Experiment on axial compression performance of glass fiber reinforced polymer-walled concrete-filled steel tube columns

-

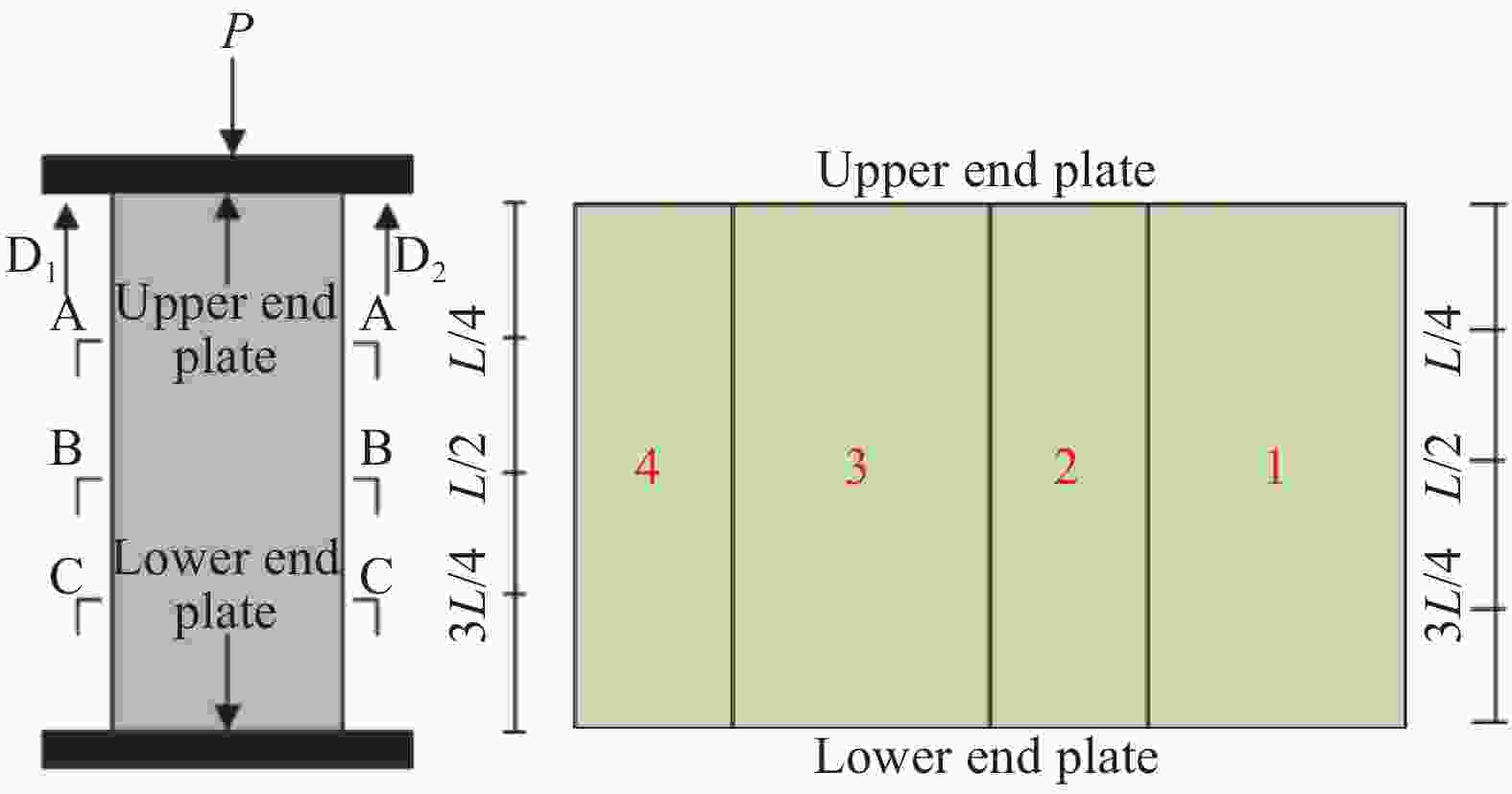

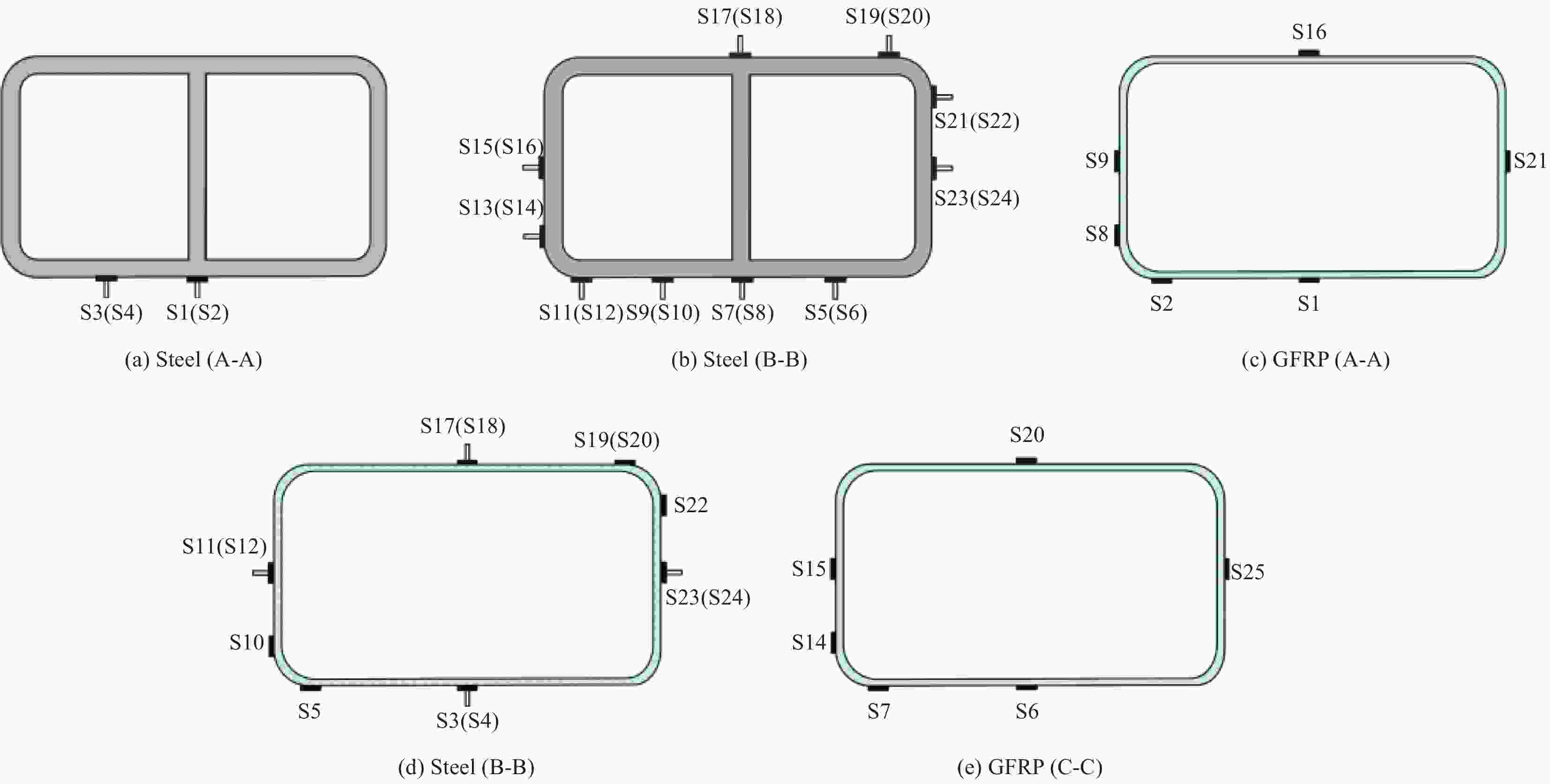

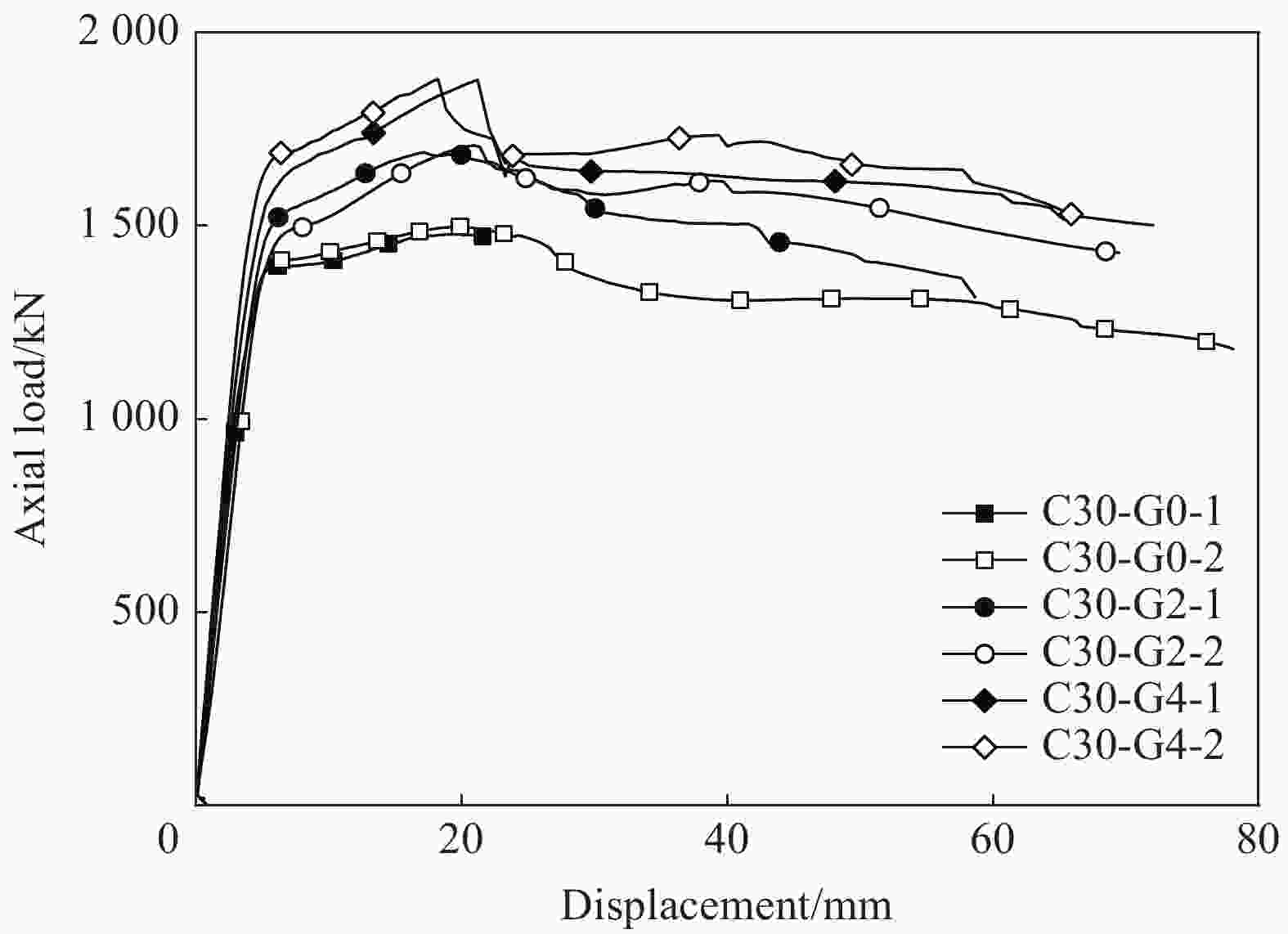

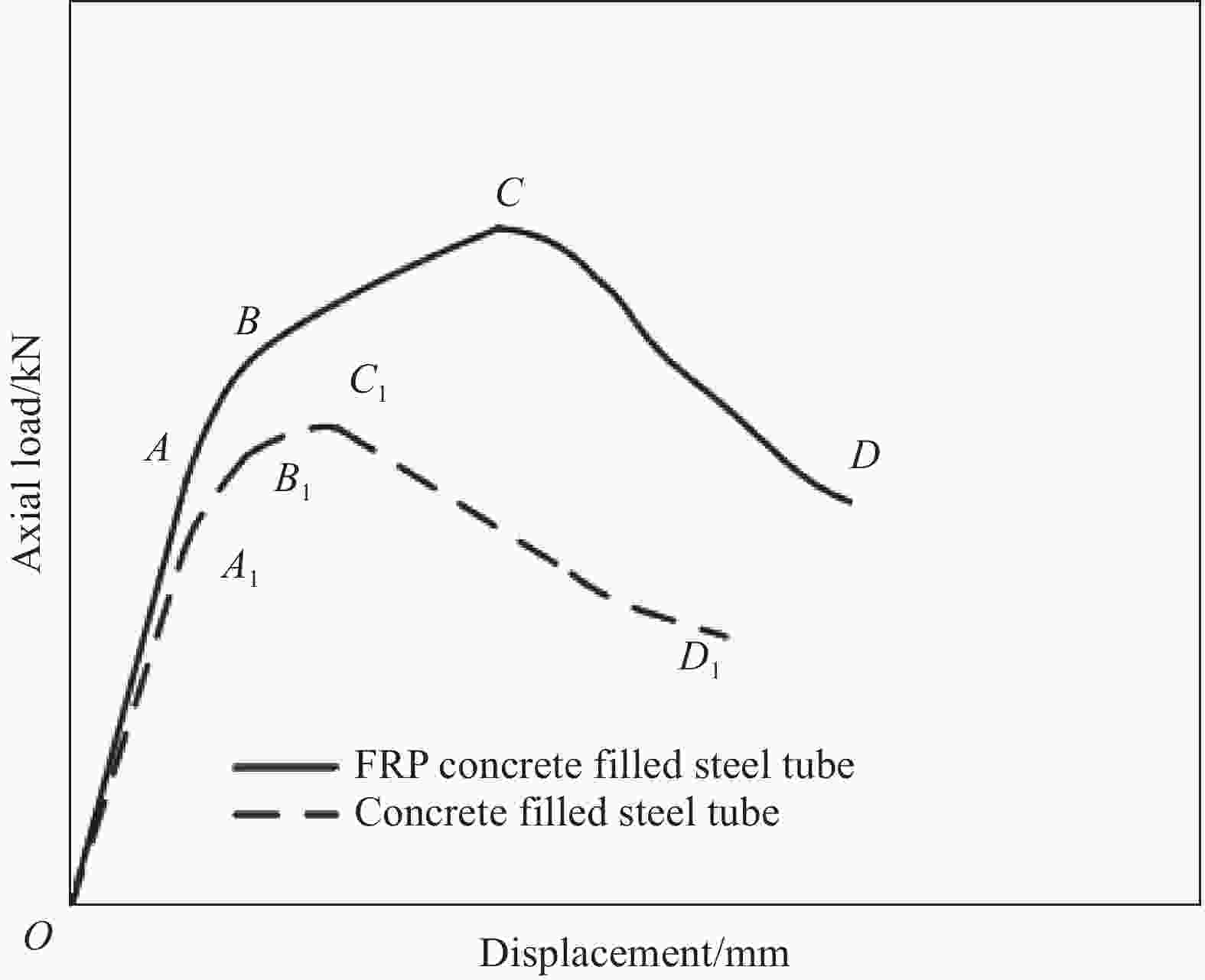

摘要: 为研究玻璃纤维增强聚合物复合材料(GFRP)约束壁式钢管混凝土矩形短柱的轴压力学性能,对1组无GFRP约束试件和2组GFRP约束试件进行静力轴压试验;根据试验结果提出壁式柱的强弱约束模型,并基于双剪统一强度理论建立GFRP约束壁式钢管混凝土柱的轴压承载力计算公式;最后建立有限元模型,将计算结果与试验对比,并进行参数化分析,研究钢材屈服强度和混凝土强度对新型壁式钢管混凝土柱轴压性能的影响。结果表明:壁式钢管混凝土柱最终因柱中混凝土压碎、钢管屈曲、试件变形过大而失效;钢材在试件第二线性段起点处开始屈服,钢材强度得到充分发挥,GFRP能有效提高构件峰值承载力,但延性有所下降;理论公式计算结果与试验值吻合较好;混凝土强度及钢材屈服强度均能有效提高承载能力,且钢材屈服强度对承载力的影响明显大于混凝土强度的影响。

-

关键词:

- 玻璃纤维增强聚合物复合材料 /

- 壁式钢管混凝土柱 /

- 矩形截面 /

- 承载力 /

- 参数分析

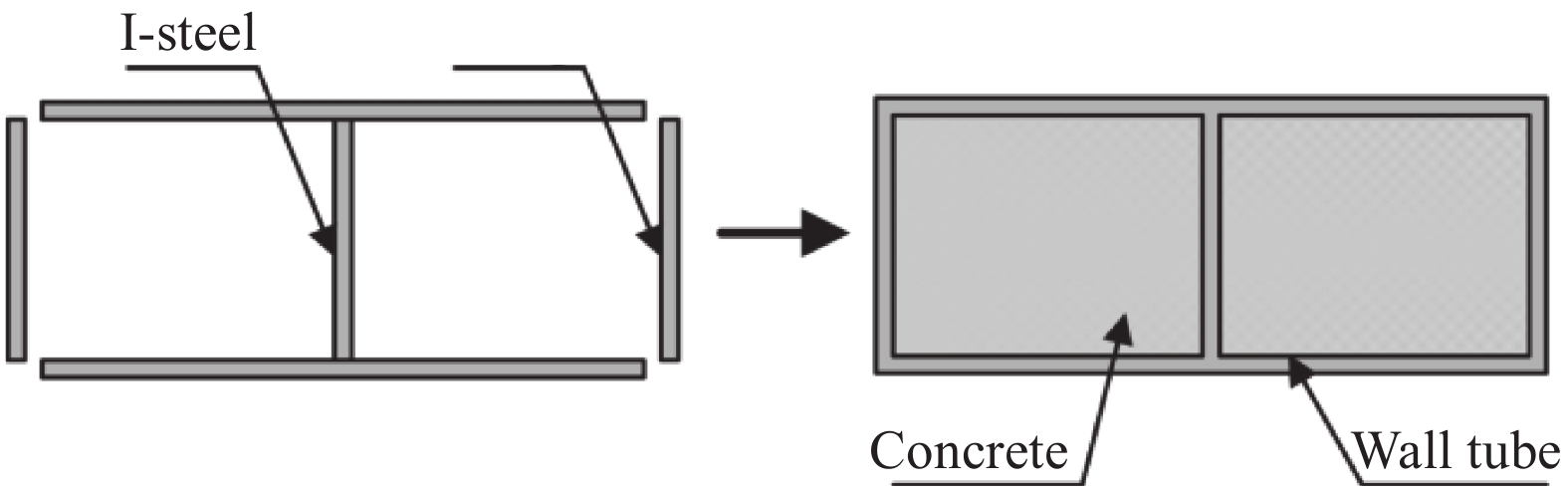

Abstract: In order to study the axial compression performance of glass fiber reinforced polymer (GFRP)-walled concrete-filled steel tube columns, the static axial compression tests were conducted on a group of non-GFRP constrained specimens and two groups of GFRP constrained specimens. According to the test results, a strong and weak constraint model of the wall column was proposed. Based on the twin-shear unified strength theory, the formula was established to calculate the axial compression bearing capacity of the GFRP-walled concrete-filled steel tube columns. Finally, the theoretical results, obtained through the establishment of the finite element model, were compared with the experimental results. And a parametric analysis was used to study the effect of the yield strength of steel and the strength of concrete on the axial compression performance of the new type wall-filled concrete-filled steel tube columns. The results show that the wall-filled concrete-filled steel tube columns eventually fail due to crushing of the concrete, buckling of the steel tube and excessive deformation of the specimens. At the beginning of the second linear section of the specimen, the steel begins to yield and its strength is fully exerted, which demonstrates that GFRP can effectively improve the peak load of the member, however, the ductility has decreased. The results of the theoretical formula are in agreement with the experimental results. The bearing capacity can be improved by increasing the strength of concrete and the yield strength of the steel. Compared with the strength of concrete, the yield strength of steel bars has a greater influence on the bearing capacity. -

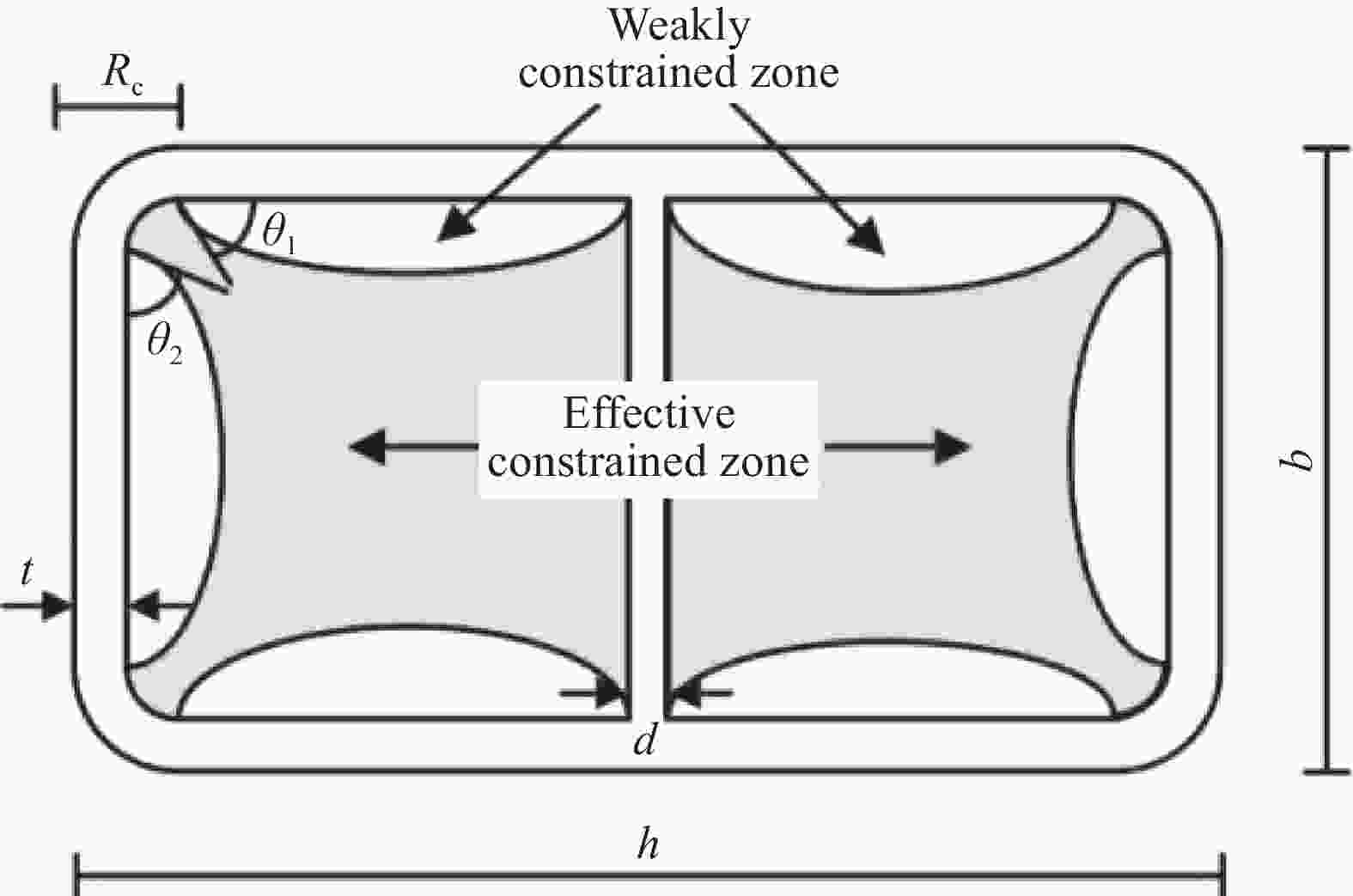

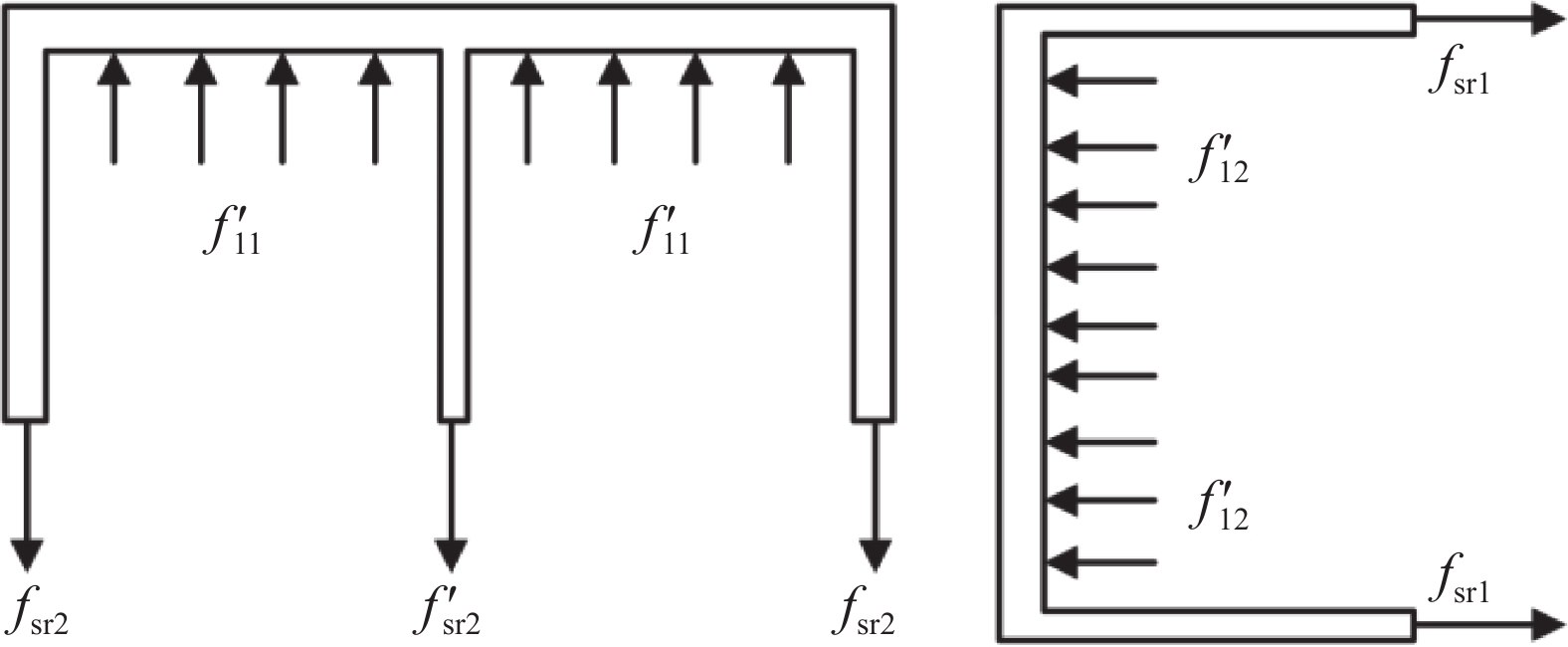

图 11 钢管截面受力示意图

Figure 11. Schematic diagram of cross-section force of steel pipe

${f_{{\rm{l1}}}} $ and ${f_{{\rm{l2}}}} $—Equivalent lateral restraint stress of rectangular steel tube long side and short side to core concrete respectively; ${f'_{{\rm{l1}}}} $ and ${f'_{{\rm{l2}}}} $—Average lateral constraint forces of long side and short side of rectangular steel tube, respectively; ${f'_{{\rm{sr2}}}} $—Circumferential stress of inner diaphragm; ${f_{{\rm{sr1}}}} $ and ${f_{{\rm{sr2}}}} $—Hoop stresses of long side and short side of wall steel tube, respectively

表 1 玻璃纤维增强聚合物复合材料(GFRP)约束壁式钢管混凝土柱参数

Table 1. Parameters of glass fiber reinforce polymer (GFRP)-walled concrete-filled steel tube columns

Number b×h×L/mm t/mm d/mm Rc/mm Fiber layer C30-G0-1 100×200×600 5 5 15 0 C30-G0-2 100×200×600 5 5 15 0 C30-G2-1 100×200×600 5 5 15 2 C30-G2-2 100×200×600 5 5 15 2 C30-G4-1 100×200×600 5 5 15 4 C30-G4-2 100×200×600 5 5 15 4 Notes: C—Concrete, the number stands for the concrete grade; G—GFRP, the numbers are the number of package layers; 1 and 2—Two different test pieces; B—Length; h—Width; L—Height; t—Wall thickness; d—Thickness of the separator; Rc—Radius of the chamfer. 表 2 钢材和混凝土的材料力学性能

Table 2. Material mechanical properties of steel and concrete

Material ${f_{\rm{y}}}/{\rm{MPa}}$ $E/{\rm{GPa}}$ ${f_{{\rm{cu}}}}/{\rm{MPa}}$ Concrete — — 32.4 Steel plate 251 196 — Notes: fy—Yield strength; E—Tensile modulus; fcu—Cube compressive strength. 表 3 GFRP布的材料力学性能

Table 3. Mechanical properties of GFRP

Material ${\sigma _{\rm{b}}}/{\rm{MPa}}$ $E/{\rm{GPa}}$ GFRP 537.4 28.7 Note: ${\sigma _{\rm{b}}}$—Tensile strength. 表 4 GFRP约束壁式钢管混凝土柱主要试验结果

Table 4. Main test results of GFRP-walled concrete-filled steel tube columns

Number ${N_{\rm{p}}}$/kN ${N_{{\rm{p1}}}}$/kN I/% C30-G0-1 1 480 1 477 - C30-G0-2 1 475 C30-G2-1 1 691 1 692 15 C30-G2-2 1 708 C30-G4-1 1 877 1 878 27 C30-G4-2 1 879 Notes: Np—Peak load; Np1—Average value of the peak load; I—Increment of Np1. 表 5 GFRP约束壁式钢管混凝土柱延性系数

Table 5. Ductility coefficients of GFRP-walled concrete-filled steel tube columns

Number ${e_{\rm{u}}}$/mm ${e_{\rm{y}}}$/mm $\mu $ $\overline \mu $ C30-G0-1 — 5.12 — 11.53 C30-G0-2 60.11 5.08 11.53 C30-G2-1 58.76 5.71 10.29 10.97 C30-G2-2 65.64 5.64 11.64 C30-G4-1 56.09 6.15 9.12 10.53 C30-G4-2 60.27 5.21 11.57 Notes: eu—Longitudinal displacement corresponding to the peak load; ey—Longitudinal displacement corresponding to the yield bearing capacity; $\mu $—Ductility coefficient;$\overline \mu $—Average ductility coefficient of each group. 表 6 GFRP约束壁式钢管混凝土柱承载力计算值与试验值对比

Table 6. Comparison of calculation and test value of bearing capacity of GFRP-walled concrete-filled steel tube columns

Number ${\varepsilon _{\rm{v}}}$/10−6 ${t_{\rm{f}}}$/mm ${A_{\rm{s}}}$/mm2 ${A_{\rm{c}}}$/mm2 ${N_{\rm{p}}}$/kN ${N_{{\rm{pre}}}}$/kN ${N_{\rm{p}}}/{N_{{\rm{pre}}}}$ ${\overline X _1}$ C30-G0-1 — 0 2 957 16 336 1 480 — — 1.06 C30-G0-2 — 1 475 1 393 1.06 C30-G2-1 4 968 1.2 1 691 1 568 1.07 1.09 C30-G2-2 6 080 1 708 1 550 1.10 C30-G4-1 10 672 2.4 1 877 1 672 1.12 1.12 C30-G4-2 10 700 1 879 1 684 1.12 $\overline X $ — — — — — — 1.09 ${\sigma _{\rm{S} } }$ — — — — — — 0.028 Notes: εv—Measured value of the high-circumferential strain of the corresponding column when GFRP breaks; tf—Thickness of GFRP; As—Effective cross-sectional area of the steel tube; Ac—Effective cross-sectional area of the concrete; Np—Peak load; Npre—Theoretically calculated value of peak load; Np/Npre—Ratio of the test value and the calculated value; ${\overline X _1}$—Average ratio of each group; $\overline X $—Mean of the ratio; ${\sigma _{\rm{S}}}$—Standard deviation of the ratio. 表 7 塑性损伤参数取值

Table 7. Concrete damaged plasticity parameter values

$\psi $ $\varepsilon $ ${\sigma _{{\rm{bo}}}}/{\sigma _{{\rm{co}}}}$ ${K_{\rm{c}}}$ $\mu $ 30 0.1 1.16 0.6667 0.005 Notes: $\psi $—Expansion angle; $\varepsilon $—Eccentricity; ${\sigma _{{\rm{bo}}}}/{\sigma _{{\rm{co}}}}$—Ratio of the biaxial compressive strength to the uniaxial compressive ultimate strength value; ${K_{\rm{c}}}$—Ratio of the invariable stress; $\mu $—Viscous parameter. 表 8 GFRP约束壁式钢管混凝土短柱有限元结果与试验对比

Table 8. Comparison of finite element results and test results of GFRP-walled concrete-filled steel tube columns

Number Fiber layer ${N_{{\rm{p1}}}}$/kN ${N_{{\rm{Aba}}}}$/kN ${N_{{\rm{p1}}}}$/${N_{{\rm{Aba}}}}$ C30-G0 0 1477 1516 0.97 C30-G2 2 1692 1747 0.97 C30-G4 4 1 878 1 981 0.95 Notes: Np1—Average value of the peak load; NAba—Peak load of the finite element simulation; Np1/NAba—Ratio of the measured peak load to the finite element simulated peak load. 表 9 GFRP约束壁式钢管混凝土短柱模拟试件几何尺寸与材料强度

Table 9. Geometric dimensions and material strength of simulated specimens of GFRP-walled concrete-filled steel tube columns

Number fcu/MPa fy/MPa TS-235-G2 30 235 TS-345-G2 30 345 TS-420-G2 30 420 TS-460-G2 30 460 TC-C30-G2 30 235 TC-C40-G2 40 235 TC-C50-G2 50 235 TC-C60-G2 60 235 Notes: T—Test; S—Steel; C—Concrete; G—GFRP; Numbers behind indicate the corresponding labels and types of materials; fcu—Concrete strength; fy—Steel yield strength. 表 10 不同钢材屈服强度的GFRP约束壁式钢管混凝土短柱有限元模拟结果

Table 10. Simulated results of GFRP-walled concrete-filled steel tube columns with different yield strength of steels

Number fy/MPa Ny/kN Np/kN I1/% TS-235-G2 235 1516 1767 — TS-345-G2 345 1 817 2572 45.55 TS-420-G2 420 1 997 2845 61.01 TS-460-G2 460 2084 3009 70.29 Notes: Ny—Yield load; Np—Peak load; I1—Increment of Np. 表 11 不同混凝土强度的GFRP约束壁式钢管混凝土短柱有限元模拟结果

Table 11. Simulated results of GFRP-walled concrete-filled steel tube columns with different strengths of concrete

Number fy/MPa Ny/kN Np/kN I1/% TC-C30-G2 30 1516 1767 — TC-C40-G2 40 1563 1 880 6.40 TC-C50-G2 50 1598 1 970 11.45 TC-C60-G2 60 1614 2083 17.89 -

[1] 魏巍. 圆端形钢管混凝土构件偏压力学性能研究[D]. 武汉: 武汉理工大学, 2019.WEI Wei. Research on eccentric compressive behavior of round-ended concrete-filled steel tubular members[D]. Wuhan: Wuhan University of Technology, 2019(in Chinese). [2] 郝际平, 孙晓岭, 薛强, 等. 绿色装配式钢结构建筑体系研究与应用[J]. 工程力学, 2017, 34(1):1-13.HAO Jiping, SUN Xiaoling, XUE Qiang, et al. Research and application of green prefabricated steel structure building system[J]. Engineering Mechanics,2017,34(1):1-13(in Chinese). [3] 孙晓岭, 郝际平, 薛强, 等. 壁式钢管混凝土柱抗震性能试验研究[J]. 建筑结构学报, 2018, 39(6):92-101.SUN Xiaoling, HAO Jiping, XUE Qiang, et al. Experimental study on seismic performance of walled concrete-filled steel tubular columns[J]. Journal of Building Structures,2018,39(6):92-101(in Chinese). [4] 杜颜胜. 高强钢矩形钢管混凝土柱理论分析及试验研究[D]. 天津: 天津大学, 2017.DU Yansheng. Theoretical analysis and experimental study on rectangular concrete-filled steel tube columns using high-strength steel[D]. Tianjin: Tianjin University, 2017(in Chinese). [5] 王灿灿, 夏之罡, 叶尹, 等. 焊缝质量对钢管混凝土柱影响研究[J]. 低温建筑技术, 2013, 35(7):69-71.WANG Cancan, XIA Zhigang, YE Yin, et al. Research on the influence of weld quality on concrete-filled steel tube columns[J]. Low Temperature Architecture Technology,2013,35(7):69-71(in Chinese). [6] 颜燕祥, 徐礼华, 蔡恒, 等. 高强方钢管超高性能混凝土短柱轴压承载力计算方法研究[J]. 建筑结构学报, 2019, 40(12): 128-137.YAN Yanxiang, XU Lihua, CAI Heng, et al. Calculation methods of axial bearing capacity of short square UHPC filled high strength steel tubular columns[J]. Journal of Building Structures, 2019, 40(12): 128-137(in Chinese). [7] 李晓霞. 倒角半径对FRP加固混凝土柱力学性能影响的试验研究[J]. 玻璃钢/复合材料, 2012, 4:19-22.LI Xiaoxia. Experimental study on mechanical behaviour of FRP-strengthend reinforced concrete columns based on the corner radius[J]. Fiber Reinforced Plastics/Composites,2012,4:19-22(in Chinese). [8] XIAO Y, HE W H, CHOI K K. Confined concrete-filled tubular columns[J]. Journal of Structural Engineering,2005,131(3):488-497. doi: 10.1061/(ASCE)0733-9445(2005)131:3(488) [9] 潘毅, 吴晓飞, 郭瑞, 等. 有初应力的FRP约束混凝土圆柱应力—应变分析型模型[J]. 中国铁道科学, 2017, 38(5):30-36.PAN Yi, WU Xiaofei, GUO Rui, et al. Stress-strain analysis model of FRP confined concrete cylinder with initial stress[J]. China Railway Science,2017,38(5):30-36(in Chinese). [10] 朱春阳, 赵颖华, 李晓飞. FRP-钢管-混凝土构件抗震性能试验研究[J]. 复合材料学报, 2013, 30(1):180-186.ZHU Chunyang, ZHAO Yinghua, LI Xiaofei. Experimental study on seismic property of concrete filled FRP-steel tube[J]. Acta Materiae Compositae Sinica,2013,30(1):180-186(in Chinese). [11] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [12] 全国钢标准化技术委员会. 金属材料拉伸试验第1部分: 室温试验方法GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011.Technical Committee on Steel of Standardization Committee of China. Metallic materials-Tensile testing-Part 1: Method of test at room temperature GB/T 228.1—2010[S]. Beijing: Standards Press of China, 2011(in Chinese). [13] American Society of Testing Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039[S]. West Conshohocken: ASTM, 2002. [14] American Society of Testing Materials. Standard test method for compressive properties of polymer matrix composite materials with unsupported gage section by shear loading: ASTM D3410[S]. West Conshohocken: ASTM, 2002. [15] 陈梦成, 刘京剑, 黄宏. 钢管再生矿渣混凝土轴压短柱试验研究[J]. 建筑结构学报, 2013, 34(S1):281-287.CHEN Mengcheng, LIU Jingjian, HUANG Hong. Experimental study on recycled slag aggregate concrete-filled steel tubular columns under axial compression[J]. Journal of Building Structures,2013,34(S1):281-287(in Chinese). [16] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Yirui, WEI Yang, BAI Jiawen, et al. Models for predicting axial compression behavior of FRP-steel compo-site circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese). [17] 张忠杰, 周新刚, 宋振宇, 等. 矩形薄壁钢管混凝土短柱轴心受压性能试验研究[J]. 烟台大学学报(自然科学与工程版), 2020, 33(2):218-224.ZHANG Zhongjie, ZHOU Xingang, SONG Zhenyu, et al. Experimental study on axially compressive behavior of rectangular concrete-filled thin-walled steel tube short column[J]. Journal of Yantai University (Natural Science and Engineering Edition),2020,33(2):218-224(in Chinese). [18] WANG X X, QI Y J, SUN Y L, et al. Compressive behavior of composite concrete columns with encased FRP confined concrete cores[J]. Sensors (Basel, Switzerland),2019,19(8):1792. [19] 冯鹏, 强翰霖, 叶列平. 材料、构件、结构的“屈服点”定义与讨论[J]. 工程力学, 2017, 34(3):36-46.FENG Peng, QIANG Hanlin, YE Lieping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics,2017,34(3):36-46(in Chinese). [20] MANDER J A B, PRIESTLEY M J N. Theoretical stress-strain model for confined concrete[J]. Journal of Structural Engineering,1988,114(8):1804-1826. doi: 10.1061/(ASCE)0733-9445(1988)114:8(1804) [21] 潘毅, 曹双寅, 敬登虎, 等. 负载下碳纤维布约束混凝土方柱轴压应力-应变关系的试验研究与分析[J]. 土木工程学报, 2009, 42(1):23-29.PAN Yi, CAO Shuangyin, JING Denghu, et al. Test and analysis of the axial stress-strain relationship of square section concrete columns confined by CFRP under preload[J]. China Civil Engineering Journal,2009,42(1):23-29(in Chinese). [22] 郭红香, 赵均海, 魏雪英. 方钢管混凝土轴压短柱承载力分析[J]. 工业建筑, 2008(3):9, 14-16.GUO Hongxiang, ZHAO Junhai, WEI Xueying. Analysis of bearing capacity of concrete-filled square steel tube column under axial load[J]. Industrial Construction,2008(3):9, 14-16(in Chinese). [23] 王娟, 赵均海, 吴赛, 等. 基于统一强度理论的矩形钢管混凝土短柱轴压承载力计算[J]. 建筑科学与工程学报, 2011, 28(3):88-92.WANG Juan, ZHAO Junhai, WU Sai, et al. Calculation of axial bearing capacity of rectangular concrete-filled steel tube short column based on twin shear unified strength theory[J]. Journal of Architecture and Civil Engineering,2011,28(3):88-92(in Chinese). [24] 陶毅, 叶思君, 陈建飞. 内置约束芯柱的方钢管混凝土组合柱轴压承载力分析[J/OL]. 建筑结构学报: 1-12[2020-07-31]. https://doi.org/10.14006/j.jzjgxb.2020.0082.TAO Yi, YE Sijun, CHEN Jianfei. Analysis of axial compression bearing capacity of concrete-filled square steel tubular columns with built-in restraint cores[J/OL]. Journal of Building Structures: 1-12[2020-07-31]. https://doi.org/10.14006/j.jzjgxb.2020.0082.(in Chinese). [25] 魏锦, 赵均海, 刘彦东, 等. 钢管混凝土轴压短柱的极限承载力分析[J]. 建筑科学与工程学报, 2008(3):81-86.WEI Jin, ZHAO Junhai, LIU Yandong, et al. Analysis of the ultimate bearing capacity of concrete-filled steel tubular axial compression short columns[J]. Journal of Architecture and Civil Engineering,2008(3):81-86(in Chinese). [26] 四川省住房和城乡建设厅. 混凝土结构加固设计规范: GB 50367—2013[S]. 北京: 中国建筑工业出版社, 2013.Sichuan housing and Urban Rural Development Department. Code for design of strengthening concrete structures: GB 50367—2013[S]. Beijing: China Architecture & Building Press, 2013(in Chinese). [27] 中国建筑科学研究院. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2015.China Academy of Building Research. Code for design of concrete structures: GB 50010—2010[S]. Beijing: China Architecture & Building Press, 2015(in Chinese). -

下载:

下载: