Influence of stack slippage process on mechanical properties of M21C laminates

-

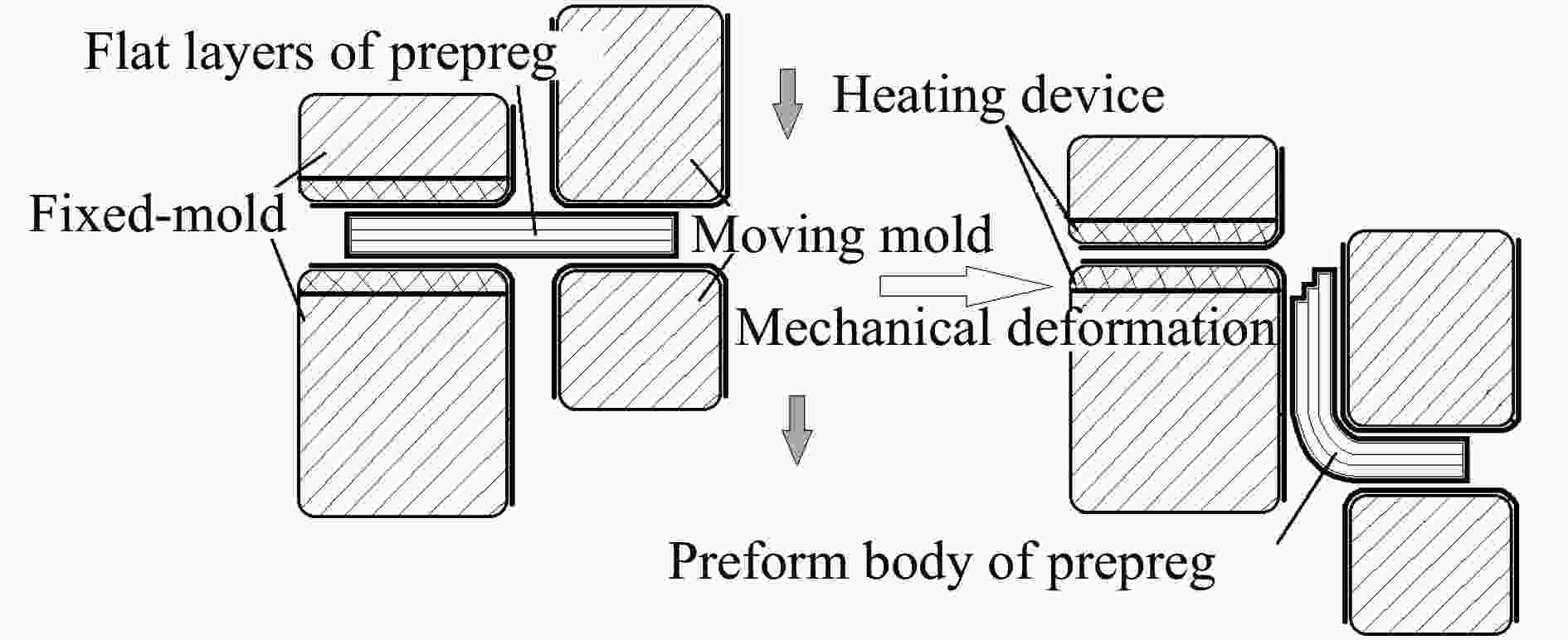

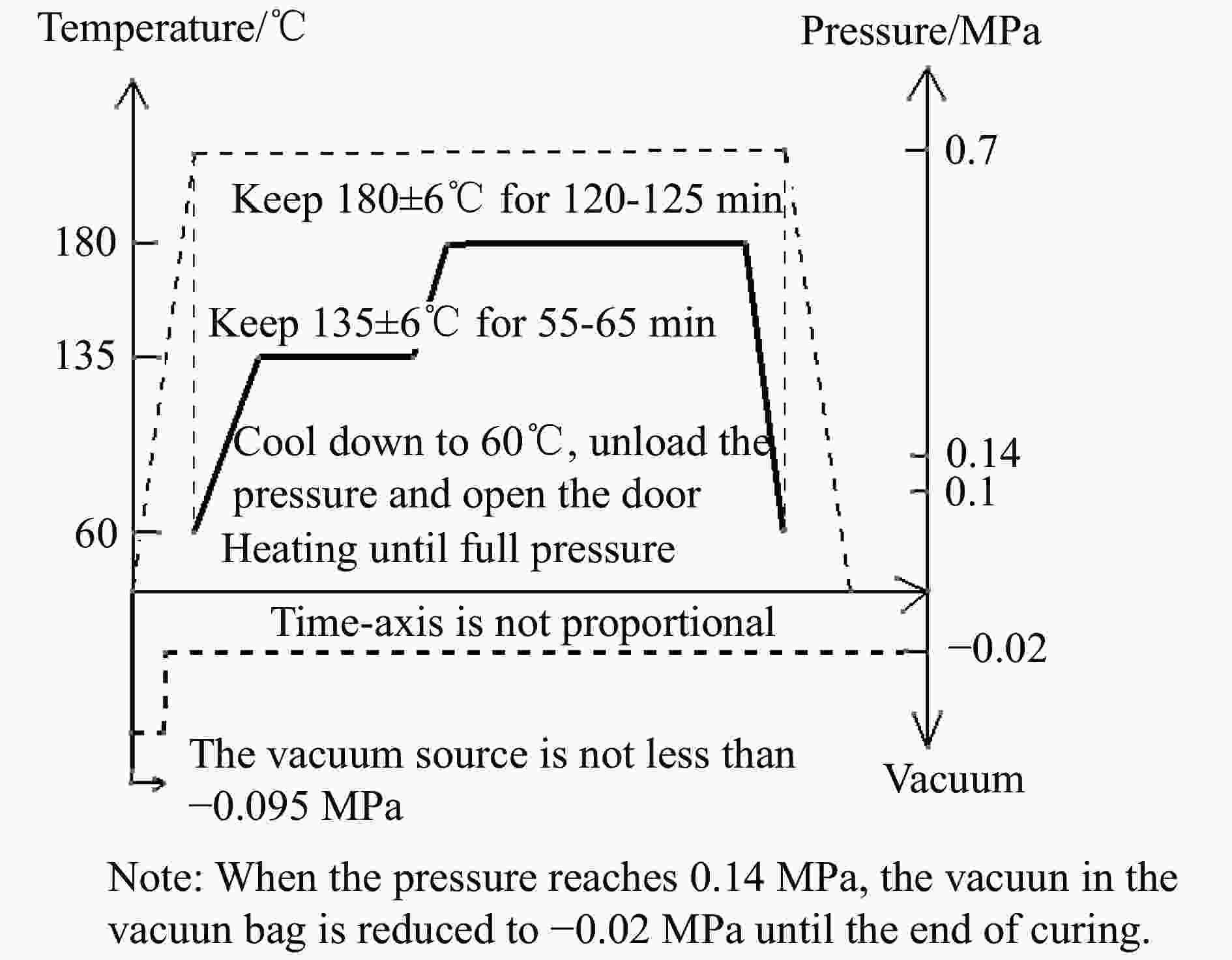

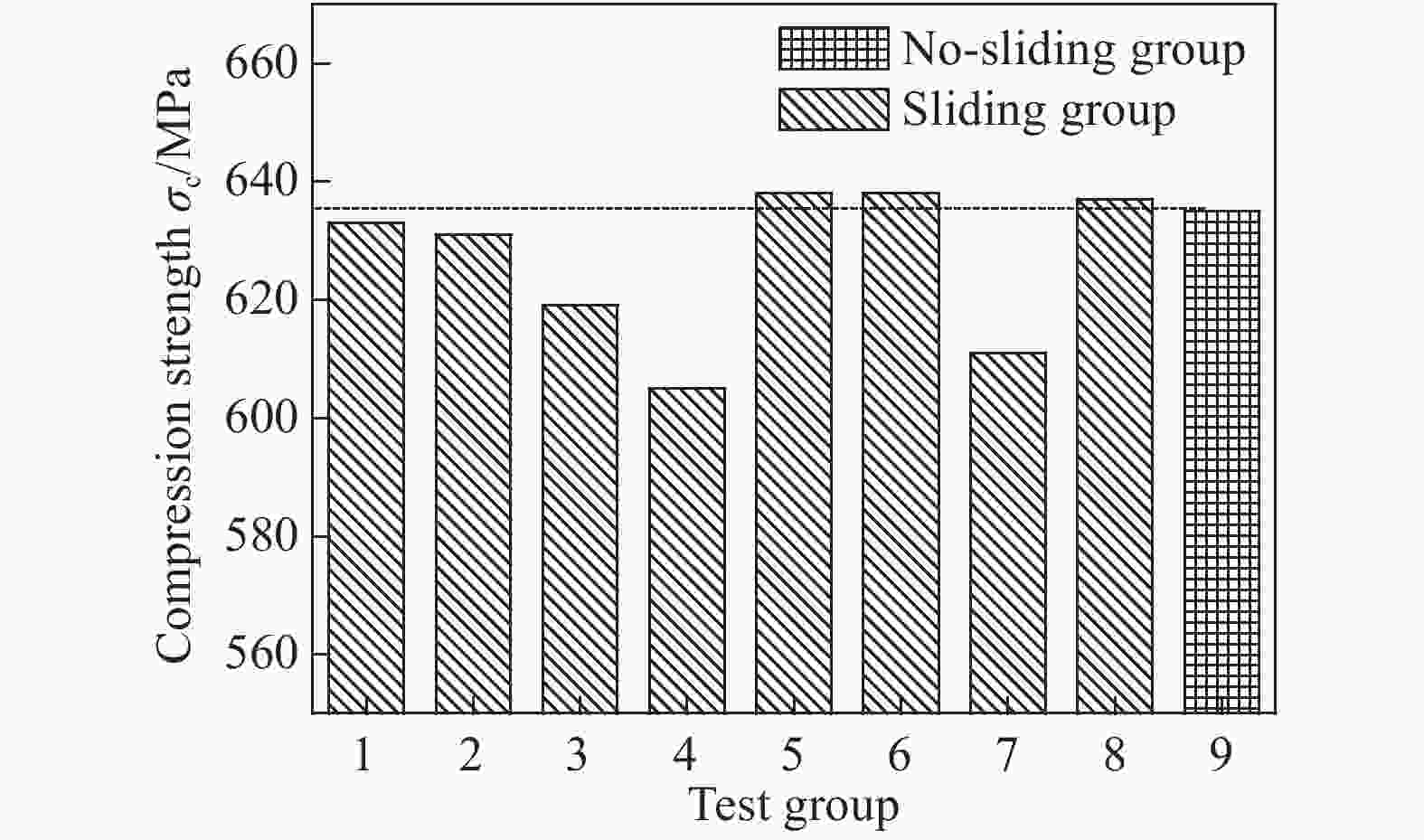

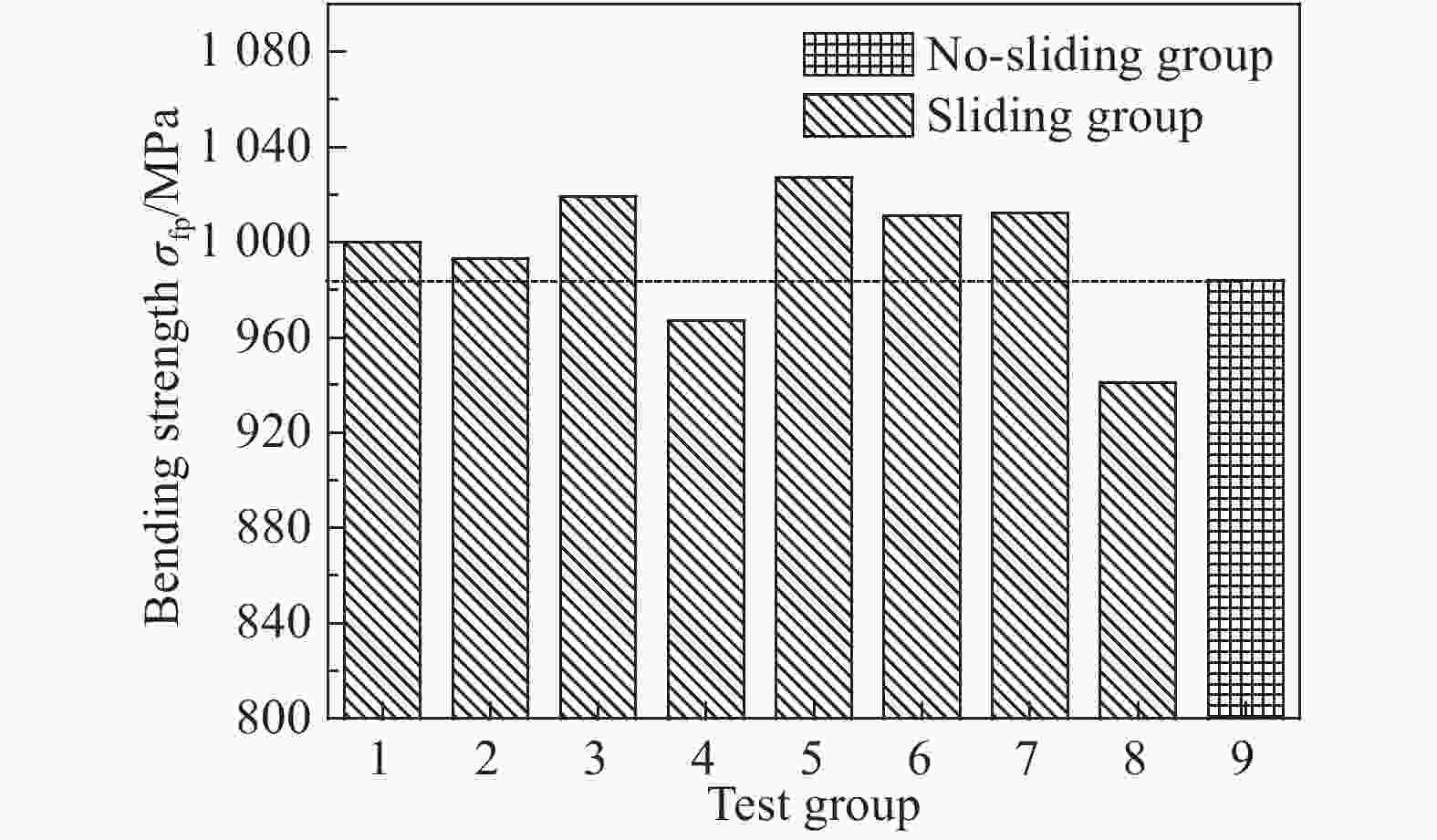

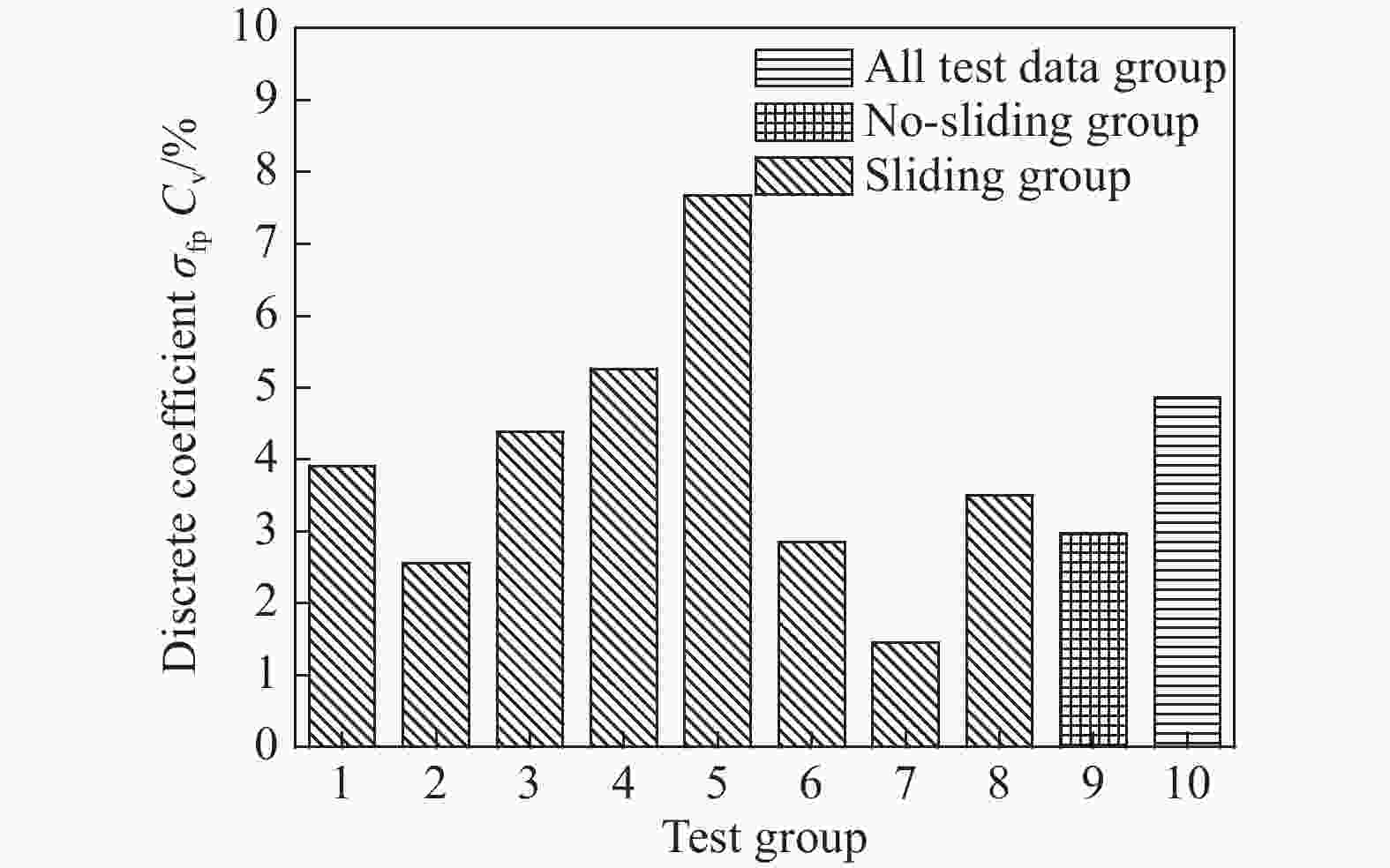

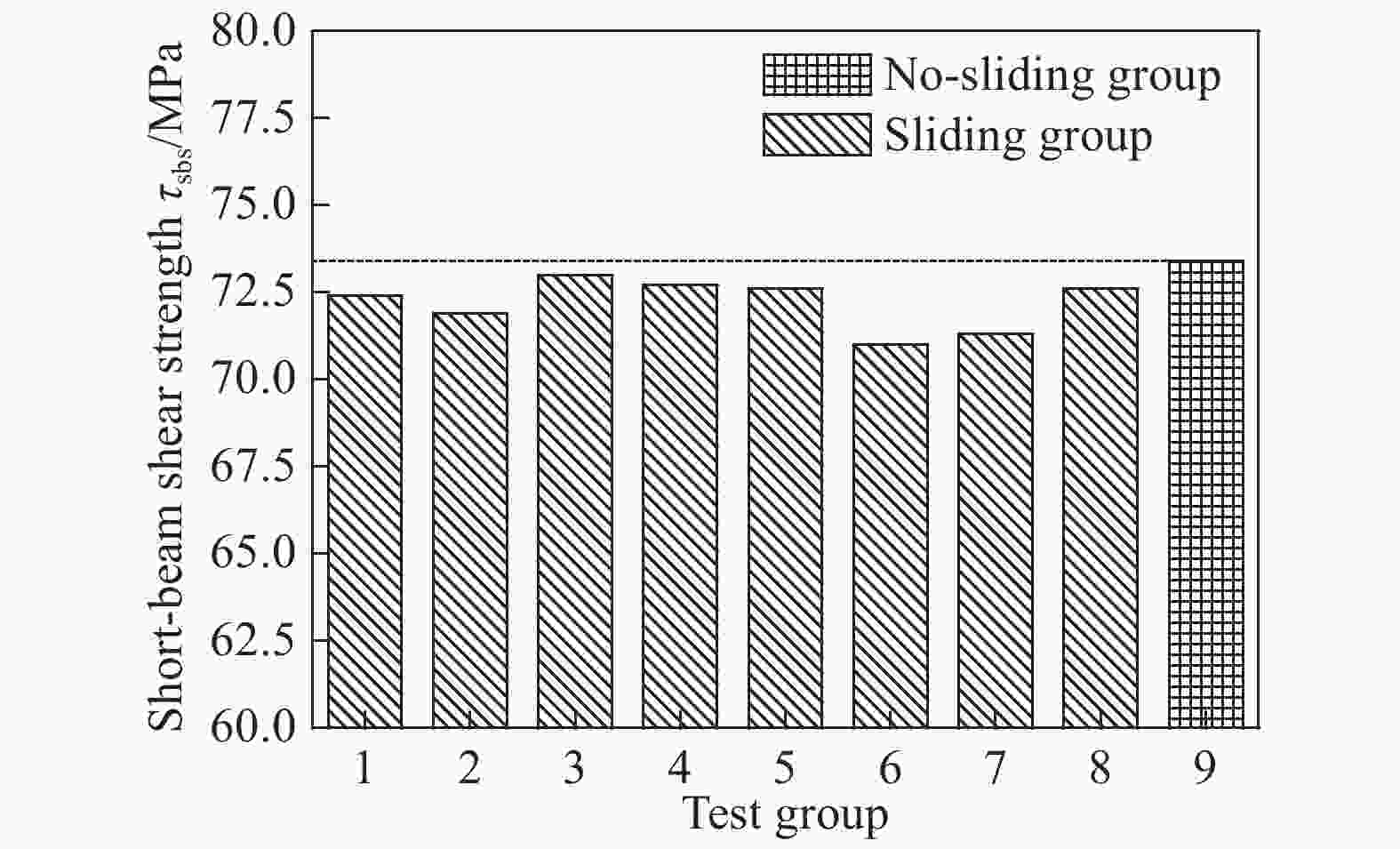

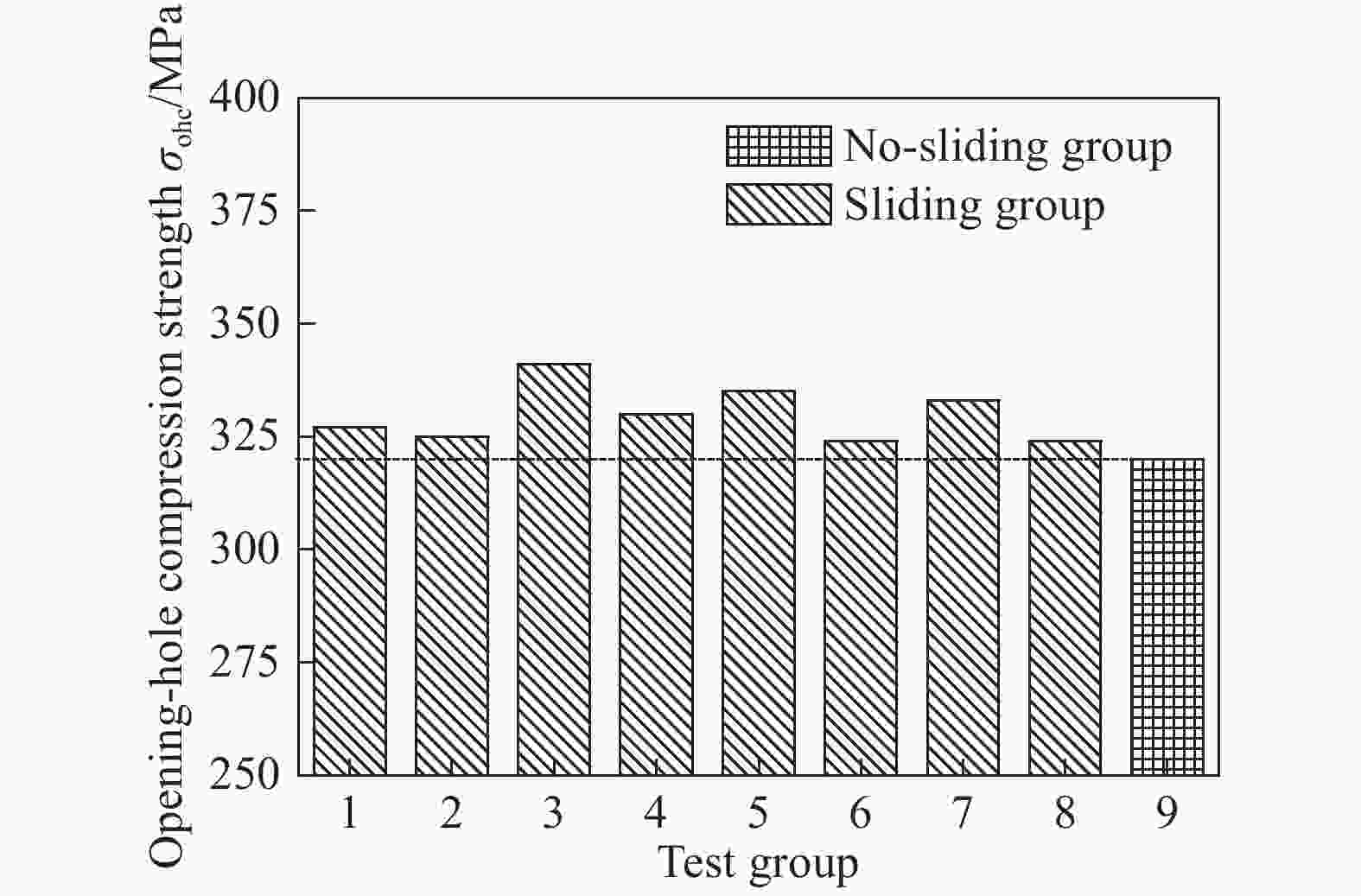

摘要: 针对复合材料长桁毛坯制备的新工艺—叠层滑移工艺,考虑叠层滑移工艺的极限参数规划相关的力学性能试验矩阵,研究叠层滑移工艺对M21C层压板拉伸性能、压缩性能、弯曲性能、短梁剪切性能、开孔压缩性能和面内剪切性能的影响。试验结果表明:叠层滑移工艺对M21C层压板的开孔压缩性能无影响,拉伸性能、压缩性能、弯曲性能、短梁剪切性能和面内剪切性能均会有一定程度的下降。Abstract: Aimed at a new process for rough preparation of composite long truss-stack slippage process, the me-chanical performance test matrix related to the limit parameter of the stack slippage process was made. The effects of stack slippage process on the tensile properties, compression properties, bending properties, shear properties of short beams, opening-hole compression properties and internal shear properties of M21C laminates were studied. The experimental results show that the stack slippage process has no effect on the opening-hole compression performance of the M21C laminates, and the tensile properties, compression properties, bending properties, shear properties of the short beams and the internal shear properties will decrease to a certain extent.

-

表 1 M21C层压板力学性能试验项目和方法

Table 1. Test projects and methods of mechanical performance for M21C laminates

Test project Layer information Test method Test condition Tensile strength [45/0/–45/90]2S ASTM D 3039[22] RT Compression strength [45/0/–45/90]2S ASTM D 6641[23] RT Bending strength [45/0/–45/90]3S ASTM D 7264[24] RT Short-beam shear strength [45/0/–45/90]2S ASTM D 2344[25] RT Opening-hole compression strength [45/0/–45/90]3S ASTM D 6484[26] RT Internal shear strength [+45/–45]4S ASTM D 3518[27] RT Note: RT—Room temperature. 表 2 M21C层压板叠层滑移试验矩阵

Table 2. Stack slip test matrix for M21C laminates

Slide rate/(mm·min−1) 1.2 12 1.2 12 1.2 12 1.2 12 Insulation time/min 1 1 30 30 1 1 30 30 Thermal temperature/℃ 60 60 60 60 80 80 80 80 Test group 1 2 3 4 5 6 7 8 Note:1-8 represent different stack slippage process test groups. 表 3 叠层滑移工艺对M21层压板力学性能的影响

Table 3. Influence of stack slippage process on mechanical properties of M21C laminates

Test project Description of the influence of stack slippage process on mechanical properties of M21C laminates Tensile strength Maximum reduction of tensile strength σt by 5 % Compression strength Maximum reduction of compression strength σc by 4.7 % Bending strength Maximum reduction of bending strength σfp by 4.36 % Short-beam shear strength Maximum reduction of short-beam shear strength τsbs by 3.27% Opening-hole compression strength Maximum increase of opening-hole compression strength σt by 6.56% Internal shear strength Maximum reduction of internal shear strength τs by 5.59% -

[1] 梁宪珠, 曹正华, 常海峰, 等. 数字技术在复合材料上壁板制造中的应用[J]. 航空制造技术, 2008(3):46-48. doi: 10.3969/j.issn.1671-833X.2008.03.007LIANG Xianzhu, CAO Zhenghua, CHANG Haifeng, et al. Application of digital technology in the manufacture of composite panels[J]. Aeronautical Manufacturing Technology,2008(3):46-48(in Chinese). doi: 10.3969/j.issn.1671-833X.2008.03.007 [2] 杨乃宾. 新一代大型客机复合材料结构[J]. 航空学报, 2008(3):596-604. doi: 10.3321/j.issn:1000-6893.2008.03.010YANG Naibin. Composite structure for new generation large commercial jet[J]. Acta Aeronautica et Astronautica Sinica,2008(3):596-604(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.010 [3] 王犇. 复合材料的应用与展望[J]. 中国新技术新产品, 2018(3):40-41. doi: 10.3969/j.issn.1673-9957.2018.03.025WANG Ben. Application and prospect of composite materials[J]. Chinese New Technology and New Products,2018(3):40-41(in Chinese). doi: 10.3969/j.issn.1673-9957.2018.03.025 [4] 李林. 大型复合材料壁板先进制造技术及应用[J]. 航空制造技术, 2017(11):105-109.LI Lin. Advanced manufacture technology and application of large-sized composite panel[J]. Aeronautical Manufacturing Technology,2017(11):105-109(in Chinese). [5] 马刚, 唐文峰. 民用航空含Ω型长桁复合材料加筋壁板制造技术研究[J]. 航空制造技术, 2017(12):74-77.MA Gang, TANG Wenfeng. Study on manufacturing technology of Ω type stiffened panel of civil aviation[J]. Aeronautical Manufacturing Technology,2017(12):74-77(in Chinese). [6] 蒲永伟, 湛利华. 先进复合材料帽形加筋构件制造关键技术探究[J]. 航空制造技术, 2015(4):78-82.PU Yongwei, ZHAN Lihua. Study on the key manufacturing technology of aeronautical advanced composite hat-stiffened structures[J]. Aeronautical Manufacturing Technology,2015(4):78-82(in Chinese). [7] 马刚, 张晓哲, 唐文峰. 大型复合材料加筋壁板自动化制造技术研究[J]. 航空制造技术, 2018, 61(14):91-95.MA Gang, ZHANG Xiaozhe, TANG Wenfeng. Research on automatic manufacturing technology of large composite reinforced panels[J]. Aeronautical Manufacturing Technology,2018,61(14):91-95(in Chinese). [8] 肖军. 航空复合材料自动铺丝技术发展概况[J]. 国际航空, 2011(12):70-72.XIAO Jun. Development of automatic composite fiber placement[J]. International Aviation,2011(12):70-72(in Chinese). [9] 黄莹. 复合材料热隔膜预成型工艺分析[J]. 机械设计与制造工程, 2015, 44(9):20-22. doi: 10.3969/j.issn.2095-509X.2015.09.006HUANG Ying. The analysis on the hot diaphragm preforming process for composite material[J]. Machine Design and Manufacturing Engineering,2015,44(9):20-22(in Chinese). doi: 10.3969/j.issn.2095-509X.2015.09.006 [10] 元振毅, 王永军, 杨凯, 等. 热固性树脂基复合材料热隔膜成型过程树脂仿真[J]. 复合材料学报, 2016, 33(7):1339-1350.YUAN Zhenyi, WANG Yongjun, YANG Kai, et al. Numerical simulation for hot diaphragm preforming process of thermosetting resin matrix composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1339-1350(in Chinese). [11] 姚双, 李敏, 顾轶卓, 等. 碳纤维复合材料C形结构热隔膜成型工艺[J]. 北京航空航天大学学报, 2013, 39(1):95-104.YAO Shuang, LI Min, GU Yizhuo, et al. Hot diaphragm preforming process of carbon fiber composite with C-shaped structure[J]. Journal of Beijing University of Aeronautics and Astronautics,2013,39(1):95-104(in Chinese). [12] 范玉青, 张丽华. 超大型复合材料机体部件应用技术的新进展[J]. 航空学报, 2009, 30(3):541-542.FAN Yuqing, ZHANG Lihua. New development of extra large composite aircraft components application technology[J]. Acta Aeronautica et Astronautica Sinica,2009,30(3):541-542(in Chinese). [13] 郝建伟, 陈亚莉. 先进复合材料主要制造工艺和专用装备[J]. 航空制造技术, 2008(10):42-44.HAO Jianwei, CHEN Yali. Manufacturing technology and special equipment for advanced composites[J]. Aeronautical Manufacturing Technology,2008(10):42-44(in Chinese). [14] 周晓芹, 段有社, 薛向晨. 飞机复材构件制造装备应用现状[J]. 航空制造技术, 2013(17):53-56. doi: 10.3969/j.issn.1671-833X.2013.17.006ZHOU Xiaoqin, DUAN Youshe, XUE Xiangchen. Application of manufacturing equipment for aircraft composites component[J]. Aeronautical Manufacturing Technology,2013(17):53-56(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.17.006 [15] GEORGE M. Composites lift off in primary areostructures[J]. Reinforced Plastics,2004,48(4):22-27. doi: 10.1016/S0034-3617(04)00193-6 [16] DAVIES L W, DAY R J, BOND D, et al. Effect of cure cycle heat transfer rates on the physical and mechanical properties of an epoxy matrix composite[J]. Composite Science and Technology,2007,67(9):1892-1899. doi: 10.1016/j.compscitech.2006.10.014 [17] KHOU L, HUBERT P. Cure shrinkage characterization of an epoxy resin system by two in situ measurement methods[J]. Polymer Composite,2010,31(9):1603-1610. doi: 10.1002/pc.20949 [18] LI S J, ZHAN L H, CHEN R, et al. The influence of curs pressure on microstructure temperature field and mechanical properties of advanced polymer-matrix composite laminates[J]. Fiber & Polymers,2014,15(11):2404-2409. [19] WANG X, XIE F, LI M, et al. Influence of core fillers on resin flow and fiber compaction of cocured skin-to-stiffener structures[J]. Polymer Composites,2010,31(8):1360-1368. [20] 梁宪珠, 薛向晨, 王永贵. 叠层滑移工艺制备L型、Π型、Z型、Ω型毛坯[C]. 第十六届全国复合材料学术年会, 2010.LIANG Xianzhu, XUE Xiangchen, Wang Yonggui, et al. Preparation of L-shaped, ∏-, Z-, Ω-shaped blanks by lamination slip process[C]. NCCM-16, 2010(in Chinese). [21] 王永贵, 梁宪珠, 薛向晨. 基于叠层滑移工艺的大长细比壁板长桁制造技术[C]. 复合材料: 创新与可持续发展(上册), 2010(2): 631-636.WANG Yonggui, LIANG Xianzhu, XUE Xiangchen. The panel stringer manufacture techniques with stack slippage[C]. Composite: Innovation and Sustainable Development(Previous), 2010(2): 631-636(in Chinese). [22] ASTM International. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M–08[S]. West Conshohocken, PA, 2008. [23] ASTM International. Standard test method for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture: ASTM D6641/D6641M–09[S]. West Conshohocken, PA, 2009. [24] ASTM International. Standard test method for flexural properties of polymer matrix composite materials: ASTM D7264/D7264M–07[S]. West Conshohocken, PA, 2007. [25] ASTM International. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344/D2344M–00(2006)[S]. West Conshohocken, PA, 2006. [26] ASTM International. Standard test method for open-hole compressive strength of polymer matrix composite laminates: ASTM D6484/D6484M-09[S]. West Conshohocken, PA, 2009. [27] ASTM International. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate: ASTM D3518/D3518M–94(2007)[S]. West Conshohocken, PA, 2007. -

下载:

下载: