Preparation of polyacrylonitrile/polyvinylidene fluoride composite fiber membrane by electrospinning and its air filtration performance

-

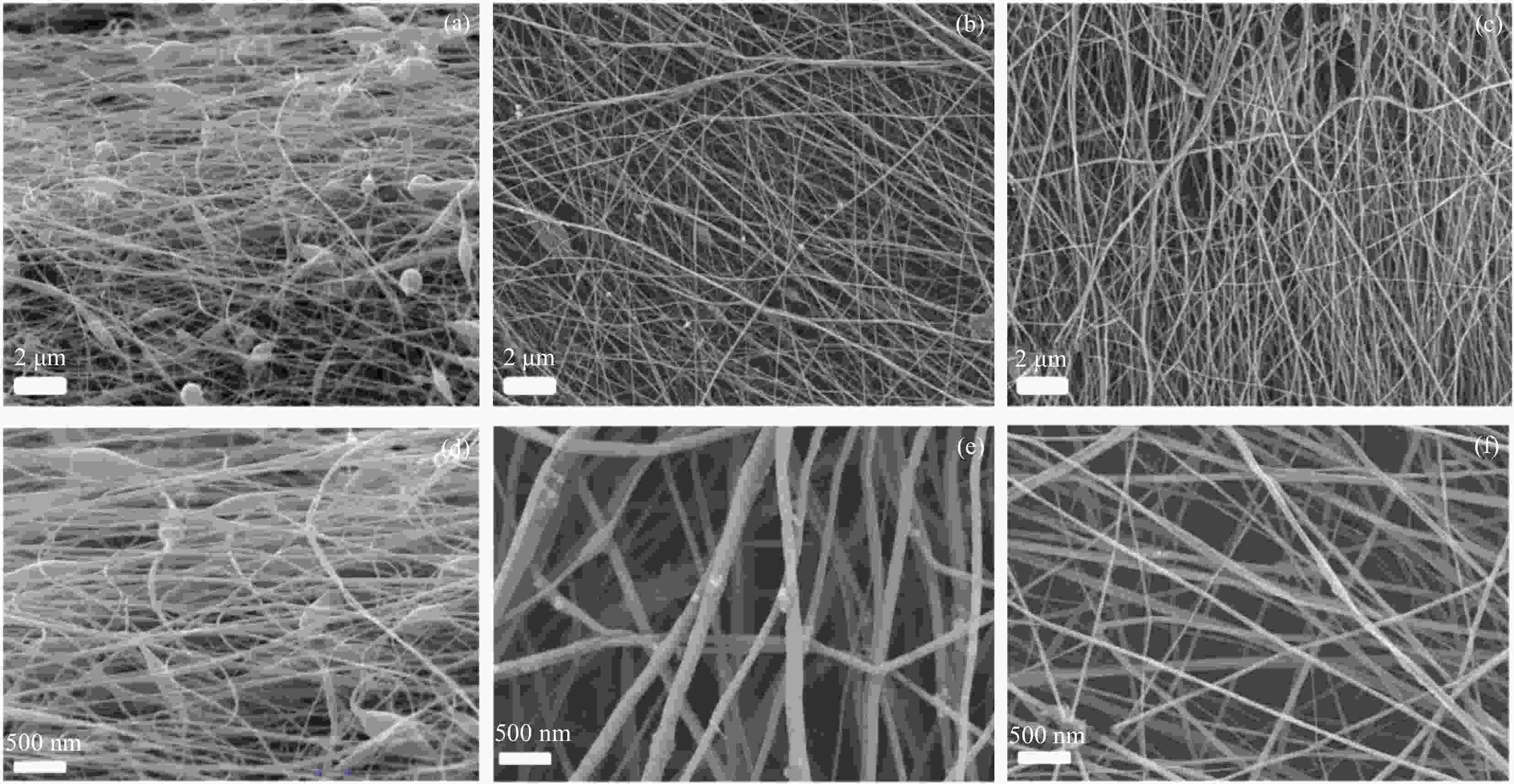

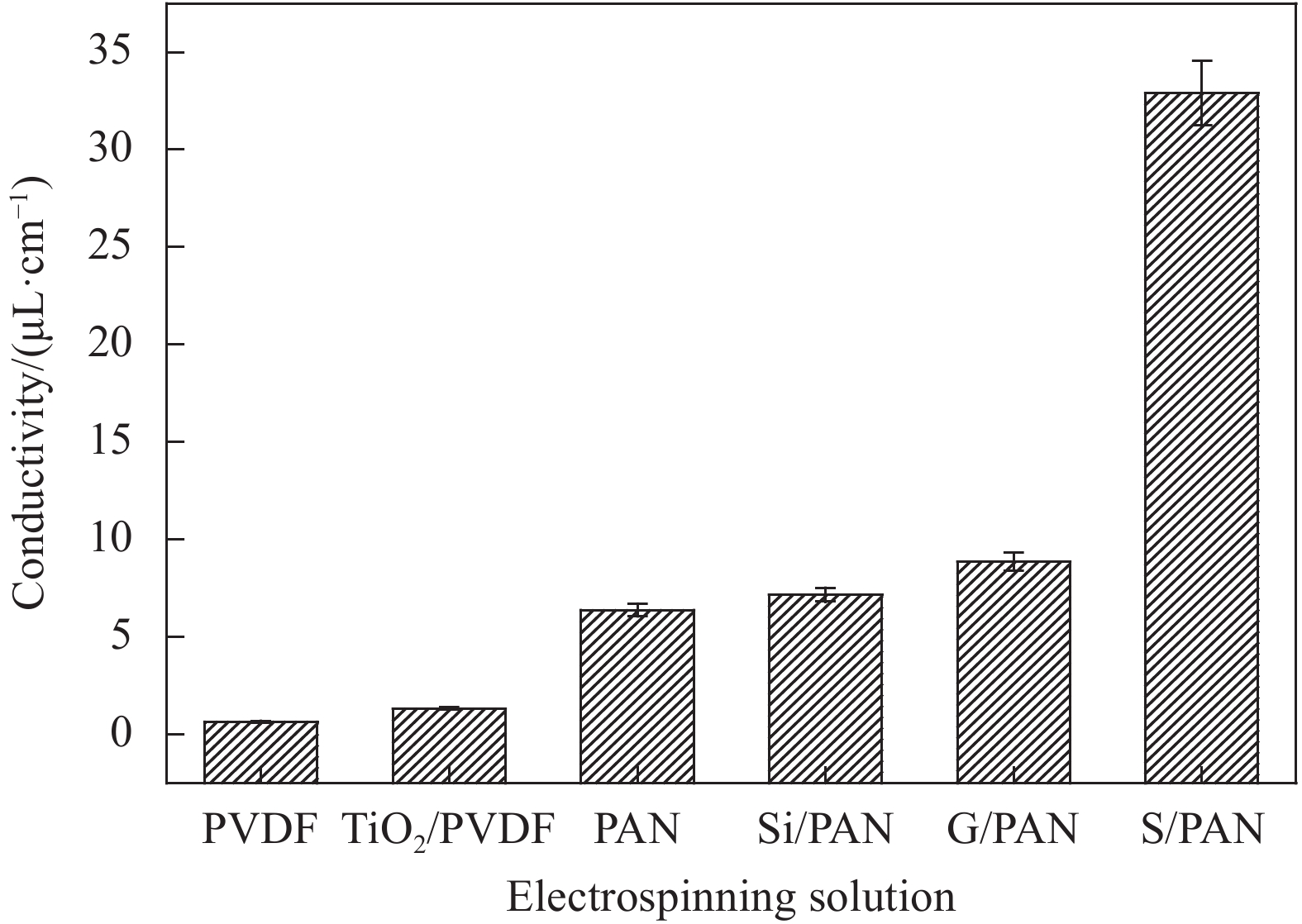

摘要: 以聚偏氟乙烯(PVDF)为芯层,聚丙烯腈(PAN)为皮层,通过同轴法静电纺丝技术制备PAN/PVDF纳米复合纤维膜。通过向纤维膜的皮层中加入纳米硅粉、气相白炭黑、硅溶胶三种不同的纳米粒子和改变皮芯层溶液挤出速度对PAN/PVDF纳米纤维膜进行结构优化。同时,采用BET、SEM、水接触角、纤维强度仪等对纤维膜的孔结构参数、表面形貌、亲水性、力学性能等进行研究。结果表明:在皮层中加入硅溶胶后的溶液导电能力达到32.90 μL/cm,PAN/PVDF纤维膜力学性能最好,纵向断裂强度达到13.02 MPa。含有硅溶胶的口罩布的品质因子达到0.0236,远大于纯聚丙烯(PP)无纺布的品质因子(0.0127),过滤性显著提高。Abstract: The polyacrylonitrile/polyvinylidene fluoride (PAN/PVDF) nanocomposite fiber membranes were prepared by the coaxial electrospinning technology using PVDF as the core layer and PAN as the skin layer. Structure optimization of PAN/PVDF nanocomposite fiber membrane was carried out by adding three different nanoparticles of nano-silica powder, fumed silica and silica sol to the PAN/PVDF nanocomposite fiber membrane and changing the extrusion speed of the skin-core layer solution. Meanwhile, its pore structure parameters, surface morphology, hydrophilicity and mechanical properties were studied by BET, SEM, water contact angle, fiber strength meter and so on. The results show that the conductivity of the solution after adding silica sol to the solution reaches 32.90 μL/cm, the PAN/PVDF nanocomposite fiber membrane has the best mechanical properties, and the longitudinal breaking strength reaches 13.02 MPa. The quality factor of mask cloth containing silica sol reaches 0.0236, which is much larger than the quality factor of pure polypropylene (PP) non-woven, which is 0.0127, and the filterability is significantly increased.

-

Key words:

- coaxial electrospinning /

- nanoparticles /

- filter performance /

- silica sol /

- fiber membrane

-

表 1 静电纺不同纤维膜时对应的皮层溶液和芯层溶液的组成及推进速度

Table 1. Composition and advancing speed of skin layer solution and core layer solution when preparing different fiber membranes by electrospinning

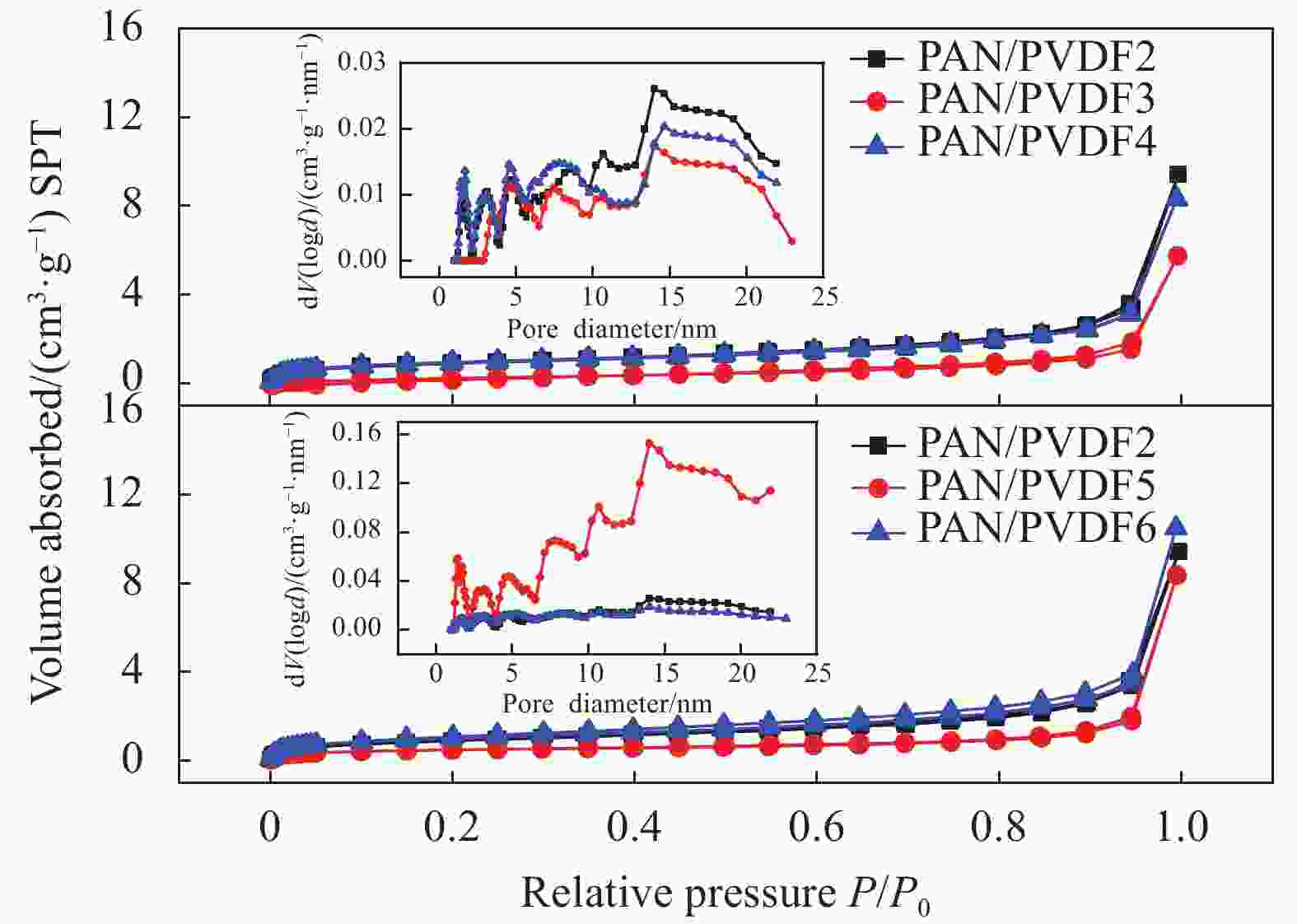

Serial number Cortical speed/(mL·h−1) Core speed/(mL·h−1) Cortical solution Core solution PAN/PVDF1 0.6 0.6 PAN PVDF PAN/PVDF2 0.6 0.6 Si/PAN TiO2/PVDF PAN/PVDF3 0.4 0.8 Si/PAN TiO2/PVDF PAN/PVDF4 0.8 0.4 Si/PAN TiO2/PVDF PAN/PVDF5 0.6 0.6 G/PAN TiO2/PVDF PAN/PVDF6 0.6 0.6 S/PAN TiO2/PVDF Notes: PAN—Polyacrylonitrile; PVDF—Polyvinylidene fluoride; Si—Nano-silica powder; G—Fumed silica; S—Silica sol; The unit of cortical speed and core speed is mL/h. 表 2 PAN/PVDF复合纤维膜的纤维膜孔结构参数

Table 2. Pore structure parameters of PAN/PVDF composite fiber membranes

Serial number SBET/(m2·g−1) Smic/(m2·g−1) Sext/(m2·g−1) Sext/SBET/% Vtotal/(cm3·g−1) PAN/PVDF1 3.453 0 3.453 100.00 6.982×10−3 PAN/PVDF2 8.802 0.092 8.711 98.97 3.938×10−2 PAN/PVDF3 3.764 0 3.764 100.00 2.846×10−2 PAN/PVDF4 10.354 1.886 8.468 81.78 4.025×10−2 PAN/PVDF5 46.749 18.715 28.034 59.97 3.432×10−1 PAN/PVDF6 8.523 1.597 6.926 81.26 3.760×10−2 Notes: SBET—Specific surface area of fiber membrane; Smic—Micropore specific surface area; Sext—External pore surface area; Sextt/SBET—Percentage of external pores in overall surface area; Vtotal—Total pore volume of fiber membrane. 表 3 PAN/PVDF复合纤维膜的断裂强度和断裂伸长率

Table 3. Breaking strength and elongation at break of PAN/PVDF composite fiber membranes

Serial number Longitudinal breaking strength/MPa Longitudinal elongation at break/% Transverse breaking strength/MPa Transverse elongation at break/% PAN/PVDF1 6.19±0.30 161.50±8.08 2.33±0.12 218.41±10.22 PAN/PVDF2 8.25±0.41 304.30±15.29 5.90±0.28 401.70±14.23 PAN/PVDF3 4.31±0.22 88.30±4.42 2.43±0.14 136.99±9.38 PAN/PVDF4 14.01±0.65 424.30±17.87 8.60±0.36 390.20±19.84 PAN/PVDF5 7.20±0.36 186.16±9.76 3.56±0.16 131.68±12.34 PAN/PVDF6 13.02±0.56 222.69±10.14 10.83±0.54 190.20±14.56 表 4 PAN/PVDF-PP和PP口罩布的过滤性能

Table 4. Filtration performance of PAN/PVDF-PP and PP non-woven fabric

Serial number Filtration resistance/mm H2O Filtration efficiency/% Quality factor PP 3.3 4.10 0.0127 PAN/PVDF-PP1 151.5 93.28 0.0178 PAN/PVDF-PP2 223.8 97.36 0.0162 PAN/PVDF-PP3 132.6 95.68 0.0236 -

[1] FISHER J E, LOFT S, ULRIK C S, et al. Physical activity, air pollution, and the risk of asthma and chronic obstructive pulmonary disease[J]. American Journal of Respiratory and Critical Care Medicine,2016,194(7):855-865. doi: 10.1164/rccm.201510-2036OC [2] BARHATE R S, RAMAKRISHNA S. Nano fibrous filtering media: Filtration problems and solution from tiny materials[J]. Journal of Membrane Science,2007,296(1):1-8. [3] ZHANG S, LIU H, YIN X, et al. Anti-deformed polyacrylonitrile/polysulfone composite membrane with binary structures for effective air filtration[J]. ACS Applied Materials & Interfaces,2016,8(12):8086-8095. [4] 于翔, 张雪寅, 李如洋, 等. TiO2/静电纺PAN基碳复合材料的制备及光催化性能[J]. 复合材料学报, 2020, 37(12):3177-3183.YU Xiang, ZHANG Xueyin, LI Ruyang, et al. Preparation and photocatalytic propreties of TiO2/electrospinning PAN-based carbon composite material[J]. Acta Materiae Compositae Sinica,2020,37(12):3177-3183(in Chinese). [5] 琚艳云, 陆志伟, 柳扬, 等. 纳米Ag-聚乙烯醇缩丁醛静电纺丝复合纳米纤维的制备及性能[J]. 复合材料学报, 2018, 35(2):418-425.JU Yanyun, LU Zhiwei, LIU Yang, et al. Preparation and characterization of nano Ag-polyvinyl butyral eletrospun composite nanofibers[J]. Acta Materiae Compositae Sinica,2018,35(2):418-425(in Chinese). [6] 魏楚, 钱晓明, 钱幺, 等. 空气过滤用微纳米聚丙烯腈/皮芯型聚乙烯-聚丙烯双组分纤维多层复合材料的制备与性能[J]. 复合材料学报, 2020, 37(7):1513-1521.WEI Chu, QIAN Xiaoming, QIAN Yao, et al. Preparation and properties of micro-nano polyacrylonitrile/sheath-core polyethylene-polypropylene bicomponent fiber multilayer composite filters[J]. Acta Materiae Compositae Sinica,2020,37(7):1513-1521(in Chinese). [7] WANG N, YANG Y, AL-DEYAB S S, et al. Ultra-light 3D nanofibre-nets binary structured nylon 6-polyacrylonitrile membranes for efficient filtration of fine particulate matter[J]. Journal of Materials Chemistry A,2015,3(47):23946-23954. doi: 10.1039/C5TA06543G [8] DING B, LI C, MIYAUCHI Y, et al. Formation of novel 2D polymer nanowebs via electrospinning[J]. Nanotechnology,2006,17(15):3685. doi: 10.1088/0957-4484/17/15/011 [9] WANG C, OTANI Y. Removal of nanoparticles from gas streams by fibrous filters: A review[J]. Industrial & Engineering Chemistry Research,2012,52(1):5-17. [10] SAMBAER W, ZATLOUKAL M, KIMMER D. 3D modeling of filtration process via polyurethane nanofiber based nonwoven filters prepared by electrospinning process[J]. Chemical Engineering Science,2011,66(4):613-623. doi: 10.1016/j.ces.2010.10.035 [11] 王群旺, 雄杰, 张红萍, 等. PBS-SF核壳结构复合超细纤维膜的制备及性能[J]. 复合材料学报, 2011, 28(2):88-93.WANG Qunwang, XIONG Jie, ZHANG Hongping, et al. Preparation and properties of PBS-SF core-shell composite ultrafine fibrous membranes by coaxial electrospinning[J]. Acta Materiae Compositae Sinica,2011,28(2):88-93(in Chinese). [12] 赵兴雷. 空气过滤用高效低阻纳米纤维材料的结构调控及构效关系研究[D]. 上海: 东华大学, 2017.ZHAO Xinglei. Research on the structure regulation and structure-activity relationship of high-efficiency and low-resistance nanofiber materials for air filtration[D]. Shanghai: Donghua University, 2017(in Chinese). [13] WANG N, SI Y, WANG N, et al. Multilevel structured polyacrylonitrile/silica nanofibrous membranes for high-performance air filtration[J]. Separation and Purification Technology,2014,126:44-51. doi: 10.1016/j.seppur.2014.02.017 [14] CHO D, NAYDICH A, FREY M W, et al. Further improvement of air filtration efficiency of cellulose filters coated with nanofibers via inclusion of electrostatically active nanoparticles[J]. Polymer,2013,54(9):2364-2372. doi: 10.1016/j.polymer.2013.02.034 [15] ESSALHI M, KHAYET M. Self-Sustained webs of polyvinylidene fluoride electrospun nano-fibers: Effects of polymer concentration and desalination by direct contact membrane distillation[J]. Journal of Membrane Science, 2014, 454: 133-143. [16] LALIA B S, GUILLEN E, ARAFAT H A, et al. Nanocrystalline cellulose reinforced PVDF-HFP membranes for membrane distillation application[J]. Desalination, 2014, 332(1): 134-141. [17] DONG Z Q, MA X H, XU Z L, et al. Super hydrophobic PVDF-PTFE electro spun nano-fibrous membranes for desalination by vacuum membrane distillation[J]. Desalination,2014,347:175-183. doi: 10.1016/j.desal.2014.05.015 [18] 王利娜, 娄辉清, 辛长征, 等. 空气过滤用电纺聚偏氟乙烯-聚丙烯腈/熔喷聚丙烯无纺布复合材料的制备及过滤性能[J]. 复合材料学报, 2019, 36(2):277-282.WANG Lina, LOU Huiqing, XIN Changzheng, et al. Preparation and filtration properties of electrospun poly(vinylidene fouoride)-polyacrylonitrile/melt-bolw polypropylene nonwoven composite filtration materials[J]. Acta Materiae Compositae Sinica,2019,36(2):277-282(in Chinese). [19] WANG Z, PAN Z J. Preparation of hierarchial structured nano-sized/porous poly(lactic acid) composite fibrous membranes for air filtration[J]. Applied Surface Science,2015,356:1168-1179. doi: 10.1016/j.apsusc.2015.08.211 [20] 林松柏. 有机树脂/二氧化硅杂化高吸水性材料的研究[D]. 天津: 天津大学, 2004.LIN Songbai. Research on organic resin/silica hybrid super absorbent material[D]. Tianjin: Tianjin University, 2004(in Chinese). [21] 邢若飞. 多级孔石墨烯材料的构筑及性能研究[D]. 青岛: 青岛科技大学, 2019.XIN Ruofei. Research on the construction and performance of hierarchical graphene materials[D]. Qingdao: Qingdao University of Science and Technology, 2019(in Chinese). [22] MIT-UPPATHAM C, NITHITANAKUL M, SUPAPHOL P. Ultrafine electrospun ployamide-6 fibers: Effect of solution condition on morphology and average fiber diameter[J]. Macromolecular Chemistry and Physics,2004,205(17):2327-2338. doi: 10.1002/macp.200400225 [23] LI D, XIA Y N. Electrospinning of nanofibers: Reinventing the wheel[J]. Advanced Materials,2004,16(14):1151-1170. doi: 10.1002/adma.200400719 [24] BAUMGARTEN P K. Electrostatic spinning of acrylic microfibers[J]. Journal of Colloid and Interface Science,1971,36(1):71-79. doi: 10.1016/0021-9797(71)90241-4 [25] ZHANG C, YUAN X, WU L, et al. Study on morphology of electrospun poly(vinyl alcohol) mats[J]. European Polymer Journal,2005,41(3):423-432. doi: 10.1016/j.eurpolymj.2004.10.027 [26] JUN Z, HOU H Q, SCHAPER A, et al. Ploy-L-lactide nanofibers by electrospinning: Influence of solution viscosity and electrical conductivity on fiber diameter and fiber morphology[J]. E-Polymers,2003,3(1):009. [27] GAO H C, YANG Y Q, AKAMPUMUZA O, et al. A low filtration resistance there-dimensional composite membrane fabricated via free surface electrospinning for effective PM2.5 capture[J]. Environmental Science: Nano,2017,4(4):864-875. doi: 10.1039/C6EN00696E -

下载:

下载: