Surface modification of nano crystalline cellulose and application in bismaleimide resin

-

摘要: 采用硫酸水解法制备了纳米晶纤维素(NCC),以N,N-羰基二咪唑(CDI)为活化剂,甲代烯丙基醇(MPO)为改性剂,通过化学取代得到含有烯丙基碳酸酯的纳米晶纤维素(PCNCC);以4,4′-二氨基二苯甲烷双马来酰亚胺(MBMI)、3,3′-二烯丙基双酚A(BBA)及双酚A双烯丙基醚(BBE)为原料制备了复合材料基体(MBAE)。采用FTIR、XRD、TEM和碘值法等对化学修饰的产物进行分析和表征。结果表明,当PCNCC中烯丙基碳酸酯的取代率为16.4%时,既能保持晶型不变,同时能在BBE中稳定悬浮;PCNCC中烯丙基碳酸酯的取代率过小或过大时均不适宜用作PCNCC/MBAE复合材料的增强相。利用原位聚合法将PCNCC掺杂在MBAE基体中制备PCNCC/MBAE复合材料,考察PCNCC质量分数对PCNCC/MBAE复合材料力学性能、介电性能及热性能的影响规律。结果显示,当PCNCC质量分数为0.2 wt%时,PCNCC/MBAE复合材料的弯曲强度和弯曲模量分别为148.1 MPa和6 GPa,较MBAE基体分别提高了50.5%和82.9%;冲击强度为13.9 kJ/m2,较MBAE基体提高54.8%;玻璃化转变温度Tg由纯MBAE的240.4℃提高到257.8℃。此时PCNCC/MBAE复合材料的介电常数明显提高,而介电损耗达到最低值。为扩展纳米晶纤维素及双马来酰亚胺树脂的应用提供了理论依据。

-

关键词:

- 纳米晶纤维素 /

- 化学改性 /

- 4,4′-二氨基二苯甲烷双马来酰亚胺(MBMI) /

- 复合材料 /

- 性能

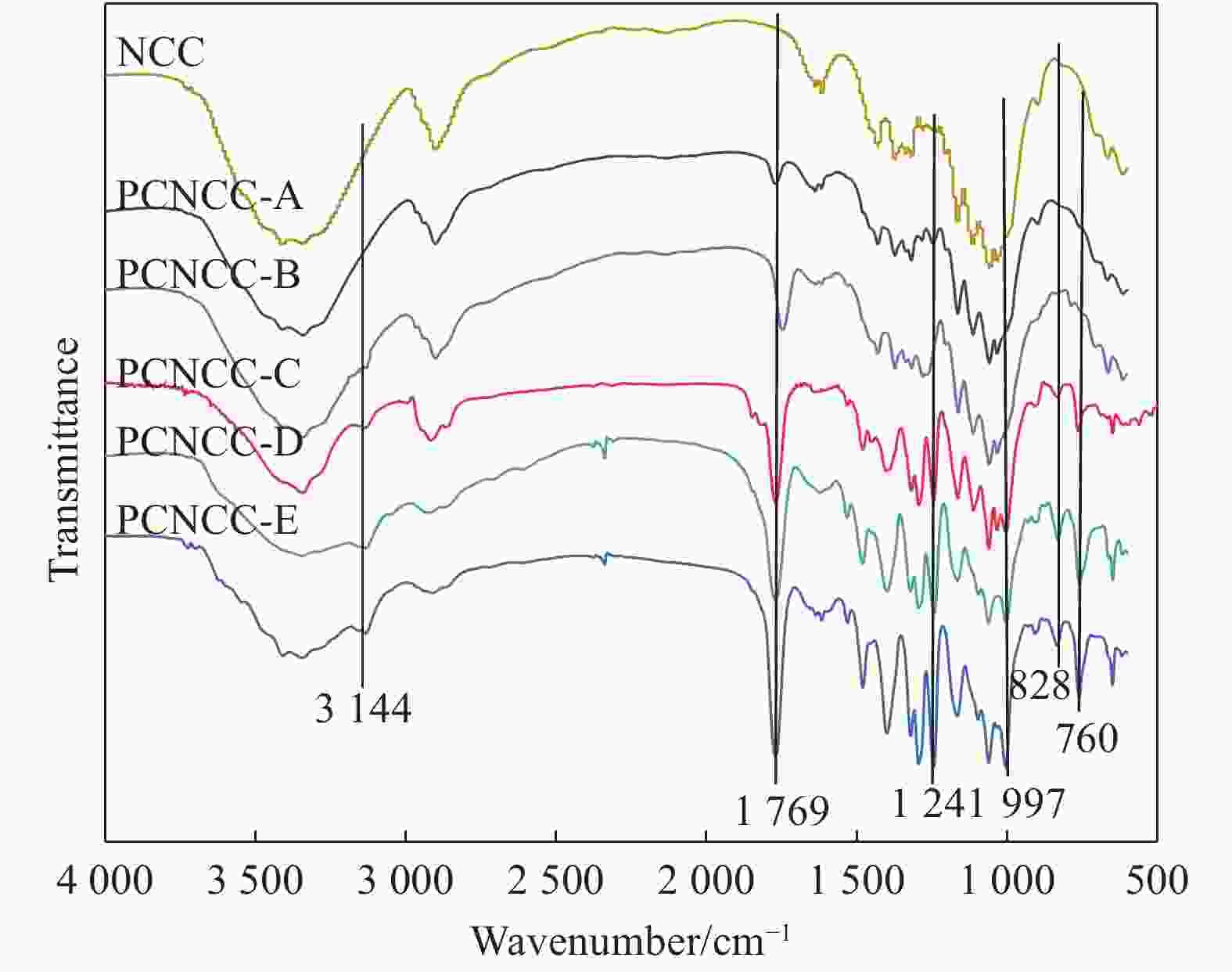

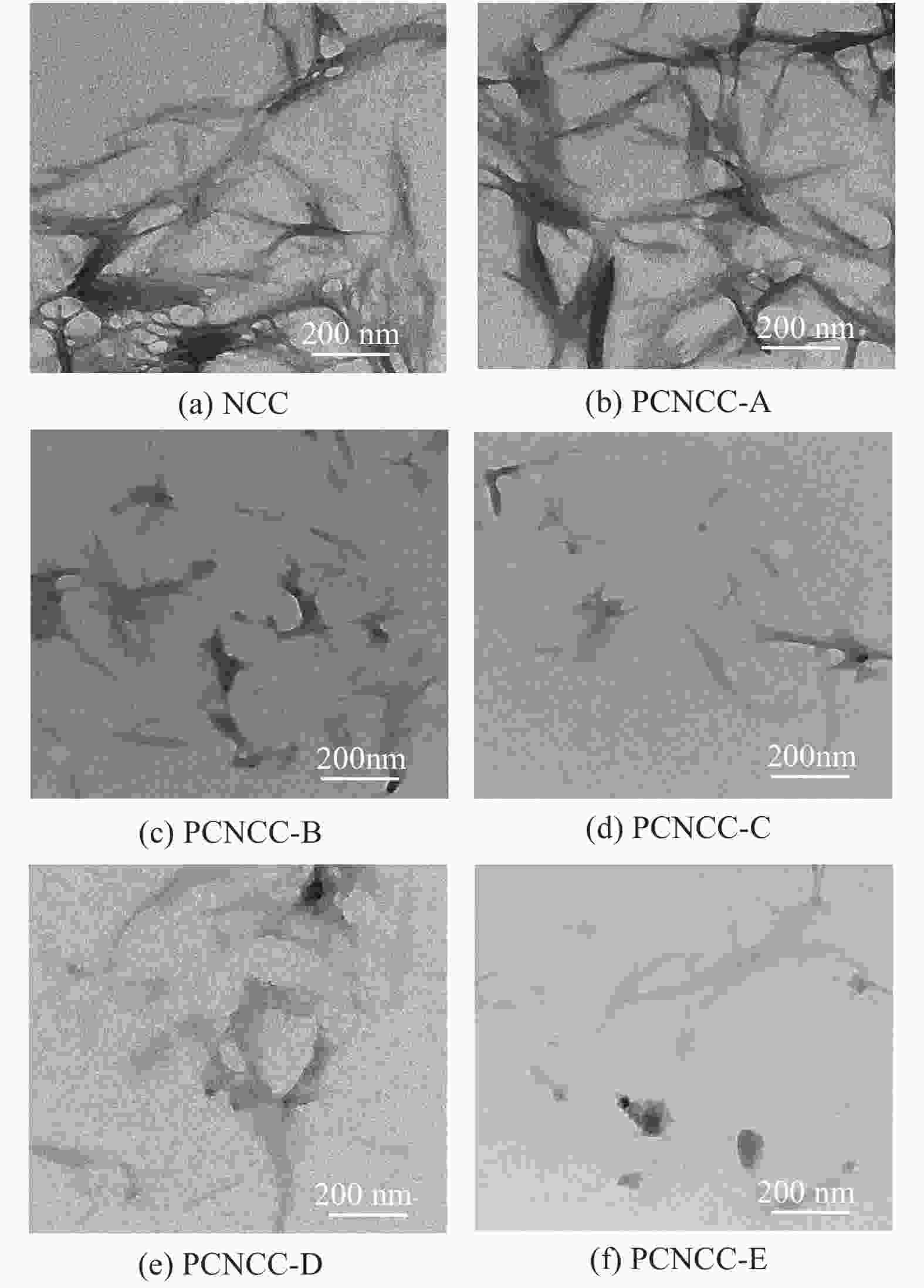

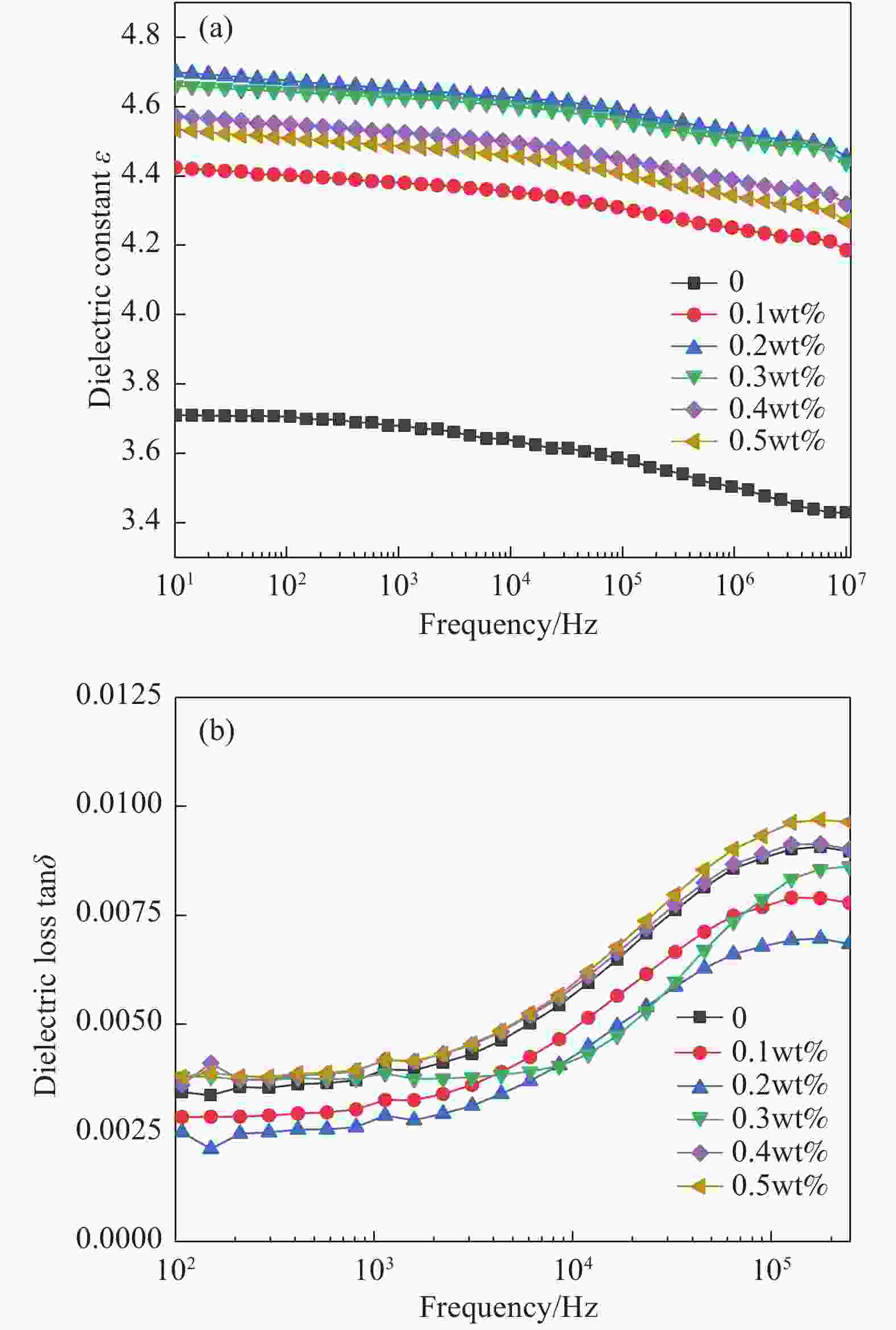

Abstract: The nano crystalline cellulose (NCC) was prepared through a sulfuric acid hydrolysis process, Then NCC was chemically modified with N, N-carbonyldiimidazole (CDI) and 2-Methyl-2-propen-1-ol (MPO) to obtain propenyl carbonate NCC (PCNCC). 4,4′-diamino diphenyl methane bismaleimide (MBMI), 3,3′-diallyl bisphenol A (BBA) and bisphenol-A diallyl ether (BBE) were used to synthesize MBMI-BBA-BBE (MBAE) matrix. The modification results were characterized by FTIR, XRD, TEM and iodine value method. When the replacement rate of PCNCC is 16.4%, the modified PCNCC preserve their type and high degree of crystallization, The PCNCC stably suspend in BBE; PCNCC with too low or too high replacement rate are not suitable for fillers in PCNCC/MBAE composites. The PCNCC/MBAE composites were prepared by doing PCNCC in an MBAE matrix by in-situ polymerization. The effects of modified PCNCC mass fraction on the mechanic properties, dielectric properties and thermal properties of PCNCC/MBAE composites were investigated. A strong interaction is observed between the PCNCC and MBAE, When the mass fraction of PCNCC is 0.2 wt%, the flexural strength and modulus of PCNCC/MBAE composite are 148.1 MPa and 6 GPa, increased by 50.5% and 82.9% than that of MBAE matrix. The impact strength of PCNCC/MBAE composite is 13.9 kJ/m2, increased by 54.8% than that of MBAE matrix, respectively. The glass transition temperature Tg value from 240.4℃ of the pure MBAE to 257.8℃. The dielectric constant of PCNCC/MBAE composite increases and the dielectric loss reaches the lowest value. The improvement of mechanical properties and thermal stability of PCNCC/MBAE composites provides theoretical data for the expansion of nano cystalline cellulose and bismaleimide resin applications. -

表 1 PCNCC/MBAE复合材料样品组分

Table 1. Component of PCNCC/MBAE composite samples

Component Mass fraction of PCNCC/wt% MBAE 0 PCNCC/MBAE 0.1−0.5 Note: MBAE—4,4′-diamino diphenyl methane bismaleimide (MBMI)-3,3′-diallyl bisphenol A (BBA)-bisphenol-A diallyl ether (BBE) matrix. 表 2 PCNCC样品的取代率

Table 2. Replacement rates of PCNCC samples

Sample PCNCC-A PCNCC-B PCNCC-C PCNCC-D PCNCC-E NCC∶CDI∶MPO mole ratio 1∶1.5∶1.5 1∶1.5∶1.5 1∶3∶1.5 1∶3∶1.5 1∶3∶3 Temperature/℃ 25 50 50 50 65 Time/h 6 6 6 12 12 Replacement rate/% 0.3 7.5 16.4 38.9 41.3 Notes:NCC—Nano crystalline cellulose;CDI—N,N-carbonyldiimidazole;MPO—2-Methyl-2-propen-1-ol. 表 3 PCNCC/MBAE复合材料的DMA特征参数

Table 3. DMA characteristics of PCNCC/MBAE composites

Sample Tg/℃ E′/MPa 60℃ 250℃ MBAE 240.4 2 190 224 0.1 wt%PCNCC/MBAE 245.5 2 330 254 0.2 wt%PCNCC/MBAE 257.8 2 611 425 0.3 wt%PCNCC/MBAE 252.7 2 486 346 0.4 wt%PCNCC/MBAE 248.4 2 424 288 0.5 wt%PCNCC/MBAE 246.2 2 260 243 Notes: Tg—Glass transition temperature; E'—Storage modulus. -

[1] TAKEICHI T, UCHIDA S, INOUE Y, et al. Preparation and properties of polymer alloys consisting of high-molecular-weight benzoxazine and bismaleimide[J]. High Performance Polymers,2014,26(3):265-273. doi: 10.1177/0954008313510958 [2] CHEN Y, WANG B, LI F, et al. Micro-structure, mechanical properties and dielectric properties of bisphenol a allyl compound-bismaleimide modified by super-critical silica and polyether-sulfone composite[J]. Journal of Electronic Materials,2017,46(7):4656-4661. doi: 10.1007/s11664-017-5468-y [3] IREDALE R J, WARD C, HAMERTON I. Modern advances in bismaleimide resin technology: A 21st century perspective on the chemistry of addition polyimides[J]. Progress in Polymer Science,2016,69:1-21. [4] EICHHORN S J, DUFRESNE A, ARANGUREN M, et al. Review: Current international research into cellulose nanofibres and nanocomposites[J]. Journal of Materials Science,2010,45(1):1-33. doi: 10.1007/s10853-009-3874-0 [5] SHWETA M, PRASHANT S K, ANIL M P. Biomass and waste materials as potential sources of nanocrystalline cellulose: Comparative review of preparation methods (2016-Till date)[J]. Carbohydrate Polymers,2019,207:418-427. doi: 10.1016/j.carbpol.2018.12.004 [6] WANG D X, YU J, ZHANG J M, et al. Transparent bionano-composites with improved properties from poly (propylene carbonate) (PPC) and cellulose nano- whiskers (CNWs)[J]. Composites Science & Technology,2013,85(85):83-89. [7] KUO P Y, YAN N, SAIN M. Influence of cellulose nanofibers on the curing behavior of epoxy/amine systems[J]. European Polymer Journal,2013,49(12):3778-3787. doi: 10.1016/j.eurpolymj.2013.08.022 [8] RAQUEZ J M, MURENA Y, GOFFIN A L, et al. Surface-modification of cellulose nanowhiskers and their use as nanoreinforcers into polylactide: A sustainably-integrated approach[J]. Composites Science & Technology,2012,72(5):544-549. [9] 巩桂芬, 王晓惠, 胡雪娇, 等. 纳米纤维素ARGET ATRP接枝PMMA改性研究[J]. 化工新型材料, 2016(3):118-120.GONG G F, WANG X H, HU X J, et al. Study on modification of nanocrystalline cellulose by grafting PMMA using ARGET ATRP method[J]. New Chemical Materials,2016(3):118-120(in Chinese). [10] XIA L, XU Y, WANG K, et al. Preparation and properties of modified bismaleimide resins by novel bismaleimide containing 1,3,4-oxadiazole[J]. Polymers for Advanced Technologies,2015,26(3):266-276. doi: 10.1002/pat.3452 [11] 张思, 张扬, 张宝艳. 双马来酰亚胺树脂增韧改性研究进展[J]. 科技导报, 2016, 34(8):31-34.ZHANG S, ZHANG Y, ZHANG B Y. Research on toughening modification of bismaleimide resin[J]. Science & Technology Review,2016,34(8):31-34(in Chinese). [12] 张静. 二元胺型苯并噁嗪/双马来酰亚胺共混树脂及其玻璃布增强的层压板[J]. 化工学报, 2015, 66(10):4288-4294. doi: 10.11949/j.issn.0438-1157.20150385ZHANG J. Diamine benzoxazine/bismaleimide blended resin and its glass cloth reinforced laminate[J]. CIESC Journal,2015,66(10):4288-4294(in Chinese). doi: 10.11949/j.issn.0438-1157.20150385 [13] 陈宇飞, 郭红缘, 耿成宝, 等. 聚醚醚酮和烯丙基化合物改性双马来酰亚胺复合材料微观结构及力学性能[J]. 复合材料学报, 2018, 35(11):169-175.CHEN Y F, GUO H Y, GENG C B, et al. Microstructure and mechanical properties of bismaleimide composites modified with poly(ether ether ketone) and allyl compounds[J]. Acta Materiae Compositae Sinica,2018,35(11):169-175(in Chinese). [14] CHENG T, YAN H, SONG L, et al. Novel phosphorus-containing polyhedral Oligomeric Silses quioxane functionalized graphene oxide: Preparation and its performance on the mechanical and flame-retardant properties of Bismaleimide composite[J]. Journal of Polymer Research,2017,24(10):157. doi: 10.1007/s10965-017-1310-8 [15] CHEN Z, YAN H, LYU Q, et al. Ternary hybrid nanoparticles of reduced graphene oxide/graphene-like MoS2/zirconia as lubricant additives for bismaleimide composites with improved mechanical and tribological properties[J]. Composites Part A: Applied Science & Manufacturing,2017,101:98-107. [16] 许小聪, 刘美华, 卢彦兵, 等. N,N′-羰基二咪唑作为活化剂在高分子合成中的研究进展[J]. 高分子通报, 2007(2):74-80. doi: 10.3969/j.issn.1003-3726.2007.02.010XU X C, LIU M H, LU Y B, et al. Research progress of N,N′-carbonyldiimidazole as activator in polymer synthesis[J]. Polymer Bulletin,2007(2):74-80(in Chinese). doi: 10.3969/j.issn.1003-3726.2007.02.010 [17] 巩桂芬, 胡雪娇, 王晓惠, 等. 聚丙烯酸甲酯接枝改性纳米纤维素[J]. 工程塑料应用, 2015, 43(2):101-103. doi: 10.3969/j.issn.1001-3539.2015.02.024GONG G F, HU X J, WANG X H, et al. Grafting of nano-cellulose by polyacrylic acid methyl ester[J]. Engineering Plastics Application,2015,43(2):101-103(in Chinese). doi: 10.3969/j.issn.1001-3539.2015.02.024 [18] 国家质量监督局. 化学试剂标准滴定溶液的制备: GB/T 601-2016[S]. 北京: 中国标准出版社, 2016.General Administration of Quality Supervision. Preparation of chemical reagent standard titration solution: GB/T 601-2016[S]. Beijing: China Standard Press, 2016(in Chinese). [19] 国家技术监督局. 硬质塑料简支梁冲击试验方法: GB/T 1043-93[S]. 北京: 中国标准出版社, 1993.Nation Bureau of Technical Supervision. Impact test method for rigid plastic simply supported beam: GB/T 1043-93[S]. Beijing: China Standard Press, 1993(in Chinese). [20] 国家质量技术监督局. 塑料试样状态调节和试验的标准环境: GB/T 2918-1998[S]. 北京: 中国标准出版社, 1998.Nation Bureau of Technical Supervision. Standard environment for state regulation and testing of plastic samples: GB/T 2918-1998[S]. Beijing: China Standard Press, 1998(in Chinese). [21] 国家质量技术监督局. 固体绝缘材料体积电阻率和表面电阻率试验方法: GB/T 1410—2006[S]. 北京: 中国标准出版社, 2006.Nation Bureau of Technical Supervision. Test method for volume resistivity and surface resistivity of solid insulating materials: GB/T 1410—2006[S]. Beijing: China Standard Press, 2006(in Chinese). [22] 高可政. 纤维素纳米纤维在储能材料上的基础应用研究[D]. 北京: 北京理工大学, 2014.GAO K Z. Basic application of cellulose nanofibers on energy storage materials[D]. Beijing: Beijing Institute of Technology, 2014(in Chinese). [23] 陈宇飞, 郭红缘, 李志超, 等. 聚醚砜/双马来酰亚胺-环氧树脂复合材料的微观结构与性能[J]. 复合材料学报, 2017, 34(5):939-944.CHEN Y F, GUO H Y, LI Z C, et al. Microstructure and properties of polyether-sulfone with bismaleimide epoxy resin composites[J]. Acta Materiae Compositae Sinica,2017,34(5):939-944(in Chinese). -

下载:

下载: