Tensile failure mechanism of carbon fiber reinforced polymer composites with ply splice

-

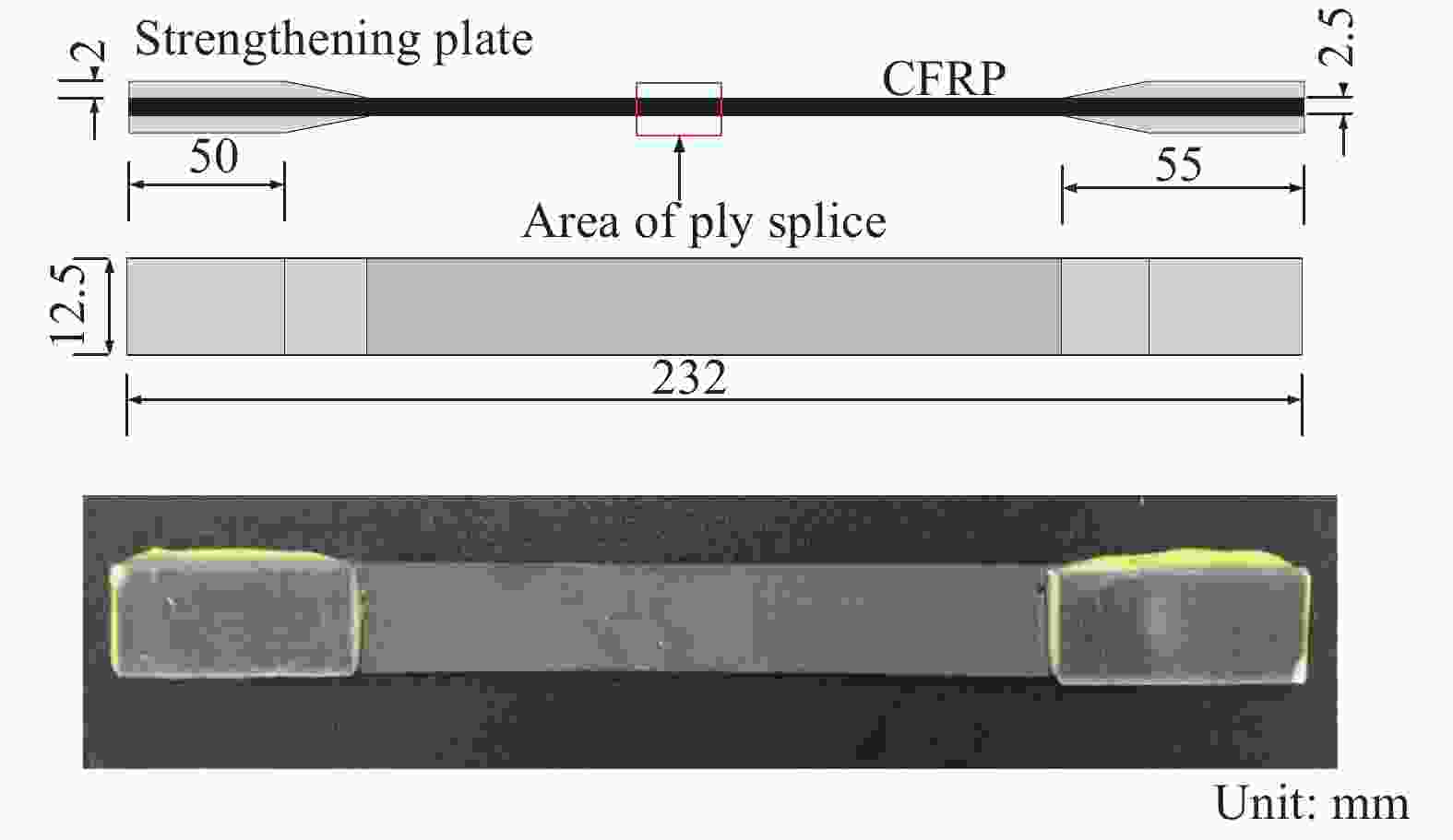

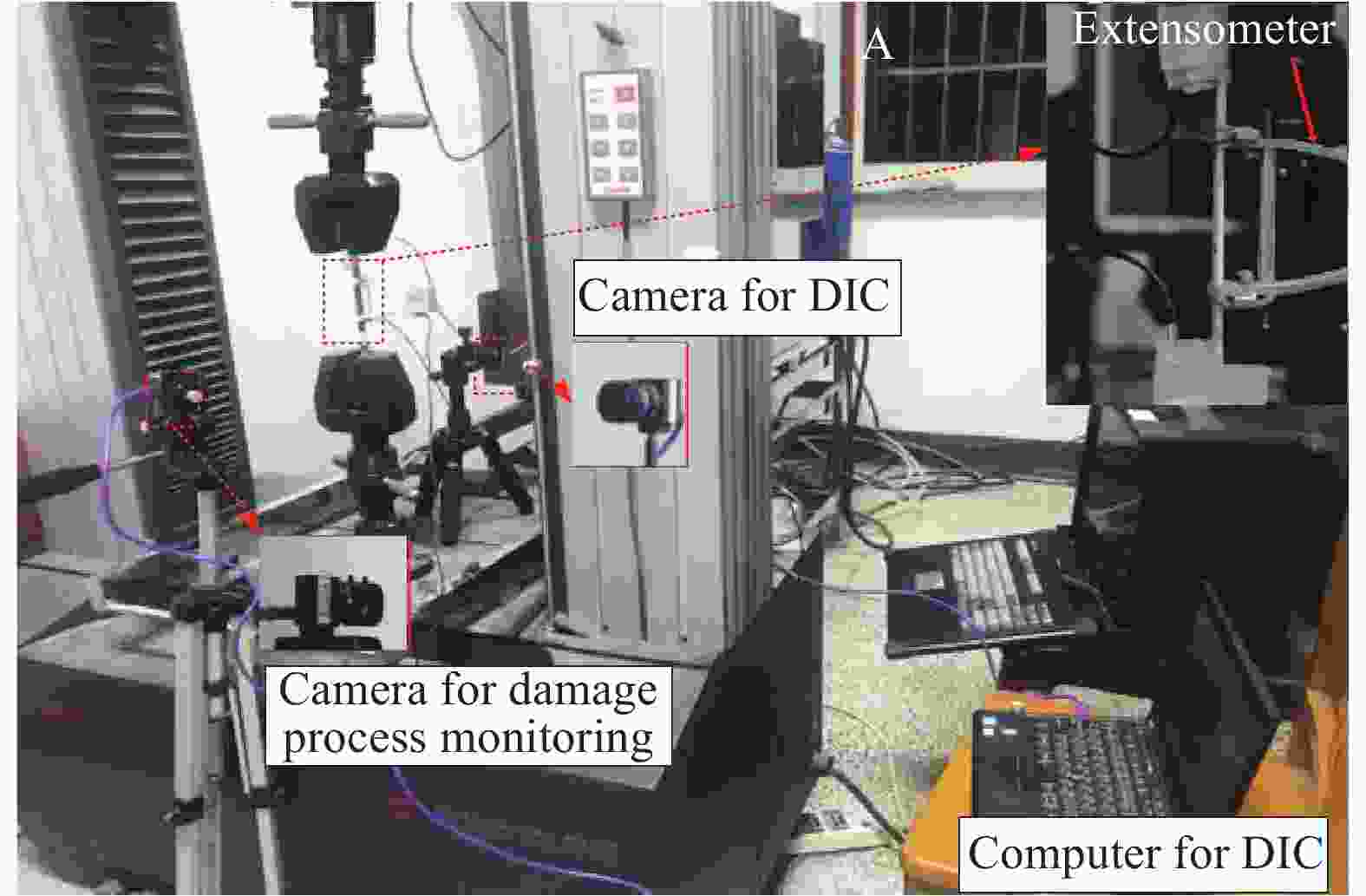

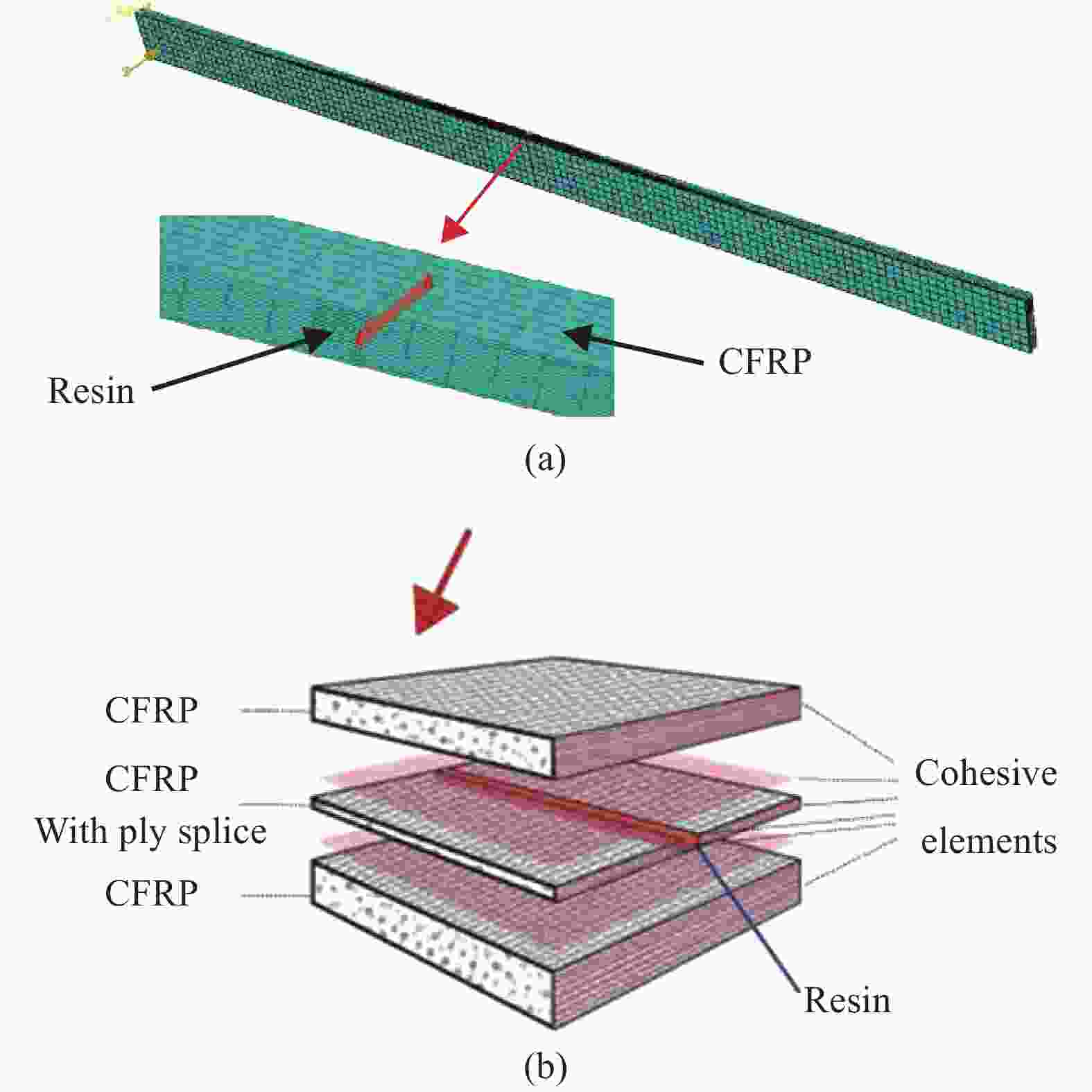

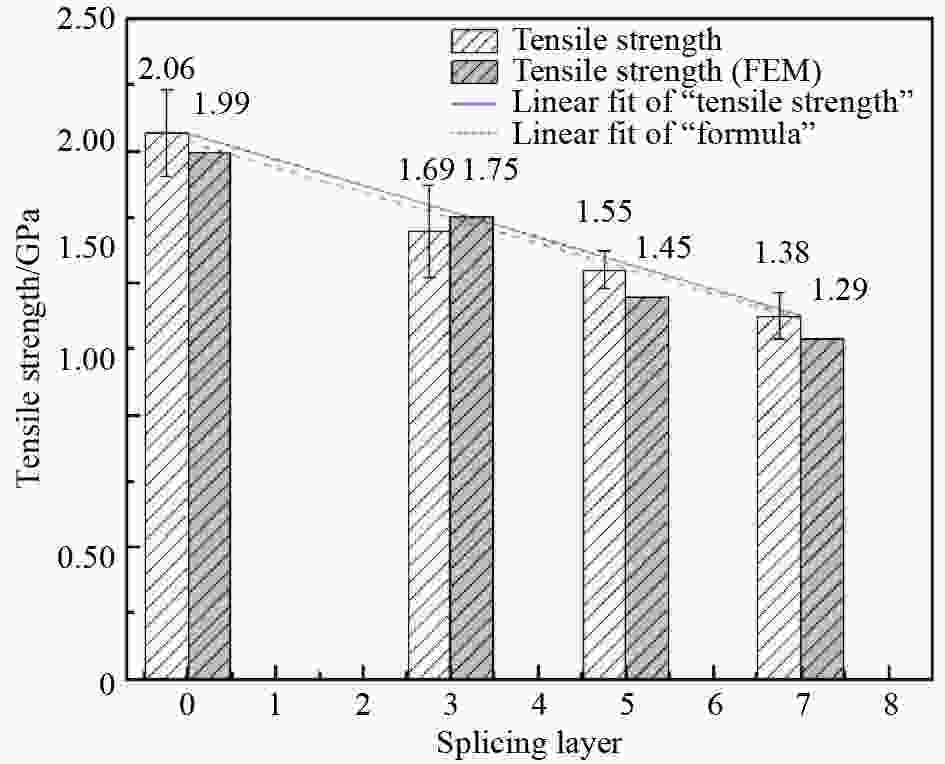

摘要: 对于尺寸较大或形状复杂的结构,通常需要在纤维增强树脂(FRP)复合材料内部对铺层进行拼接处理。铺层拼接会在材料内部引起复杂的应力分布,具有突出的安全隐患。以同一位置处出现不同层数铺层拼接的单向碳纤维增强树脂(CFRP)复合材料为研究对象,重点分析了铺层拼接对材料拉伸力学性能的影响机制。通过拉伸实验,测试了拼接对其力学强度的影响;用相机记录了破坏过程,并结合数字图像相关技术(DIC)对拼接位置附近的应变场进行了监测。利用有限元模型(FEM)模拟和分析结构的破坏机制,采用3D-Hashin准则和渐进损伤模型对CFRP复合材料铺层进行模拟;采用内聚力模型对胶层失效行为进行描述。实验结果表明,拼接结构的引入大幅降低了材料的抗拉强度。FEM模拟与实验测试结果吻合度高,说明了模型的有效性。综合实验结果和模拟分析得到,铺层拼接处产生应力集中,造成被拼接的两部分分离并伴随拼接铺层和连续铺层的层间剪切破坏;层间破坏发生后,拉伸载荷完全由连续铺层承载。因此,材料的最终承载能力由材料中连续铺层数决定。

-

关键词:

- 纤维增强树脂复合材料 /

- 拼接铺层 /

- 拉伸 /

- 3D-Hashin /

- 内聚力

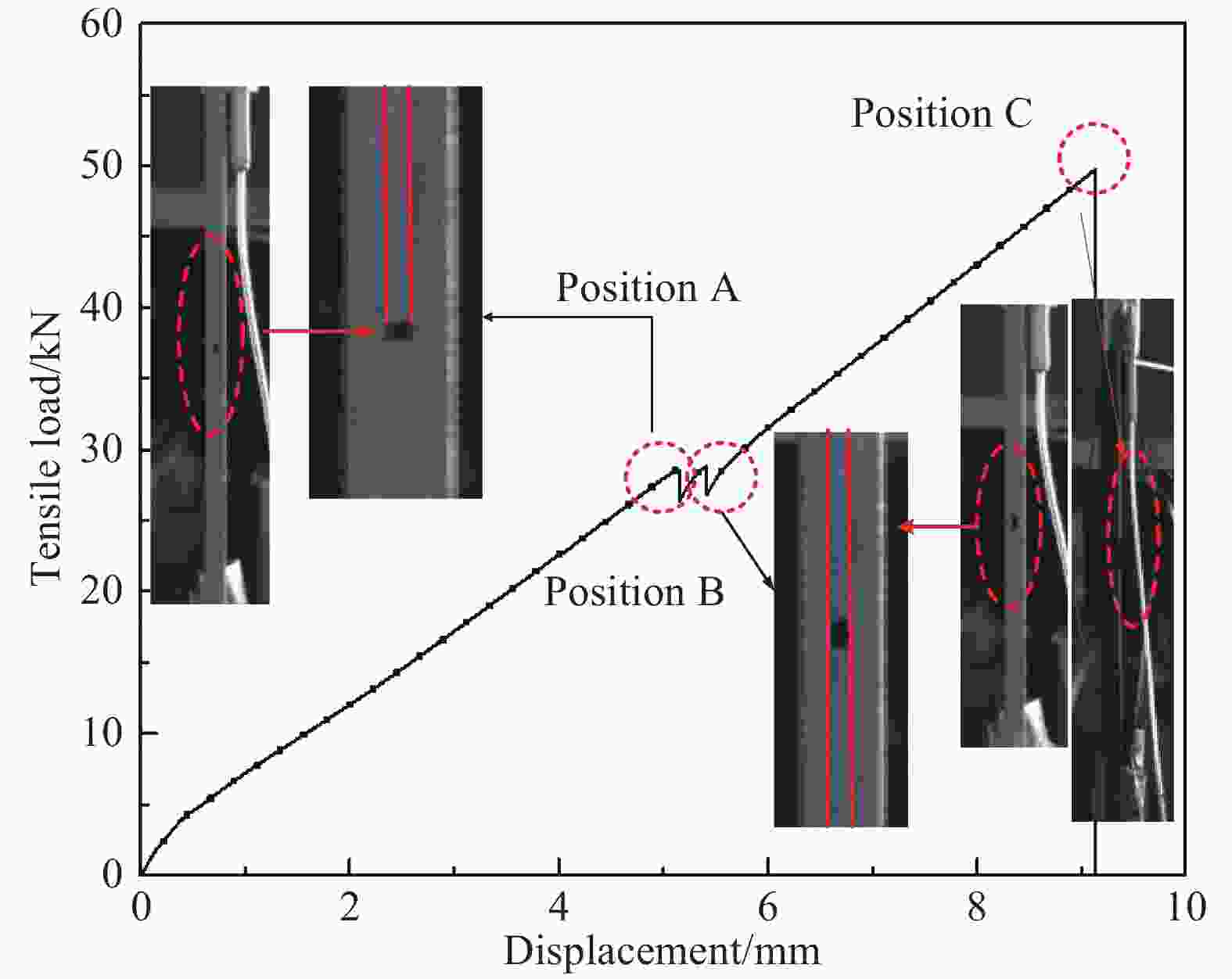

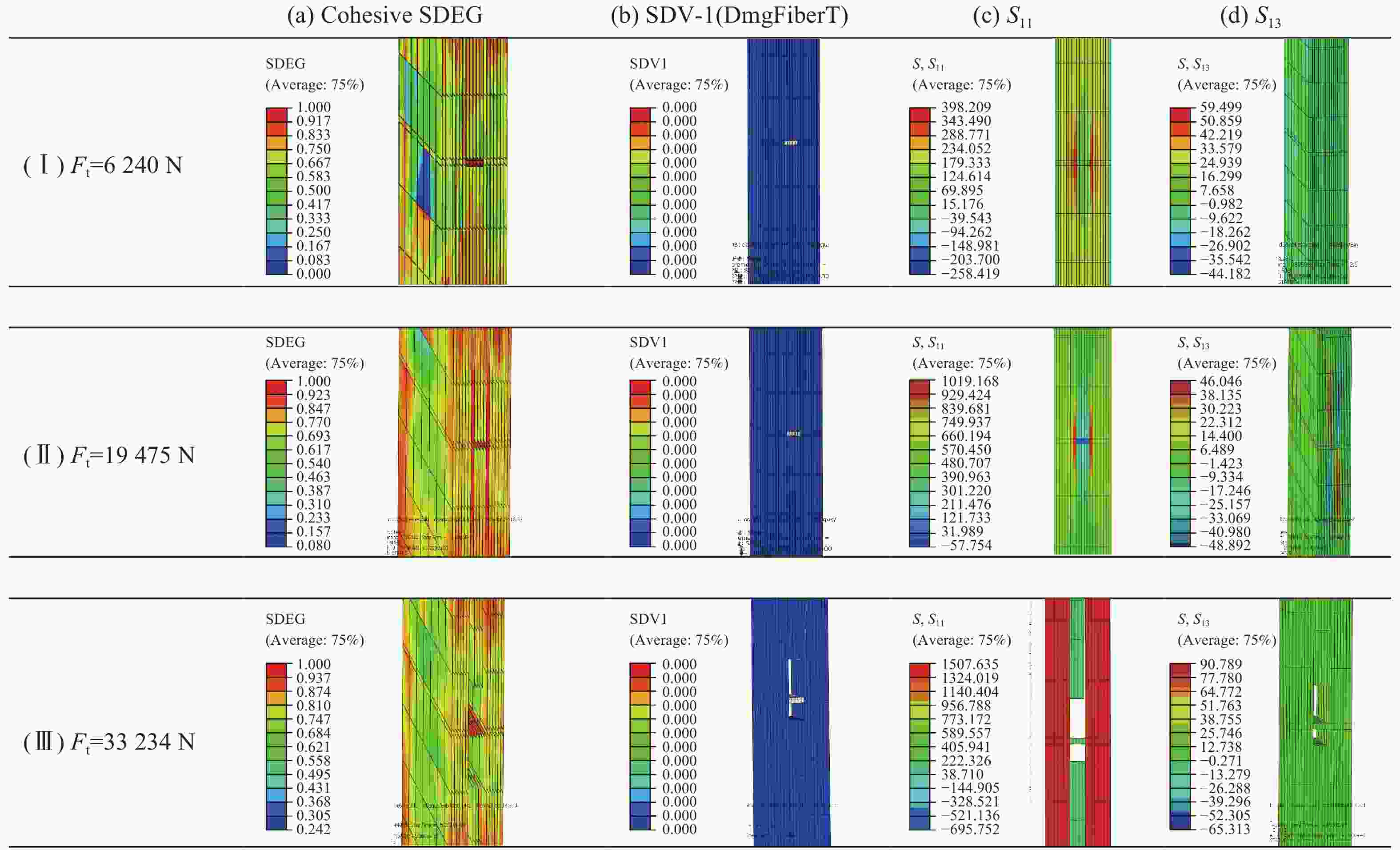

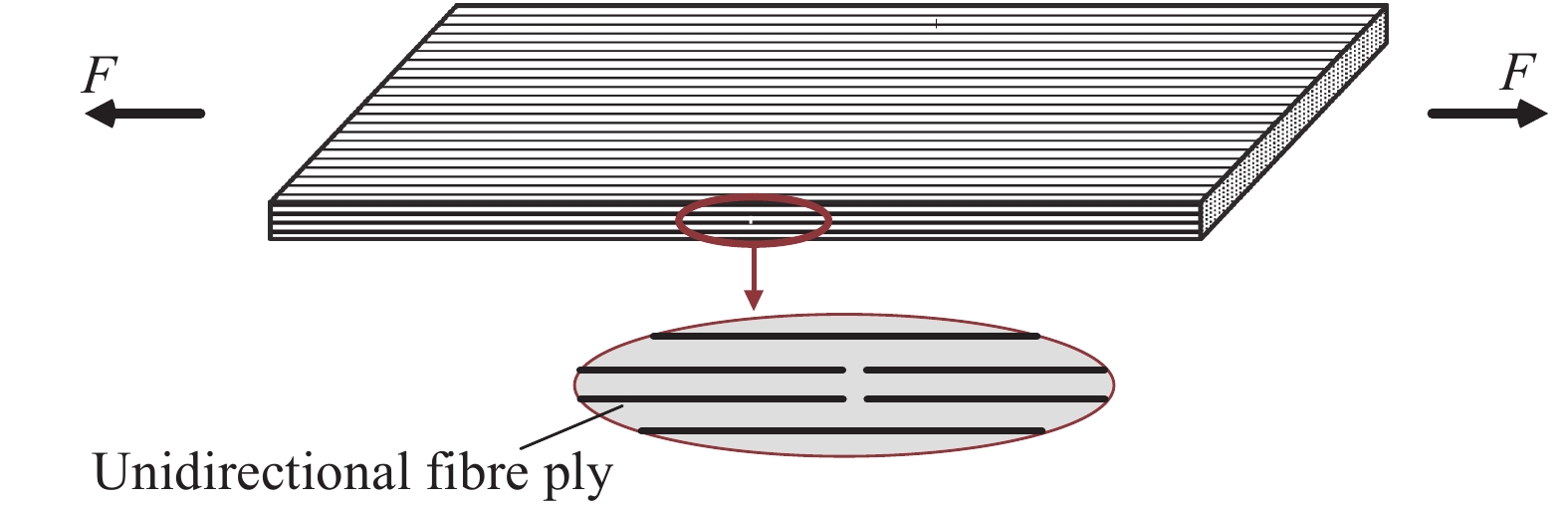

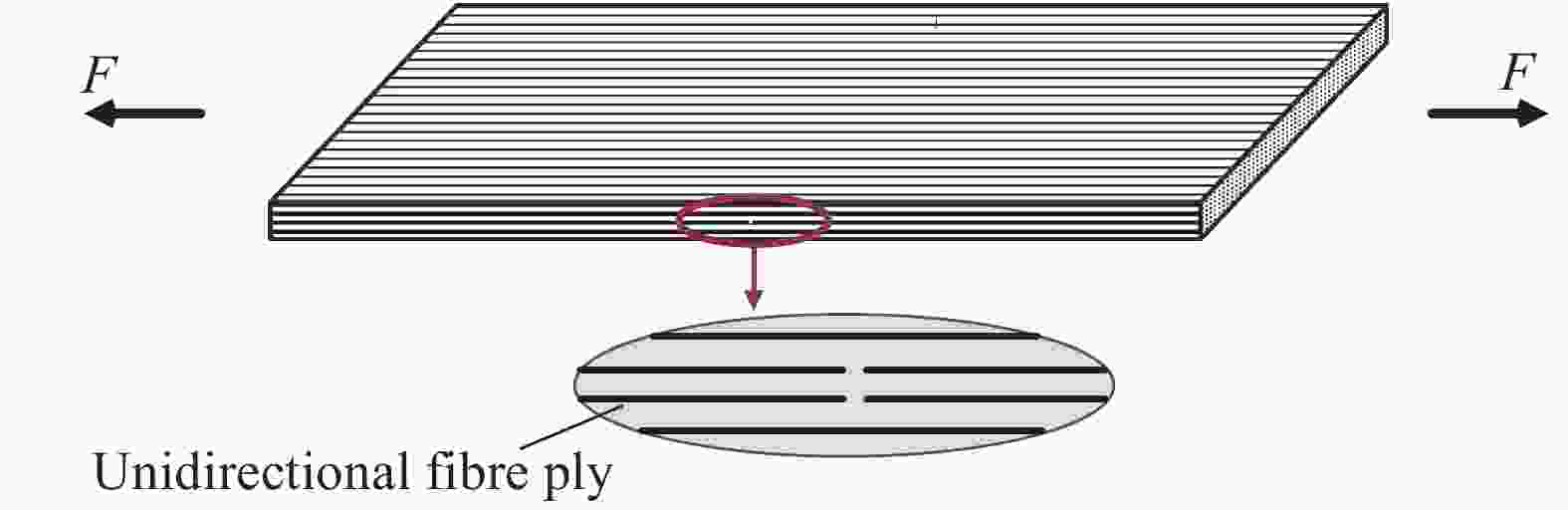

Abstract: When facing large scale and complex shapes situations, it is inevitable for fiber reinforced plastics (FRP) to splice two or more plies to meet the requirements. However, the complicated stress distribution within the splice structure may lead to serious safety problems. In this paper, the unidirectional carbon fiber reinforced polymer (CFRP) composite with splicing of different layers at the same location was taken as the research object. The effect mechanism of splicing on the tensile mechanical properties of CFRP composite was emphatically analyzed. The influence of ply splice on its mechanical strength was tested by tensile experiment. The damage process was recorded by camera, and the strain field near the splicing site was monitored by digital image correlation technology (DIC). The finite element model (FEM) was used to simulate and analyze the failure mechanism of the structure, and 3D-Hashin criterion and progressive damage model were used. The failure behavior of adhesive layer was described by cohesive zone model. The results show that the tensile strength of CFRP composite with the ply splice structure decreases obviously. The FEM simulation results agree well with the experimental results, which indicates the effectiveness of the model. According to the experimental results and simulation analysis, the stress concentration at the ply splice results in the separation of two splicing parts and the interlayer shear failure of splicing layer and continuous layer. After the interlaminar failure, the tensile load is completely carried by the continuous layer. Therefore, the ultimate bearing capacity of CFRP composite is determined by the number of continuous layers in the material.-

Key words:

- fiber reinforced plastics /

- ply splice /

- tension /

- 3D-Hashin /

- cohesive zone model

-

图 9 CFRP复合材料D5试样数字图像相关(DIC)及数值模拟纵向应变、剪切应变云图

Figure 9. Image of tensile strain and shear strain of digital image correlation (DIC) technology and FEM of the CFRP composites specimen D5 ((a) Tensile strain eyy of DIC; (b) Tensile strain eyy of FEM; (c) Shear strain exy of DIC; (d) Shear strain exy of FEM)

表 1 T300/E901 CFRP复合材料力学性能和强度参数

Table 1. Material properties and strength parameters of T300/E901 CFRP composites

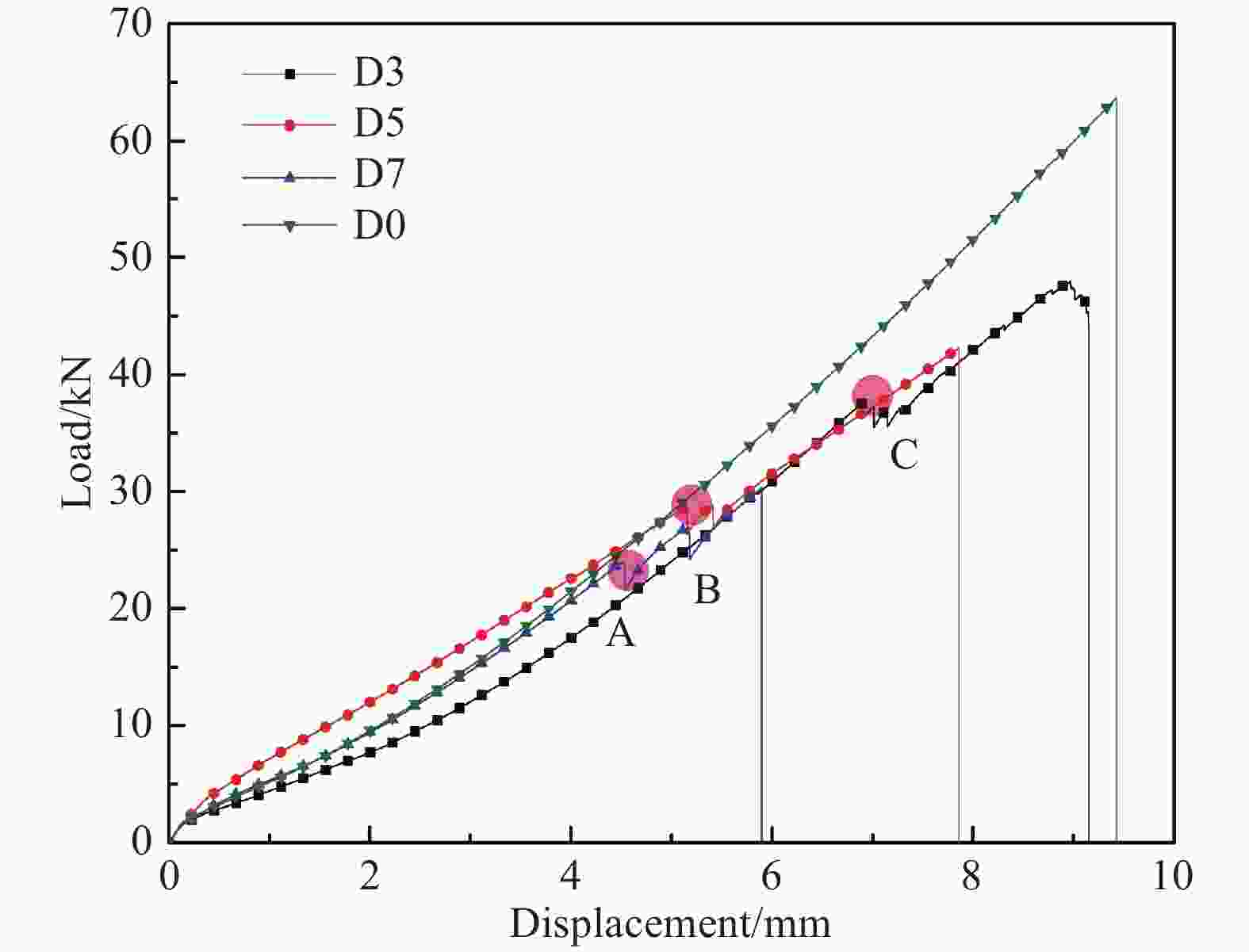

Material Mechanical parameters Value Epoxy resin E901 E/GPa 3.78 ν 0.35 Unidirectional CFRP E1/GPa 127.34 E2/GPa 7.78 E3/GPa 7.78 ν12 0.27 ν13 0.27 ν23 0.42 G12/GPa 5.00 G13/GPa 5.00 G23/GPa 3.08 Xt/MPa 2 114 Xc/MPa 704 Yt/MPa 80 Yc/MPa 68 S12=S13/MPa 80 S23/MPa 55 Notes: E—Young’s modulus; ν—Poisson's ratio; G—Shear modulus; X, Y—Strength; Subscript 1, 2 and 3—Direction 1, 2 and 3; Subscript t—Tension; Subscript c—Compression. 表 2 含拼接铺层CFRP复合材料分层起始载荷FEM模拟值与实验均值对比

Table 2. Comparison of initial damage loads of experiment and FEM for CFRP composites with ply splice

Initial damage load

for experiment/NInitial damage load

for FEM/NError/% D3 38 936.94 43 473.7 11.6 D5 30 243.57 32 568.5 7.6 D7 26 098.17 25 489.1 6.4 表 3 含拼接铺层CFRP复合材料极限载荷EMF模拟值与实验均值对比

Table 3. Comparison of ultimate loads of experiment and FEM for CFRP composites with ply splice

Ultimate load for experiment/N Ultimate load for FEM/N Error/% D0 63 731.48 62 850.3 1.7 D3 47 655.43 55 253.5 16.1 D5 41 354.25 45 521.9 10.1 D7 40 472.96 40 627.3 0.3 -

[1] 罗益锋, 罗晰旻. 现代飞机用特种纤维及其复合材料的最新进展[J]. 纺织导报, 2018(S1):63-69.LUO Yifeng, LUO Ximin. Latest development of specialty fibers and its composites for modern aircraft[J]. China Textile Leader,2018(S1):63-69(in Chinese). [2] CASADEI P, GALATI N, PARRETTI R. Strength-ening of a bridge using two FRP technologies[C]. In: ACI (American Concrete Institute) Fall 2003 Convention, Boston, MA(US); 2003. [3] 李亮, 贾普荣, 矫桂琼, 等. 含铺层拼接层合板的力学性能[J]. 航空制造技术, 2009(S1):126-128.LI Liang, JIA Purong, JIAO Guiqiong, et al. Mechanical property of laminate with ply splice[J]. Aeronautica Manufacturin Technology,2009(S1):126-128(in Chinese). [4] 李亮, 贾普荣, 矫桂琼. 单向拼接复合材料层合板的抗拉强度研究[J]. 机械强度, 2013, 170(6):795-798.LI Liang, JIA Purong, JIAO Guiqiong. Tensile strength of unidirectional laminate with ply-splicing[J]. Journal of Mechanical Strength,2013,170(6):795-798(in Chinese). [5] 王建业, 贾普荣, 矫桂琼, 等. 含铺层拼接层合板的等效刚度估算[J]. 科学技术与工程, 2010(3):822-825. doi: 10.3969/j.issn.1671-1815.2010.03.055WANG Jianye, JIA Purong, JIAO Guiqiong, et al. Equivalent rigidity estimation of the laminate with ply splice[J]. Science Technology and Engineering,2010(3):822-825(in Chinese). doi: 10.3969/j.issn.1671-1815.2010.03.055 [6] 王玲, 贾普荣, 王文贵, 等. 含铺层拼接层合板面内剪切强度[J]. 材料科学与工程, 2010, 28(3):341-344.WANG Ling, JIA Purong, WANG Wengui, et al. In-plane shear strength of laminate with spliced plies[J]. Journal of Materials Science and Engineering,2010,28(3):341-344(in Chinese). [7] 钟安彪, 岳珠峰, 耿小亮, 等. 错位铺层拼接层合板力学性能分析与模拟方法探索[J]. 固体力学学报, 2015(s1):111-116.ZHONG Anbiao, YUE Zhufeng, GENG Xiaoliang, at el. The mechanical performance analysis and simulation method exploration of spliced ply with misalignment seams[J]. Chinese Journal of Solid Mechanics,2015(s1):111-116(in Chinese). [8] 王刚, 贾普荣, 黄涛, 等. 含切口复合材料层合板拉伸应变集中与失效分析[J]. 材料工程, 2018, 46(2):134-141. doi: 10.11868/j.issn.1001-4381.2016.000847WANG Gang, JIA Purong, HUANG Tao, et al. Strain concentration and failure analysis of notched composite laminates under tensile loading[J]. Journal of Materials Engineering,2018,46(2):134-141(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.000847 [9] 陈丁丁, 王曼漪, 新川和夫, 等. 纤维增强树脂基复合材料拼接结构拉伸性能[J]. 复合材料学报, 2017(11):95-100.CHEN Dingding, WANG Manyi, ARAKAWA Kazuo, et al. Tensile properties of FRP ply splice structures[J]. Acta Materiae Compositae Sinica,2017(11):95-100(in Chinese). [10] 黄剑贤, 耿小亮, 张永久. 错位铺层拼接层合板承载机制的试验与模拟研究[J]. 应用力学学报, 2013(5):787-791. doi: 10.11776/cjam.30.05.B013HUANG Jianxian, GENG Xiaoliang, ZHANG Yongjiu. Experimental and numerical research for mechanical properties of ply splice laminates[J]. Chinese Journal of Applied Mechanics,2013(5):787-791(in Chinese). doi: 10.11776/cjam.30.05.B013 [11] 李澄. 拼接与搭接铺层对复合材料性能影响研究[J]. 山东工业技术, 2019(1):14-16.LI Cheng. Study on the effects of splicing and lapping on the properties of composite materials[J]. Shandong Industrial Technology,2019(1):14-16(in Chinese). [12] 张顺庆, 高晨家, 张龙. 数字图像相关技术在应力应变测量中的发展与最新应用[J]. 影像科学与光化学, 2017, 35(2):193-198. doi: 10.7517/j.issn.1674-0475.2017.02.193ZHANG Shunqing, GAO Chenjia, ZHANG Long. The development and latest applications of digital image correlation in stress and strain measurement[J]. Imaging Science and Photochemistry,2017,35(2):193-198(in Chinese). doi: 10.7517/j.issn.1674-0475.2017.02.193 [13] COMER A J, KATNAM K B, STANLEY W F. Characterising the behavior of composite single lap bonded joints using digital image correlation[J]. International Journal of Adhesion & Adhesives,2013,40(40):215-223. [14] KASHFUDDOJA M, RAMJI M. Whole-field strain analysis and damage assessment of adhesively bonded patch repair of CFRP laminates using 3D-DIC and FEA[J]. Composites Part B: Engineering,2013,53(5):46-61. [15] 张文东, 樊俊铃, 陈莉, 等. 二维数字图像相关法在准静态拉伸实验中的应用[J]. 应用力学学报, 2018, 35(5):138-144, 267.ZHANG Wendong, FAN Junling, CHEN Li, et al. Study on the application of two-dimensional digital image correlation method in quasistatic tension test[J]. Chinese Journal of Applied Mechanics,2018,35(5):138-144, 267(in Chinese). [16] 全国纤维增强塑料标准化技术委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014 [S]. 北京: 中国标准出版社, 2015.Standardization Administration of the People’s Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Standards Press, 2015(in Chinese). [17] 王曼漪, 胡其高, 陈丁丁, 等. DIC方法位移与应变测试结果可靠性实验研究[C]//2017第26届全国结构工程学术会议论文集(第Ⅲ册), 2017: 628-633.WANG Manyi, HU Qigao, CHEN Dingding, at el. Experimental research of reliability of DIC method in the displacement and strain tests[C]//The 26th Session of the National Construction Engineering Academic Conference Proceedings, The First Ⅲ Copies, 2017: 628-633(in Chinese). [18] SUNG N, SUH N. Effect of fiber orientation on friction and wear of fiber reinforced polymeric composites[J]. Wear,1979,53(1):129-141. doi: 10.1016/0043-1648(79)90224-2 [19] SCHON J. Coefficient of friction of composite delamination surfaces[J]. Wear,2000,237(1):77-89. doi: 10.1016/S0043-1648(99)00315-4 [20] BING Q , SUN C T . Effect of compressive transverse normal stress on mode II fracture toughness in polymeric composites[J]. International Journal of Fracture, 2007, 145(2):89-97. [21] 陈建霖, 励争, 储鹏程. 大开口复合材料层合板强度破坏研究[J]. 力学学报, 2016, 48(6):1326-1333. doi: 10.6052/0459-1879-16-169CEHEN Jianlin, LI Zheng, CHU Pengcheng. Strength analysis of fiber reinforced composite laminates with big cutous[J]. Chinses Journal of Theoretical and Applied Mechanics,2016,48(6):1326-1333(in Chinese). doi: 10.6052/0459-1879-16-169 [22] 王刚, 贾普荣, 黄涛, 等. 含切口复合材料层合板拉伸应变集中与失效分析[J]. 材料工程, 2018, 2(46):134-141.WANG Gang, JIA Purong, HUANG Tao, at el. Strain concentration and failure analysis of notched composite laminates under tensile loading[J]. Journal of Materials Engineering,2018,2(46):134-141(in Chinese). [23] 冯威, 徐绯, 袁佳雷. 双斜接修补复合材料层合版的拉伸行为及影响因素[J]. 复合材料学报, 2019, 36(6):1421-1427.FENG Wei, XU Fei, YUAN Jialei. Investigation on tensile behavior and effect factor analysis of double scarf-repaired composite laminates[J]. Acta Materiae Compositae Sinica,2019,36(6):1421-1427(in Chinese). [24] HASHIN Z, ROTEM A. A fatigue failure criteri-on for fiber reinforced materials[J]. Journal of Composite Materials,1973,7(4):448-464. doi: 10.1177/002199837300700404 [25] HASHIN Z. Fatigue failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics,1981,48(4):846. doi: 10.1115/1.3157744 [26] CHANG F K, CHANG K Y. A progressive damage model for laminated composites containing stress concentrations[J]. Journal of Composite Materials,1987,21(9):834-855. doi: 10.1177/002199838702100904 [27] TSERPES K I, LABEAS G, PAPANIKOS P, et al. Strength prediction of bolted joints in graphite/epoxy composite laminates[J]. Composites Part B: Engineering,2002,33(7):521-529. doi: 10.1016/S1359-8368(02)00033-1 -

下载:

下载: