Stability of composite stiffened panels under compression

-

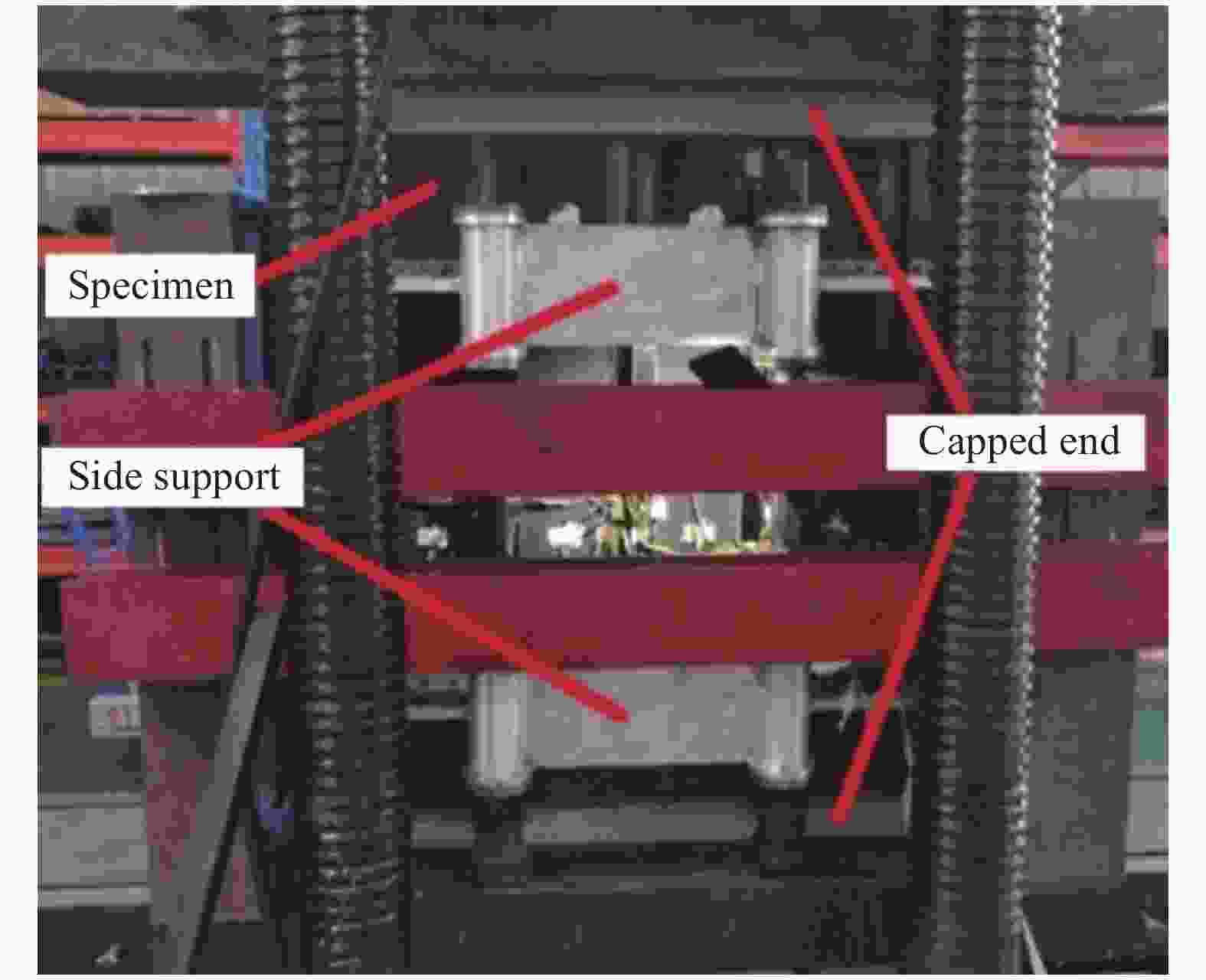

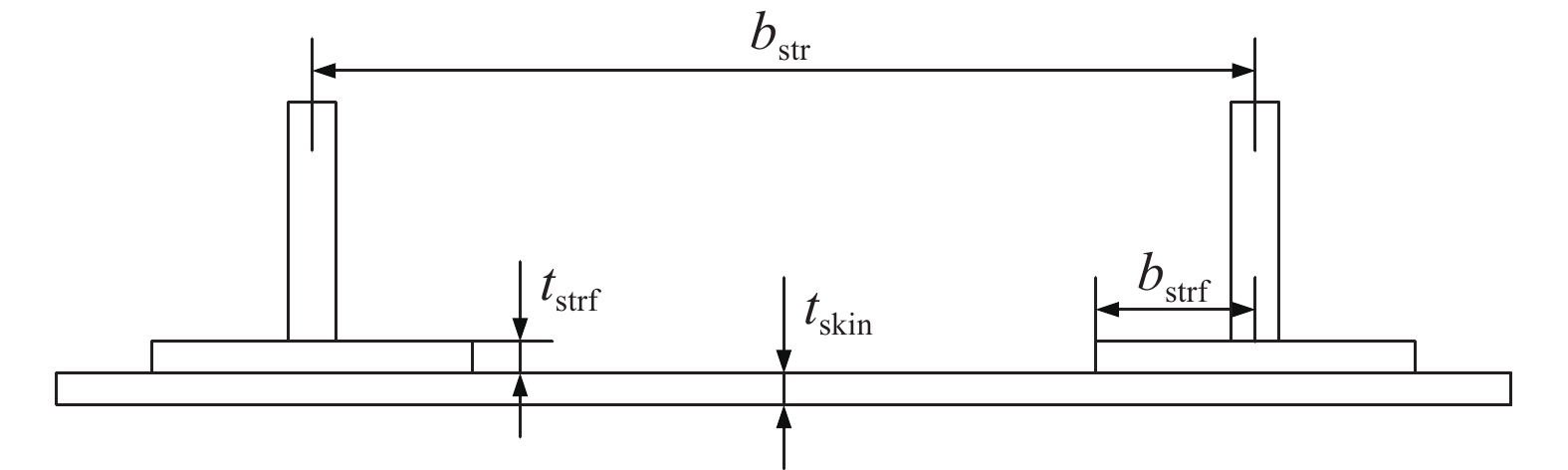

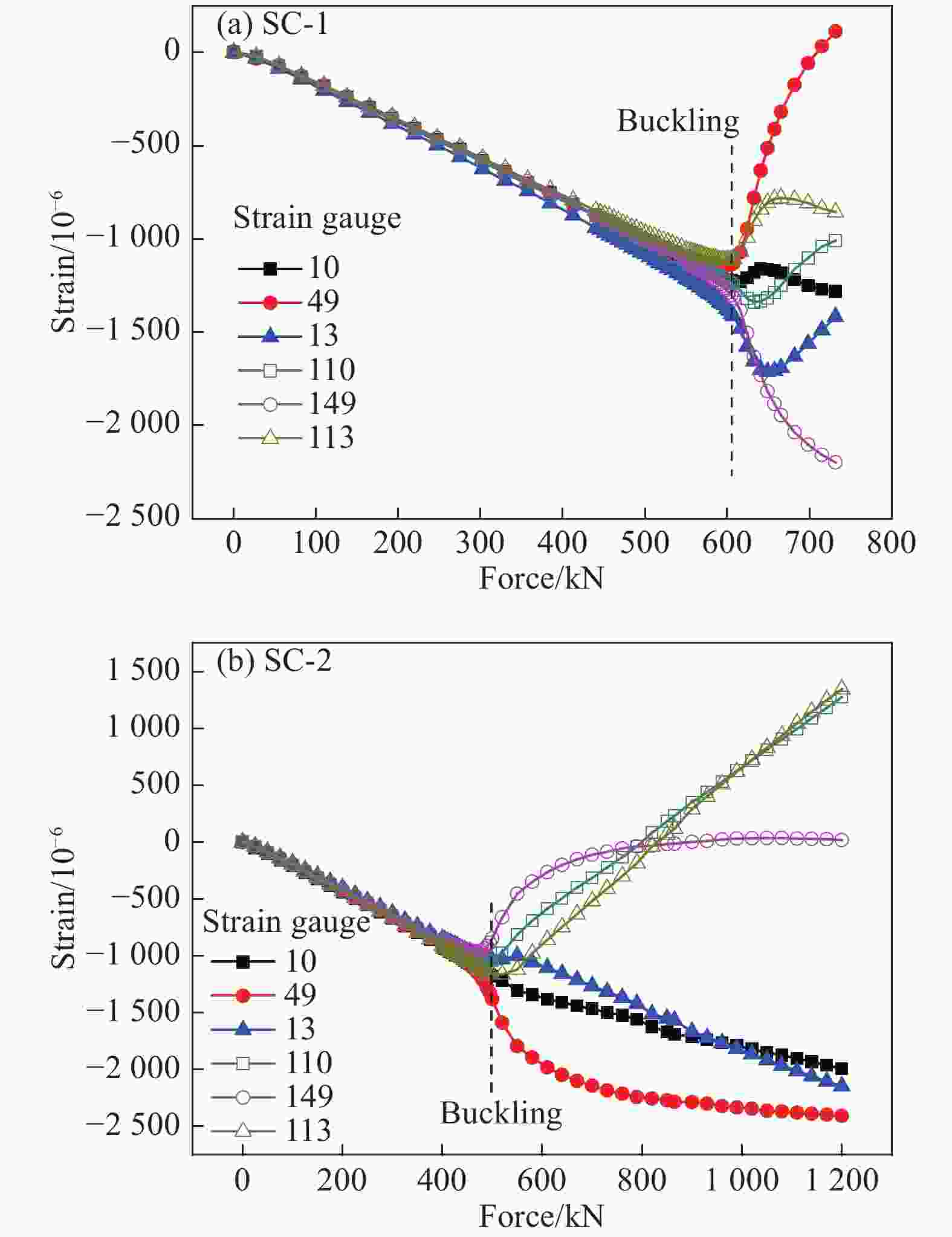

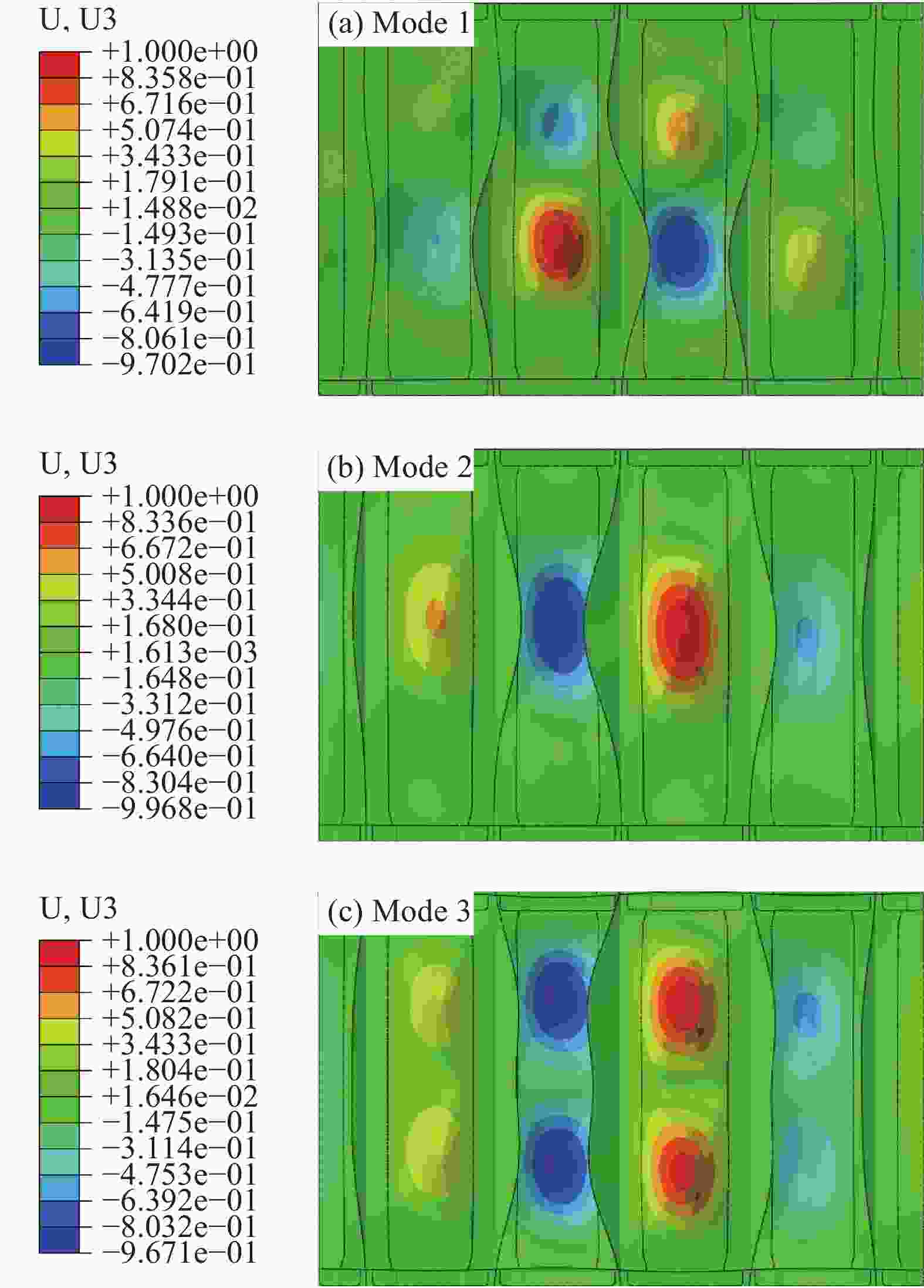

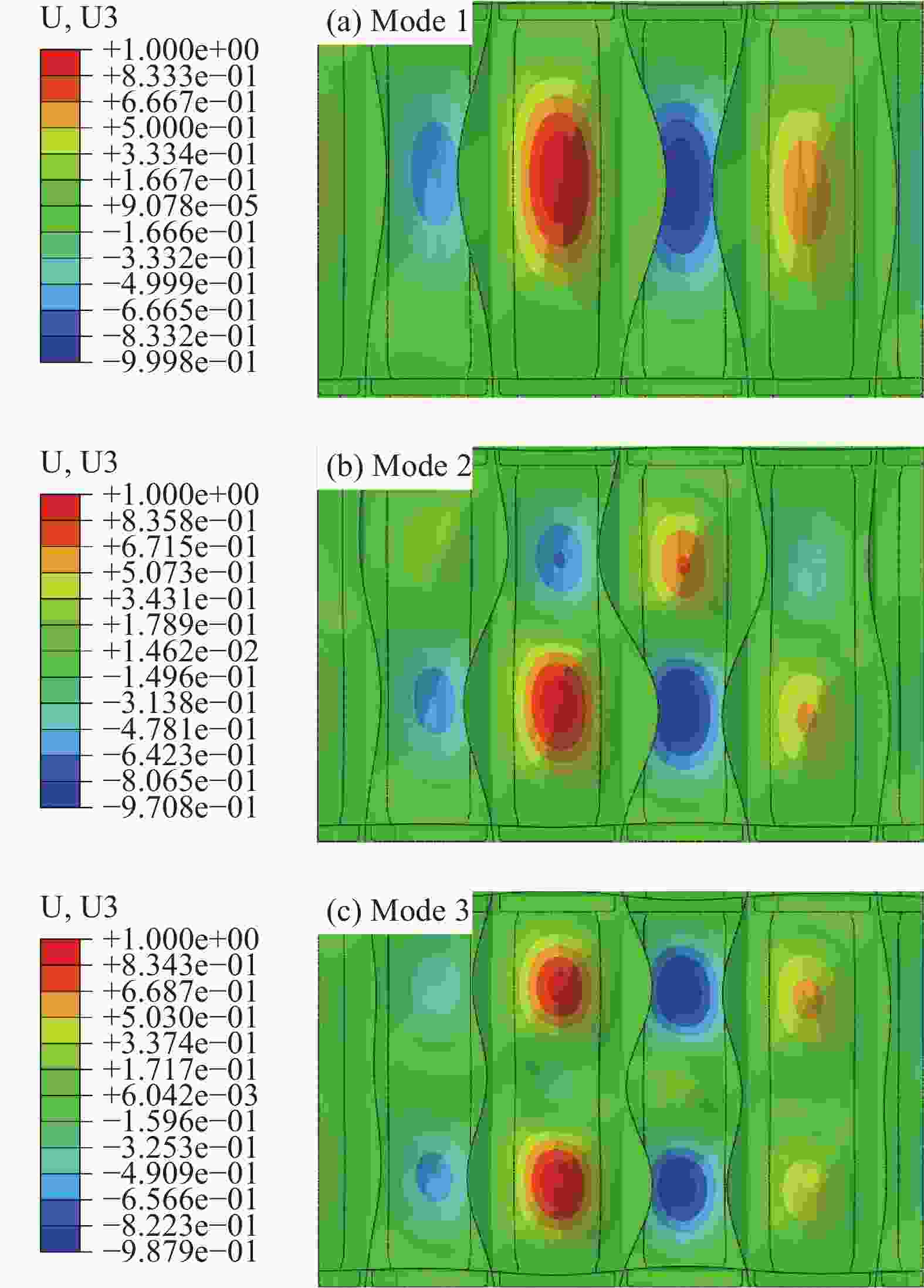

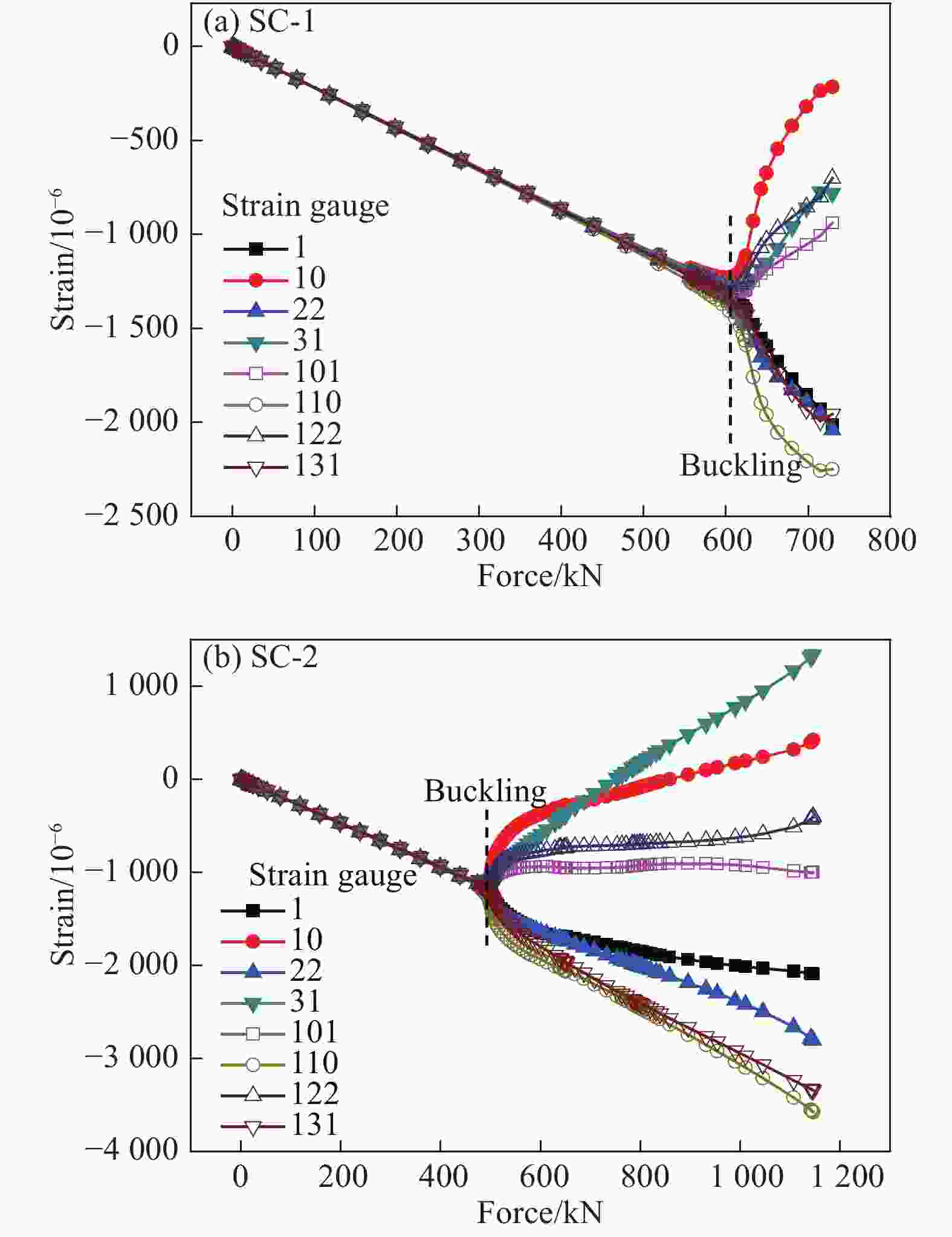

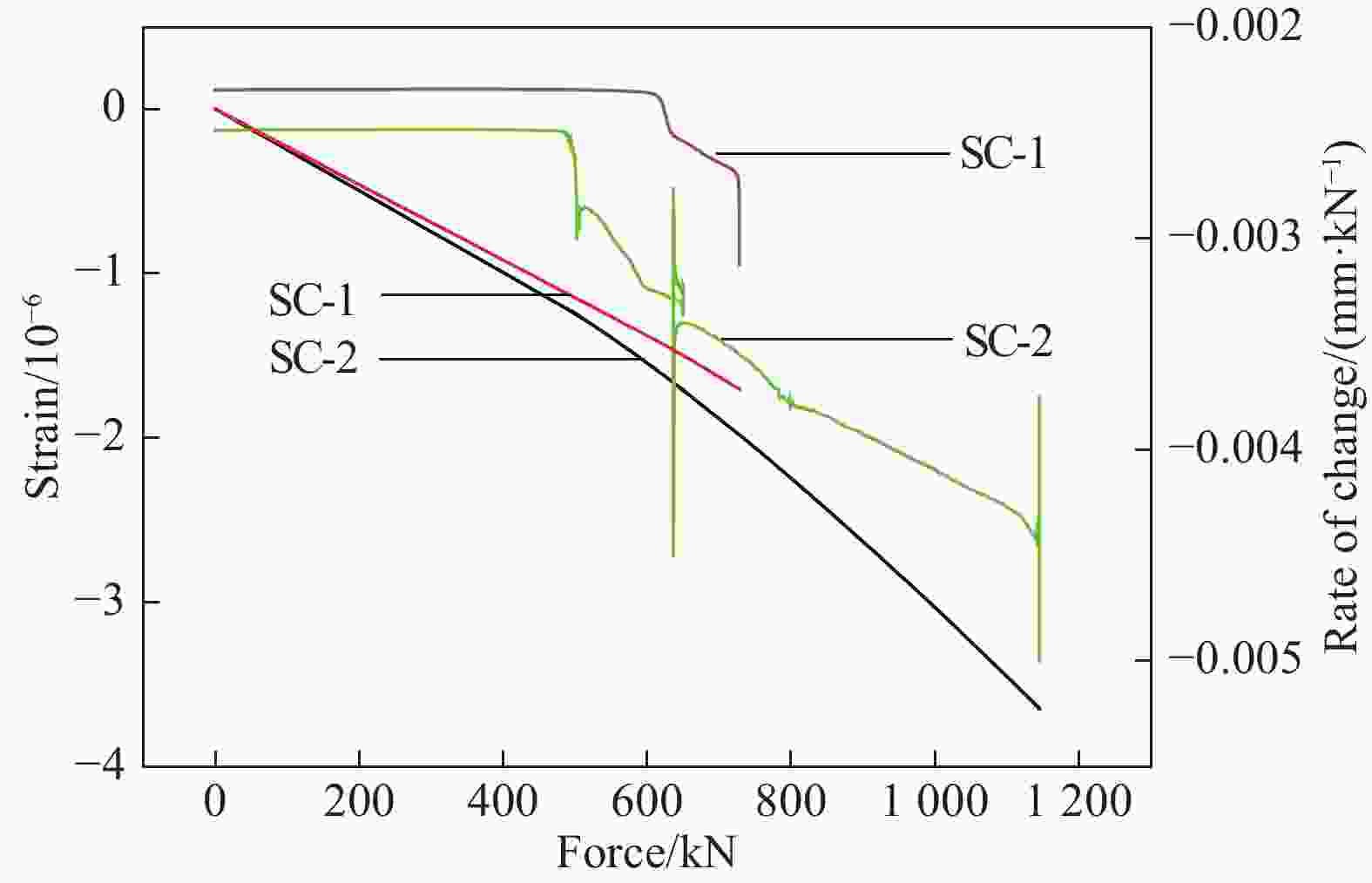

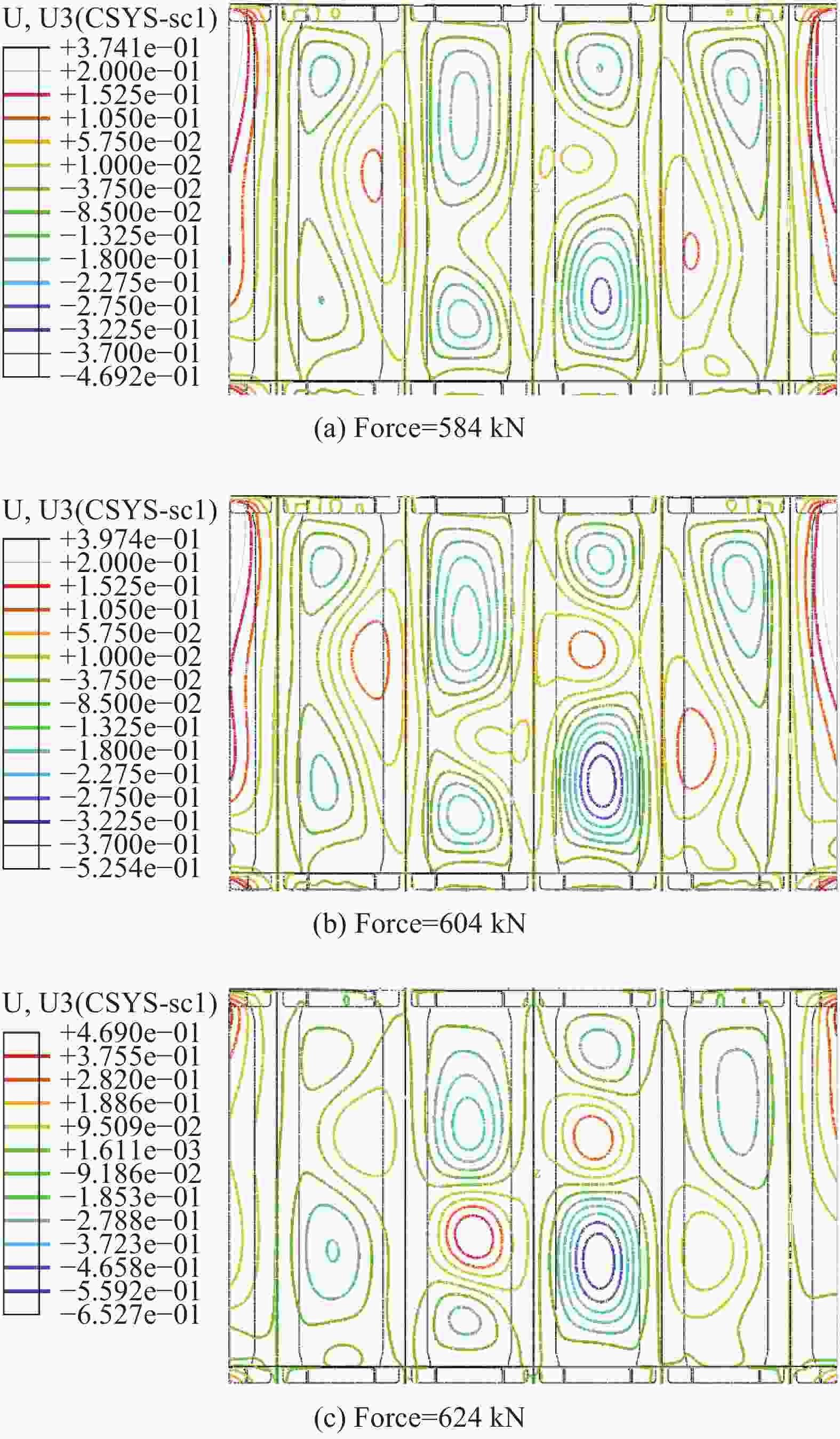

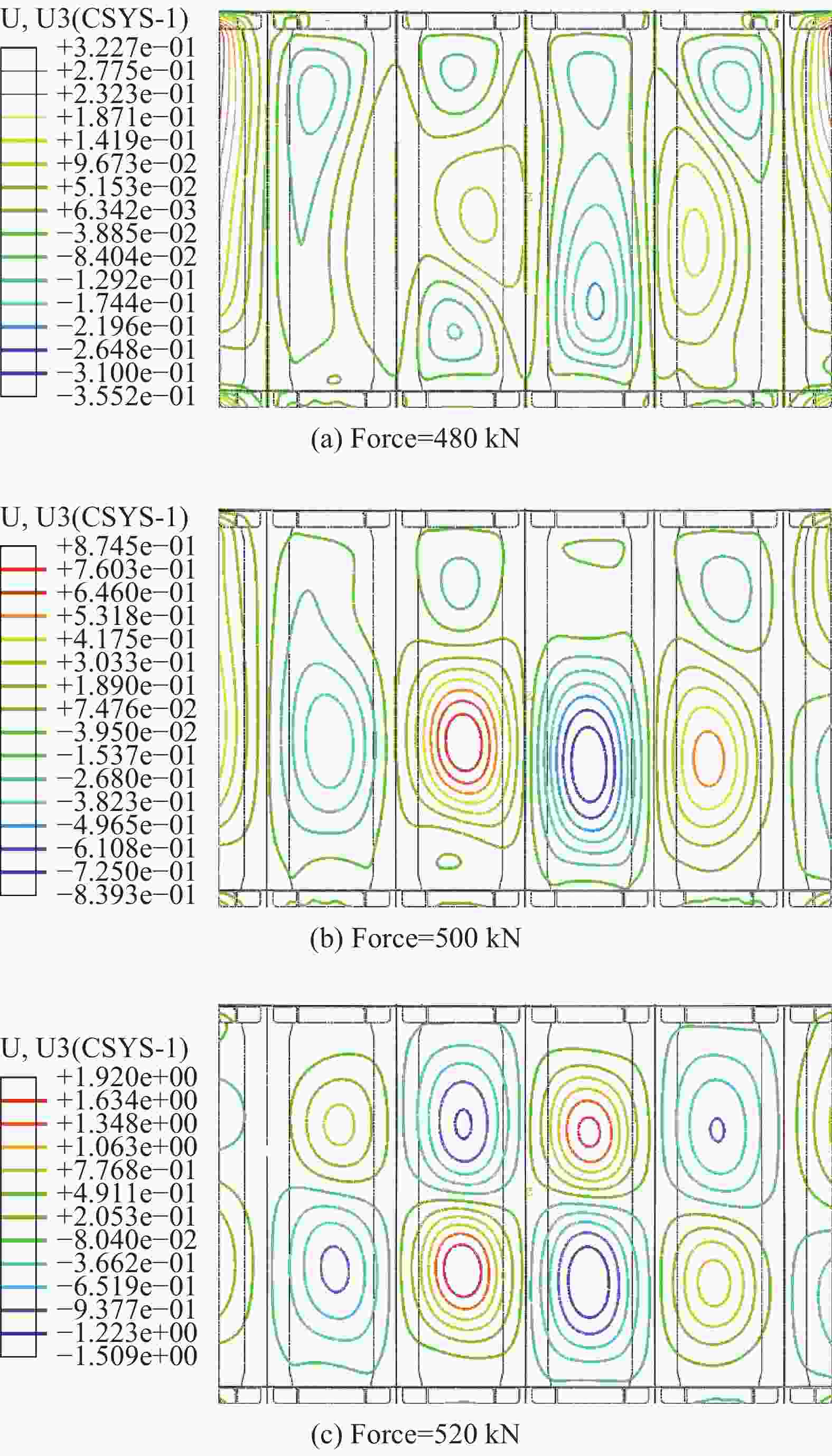

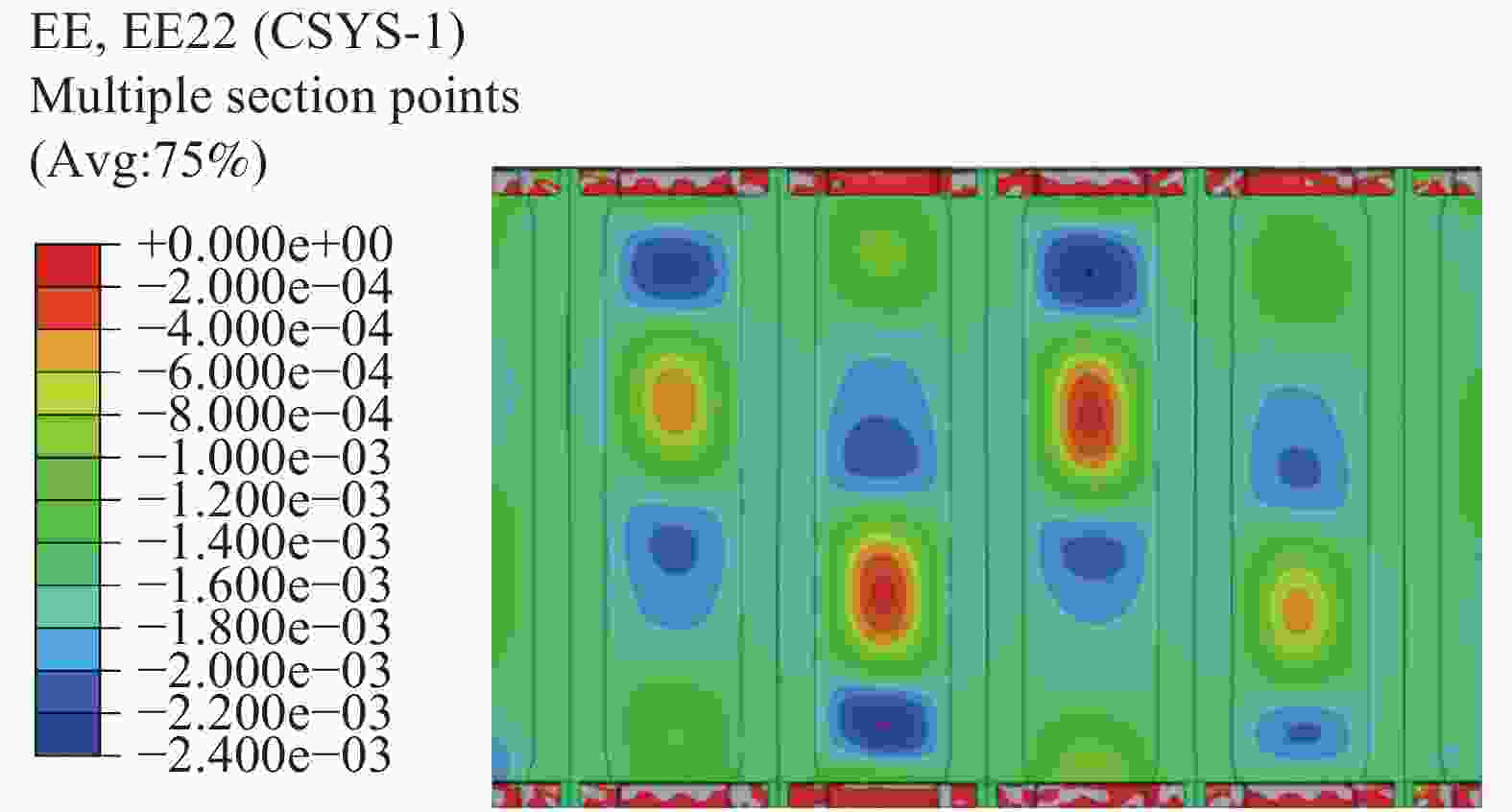

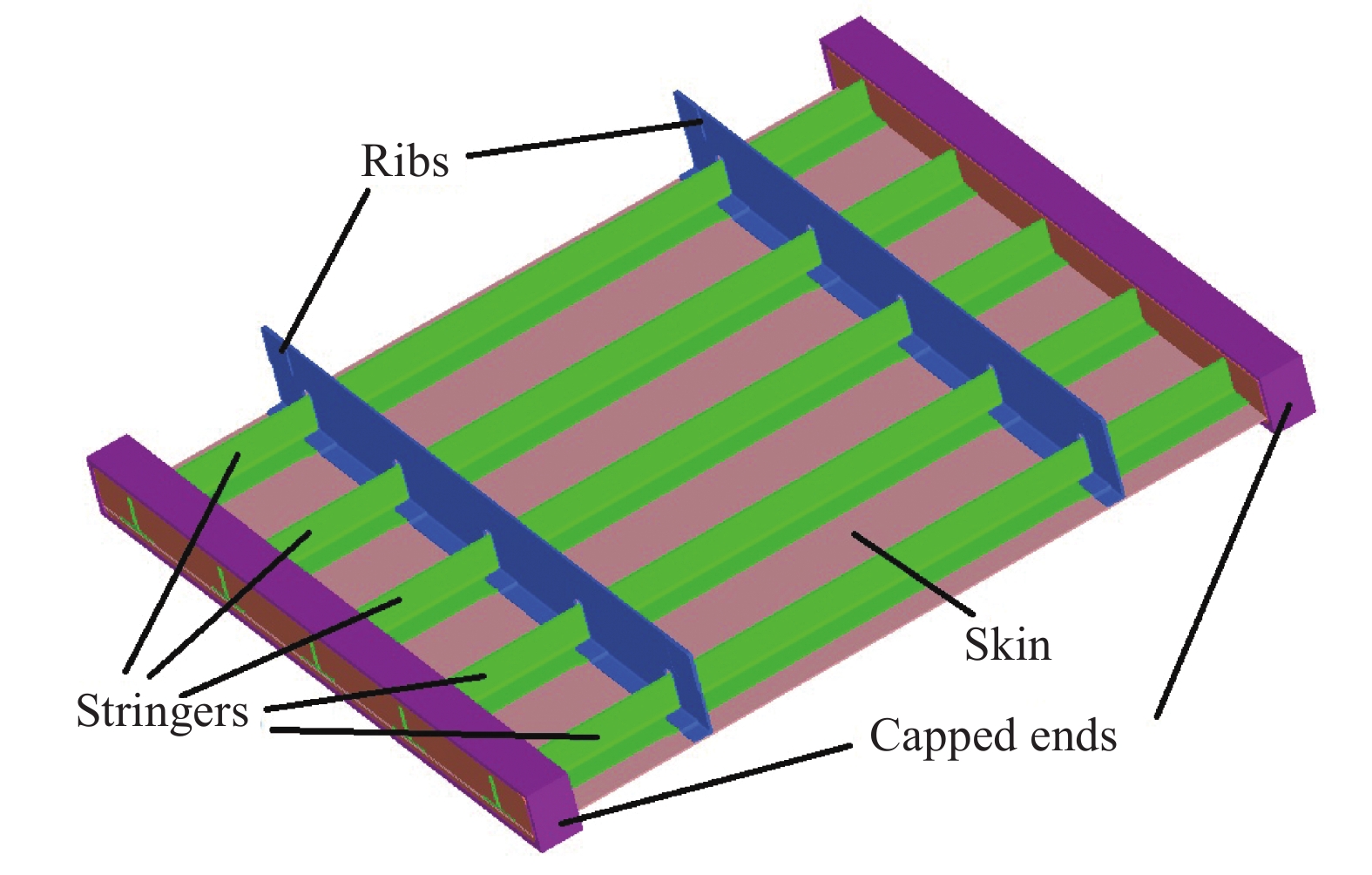

摘要: 基于T型长桁铺层数不同的两块复合材料翼面加筋壁板试件SC-1和SC-2,开展轴压稳定性试验研究,并提出一种预测屈曲载荷及最小后屈曲承载能力的工程分析方法,结合有限元特征值屈曲分析方法、有限元弧长法对试件的屈曲载荷、屈曲模态及后屈曲承载能力进行分析。试验结果表明,铺层数较多的试件SC-1的蒙皮局部屈曲应变较高,壁板也具有更高的屈曲载荷。在后屈曲阶段,SC-2加载到试验屈曲载荷的2.4倍未发生材料破坏和长桁蒙皮间脱粘损伤。工程分析方法和特征值屈曲分析能够准确预测壁板的屈曲载荷,最大误差分别为-9.3%和-2.8%,工程分析得到SC-2的最小后屈曲承载能力为试验屈曲载荷的2.09倍。有限元弧长法分析得到两件试件的屈曲载荷误差均小于1%,并具有壁板轴压屈曲模态预测和变形跟踪能力。Abstract: Experiments for compression stability analysis were conducted on composite stiffened panels SC-1 and SC-2 with different T-stringer lay-ups. A proposed engineering method was introduced to predict the buckling load and the least post-buckling carrying capability, and finite element analysis with eigenvalue method and arc-length method were carried out to investigate the bucking load, buckling mode, and post-buckling carrying capability. Experiment results show that SC-1 with more stringer ply-ups possess the higher local bucking strain of skin and the higher buckling load of the panel, and SC-2 can sustain a post-buckling carrying capability of 2.4 times of buckling load without material damage and stringer-skin debonding. The engineering method and eigenvalue method acquire the buckling loads of the panels with errors of -9.3% and -2.8% respectively, and the minimum post-buckling carrying capability of SC-2 is 2.09 times of experimental buckling load by engineering method. The errors of buckling loads by arc-length method are less than 1% for both SC-1 and SC-2, and the buckling modes and distortion are well trailed with load increasing.

-

Key words:

- stiffened panels /

- compression stability /

- buckling /

- engineering method /

- eigenvalue /

- arc-length method

-

表 1 X850 CFRP复合材料单向带的力学性能

Table 1. Mechanical properties of X850 CFRP composite prepreg

E11/MPa E22/MPa G12/MPa ν12 158 000 9 000 4 140 0.319 Notes: E11—Elastic modulus in fibre direction; E22—Elastic modulus transverse to fibre direction; G12—Shear modulus; ν12—Poisson’s ratio. 表 2 CFRP复合材料加筋壁板铺层顺序

Table 2. Stacking sequences of CFRP composite stiffened panels

Region Stacking sequence Skin [45/−45/0/45/−45/0/0/90]s L_left(SC-1) [−45/45/0/0/0/90/−45/0/45/45/0/−45/90/0] L_left(SC-2) [−45/45/0/0/0/90/−45/0/45/90/0] L_right(SC-1) [45/−45/0/0/0/90/45/0/−45/−45/0/45/90/0] L_right(SC-2) [45/−45/0/0/0/90/45/0/−45/90/0] Insert plys [45/−45/0/0] 表 3 CFRP复合材料加筋壁板轴压屈曲载荷工程方法分析结果

Table 3. Buckling load of CFRP composite stiffened panels under compression by engineering method

Specimen tply,equ/mm $\eta $ Pb/kN ${\varepsilon _{{\rm{blk}}}}$/10−3 SC-1 0.265 0.158 549 −1.188 SC-2 0.252 0.164 453 −1.066 Notes: tply,equ—Equivalent ply thickness; Pb—Buckling load; ${\varepsilon _{{\rm{blk}}}}$—Buckling strain; η—Stiffness ratio of a single skin to a whole stiffened wall. 表 4 CFRP复合材料加筋壁板轴压稳定性特征值分析结果

Table 4. Results of compression stability analysis of CFRP composite stiffened panels by eigenvalue method

Mode Eigenvalue Buckling load/kN SC-1 SC-2 SC-1 SC-2 1 1.545 1.214 618 486 2 1.547 1.217 619 487 3 1.553 1.265 621 506 4 1.612 1.338 645 535 5 1.668 1.400 667 560 6 1.684 1.403 674 561 -

[1] MA X Q, YANG Z J, GU Y Z, et al. Manufacture and characterization of carbon fibre composite stiffened skin by resin film infusion/prepreg co-curing process[J]. Journal of Reinforced Plastics and Composites,2014,33(17):1559-1573. doi: 10.1177/0731684414543213 [2] HUANG C K. Study on co-cured composite panels with blade-shaped stiffeners[J]. Composites Part A: Applied Science and Manufacturing,2003,34(5):403-410. doi: 10.1016/S1359-835X(03)00081-2 [3] SERESTA O, GURDAL Z, ADAMS D B, et al. Optimal design of composite wing structures with blended laminates[J]. Composites Part B: Engineering,2007,38(4):469-480. doi: 10.1016/j.compositesb.2006.08.005 [4] 周雷敏, 孙沛. 波音787客机的复合材料国际化制造[J]. 高科技纤维与应用, 2013, 38(2):57-61. doi: 10.3969/j.issn.1007-9815.2013.02.011ZHOU Leimin, SUN Pei. Boeing 787 composites’ international manufacturing[J]. Hi-Tech Fiber & Application,2013,38(2):57-61(in Chinese). doi: 10.3969/j.issn.1007-9815.2013.02.011 [5] 吴志恩. A350的复合材料构件制造[J]. 航空制造技术, 2013(13):32-35. doi: 10.3969/j.issn.1671-833X.2013.13.003WU Zhien. Manufacture of A350 composites structure[J]. Aeronautical Manufacturing Technology,2013(13):32-35(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.13.003 [6] 霍世慧, 王富生, 王佩艳, 等. 复合材料机翼加筋壁板稳定性分析[J]. 应用力学学报, 2010, 27(2):423-428.HUO Shihui, WANG Fusheng, WANG Peiyan, et al. Stability analysis on the ribbed panel of the composite wing[J]. Chinese Journal of Applied Mechanics,2010,27(2):423-428(in Chinese). [7] 展全伟, 范学领, 徐红炉. 复合材料加筋壁板稳定性影响分析[J]. 机械设计与制造, 2012(3):37-39.ZHAN Quanwei, FAN Xueling, XU Honglu. Influence analysis on the stability of composite ribbed panel[J]. Machinery Design & Manufacture,2012(3):37-39(in Chinese). [8] 裴金利, 陈秀华. 复合材料帽形加筋结构稳定性研究[J]. 航空计算技术, 2011, 41(6):84-87. doi: 10.3969/j.issn.1671-654X.2011.06.022PEI Jinli, CHEN Xiuhua. Research on stability of hat-stiffened composites structures[J]. Aeronautical Compu-ting Technique,2011,41(6):84-87(in Chinese). doi: 10.3969/j.issn.1671-654X.2011.06.022 [9] 郑洁, 任善. 复合材料加筋壁板稳定性分析方法研究[J]. 航空科学技术, 2015, 26(3):44-48. doi: 10.3969/j.issn.1007-5453.2015.03.010ZHENG Jie, REN Shan. Study on stability analysis method of composite stiffened plates[J]. Aeronautical Science & Technology,2015,26(3):44-48(in Chinese). doi: 10.3969/j.issn.1007-5453.2015.03.010 [10] 穆朋刚, 万小朋, 赵美英. 复合材料加筋壁板稳定性分析研究[J]. 机械科学与技术, 2009, 28(9):1190-1193. doi: 10.3321/j.issn:1003-8728.2009.09.016MU Penggang, WAN Xiaopeng, ZHAO Meiying. A study of the stability of composite stiffened plates[J]. Mechanical Science and Technology for Aerospace Engineering,2009,28(9):1190-1193(in Chinese). doi: 10.3321/j.issn:1003-8728.2009.09.016 [11] 李乐坤, 李曙林, 常飞, 等. 复合材料加筋壁板压缩屈曲与后屈曲分析[J]. 南京航空航天大学学报, 2016, 48(4):563-568.LI Lekun, LI Shulin, CHANG Fei, et al. Buckling and post-buckling of composite stiffened panel under compression[J]. Journal of Nanjing University of Aeronautics & Astronautic,2016,48(4):563-568(in Chinese). [12] LEI G, YANG S S. A study on the buckling of stiffened composite fuselage panel[J]. Hydromechatronics Engineering,2015,43(6):91-94, 101. [13] 王菲菲, 崔德刚, 熊强, 等. 复合材料加筋板后屈曲承载能力工程分析方法[J]. 北京航空航天大学学报, 2013, 39(4):494-497.WANG Feifei, CUI Degang, XIONG Qiang, et al. Engineering analysis of postbuckling loading capability for composite stiffened panels[J]. Journal of Beijing University of Aeronautics and Astronautics,2013,39(4):494-497(in Chinese). [14] 谭翔飞, 何宇廷, 冯宇. 航空碳纤维树脂基复合材料加筋板压缩屈曲及后屈曲性能[J]. 航空动力学报, 2016, 31(10):2359-2369.TAN Xiangfei, HE Yuting, FENG Yu. Buckling and post-buckling performance of aeronautic carbon fibre reinforced resin composite stiffened panel under compression[J]. Journal of Aerospace Power,2016,31(10):2359-2369(in Chinese). [15] STEVEN G P, FALZON B G. Buckling mode transition in hat-stiffened composite panels loaded in uniaxial compression[J]. Composite Structures,1997,37(2):253-267. doi: 10.1016/S0263-8223(97)80017-7 [16] 万玉敏, 张发, 刘长喜, 等. 飞机典型薄壁复合材料夹层结构整体屈曲[J]. 复合材料学报, 2018, 35(8):2235-2245.WAN Yumin, ZHANG Fa, LIU Changxi, et al. Overall buckling of typical thin-wall sandwich composite applied on the aircraft[J]. Acta Materiae Compositae Sinica,2018,35(8):2235-2245(in Chinese). [17] FENG Y, HE Y T, ZHANG H Y, et al. Effect of fatigue loading on impact damage and buckling/post-buckling behaviors of stiffened composite panels under axial com-pression[J]. Composite Structures,2017(164):248-262. [18] 刘璐, 关志东, 徐荣章, 等. 脱胶缺陷尺寸对复合材料加筋板屈曲及后屈曲特性的影响[J]. 复合材料学报, 2014, 31(3):749-758.LIU Lu, GUAN Zhidong, XU Rongzhang, et al. Effect of debond size on buckling and post-buckling behaviors of composite stiffened panels[J]. Acta Materiae Compositae Sinica,2014,31(3):749-758(in Chinese). [19] FALZON B G, STEVENS K A, DAVIES G O. Postbuckling behavior of a blade-stiffened composite panel loaded in uniaxial compression[J]. Composites Part A: Applied Science and Manufacturing,2000,31(5):459-468. doi: 10.1016/S1359-835X(99)00085-8 [20] DAVILA G C, CAMANHO P P, TURON A. Effective simulation of delamination in aeronautical structures using shells and cohesive elements[J]. Journal of Aircraft,2008,45(2):663-672. doi: 10.2514/1.32832 [21] TURON A, CAMANHO P P, COSTA J, et al. A damage model for the simulation of delamination in advanced compo-sites under variable-mode loading[J]. Mechanics of Materials,2006,38(11):1072-1089. doi: 10.1016/j.mechmat.2005.10.003 [22] LYNCH C, MURPHY A, PRICE M, et al. The computational post buckling analysis of fuselage stiffened panels loaded in compression[J]. Thin-Walled Structures,2008,42(10):1445-1464. [23] FAROOQN U, MYLER P. Finite element simulation of buckling-induced failure of carbon fibre-reinforced laminated composite panels embedded with damage zones[J]. Acta Astronautica,2015,115:314-329. doi: 10.1016/j.actaastro.2015.05.039 [24] GREENHALGH E, MEEKS C, CLARKE A, et al. The effect of defects on the performance of post-buckled CFRP stringer-stiffened panels[J]. Composites Part A: Applied Science and Manufacturing,2003,34(7):623-633. doi: 10.1016/S1359-835X(03)00098-8 [25] ORIFICI C, SHAH S A, HERSZBERG I, et al. Failure analysis in postbuckled composite T-sections[J]. Composite Structures,2008,86(1-3):146-153. doi: 10.1016/j.compstruct.2008.03.022 [26] 修英姝, 崔德刚. 复合材料层合板稳定性的铺层优化设计[J]. 工程力学, 2015, 22(6):212-216.XIU Yingshu, CUI Degang. Ply optimization design for stability of composite laminates[J]. Engineering Mechanics,2015,22(6):212-216(in Chinese). [27] TODOROKI A, SEKISHIRO M. Stacking sequence optimization to maximize the buckling load of blade-stiffened panels with strength constraints using the iterative fractal branch and bound method[J]. Composites Part B: Engineering,2008,39(5):842-850. doi: 10.1016/j.compositesb.2007.10.003 [28] VOSOUGHI A R, DARABI A, DEHGHANI FORKHORJI H. Optimum stacking sequences of thick laminated compo-site plates for maximizing buckling load using FE-GAs-PSO[J]. Composite Structures,2017,159:361-367. doi: 10.1016/j.compstruct.2016.09.085 [29] KAZEMI M, VERCHERY G. Design of composite laminated plates for maximum buckling load with stiffness and elastic modulus constraints[J]. Composite Structures,2017,148:27-38. [30] 中国航空研究院. 复合材料结构稳定性分析指南[M]. 北京: 航空工业出版社, 2002.Institute of Aeronautics China. Stability handbook of composites structure design[M]. Beijing: Aviation Industry Press, 2002(in Chinese). [31] 汪厚冰, 陈昊, 雷安民, 等. 复合材料帽形加筋壁板轴压屈曲与后屈曲性能[J]. 复合材料学报, 2018, 35(8):2014-2022.WANG Houbing, CHEN Hao, LEI Anmin, et al. Buckling and post-buckling performance of hat-stiffened composite panels under axial compression load[J]. Acta Materiae Compositae Sinica,2018,35(8):2014-2022(in Chinese). [32] Composite Materials Handbook. Volume 3. Polymer matrix composites materials usage, design, and Analysis: MIL-HDBK-17-3F[S]. US: [s. n.], 2002. [33] TURON A, DAVILA C G, CAMANHO P P, et al. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models[J]. Engineering Fracture Mechanics,2007(74):1665-1682. [34] HASHIN Z, ROTEM A. A fatigue criterion for fiber-reinforced materials[J]. Journal of Composite Materials,1973,7:448-464. doi: 10.1177/002199837300700404 -

下载:

下载: