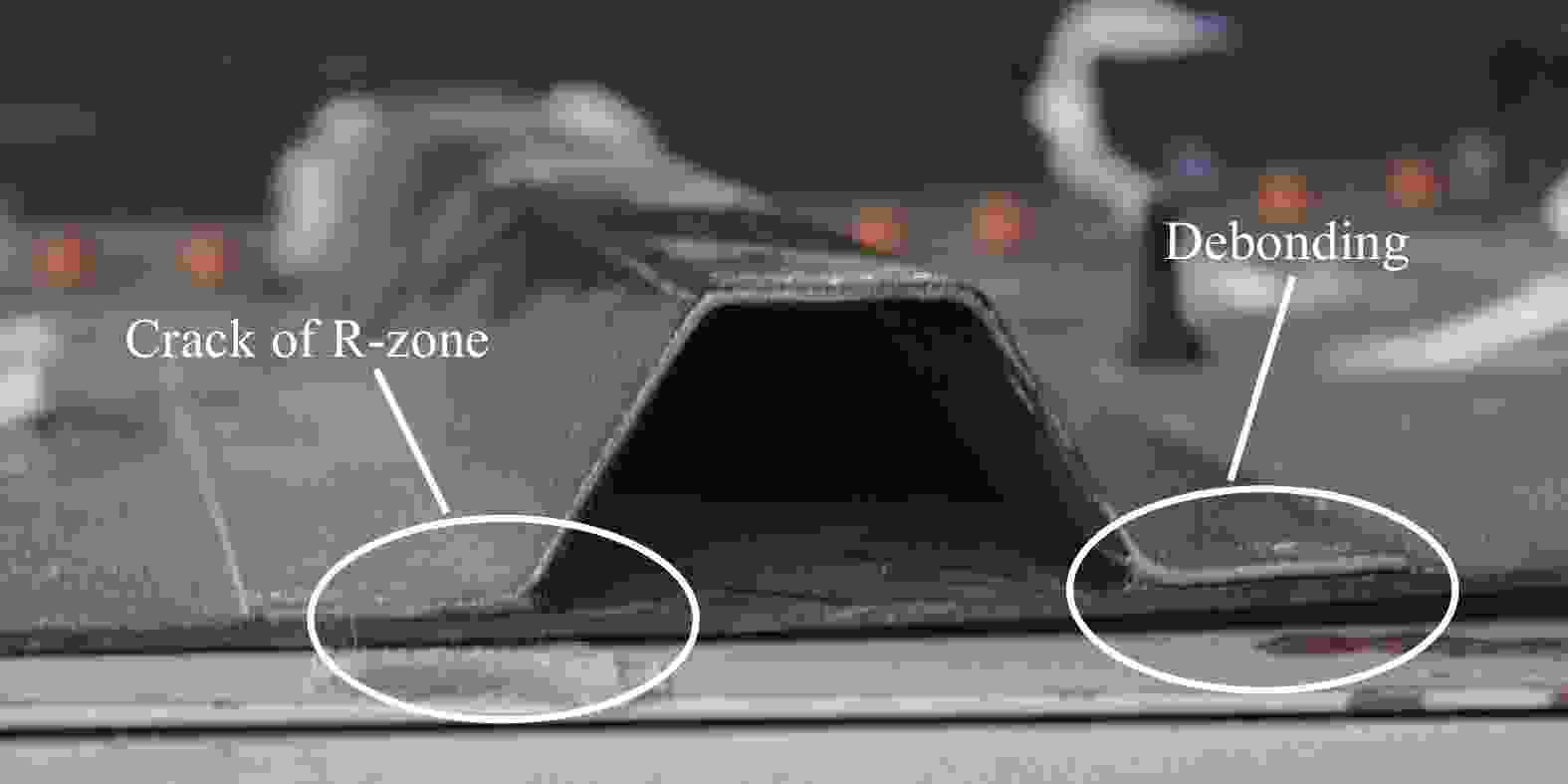

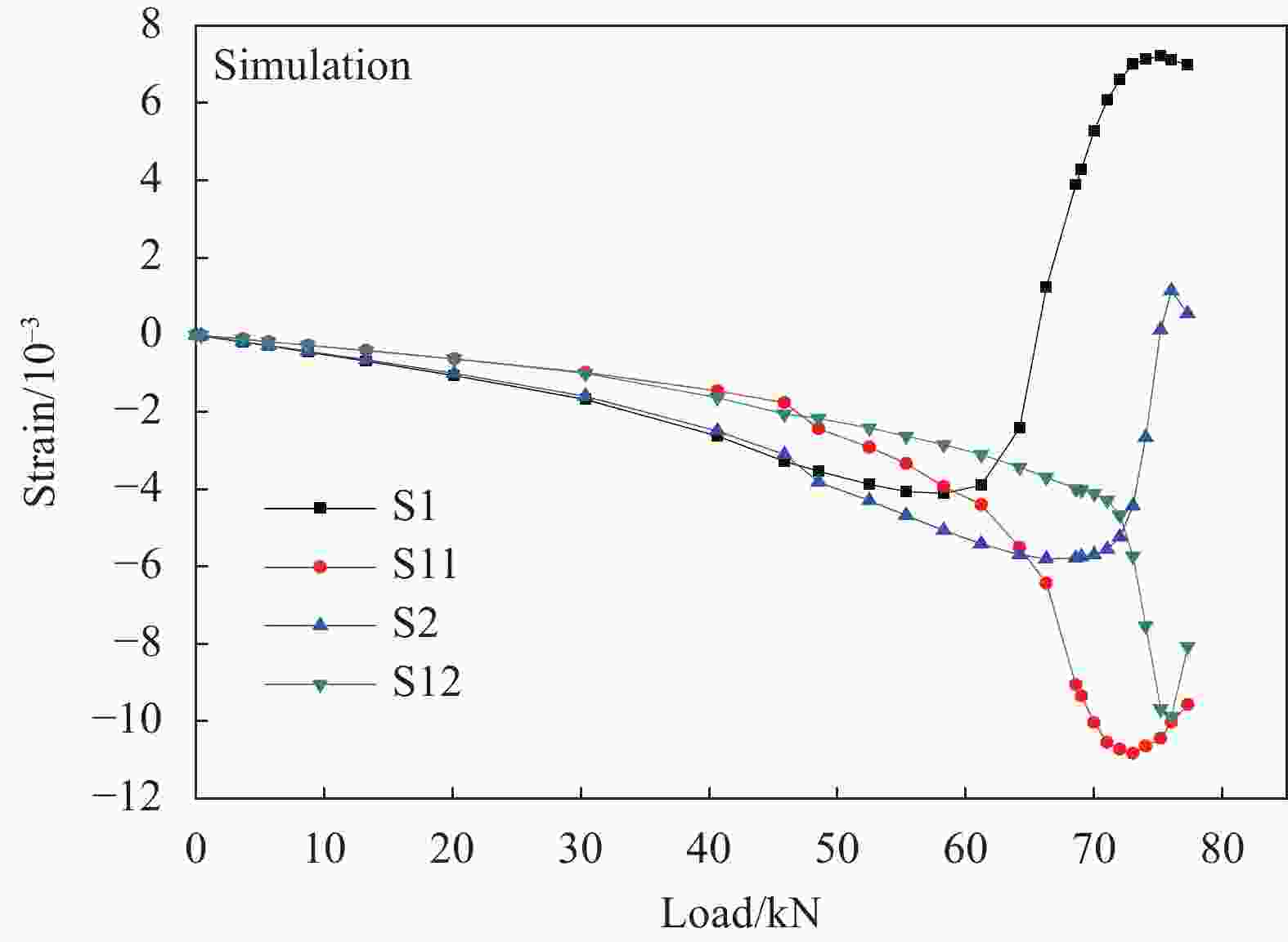

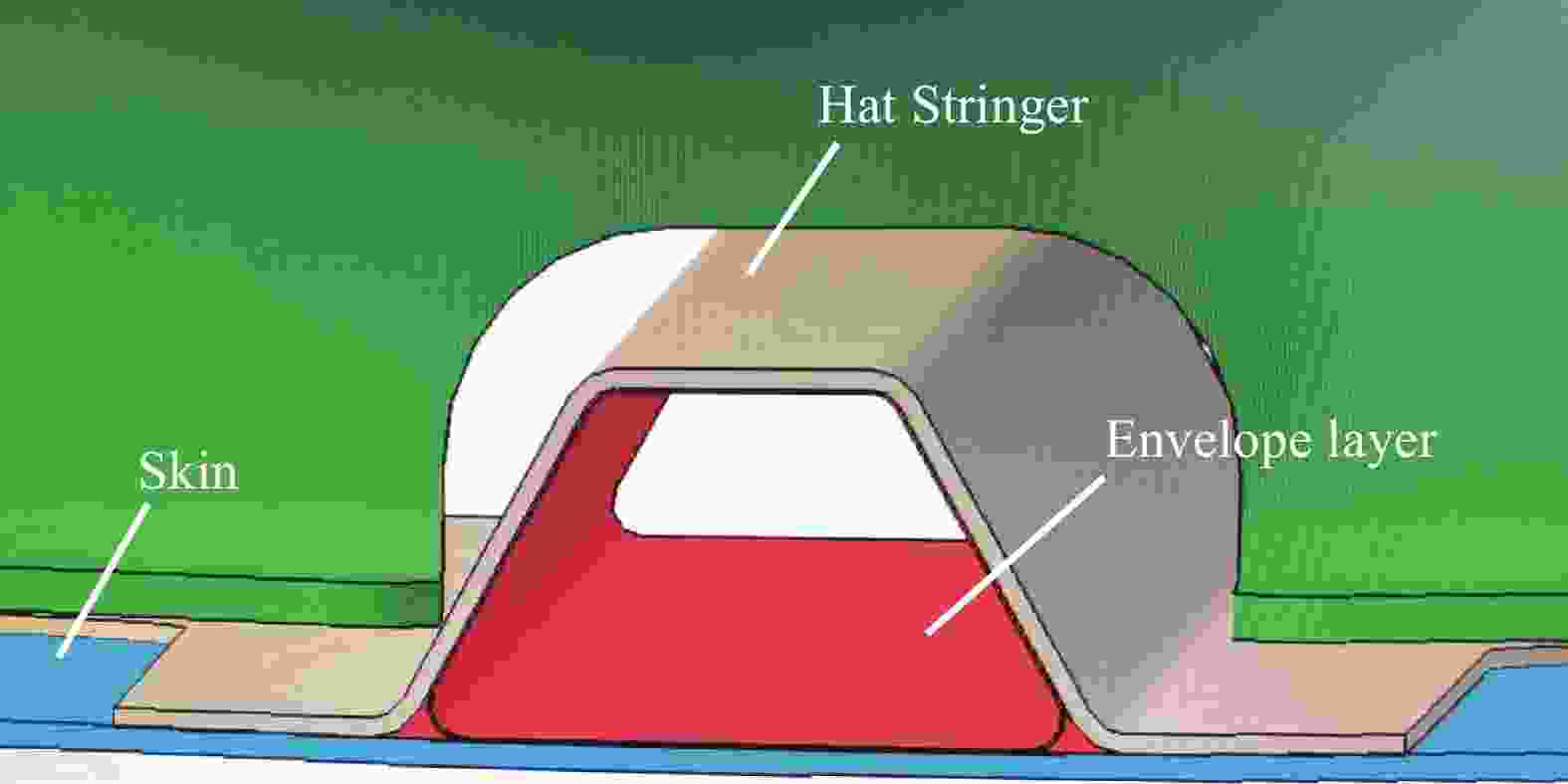

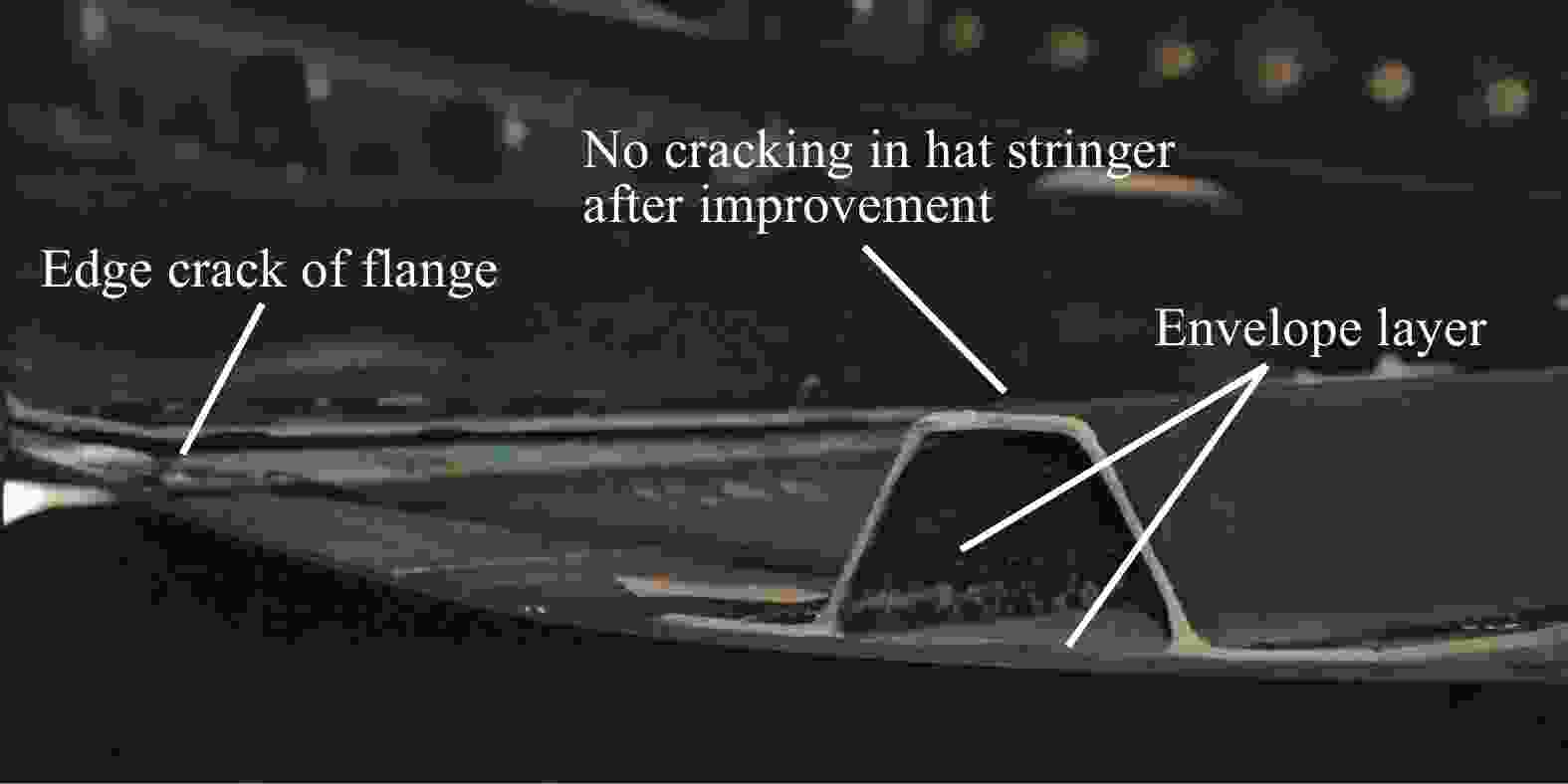

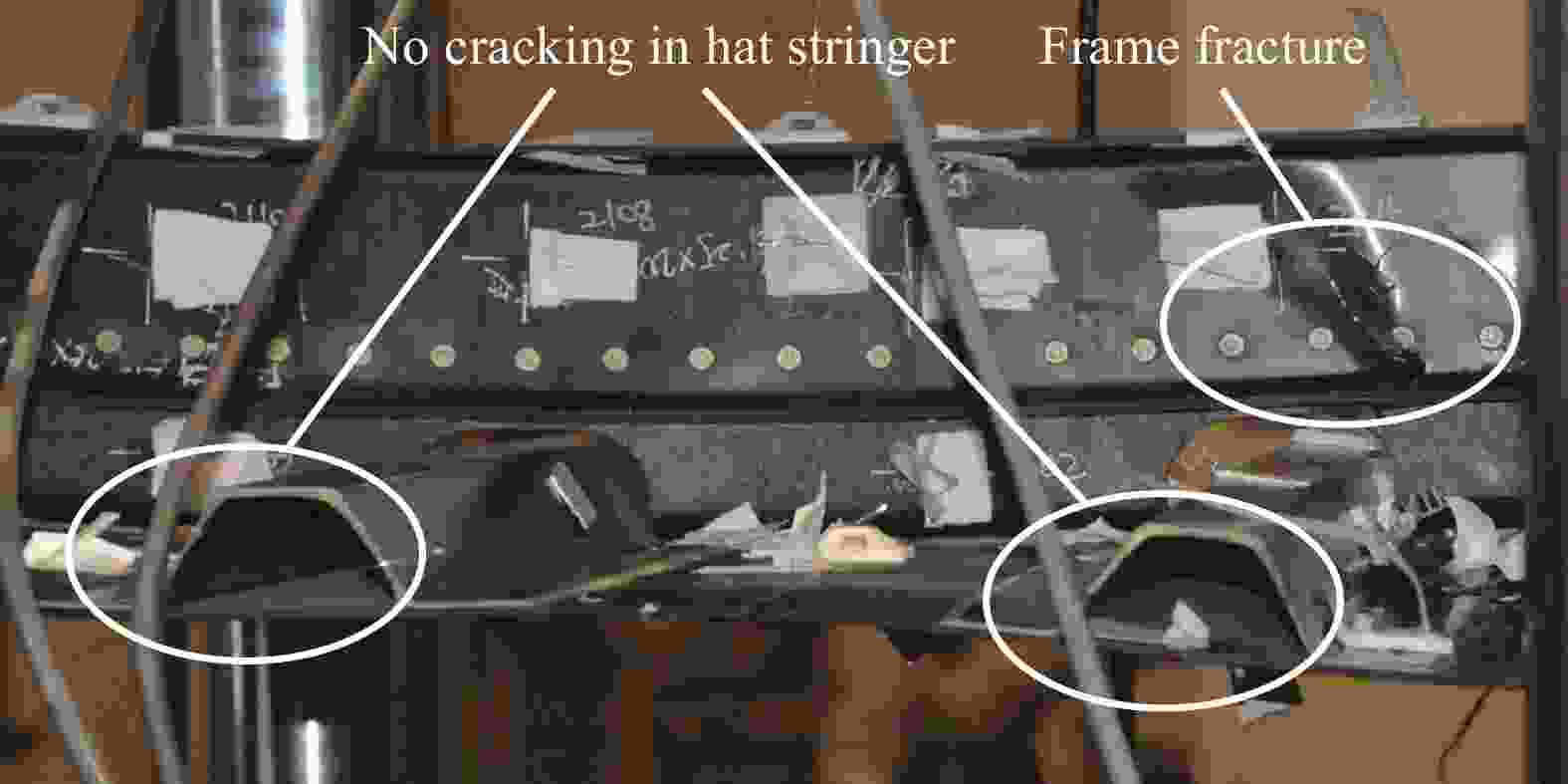

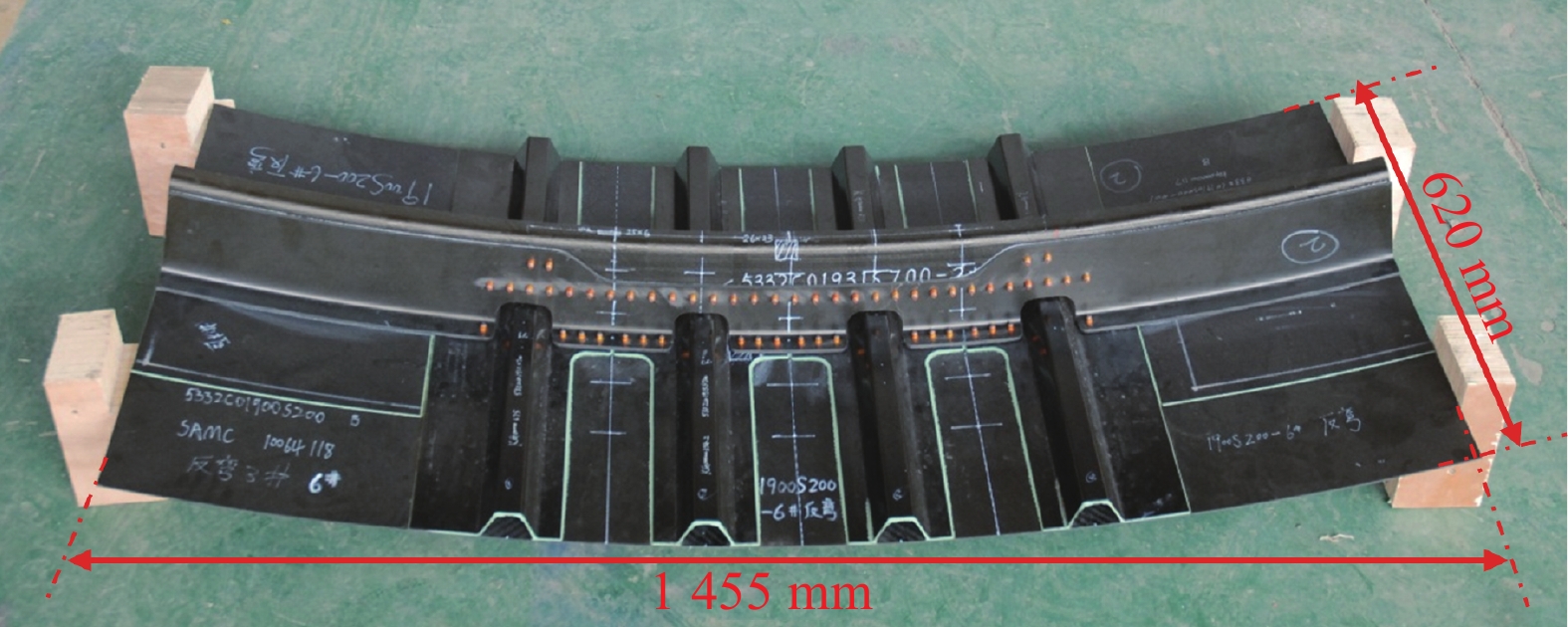

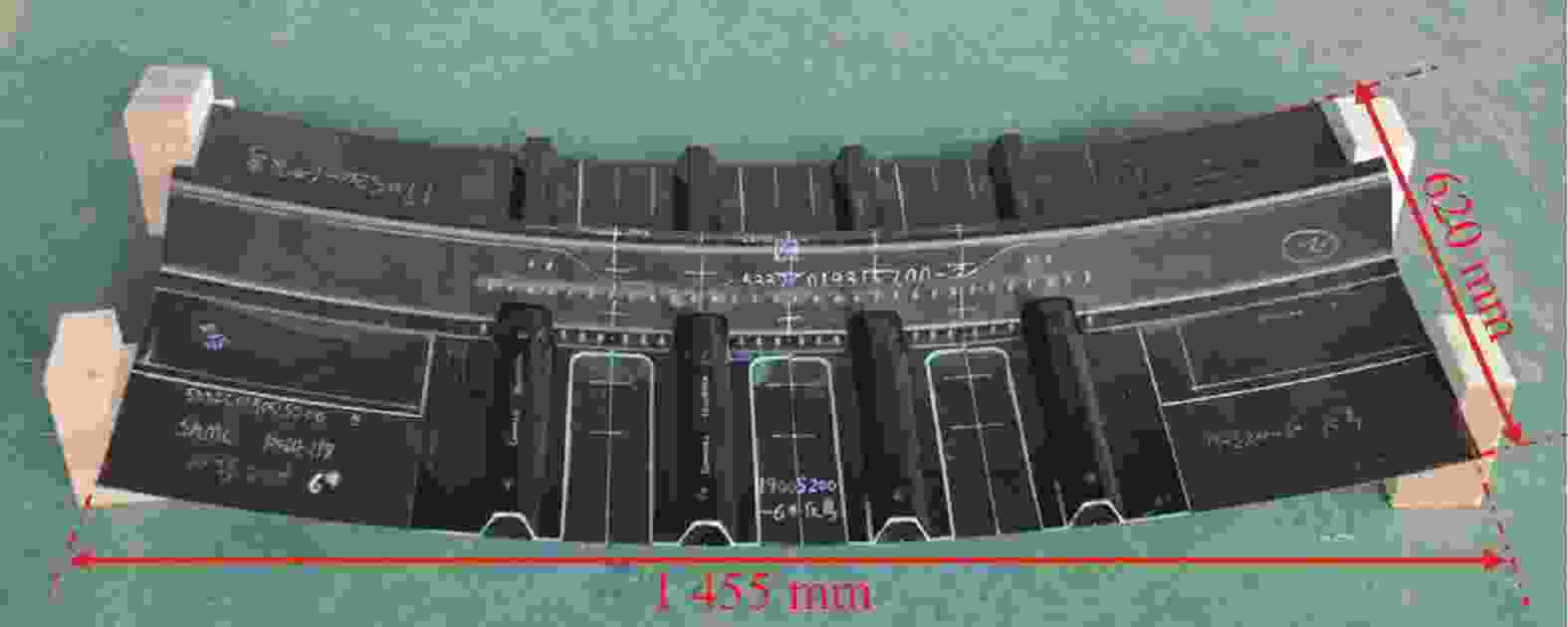

摘要: 对复合材料机身曲板进行了环向弯曲加载试验,采用四点弯加载方式对考核段进行纯弯加载,设计一种加强连接方式避免加载段提前破坏,通过试验对机身曲板的环向稳定性和破坏模式进行了分析。同时,建立了基于内聚力单元的考虑长桁与蒙皮粘接界面损伤的有限元模型,分别使用Quads准则和Hashin准则作为界面和层合板的失效判据分析曲板结构的失效机制,计算结果与试验结果吻合较好。试验及有限元分析结果表明,长桁帽底蒙皮的局部屈曲引起长桁与蒙皮粘接的R区出现初始开裂,并最终扩展为长桁脱粘。随着蒙皮屈曲及长桁脱粘的扩大,蒙皮由局部屈曲变为整体失稳而失去承载能力,最终导致隔框承载过大而发生断裂。根据初始损伤模式,采取了长桁帽内全包工艺改进设计,改进后的曲板结构稳定性和承载能力分别提高了21.9%和16.8%。Abstract: The failure mechanism of the composite fuselage curved panel under circumferential bending load was studied by four-point bending test and finite element analysis (FEA). A set of strengthening and connecting fixture was designed to avoid undesirable failure. A finite element model was also established, in which cohesive element was used to simulate the interface between the hat stringer and skin. Quads criterion and Hashin criterion were used as failure criteria of the interface and the laminate respectively. The results obtained by experiment and FEA are in good agreement. It can be concluded the crack initiates from the R-zone of the bonding area between the hat stringer and skin, due to local buckling of the skin at the bottom of the hat stringer. Then it extends and causes debonding of the hat stringers. With the extension of skin buckling and stringer debonding, the skin shows global instability and loses its bearing capacity, which eventually leads to the failure of the frame due to excessive load. According to the initial damage mode, the full around bonding process between the hat stringer and skin is adopted to improve the circumferential stability of the curved composite panel. The bending test result shows that the bending loads of the initial buckling and overall failure increase 21.9%and 16.8%, respectively.

-

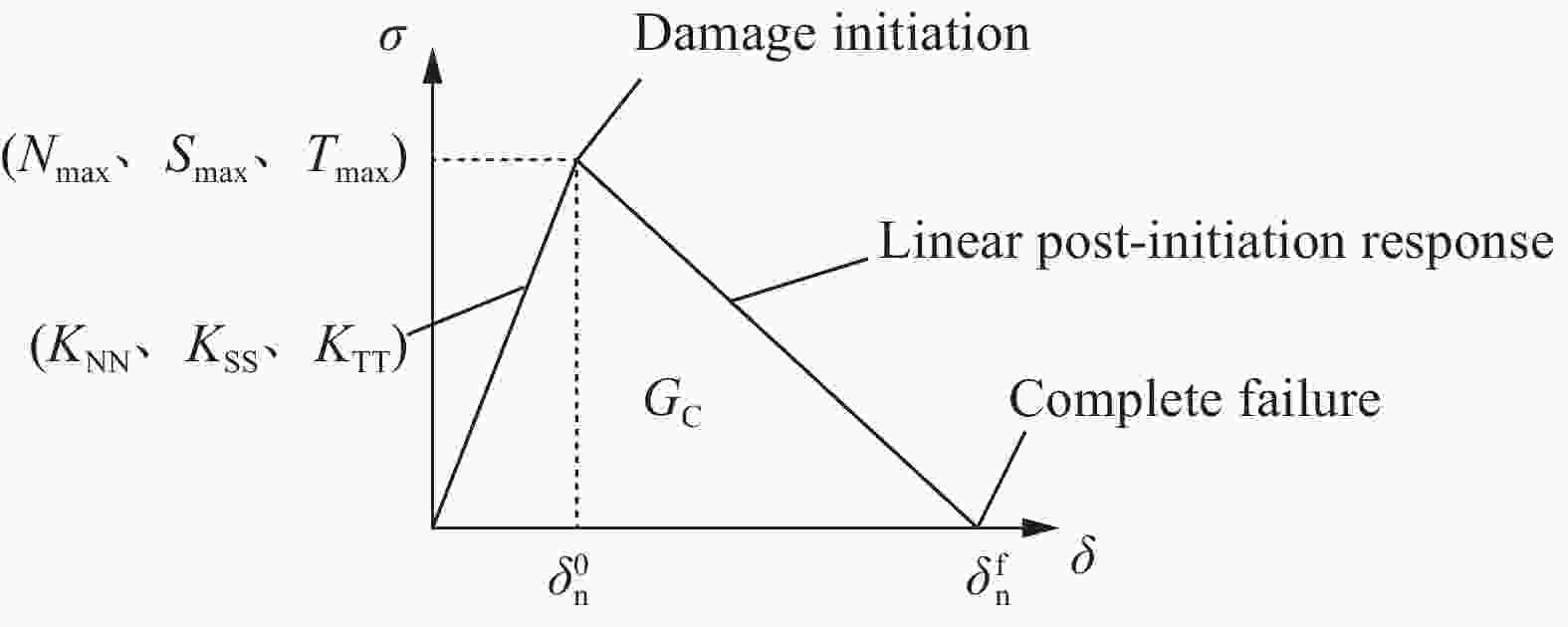

图 8 Cohesive内聚力单元本构关系

Figure 8. Constitutive relation of cohesive element

KNN —Normal stiffness; KSS—Longitudinal shear stiff-ness; KTT—Transvers shear stiffness; Nmax—Tensile strength; Smax— Longitudinal shear strength; Tmax—Transvers shear strength; $\delta _{\rm{n}}^{\rm{0}}$—Original relative displacement; $\delta _{\rm{n}}^{\rm{f}} $—Relative displacement at failure; Gc— Equivalent fracture toughness

表 1 M21E碳纤维/IMA环氧树脂复合材料性能

Table 1. Material properties of M21E carbon fiber/IMA epoxy resin composite

Elastic property Value Strength property Value E11/GPa 154 XT/MPa 2 610 E22/GPa 8.5 XC/MPa 1 450 G12/GPa 4.2 YT/MPa 55 ν12 0.35 YC/MPa 285 S12/MPa 105 Notes: E11—Longitudinal tensile modulus; E22—Transverse tensile modulus; G12—Shear modulus; ν12—Poisson’s ratio; XT—Longitudinal tensile strength; XC—Longitudinal compressive strength; YT—Transverse tensile strength; YC—Transverse compressive strength; S12—Shear strength. 表 2 M21E碳纤维/IMA环氧树脂复合材料试件各部件铺层顺序

Table 2. Layup orientation of M21E carbon fiber/IMA epoxy resin composite parts

Part Patch layup Skin [45/−45/−45/90/45/0]s Shear-clip [45/−45/0/90/−45/45/0/0/45/−45/90/0/−45/45] Stringer [45/0/0/−45/90/−45/0/0/45] Frame [45/−45/0/90/45/−45/90/0/−45/45] 表 3 M21E碳纤维/IMA环氧树脂复合材料机身曲板界面性能参数

Table 3. Material properties of adhesive of M21E carbon fiber/IMA epoxy resin composite fuselage curved panel

Parameter Value Interface strength /MPa Nmax Smax Tmax 40 65 65 Fracture Toughness /(kJ·mm−2) GⅠC GⅡC GⅢC 0.37 0.6 0.6 Elastic constant /(GPa·mm−1) KNN KSS KTT 4 324 7 027 7 027 -

[1] 中国航空研究院. 复合材料结构设计手册[M]. 北京: 航空工业出版社, 2001: 81-86.Institute of Aeronautics China. Design manual of compo-site strcture [M]. Beijing: National Defence Industrial Press, 2001: 81-86(in Chinese). [2] ALBERT R A, ADAM P K. Vibroacoustic tailoring of a rod-stiffened composite fuselage panel with multidisciplinary considerations[J]. Journal of Aircraft,2015,52(2):692-702. doi: 10.2514/1.C033071 [3] 陈业标, 汪海. 飞机复合材料结构强度分析[M]. 上海: 上海交通大学出版社, 2011: 152-159.CHEN Yebiao, WANG Hai. Strength analysis of composite aircraft strctures[M]. Shanghai: ShangHai JiaoTong University Press, 2011: 152-159(in Chinese). [4] 汪厚冰, 陈昊, 雷安民, 等. 复合材料帽形加筋壁板轴压屈曲与后屈曲性能[J]. 复合材料学报, 2018, 35(8):2014-2022.WANG Houbing, CHEN Hao, LEI Anmin, et al. Bcukling and psot-buckling performance of hat-stiffened composite panels under axial compression load[J]. Acta Materiae Compositae Sinica,2018,35(8):2014-2022(in Chinese). [5] MAHER B Z, TAREK L B, MOHAMED S. Mechanical response of a hexagonal grid stiffened design of a pressurized cylindrical shell-application to aircraft fuselage[J]. Thin-Walled Structures,2018(127):40-50. [6] 孔斌, 叶强, 陈普会, 等. 复合材料整体加筋板轴压后屈曲失效表征[J]. 复合材料学报, 2010, 27(5):150-155.KONG Bin, YE Qiang, CHEN Puhui, et al. Post-buckling failure characterization of an integrated stiffened composite panel under uniaxial compression[J]. Acta Materiae Compositae Sinica,2010,27(5):150-155(in Chinese). [7] 刘从玉, 许希武, 陈康. 考虑脱粘的复合材料加筋板屈曲后屈曲及承载能力数值分析[J]. 复合材料学报, 2010, 27(6):158-166.LIU Congyu, XU Xiwu, CHEN Kang. Buckling, post-buckling and collapse analysis of stiffened composite panels with debonding damage[J]. Acta Materiae Compositae Sinica,2010,27(6):158-166(in Chinese). [8] MO Yuming, GE Dongyun, ZHOU Jiangfan. Experiment and analysis of hat-stringer-stiffened composite curved panels under axial compression[J]. Composite Structures,2015,123:150-160. doi: 10.1016/j.compstruct.2014.11.074 [9] 孙晶晶, 张晓晶, 宫占峰, 等. 复合材料帽型筋条脱粘的失效机理分析[J]. 航空学报, 2013, 34(7):1616-1626.SUN Jingjing, ZHANG Xiaojing, GONG Zhanfeng, et al. Failure mechanism study on omega stringer debonding[J]. Acta Aeronautic et Astronautica Sinica,2013,34(7):1616-1626(in Chinese). [10] 张永久, 耿小亮, 甘建, 等. 考虑损伤和界面脱粘的复合材料加筋板稳定性试验与模拟研究[J]. 应用力学学报, 2013, 30(1):19-25. doi: 10.11776/cjam.30.01.B023ZHANG Yongjiu, GENG Xiaoliang, GAN Jian, et al. Experiment and simulations of stiffened panel buckling with composite damage and interfacial delamination[J]. Chinese Journal of Applied Mechanics,2013,30(1):19-25(in Chinese). doi: 10.11776/cjam.30.01.B023 [11] CAMANHO P P, DAVILA C G. Mixed-mode decohesion elements for the simulation of delamination in composite materials, TM-2002-211737[R]. Washington: NASA, 2002. [12] DAVILA C G, CAMANHO P P. Analysis of the effects of residual strains and defects on skin/stiffener debonding using decohesion elements[C]//Proceedings of the 44th AIAA/ ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Norfolk, VA: AIAA, 2003: 1455-1465. [13] DAVILA G C, CAMANHO P P, TURON A. Effective simulation of delamination in aeronautical structures using shells and cohesive elements[J]. Journal of Aircraft,2008,4(2):663-672. [14] BERTOLINI J, CASTANIE B, BARRAU J J, et al. Multi-level experimental and numerical analysis of composite stiffener debonding Part1: Non-specific specimen level[J]. Composite Structures,2009,90(4):381-391. doi: 10.1016/j.compstruct.2009.04.001 [15] 常园园, 许希武, 郭树祥. 压缩载荷下复合材料整体加筋板渐进损伤非线性数值分析[J]. 复合材料学报, 2011, 28(4):202-211.CHANG Yuanyuan, XU Xiwu, GUO Shuxiang. Nonlinear progressive damage analysis of integral stiffened compo-site panels under compressive load[J]. Acta Materiae Compositae Sinica,2011,28(4):202-211(in Chinese). [16] 孙立, 许希武, 徐焜. 含脱粘损伤的复合材料加筋板压缩破坏渐进损伤数值分析[J]. 材料科学与工程学报, 2009, 27(5):740-744.SUN Li, XU Xiwu, XU Kun. Progressive damage analysis of stiffened composite panels with debonding damage under compressive load[J]. Journal of Materials Science & Engineering,2009,27(5):740-744(in Chinese). [17] 何周理, 何林锋, 李萍. 飞机复合材料C型框研究[J]. 装备制造技术, 2015, 11:215-221. doi: 10.3969/j.issn.1672-545X.2015.05.077HE Z L, HE L F, LI P. Study on composite C-frame structure of aircraft[J]. Equipment Manufacturing Technology,2015,11:215-221(in Chinese). doi: 10.3969/j.issn.1672-545X.2015.05.077 [18] 高宾华, 任毅如. 编织复合材料机身隔框的冲击动力学特性[J]. 复合材料学报, 2017, 34(8):1780-1787.GAO B H, REN Y R. Impact dynamic characteristics of braided composite fuselage frame[J]. Acta Materiae Compositae Sinica,2017,34(8):1780-1787(in Chinese). [19] HEIMBS S, HOFFMANN M, WAIMER M, et al. Dynamic testing and modelling of composite fuselage frames and fasteners for aircraft crash simulations[J]. International Journal of Crashworthiness,2013,18:406-422. doi: 10.1080/13588265.2013.801294 [20] 范振民, 赵海涛, 陈吉安, 等. 复合材料加筋板后屈曲快速计算方法研究[J]. 计算机仿真, 2019, 29(9):392-397.FAN Zhenmin, ZHAO Haitao, CHEN Ji'an, et al. Anlytical method for post-buckling behavior prediction of stiffened panel based on effective width method[J]. Computer Simulation,2019,29(9):392-397(in Chinese). [21] American Society for Testing and Materials. Short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344—2016:[S]. West Conshohocken: ASTM, 2016. [22] American Society for Testing and Materials. Through-thickness “flatwise” tensile strength and elastic modulus of a fiber-reinforced polymer matrix composite material: ASTM D7291—2015[S]. West Conshohocken: ASTM, 2015. [23] American Society for Testing and Materials. Determination of the mode Ⅰ interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528—2013[S]. West Conshohocken: ASTM, 2013. [24] American Society for Testing and Materials. Determination of the mode Ⅱ interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905—2014[S]. West Conshohocken: ASTM, 2014. [25] NADEEM S M, VISWAMURTHY S R, KUMAR A S, et al. Simulation and validation of disband growth in co-cured composite skin-stringer specimens using cohesive elements[J]. Journal of Composite Materials,2018,52(6):807-822. doi: 10.1177/0021998317715505 [26] DIEHL T. On using a penalty-based cohesive-zone finite element approach. Part II: Inelastic peeling of an epoxy bonded aluminum strip[J]. International Journal of Adhesion & Adhesives,2008,28:256-265. -

下载:

下载: