2024 Vol. 41, No. 1

2024, 41(1): 1-15.

doi: 10.13801/j.cnki.fhclxb.20230921.002

Abstract:

Compared to traditional liquid-state lithium batteries, solid-state lithium batteries have distinct advantages such as high safety and high specific energy, and have attracted widespread attention in both academia and industry. Exploring organic-inorganic composite solid electrolytes that combine excellent mechanical properties, high ion conductivity, and large electrochemical windows is a feasible solution to developing high-performance solid-state lithium batteries. In recent years, composite solid-state electrolytes based on polymer electrolytes and inorganic materials have become a hot topic. In this tutorial review, we focus on recent advances in various classes of organic-inorganic composite electrolytes and summarize the state-of-the-art strategies for improving the performance (Especially the ionic conductivity) of solid-state electrolytes. This is followed by detailed discussions on the implementation of composite solid-electrolytes in various energy storage systems, including solid-state lithium-metal batteries, solid-state lithium-sulfur batteries and solid-state lithium-air batteries, and the current challenges and future opportunities of organic-inorganic composite solid-state electrolytes for lithium batteries are also provided.

Compared to traditional liquid-state lithium batteries, solid-state lithium batteries have distinct advantages such as high safety and high specific energy, and have attracted widespread attention in both academia and industry. Exploring organic-inorganic composite solid electrolytes that combine excellent mechanical properties, high ion conductivity, and large electrochemical windows is a feasible solution to developing high-performance solid-state lithium batteries. In recent years, composite solid-state electrolytes based on polymer electrolytes and inorganic materials have become a hot topic. In this tutorial review, we focus on recent advances in various classes of organic-inorganic composite electrolytes and summarize the state-of-the-art strategies for improving the performance (Especially the ionic conductivity) of solid-state electrolytes. This is followed by detailed discussions on the implementation of composite solid-electrolytes in various energy storage systems, including solid-state lithium-metal batteries, solid-state lithium-sulfur batteries and solid-state lithium-air batteries, and the current challenges and future opportunities of organic-inorganic composite solid-state electrolytes for lithium batteries are also provided.

2024, 41(1): 16-37.

doi: 10.13801/j.cnki.fhclxb.20230814.002

Abstract:

Thermal conductive composites have a wide range of applications in the fields of electronic packaging, motor materials, batteries and heat exchange equipment. Polyvinylidene fluoride (PVDF) has excellent electrical properties, good mechanical strength and high temperature resistance. It is one of the ideal materials for applications in electronics, aerospace and other industries. However, the low thermal conductivity restricts its further development. It is urgent to develop PVDF-based high thermal conductivity composites. The key to its preparation is how to select high thermal conductivity fillers, design thermal conduction pathways, and regulate interface thermal resistance. Based on the theoretical knowledge of the mechanism, model, equation and numerical simulation of polymer-based thermal conductive composites, combined with the crystal structure of PVDF, this paper introduces the current development level of thermal conductivity of PVDF-based thermal conductive composites, and the different effects of various fillers and preparation processes on their thermal conductivity. The latest research progress of high thermal conductivity PVDF composites is reviewed from the perspectives of composite strategy, network structure and interface bonding. In addition, its future development is also prospected.

Thermal conductive composites have a wide range of applications in the fields of electronic packaging, motor materials, batteries and heat exchange equipment. Polyvinylidene fluoride (PVDF) has excellent electrical properties, good mechanical strength and high temperature resistance. It is one of the ideal materials for applications in electronics, aerospace and other industries. However, the low thermal conductivity restricts its further development. It is urgent to develop PVDF-based high thermal conductivity composites. The key to its preparation is how to select high thermal conductivity fillers, design thermal conduction pathways, and regulate interface thermal resistance. Based on the theoretical knowledge of the mechanism, model, equation and numerical simulation of polymer-based thermal conductive composites, combined with the crystal structure of PVDF, this paper introduces the current development level of thermal conductivity of PVDF-based thermal conductive composites, and the different effects of various fillers and preparation processes on their thermal conductivity. The latest research progress of high thermal conductivity PVDF composites is reviewed from the perspectives of composite strategy, network structure and interface bonding. In addition, its future development is also prospected.

2024, 41(1): 38-49.

doi: 10.13801/j.cnki.fhclxb.20230423.001

Abstract:

Bone defects caused by bone diseases are a very challenging issue in modern medicine. Both pathological changes in normal bone tissue and physical damage caused by external factors can lead to difficult-to-heal bone defects. The complex microenvironment of the bone defect site makes treatment conditions more demanding. Constructing scaffolds for bone defects is an important direction in bone tissue engineering technology and a crucial means to solve the problem of bone defect diseases. This article briefly introduces the preparation principles and methods of hydroxyapatite/graphene oxide (HA/GO) composite materials. HA/GO has no apparent toxicity to bone cells, and its rough surface structure is more conducive to the proliferation and differentiation of bone cells. Based on this, the construction methods and performance of HA/GO composite scaffolds for treating bone defect diseases are described in detail. Finally, the development prospects and challenges of HA/GO composite scaffolds in the treatment of bone diseases are discussed.

Bone defects caused by bone diseases are a very challenging issue in modern medicine. Both pathological changes in normal bone tissue and physical damage caused by external factors can lead to difficult-to-heal bone defects. The complex microenvironment of the bone defect site makes treatment conditions more demanding. Constructing scaffolds for bone defects is an important direction in bone tissue engineering technology and a crucial means to solve the problem of bone defect diseases. This article briefly introduces the preparation principles and methods of hydroxyapatite/graphene oxide (HA/GO) composite materials. HA/GO has no apparent toxicity to bone cells, and its rough surface structure is more conducive to the proliferation and differentiation of bone cells. Based on this, the construction methods and performance of HA/GO composite scaffolds for treating bone defect diseases are described in detail. Finally, the development prospects and challenges of HA/GO composite scaffolds in the treatment of bone diseases are discussed.

2024, 41(1): 50-59.

doi: 10.13801/j.cnki.fhclxb.20230731.004

Abstract:

Nanostructured catalytic materials are considered to be a favorable design concept for various energy conversion and storage systems. Nanosized metal catalysts supported on oxide scaffolds have been adopted in numerous fields, including fuel cells, gas sensors, and chemical reforming devices. Nevertheless, nanometal catalysts often suffer from durability issues. Although surface-decorated nanometal catalysts can deliver sufficient catalytic activity, some of them still exhibit durability issues in severe operating environments. Recently, nanocatalysts produced by in situ exsolution have been demonstrated to overcome the practical limitations of conventional nanometal catalysts. The exsolution is defined as a process in which a catalytically active dopant in perovskite oxide is exsolved on its surface as highly dispersed nanometal catalysts. In particular, exsolution nanocatalysts embedded on perovskite oxides exhibit higher nanoparticle densities and greater resistance to particle agglomeration than conventional nanometal catalysts. This perspective presents an overview of recent advances in exsolution materials for energy applications including fundamental mechanisms, design strategies for host oxides, and practical applications. The future prospects of these materials and the scope for further optimization are also discussed.

Nanostructured catalytic materials are considered to be a favorable design concept for various energy conversion and storage systems. Nanosized metal catalysts supported on oxide scaffolds have been adopted in numerous fields, including fuel cells, gas sensors, and chemical reforming devices. Nevertheless, nanometal catalysts often suffer from durability issues. Although surface-decorated nanometal catalysts can deliver sufficient catalytic activity, some of them still exhibit durability issues in severe operating environments. Recently, nanocatalysts produced by in situ exsolution have been demonstrated to overcome the practical limitations of conventional nanometal catalysts. The exsolution is defined as a process in which a catalytically active dopant in perovskite oxide is exsolved on its surface as highly dispersed nanometal catalysts. In particular, exsolution nanocatalysts embedded on perovskite oxides exhibit higher nanoparticle densities and greater resistance to particle agglomeration than conventional nanometal catalysts. This perspective presents an overview of recent advances in exsolution materials for energy applications including fundamental mechanisms, design strategies for host oxides, and practical applications. The future prospects of these materials and the scope for further optimization are also discussed.

2024, 41(1): 60-77.

doi: 10.13801/j.cnki.fhclxb.20230802.001

Abstract:

Textiles are widely used for drug loading because of their large specific surface area, good flexibility, wide applicability, good loading of drugs and slow release and controlled release ability. The preparation methods of drug-loaded textiles mainly include spinning method, finishing method and composite method. The preparation methods of drug-loaded textiles were used as the starting point to classify the drug-loaded textiles, the preparation methods, drug release characteristics, applicability and current research status of each type of drug-loaded textiles were described, the preparation characteristics, advantages and disadvantages of preparation methods of each type of drug-loaded textiles were summarized, and finally the future research directions of drug-loaded textiles were proposed, to provide reference for further research on drug-loaded textiles and their preparation methods.

Textiles are widely used for drug loading because of their large specific surface area, good flexibility, wide applicability, good loading of drugs and slow release and controlled release ability. The preparation methods of drug-loaded textiles mainly include spinning method, finishing method and composite method. The preparation methods of drug-loaded textiles were used as the starting point to classify the drug-loaded textiles, the preparation methods, drug release characteristics, applicability and current research status of each type of drug-loaded textiles were described, the preparation characteristics, advantages and disadvantages of preparation methods of each type of drug-loaded textiles were summarized, and finally the future research directions of drug-loaded textiles were proposed, to provide reference for further research on drug-loaded textiles and their preparation methods.

2024, 41(1): 78-91.

doi: 10.13801/j.cnki.fhclxb.20230731.003

Abstract:

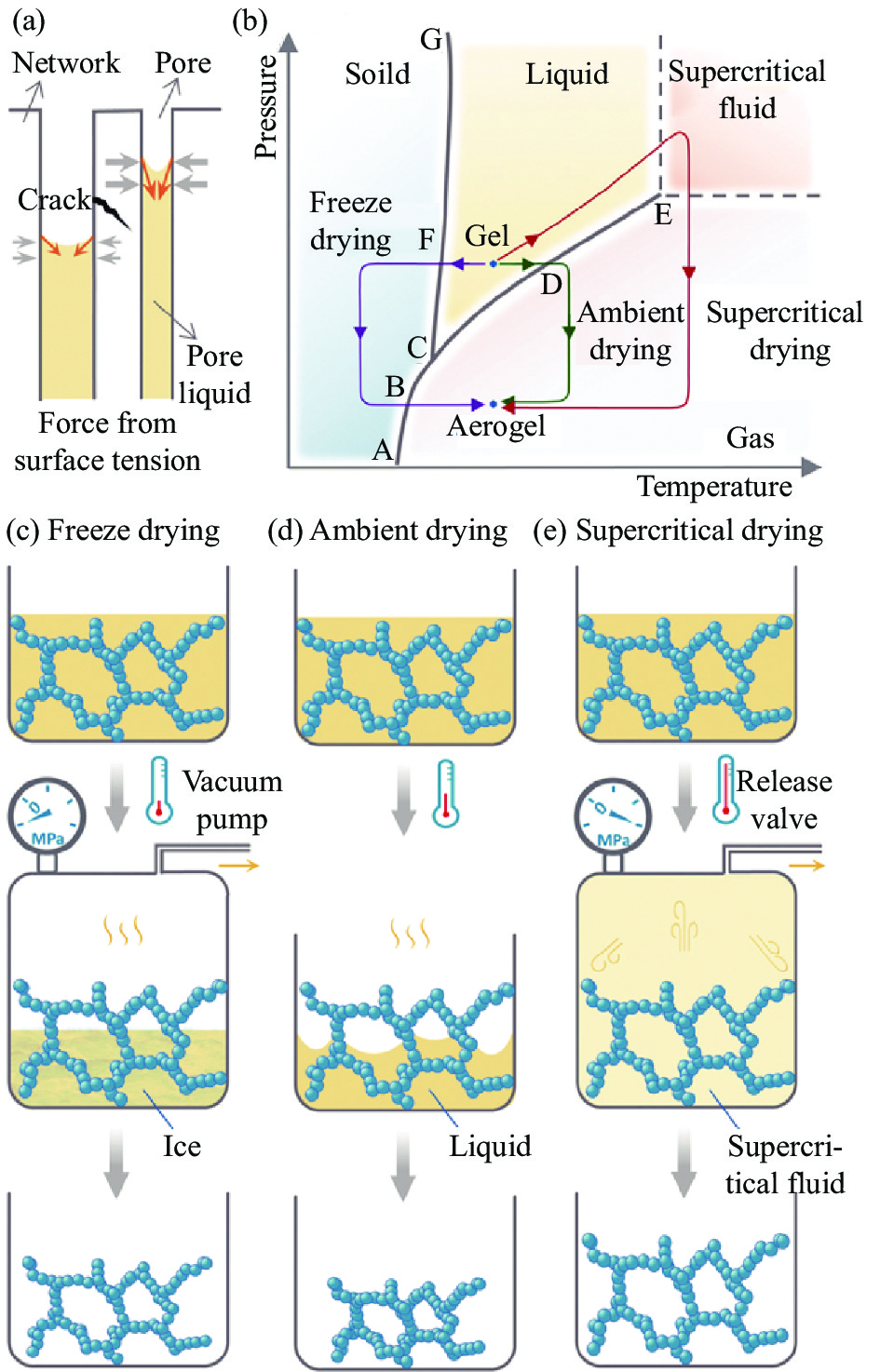

MXene materials have been widely used in many fields, such as electromagnetic shielding, sensing, and wastewater treatment. The excellent electrochemical properties of MXene makes it demonstrate broad application prospects in the field of energy storage as well. However, the self-stacking and easy oxidation characteristics of MXene limit its further development. The assembly of MXene into three-dimensional (3D) structural composites is one of the effective way to solve the above problems. The 3D porous structure can provide more channels and active sites for ion transport or storage, which can effectively improve the electrochemical performance. This article reviews the recent researches of MXene composite aerogels. The preparation methods and applications of MXene composite aerogels in energy storage, such as batteries and supercapacitors, are discussed in detail. Finally, the prospects for its future development direction were also presented.

MXene materials have been widely used in many fields, such as electromagnetic shielding, sensing, and wastewater treatment. The excellent electrochemical properties of MXene makes it demonstrate broad application prospects in the field of energy storage as well. However, the self-stacking and easy oxidation characteristics of MXene limit its further development. The assembly of MXene into three-dimensional (3D) structural composites is one of the effective way to solve the above problems. The 3D porous structure can provide more channels and active sites for ion transport or storage, which can effectively improve the electrochemical performance. This article reviews the recent researches of MXene composite aerogels. The preparation methods and applications of MXene composite aerogels in energy storage, such as batteries and supercapacitors, are discussed in detail. Finally, the prospects for its future development direction were also presented.

2024, 41(1): 92-107.

doi: 10.13801/j.cnki.fhclxb.20230728.002

Abstract:

Carbon dots (CDs) have advantages such as low toxicity, water tolerance, good biocompatibility, easy modification, excellent electrochemical activity, and optical properties. CDs can be used for the modification of polymer materials, endowing them with good optical properties and various other functionalities. Adding CDs to polyvinyl alcohol (PVA) not only effectively improves the mechanical properties and thermal stability of PVA, but also endows PVA with new properties, such as improved conductivity, dielectric properties, thermoelectric properties, and other electrical parameters, optical properties such as fluorescence, phosphorescence, and UV resistance, antibacterial, antioxidant, and water resistance, which make PVA stand out in the fields of electromagnetic shielding, storage devices, capacitors, sensors, optical devices and functional packaging bags. This article focuses on the latest research progress in the properties of PVA modified with CDs (CDs/PVA), and prospects the future application of CDs/PVA, which is of great significance for expanding its application fields.

Carbon dots (CDs) have advantages such as low toxicity, water tolerance, good biocompatibility, easy modification, excellent electrochemical activity, and optical properties. CDs can be used for the modification of polymer materials, endowing them with good optical properties and various other functionalities. Adding CDs to polyvinyl alcohol (PVA) not only effectively improves the mechanical properties and thermal stability of PVA, but also endows PVA with new properties, such as improved conductivity, dielectric properties, thermoelectric properties, and other electrical parameters, optical properties such as fluorescence, phosphorescence, and UV resistance, antibacterial, antioxidant, and water resistance, which make PVA stand out in the fields of electromagnetic shielding, storage devices, capacitors, sensors, optical devices and functional packaging bags. This article focuses on the latest research progress in the properties of PVA modified with CDs (CDs/PVA), and prospects the future application of CDs/PVA, which is of great significance for expanding its application fields.

2024, 41(1): 108-120.

doi: 10.13801/j.cnki.fhclxb.20230802.003

Abstract:

Thermal insulation of buildings plays an important role to reduce energy consumption for maintaining an optimal atmosphere inside the building. Hence, it is crucial to improve the thermal insulation performance of the building materials, especially to achieve energy savings through the reduction of energy losses for heating-cooling purposes. Therefore, the research on building materials with excellent thermal insulation properties has become one of the focuses of current thermal insulation research. Compared with traditional thermal insulation building materials, biomass-based cellulose thermal insulation aerogel has superior physical and chemical properties, such as low thermal conductivity, high specific surface area, renewable, cost-effective and environment-friendly. It is an ideal new building material for future building energy saving technology. In this paper, the preparation technology, research status, existing problems and application of biomass-based cellulose thermal insulation aerogel in building materials (roof, interior and exterior walls and glass, etc.) in recent years are reviewed. Finally, the challenges faced by biomass-based cellulose aerogel in the application of thermal insulation materials are briefly discussed, and its future development direction is prospected.

Thermal insulation of buildings plays an important role to reduce energy consumption for maintaining an optimal atmosphere inside the building. Hence, it is crucial to improve the thermal insulation performance of the building materials, especially to achieve energy savings through the reduction of energy losses for heating-cooling purposes. Therefore, the research on building materials with excellent thermal insulation properties has become one of the focuses of current thermal insulation research. Compared with traditional thermal insulation building materials, biomass-based cellulose thermal insulation aerogel has superior physical and chemical properties, such as low thermal conductivity, high specific surface area, renewable, cost-effective and environment-friendly. It is an ideal new building material for future building energy saving technology. In this paper, the preparation technology, research status, existing problems and application of biomass-based cellulose thermal insulation aerogel in building materials (roof, interior and exterior walls and glass, etc.) in recent years are reviewed. Finally, the challenges faced by biomass-based cellulose aerogel in the application of thermal insulation materials are briefly discussed, and its future development direction is prospected.

2024, 41(1): 121-133.

doi: 10.13801/j.cnki.fhclxb.20230724.003

Abstract:

Under the background of the "dual carbon" strategy, the research progress of bio-based fluorescent intelligent materials and their multifunctional applications have attracted much attention. Cellulose is the most abundant natural polymer material in nature. Cellulose-based solid-state fluorescence sensors not only have the advantages of green, low cost, biodegradability, good hydrophilicity, good biocompatibility, and non-toxicity, but also have advantages such as portability, efficiency, long lifespan, high stability, and wide applicability compared to traditional fluorescent molecular probes. The research progress of cellulose-based solid-state fluorescent sensors prepared by chemical modification in recent years was reviewed. The mechanism of the combination of cellulose with different fluorescent molecules was clarified. Fluorescent molecules were introduced to the surface of cellulose by covalent crosslinking or introduction of functional groups. Various types of cellulose-based solid-state fluorescence sensors, including cationic, anionic, pH-type, nitroaromatic, gas-type and double (multi) re-responsive types, were introduced. The advantages of cellulose-based solid-state fluorescence sensors in environmental detection, bioimaging, food safety, fluorescence printing and anti-counterfeiting applications were also introduced. Finally, the relevant research on cellulose-based fluorescent smart sensors is discussed in detail, and their development opportunities and future challenges are prospected.

Under the background of the "dual carbon" strategy, the research progress of bio-based fluorescent intelligent materials and their multifunctional applications have attracted much attention. Cellulose is the most abundant natural polymer material in nature. Cellulose-based solid-state fluorescence sensors not only have the advantages of green, low cost, biodegradability, good hydrophilicity, good biocompatibility, and non-toxicity, but also have advantages such as portability, efficiency, long lifespan, high stability, and wide applicability compared to traditional fluorescent molecular probes. The research progress of cellulose-based solid-state fluorescent sensors prepared by chemical modification in recent years was reviewed. The mechanism of the combination of cellulose with different fluorescent molecules was clarified. Fluorescent molecules were introduced to the surface of cellulose by covalent crosslinking or introduction of functional groups. Various types of cellulose-based solid-state fluorescence sensors, including cationic, anionic, pH-type, nitroaromatic, gas-type and double (multi) re-responsive types, were introduced. The advantages of cellulose-based solid-state fluorescence sensors in environmental detection, bioimaging, food safety, fluorescence printing and anti-counterfeiting applications were also introduced. Finally, the relevant research on cellulose-based fluorescent smart sensors is discussed in detail, and their development opportunities and future challenges are prospected.

2024, 41(1): 134-143.

doi: 10.13801/j.cnki.fhclxb.20230404.002

Abstract:

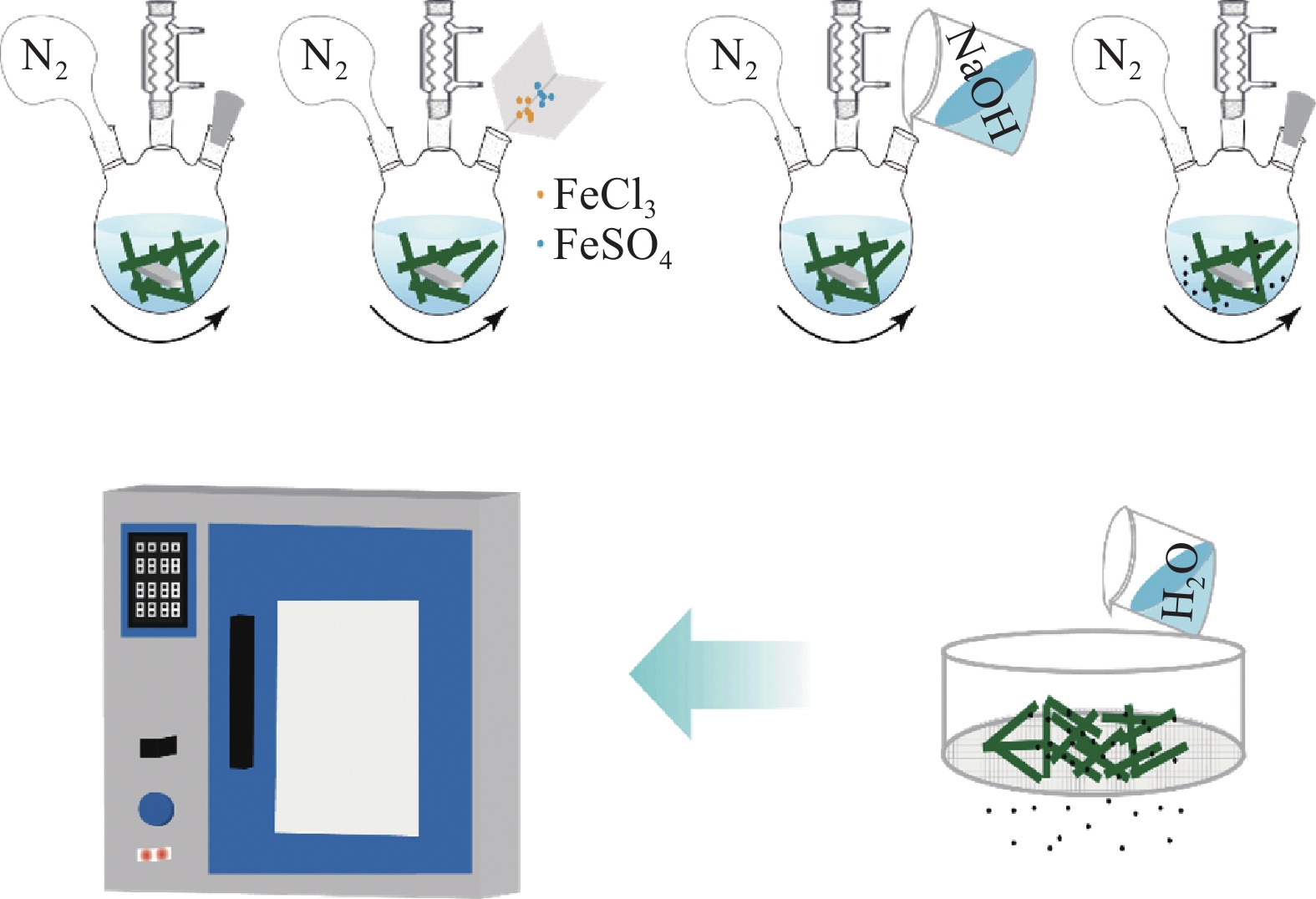

With the increasing integration density and power density of electronic products. It is particularly important to optimize the research of thermal interface materials. In this paper, one-dimensional silicon carbide whisker (SiCw) was used as filler and silicone rubber was used as matrix to prepare thermal conductive silicone rubber composites. The microstructure, phase structure, thermal conductivity and insulation of the composites were comprehensively analyzed. Firstly, the modified material of SiCw coated by Fe3O4 was prepared by coprecipitation method. Secondly, SiCw coated with Fe3O4 was evenly dispersed in the liquid silicone rubber matrix. Finally, it is placed in a constant magnetic field to complete whisker orientation and matrix curing. The results show that the surface of SiCw whiskers is coated with Fe3O4 nanoparticles, and they are oriented in the silicone rubber matrix. Silicone rubber composites with SiCw oriented structure were prepared. When the oriented SiCw reaches 10wt%, the thermal conductivity can be increased by 72% compared with pure silicone rubber, and it is 40% higher than that filled with non-oriented 10wt%SiCw. Compared with pure silicone rubber, the volume resistivity decreases by two orders of magnitude. But it still has good insulation. The silicone rubber composites with randomly dispersed and oriented SiCw were simulated by COMSOL. The simulation results show that the thermal conductivity of silicone rubber can be improved by 60% with 10wt%SiCw. The volume resistivity is above 1015 Ω∙cm. However, 10wt% oriented SiCw can improve the thermal conductivity of silicone rubber by 170% and the volume resistivity is above 1014 Ω∙cm. It is consistent with the trend of experimental results.

With the increasing integration density and power density of electronic products. It is particularly important to optimize the research of thermal interface materials. In this paper, one-dimensional silicon carbide whisker (SiCw) was used as filler and silicone rubber was used as matrix to prepare thermal conductive silicone rubber composites. The microstructure, phase structure, thermal conductivity and insulation of the composites were comprehensively analyzed. Firstly, the modified material of SiCw coated by Fe3O4 was prepared by coprecipitation method. Secondly, SiCw coated with Fe3O4 was evenly dispersed in the liquid silicone rubber matrix. Finally, it is placed in a constant magnetic field to complete whisker orientation and matrix curing. The results show that the surface of SiCw whiskers is coated with Fe3O4 nanoparticles, and they are oriented in the silicone rubber matrix. Silicone rubber composites with SiCw oriented structure were prepared. When the oriented SiCw reaches 10wt%, the thermal conductivity can be increased by 72% compared with pure silicone rubber, and it is 40% higher than that filled with non-oriented 10wt%SiCw. Compared with pure silicone rubber, the volume resistivity decreases by two orders of magnitude. But it still has good insulation. The silicone rubber composites with randomly dispersed and oriented SiCw were simulated by COMSOL. The simulation results show that the thermal conductivity of silicone rubber can be improved by 60% with 10wt%SiCw. The volume resistivity is above 1015 Ω∙cm. However, 10wt% oriented SiCw can improve the thermal conductivity of silicone rubber by 170% and the volume resistivity is above 1014 Ω∙cm. It is consistent with the trend of experimental results.

2024, 41(1): 144-154.

doi: 10.13801/j.cnki.fhclxb.20230616.006

Abstract:

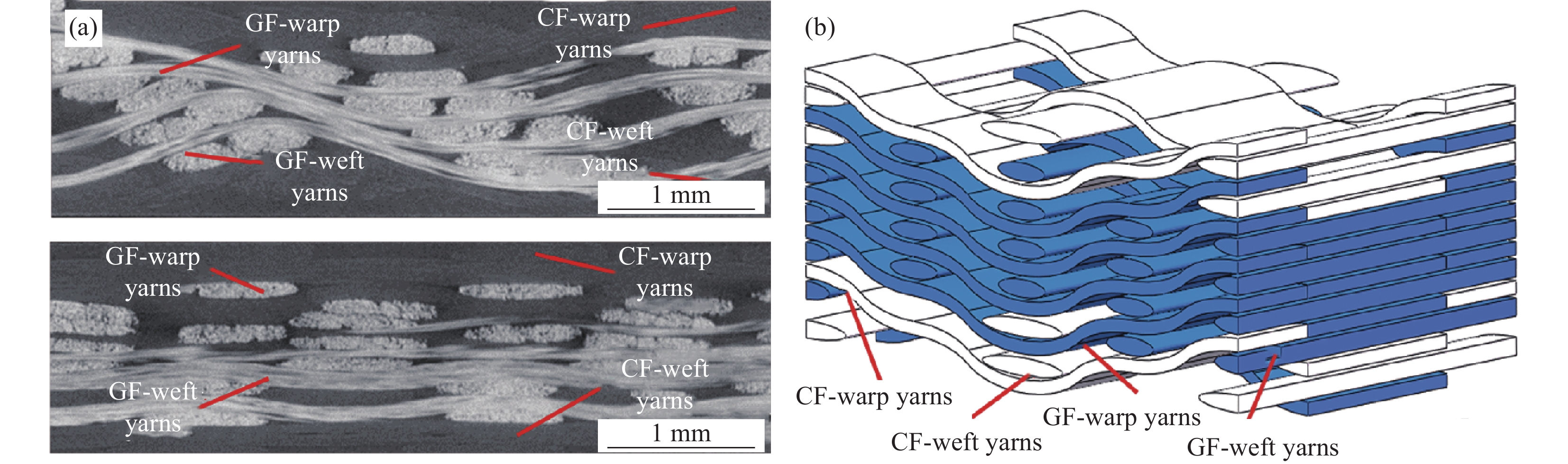

2.5D woven carbon fiber-glass fiber/bismaleimide resin composite was prepared by three-dimensional textile technology and resin transfer molding (RTM), and the mechanical properties of three-point bending and interlaminar shear were tested at room temperature (25℃) and high temperature (150℃, 240℃, 300℃), respectively, and the influence of temperature on the mechanical behavior and damage mechanism of the composites was explored. The results show that temperature has a significant effect on the mechanical properties and damage mode of 2.5D woven carbon fiber-glass fiber/bismaleimide resin composites. Temperature rise leads to weakening of fiber/matrix interface adhesion. Compared with the room temperature environment, the flexural strength, flexural modulus and interlaminar shear strength of the composite at 300℃ decrease by 23.06%, 70.01% and 18.93%. Under bending load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly dominated by local fiber fracture and matrix cracking, while high temperature damage is dominated by fiber/matrix interface debonding. Under shear load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly stratified failure. With the increase of temperature, the composites appear plastic deformation due to the softening of matrix, matrix cracking, interface debonding and stratified failure determine the final failure of the material.

2.5D woven carbon fiber-glass fiber/bismaleimide resin composite was prepared by three-dimensional textile technology and resin transfer molding (RTM), and the mechanical properties of three-point bending and interlaminar shear were tested at room temperature (25℃) and high temperature (150℃, 240℃, 300℃), respectively, and the influence of temperature on the mechanical behavior and damage mechanism of the composites was explored. The results show that temperature has a significant effect on the mechanical properties and damage mode of 2.5D woven carbon fiber-glass fiber/bismaleimide resin composites. Temperature rise leads to weakening of fiber/matrix interface adhesion. Compared with the room temperature environment, the flexural strength, flexural modulus and interlaminar shear strength of the composite at 300℃ decrease by 23.06%, 70.01% and 18.93%. Under bending load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly dominated by local fiber fracture and matrix cracking, while high temperature damage is dominated by fiber/matrix interface debonding. Under shear load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly stratified failure. With the increase of temperature, the composites appear plastic deformation due to the softening of matrix, matrix cracking, interface debonding and stratified failure determine the final failure of the material.

2024, 41(1): 155-169.

doi: 10.13801/j.cnki.fhclxb.20230529.006

Abstract:

Polydicyclopentadiene (PDCPD) as a thermosetting resin with excellent comprehensive performance, can be composited with continuous carbon fibers (CF), for the application of various engineering field to meet the requirements of lightweight, energy conservation and environmental protection. In this paper, firstly, the viscosity of the DCPD prepolymer could meet the demands of vacuum assisted resin infusion (VARI) molding process by adjusting the content of Grubbs 2 catalyst. Subsequently, the carbon fiber was subjected desizing treatment, and then compounded with the prepolymer added with sufficient catalyst. The tensile, flexural, V-notch shear, interlaminar fracture toughness, impact, and thermodynamic properties of PDCPD/CF composites were compared with thegeneral epoxy resin (EP)/CF composites, The failure mechanisms of PDCPD/CF composites under different loading modes were detected, and the key points and directions for their application in the engineering field were explored. The results show that the interface between the carbon fibers after desizing and PDCPD is well bonded, and the strength of PDCPD/CF composite is comparable to that of EP/CF composite. Although PDCPD/CF composite had weaker deformation resistance, they still had a certain degree of bearing capacity after being subjected to the ultimate loads. From the perspective of interlaminar fracture toughness, PDCPD/CF composites have excellent delamination resistance, with mode I and mode II fracture toughness equivalent to 406% and 250% of CF/EP composites, respectively. A barely visible impact damage (BVID) has formed on the top surface of a 3.2 mm-thickness PDCPD laminate after being subjected to a 40 J impact, while there is no significant fiber breakage on the bottom surface. The residual compression strength of PDCPD/CF composites is 34.7% higher than the EP/CF composite.

Polydicyclopentadiene (PDCPD) as a thermosetting resin with excellent comprehensive performance, can be composited with continuous carbon fibers (CF), for the application of various engineering field to meet the requirements of lightweight, energy conservation and environmental protection. In this paper, firstly, the viscosity of the DCPD prepolymer could meet the demands of vacuum assisted resin infusion (VARI) molding process by adjusting the content of Grubbs 2 catalyst. Subsequently, the carbon fiber was subjected desizing treatment, and then compounded with the prepolymer added with sufficient catalyst. The tensile, flexural, V-notch shear, interlaminar fracture toughness, impact, and thermodynamic properties of PDCPD/CF composites were compared with thegeneral epoxy resin (EP)/CF composites, The failure mechanisms of PDCPD/CF composites under different loading modes were detected, and the key points and directions for their application in the engineering field were explored. The results show that the interface between the carbon fibers after desizing and PDCPD is well bonded, and the strength of PDCPD/CF composite is comparable to that of EP/CF composite. Although PDCPD/CF composite had weaker deformation resistance, they still had a certain degree of bearing capacity after being subjected to the ultimate loads. From the perspective of interlaminar fracture toughness, PDCPD/CF composites have excellent delamination resistance, with mode I and mode II fracture toughness equivalent to 406% and 250% of CF/EP composites, respectively. A barely visible impact damage (BVID) has formed on the top surface of a 3.2 mm-thickness PDCPD laminate after being subjected to a 40 J impact, while there is no significant fiber breakage on the bottom surface. The residual compression strength of PDCPD/CF composites is 34.7% higher than the EP/CF composite.

2024, 41(1): 170-179.

doi: 10.13801/j.cnki.fhclxb.20230515.003

Abstract:

The liquid oxygen tanks that made of carbon fiber/epoxy resin composites are vital for weight reduction in new generation spacecraft such as heavy rockets and space shuttles. However, the incompatibility of epoxy resin with liquid oxygen limits their application. Thermogravimetric analyser, the Kissinger method, the Coasts-Redfern method and thermogravimetric-infrared-gas chromatography/mass spectrometry were used to investigate the thermal degradation behaviors and mechanism of 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphafi-10-oxide (ODOPB)-modified liquid oxygen-compatible epoxy resin (ODOPB-EP). The results show that the thermal degradation mechanism of ODOPB-EP is a phase boundary reaction, corresponding to the degradation mechanism function g(α)=1−(1−α)1/3, α is conversion rate. During the thermal degradation process, the resin breaks from the weak bonds of C—N and C—O. With the increase of temperature, aromatic substances such as phenol and its derivatives are released. Besides, ODOPB part in resin produces biphenyl and other substances, accompanied by the release of phosphorus-containing radicals. The phosphorus-containing radicals could exert quenching effects, which is conducive to improving the compatibility of the resin with liquid oxygen. This study provides a theoretic basis for verifying the compatible mechanism of polymers with liquid oxygen.

The liquid oxygen tanks that made of carbon fiber/epoxy resin composites are vital for weight reduction in new generation spacecraft such as heavy rockets and space shuttles. However, the incompatibility of epoxy resin with liquid oxygen limits their application. Thermogravimetric analyser, the Kissinger method, the Coasts-Redfern method and thermogravimetric-infrared-gas chromatography/mass spectrometry were used to investigate the thermal degradation behaviors and mechanism of 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphafi-10-oxide (ODOPB)-modified liquid oxygen-compatible epoxy resin (ODOPB-EP). The results show that the thermal degradation mechanism of ODOPB-EP is a phase boundary reaction, corresponding to the degradation mechanism function g(α)=1−(1−α)1/3, α is conversion rate. During the thermal degradation process, the resin breaks from the weak bonds of C—N and C—O. With the increase of temperature, aromatic substances such as phenol and its derivatives are released. Besides, ODOPB part in resin produces biphenyl and other substances, accompanied by the release of phosphorus-containing radicals. The phosphorus-containing radicals could exert quenching effects, which is conducive to improving the compatibility of the resin with liquid oxygen. This study provides a theoretic basis for verifying the compatible mechanism of polymers with liquid oxygen.

2024, 41(1): 180-187.

doi: 10.13801/j.cnki.fhclxb.20230525.001

Abstract:

Carbon soot particles (CSPS) widely exists and is easy to collect in the production and living, with the size of the nanoscale and good photothermal properties, is one of the important candidate materials for photothermal materials. CSPS are obtained by collecting the incomplete combustion by-products of fuels such as candles and edible oils. The composite coating CSPS/MPVDF-ER was constructed with carbon soot particles, alkali modified polyvinylidene fluoride (MPVDF) and epoxy resin (ER) as the main raw materials, and various factors affecting the photothermal properties, hydrophobicity of the composite coating were studied. The results show that the water repellency of CSPS/MPVDF-ER is significantly improved with the addition of CSPS (Water contact angle (WCA)>163°, water sliding angle (WSA)<1°). With the addition of CSPS, the photothermal efficiency of CSPS/MPVDF-ER coating is gradually increased, and the contact angle and water impact resistance of CSPS/MPVDF-ER coating are gradually enhanced. The maximum photothermal efficiency (temperature difference with the environment ΔT=88℃) of the coating is reached when the mass ratio of CSPS and MPVDF-ER is 0.05, CSPS/MPVDF-ER coating has good resistance to acid, alkali and UV. The CSPS/MPVDF-ER coating prepared by a simple method from a wide range of CSPS nanoparticles has excellent photothermal conversion efficiency and superhydrophobic properties, which provides a feasible method for the preparation of low-cost and high-strength superhydrophobic antifouling photothermal coatings.

Carbon soot particles (CSPS) widely exists and is easy to collect in the production and living, with the size of the nanoscale and good photothermal properties, is one of the important candidate materials for photothermal materials. CSPS are obtained by collecting the incomplete combustion by-products of fuels such as candles and edible oils. The composite coating CSPS/MPVDF-ER was constructed with carbon soot particles, alkali modified polyvinylidene fluoride (MPVDF) and epoxy resin (ER) as the main raw materials, and various factors affecting the photothermal properties, hydrophobicity of the composite coating were studied. The results show that the water repellency of CSPS/MPVDF-ER is significantly improved with the addition of CSPS (Water contact angle (WCA)>163°, water sliding angle (WSA)<1°). With the addition of CSPS, the photothermal efficiency of CSPS/MPVDF-ER coating is gradually increased, and the contact angle and water impact resistance of CSPS/MPVDF-ER coating are gradually enhanced. The maximum photothermal efficiency (temperature difference with the environment ΔT=88℃) of the coating is reached when the mass ratio of CSPS and MPVDF-ER is 0.05, CSPS/MPVDF-ER coating has good resistance to acid, alkali and UV. The CSPS/MPVDF-ER coating prepared by a simple method from a wide range of CSPS nanoparticles has excellent photothermal conversion efficiency and superhydrophobic properties, which provides a feasible method for the preparation of low-cost and high-strength superhydrophobic antifouling photothermal coatings.

2024, 41(1): 188-195.

doi: 10.13801/j.cnki.fhclxb.20230512.002

Abstract:

The low frequency radar-stealth performance of the dielectric metamaterial for broadband wave-absorbing honeycomb sandwich composites was studied. The electromagnetic response characteristics of the carbon fiber dielectric metamaterial units and their effects on the electrical and mechanical properties of wave-absorbing honeycomb sandwich composites were analyzed. The results show that the electromagnetic response of the carbon fiber metamaterial units can be comparable to that of the metal metamaterial units. When the height of the wave-absorbing honeycomb is 50 mm and the thickness of the wave-transmitting skin is 1 mm, the introduction of the carbon fiber metamaterial units can significantly improve the low-frequency wave-absorbing performance of the honeycomb sandwich composites. The weakest reflectivity and the averaged reflectivity in the L-band are increased by more than 2 dB and 4 dB, respectively. The mechanical properties of the wave-transmitting skin with carbon fiber dielectric metamaterial are close to that without metamaterial units. The introduction of carbon fiber dielectric metamaterial units shows no negative effects on the mechanical properties of the wave-transmitting skin.

The low frequency radar-stealth performance of the dielectric metamaterial for broadband wave-absorbing honeycomb sandwich composites was studied. The electromagnetic response characteristics of the carbon fiber dielectric metamaterial units and their effects on the electrical and mechanical properties of wave-absorbing honeycomb sandwich composites were analyzed. The results show that the electromagnetic response of the carbon fiber metamaterial units can be comparable to that of the metal metamaterial units. When the height of the wave-absorbing honeycomb is 50 mm and the thickness of the wave-transmitting skin is 1 mm, the introduction of the carbon fiber metamaterial units can significantly improve the low-frequency wave-absorbing performance of the honeycomb sandwich composites. The weakest reflectivity and the averaged reflectivity in the L-band are increased by more than 2 dB and 4 dB, respectively. The mechanical properties of the wave-transmitting skin with carbon fiber dielectric metamaterial are close to that without metamaterial units. The introduction of carbon fiber dielectric metamaterial units shows no negative effects on the mechanical properties of the wave-transmitting skin.

2024, 41(1): 196-206.

doi: 10.13801/j.cnki.fhclxb.20230427.002

Abstract:

Due to the poor conductivity, carbon fiber reinforced resin matrix composites (CFRP) cannot meet the lightning strike protection requirement of aircrafts. The metallization of carbon nanotube (CNT) films are lightweight, and possess high conductivity and high current-carrying capacity, making them promising for lightning strike protection of composite materials. CNT/Cu composite films were successfully prepared by electrochemical deposition process, and its microstructure, electrical properties and current-carrying failure behavior were characterized and analyzed. The results show that CNT/Cu composite films are flexible and have gradient microstructures, where the content of Cu gradually decreases from one side to another. The electrical conductivity of the composite films is 2.16×107 S/m, and their specific conductivity is 2 times of pure Cu, and the current carrying capacity and specific current carrying capacity are 1.4 times and 7 times of copper mesh, respectively. CNTs in the composite film can inhibit the electromigration of Cu, thus prolonging its current-carrying failure time. CFRPs for lightning strike protection testing were prepared by using CNT/Cu composite films, and the lightning strike protection performance was evaluated by artificial simulation lightning test and damage analysis. Compared with copper mesh, CNT/Cu composite films are 61% lighter and showed more excellent lightning protection performance.

Due to the poor conductivity, carbon fiber reinforced resin matrix composites (CFRP) cannot meet the lightning strike protection requirement of aircrafts. The metallization of carbon nanotube (CNT) films are lightweight, and possess high conductivity and high current-carrying capacity, making them promising for lightning strike protection of composite materials. CNT/Cu composite films were successfully prepared by electrochemical deposition process, and its microstructure, electrical properties and current-carrying failure behavior were characterized and analyzed. The results show that CNT/Cu composite films are flexible and have gradient microstructures, where the content of Cu gradually decreases from one side to another. The electrical conductivity of the composite films is 2.16×107 S/m, and their specific conductivity is 2 times of pure Cu, and the current carrying capacity and specific current carrying capacity are 1.4 times and 7 times of copper mesh, respectively. CNTs in the composite film can inhibit the electromigration of Cu, thus prolonging its current-carrying failure time. CFRPs for lightning strike protection testing were prepared by using CNT/Cu composite films, and the lightning strike protection performance was evaluated by artificial simulation lightning test and damage analysis. Compared with copper mesh, CNT/Cu composite films are 61% lighter and showed more excellent lightning protection performance.

2024, 41(1): 207-218.

doi: 10.13801/j.cnki.fhclxb.20230531.003

Abstract:

Microstructuring is one of the important techniques to improve the performance of flexible pressure sensors. In this paper, a method for designing and fabricating hierarchical microstructures based on micro/nano fibers was proposed. First, a sacrificial mold with hierarchical microstructures was prepared by integrating near-field direct writing and fused deposition modeling. Carbon nanotubes (CNTs) were doped into polydimethylsiloxane (PDMS) as the dielectric layer material for the flexible sensor. The CNTs/PDMS flexible dielectric layer with hierarchical microstructures was then prepared by sacrificial template method. Furthermore, the effect of design parameters of hierarchical microstructures on the sensing performance was studied. The experimental results show that the designed microstructures can significantly enhance the output electrical performance of the flexible sensor. Among them, the hierarchical microstructure with a height of 1.3 mm and a spacing of 1.5 mm exhibits the best output electrical performance under a pressure load of 14 N at a frequency of 3 Hz. In addition, the fabricated sensor exhibits good stability and durability after 20000 cycles of testing. Finally, a flexible pressure sensing insole was designed for observing the distribution of foot pressure and gait detection, which demonstrates good sensitivity and stability. This study provides a new approach for low-cost and rapid fabrication of hierarchical microstructures and serves as a reference for the development of high-performance flexible pressure sensors.

Microstructuring is one of the important techniques to improve the performance of flexible pressure sensors. In this paper, a method for designing and fabricating hierarchical microstructures based on micro/nano fibers was proposed. First, a sacrificial mold with hierarchical microstructures was prepared by integrating near-field direct writing and fused deposition modeling. Carbon nanotubes (CNTs) were doped into polydimethylsiloxane (PDMS) as the dielectric layer material for the flexible sensor. The CNTs/PDMS flexible dielectric layer with hierarchical microstructures was then prepared by sacrificial template method. Furthermore, the effect of design parameters of hierarchical microstructures on the sensing performance was studied. The experimental results show that the designed microstructures can significantly enhance the output electrical performance of the flexible sensor. Among them, the hierarchical microstructure with a height of 1.3 mm and a spacing of 1.5 mm exhibits the best output electrical performance under a pressure load of 14 N at a frequency of 3 Hz. In addition, the fabricated sensor exhibits good stability and durability after 20000 cycles of testing. Finally, a flexible pressure sensing insole was designed for observing the distribution of foot pressure and gait detection, which demonstrates good sensitivity and stability. This study provides a new approach for low-cost and rapid fabrication of hierarchical microstructures and serves as a reference for the development of high-performance flexible pressure sensors.

2024, 41(1): 219-226.

doi: 10.13801/j.cnki.fhclxb.20230614.001

Abstract:

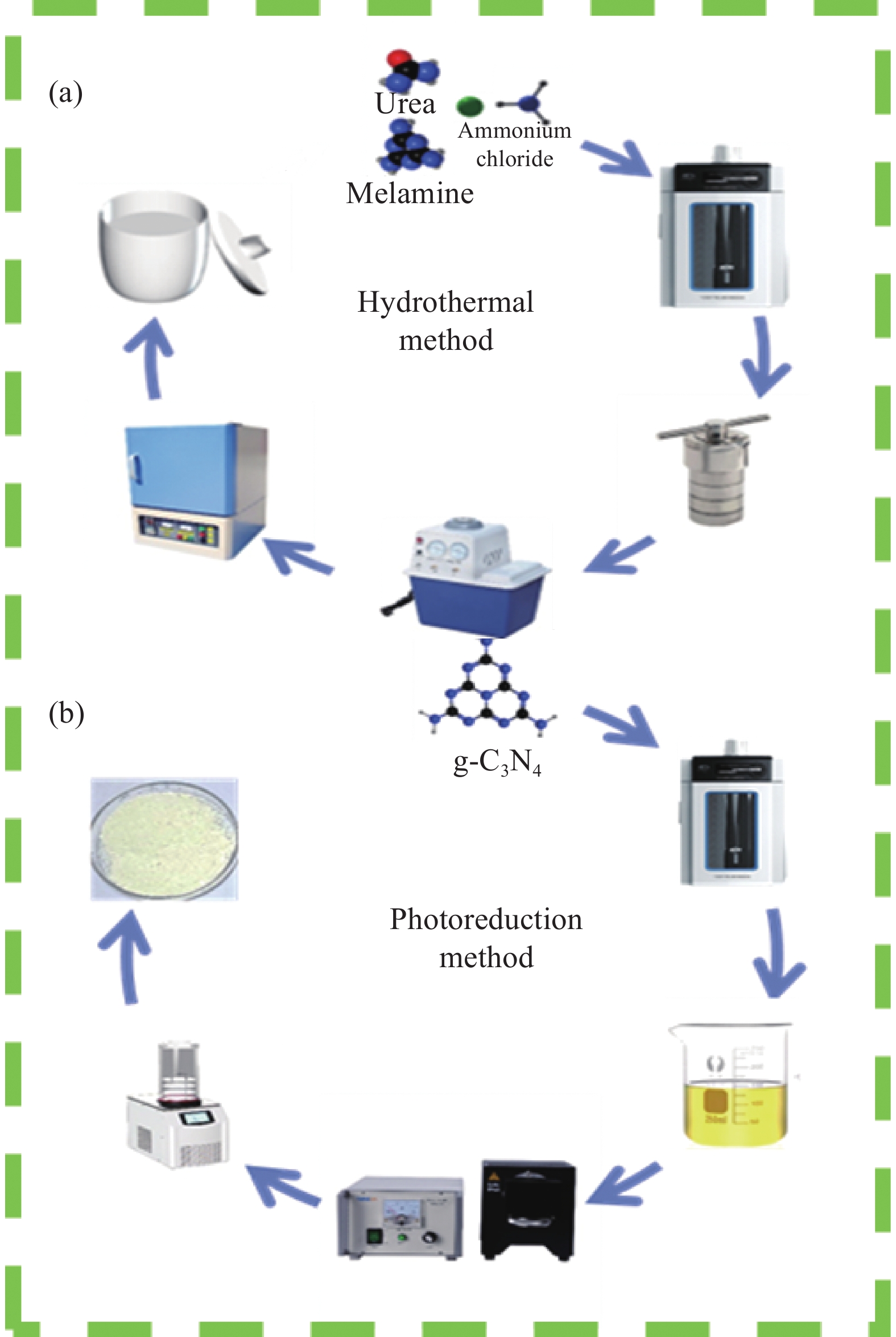

Noble-metal, as co-catalysts, can improve the photocatalytic hydrogen production performance of graphitic carbon nitride (g-C3N4). It has been paid extensive attention, however, due to the non-renewability and high expense of noble-metal, "less noble-metal, better performance" is always the goal. To achieve this goal, composite CN with different Pt loadings (Pt/CN) was successfully prepared by photoreduction deposition and used for photocatalytic hydrogen production. The results show that Pt/CN with different Pt loadings can improved photocatalytic hydrogen production performance than CN. It is found that Pt/CN loaded with 0.5wt%Pt have the best photocatalytic hydrogen production activity, with a hydrogen production rate of 409.2 μmol/g, which is 23 times higher than that of CN (17.8 μmol/g). At the same time, it is confirmed that a Schottky barrier is formed between Pt and CN, which makes the electrons of the conduction band migrate rapidly to Pt, which reduces the electron-hole recombination rate of CN. Moreover, Pt is used as the active site of photocatalytic water splitting, which promotes the rapid adsorption of most of the hydrogen protons in the water to the Pt site, and the electrons are reduced to hydrogen, realizing efficient photocatalytic hydrogen production.

Noble-metal, as co-catalysts, can improve the photocatalytic hydrogen production performance of graphitic carbon nitride (g-C3N4). It has been paid extensive attention, however, due to the non-renewability and high expense of noble-metal, "less noble-metal, better performance" is always the goal. To achieve this goal, composite CN with different Pt loadings (Pt/CN) was successfully prepared by photoreduction deposition and used for photocatalytic hydrogen production. The results show that Pt/CN with different Pt loadings can improved photocatalytic hydrogen production performance than CN. It is found that Pt/CN loaded with 0.5wt%Pt have the best photocatalytic hydrogen production activity, with a hydrogen production rate of 409.2 μmol/g, which is 23 times higher than that of CN (17.8 μmol/g). At the same time, it is confirmed that a Schottky barrier is formed between Pt and CN, which makes the electrons of the conduction band migrate rapidly to Pt, which reduces the electron-hole recombination rate of CN. Moreover, Pt is used as the active site of photocatalytic water splitting, which promotes the rapid adsorption of most of the hydrogen protons in the water to the Pt site, and the electrons are reduced to hydrogen, realizing efficient photocatalytic hydrogen production.

2024, 41(1): 227-239.

doi: 10.13801/j.cnki.fhclxb.20230511.001

Abstract:

In order to improve the durability of superhydrophobic coatings, in this work, we designed a bottom-up coating system of “substrate-viscous self-healing polymer-hydrophobic particle”, thereby the superhydrophobic surface with self-healing function was successfully fabricated: Hyperbranched polydimethylsiloxane (HB-PDMS) with abundant hydrogen bonds as viscous self-healing polymer; Nano-SiO2 was hydrophobic modified by myristic acid (MA) as hydrophobic particles to construct rough surface structure. When the mass ratio of MA to SiO2 is 1∶1 and the modification time is 3 h, the superhydrophobic coating prepared has a contact angle of 152.61° and a sliding angle of 1.9°, which has excellent antifouling performance. The coating can be healed by simple heat treatment after being scratched by the blade, and has excellent self-healing performance. Compared with pure aluminum, the composite coating has better anti-corrosion performance and the corrosion inhibition efficiency can reach 87.53%. In addition, After 5 tape peel tests, linear wear tests with a wear length of 30 cm, ultrasonic shock tests of 50 min, 10 temperature differential cycles and 24 h ultraviolet irradiation, the contact angle remained above 150°, indicating that the coating has good mechanical stability and weather resistance. This study provides a new effective strategy for the preparation of self-healing superhydrophobic coatings, which is expected to be applied in the field of building antifouling.

In order to improve the durability of superhydrophobic coatings, in this work, we designed a bottom-up coating system of “substrate-viscous self-healing polymer-hydrophobic particle”, thereby the superhydrophobic surface with self-healing function was successfully fabricated: Hyperbranched polydimethylsiloxane (HB-PDMS) with abundant hydrogen bonds as viscous self-healing polymer; Nano-SiO2 was hydrophobic modified by myristic acid (MA) as hydrophobic particles to construct rough surface structure. When the mass ratio of MA to SiO2 is 1∶1 and the modification time is 3 h, the superhydrophobic coating prepared has a contact angle of 152.61° and a sliding angle of 1.9°, which has excellent antifouling performance. The coating can be healed by simple heat treatment after being scratched by the blade, and has excellent self-healing performance. Compared with pure aluminum, the composite coating has better anti-corrosion performance and the corrosion inhibition efficiency can reach 87.53%. In addition, After 5 tape peel tests, linear wear tests with a wear length of 30 cm, ultrasonic shock tests of 50 min, 10 temperature differential cycles and 24 h ultraviolet irradiation, the contact angle remained above 150°, indicating that the coating has good mechanical stability and weather resistance. This study provides a new effective strategy for the preparation of self-healing superhydrophobic coatings, which is expected to be applied in the field of building antifouling.

2024, 41(1): 240-249.

doi: 10.13801/j.cnki.fhclxb.20230417.002

Abstract:

In order to improve the utilization rate of active substances, chitosan-polyvinylpyrrolidone hydrogel film loaded with tea polyphenols with pH response was prepared by selecting chitosan, polyvinylpyrrolidone as the substrate, glycerin as plasticizer, glutaraldehyde as crosslinker and tea polyphenol as antioxidant. The microstructure of the film was characterized by SEM and FTIR, and the water vapor transmittance, mechanical properties, swelling, gel content and oxidation resistance of the film were tested, and then the release rate of tea polyphenols in hydrogel films under different pH values was determined, the pH responsiveness was explored, and the release law of tea polyphenols was determined by constructing a kinetic model. The results show that the interaction between the crosslinker and chitosan forms a stable hydrogel structure, while the addition of tea polyphenols further improves the crosslinking strength and more stable structure between the components. The addition of crosslinking agent and tea polyphenols improves the physical and chemical properties of the film as a whole, the water vapor transmittance of the hydrogel film is (0.159±0.010) g·mm/(m2·h·kPa), the tensile strength was (40.58±2.11) MPa, the elongation at break is 62.32%±3.50%, the swelling ratio at swelling equilibrium is 346.27%±3.16%, and the gel content is 87.94%±0.50%. Compared with traditional films, the antioxidant activity is nearly 5 times higher. The hydrogel film loaded with tea polyphenols can effectively respond to pH changes, when the pH value is smaller, the cumulative release rate of tea polyphenols is larger, compared with the Higuchi and Ritger-Peppas model, the release law of tea polyphenols is consistent with the first-order kinetic model. Chitosan-polyvinylpyrrolidone hydrogel film loaded with tea polyphenols can effectively realize the pH response release of tea polyphenols and other active substances, and has the potential to be used in the field of food packaging.

In order to improve the utilization rate of active substances, chitosan-polyvinylpyrrolidone hydrogel film loaded with tea polyphenols with pH response was prepared by selecting chitosan, polyvinylpyrrolidone as the substrate, glycerin as plasticizer, glutaraldehyde as crosslinker and tea polyphenol as antioxidant. The microstructure of the film was characterized by SEM and FTIR, and the water vapor transmittance, mechanical properties, swelling, gel content and oxidation resistance of the film were tested, and then the release rate of tea polyphenols in hydrogel films under different pH values was determined, the pH responsiveness was explored, and the release law of tea polyphenols was determined by constructing a kinetic model. The results show that the interaction between the crosslinker and chitosan forms a stable hydrogel structure, while the addition of tea polyphenols further improves the crosslinking strength and more stable structure between the components. The addition of crosslinking agent and tea polyphenols improves the physical and chemical properties of the film as a whole, the water vapor transmittance of the hydrogel film is (0.159±0.010) g·mm/(m2·h·kPa), the tensile strength was (40.58±2.11) MPa, the elongation at break is 62.32%±3.50%, the swelling ratio at swelling equilibrium is 346.27%±3.16%, and the gel content is 87.94%±0.50%. Compared with traditional films, the antioxidant activity is nearly 5 times higher. The hydrogel film loaded with tea polyphenols can effectively respond to pH changes, when the pH value is smaller, the cumulative release rate of tea polyphenols is larger, compared with the Higuchi and Ritger-Peppas model, the release law of tea polyphenols is consistent with the first-order kinetic model. Chitosan-polyvinylpyrrolidone hydrogel film loaded with tea polyphenols can effectively realize the pH response release of tea polyphenols and other active substances, and has the potential to be used in the field of food packaging.

2024, 41(1): 250-260.

doi: 10.13801/j.cnki.fhclxb.20230504.003

Abstract:

In this study, a graphene-carbon nanotube-poly(lactic acid)/polyethylene glycol (Gr-CNT-PLA/PEG) phase change energy storage composite material was prepared using a solution-melt blending method. The effects of conductive particles and PEG on the crystallization behavior, electrical conductivity, and temperature-sensitive response of the PLA phase change energy storage composite material were investigated in detail. During the solution-melt blending process, the two-dimensional graphene and one-dimensional carbon nanotubes can physically hybridize into three-dimensional Gr-CNT hybrid particles under the influence of thermodynamic and kinetic factors, improving the dispersion of conductive particles in the composite material and reducing the percolation threshold to about 0.51wt%. Furthermore, the electrical conductivity and crystallization behavior of the Gr-CNT-PLA/PEG composite material are further improved by the interaction between PEG phase change energy storage material and conductive particles, and the crystallization temperature is increased from 100℃ (PLA) to about 130℃ ((Gr-CNT50)0.6-PLA/PEG10). In the constant temperature-resistance test, the conductivity of the Gr-CNT-PLA/PEG composite material decreases and then increases with the increase of isothermal heat treatment temperature. In the cyclic temperature-resistance test, the Gr-CNT-PLA composite material exhibites low-temperature PTC and high-temperature NTC effects in the cyclic temperature range of 37℃ to 140℃. Through the synergistic regulation of phase change energy storage material PEG and cyclic temperature value, the Gr-CNT-PLA/PEG composite material exhibites a good phase transition energy storage platform during cooling, successfully achieving a monotonic PTC effect and high-temperature sensitivity, with a sensitivity (ΔR/R0) up to 3000%. Moreover, with the increase of PEG mass content, the energy storage platform of the composite material can be effectively widened, up to 16.28 min, providing a basis for the preparation of high-sensitivity temperature sensors.

In this study, a graphene-carbon nanotube-poly(lactic acid)/polyethylene glycol (Gr-CNT-PLA/PEG) phase change energy storage composite material was prepared using a solution-melt blending method. The effects of conductive particles and PEG on the crystallization behavior, electrical conductivity, and temperature-sensitive response of the PLA phase change energy storage composite material were investigated in detail. During the solution-melt blending process, the two-dimensional graphene and one-dimensional carbon nanotubes can physically hybridize into three-dimensional Gr-CNT hybrid particles under the influence of thermodynamic and kinetic factors, improving the dispersion of conductive particles in the composite material and reducing the percolation threshold to about 0.51wt%. Furthermore, the electrical conductivity and crystallization behavior of the Gr-CNT-PLA/PEG composite material are further improved by the interaction between PEG phase change energy storage material and conductive particles, and the crystallization temperature is increased from 100℃ (PLA) to about 130℃ ((Gr-CNT50)0.6-PLA/PEG10). In the constant temperature-resistance test, the conductivity of the Gr-CNT-PLA/PEG composite material decreases and then increases with the increase of isothermal heat treatment temperature. In the cyclic temperature-resistance test, the Gr-CNT-PLA composite material exhibites low-temperature PTC and high-temperature NTC effects in the cyclic temperature range of 37℃ to 140℃. Through the synergistic regulation of phase change energy storage material PEG and cyclic temperature value, the Gr-CNT-PLA/PEG composite material exhibites a good phase transition energy storage platform during cooling, successfully achieving a monotonic PTC effect and high-temperature sensitivity, with a sensitivity (ΔR/R0) up to 3000%. Moreover, with the increase of PEG mass content, the energy storage platform of the composite material can be effectively widened, up to 16.28 min, providing a basis for the preparation of high-sensitivity temperature sensors.

2024, 41(1): 261-270.

doi: 10.13801/j.cnki.fhclxb.20230504.001

Abstract:

The styrene-acrylic emulsion used to prepare waterborne damping coatings needs to further increase the damping factor and broaden the effective damping temperature range. In order to improve the damping performance of styrene-acrylic emulsion, oleic acid (OA) modified nano-Fe3O4 (OA-Fe3O4) was used as the coated filler to prepare Fe3O4/poly(styrene acrylate) (Fe3O4/P(St-2-EHA)) composite damping emulsion via miniemulsion polymerization. The composite emulsion and its latex film were characterized by FTIR, XRD, TEM, SEM, DLS, TG and DMA. The effects of copolymer composition, surface properties and content of nano-Fe3O4 on the structure and performance of the emulsion and latex film were studied. The results show that the direct agglomeration of OA-Fe3O4 nanoparticles is weakened, and its dispersion in the composite emulsion is significantly improved. When the mass ratio of monomer St to 2-EHA is 5∶5, the obtained P(St-2-EHA) latex film has the highest loss factor (tanδ) peak (1.926). When the mass ratio of OA-Fe3O4 to the total mass of St and 2-EHA is 10wt%, the obtained Fe3O4/P(St-2-EHA) composite latex film has the best performance. Its tanδ peak value and effective damping temperature range width are 2.066 and 59.2℃, which are better than pure P(St-2-EHA) latex film and composite latex film prepared by blending method. Its water absorption rate is 3.4% and 10.4% lower than the latter two respectively. And the initial thermal decomposition temperature is higher, with the thermal stability improved.

The styrene-acrylic emulsion used to prepare waterborne damping coatings needs to further increase the damping factor and broaden the effective damping temperature range. In order to improve the damping performance of styrene-acrylic emulsion, oleic acid (OA) modified nano-Fe3O4 (OA-Fe3O4) was used as the coated filler to prepare Fe3O4/poly(styrene acrylate) (Fe3O4/P(St-2-EHA)) composite damping emulsion via miniemulsion polymerization. The composite emulsion and its latex film were characterized by FTIR, XRD, TEM, SEM, DLS, TG and DMA. The effects of copolymer composition, surface properties and content of nano-Fe3O4 on the structure and performance of the emulsion and latex film were studied. The results show that the direct agglomeration of OA-Fe3O4 nanoparticles is weakened, and its dispersion in the composite emulsion is significantly improved. When the mass ratio of monomer St to 2-EHA is 5∶5, the obtained P(St-2-EHA) latex film has the highest loss factor (tanδ) peak (1.926). When the mass ratio of OA-Fe3O4 to the total mass of St and 2-EHA is 10wt%, the obtained Fe3O4/P(St-2-EHA) composite latex film has the best performance. Its tanδ peak value and effective damping temperature range width are 2.066 and 59.2℃, which are better than pure P(St-2-EHA) latex film and composite latex film prepared by blending method. Its water absorption rate is 3.4% and 10.4% lower than the latter two respectively. And the initial thermal decomposition temperature is higher, with the thermal stability improved.

2024, 41(1): 271-280.

doi: 10.13801/j.cnki.fhclxb.20230524.001

Abstract:

In this paper, two kinds of multi-functional composites integrated with heat-shielding and radar-absorbing were prepared by high pressure resin transfer molding (HP-RTM), employing traditional phenolic and silicone resin as matrix, needle stitched quartz fiber fabric as reinforcing material, and metamaterials as radar absorbing layers. The effects of microstructure, mechanical properties, and ablation on the microwave absorbing properties of the multi-functional composites were systematically investigated. The results show that the two multi-functional composites prepared have uniform microstructure and excellent mechanical properties. The average reflectivity of the composites in 2-18 GHz are lower than −10 dB, especially in S, C, and X bands, and the effective bandwidth is wider than 9 GHz, which is ascribed to the good transmissivity of the medium layer and the resonant absorption effect of metamaterial layers. However, a continuous carbon layer with high conductivity are formed on the surface of phenolic matrix composite after ablation, which seriously degraded its wave absorbing property. In contrast, the wave absorbing property of silicone matrix composite remains the same due to discontinuity of the carbon layer with band shifting to high frequency, which shows its great application potential in high temperature ablation/stealth field.

In this paper, two kinds of multi-functional composites integrated with heat-shielding and radar-absorbing were prepared by high pressure resin transfer molding (HP-RTM), employing traditional phenolic and silicone resin as matrix, needle stitched quartz fiber fabric as reinforcing material, and metamaterials as radar absorbing layers. The effects of microstructure, mechanical properties, and ablation on the microwave absorbing properties of the multi-functional composites were systematically investigated. The results show that the two multi-functional composites prepared have uniform microstructure and excellent mechanical properties. The average reflectivity of the composites in 2-18 GHz are lower than −10 dB, especially in S, C, and X bands, and the effective bandwidth is wider than 9 GHz, which is ascribed to the good transmissivity of the medium layer and the resonant absorption effect of metamaterial layers. However, a continuous carbon layer with high conductivity are formed on the surface of phenolic matrix composite after ablation, which seriously degraded its wave absorbing property. In contrast, the wave absorbing property of silicone matrix composite remains the same due to discontinuity of the carbon layer with band shifting to high frequency, which shows its great application potential in high temperature ablation/stealth field.

2024, 41(1): 281-292.

doi: 10.13801/j.cnki.fhclxb.20230511.005

Abstract:

The control of the morphology and structure has an important influence on the electrochemical properties of materials. In this work, NiCo2O4 samples with different morphologies and structures were synthesized by solvothermal method combined with calcination at different solvent ratios and temperatures. The phase composition and morphology of the samples were characterized by XRD, SEM and TEM et al, and the electrochemical performance was further studied. The results show that the sample is hollow sea urchin-like NiCo2O4, when the volume ratio of water to ethanol is 1∶1. With the increase of the content of water, the morphology gradually changes to regular central radial needle-like morphology, and there is a second phase substance. Under the condition of the volume ratio of water to ethanol is 1∶1, with the increase of temperature, the morphology mainly changes from fluffy ball to a flower-like, sea urchin-like, and center-radiating needle, while the phases of samples are pure NiCo2O4. The sample synthesized at 90℃ exhibits better electrochemical performance. The specific capacitance is up to 1287.5 F·g−1 at a current density of 1 A·g−1. The specific capacitance retention rate reaches 59.4% with the scan rate changes from 20-100 mV·s−1, and the specific capacitance retention rate is up to 80.1% after 1500 cycles. In addition, the whole electrochemical reaction is dominated by the diffusion-controlled process.

The control of the morphology and structure has an important influence on the electrochemical properties of materials. In this work, NiCo2O4 samples with different morphologies and structures were synthesized by solvothermal method combined with calcination at different solvent ratios and temperatures. The phase composition and morphology of the samples were characterized by XRD, SEM and TEM et al, and the electrochemical performance was further studied. The results show that the sample is hollow sea urchin-like NiCo2O4, when the volume ratio of water to ethanol is 1∶1. With the increase of the content of water, the morphology gradually changes to regular central radial needle-like morphology, and there is a second phase substance. Under the condition of the volume ratio of water to ethanol is 1∶1, with the increase of temperature, the morphology mainly changes from fluffy ball to a flower-like, sea urchin-like, and center-radiating needle, while the phases of samples are pure NiCo2O4. The sample synthesized at 90℃ exhibits better electrochemical performance. The specific capacitance is up to 1287.5 F·g−1 at a current density of 1 A·g−1. The specific capacitance retention rate reaches 59.4% with the scan rate changes from 20-100 mV·s−1, and the specific capacitance retention rate is up to 80.1% after 1500 cycles. In addition, the whole electrochemical reaction is dominated by the diffusion-controlled process.

2024, 41(1): 293-306.

doi: 10.13801/j.cnki.fhclxb.20230425.004

Abstract:

With the deepening standards and requirements of zero wastewater discharge, efficient and sustainable membrane separation water treatment technology has become a research hotspot, but faces problems such as low water flux and easy pollution. In this work, photocatalytic self-cleaning composite membranes were prepared by the organic combination of graphitic carbon nitride (g-C3N4), bacterial cellulose (BC) and bismuth sulfide (Bi2S3) by vacuum-assisted filtration. The effects of different additions of g-C3N4 and Bi2S3 on the dye separation performance of the composite membranes were investigated through a series of characterization methods to analyze the physical structure and elemental energy states of the powders and membrane materials, and the degradation mechanism of the dyes under photocatalysis were explored. The results show that 60wt%g-C3N4, 10wt%BC, 30wt%Bi2S3 and the composite membrane have the best overall performance, with the water flux and rejection rate of 23.48 L·m−2·h−1 and 100%, respectively. The water flux of 16.65 L·m−2·h−1 and dye rejection rate of about 90% are still maintained in the long term filtration. The flux recovery rate reach 96.5% after soaking for 3 h under light, indicating that the membrane has good photocatalytic self-cleaning performance. This paper provides new ideas and basic exploration for the design of high-throughput and sustainable separation membranes.

With the deepening standards and requirements of zero wastewater discharge, efficient and sustainable membrane separation water treatment technology has become a research hotspot, but faces problems such as low water flux and easy pollution. In this work, photocatalytic self-cleaning composite membranes were prepared by the organic combination of graphitic carbon nitride (g-C3N4), bacterial cellulose (BC) and bismuth sulfide (Bi2S3) by vacuum-assisted filtration. The effects of different additions of g-C3N4 and Bi2S3 on the dye separation performance of the composite membranes were investigated through a series of characterization methods to analyze the physical structure and elemental energy states of the powders and membrane materials, and the degradation mechanism of the dyes under photocatalysis were explored. The results show that 60wt%g-C3N4, 10wt%BC, 30wt%Bi2S3 and the composite membrane have the best overall performance, with the water flux and rejection rate of 23.48 L·m−2·h−1 and 100%, respectively. The water flux of 16.65 L·m−2·h−1 and dye rejection rate of about 90% are still maintained in the long term filtration. The flux recovery rate reach 96.5% after soaking for 3 h under light, indicating that the membrane has good photocatalytic self-cleaning performance. This paper provides new ideas and basic exploration for the design of high-throughput and sustainable separation membranes.

2024, 41(1): 307-314.

doi: 10.13801/j.cnki.fhclxb.20230523.004

Abstract:

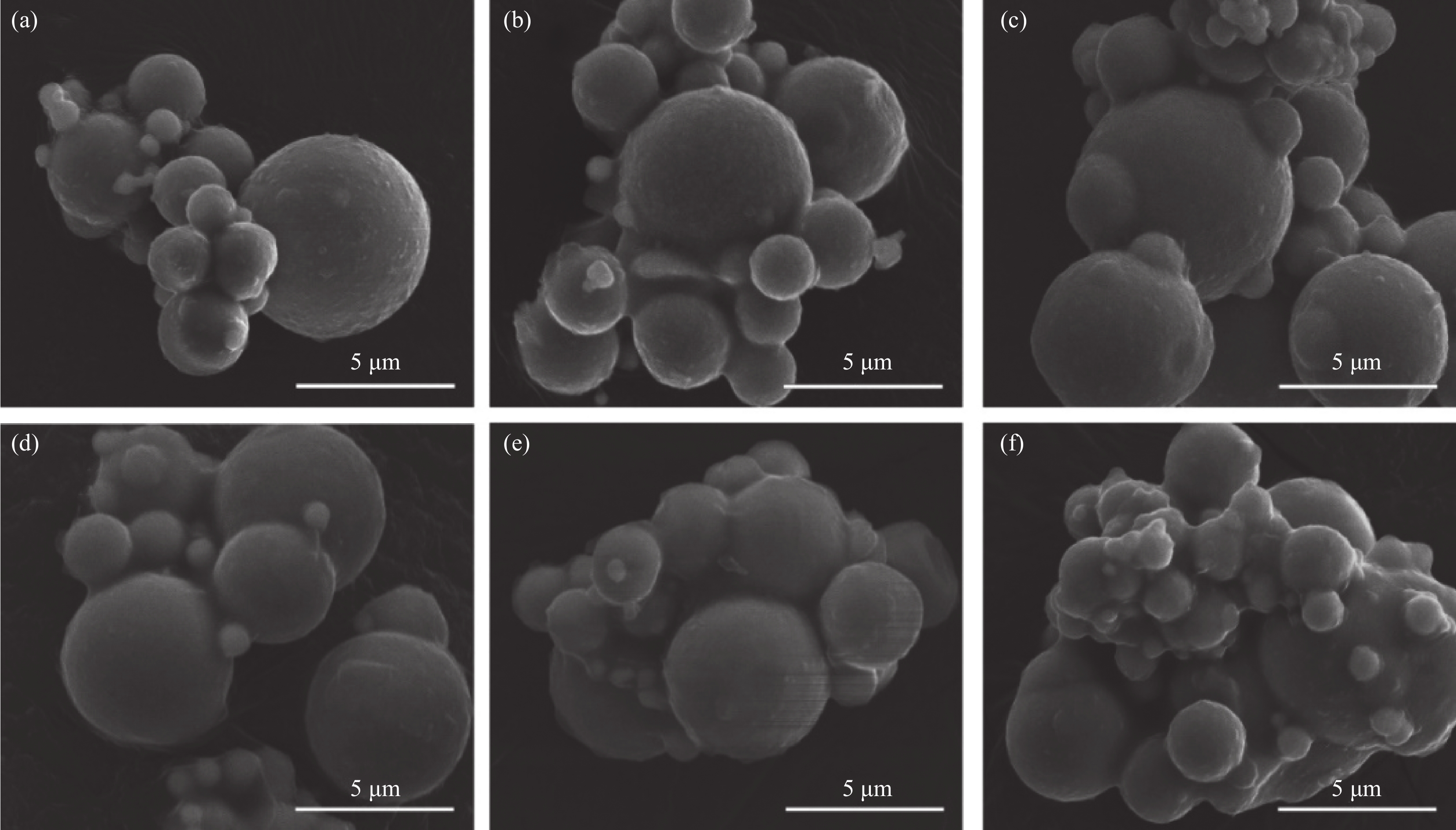

The unique asymmetry of chemistry or composition of external and internal surface for Janus cage allows it to be used as a special microcontainer for separation, enrichment, transport and restricted reactions. To some extent, large aperture of cage can enhance the material transport efficiency between microcontainer and the environment. A two-step method to prepare magnetic organic/inorganic composite Janus cages with large aperture and pH responsiveness was introduced in this paper. Firstly, a magnetic inorganic Janus cage with a well-supported shell and adjustable aperture was prepared by the sol-gel of silane coupling agents and microphase separation of two surfactants at the interface. Then pH-responsive polymer poly diethylaminoethyl methacrylate (PDEAEMA) was grafted on the interior surface of inorganic Janus cage by Cu-mediated controlled radical polymerization to obtain functional Janus composite cages. SEM, TEM, FTIR and TGA were performed on composite cages. The size of cages is about 1-3 μm, with tunable pore size from 40 nm to 1 μm. The proportion of polymer in the composite cages is 41.7wt%. Controlled absorption and release of oil and oriented transport of substance can be achieved by changing pH and magnetic manipulation respectively with these composite Janus cages, which means it is promising for drug loading and targeted release in vivo.

The unique asymmetry of chemistry or composition of external and internal surface for Janus cage allows it to be used as a special microcontainer for separation, enrichment, transport and restricted reactions. To some extent, large aperture of cage can enhance the material transport efficiency between microcontainer and the environment. A two-step method to prepare magnetic organic/inorganic composite Janus cages with large aperture and pH responsiveness was introduced in this paper. Firstly, a magnetic inorganic Janus cage with a well-supported shell and adjustable aperture was prepared by the sol-gel of silane coupling agents and microphase separation of two surfactants at the interface. Then pH-responsive polymer poly diethylaminoethyl methacrylate (PDEAEMA) was grafted on the interior surface of inorganic Janus cage by Cu-mediated controlled radical polymerization to obtain functional Janus composite cages. SEM, TEM, FTIR and TGA were performed on composite cages. The size of cages is about 1-3 μm, with tunable pore size from 40 nm to 1 μm. The proportion of polymer in the composite cages is 41.7wt%. Controlled absorption and release of oil and oriented transport of substance can be achieved by changing pH and magnetic manipulation respectively with these composite Janus cages, which means it is promising for drug loading and targeted release in vivo.

2024, 41(1): 315-322.

doi: 10.13801/j.cnki.fhclxb.20230509.003

Abstract:

With the rapid development of mobile communication, intelligent manufacturing, automotive electronics, electronic new energy and other emerging fields, reducing the magnetic loss and improving other properties of SMCs are required. The silicone resin mixed with epoxy resin was used to coat the phosphatized carbonyl iron powder (CIP). And the coated powders were fabricated into iron based soft magnetic composites (SMCs) through compression and curing. The effects of different mixed resins on the microstructure and electromagnetic properties of iron-based SMCs were studied. The results show that the mixed resin has been formed a reasonable coating layer on the surface of powders, which leads to reduce the strain of the powders introduced during compression and isolate the powders to cut off the eddy current. As a result, the density of SMCs can reach 6.82 g/cm3, the resistivity is as high as 1.1×106 Ω·cm. Meanwhile, its quality factor is improved and the magnetic loss at high frequency is reduced. When the mixed resin is composed of 33.3wt% epoxy resin and 66.7wt% silicone resin, the SMCs are provided with optimal comprehensive performance with 1182.7 kW/m3 loss only at 200 kHz. The magnetic properties of iron-based SMCs are further optimized through selecting the blending resin coating agent with suitable composition, which has a broad application prospect in the field of medium and high frequency.

With the rapid development of mobile communication, intelligent manufacturing, automotive electronics, electronic new energy and other emerging fields, reducing the magnetic loss and improving other properties of SMCs are required. The silicone resin mixed with epoxy resin was used to coat the phosphatized carbonyl iron powder (CIP). And the coated powders were fabricated into iron based soft magnetic composites (SMCs) through compression and curing. The effects of different mixed resins on the microstructure and electromagnetic properties of iron-based SMCs were studied. The results show that the mixed resin has been formed a reasonable coating layer on the surface of powders, which leads to reduce the strain of the powders introduced during compression and isolate the powders to cut off the eddy current. As a result, the density of SMCs can reach 6.82 g/cm3, the resistivity is as high as 1.1×106 Ω·cm. Meanwhile, its quality factor is improved and the magnetic loss at high frequency is reduced. When the mixed resin is composed of 33.3wt% epoxy resin and 66.7wt% silicone resin, the SMCs are provided with optimal comprehensive performance with 1182.7 kW/m3 loss only at 200 kHz. The magnetic properties of iron-based SMCs are further optimized through selecting the blending resin coating agent with suitable composition, which has a broad application prospect in the field of medium and high frequency.

2024, 41(1): 323-334.

doi: 10.13801/j.cnki.fhclxb.20230522.001

Abstract: