Effect of silane coupling agent MPS on crosslinking structure and shear orientation ability of SiO2-polyacrylate composite particles

-

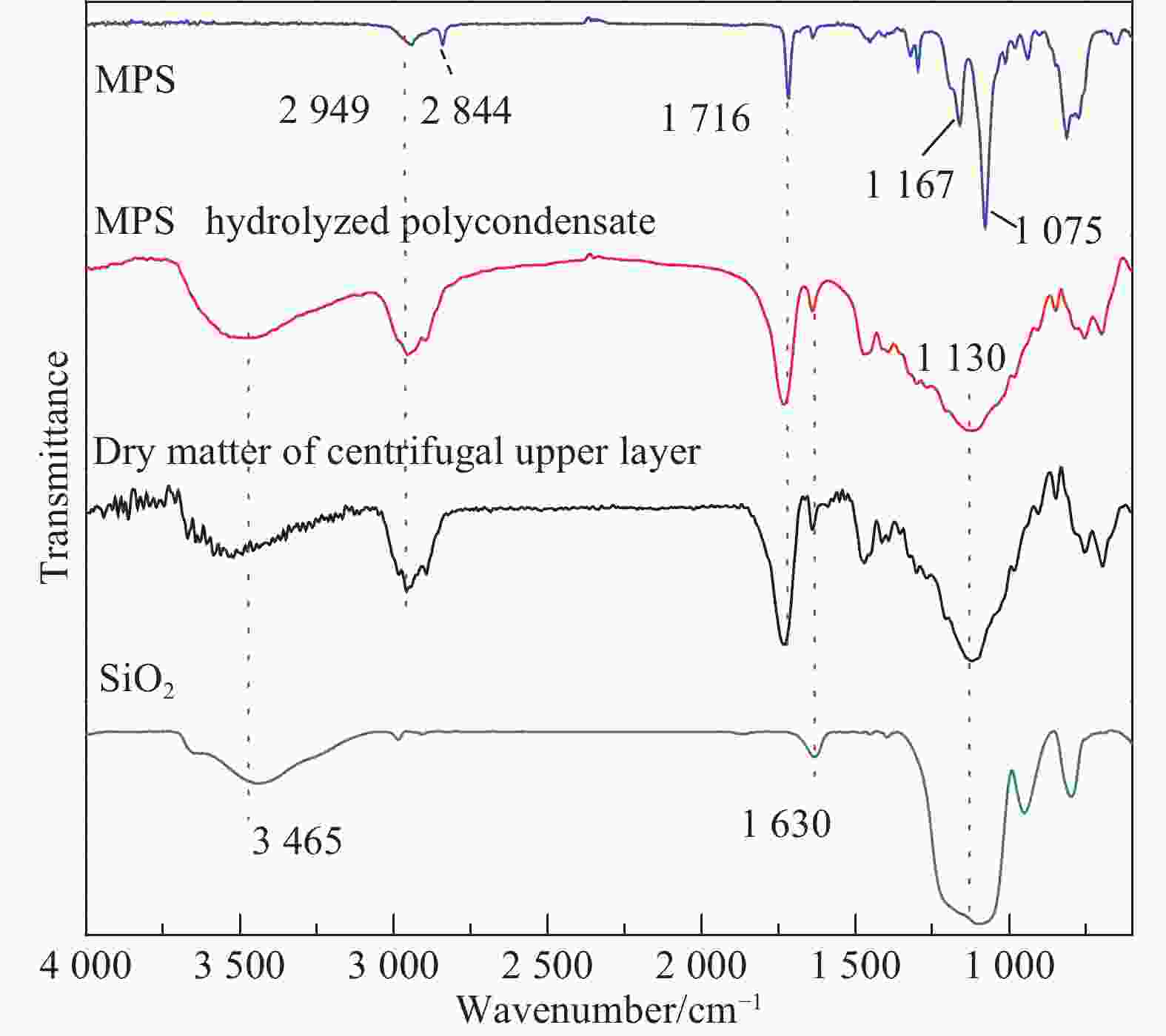

摘要: 为了探究γ-甲基丙烯酰氧基丙基三甲氧基硅烷(MPS)对SiO2-聚丙烯酸酯(PAcr)复合微球结构与性能的影响,在丙烯酸丁酯与甲基丙烯酸甲酯的自由基悬浮共聚合体系中加入MPS、MPS偶联改性的SiO2(MPS-SiO2)纳米粒子或MPS偶联改性SiO2纳米粒子的原始分散液,分别考察了非偶联MPS的量、偶联MPS的量、偶联与非偶联MPS的相对含量对SiO2-PAcr复合微球交联程度和交联结构的作用规律,并进一步对比了具有不同交联结构复合微球的剪切取向能力。通过TEM观察发现,非偶联MPS会水解自缩聚产生直径约6 nm的颗粒(即MPS水解颗粒),表面带有可聚合双键,能起到交联作用。MPS偶联改性SiO2纳米粒子原始分散液除含有MPS-SiO2纳米粒子外,还含有MPS水解颗粒,因而能构筑双重交联结构。具有这种双重交联结构的复合微球在HAAKE转矩流变仪中经熔融剪切可形成平均长径比高达12.0的取向体,而单独以MPS水解颗粒或MPS-SiO2纳米粒子为交联点的微球经相同的熔融剪切过程只能形成平均长径比分别为9.1和8.8的取向体。这表明,偶联和非偶联MPS所构造的两种不同尺度的交联结构对SiO2-PAcr复合微球剪切取向能力的提高有着显著的协同作用。

-

关键词:

- 复合微球 /

- γ-甲基丙烯酰氧基丙基三甲氧基硅烷 /

- 双重交联 /

- 剪切取向 /

- 协同作用

Abstract: In order to reveal the effect of γ-methacryloxypropyl trimethoxysilane (MPS) on the structure and property of SiO2-polyacrylate (PAcr) composite particles, MPS, MPS modified SiO2 (MPS-SiO2) nanoparticles, and the raw dispersions obtained from the modification of SiO2 nanoparticles with MPS were used as the additives in the radical suspension copolymerization of butyl acrylate and methyl methacrylate. The influence of the amount of coupled and uncoupled MPS and the ratio of coupled MPS to uncoupled MPS on the crosslinking degree and crosslinking structure of SiO2-PAcr composite particles was investigated, and the shear orientation abilities of the composite particles with different crosslinking structures were compared. TEM observation shows that some irregular particles with diameter at about 6 nm are formed by the hydrolytic condensation of uncoupled MPS (i.e. MPS condensed particles). The MPS condensed particles can act as the crosslinking points owing to the double bonds on their surface. By adding the raw dispersions from MPS modification of SiO2 nanoparticles, dual-crosslinking structure can be formed in the SiO2-PAcr composite particles because both coupled and uncoupled MPS are included in the polymerization system. The as-prepared dual-crosslinked particles can be deformed into the orientated structure with a high aspect ratio of 12.0 in HAAKE torque rheometer. However, the aspect ratio after the same shear orientation process can only reach 8.8 and 9.1 with coupled or uncoupled MPS as additives, respectively. The coupled and uncoupled MPS can lead to two different kinds of crosslinking structures, which improves the shear orientation ability of SiO2-PAcr composite particles synergistically. -

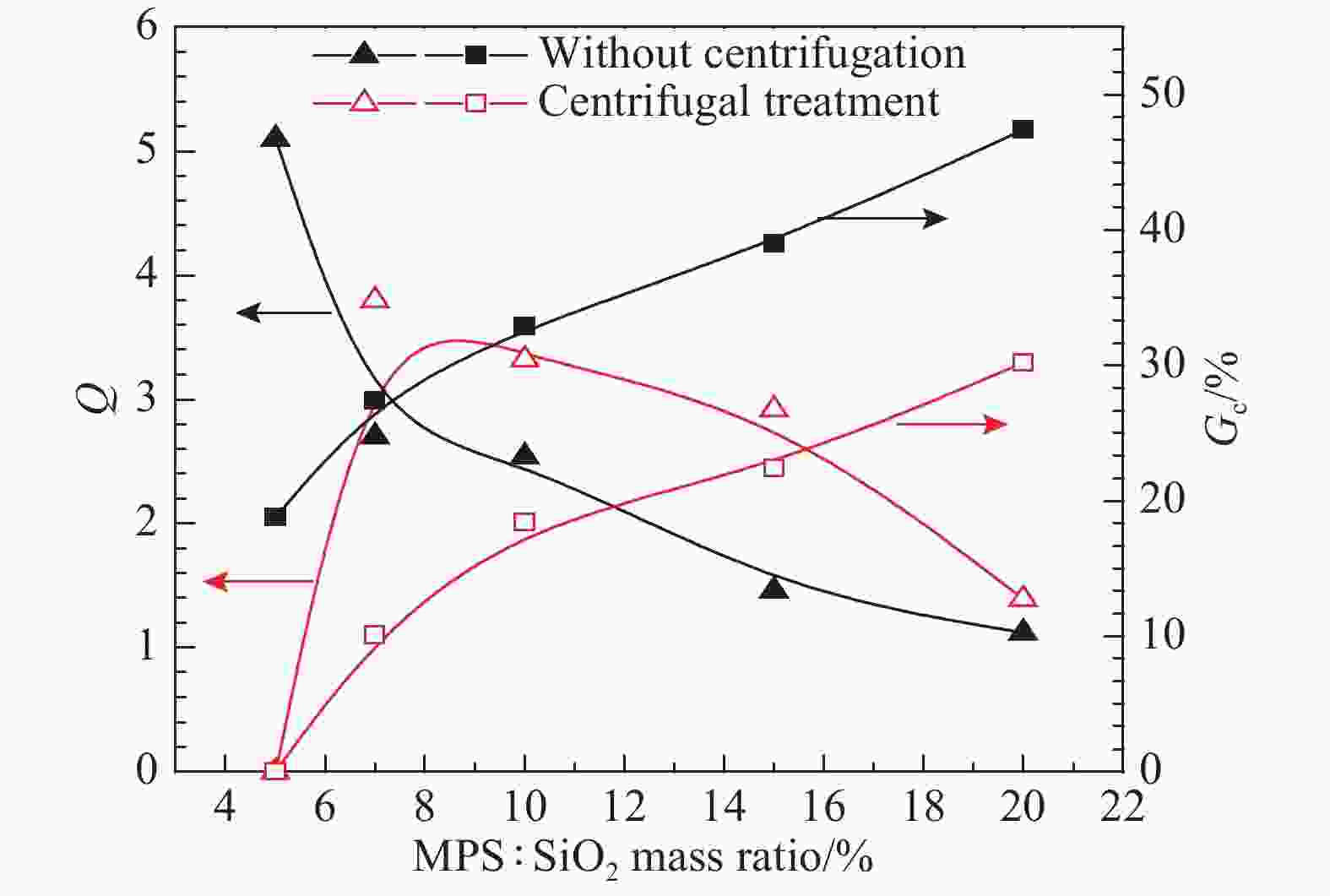

图 2 以γ-甲基丙烯酰氧基丙基三甲氧基硅烷(MPS)-SiO2纳米粒子或其未经离心的原始分散液为添加剂时,MPS用量(MPS与SiO2质量比)与复合微球凝胶率(Gc)、平衡溶胀比(Q)之间的关系(SiO2用量为4 g)

Figure 2. Effect of γ-methacryloxypropyl trimethoxysilane(MPS) content (MPS:SiO2 mass ratio) on gel rate (Gc) and equilibrium swelling ratio (Q) of composite particles prepared using MPS modified SiO2 nanoparticle or its raw dispersions as additive (mass of SiO2 is 4 g)

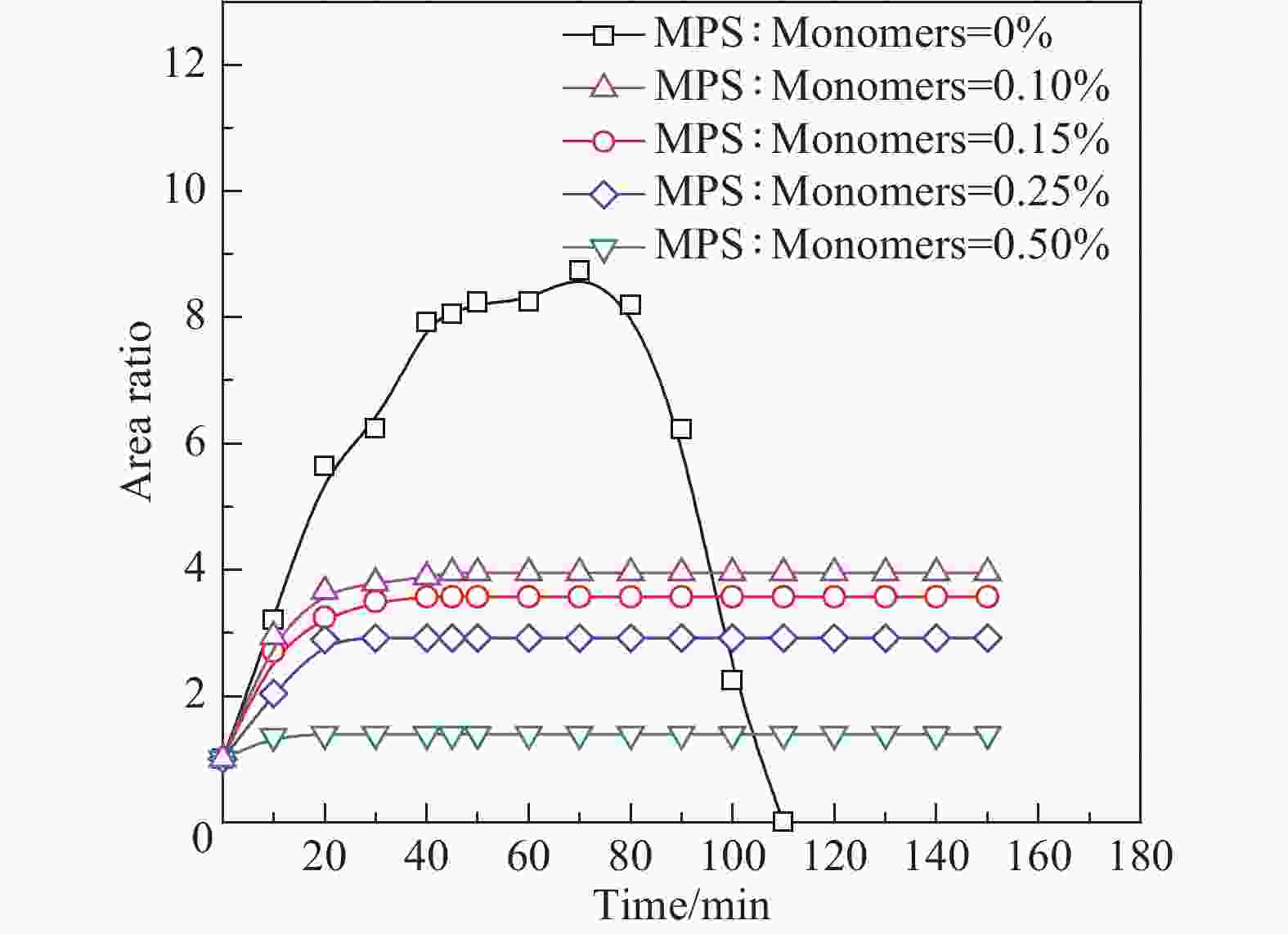

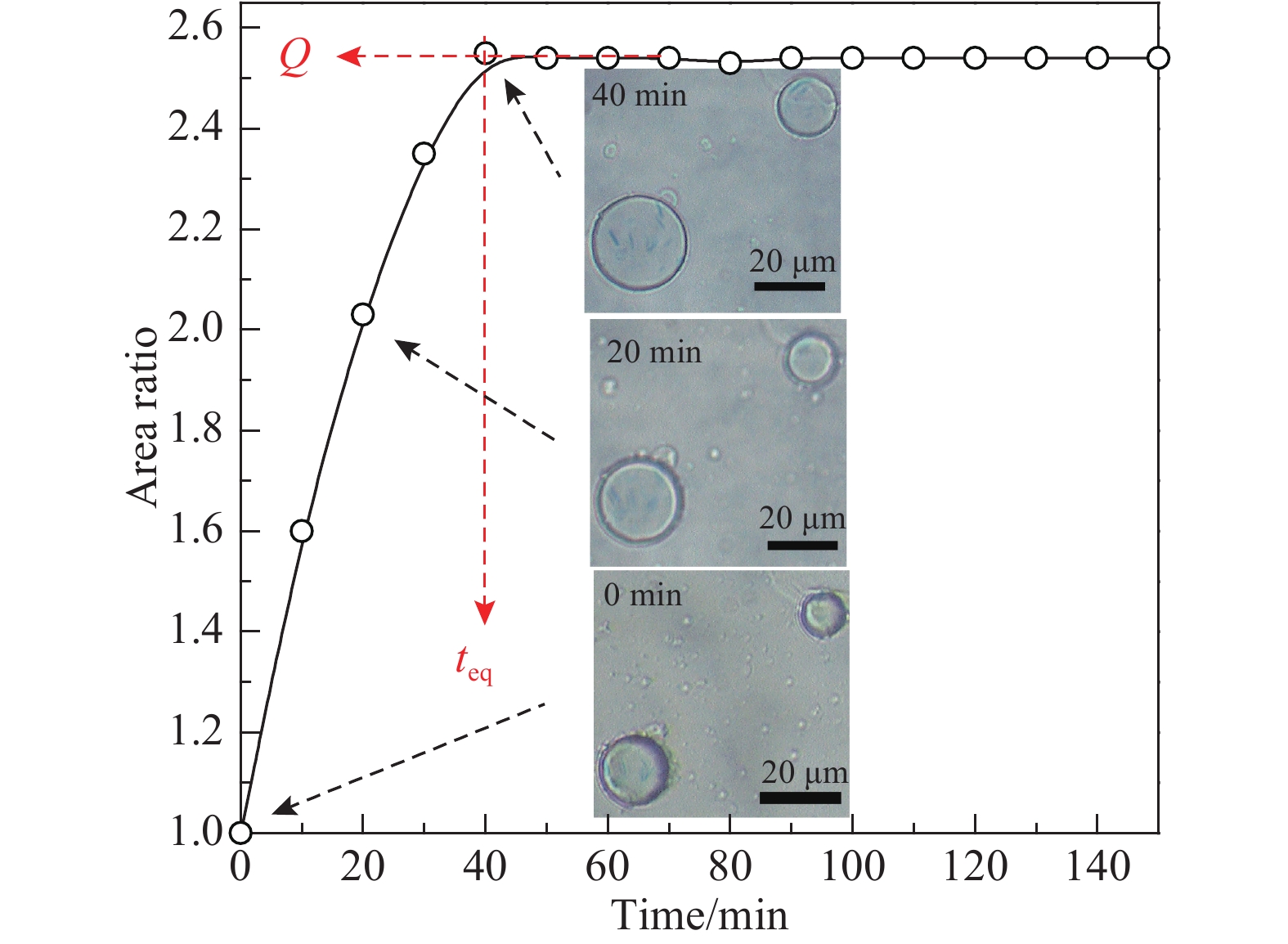

图 6 不同SiO2用量(SiO2与MMA和BA单体质量比) MPSuncoupled-SiO2-PAcr复合微球投影面积随溶胀时间变化曲线(MPS与单体的质量比为0.2%)

Figure 6. Time-dependent projection area ratio curves of MPSuncoupled-SiO2-PAcr composite particles prepared at different SiO2 contents (mass ratio of SiO2 to monomers of MMA and BA, MPS:Monomers mass ratio=0.2%)

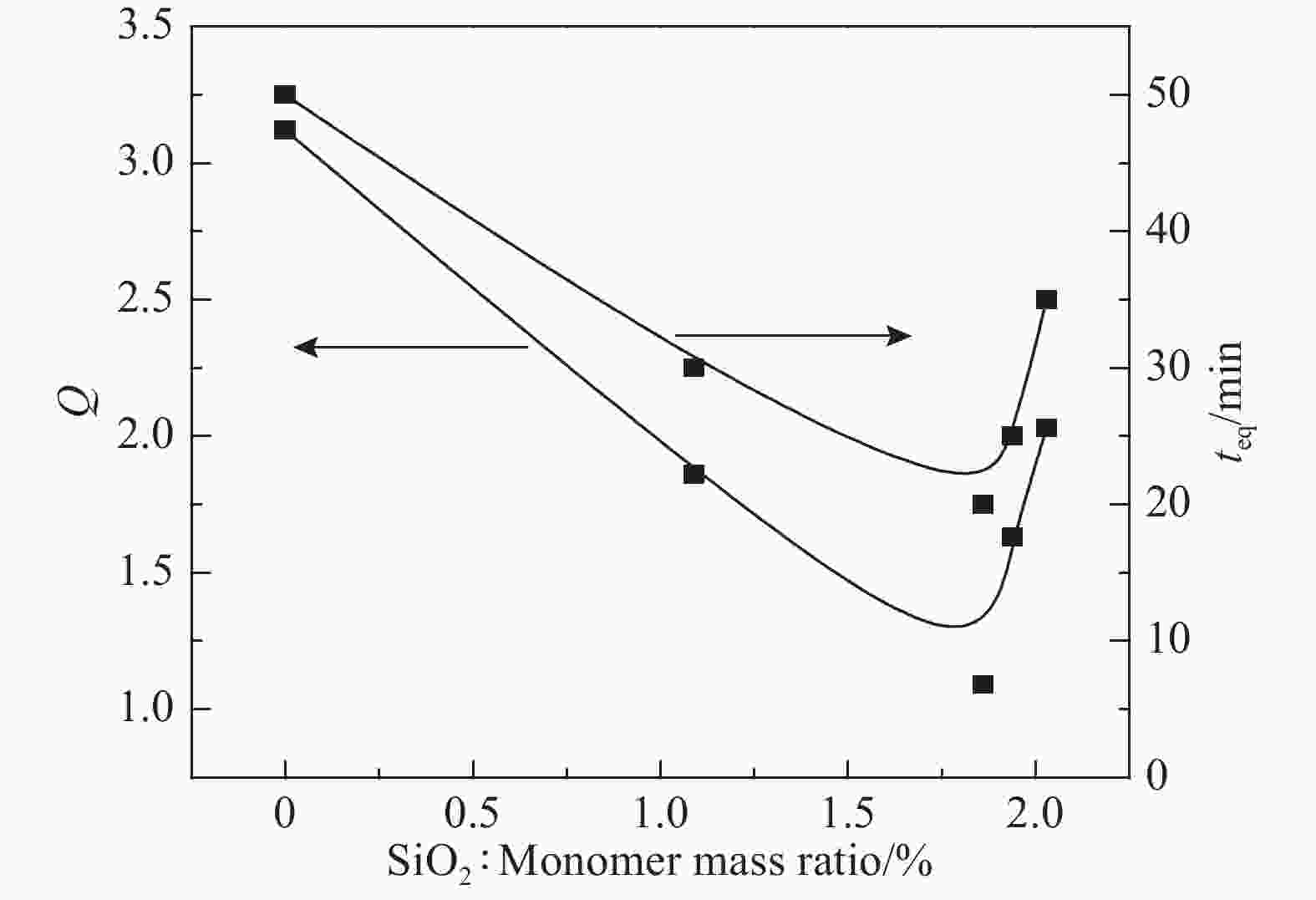

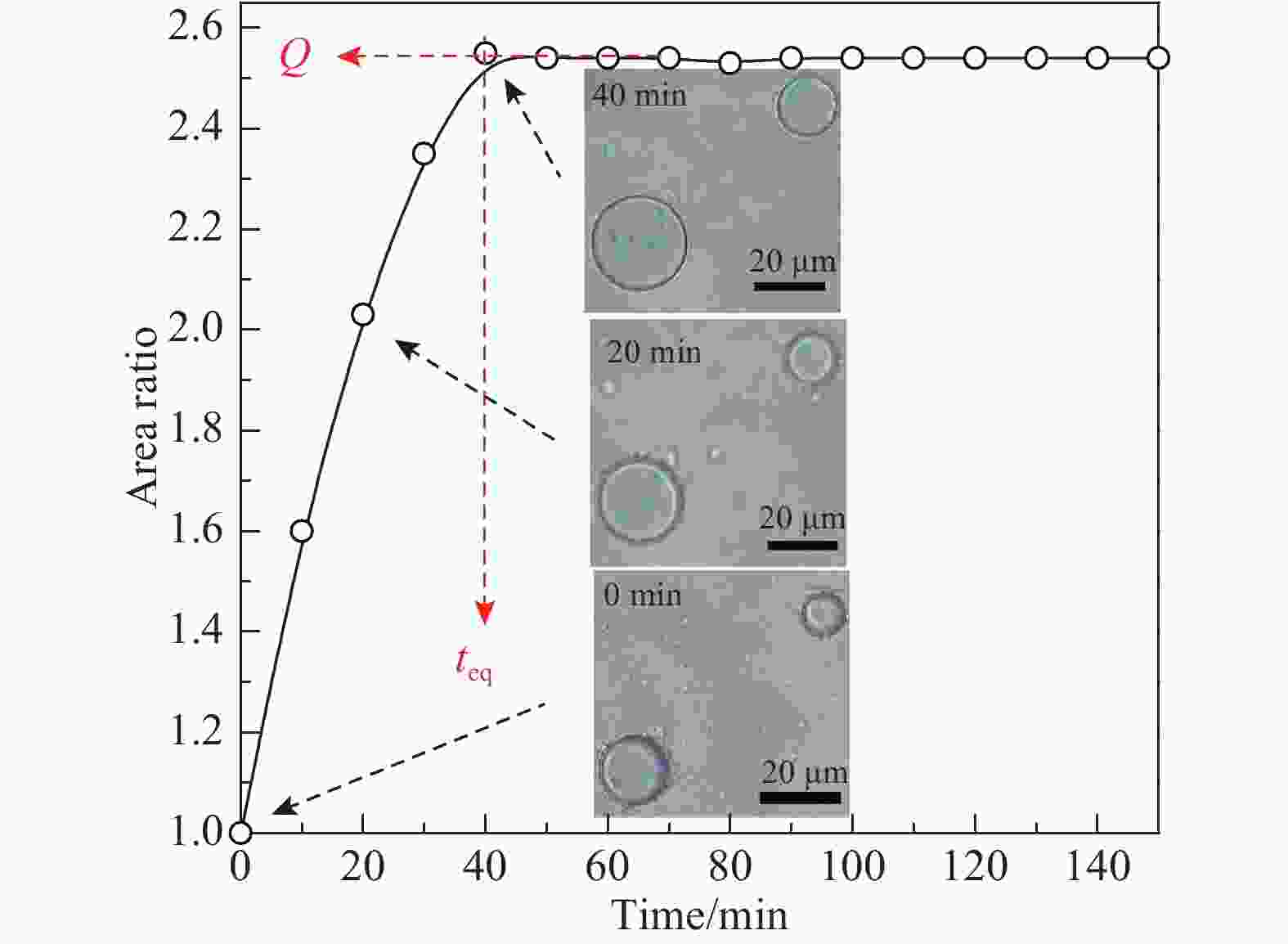

图 7 不同SiO2用量(SiO2与MMA和BA单体质量比) MPSuncoupled-SiO2-PAcr复合微球的平衡溶胀比(Q)与溶胀平衡时间(teq)(MPS与单体的质量比为0.2%)

Figure 7. Equilibrium swelling ratio (Q) and equilibrium swelling time (teq) of MPSuncoupled-SiO2-PAcr composite particles prepared at different SiO2 contents (mass ratio of SiO2 to monomers of MMA and BA, MPS : Monomers mass ratio=0.2%)

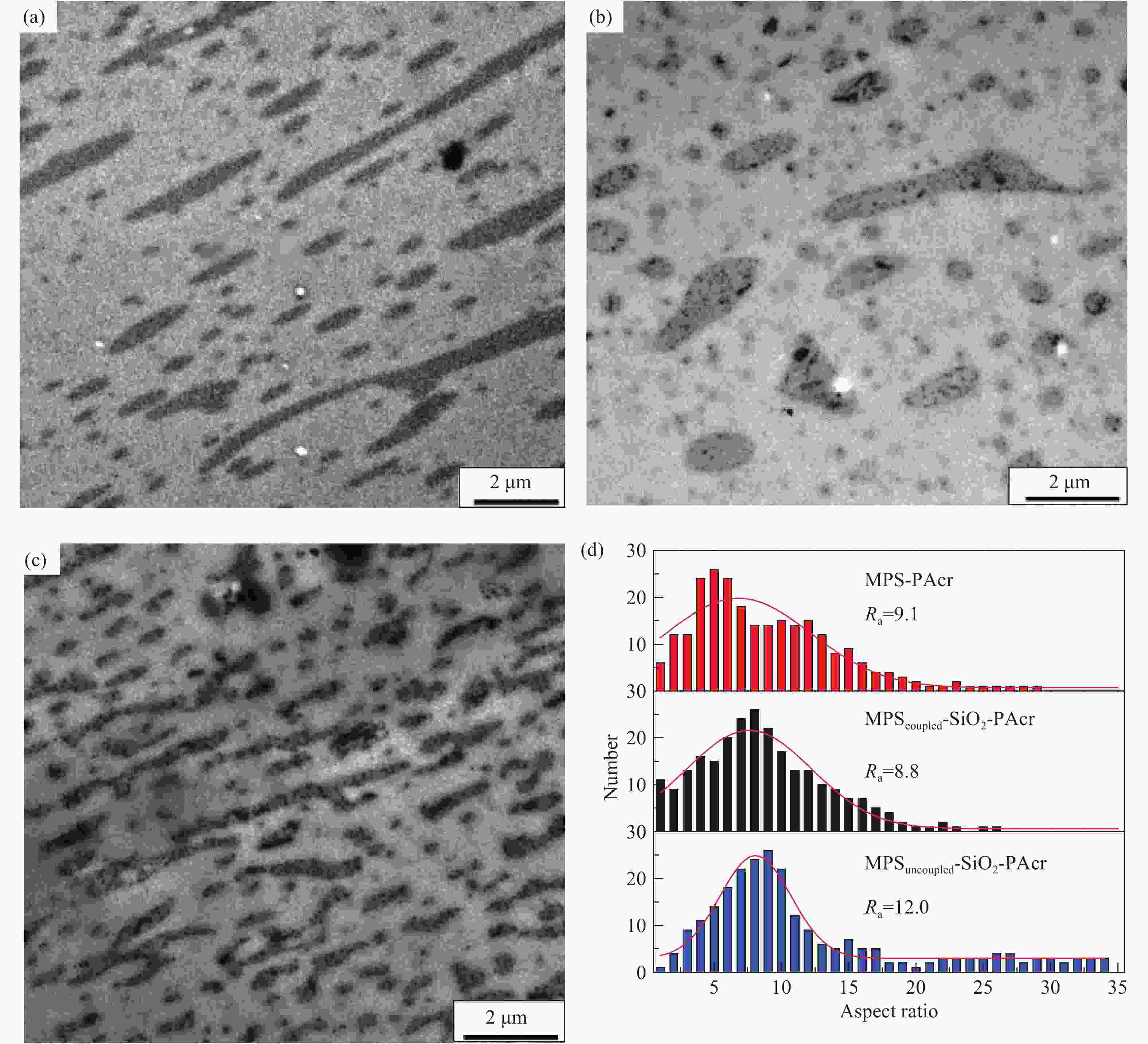

图 10 MPS-PAcr复合微球(a)、MPScoupled-SiO2-PAcr复合微球(b)、MPSuncoupled-SiO2-PAcr复合微球(c)与聚甲基丙烯酸甲酯(PMMA)在HAAKE转矩流变仪中熔融剪切共混产物切片的TEM图像及图中取向体的长径比统计结果(d)

Figure 10. TEM images of MPS-PAcr(a), MPScoupled-SiO2-PAcr(b) and MPSuncoupled-SiO2-PAcr(c) composite particles after shear orientation in polymethyl methacrylate(PMMA) matrix and aspect ratio distributions of MPS-PAcr, MPScoupled-SiO2-PAcr and MPSuncoupled-SiO2-PAcr(d)

表 1 制备SiO2-聚丙烯酸酯(PAcr)复合微球的基础配方(g)

Table 1. Basic recipe for the fabrication of SiO2- polyacrylate(PAcr) composite particles (g)

MMA BA BPO H2O Mg(OH)2 SDS NaNO2 40 40 1.5 200 8.7 0.075 0.15 Notes: MMA—Methyl methacrylate; BA—Butyl acrylate; BPO—Benzoyl peroxide; SDS—Sodium dodecyl sulfonate. -

[1] 成滨, 扈艳红, 邓诗峰, 等. 一种含腈基的硅烷偶联剂改性石英纤维/含硅芳炔复合材料[J]. 复合材料学报, 2019, 36(3):545-554.CHENG Bin, HU Yanhong, DENG Shifeng, et al. Interfacial modification of quartz fiber/silicon-containing aryla-cetylen composites using novel dicyanide-containing silane coupling agent[J]. Acta Materiae Compositae Sinica,2019,36(3):545-554(in Chinese). [2] HONG R Y, LI J H, CHEN L L, et al. Synthesis, surface modification and photocatalytic property of ZnO nanopar-ticles[J]. Powder Technology,2009,189(3):426-432. doi: 10.1016/j.powtec.2008.07.004 [3] LIU F D, WANG Z L, ZHOU Y J, et al. Preparation of hybrid composite microspheres containing nanosilicon via microsuspension polymerization[J]. Journal of Applied Pol-ymer Science,2016,133(12):43101. [4] CHANG Y, SU Z. Preparation and characterization of ther-mosensitive magnetic particles[J]. Materials Science & En-gineering A,2002,333(1):155-159. [5] 王绍辉, 徐曼, 罗潘, 等. 不同偶联剂对解控分子筛MCM-41的表面修饰及对MCM-41、环氧树脂性能的影响[J]. 复合材料学报, 2016, 33(2):249-258.WANG Shaohui, XU Man, LUO Pan, et al. Surface modification of different coupling agents on mesoporous molecular sieve MCM-41 and effects on properties of MCM-41/epoxy[J]. Acta Materiae Compositae Sinica,2016,33(2):249-258(in Chinese). [6] SHI N, GAO B J, YANG Q. Adsorption characteristics of bovine serum albumin on cationic grafted particles QPDMAEMA/SiO2 with brush structure[J]. Acta Physico-Chimica Sinica,2014,30(11):2168-2176. [7] HARAGUCHI K, FARNWORTH R, OHBAYASHI A A, et al. Compositional effects on mechanical properties of nano-composite hydrogels composed of poly (N, N-dimethylacrylamide) and clay[J]. Macromolecules,2003,36(15):5732-5741. doi: 10.1021/ma034366i [8] ZHAO J, MILANOVA M, WARMOESKERKEN M M C G, et al. Surface modification of TiO2 nanoparticles with silane coupling agents[J]. Colloids and Surfaces A: Physicochemi-cal and Engineering Aspects,2012,413:273-279. [9] 洪浩群, 刘灏, 张海燕. 甘蔗渣的改性方法对甘蔗渣/聚乳酸复合材料结构与性能的影响[J]. 复合材料学报, 2018, 35(9):2369-2378.HONG Haoqun, LIU Hao, ZHANG Haiyan. Effect of modifying method of bagasse on structure and properties of bagasse/polylactic acid composites[J]. Acta Materiae Com-positae Sinica,2018,35(9):2369-2378(in Chinese). [10] PANTOJA M, DÍAZ-BENITO B, VELASCO F, et al. Analysis of hydrolysis process of γ-methacryloxypropyltrimethoxysilane and its influence on the formation of silane coatings on 6063 aluminum alloy[J]. Applied Surface Science,2009,255(12):6386-6390. doi: 10.1016/j.apsusc.2009.02.022 [11] SALON M C B, GERBAUD G, ABDELMOULEH M, et al. Studies of interactions between silane coupling agents and cellulose fibers with liquid and solid-state NMR[J]. Magnetic Resonance in Chemistry,2007,45(6):473-483. doi: 10.1002/mrc.1994 [12] SALON M C, ABDELMOULEH M, BOUFI S, et al. Silane adsorption onto cellulose fibers: Hydrolysis and condensation reactions[J]. Journal of Colloid & Interface Science,2005,289(1):249-261. [13] XIE Y, HILL C A S, XIAO Z, et al. Silane coupling agents used for natural fiber/polymer composites: A review[J]. Composites Part A: Applied Science and Manufacturing,2010,41(7):806-819. doi: 10.1016/j.compositesa.2010.03.005 [14] 王振. 剪切流动场中PAcr/MPS-SiO2复合微球取向结构的形成规律[D]. 杭州: 浙江理工大学, 2017: 26.WANG Zhen. Oriented structure formation of PAcr/MPS-SiO2 composite particle in shear flow field[D]. Hangzhou: Zhejiang Sci-Tech University, 2017: 26(in Chinese). [15] YANG Z K, WANF Z L, MAO Z M, et al. Innovative one-step synthesis of hollow polymer particles by microsuspension polymerization of styrene and methyl acrylate with Mg(OH)2 as dispersant[J]. Colloid and Polymer Science,2017,295(4):565-572. doi: 10.1007/s00396-017-4045-5 [16] QI D M, LIU C H, CHEN Z J, et al. In situ emulsion co-polymerization of methyl methacrylate and butyl acrylate in the presence of SiO2, with various surface coupling densities[J]. Colloid & Polymer Science,2015,293(2):463-471. [17] 王彦, 夏琳, 董月, 等. 发泡CaCO3/杜仲胶形状记忆复合材料的制备与表征[J]. 复合材料学报, 2018, 35(8):1994-2001.WANG Yan, XIA Lin, DONG Yue, et al. Preparation and characterization of foamed CaCO3/eucommia ulmoides gum shape memory composites[J]. Acta Materiae Compositae Sinica,2018,35(8):1994-2001(in Chinese). [18] LEE C K, DEISENDRUCK C E, LU E, et al. Solvent swelling activation of a mechanophore in a polymer network[J]. Macromolecules,2014,47(8):2690-2694. doi: 10.1021/ma500195h [19] 邵建中, 袁艳, 戚栋明, 等. 高分散性SiO2/PMMA复合材料的制备与表征—纳米SiO2在MMA中的分散[J]. 高分子学报, 2011(7):745-751.SHAO Jianzhong, YUAN Yan, QI Dongming, et al. Preparation and characterization of silica/PMMA composites with highly dispersed silica nanoparticles: Dispersion of nanosilica in MMA[J]. Acta Polymerica Sinica,2011(7):745-751(in Chinese). [20] 曾重, 刘文芳, 郭朝霞, 等. PS/SiO2纳米复合粒子的制备及反应机理研究[J]. 高等学校化学学报, 2005, 26(4):760-764. doi: 10.3321/j.issn:0251-0790.2005.04.030ZENG Zhong, LIU Wenfang, GUO Zhaoxia, et al. Preparation and reaction mechanism of PS/SiO2 composite nanoparticles[J]. Chemical Journal of Chinese Universities,2005,26(4):760-764(in Chinese). doi: 10.3321/j.issn:0251-0790.2005.04.030 [21] 雷中秋, 汪继承, 戚栋明, 等. 聚丙烯酸酯-纳米SiO2接枝复合胶粒在熔融剪切场中的取向重排[J]. 复合材料学报, 2019, 36(4):972-981.LEI Zhongqiu, WANG Jicheng, QI Dongming, et al. Orientation rearrangement of polyacrylate-nano SiO2 grafted composite particles in melt shear field[J]. Acta Materiae Compositae Sinica,2019,36(4):972-981(in Chinese). [22] XIE L, XU H, LI Z M, et al. Unprecedented Access to strong and ductile poly(lactic acid) by introducing in situ nanofibrillar poly(butylene succinate) for green packaging[J]. Biomacromolecules,2014,15(11):4054-4064. doi: 10.1021/bm5010993 [23] 戚栋明, 袁艳, 张睿, 等. 高分散性SiO2/PMMA复合材料的制备与表征: 接枝与交联[J]. 高分子学报, 2011(11):1258-1265.QI Dongming, YUAN Yan, ZHANG Rui, et al. Preparation and characterization of silica composites with highly dispersed silica-grafting and crosslinking[J]. Acta Polymerica Sinica,2011(11):1258-1265(in Chinese). [24] 王振, 雷中秋, 戚栋明, 等. 微悬浮聚合法制备的PA/MPS-SiO2接枝复合胶粒的溶胀性能研究[J]. 浙江理工大学学报, 2017, 37(4):480-484.WANG Zhen, LEI Zhongqiu, QI Dongming, et al. Swelling property of PA/MPS-SiO2 composite colloidal particles prepared by micro-suspension polymerization[J]. Journal of Zhejiang Sci-Tech University,2017,37(4):480-484(in Chinese). [25] LI H, ZHOU S X, YOU B, et al. Morphology evolution of poly(St-co-BuA)/silica nanocomposite particles synthesized by emulsion polymerization[J]. Chinese Journal of Polymer Science,2006,24(3):323-331. doi: 10.1142/S0256767906001357 [26] QI D M, LIU C H, CHEN Z J, et al. Formation mechanism of guava-like polymer/SiO2 nanocomposite particles in insitu emulsion polymerization systems[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2016,489:265-274. [27] YAO J, CAO Z H, QI D M, et al. Preparation of polymer-ic/inorganic nanocomposite particles in miniemulsions II: Narrowly size-distributed polymer/SiO2 nanocomposite particles[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2017,530:104-116. doi: 10.1016/j.colsurfa.2017.07.047 [28] BOURGEATLAMI E, FARZI G A, DAVID L, et al. Silica encapsulation by miniemulsion polymerization: Distribution and localization of the silica particles in droplets and latex particles[J]. Langmuir,2012,28(14):6021-6031. doi: 10.1021/la300587b -

下载:

下载: