Preparation and characterization of silicon-calcium composite film on piezoelectric ceramic surface

-

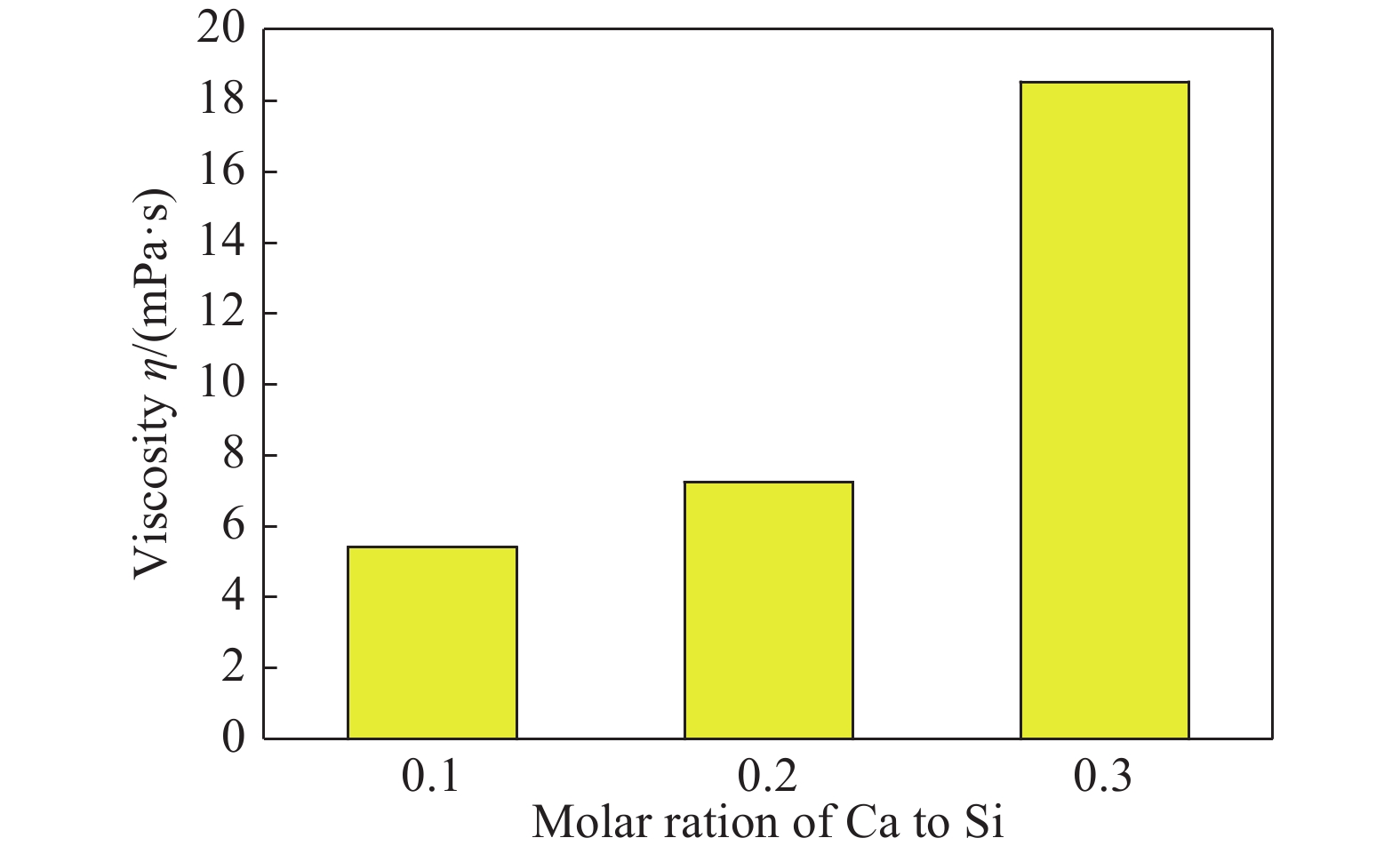

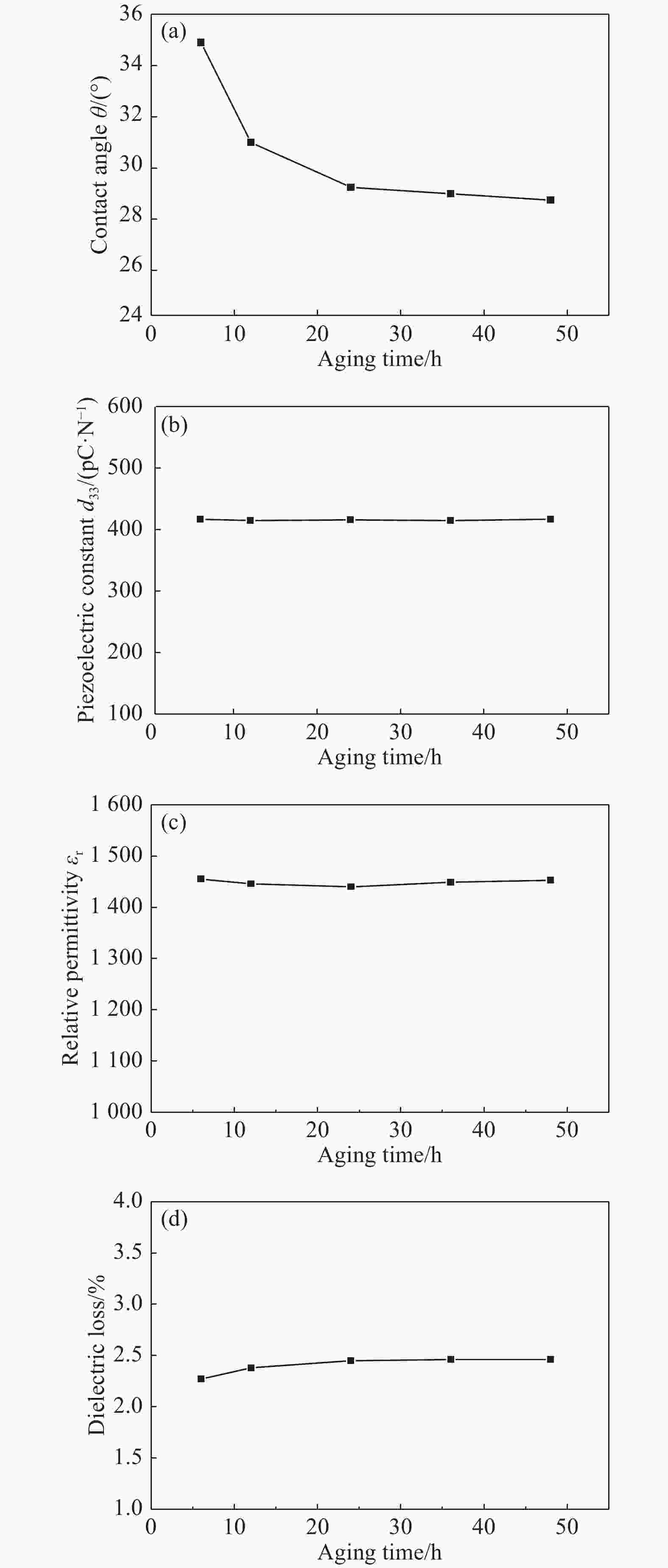

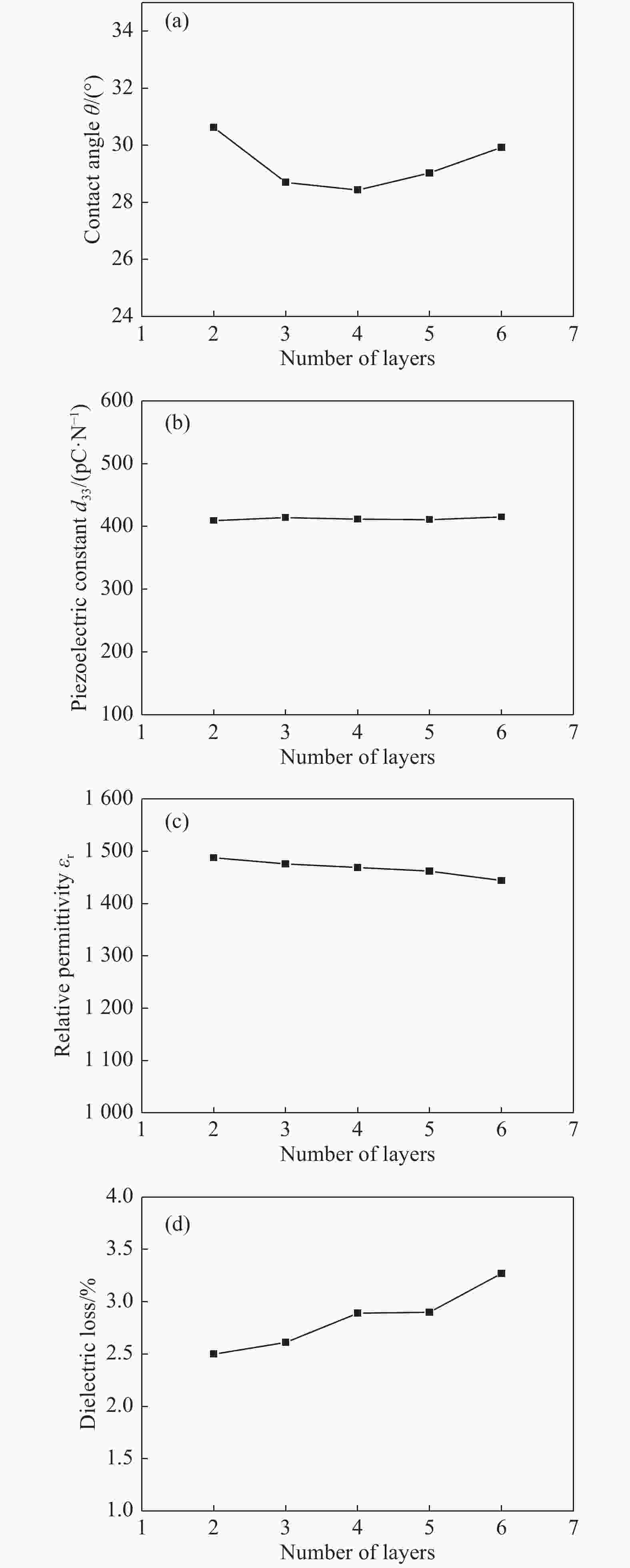

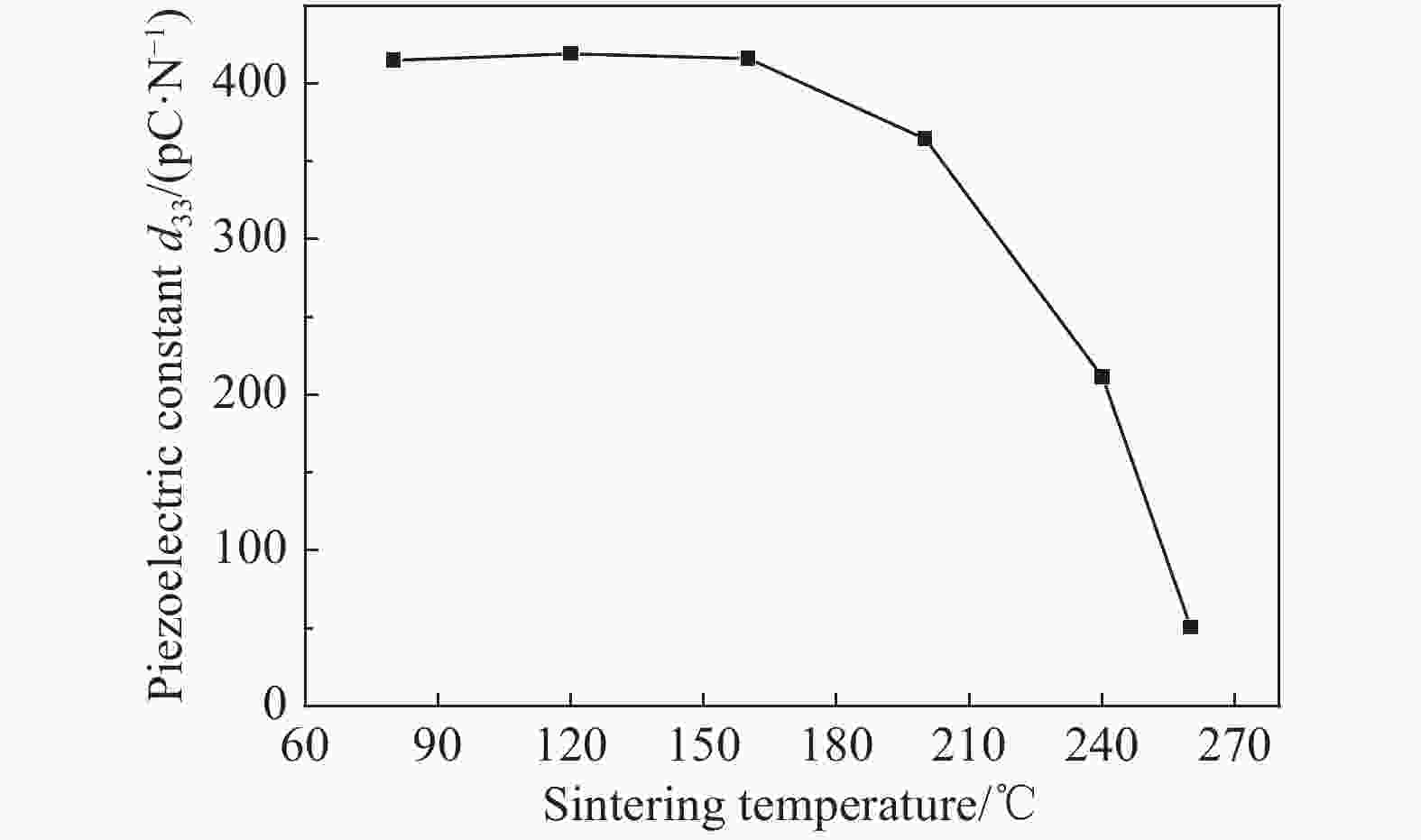

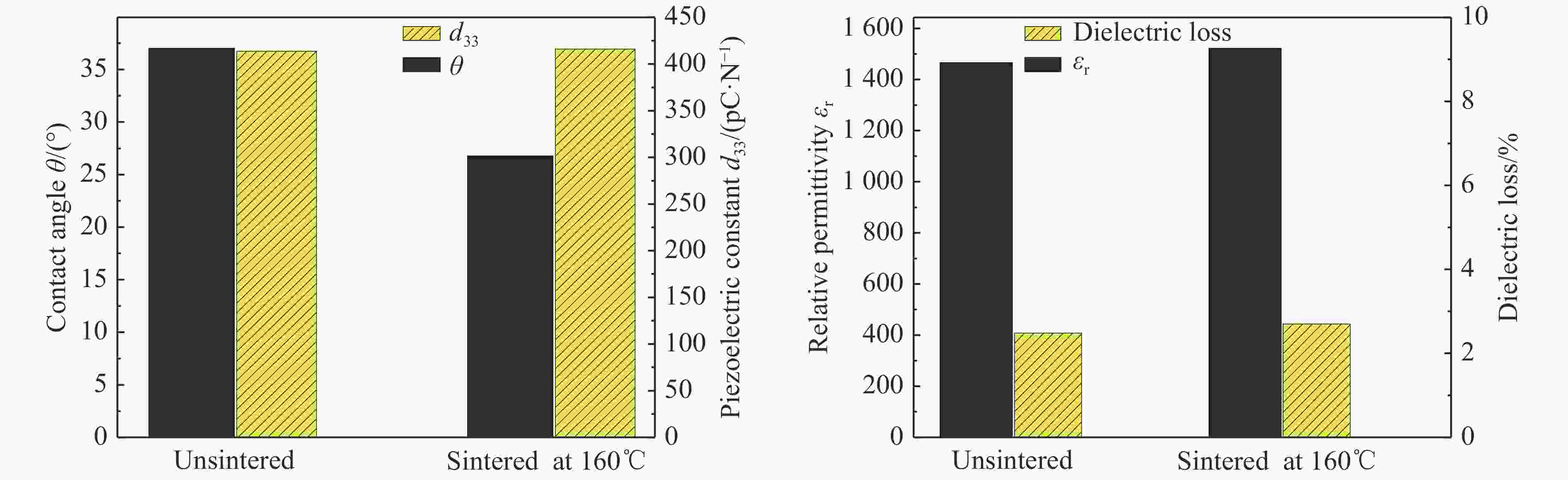

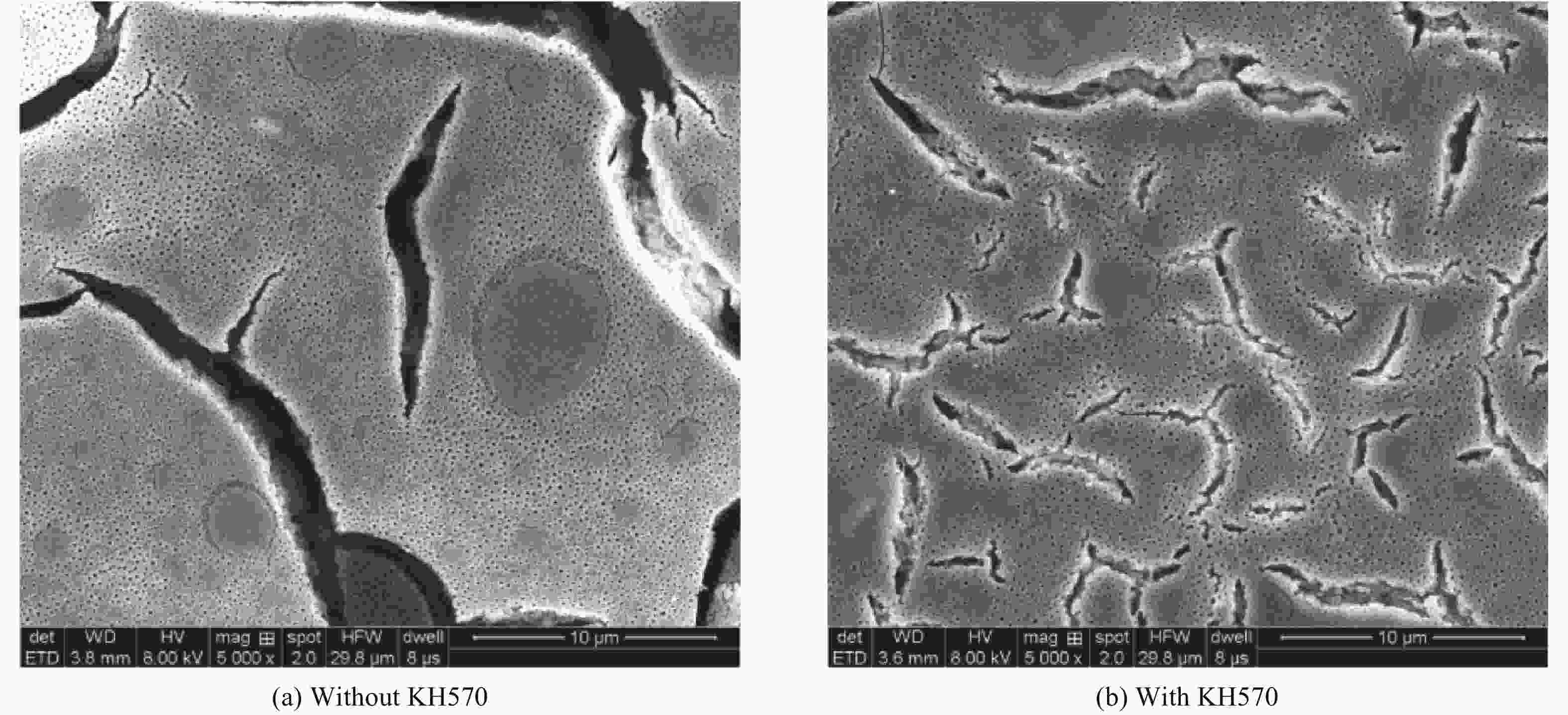

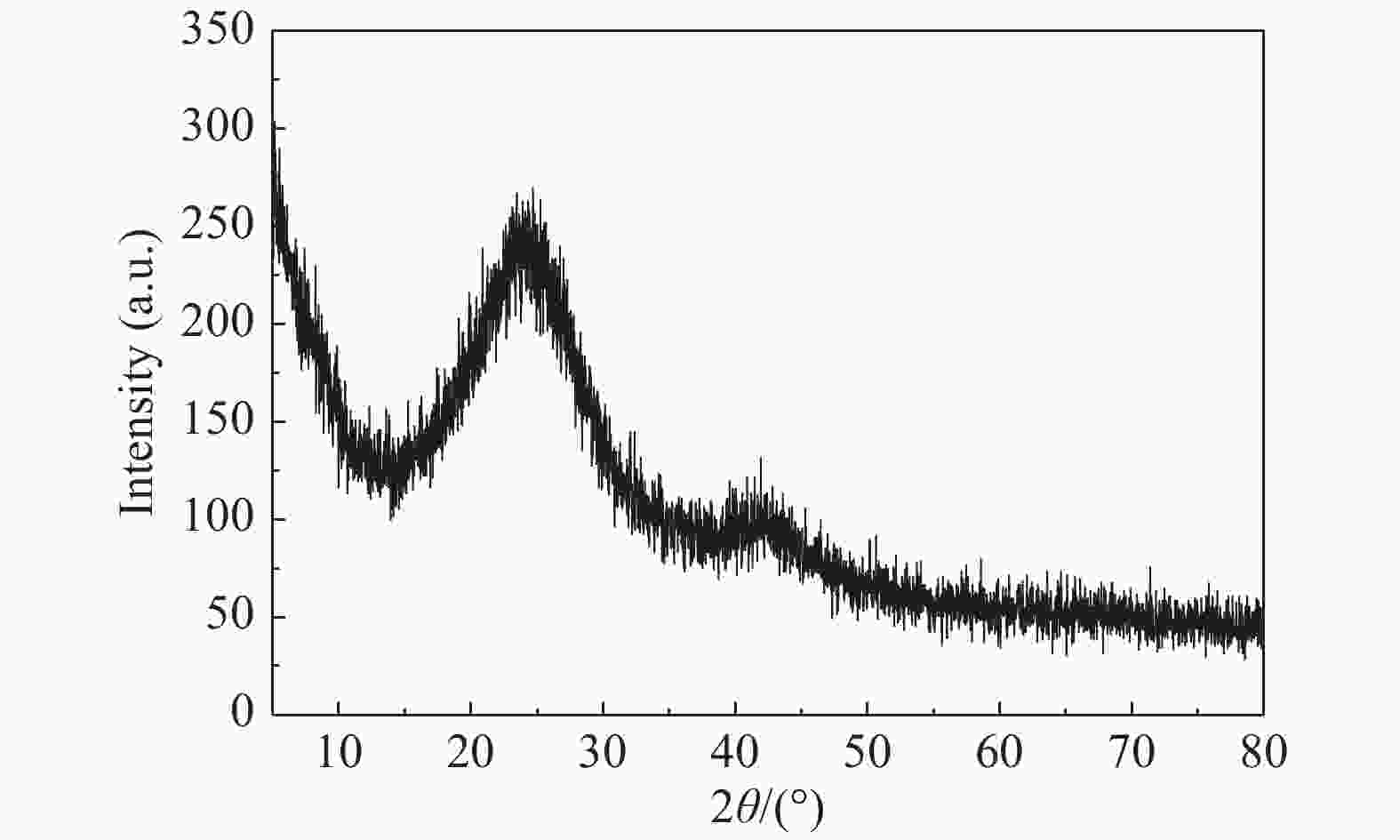

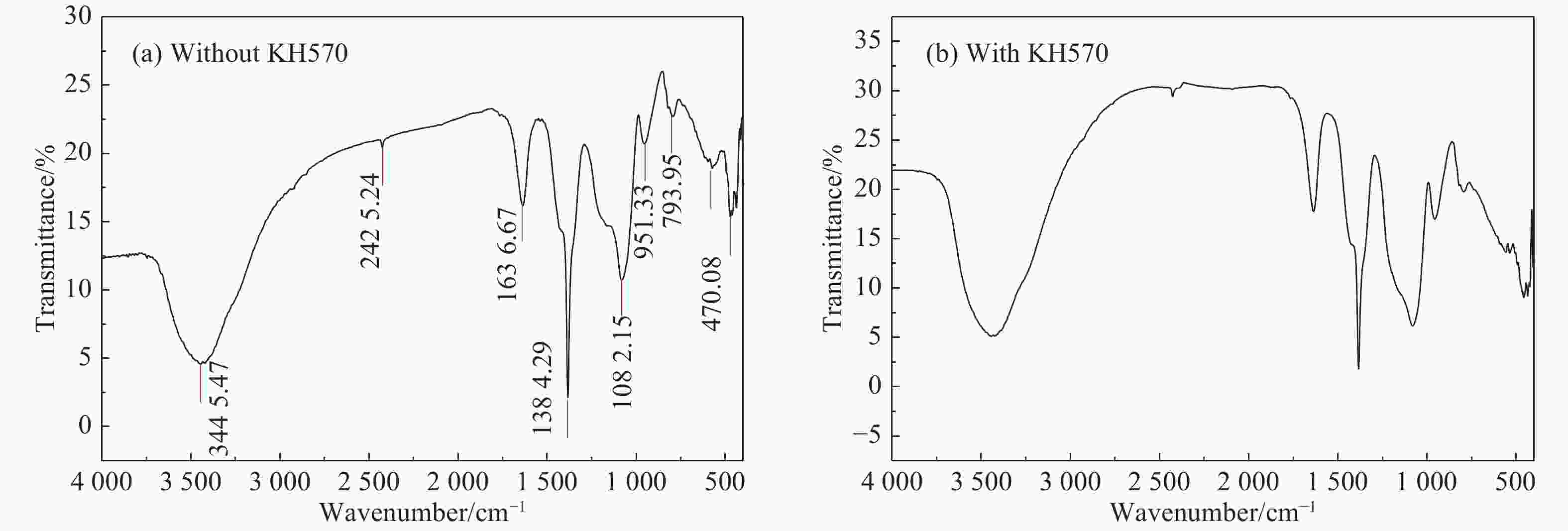

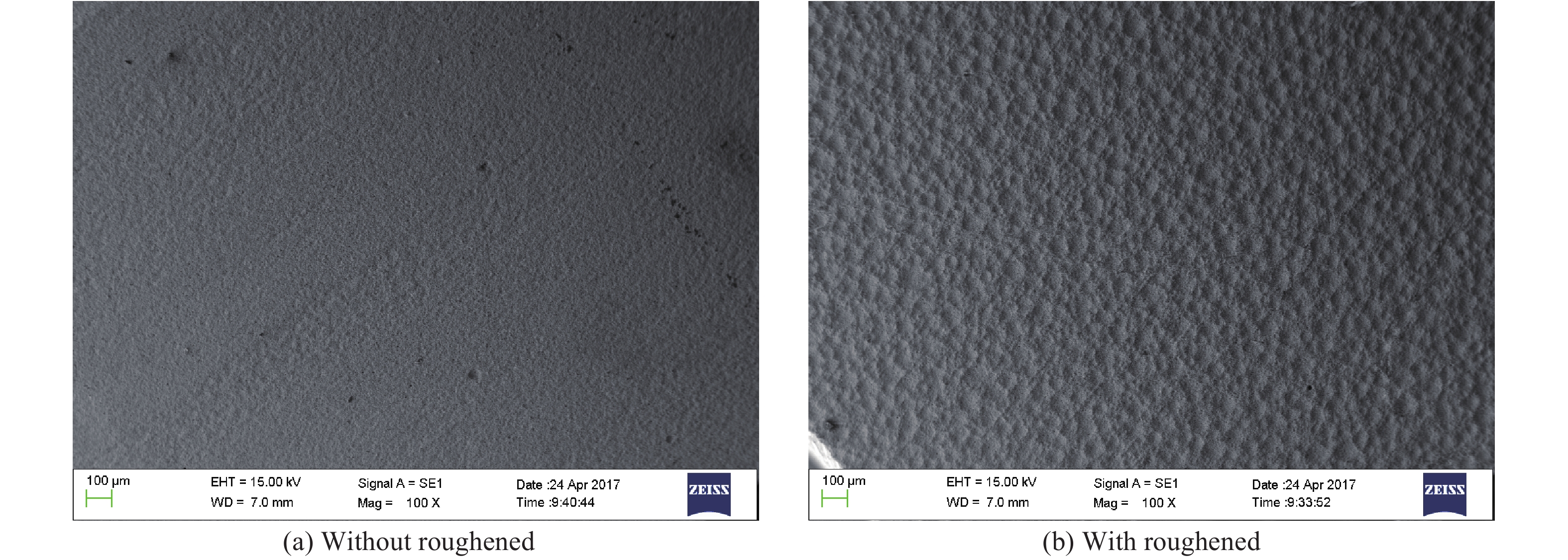

摘要: 采用溶胶-凝胶法制备了硅钙复合溶胶,并在压电陶瓷表面制备硅钙复合膜,以改善水泥基压电陶瓷复合材料界面。确定了溶胶配比,研究了陈化、低温热处理和硅烷偶联剂对覆硅钙复合膜压电陶瓷接触角、压电和介电性能的影响。结果表明,硅钙复合溶胶中Ca与Si摩尔比>0.2时不利于成膜;提高陈化温度和延长陈化时间可明显减小硅钙复合膜的接触角;硅钙复合膜层数最佳为3层,烧结温度不大于160℃;加入微量硅烷偶联剂可有效改善膜层开裂。制备的硅钙复合膜接触角最小为27°,亲水性好。Abstract: The silica-calcium composite sol was prepared by sol-gel method, and silica-calcium composite film was prepared on the surface of piezoelectric ceramics to improve the interface of cement-based piezoelectric ceramic composites. The sol ratio was determined, and the effects of aging, low temperature heat treatment and silane coupling agent on the contact angle, piezoelectricity and dielectric properties of piezoelectric ceramics with silica-calcium composite film were investigated. The results show that the molar ratio of Ca to Si greater than 0.2 in silica-calcium composite sol is not conducive to film formation; increasing the aging temperature and prolong the aging time can significantly reduce the contact angle; the optimal number of layers of silica-calcium composite film is 3, and sintering temperature is not more than 160℃; the addition of a trace amount of a silane coupling agent can effectively improve the cracking of the film layer. The prepared silica-calcium film has a minimum contact angle of 27° and good hydrophilicity.

-

Key words:

- piezoelectric ceramic /

- silicon-calcium composite film /

- contact angle /

- sol-gel method /

- viscosity

-

表 1 引入钙源的SiO2溶胶稳定性实验结果

Table 1. Experimental results of stability of SiO2 sol incorporating calcium source

Type of calcium source Method (1) Method (2) Ca(CH3COO)2 Produces white floc, the agitation does not disappear, and a milky white sand is formed quickly. Solubility is very slow, and sol gelation occurs when added in small amounts. Ca(NO3)2 Transparent sol, but gelled during aging. Dissolve quickly and completely, no change at room temperature. -

[1] 欧进萍. 重大工程结构智能传感网络与健康监测系统的研究与应用[J]. 中国科学基金, 2005, 19(1):8-12. doi: 10.3969/j.issn.1000-8217.2005.01.002OU Jinping. Research and application of intelligent sensor network and health monitoring system for major engineering structures[J]. China Science Foundation,2005,19(1):8-12(in Chinese). doi: 10.3969/j.issn.1000-8217.2005.01.002 [2] 李宏男. 结构健康监测[M]. 大连: 大连理工大学出版社, 2004.LI Hongnan. Structural health monitoring[M]. Dalian: Dalian University of Technology Press, 2004(in Chinese). [3] BANKS H T, SMITH R C, WANG Y. Smart material structures: Modeling estimation and control[M]. New York: John Wiley & Sons Inc, 1996: 52-74. [4] HOUSSNER G W, BERGMAN L A, CAUGHEY T K, et al. Structural control: Past, present and future[J]. Journal of Engineering Mechanics,1997,123(9):897-971. [5] JONACHA H. Adaptronics and smart structures[M]. Berlin: Springer, 1999. [6] ROH Y S, CHANG F K. Built in diagnostics for identifying an anomaly in plates using wave scattering[D]. California: Stanford University, 1999. [7] MONKHOUSE R S C, WILCOX P W, LOWE M J S, et al. Therapid monitoring of structures using interdigital lamb wave transducers[J]. Smart Materials and Structures,2000,9(3):304-309. doi: 10.1088/0964-1726/9/3/309 [8] CHUNG D D L. Piezoresistive cement-based materials for strain sensing[J]. Journal of Intelligent Material Systems and Structures,2002,13(9):599-609. doi: 10.1106/104538902031861 [9] LI Z J, ZHANG D, WU K R. Cement-based 0-3 piezoelectric composites[J]. ChemInform,2002,33(21):200221010. doi: 10.1002/chin.200221010 [10] 王治. 水泥基压电复合材料的模拟与优化设计[D]. 杭州: 浙江大学, 2014.WANG Zhi. Simulation and optimization design of cement-based piezoelectric composites[D]. Hangzhou: Zhejiang University, 2014(in Chinese). [11] DONG B Q, XING F, LIZ J. The study of poling behavior and modeling of cement-based piezoelectric ceramic composites[J]. Materials Science and Engineering A,2007,456(1-2):317-322. doi: 10.1016/j.msea.2006.11.139 [12] HUANG S F, CHANG J, LU L C, et al. Preparation and polarization of 0-3 cement based piezoelectric composites[J]. Materials Research Bulletin,2006,41(2):291-297. doi: 10.1016/j.materresbull.2005.08.026 [13] LAM K H, CHAN H L W. Piezoelectric cement-based 1-3 composites[J]. Applied Physics A,2005,81(7):1451-1454. doi: 10.1007/s00339-005-3226-0 [14] GONG H Y, ZHANG Y J, QUAN J, et al. Preparation and properties of cement based piezoelectric composites modified by CNTs[J]. Current Applied Physics,2011,11(3):653-656. doi: 10.1016/j.cap.2010.10.021 [15] XING F, DONG B Q, LI Z J. Dielectric, piezoelectric, and elastic properties of cement-based piezoelectric ceramic composites[J]. Journal of the American Ceramic Society,2008,91(9):2886-2891. doi: 10.1111/j.1551-2916.2008.02387.x [16] HUNPRATUB S, YAMWONG T, SRILOMSAK S, et al. Effect of particle size on the dielectric and piezoelectric properties of 0-3 BCTZO/cement composites[J]. Ceramics International,2014,40(1):1209-1213. doi: 10.1016/j.ceramint.2013.05.118 [17] POTONG R, RIANYOI R, NGAMJARUROJANA A, CHAIPANICH A. Dielectric and piezoelectric properties of 1-3 non-lead barium zirconate titanate-Portland cement composites[J]. Ceramics International,2013,39(s1):53-57. doi: 10.1016/j.ceramint.2012.10.034 [18] LIU D M, TROCZYNSKI, TSENG W J. Aging effect on the phase evolution of water-based sol-gel hydroxyapatite[J]. Biomaterials,2002,23(4):1227-1236. doi: 10.1016/S0142-9612(01)00242-3 [19] ESHTIAGH-HOSSEINI H, HOUSAINDOKHT M R, CHANKANDI M. Effects of parameters of sol-gel process on the phase evolution of sol-gel-derived hydroxyapatite[J]. Meterials Chenisrtry and Physics,2007,106(2-3):310-316. [20] SMITHA S, SHAJESH P, ARAVIND P R, et al. Effect of aging time and concentration of aging solution on the porosity characteristics of suberitically dried sillca aerogels[J]. Micropoporous and Mesoporous Materals,2006,91(1-3):286-292. doi: 10.1016/j.micromeso.2005.11.051 [21] 毋伟,贾梦秋, 陈建峰,等. 硅烷偶联剂对溶胶凝胶法纳米二氧化硅复合材料制备及应用的影响[J]. 复合材料报, 2019, 36(2):70-75.WU Wei, JIA Mengqiu, CHEN Jianfeng, et al. Effect of silane coupling agent on preparation and application of sol-gel nano-silica composites[J]. Acta Materiae Compositae Sinica,2019,36(2):70-75(in Chinese). -

下载:

下载: