Stability of composite stiffened panels in plane shear

-

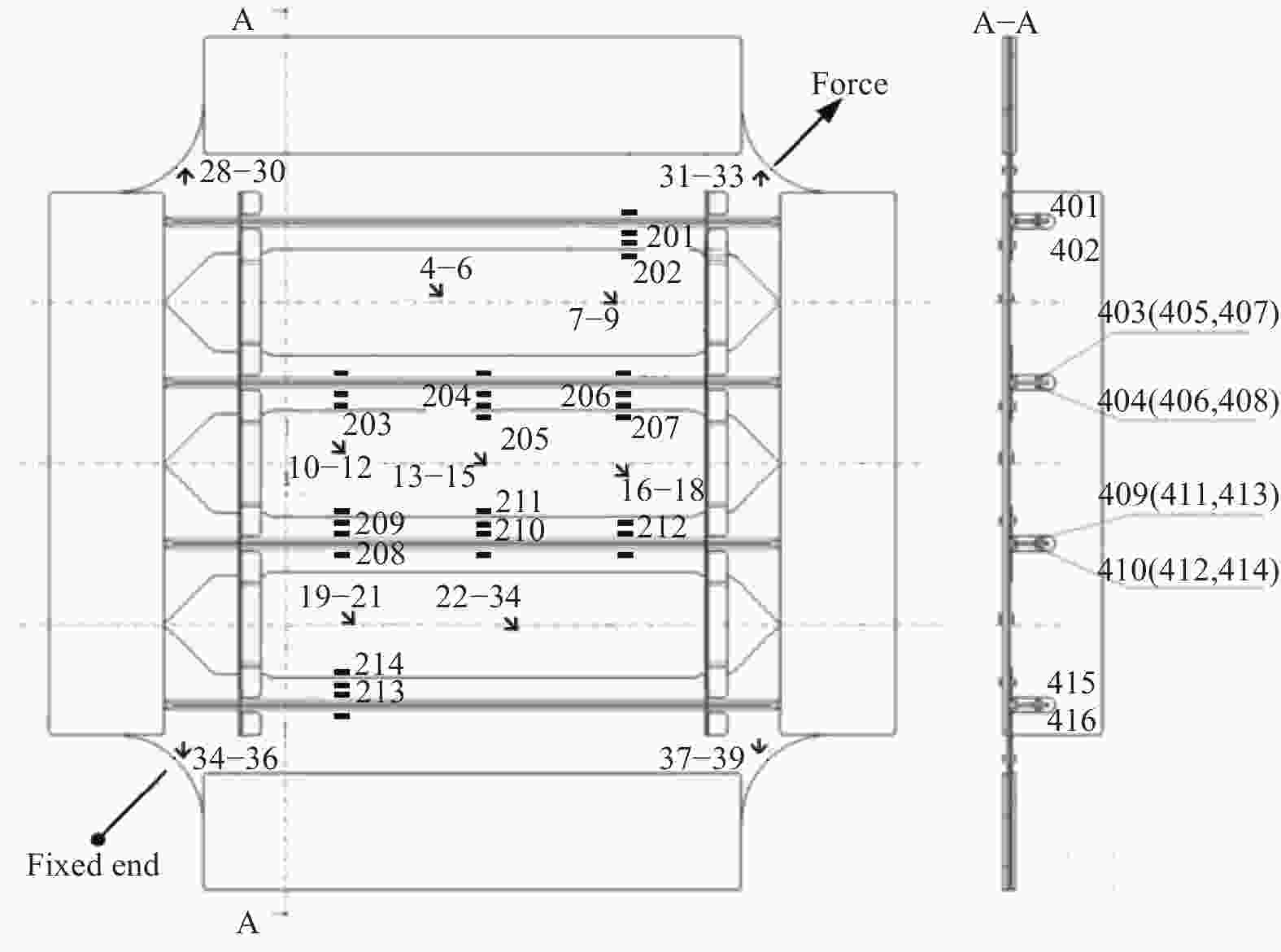

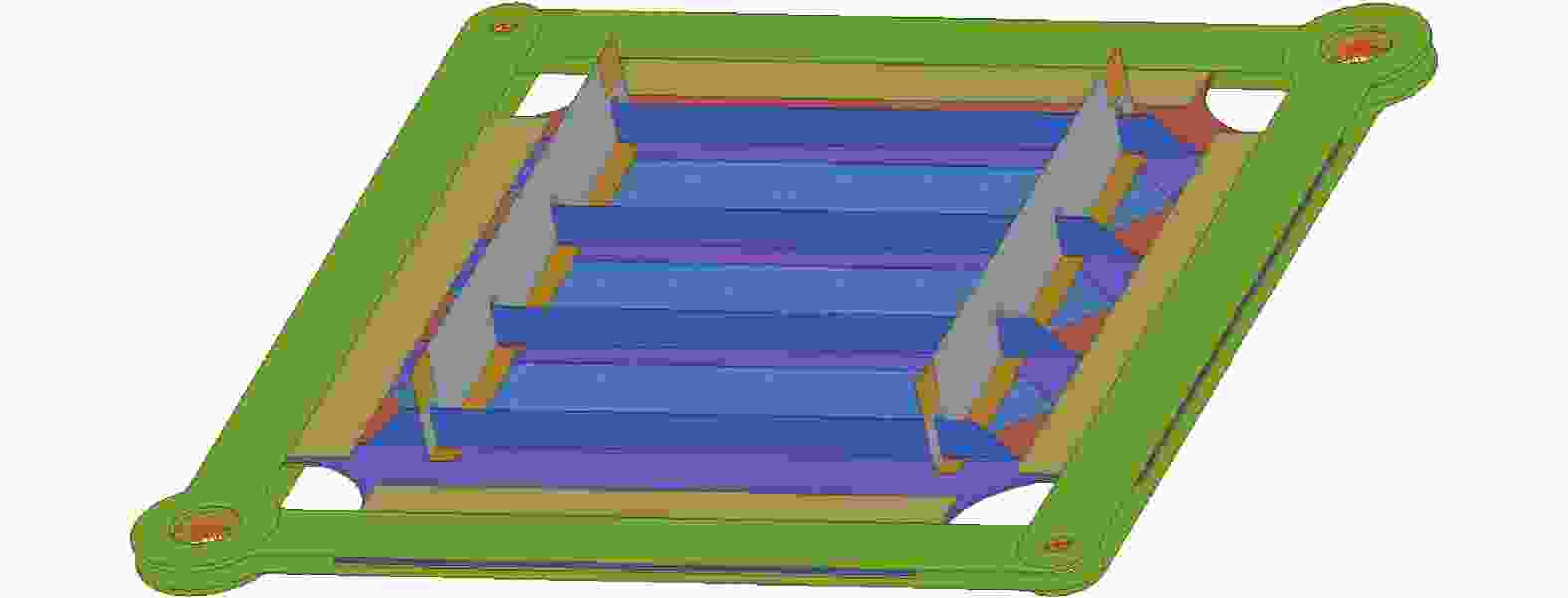

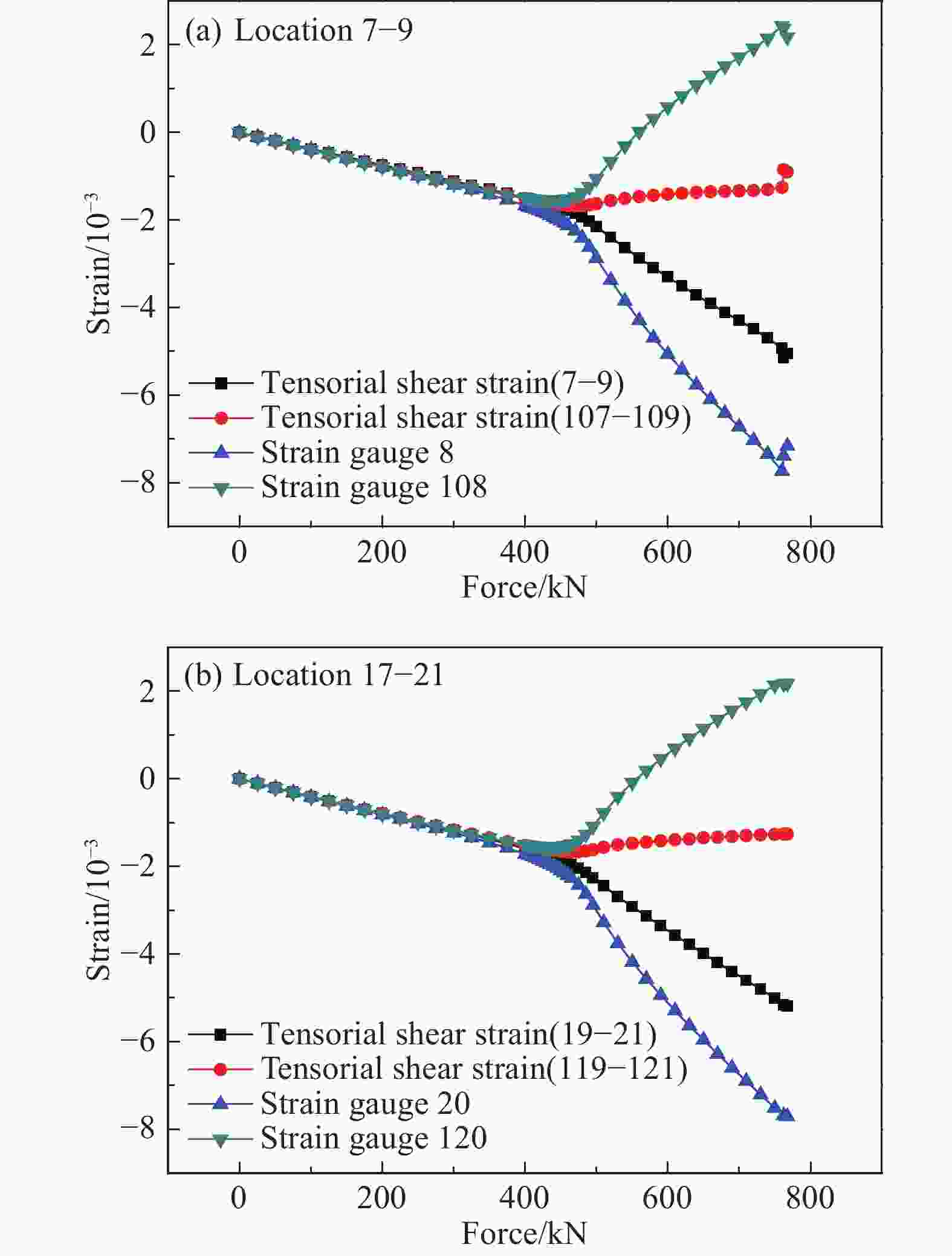

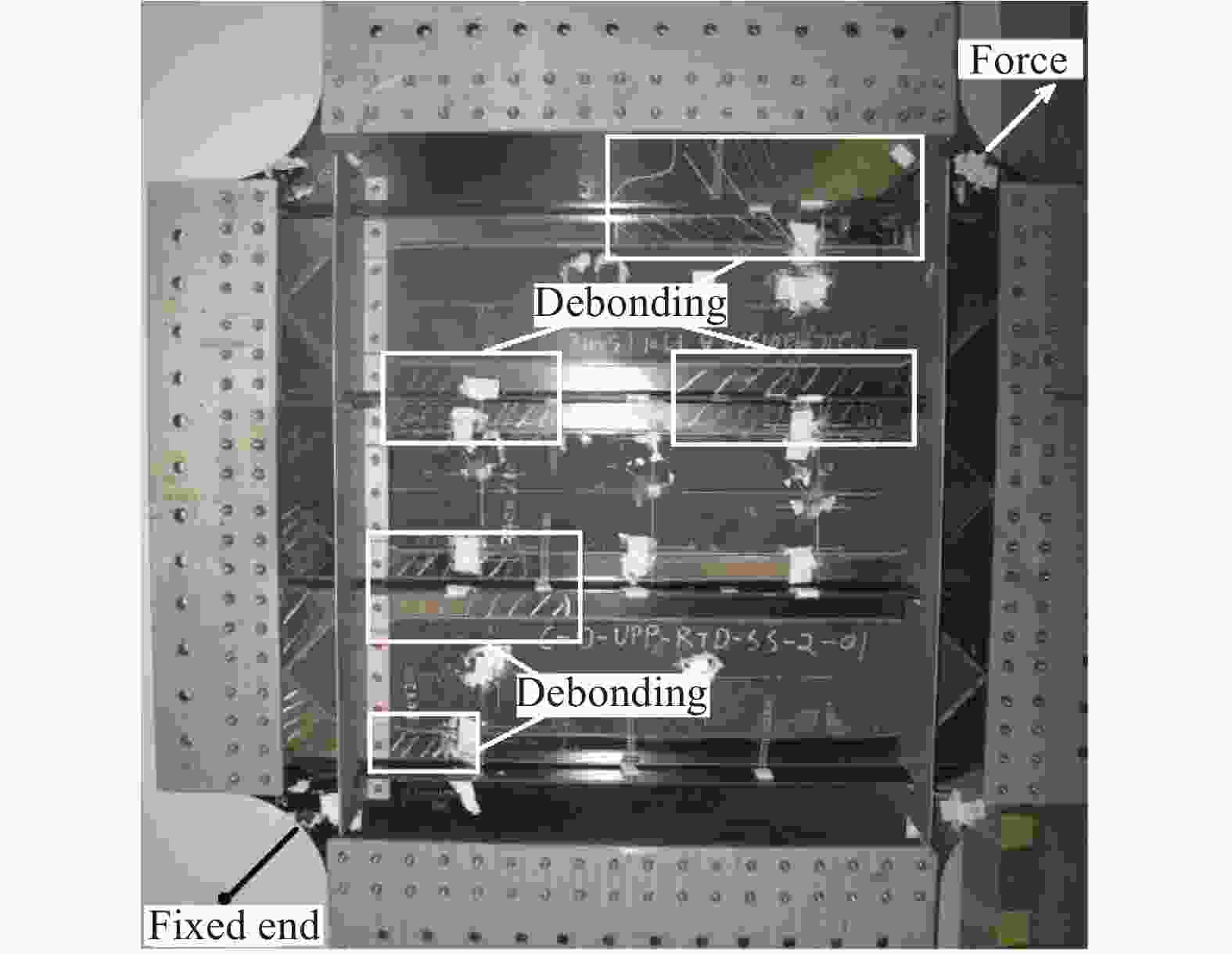

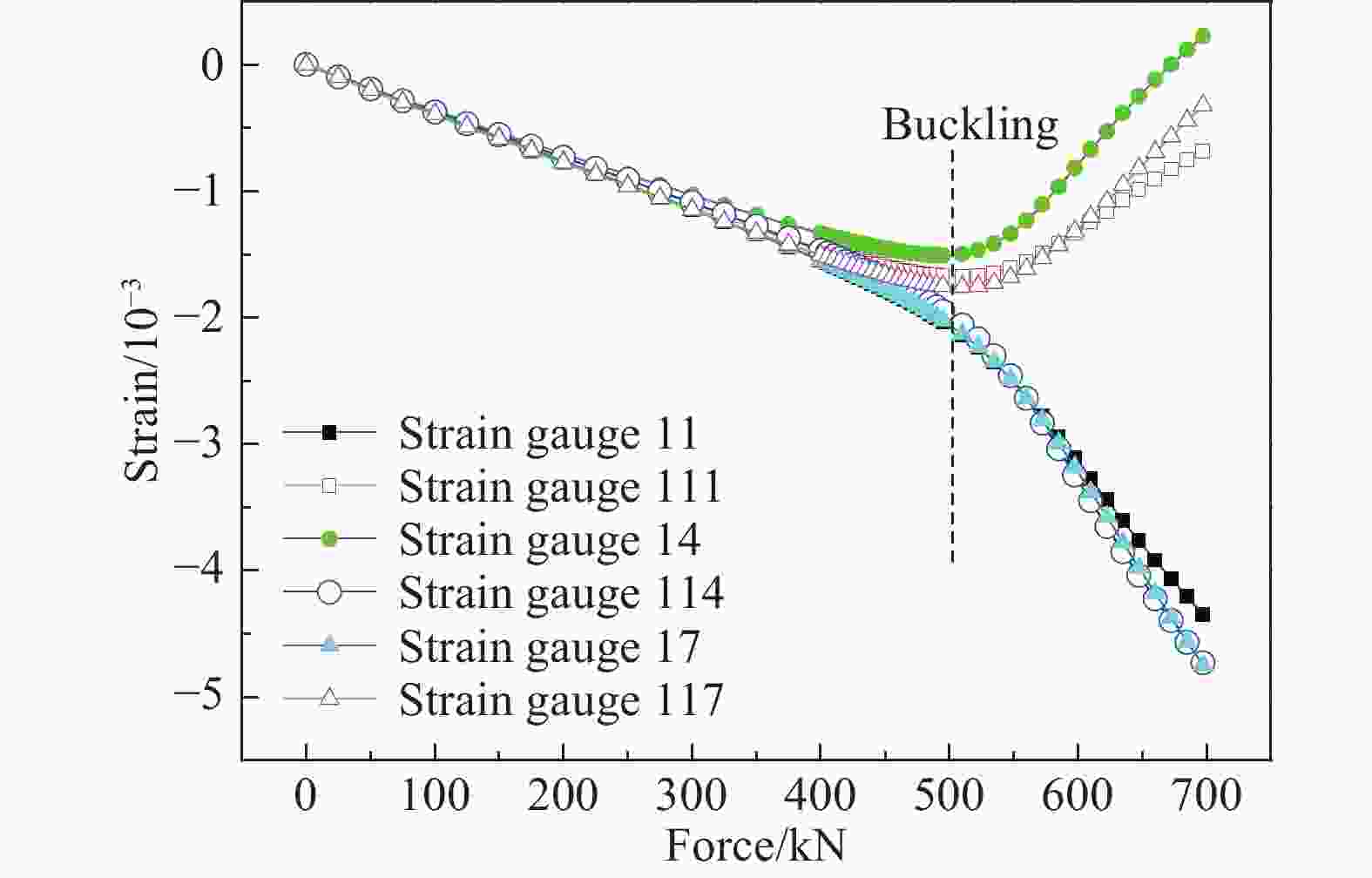

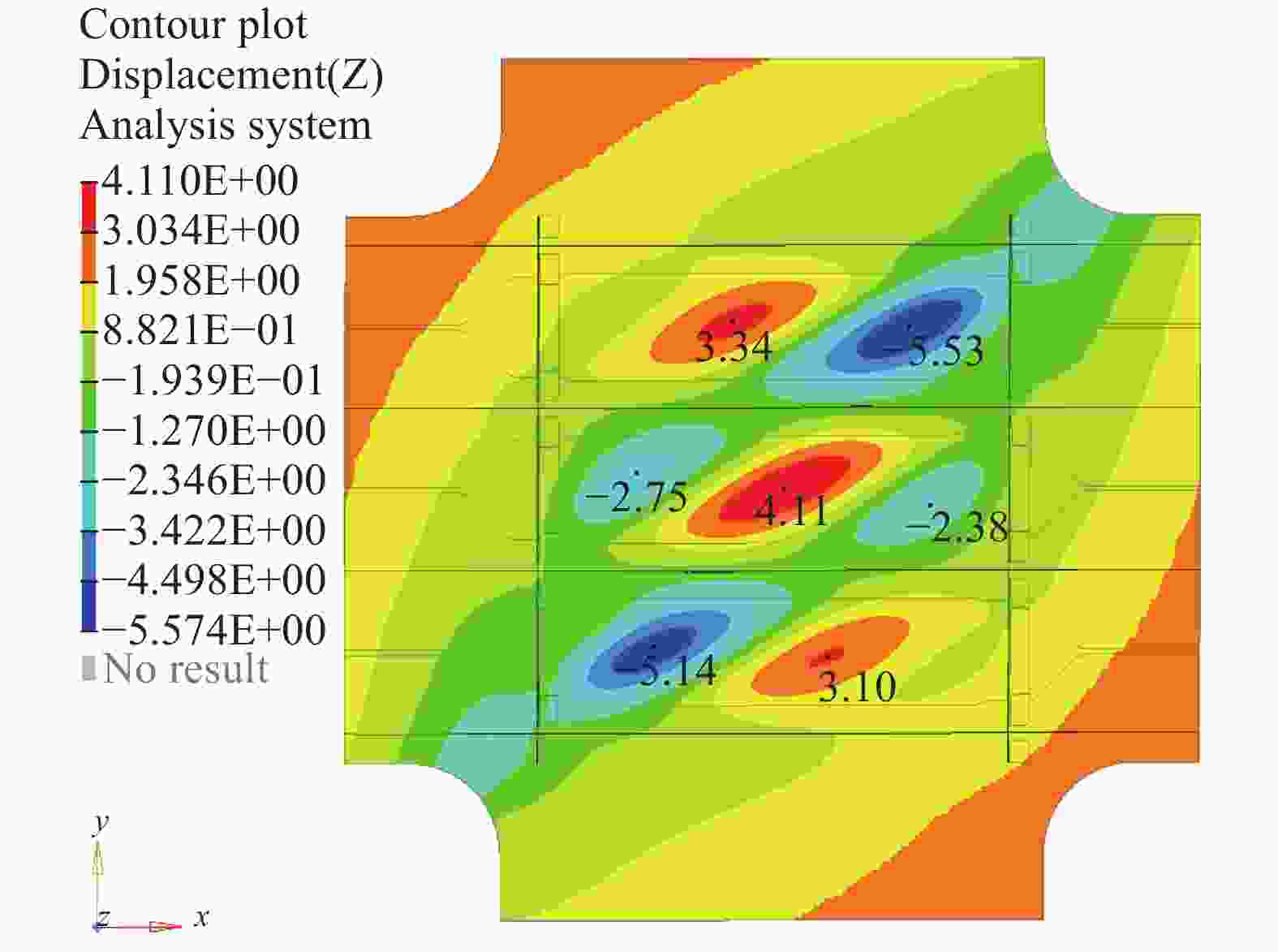

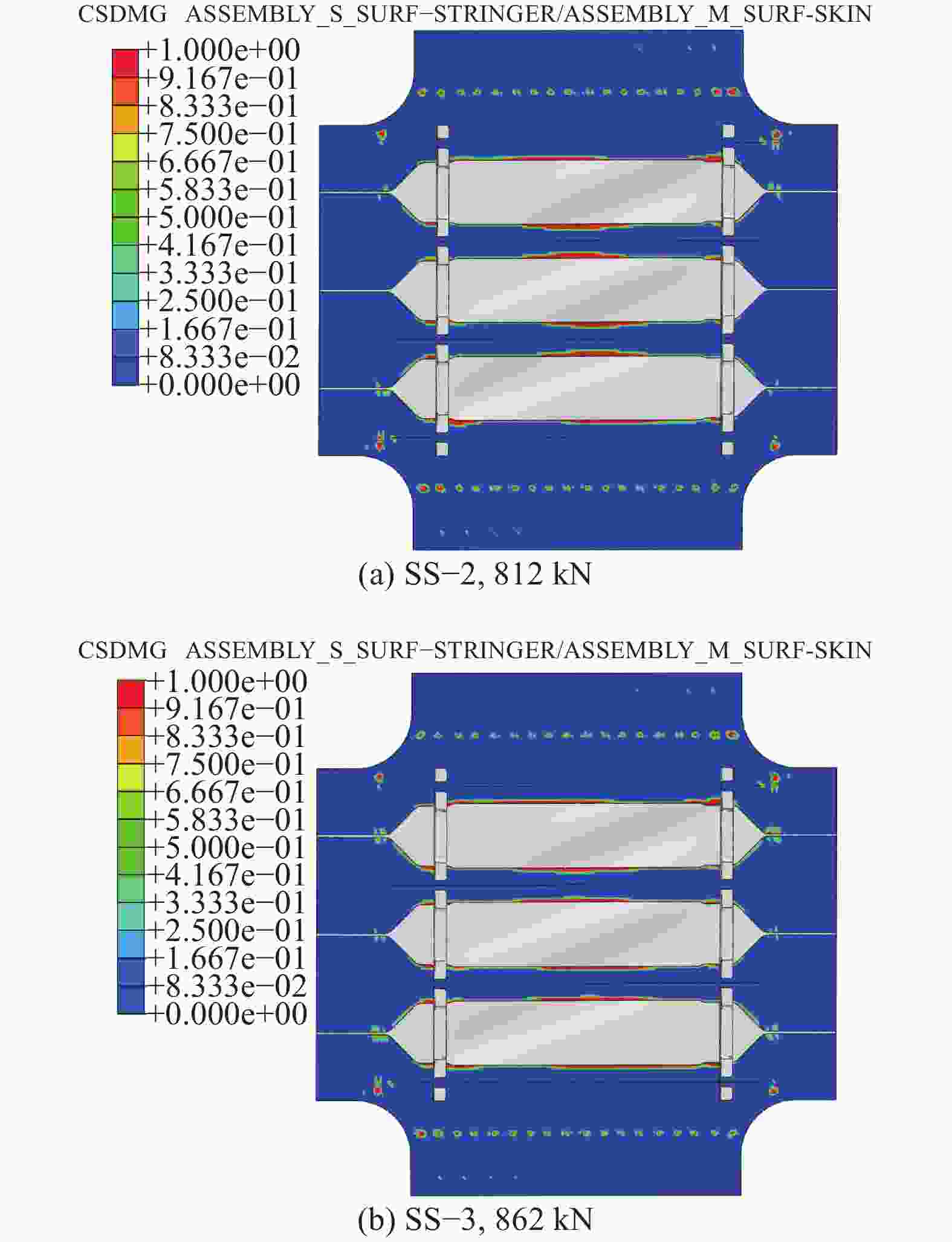

摘要: 基于长桁铺层数不同的两块复合材料翼面T型加筋壁板试件SS-1和SS-2开展剪切稳定性试验。试件SS-1和SS-2的L型层合板铺层分别为11层和14层,腹板铺层分别为22层和28层,缘条铺层分别为15层和18层。采用提出的工程方法进行壁板的剪切屈曲应变分析,方法中考虑了长桁尺寸和铺层数的影响,并应用有限元弧长法进行试件屈曲载荷、后屈曲承载能力及剪切屈曲模态分析。试验结果表明,屈曲发生之前试件蒙皮处于均匀纯剪切应变状态,后屈曲阶段试件发生了长桁-蒙皮脱粘破坏失效,长桁铺层数较多的试件SS-2具有更高的屈曲载荷和蒙皮局部屈曲应变。工程方法计算得到试件SS-1和SS-2的剪切屈曲应变相对于试验结果的误差分别为–14.9%和–9.2%。有限元弧长法分析得到试件SS-1的屈曲载荷和屈曲应变误差分别为1.9%和2.7%,且剪切屈曲模态与试验结果一致。弧长法对不同长桁铺层数的研究结果表明,长桁铺层较少时,壁板发生整体失稳的材料破坏,而长桁铺层数较多时,更容易发生长桁与蒙皮的脱粘失效。Abstract: Experiments for shear stability analysis were conducted on composite stiffened panels SS-1 and SS-2 with different T-stringer layups. The L laminate layers of SS-1 and SS-2 were 11 and 14 layers respectively, the web laminate layers were 22 and 28 layers respectively, and the edge strip laminate layers were 15 and 18 layers respectively. Considering the differences of dimension and ply number of stringers, a proposed engineering method was used to investigate the shear buckling strain of skins, and finite element analysis (FEA) with arc-length method was also carried out to predict the shear buckling load, post-buckling carrying capabilities, and buckling modes. Experimental results show that the skins between stringers are in pure shear with uniform shear strains before buckling, and debonding failure of skin and stringers occur during post-buckling stage, and SS-2 with more stringer plys poses higher buckling resistance with larger buckling load and strain. The errors of buckling shear strain for SS-1 and SS-2 by the proposed engineering method are –14.9% and –9.2%, respectively. The errors of buckling load and buckling strain by arc-length method for SS-1 are 1.9% and 2.7%, respectively, and the buckling modes are also consistent with the experiment results. The FEA results by arc-length method also reveal that material failure will occur with less stringer plys due to overall buckling of panels, and the debonding of skin and stringers are more readily realized with more stringer plys.

-

Key words:

- composite stiffened panel /

- shear stability /

- engineering method /

- buckling /

- arc-length method /

- debonding failure

-

表 1 X850碳纤维增强树脂复合材料单向带力学性能

Table 1. Mechanical properties of X850 carbon fiber reinforced polymer prepreg

E11/MPa E22/MPa G12/MPa υ12 158 000 9 000 4 140 0.319 Notes: E11—Elastic modulus in fibre direction; E22—Elastic modulus transverse to fibre direction; G12—Shear modulus; υ12—Poisson’s ratio. 表 2 复合材料加筋壁板铺层顺序

Table 2. Stacking sequences of composite stiffened panels

Region Stacking sequence Skin [45/−45/0/45/−45/0/0/90]S L_left(SS-1) [–45/45/0/0/0/90/−45/0/45/90/0] L_left(SS-2) [–45/45/0/0/0/90/−45/0/45/45/0/−45/90/0] L_right(SS-1) [45/−45/0/0/0/90/45/0/−45/90/0] L_right(SS-2) [45/−45/0/0/0/90/45/0/−45/−45/0/45/90/0] Insert plys [45/−45/0/0] 表 3 复合材料加筋壁板模型SS-0和SS-3的长桁铺层

Table 3. Stacking sequences of stringers for composite stiffened panel models SS-0 and SS-3

Region Stacking sequence L_left(SS-0) [−45/45/0/0/0/90/90/0] L_left(SS-3) [−45/45/0/0/0/90/−45/0/45/45/0/−45/90/0/0/90/0] L_right(SS-0) [45/−45/0/0/0/90/90/0] L_right(SS-3) [45/−45/0/0/0/90/45/0/−45/−45/0/45/90/0/0/90/0] 表 4 屈曲载荷下复合材料加筋壁板SS-1蒙皮工程剪切应变试验值

Table 4. Engineering shear strain of skin by test at buckling load of composite stiffened panel SS-1

Gauge Shear strain ${\gamma _{\rm{e}}}$/10−3 Avg. shear strain/10−3 Error/% 4-6 −3.850 −3.667 5.0 7-9 −3.565 −2.8 10-12 −3.763 2.6 13-15 −3.387 −7.6 16-18 −3.687 0.5 19-21 −3.688 0.6 22-24 −3.731 1.7 表 5 屈曲载荷下复合材料加筋壁板SS-2蒙皮工程剪切应变试验值

Table 5. Engineering shear strains of skin by test at buckling load of composite stiffened panel SS-2

Gauge Shear strain ${\gamma _{\rm{e}}}$/10−3 Avg. shear strain/10−3 Error/% 4-6 −3.737 −3.761 −0.6 7-9 −3.713 −1.3 10-12 −3.840 2.1 13-15 −3.600 −4.2 16-18 −3.925 4.4 19-21 −3.814 1.5 22-24 −3.700 −1.5 表 6 复合材料加筋壁板剪切屈曲应变工程分析结果

Table 6. Buckling strains of composite stiffened panels under shear load by engineering method

Specimen ${N_{{\rm{skin}}}}$/(N·mm–1) ${\gamma _{\rm{e}}}$/10−3 ${\gamma _{\rm{e}}}$−test/10−3 Error/% SS-1 213 −3.119 −3.667 −14.9 SS-2 233 −3.416 −3.761 −9.2 表 7 复合材料加筋壁板SS-1剪切屈曲特征值及屈曲载荷

Table 7. Eigenvalues and buckling loads of composite stiffened panel SS-1 under shear by eigenvalue method

Mode 1 2 3 4 Eigenvalue 2.55 2.62 2.78 2.84 Bucking load/kN 509 524 557 568 表 8 弧长法得到的屈曲载荷为486 kN时复合材料加筋壁板SS-1蒙皮剪切屈曲应变

Table 8. Shear strains at buckling load of 486 kN of skins of composite stiffened panel SS-1 by arc-length method

Gauge location Engineering shear strain/10−3 Avg. shear strain/10−3 Error/% 4-6 −3.815 −3.767 1.3 7-9 −3.820 1.4 10-12 −3.758 −0.2 13-15 −3.509 −6.9 16-18 −3.877 2.9 19-21 −3.795 0.7 22-24 −3 796 0.8 -

[1] 周雷敏, 孙沛. 波音787客机的复合材料国际化制造[J]. 高科技纤维与应用, 2013, 38(2):57-61. doi: 10.3969/j.issn.1007-9815.2013.02.011ZHOU Leiming, SUN Pei. Boeing 787 composites’ international manufacturing[J]. Hi-Tech Fiber & Application,2013,38(2):57-61(in Chinese). doi: 10.3969/j.issn.1007-9815.2013.02.011 [2] 吴志恩. A350的复合材料构件制造[J]. 航空制造技术, 2013(13):32-35. doi: 10.3969/j.issn.1671-833X.2013.13.003WU Zhien. Manufacture of A350 composites structure[J]. Aeronautical Manufacturing Technology,2013(13):32-35(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.13.003 [3] 赵稼祥. 碳纤维复合材料在民用航空上的应用[J]. 高科技纤维与应用, 2003, 28(3):1-4. doi: 10.3969/j.issn.1007-9815.2003.03.001ZHAO Jiaxiang. Application of carbon composite materials for civil aviation[J]. Hi-Tech Fiber & Application,2003,28(3):1-4(in Chinese). doi: 10.3969/j.issn.1007-9815.2003.03.001 [4] QIAO P Z, HUO X P. Explicit local buckling analysis of rotationally restrained orthotropic plates under uniform shear[J]. Composite Structures,2011,93(11):2785-2794. doi: 10.1016/j.compstruct.2011.05.026 [5] KUMAR D, SINGH S B. Effects of flexural boundary conditions on failure and stability of composite laminate with cutouts under combined in-plane loads[J]. Composites Part B: Engineering,2013,45(1):657-665. doi: 10.1016/j.compositesb.2012.08.016 [6] KUMAR D, SINGH S B. Stability and failure of composite laminates with various shaped cutouts under combined in-plane loads[J]. Composites Part B: Engineering,2012,43(2):142-149. doi: 10.1016/j.compositesb.2011.09.005 [7] MITTELSTEDT C, ERDMANN H, SCHROEDER K. Postbuckling of imperfect rectangular composite plate under inplane shear closed-form approximate solution[J]. Archive of Applied Mechanics,2011,81(10):1409-1426. doi: 10.1007/s00419-010-0491-y [8] 万玉敏, 张发, 刘长喜, 等. 飞机典型薄壁复合材料夹层结构整体屈曲[J]. 复合材料学报, 2018, 35(8):2235-2245.WAN Yumin, ZHANG Fa, LIU Changxi, et al. Overall buckling of typical thin-wall sandwich composite applied on the aircraft[J]. Acta Materiae Compositae Sinica,2018,35(8):2235-2245(in Chinese). [9] 刘毅, 聂坤, 戴瑛. 任意铺层复合材料加筋板屈曲/后屈曲行为的解析解[J]. 南京航空航天大学学报, 2018, 50(1):1-10.LIU Yi, NIE Kun, DAI Ying. Analytical solution for buckling and postbuckling behavior of stiffened arbitrary laminated composite panels[J]. Journal of Nanjing University of Aeronautics & Astronautic,2018,50(1):1-10(in Chinese). [10] 谭翔飞, 何宇廷, 冯宇, 等. 航空复合材料加筋板剪切稳定性及后屈曲承载性能[J]. 复合材料学报, 2018, 35(2):320-331.TAN Xiangfei, HE Yuting, FENG Yu, et al. Stability and post-buckling carrying capability of aeronautic composite stiffened panel under shear loading[J]. Acta Materiae Compositae Sinica,2018,35(2):320-331(in Chinese). [11] NDOGMO J, MENSINGER M, BOTH I. Buckling behavior of stiffened plate under biaxial compression and shear[J]. Procedia Engineering,2016,156:272-279. [12] 王新年, 赵伟, 吴师, 等. 复合材料平尾加筋壁板剪切稳定性[J]. 南京航空航天大学学报, 2017, 49(6):812-819.WANG Xinnian, ZHAO Wei, WU Shi, et al. Buckling behavior of stiffened composite tail panel subjected to shear loading[J]. Journal of Nanjing University of Aeronautics & Astronautic,2017,49(6):812-819(in Chinese). [13] 何吕龙, 尚柏林, 常飞, 等. 筋条参数对复合材料加筋壁板剪切承载能力的影响[J]. 机械工程材料, 2015, 39(9):49-52. doi: 10.11973/jxgccl201509011HE Lvlong, SHANG Bolin, CHANG Fei, et al. Effects of stiffener parameter on shear carrying capacity of composite stiffened wall panel[J]. Materials for Mechanical Engineering,2015,39(9):49-52(in Chinese). doi: 10.11973/jxgccl201509011 [14] MALLELA U K, UPADHYAY A. Buckling of laminated composite stiffened panels subjected to in-plane shear: A parametric study[J]. Thin-Walled Structures,2006,44(3):354-361. doi: 10.1016/j.tws.2006.03.008 [15] 邵青, 何宇廷. 复合材料加筋板剪切稳定性研究[J]. 航空精密制造技术, 2010, 46(6):34, 46-48.SHAO Qing, HE Yuting. Study on shear stability performance of composite stiffened panel[J]. Aviation Precision Manufacturing Technology,2010,46(6):34, 46-48(in Chinese). [16] RAJU G, WU Z M, WEAVER P M. Buckling and post-buckling of variable angle tow composite plates under in-plane shear loading[J]. International Journal of Solids and Structures,2015,58(1):270-287. [17] 顾杰斐, 陈普会, 孔斌, 等. 考虑制造因素的变刚度层合板的抗屈曲铺层优化设计[J]. 复合材料学报, 2018, 35(4):866-875.GU Jiefei, CHEN Puhui, KONG Bin, et al. Layup optimization for maximum buckling load of variable-stiffness laminates considering manufacturing factors[J]. Acta Materiae Compositae Sinica,2018,35(4):866-875(in Chinese). [18] VILLANI A D P G, DONADON M V, ARBELO M A, et al. The postbuckling behavior of adhesively bonded stiffened panels[J]. Aerospace Science and Technology,2015(46):30-41. [19] 陈静, 沈安澜. 复合材料开孔薄壁加筋板剪切屈曲及后屈曲研究[J]. 直升机技术, 2018(1):13-19. doi: 10.3969/j.issn.1673-1220.2018.01.003CHEN Jing, SHEN Anlan. Buckling and post-buckling of composite shear stiffened plates with cutout[J]. Helicopter Technique,2018(1):13-19(in Chinese). doi: 10.3969/j.issn.1673-1220.2018.01.003 [20] 张国凡, 孙侠生, 孙中雷. 复合材料加筋壁板剪切破坏试验与后屈曲分析[J]. 机械科学与技术, 2016, 35(8):1280-1285.ZHANG Guofan, SUN Xiasheng, SUN Zhonglei. Failure test and post-buckling analysis of composite stiffened panels under shear load[J]. Mechanical Science and Technology for Aerospace Engineering,2016,35(8):1280-1285(in Chinese). [21] 中国航空研究院. 复合材料结构稳定性分析指南[M]. 北京: 航空工业出版社, 2002.Chinese Institute of Aeronautics. Analysis guide for composite structural stability[M]. Beijing: Aviation Industry Press, 2002(in Chinese). [22] TURON A, DAVILA C G, CAMANHO P P, et al. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models[J]. Engineering Fracture Mechanics,2007,74(10):1665-1682. doi: 10.1016/j.engfracmech.2006.08.025 [23] HASHIN Z, ROTEM A. A fatigue criterion for fiber-reinforced materials[J]. Journal of Composite Materials,1973,7(4):448-464. doi: 10.1177/002199837300700404 -

下载:

下载: