Effect of nano TiO2 on UV aging resistance of wood fiber/polypropylene composites

-

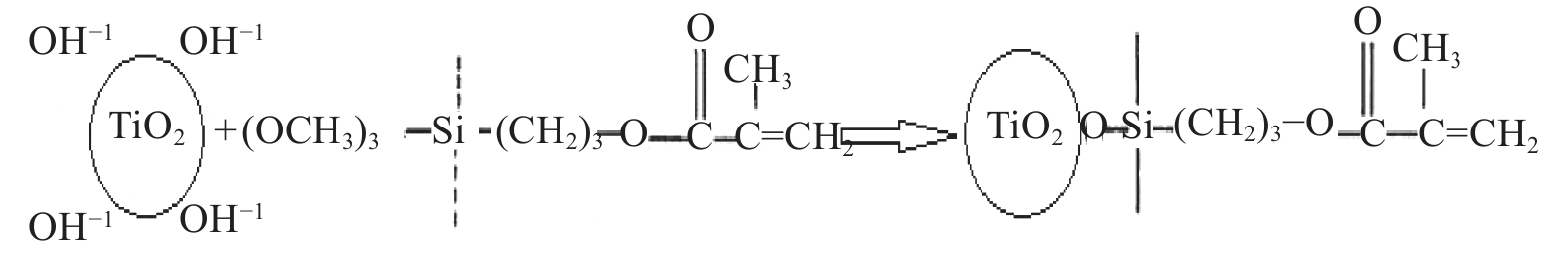

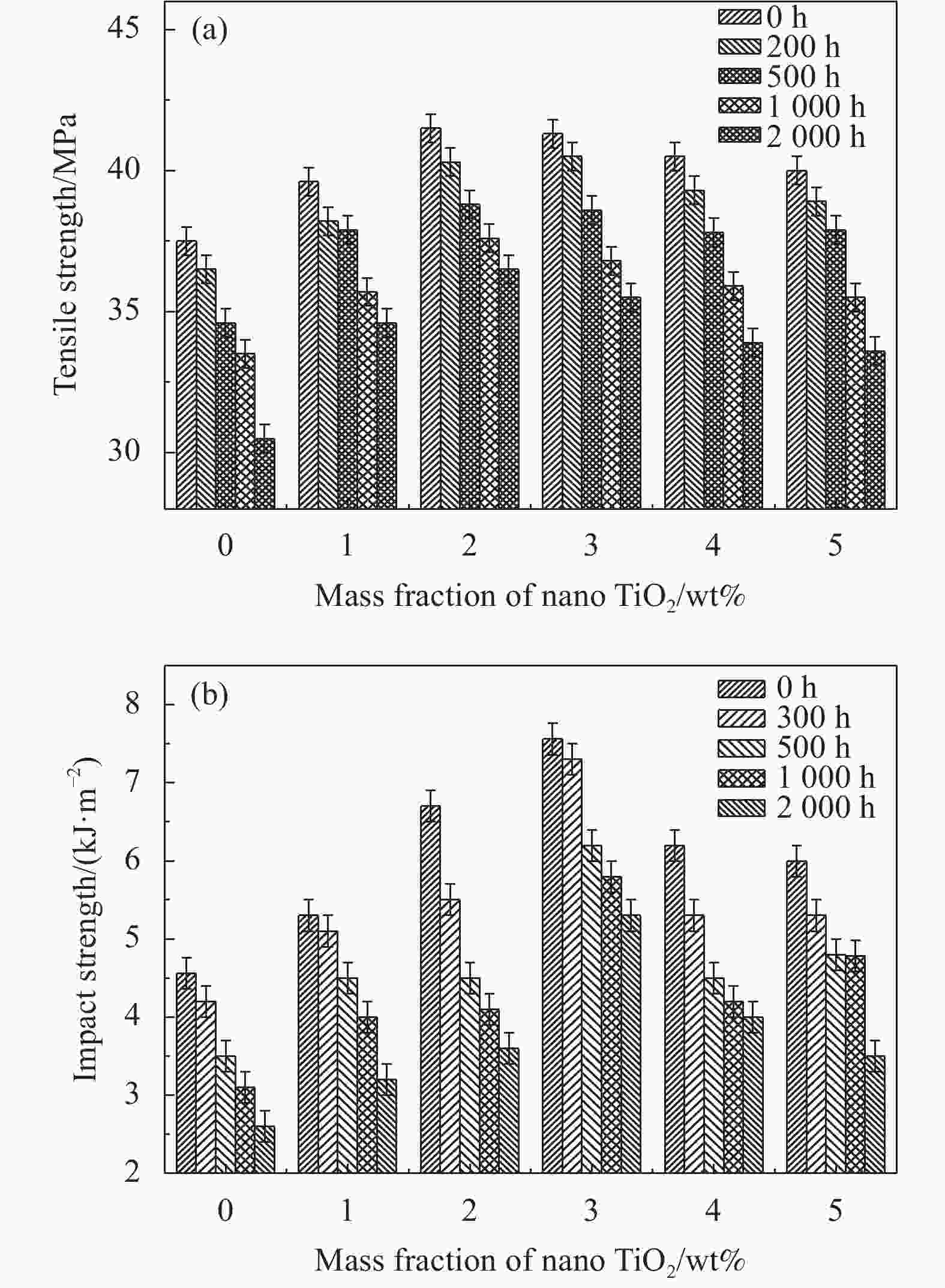

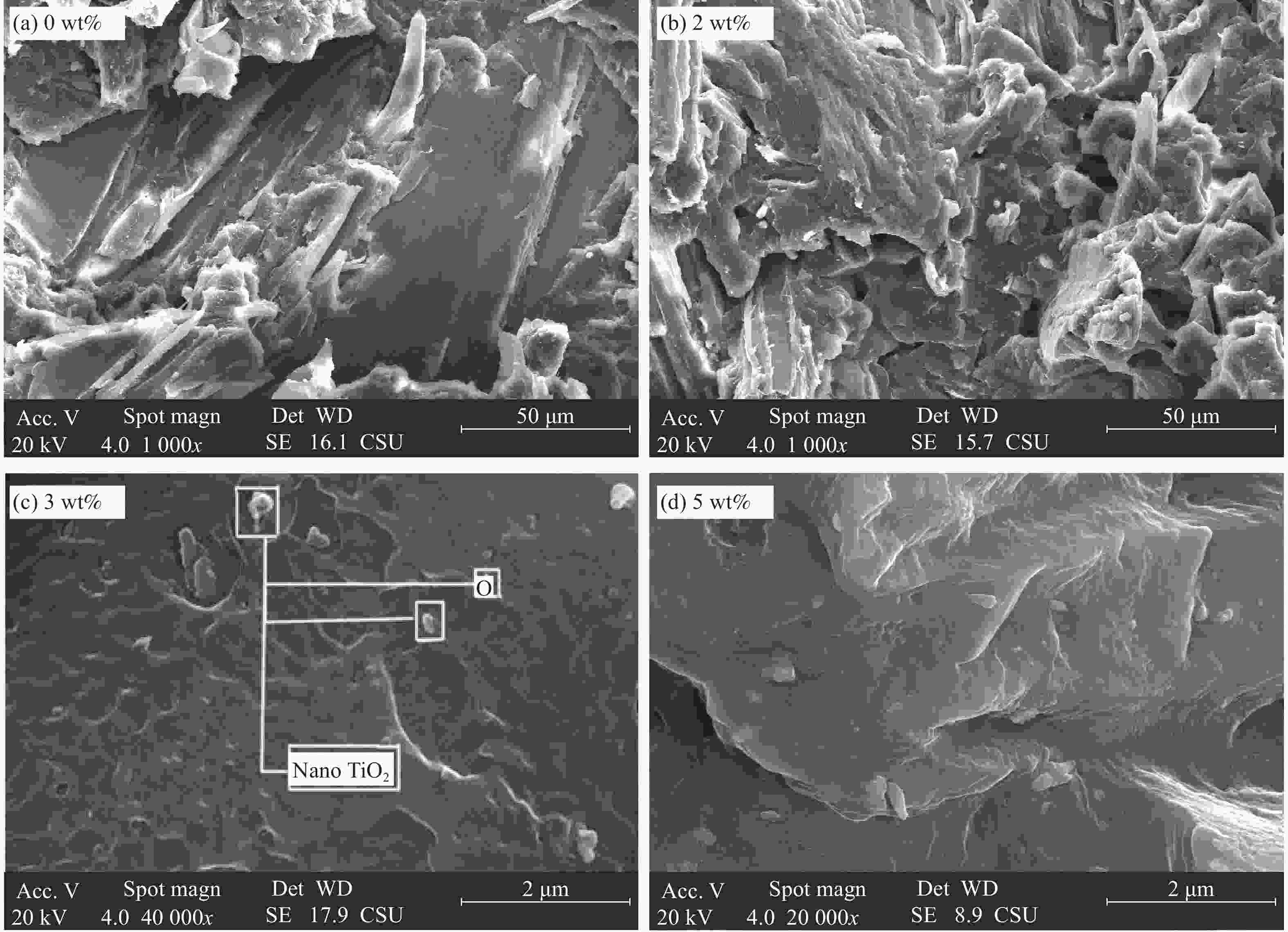

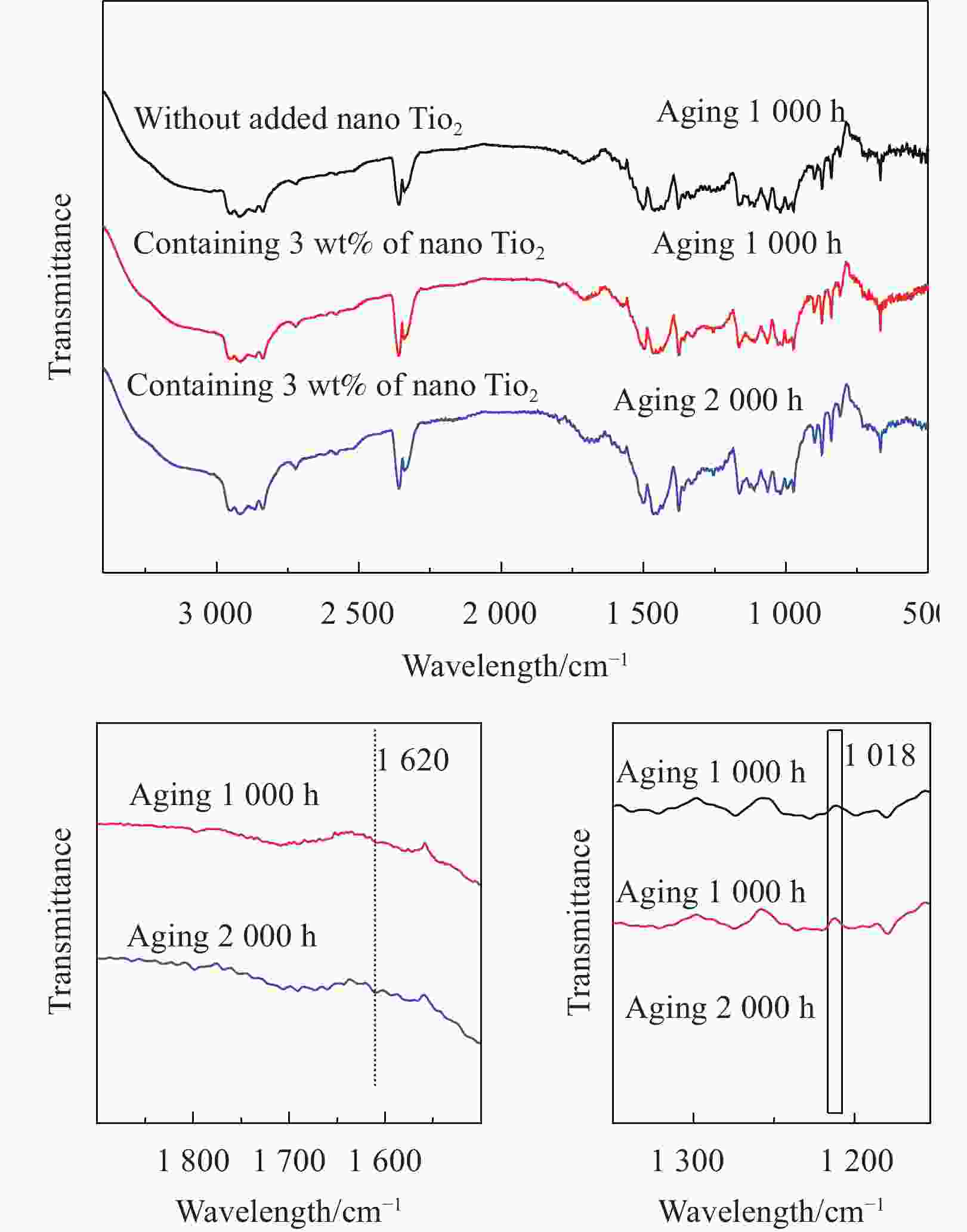

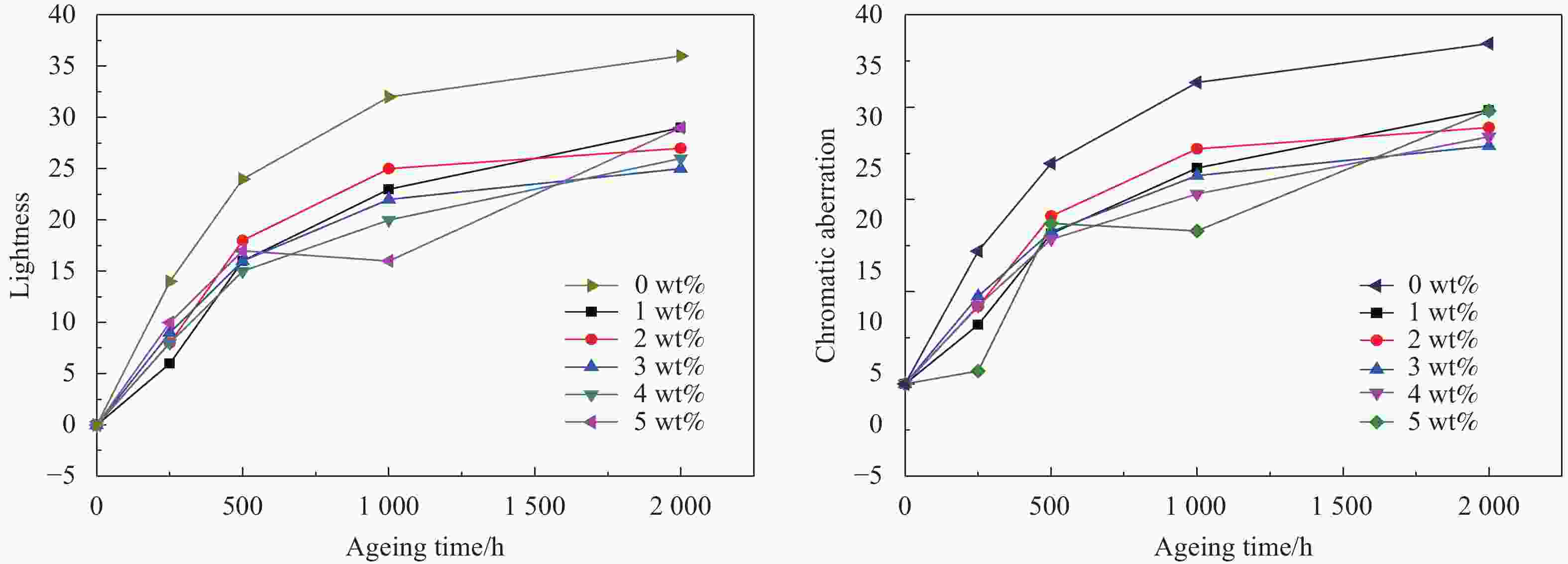

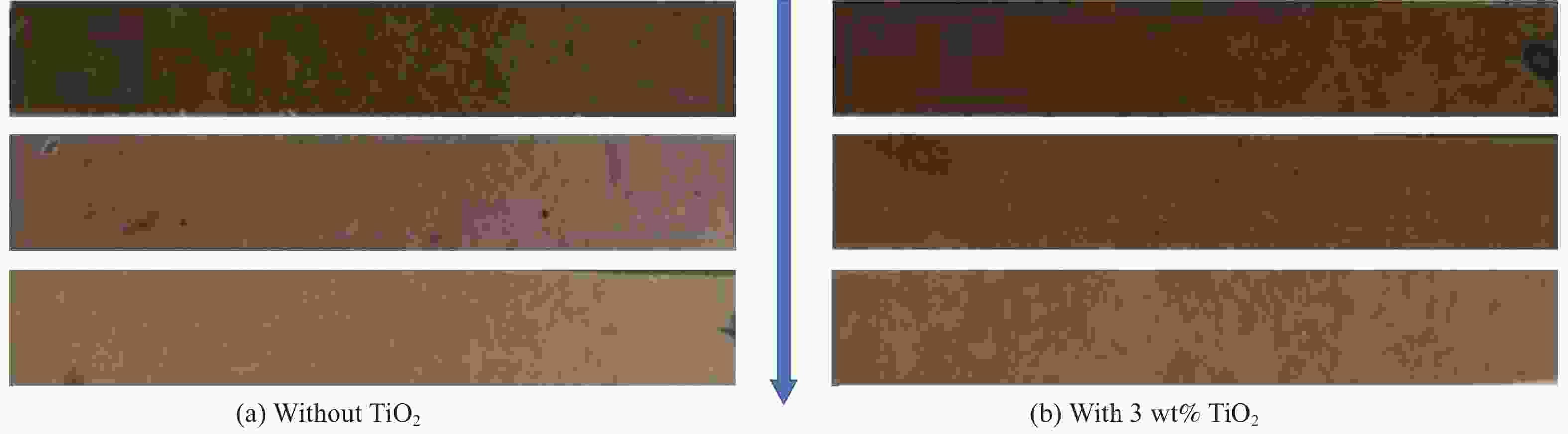

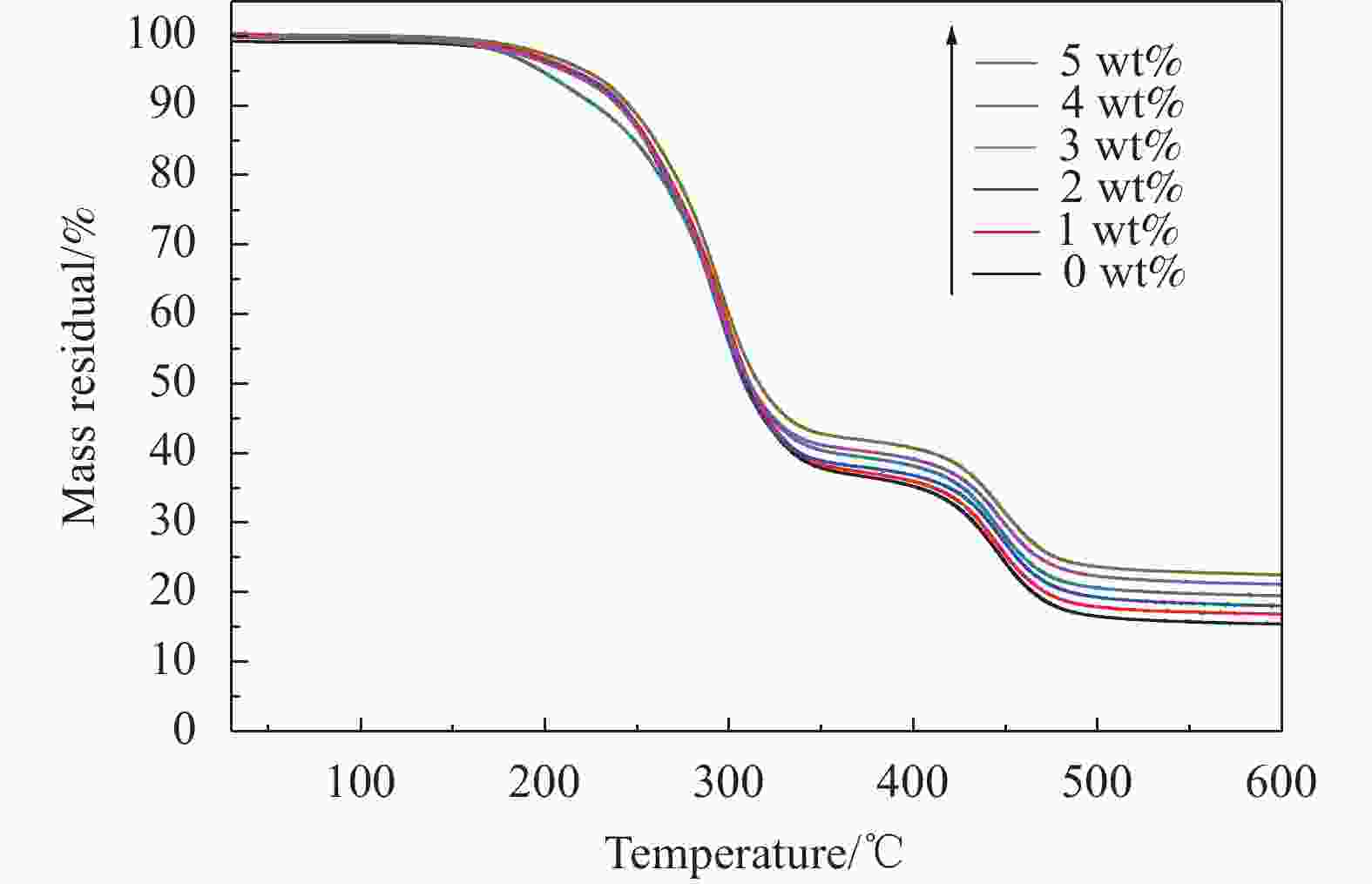

摘要: 木塑复合材料作为室外建筑装饰材料时,暴露在紫外光的照射下,易老化导致其力学性能降低、使用寿命减少。将具有高效紫外线屏蔽能力的金红石型纳米TiO2经硅烷偶联剂KH-570表面改性后,与木纤维(WF)、聚丙烯(PP)等制备了TiO2-WF/PP复合材料。对TiO2-WF/PP复合材料进行了人工加速紫外老化,并利用FTIR、TG、SEM、力学性能分析、颜色变化分析等手段,探究了纳米TiO2对WF/PP复合材料抗紫外老化的影响。结果表明:改性纳米TiO2粒子在WF/PP复合材料中均匀分散,无明显团聚,且其加入显著提高了复合材料的热稳定性;TiO2-WF/PP复合材料随着老化时间的延长,力学性能下降相对较小且颜色变化较小。当纳米TiO2的质量分数为2 wt%~3 wt%,老化2 000 h时后,TiO2-WF/PP复合材料的拉伸强度、冲击强度仅分别下降10.0%和12.6%;未加入纳米TiO2颗粒的WF/PP复合材料,则分别下降20.2%和22.6%。Abstract: When wood-plastic composites are used as outdoor building decoration materials, they are exposed to ultraviolet light, resulting in mechanical properties and service life reducing. The rutile nano TiO2 with high-efficiency ultraviolet shielding ability was surface-modified with a silane coupling agent KH-570, and then TiO2-WF/PP composites were prepared with wood fiber (WF), polypropylene (PP). The artificial accelerated UV aging of the composites was carried out. The effects of nano TiO2 on the UV aging of WF/PP composites were investigated by means of FTIR, TG, SEM, mechanical properties analysis and color change analysis. The results show that the modified nano TiO2 particles can be uniformly dispersed in WF/PP composites without obvious agglomeration, and their addition significantly improves the thermal stability of the composites; with the aging time prolonged, the decrease of the mechanical properties of WF/PP composites is relatively small and the color change scope is small. When the mass fraction of nano TiO2 particles is 2 wt%-3 wt% and aging for 2 000 h, the tensile strength and impact strength of the TiO2-WF/PP composites only decrease by 10.0% and 12.6%, respectively, while those without the addition of nano TiO2 particles decrease by 20.2% and 22.6%, respectively.

-

Key words:

- nano TiO2 /

- wood fiber(WF) /

- polypropylene(PP) /

- composites /

- surface modification /

- anti-ultraviolet aging

-

表 1 TiO2-木质纤维/聚丙烯(TiO2-WF/PP)复合材料的主要成分

Table 1. Ingredients for TiO2-wood fiber/polypropulene(TiO2-WF/PP) composites

Sample Modified TiO2/wt% WF/wt% PP/wt% ZnO/wt% CaCO3/wt% Stabilizer/wt% 0 0 29 66.5 0.5 3 1 1 1 29 65.5 0.5 3 1 2 2 29 64.5 0.5 3 1 3 3 29 63.5 0.5 3 1 4 4 29 62.5 0.5 3 1 5 5 29 61.5 0.5 3 1 -

[1] 杨青, 张宝华, 毛志平, 等. 聚丙烯/改性纳米二氧化钛复合材料的制备与性能[J]. 高分子材料科学与工程, 2009, 25(1):48-51. doi: 10.3321/j.issn:1000-7555.2009.01.014YANG Qing, ZHANG Baohua, MAO Zhiping, et al. Preparation and properties of polypropylene/modified nanometer titania composite[J]. Polymer Materials Science and Engineering,2009,25(1):48-51(in Chinese). doi: 10.3321/j.issn:1000-7555.2009.01.014 [2] 冷李超, 张元明, 韩光亭, 等. 不同受阻胺光稳定剂改性聚丙烯耐光老化性能研究[J]. 应用化工, 2014(5):864-867.LENG Lichao, ZHANG Yuanming, HAN Guangting, et al. Study on photoaging resistance of polypropylene modified with different blocking amine light stabilizers[J]. Applied Chemistry,2014(5):864-867(in Chinese). [3] 李正印, 王伟宏. 高木材纤维含量聚丙烯基复合材料的制备及其性能[J]. 林业工程学报, 2017, 2(2):9-15.LI Zhengyin, WANG Weihong. Preparation and properties of polypropylene based composites with high wood fibers content[J]. Journal of Forestry Engineering,2017,2(2):9-15(in Chinese). [4] 侯人鸾, 何春霞, 薛娇, 等. 小麦秸秆/PP复合材料的紫外线加速老化性能[J]. 复合材料学报, 2013, 30(5):86-93. doi: 10.3969/j.issn.1000-3851.2013.05.014HOU Renluan, HE Chunxia, XUE Jiao, et al. UV accelerated ageing properties of wheat straw/PP wood plastic compo-site[J]. Acta Materiae Compositae Sinica,2013,30(5):86-93(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.05.014 [5] WEN Jiuqing, LI Xin, LIU Wei. Photocatalysis fundamentals and surface modification of TiO2 nanomaterials[J]. Chinese Journal of Catalysis,2015,12(36):2049-2070. [6] 薛娇, 何春霞, 侯人鸾, 等. 百菌清对麦秸秆/PP复合材料耐腐蚀性能的影响[J]. 合成材料老化与应用, 2013, 42(1):6-10. doi: 10.3969/j.issn.1671-5381.2013.01.002XUE Jiao, HE Chunxia, HOU Renluan, et al. Effects of chlorothalonil on corrosion resistance of wheat straw/PP composites[J]. Synthetic Materials Aging and Appliction,2013,42(1):6-10(in Chinese). doi: 10.3969/j.issn.1671-5381.2013.01.002 [7] 杨守禄, 李丹, 吴义强, 等. 木塑复合材料功能化改性研究进展[J]. 材料导报, 2018, 32(9):3090-3098.YANG Shoulu, LI Dan, WU Yiqiang, et al. Research progress on functional modification of WPC composites[J]. Materials Review,2018,32(9):3090-3098(in Chinese). [8] 左迎峰, 李文豪, 李萍, 等. 竹纤维/聚乳酸可降解复合材料的增塑改性[J]. 林业工程学报, 2018, 3(1):77-82.ZUO Yingfeng, LI Wenhao, LI Ping, et al. Plastication of bamboo fiber/polylactic acid degradeable composite[J]. Journal of Forestry Engineering,2018,3(1):77-82(in Chinese). [9] 付自政. HDPE/木粉复合材料的制备及其紫外加速老化性能研究[D]. 武汉: 华中农业大学, 2009.FU Zizheng. Preparation of HDPE/wood flour composite and its UV accelerated aging properties[D]. Wuhan: Huazhong Agricultural University, 2009(in Chinese). [10] 徐兵, 梅长彤, 刘朝政, 等. 光稳定剂复配对核壳WPC抗紫外老化性能的影响[J]. 工程塑料应用, 2017, 45(4):17-23. doi: 10.3969/j.issn.1001-3539.2017.04.004XU Bing, MEI Changtong, LIU Zhaozheng, et al. Effect of photostabilizer on anti-ultraviolet aging properties of nuclear WPC[J]. Engineering Plastics Application,2017,45(4):17-23(in Chinese). doi: 10.3969/j.issn.1001-3539.2017.04.004 [11] ALLEN N S, MCINTYRE R, KERROD J M, et al. Photo-stabilisation and UV blocking efficacy of coated macro and nano-rutile titanium dioxide particles in paints and coatings[J]. Journal of Polymers and the Environment,2018,26(11):4243-4257. doi: 10.1007/s10924-018-1298-0 [12] REDHWI H H, SIDDIQUI M N, ANDRADY A L, et al. Weatherability of conventional composite and nano-composites of PVC and rutile Titanium Dioxide[J]. Polymer Composites,2018,39(6):2135-2141. doi: 10.1002/pc.24176 [13] LI C, CHANG S J, TAI M Y. Surface chemistry and dispersion property of TiO2 nano particles[J]. Journal of the American Ceramic Society,2010,93(12):4008-4010. doi: 10.1111/j.1551-2916.2010.04222.x [14] 潘其维, 王兵兵, 陈朝晖. 表面接枝防老剂的白炭黑在天然橡胶中的应用[J]. 复合材料学报, 2013, 30(5):1-8. doi: 10.3969/j.issn.1000-3851.2013.05.001PAN Qiwei, WANG Bingbing, CHEN Zhaohui, et al. Application of antioxidant functionalized silicas in natural rubber[J]. Acta Material Composite Sinica,2013,30(5):1-8(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.05.001 [15] 郭刚, 于杰, 罗筑, 等. 聚丙烯/纳米级金红石型二氧化钛/聚烯烃弹性体复合材料的抗老化性能研究[J]. 高分子学报, 2006(2):119-224.GUO Gang, YU Jie, LUO Zhu, et al. Study on ageing resistance of polyp-ropyene/nano scale rutile titanium dioxide/poepolyolefin elastomer composites[J]. Acta Polymerica Sinica,2006(2):119-224(in Chinese). [16] DEVI R R, GOGOI K, KONWAR B K, et al. Synergistic effect of nanoTiO2 and nanoclay on mechanical, flame retard ancy, UV stability, and antibacterial propertie of wood polymer composites[J]. Polymer Bulletin,2013,70(4):1397-1413. doi: 10.1007/s00289-013-0928-x [17] DU H, WANG W, WANG Q, et al. Effects of pigments on the UV degradation of wood-flour/HDPE composites[J]. Journal of Applied Polymer Science,2010,118(2):1068-1076. [18] American Society for Testing and Materials International. Standard test method for tensile properties of plastic: ASTM D638—03[S]. West Conshohocken: ASTMInternational, 2015. [19] 中华人民共和国国家质量监督检验检疫总局.塑料.简支梁冲击性能的测定I:非仪器化冲击试验: GB/T1043.1—2008 [S]. 北京: 中国标准出版社, 2009.Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Plastics. Plastics: Determination of impact performance part1: General principles: GB/T 1040.1-2008[S]. Beijing: China Standards Press, 2009(in Chinese). [20] American Society for Testing and Materials International. Standard properties for calculation of color tolerances and color differences from instrumentally measured color coordinates: ASTM D 2244[S]. West Conshohocken: ASTM International, 2007. [21] 郝喜海, 李慧敏, 李菲, 等. 纳米二氧化钛的表面改性研究[J]. 无机盐工业, 2012, 44(1):30-33. doi: 10.3969/j.issn.1006-4990.2012.01.009HAO Xihai, LI Huimin, LI Fei, et al. Study on surface modification of nano-sized titania[J]. Iinorganic Chemicals Industry,2012,44(1):30-33(in Chinese). doi: 10.3969/j.issn.1006-4990.2012.01.009 [22] 贺超峰, 曹新鑫, 孙得翔, 等. 紫外光老化TiO2/聚丙烯复合材料的热降解行为[J]. 高分子材料科学与工程, 2015, 31(7):92-95.HE Chaofeng, CAO Xinxin, SUN Dexiang, et al. Thermal degradation behavior of TiO2/polypropylene composites after UV aging[J]. Polymer Materials Science&Engineering,2015,31(7):92-95(in Chinese). [23] 李永峰, 刘一星, 于海鹏, 等. 甲基丙烯酸缩水甘油酯改善木塑复合材料性能[J]. 复合材料学报, 2009, 26(5):1-7. doi: 10.3321/j.issn:1000-3851.2009.05.001LI Yongfeng, LIU Yixing, YU Haipeng, et al. Property improvement of wood polymer composites with glycidyl methacrylate[J]. Acta Materiae Compositae Sinica,2009,26(5):1-7(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.05.001 [24] 王宣博, 陈小丹, 陈佳伟, 等. 纳米TiO2含量对PVC/稻壳粉木塑复合材料性能的影响[J]. 工程塑料应用, 2016(7):31-36. doi: 10.3969/j.issn.1001-3539.2016.07.006WANG Xuanbo, CHEN Xiaodan, CHEN Jiawei, et al. Effect of nano-TiO2 content on properties of PVC/rice-shell wood-plastic composites[J]. Engineering Plastics Application,2016(7):31-36(in Chinese). doi: 10.3969/j.issn.1001-3539.2016.07.006 [25] 周箭, 张启龙, 杨辉, 等. 抗紫外PV DF基木塑复合材料的热分析[J]. 材料科学与工程学报, 2009, 27(6):845-849.ZHOU Jian, ZHANG Qilong, YANG Hui, et al. Thermal analysis of anti-ultraviolet poly(vinylidene fluoride)/wood flour composites[J]. Journal of Materiaks Science and Engineering,2009,27(6):845-849(in Chinese). [26] 付菁菁, 何春霞, 常萧楠, 等. 麦秸秆/聚丙烯发泡复合材料的热稳定性与微观结构[J]. 复合材料学报, 2016, 33(3):469-476.FU Jingjing, HE Chunxia, CHANG Xiaonan, et al. Thermostability and microstructure of wheat straw/polypropylene foamed composites[J]. Acta Materiae Compositae Sinica,2016,33(3):469-476(in Chinese). -

下载:

下载: