Experiment on bonding and anchoring performance between high-strength stainless steel wire mesh and engineered cementitious composites

-

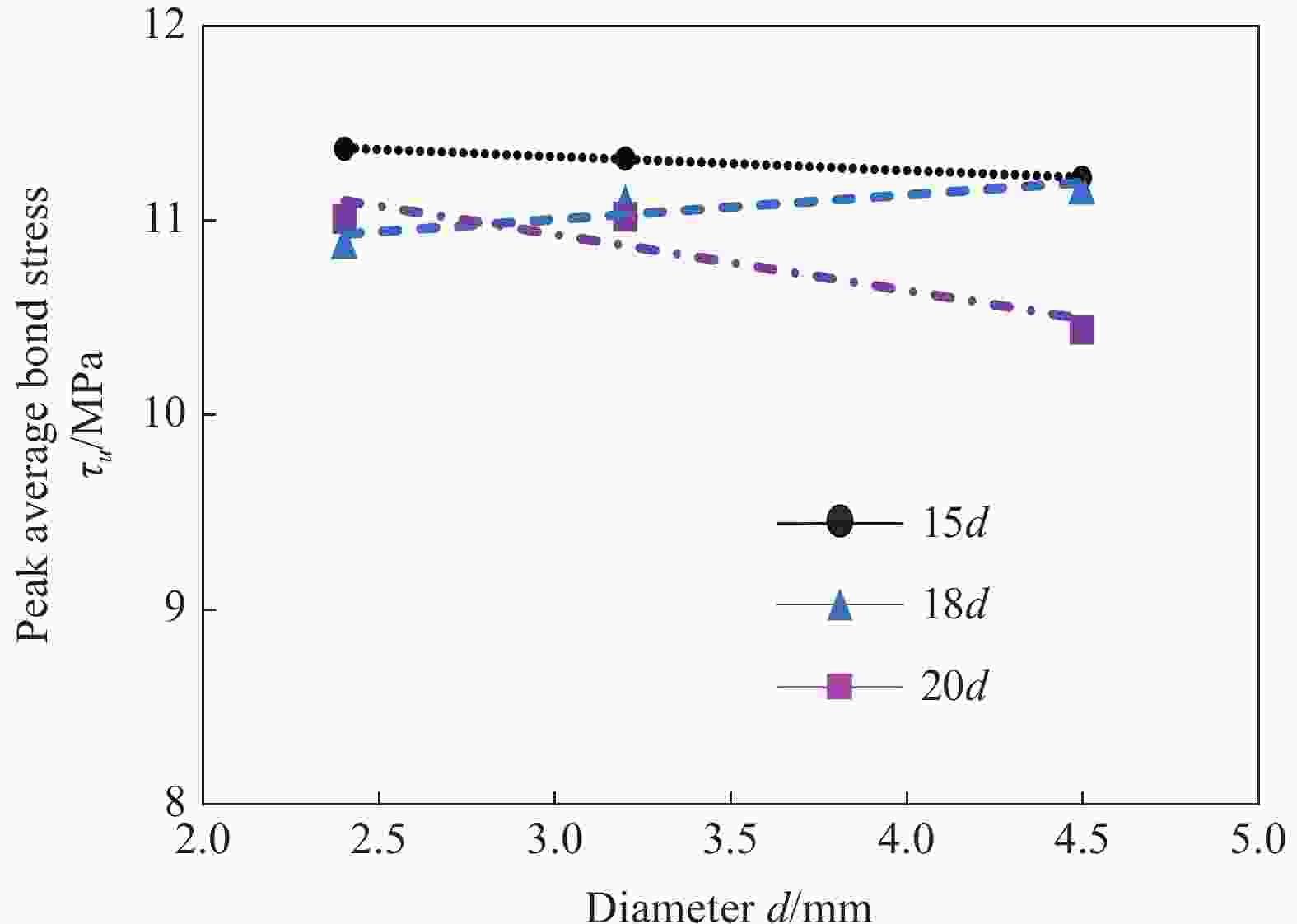

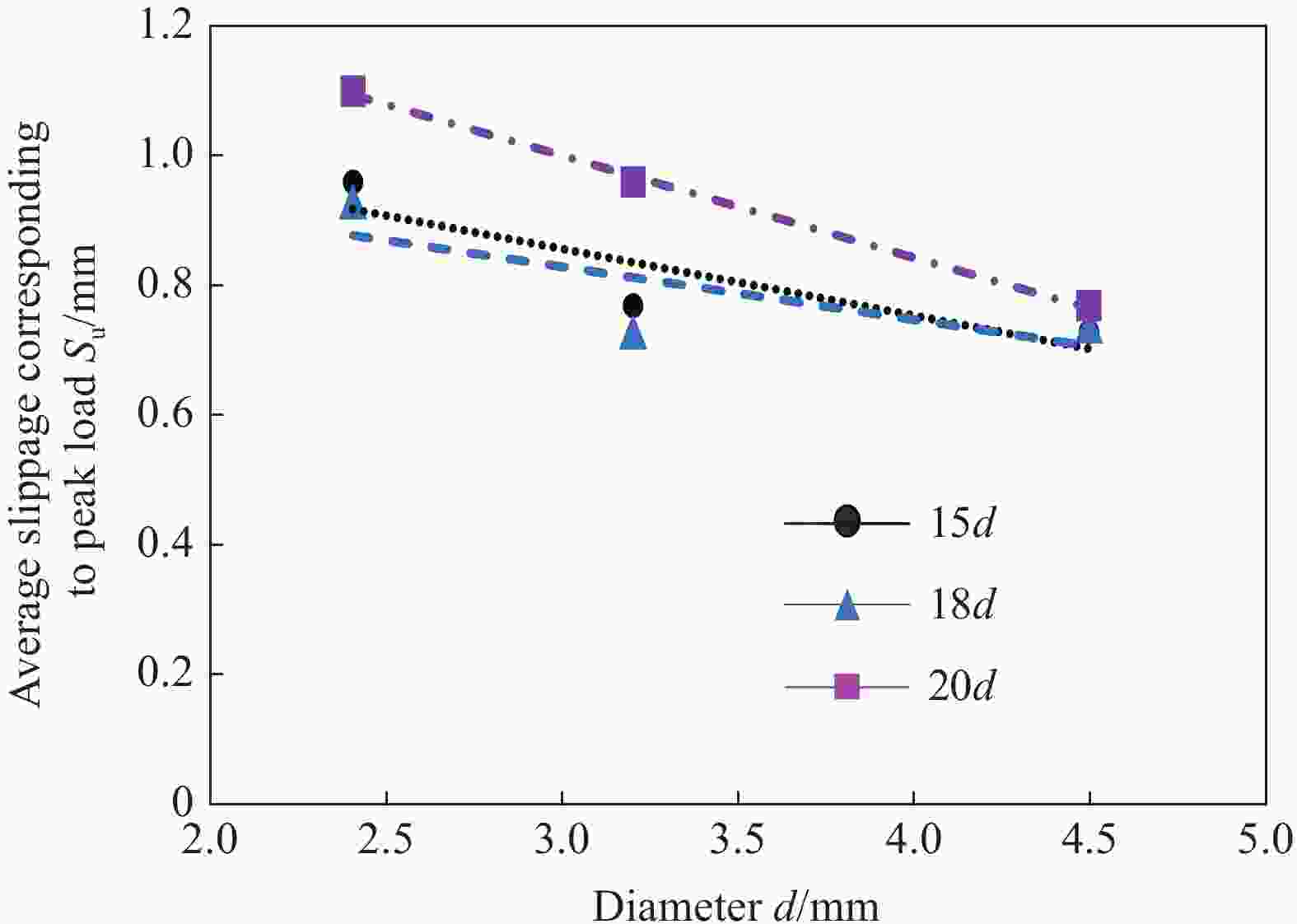

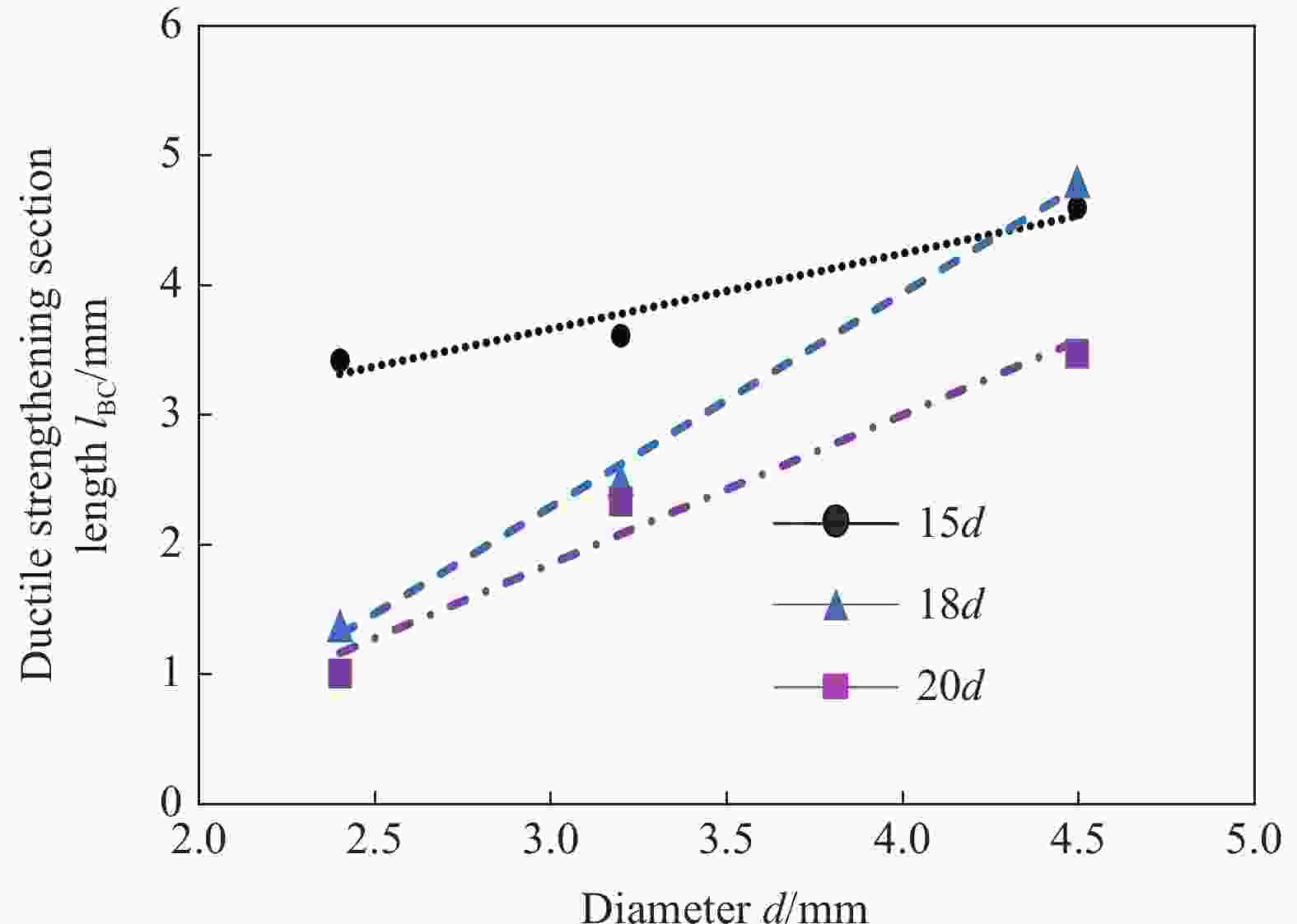

摘要: 为研究高强不锈钢绞线网在工程水泥基复合材料(ECC)中的黏结锚固性能,考虑了横向钢绞线间距、相对锚固长度和钢绞线直径三个影响因素,对设计制作的17组51个试件进行了单边拉拔试验。结果表明:横向钢绞线的设置使黏结破坏具有明显的延性破坏特征;横向钢绞线间距对黏结强度影响不大,但延性强化段长度(延性)随横向钢绞线间距的减小而增大;钢绞线网与ECC的峰值平均黏结应力与锚固长度及钢绞线直径均呈负相关,其延性随钢绞线直径的增大而提高,但随锚固长度的增大而降低。试验结果及分析验证了钢绞线网在ECC中的临界锚固长度计算可采用单根钢绞线的临界锚固长度计算公式。

-

关键词:

- 高强不锈钢绞线网 /

- 工程水泥基复合材料(ECC) /

- 黏结锚固 /

- 拉拔试验 /

- 黏结-滑移

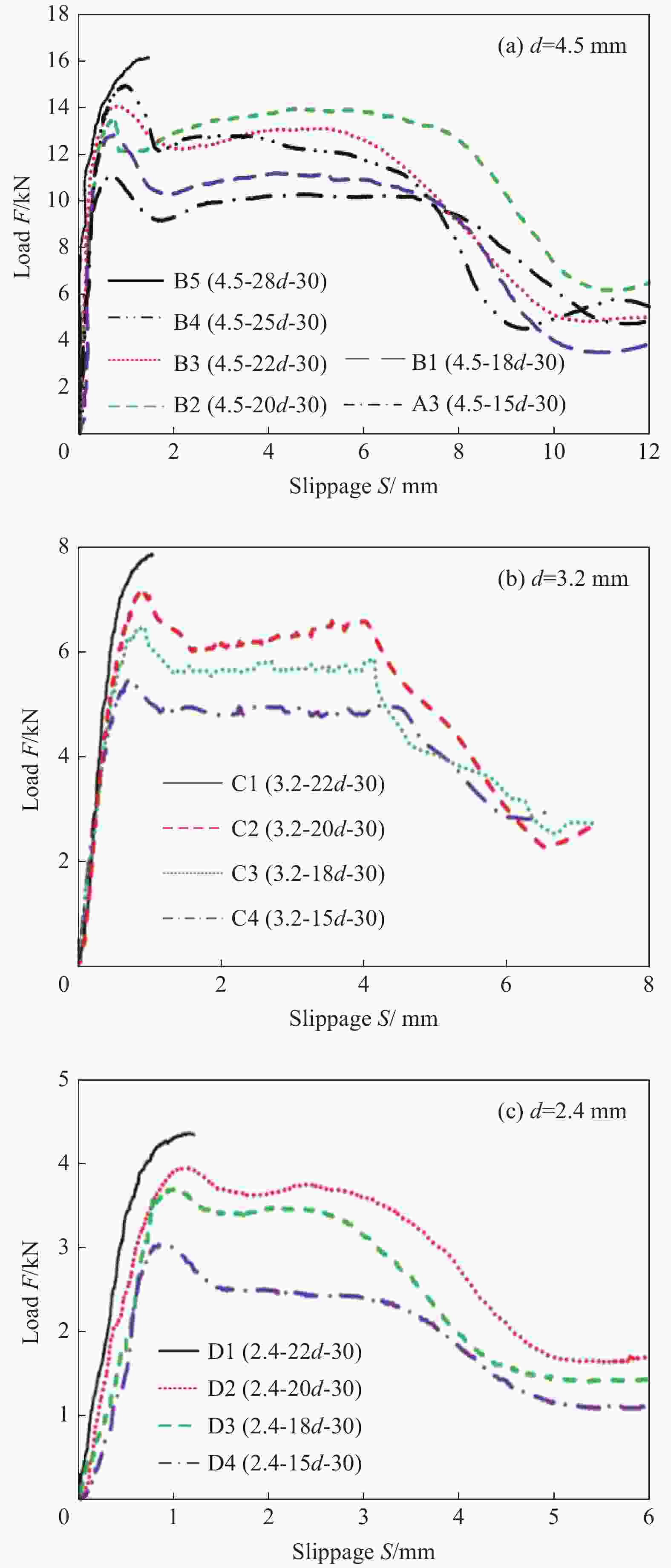

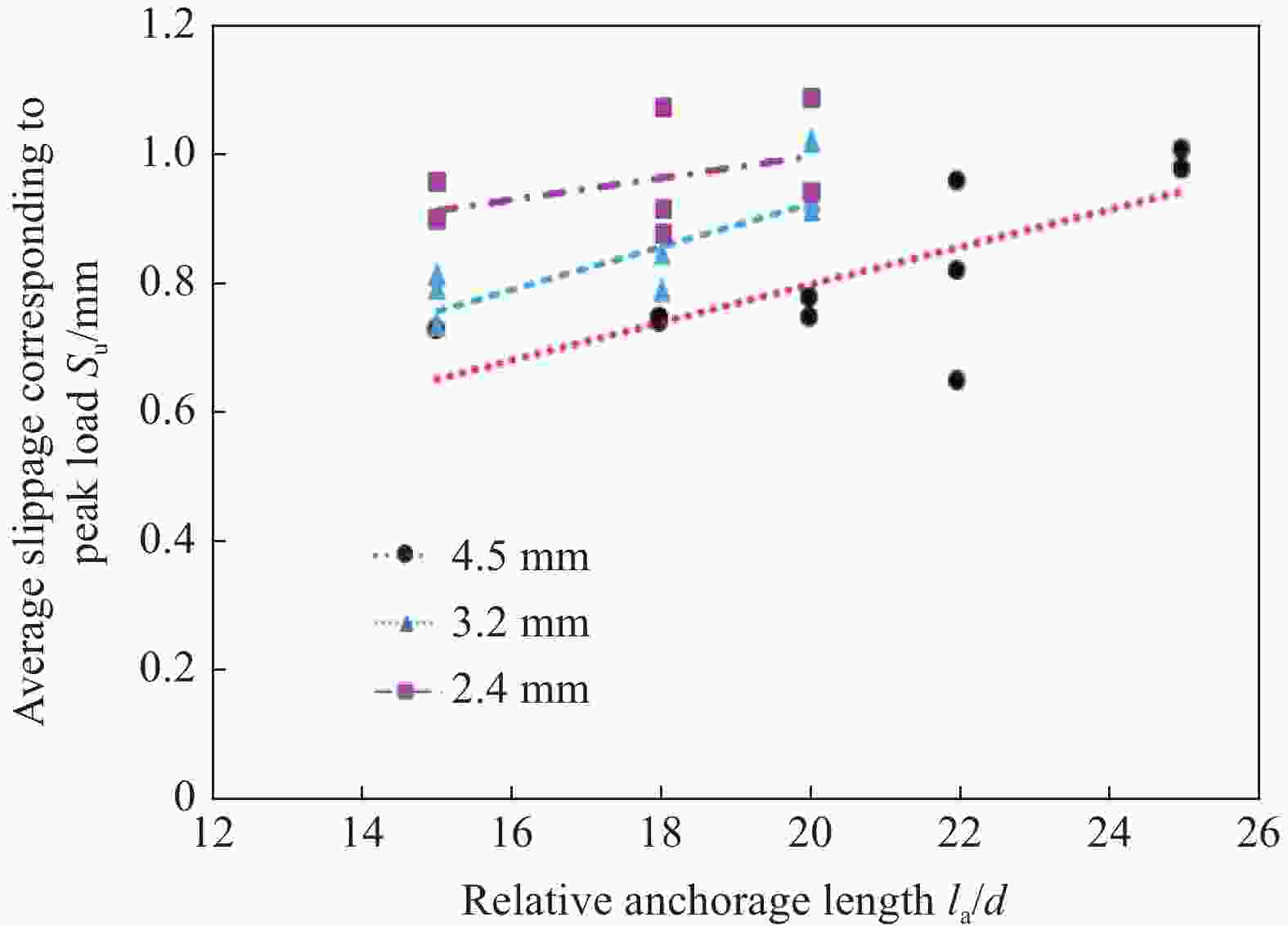

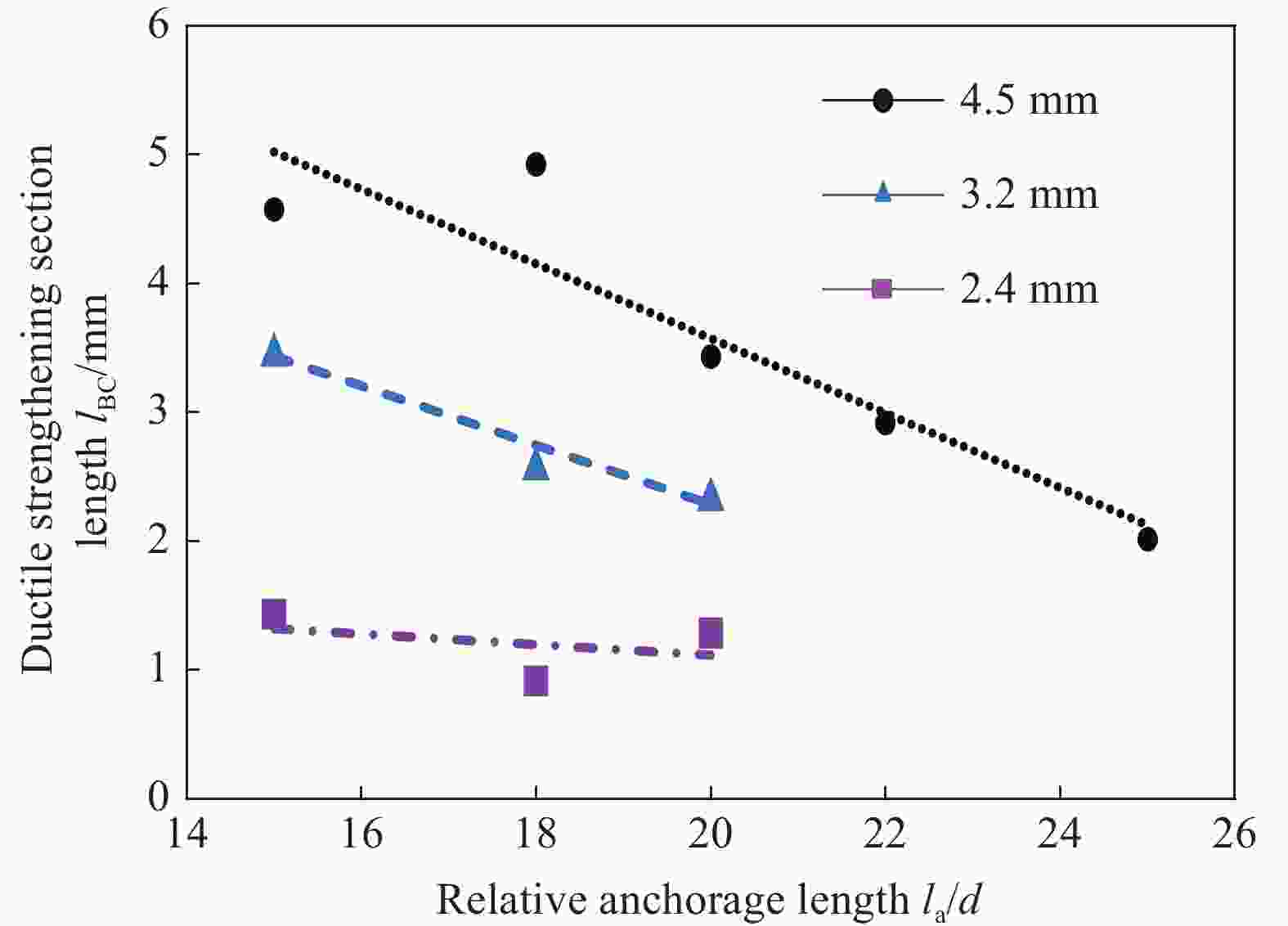

Abstract: In order to investigate the bonding and anchoring performance of high-strength stainless steel wire mesh in engineered cementitious composites (ECC), three parameters of transverse steel strand spacing, relative anchorage length and steel strand diameter were considered, and a total of 51 specimens in 17 groups were designed and carried out by the uniaxial pull-out test. The results show that the setting of transverse steel strand has obvious ductile failure characteristics. The transverse steel strand spacing has little effect on the bond strength, but the length of ductile strengthening section (ductility) increases with the decreasing of transverse steel strand spacing. The peak average bonding stress between the steel wire mesh and ECC is negatively correlated with the anchorage length and the steel strand diameter. The ductility increases with the increasing of the steel strand diameter, but decreases with the increasing of the anchorage length. The test results and analysis verify that the critical anchorage length calculation of the steel wire mesh in ECC can be calculated by using the critical anchorage length formula of a single steel strand. -

表 1 水泥基复合材料(ECC)配合比

Table 1. Mix proportion of engineered cementitious composites (ECC)

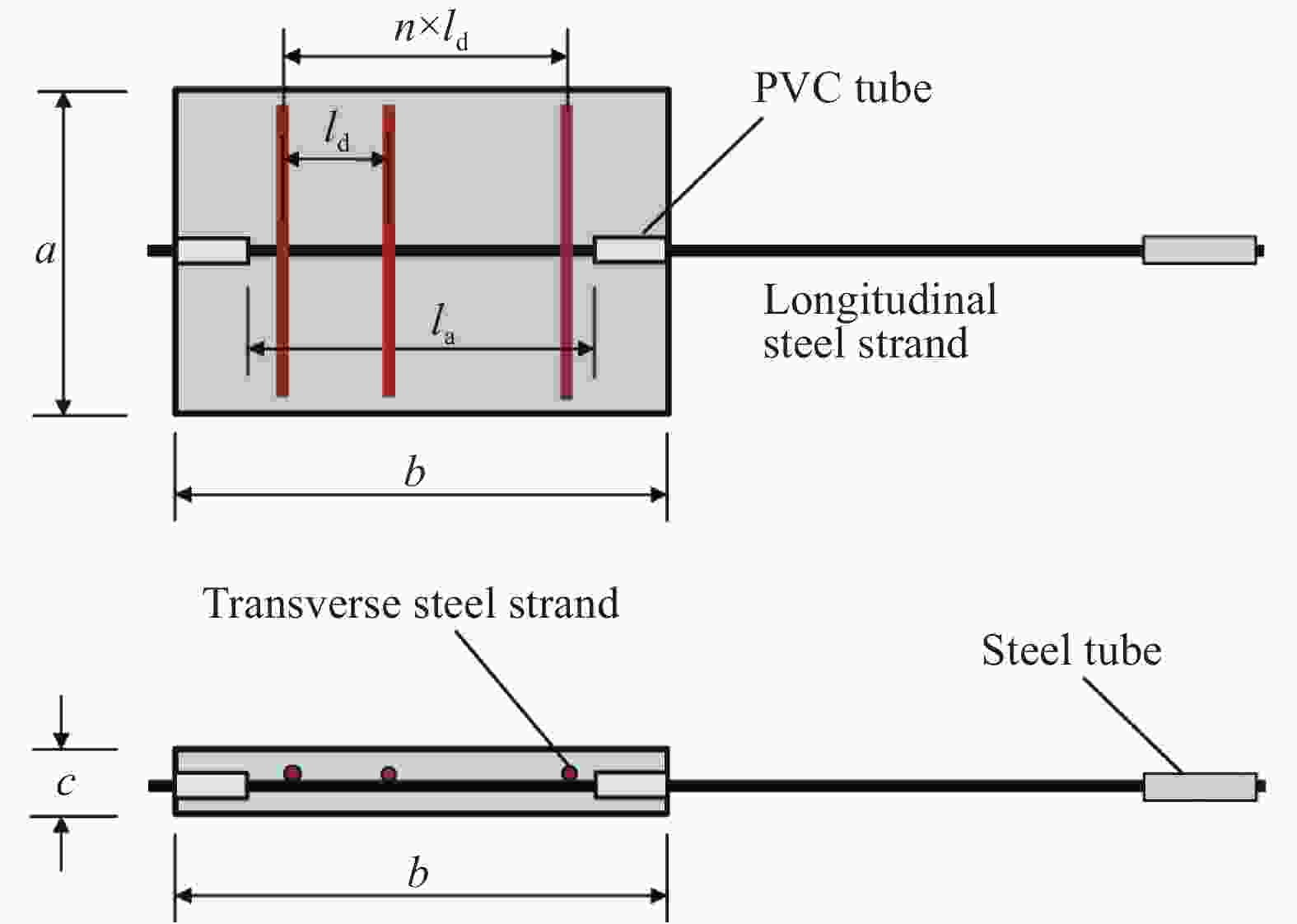

Material Proportion (Mass ratio) Cement 1 Sand 0.4 Fly ash 2.5 Water 1.15 Addition agent 0.151 PVA fiber 2% (Volume ratio) Note: PVA—Polyvinyl alcohol. 表 2 高强不锈钢绞线网增强ECC试件参数

Table 2. Parameters of high-strength stainless steel wire mesh reinforced ECC specimens

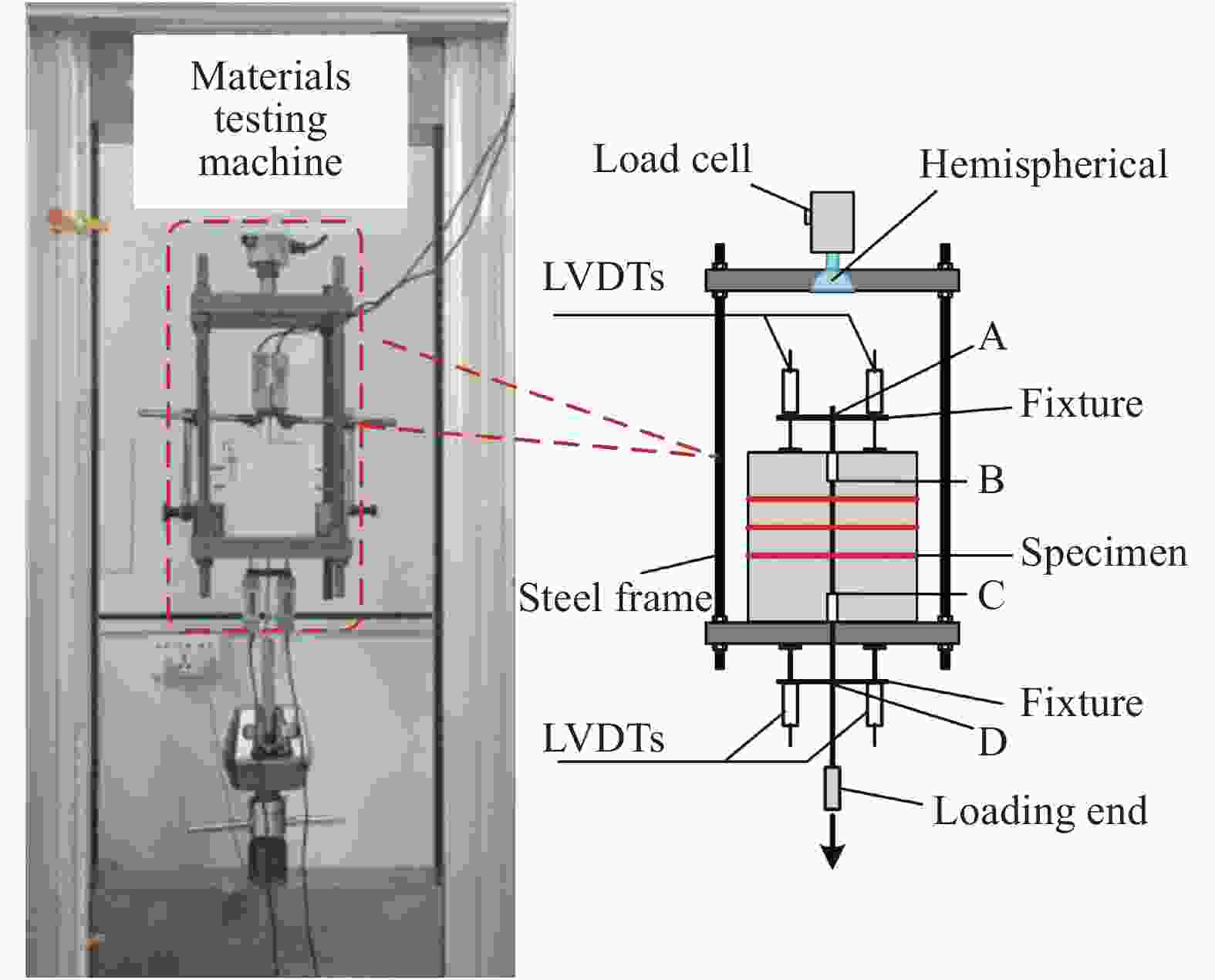

Group number d/mm la/mm ld/mm Size(a×b×c)/mm A1 4.5 15d 0 150×150×50 A2 4.5 15d 20 A3 4.5 15d 30 A4 4.5 15d 40 B1 4.5 18d 30 150×150×50 B2 4.5 20d 30 B3 4.5 22d 30 B4 4.5 25d 30 150×170×50 B5 4.5 28d 30 C1 3.2 15d 30 150×100×37 C2 3.2 18d 30 C3 3.2 20d 30 C4 3.2 22d 30 D1 2.4 15d 30 150×100×27 D2 2.4 18d 30 D3 2.4 20d 30 D4 2.4 22d 30 Notes: d—Diameter of steel strand; la—Relative anchorage length; ld—Spacing of transverse steel strand. 表 3 钢绞线性能参数

Table 3. Performance parameters of steel strand

d/mm Ultimate load/kN Ultimate tensile strength/MPa Modulus of elasticity/GPa Ultimate tensile strain/% 2.4 4.42 1 568.30 130 3.07 3.2 7.87 1 589.23 97 4.08 4.5 16.23 1 687.45 108 3.78 表 4 高强不锈钢绞线网与ECC黏结锚固性能试验结果

Table 4. Test results of bonding and anchoring performance between high-strength stainless steel wire mesh and ECC

Group number Specimen number Fu/kN τu/MPa Su/mm SB/mm SC/mm lBC/mm Result A1 4.5-15d-0-1 10.74 11.18 0.91 − − − P 4.5-15d-0-2 10.92 11.37 − − − P 4.5-15d-0-3 10.80 11.24 − − − P A2 4.5-15d-20-1 11.14 11.59 0.71 1.79 8.99 7.20 P 4.5-15d-20-2 10.66 11.09 1.76 8.87 7.11 P 4.5-15d-20-3 10.74 11.18 1.72 8.66 6.94 P A3 4.5-15d-30-1 11.10 11.55 0.73 1.71 6.31 4.60 P 4.5-15d-30-2 10.65 11.08 1.75 6.40 4.65 P 4.5-15d-30-3 10.63 11.06 1.86 6.29 4.43 P A4 4.5-15d-40-1 10.38 10.80 0.85 1.96 4.16 2.20 P 4.5-15d-40-2 10.14 10.55 1.78 4.17 2.39 P 4.5-15d-40-3 10.64 11.07 1.82 4.22 2.40 P B1 4.5-18d-30-1 12.11 10.58 0.75 1.82 8.42 6.60 P 4.5-18d-30-2 12.84 11.22 1.91 5.14 3.23 P 4.5-18d-30-3 12.75 11.14 − − − R B2 4.5-20d-30-1 12.81 10.07 0.77 2.79 6.16 3.37 P 4.5-20d-30-2 13.49 10.61 1.95 5.33 3.38 P 4.5-20d-30-3 13.56 10.66 1.92 5.42 3.50 P B3 4.5-22d-30-1 14.11 10.09 0.81 1.97 4.28 2.31 P 4.5-22d-30-2 14.21 10.16 2.14 6.08 3.94 P 4.5-22d-30-3 14.89 10.64 1.92 4.41 2.49 P B4 4.5-25d-30-1 14.93 9.35 0.99 1.72 3.53 1.81 P 4.5-25d-30-2 16.24 9.39 − − − R 4.5-25d-30-3 15.03 9.41 1.81 4.03 2.22 P B5 4.5-28d-30-1 16.18 9.09 1.55 − − − R 4.5-28d-30-2 16.34 9.18 − − − R 4.5-28d-30-3 16.26 9.13 − − − R C1 3.2-15d-30-1 5.49 11.38 0.77 1.28 4.42 3.14 P 3.2-15d-30-2 5.46 11.31 1.32 5.02 3.70 P 3.2-15d-30-3 5.45 11.30 1.24 4.85 3.61 P C2 3.2-18d-30-1 6.47 11.17 0.82 1.46 4.15 2.69 P 3.2-18d-30-2 6.39 11.05 1.54 4.04 2.50 P 3.2-18d-30-3 5.37 9.28 − − − P C3 3.2-20d-30-1 7.08 11.04 0.96 1.59 3.95 2.36 P 3.2-20d-30-2 7.59 11.79 − − − R 3.2-20d-30-3 7.07 10.02 1.69 4.04 2.36 P C4 3.2-22d-30-1 7.56 10.75 1.04 − − − R 3.2-22d-30-2 7.77 11.01 − − − R 3.2-22d-30-3 7.86 11.17 − − − R D1 2.4-15d-30-1 3.19 11.76 0.89 1.63 3.06 1.64 P 2.4-15d-30-2 3.08 11.27 − − − P 2.4-15d-30-3 3.04 11.12 − − − P D2 2.4-18d-30-1 3.73 11.25 0.93 1.60 2.54 1.41 P 2.4-18d-30-2 3.67 11.08 1.54 2.42 1.22 P 2.4-18d-30-3 3.72 11.21 − − − P D3 2.4-20d-30-1 3.94 10.88 1.10 1.34 2.97 1.52 P 2.4-20d-30-2 3.97 10.97 1.94 2.70 1.09 P 2.4-20d-30-3 4.05 11.19 1.81 3.28 0.99 P D4 2.4-22d-30-1 4.37 10.94 1.16 − − − R 2.4-22d-30-2 4.34 10.87 − − − R 2.4-22d-30-3 4.37 10.94 − − − R Notes: Fu—Peak load; τu—Peak average bond stress; Su—Average slippage corresponding to peak load; SB—Slippage of point B; SC—Slippage of point C; lBC—Ductile strengthening section length; Specimen number: 4.5-15d-0-1 (a-b-c-d), in which 4.5 (a) represents the diameter of the steel strand, 15d (b) represents the relative anchorage length, 0 (c) represents the transverse steel strand spacing and 1 (d) is the specimen number in the same group; P—Pull-out failure; R—Rupture failure. 表 5 高强不锈钢绞线网增强ECC试件临界锚固长度对比

Table 5. Comparison of critical anchorage length of high-strength stainless steel wire mesh reinforced ECC specimens

d/mm ft/MPa fy/MPa la,c/mm la,u/mm la,c/la,u 2.4 2.83 1 568.30 54.53 53 0.97 3.2 2.83 1 589.23 73.68 70 0.95 4.5 2.83 1 687.45 112.46 115 1.02 Notes: la,c—Calculated value of critical anchorage length; la,u—Measured value of critical anchorage length. -

[1] SUTHIWARAPIRAK P, MATSUMOTO T, KANDA T. Flexural fatigue failure characteristics of an engineered cementitious composite and polymer cement mortars[J]. Doboku Gakkai Ronbunshu,2002,718(718):121-134. [2] ZHANG J, LEUNG C K Y, GAO Y. Simulation of crack propagation of fiber reinforced cementitious composite under direct tension[J]. Engineering Fracture Mechanics,2011,78(12):2439-2454. doi: 10.1016/j.engfracmech.2011.06.003 [3] 高淑玲, 徐世烺. PVA纤维增强水泥基复合材料拉伸特性试验研究[J]. 大连理工大学学报, 2007, 47(2):233-239. doi: 10.3321/j.issn:1000-8608.2007.02.016GAO Shuling, XU Shilang. Experimental research on tension property of polyvinyl alcohol fiber reinforced cementitious composites[J]. Journal of Dalian University of Technology,2007,47(2):233-239(in Chinese). doi: 10.3321/j.issn:1000-8608.2007.02.016 [4] 张君, 公成旭, 居贤春, 等. 延性纤维增强水泥基复合材料的抗弯性能[J]. 工程力学, 2010, 27(3):112-115.ZHANG Jun, GONG Chengxu, JU Xianchun, et al. Bending performance of ductile fiber reinforced cementitious composites[J]. Engineering Mechanics,2010,27(3):112-115(in Chinese). [5] 刘曙光, 白茹, 张菊, 等. 配筋聚乙烯醇纤维增强水泥复合材料梁的曲率延性[J]. 复合材料学报, 2020, 37(2):451-460.LIU Shuguang, BAI Ru, ZHANG Ju, et al. Flexural ductility of steel-polyvinyl alcohol fiber reinforced cement composite beam[J]. Acta Materiae Compositae Sinica,2020,37(2):451-460(in Chinese). [6] 徐世烺, 李庆华, 李贺东. 碳纤维编织网增强超高韧性水泥基复合材料弯曲性能的试验研究[J]. 土木工程学报, 2007, 40(12):69-76. doi: 10.3321/j.issn:1000-131x.2007.12.009XU Shilang, LI Qinghua, LI Hedong. An experimental study on the flexural properties of carbon textile reinforced ECC[J]. China Civil Engineering Journal,2007,40(12):69-76(in Chinese). doi: 10.3321/j.issn:1000-131x.2007.12.009 [7] 夏立鹏, 张黎飞, 郑愚. CFRP增强工程水泥基复合材料桥面连接板的结构和性能[J]. 复合材料学报, 2019, 36(4):848-859.XIA Lipeng, ZHANG Lifei, ZHENG Yu. Structural performance of CFRP reinforced ECC link slabs in jointless bridge decks[J]. Acta Materiae Compositae Sinica,2019,36(4):848-859(in Chinese). [8] 朱忠锋, 王文炜. FRP编织网/ECC复合加固钢筋混凝土圆柱力学性能的试验研究[J]. 东南大学学报(自然科学版), 2016, 46(5):1082-1087. doi: 10.3969/j.issn.1001-0505.2016.05.031ZHU Zhongfeng, WANG Wenwei. Experimental study on mechanical behavior of circular reinforced concrete columns strengthened with FRP textile and ECC[J]. Journal of Southeast University (Natural Science Edition),2016,46(5):1082-1087(in Chinese). doi: 10.3969/j.issn.1001-0505.2016.05.031 [9] 聂建国, 王寒冰, 张天申, 等. 高强不锈钢绞线网-渗透性聚合砂浆抗弯加固的试验研究[J]. 建筑结构学报, 2005, 26(2):1-9. doi: 10.3321/j.issn:1000-6869.2005.02.001NIE Jianguo, WANG Hanbing, ZHANG Tianshen, et al. Experimental study on flexural behavior of RC beams strengthened with stainless steel wire mesh and permeability polymer mortar[J]. Journal of Building Structures,2005,26(2):1-9(in Chinese). doi: 10.3321/j.issn:1000-6869.2005.02.001 [10] 聂建国, 蔡奇, 张天申, 等. 高强不锈钢绞线网-渗透性聚合砂浆抗剪加固的试验研究[J]. 建筑结构学报, 2005, 26(2):10-17. doi: 10.3321/j.issn:1000-6869.2005.02.002NIE Jianguo, CAI Qi, ZHANG Tianshen, et al. Experimental study on shear behavior of RC beams strengthened with stainless steel wire mesh and permeability polymer mortar[J]. Journal of Building Structures,2005,26(2):10-17(in Chinese). doi: 10.3321/j.issn:1000-6869.2005.02.002 [11] 王亚勇, 姚秋来, 巩正光, 等. 高强钢绞线网-聚合物砂浆在郑成功纪念馆加固工程中的应用[J]. 建筑结构, 2005, 35(8):41-42.WANG Yayong, YAO Qiulai, GONG Zhengguang, et al. Application of strengthened technology by composite cover combined with high strength wire cable mesh and polymeric mortar in Zheng Chenggong Memorial strengthening engineering[J]. Building Structure,2005,35(8):41-42(in Chinese). [12] 王大愚, 仝胜强, 朱同然, 等. 中国美术馆加固改造综合施工技术[J]. 施工技术, 2009, 38(6):60-62.WANG Dayu, TONG Shengqiang, ZHU Tongran, et al. Comprehensive construction technology of reinforcement and reconstruction in China Art Gallery[J]. Construction Technology,2009,38(6):60-62(in Chinese). [13] 徐世烺, 王洪昌. 超高韧性水泥基复合材料与钢筋粘结本构关系的试验研究[J]. 工程力学, 2008, 25(11):53-61.XU Shilang, WANG Hongchang. Experimental study on bond-slip between ultra-high toughness cementitious composites and steel bar[J]. Engineering Mechanics,2008,25(11):53-61(in Chinese). [14] 金贺楠. 纤维编织网与自应力混凝土黏结性能试验研究[D]. 长春: 吉林大学, 2015.JIN He'nan. Experimental study on bond behavior between textile and self-stressing concrete[D]. Changchun: Jilin University, 2015(in Chinese). [15] YOO D Y, KWON K Y, PARK J J, et al. Local bond-slip response of GFRP rebar in ultra-high-performance fiber-reinforced concrete[J]. Composite Structures,2015,120:53-64. doi: 10.1016/j.compstruct.2014.09.055 [16] 吴丽丽, 王云飞, 谢灵慧, 等. 玻璃纤维增强聚合物基复合材料筋与工程水泥基复合材料粘结性能[J]. 复合材料学报, 2020, 37(3):696-706.WU Lili, WANG Yunfei, XIE Linghui, et al. Study on bonding behavior between glass fiber reinforced polymer and engineered cementitious composite[J]. Acta Materiae Compositae Sinica,2020,37(3):696-706(in Chinese). [17] KARUNAGARAN N, RAJADURAI A. Effect of surface treatment on mechanical properties of glass fiber/stainless steel wire mesh reinforced epoxy hybrid composites[J]. Journal of Mechanical Science and Technology,2016,30(6):2475-2482. doi: 10.1007/s12206-016-0507-9 [18] 曹俊, 王志浩. 高强不锈钢绞线在聚合砂浆中粘结锚固性能的试验研究[J]. 建筑结构, 2006, 36(9):37-38, 80.CAO Jun, WANG Zhihao. Experimental study on bond-anchorage of high-strength stainless steel wire in polymer mortar[J]. Building Structure,2006,36(9):37-38, 80(in Chinese). [19] 朱俊涛, 李燚, 王新玲. 考虑横向钢绞线影响的钢绞线网/工程水泥基复合材料黏结性能试验研究[J]. 工业建筑, 2018, 48(11):143-148.ZHU Juntao, LI Yi, WANG Xinling. Experimental research on bonding performance of stainless steel wire mesh/ECC with horizontal steel wire[J]. Industrial Construction,2018,48(11):143-148(in Chinese). [20] 周擎威. 高强不锈钢绞线与ECC粘结锚固性能试验研究[D]. 郑州: 郑州大学, 2018.ZHOU Qingwei. Experimental study on bonding performance of high-strength stainless steel stranded wire and ECC[D]. Zhengzhou: Zhengzhou University, 2018(in Chinese). -

下载:

下载: