2021 Vol. 38, No. 5

2021, 38(5): 1526-1534.

doi: 10.13801/j.cnki.fhclxb.20201106.001

Abstract:

Based on the replacement of natural sand by recycled fine aggregate from construction waste, the comprehensive physical properties and hydration mechanism of graphene oxide (GO) modified recycled cement-based composites were studied. The recycled cement-based composites were prepared by ultrasonic dispersion GO and vibration stirring. The comprehensive durability test results show that compared with recycled cement-based materials without GO, the flexural and compressive strength of the GO/recycled cement-based composites modified with 0.03% GO at 7 d age increase by 16% and 21%, respectively. The flexural strength and compressive strength of GO/recycled cement-based composites modified by 0.02% GO at 28 d age increase by 13.7% and 13.6%, respectively. The GO/recycled cement-based composite has a 7 d weather resistance and good mechanical properties after 50 freeze-thaw cycles; the chloride ion content is less than 0.06%. The radioactivity test results show that internal exposure index IRa and external exposure index Ir of GO/recycled cement-based composites belong to Class A building materials. The hydration mechanism of the GO/recycled cement-based composites was studied by XRD, TG-DTA, SEM and other means, the results show that GO promotes the large-scale formation of ettringite (AFt) crystals, and the presence of more free water in the gel pores, and has an inhibitory effect on the later generation of calcium hydroxide (CH), thereby improving the synthesis of GO/recycled cement-based composites physical properties.

Based on the replacement of natural sand by recycled fine aggregate from construction waste, the comprehensive physical properties and hydration mechanism of graphene oxide (GO) modified recycled cement-based composites were studied. The recycled cement-based composites were prepared by ultrasonic dispersion GO and vibration stirring. The comprehensive durability test results show that compared with recycled cement-based materials without GO, the flexural and compressive strength of the GO/recycled cement-based composites modified with 0.03% GO at 7 d age increase by 16% and 21%, respectively. The flexural strength and compressive strength of GO/recycled cement-based composites modified by 0.02% GO at 28 d age increase by 13.7% and 13.6%, respectively. The GO/recycled cement-based composite has a 7 d weather resistance and good mechanical properties after 50 freeze-thaw cycles; the chloride ion content is less than 0.06%. The radioactivity test results show that internal exposure index IRa and external exposure index Ir of GO/recycled cement-based composites belong to Class A building materials. The hydration mechanism of the GO/recycled cement-based composites was studied by XRD, TG-DTA, SEM and other means, the results show that GO promotes the large-scale formation of ettringite (AFt) crystals, and the presence of more free water in the gel pores, and has an inhibitory effect on the later generation of calcium hydroxide (CH), thereby improving the synthesis of GO/recycled cement-based composites physical properties.

2021, 38(5): 1535-1542.

doi: 10.13801/j.cnki.fhclxb.20200826.001

Abstract:

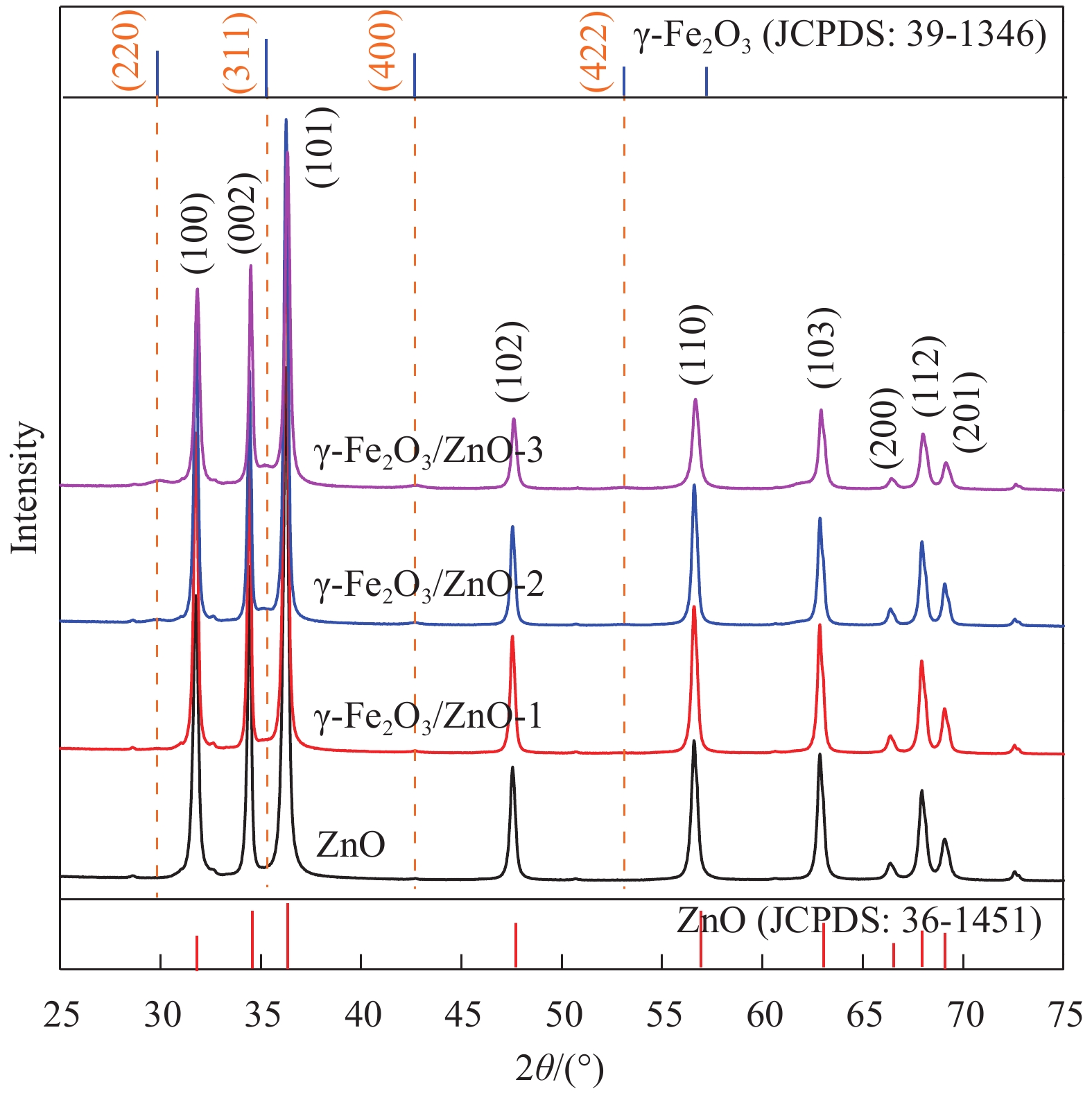

In order to solve the problem of poor photocatalytic activity of traditional ZnO, band-like γ-Fe2O3/ZnO heterojunction photocatalyst was prepared by an one-pot method under hydrothermal conditions using Zn(CH3COO)2 and FeCl3 as precursors in this paper. The chemical structure of as-prepared γ-Fe2O3/ZnO heterojunction photocatalyst was characterized by XRD, BET specific surface area tester, TEM, UV-Vis diffuse reflection and electron paramagnetic resonance (EPR). The tetracycline photodegradation by the γ-Fe2O3/ZnO heterojunction photocatalyst with different loading of γ-Fe2O3 was explored under visible light. The results show that due to γ-Fe2O3 loading onto the ZnO, the specific surface area and light absorption significantly increase, while the band gap reduces. After visible light illumination about 120 minutes, the photodegradation ratio of tetracycline is up to 97.2% by γ-Fe2O3/ZnO heterojunction photocatalyst when n(Zn)∶n(Fe) (atomic ratio) is 20∶1, and the tetracycline photodegradation ratio remains above 95% after repeated use.

In order to solve the problem of poor photocatalytic activity of traditional ZnO, band-like γ-Fe2O3/ZnO heterojunction photocatalyst was prepared by an one-pot method under hydrothermal conditions using Zn(CH3COO)2 and FeCl3 as precursors in this paper. The chemical structure of as-prepared γ-Fe2O3/ZnO heterojunction photocatalyst was characterized by XRD, BET specific surface area tester, TEM, UV-Vis diffuse reflection and electron paramagnetic resonance (EPR). The tetracycline photodegradation by the γ-Fe2O3/ZnO heterojunction photocatalyst with different loading of γ-Fe2O3 was explored under visible light. The results show that due to γ-Fe2O3 loading onto the ZnO, the specific surface area and light absorption significantly increase, while the band gap reduces. After visible light illumination about 120 minutes, the photodegradation ratio of tetracycline is up to 97.2% by γ-Fe2O3/ZnO heterojunction photocatalyst when n(Zn)∶n(Fe) (atomic ratio) is 20∶1, and the tetracycline photodegradation ratio remains above 95% after repeated use.

2021, 38(5): 1543-1550.

doi: 10.13801/j.cnki.fhclxb.20200831.001

Abstract:

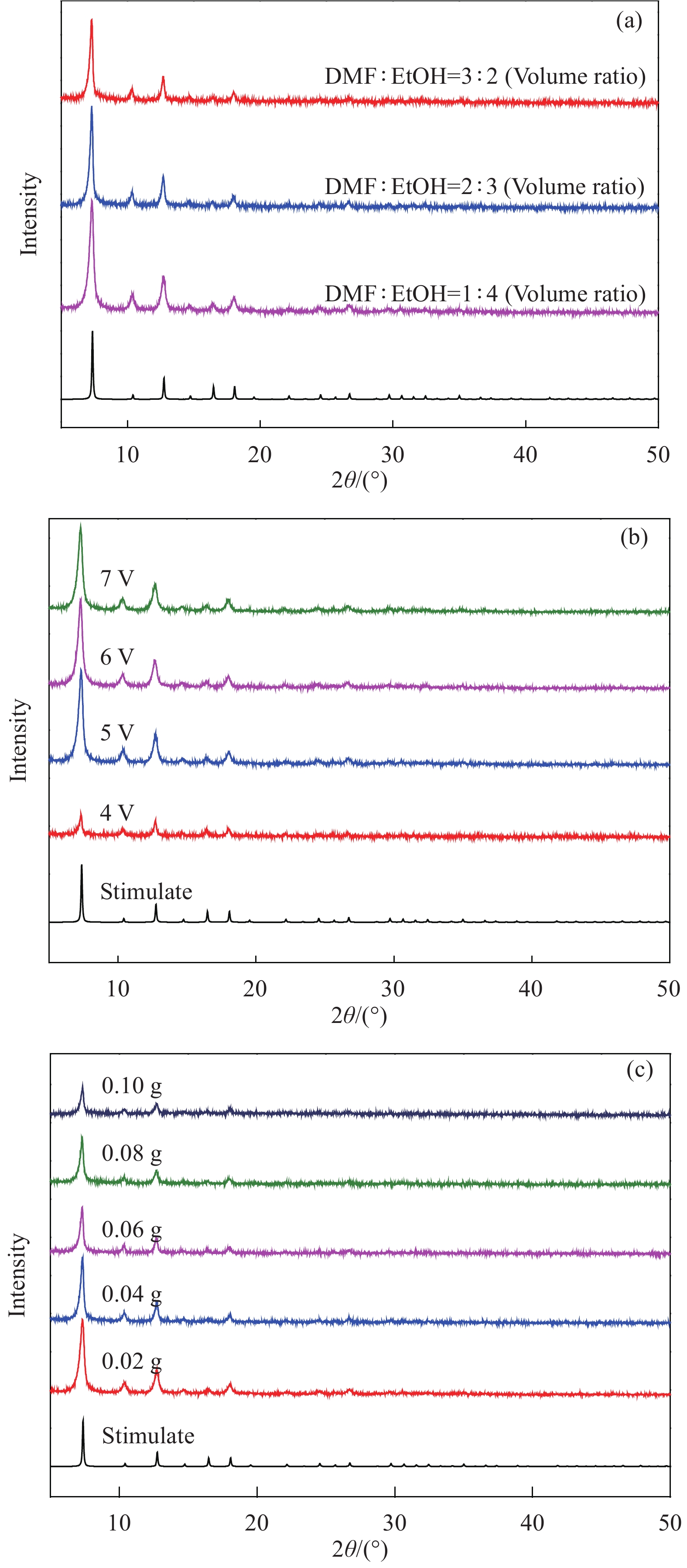

In-situ synthesis of bimetallic Zn/Co-zeolitic imidazolate frameworks (ZIF) was successfully achieved by electrochemical method. The optimal synthesis conditions of the Zn/Co-ZIF were explored by changing the reaction solvent ratio, the applied voltage and the amount of metal cobalt salt added. The results show that Zn/Co-ZIF with irregular layered particle structure is obtained under the conditions of the volume ratio of N,N-dimethylformamide (DMF) to ethanol (EtOH) is 1∶4, the applied voltage is 5 V, and the added metal cobalt salt is 0.08 g. The electrode was prepared with Zn/Co-ZIF as the active material for the study of supercapacitor performance, and compared with ZIF-8 synthesized in situ by electrochemical method under the same conditions. Capacitance performance was explored through cyclic voltammetry (CV), galvanostatic charge-discharge (GCD), and electrochemical impedance spectroscopy (EIS). The results show that the CV curves of Zn/Co-ZIF electrode materials at different scanning speeds have a pair of redox peaks, which show obvious pseudo-capacitance characteristics. At a current density of 1 A/g, the specific capacitance of the Zn/Co-ZIF electrode material is 189 F/g, which is higher than that of the ZIF-8 electrode (72 F/g). After 2000 cycles, the specific capacitance value is still can maintain 90.5% of the initial value.

In-situ synthesis of bimetallic Zn/Co-zeolitic imidazolate frameworks (ZIF) was successfully achieved by electrochemical method. The optimal synthesis conditions of the Zn/Co-ZIF were explored by changing the reaction solvent ratio, the applied voltage and the amount of metal cobalt salt added. The results show that Zn/Co-ZIF with irregular layered particle structure is obtained under the conditions of the volume ratio of N,N-dimethylformamide (DMF) to ethanol (EtOH) is 1∶4, the applied voltage is 5 V, and the added metal cobalt salt is 0.08 g. The electrode was prepared with Zn/Co-ZIF as the active material for the study of supercapacitor performance, and compared with ZIF-8 synthesized in situ by electrochemical method under the same conditions. Capacitance performance was explored through cyclic voltammetry (CV), galvanostatic charge-discharge (GCD), and electrochemical impedance spectroscopy (EIS). The results show that the CV curves of Zn/Co-ZIF electrode materials at different scanning speeds have a pair of redox peaks, which show obvious pseudo-capacitance characteristics. At a current density of 1 A/g, the specific capacitance of the Zn/Co-ZIF electrode material is 189 F/g, which is higher than that of the ZIF-8 electrode (72 F/g). After 2000 cycles, the specific capacitance value is still can maintain 90.5% of the initial value.

2021, 38(5): 1551-1557.

doi: 10.13801/j.cnki.fhclxb.20200925.001

Abstract:

Magnetic CoFe2O4 submicrospheres were prepared by solvothermal method, and dopamine (DA) was polymerized on the surface under alkaline conditions with CoFe2O4 as the core. The polyhydroxyl reducibility of ethylene glycol and polydopamine (PDA) was used to reduce the Pt in situ on the surface of CoFe2O4@PDA to synthesize nano CoFe2O4@PDA@Pt composite. The micro morphology, structure and crystal morphology of the CoFe2O4@PDA@Pt composites were characterized by TEM, XRD, vibration sample magnetometer (VSM) and XPS. The catalytic activity of inorganic dye potassium ferrocyanate and organic dye p-nitrophenol were investigated as the target pollutants. The results show that the degradation rate of potassium ferrocyanate is over 95% and the degradation rate of p-nitrophenol is about 99.3% within 2 minutes.

Magnetic CoFe2O4 submicrospheres were prepared by solvothermal method, and dopamine (DA) was polymerized on the surface under alkaline conditions with CoFe2O4 as the core. The polyhydroxyl reducibility of ethylene glycol and polydopamine (PDA) was used to reduce the Pt in situ on the surface of CoFe2O4@PDA to synthesize nano CoFe2O4@PDA@Pt composite. The micro morphology, structure and crystal morphology of the CoFe2O4@PDA@Pt composites were characterized by TEM, XRD, vibration sample magnetometer (VSM) and XPS. The catalytic activity of inorganic dye potassium ferrocyanate and organic dye p-nitrophenol were investigated as the target pollutants. The results show that the degradation rate of potassium ferrocyanate is over 95% and the degradation rate of p-nitrophenol is about 99.3% within 2 minutes.

2021, 38(5): 1558-1566.

doi: 10.13801/j.cnki.fhclxb.20201111.005

Abstract:

Graphite-phase carbon nitride (g-C3N4) was prepared by heat shrinkage polymerization method using urea as raw material, and phosphorus-doped g-C3N4 with different phosphorus content (xP-CN) was prepared by using hydrogen phosphate diamine as a phosphorus source. The effect of doping on the microstructure, morphology, and electrochemical performance of xP-CN/S composites as cathode materials for lithium-sulfur batteries was studied. The studies show that the layer spacing of xP-CN increases after phosphorus doping, the electrical conductivity increases, and the specific surface area becomes larger. The specific surface area of the 10% P-CN reaches 101.741 m2·g−1. The initial discharge specific capacity of the 10% P-CN/S composite at 0.05 C (1 C=1675 mA·h·g−1) reaches 1383.8 mA·h·g−1. The reversible specific capacity after 100 cycles at 0.2 C is 860.0 mA·h·g−1, the reversible specific capacity of g-C3N4/S composite is only 178.3 mA·h·g−1; The specific capacity of 10% P-CN/S composite can be restored to 93.6% at 0.2 C after the rate test, showing good cycle performance and rate performance.

Graphite-phase carbon nitride (g-C3N4) was prepared by heat shrinkage polymerization method using urea as raw material, and phosphorus-doped g-C3N4 with different phosphorus content (xP-CN) was prepared by using hydrogen phosphate diamine as a phosphorus source. The effect of doping on the microstructure, morphology, and electrochemical performance of xP-CN/S composites as cathode materials for lithium-sulfur batteries was studied. The studies show that the layer spacing of xP-CN increases after phosphorus doping, the electrical conductivity increases, and the specific surface area becomes larger. The specific surface area of the 10% P-CN reaches 101.741 m2·g−1. The initial discharge specific capacity of the 10% P-CN/S composite at 0.05 C (1 C=1675 mA·h·g−1) reaches 1383.8 mA·h·g−1. The reversible specific capacity after 100 cycles at 0.2 C is 860.0 mA·h·g−1, the reversible specific capacity of g-C3N4/S composite is only 178.3 mA·h·g−1; The specific capacity of 10% P-CN/S composite can be restored to 93.6% at 0.2 C after the rate test, showing good cycle performance and rate performance.

2021, 38(5): 1567-1575.

doi: 10.13801/j.cnki.fhclxb.20200827.002

Abstract:

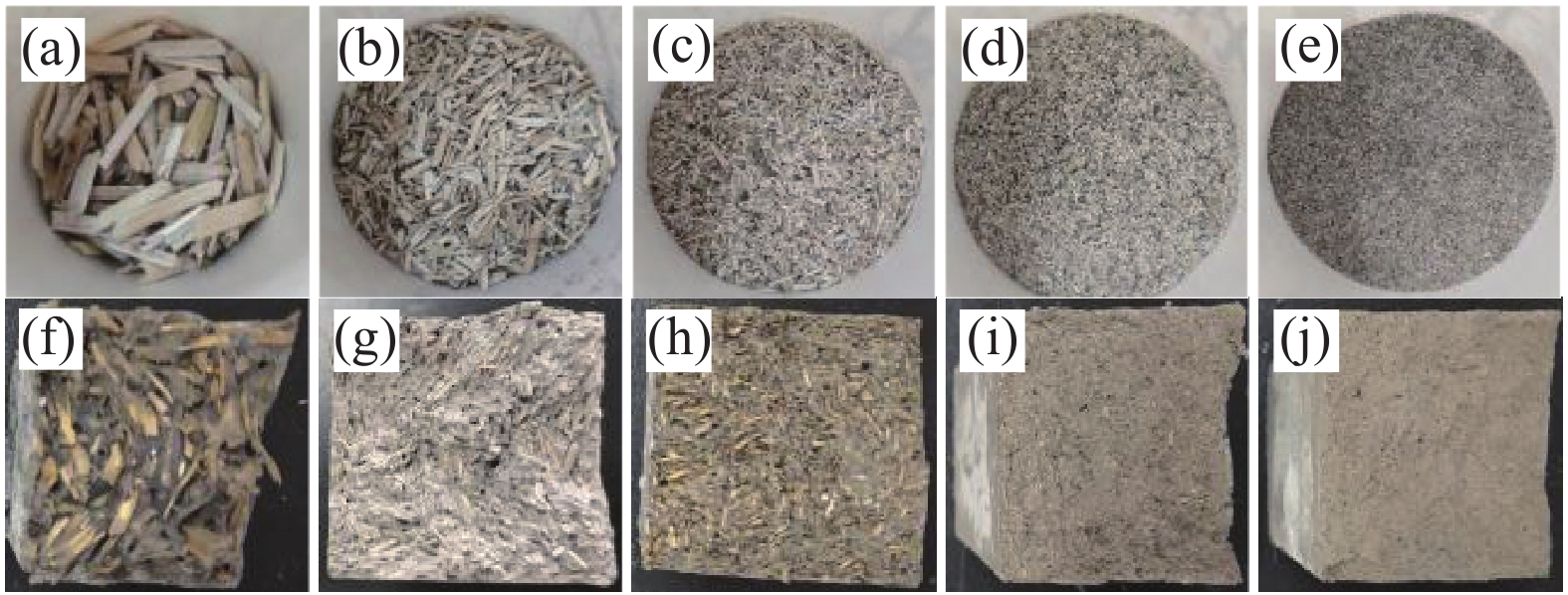

In order to solve the problem of poor mechanical properties of hemp straw fiber/cementitious composite, a modified method of hemp straw fiber/cementitious composite by polyvinyl alcohol (PVA) emulsion was proposed. After optimizing the particle size and mixing amount of hemp straw fiber, PVA emulsion was blended with hemp straw fiber and cement to form the modified hemp straw fiber/cementitious composite. The effects of PVA emulsion with different mass ratios on the flexural strength, density, specific strength and flexural toughness of modified hemp straw fiber/cementitious composite were studied. The modification mechanism was revealed by moisture content, water absorption and fourier infrared spectroscopic analysis. The results show that when the particle size is 1700 μm and the mixing amount is 12%, the hemp straw fiber has the best reinforced effect on hemp straw fiber/cementitious composite. With the mass ratio of PVA emulsion increasing, the density of the modified hemp straw fiber/cementitious composite declines and the flexural toughness improves gradually. When the mass ratio of PVA emulsion is 4.8%, the flexural strength and specific strength of the modified hemp straw fiber/cementitious composite are increased by 17.17% and 20.50%, respectively, compared with the unmodified hemp straw fiber/cementitious composite. The interface between straw fiber and cement in hemp straw fiber/cementitious composite is improved and the negative effect of hemp straw fiber on hydration reaction is alleviated.

In order to solve the problem of poor mechanical properties of hemp straw fiber/cementitious composite, a modified method of hemp straw fiber/cementitious composite by polyvinyl alcohol (PVA) emulsion was proposed. After optimizing the particle size and mixing amount of hemp straw fiber, PVA emulsion was blended with hemp straw fiber and cement to form the modified hemp straw fiber/cementitious composite. The effects of PVA emulsion with different mass ratios on the flexural strength, density, specific strength and flexural toughness of modified hemp straw fiber/cementitious composite were studied. The modification mechanism was revealed by moisture content, water absorption and fourier infrared spectroscopic analysis. The results show that when the particle size is 1700 μm and the mixing amount is 12%, the hemp straw fiber has the best reinforced effect on hemp straw fiber/cementitious composite. With the mass ratio of PVA emulsion increasing, the density of the modified hemp straw fiber/cementitious composite declines and the flexural toughness improves gradually. When the mass ratio of PVA emulsion is 4.8%, the flexural strength and specific strength of the modified hemp straw fiber/cementitious composite are increased by 17.17% and 20.50%, respectively, compared with the unmodified hemp straw fiber/cementitious composite. The interface between straw fiber and cement in hemp straw fiber/cementitious composite is improved and the negative effect of hemp straw fiber on hydration reaction is alleviated.

2021, 38(5): 1576-1587.

doi: 10.13801/j.cnki.fhclxb.20200907.002

Abstract:

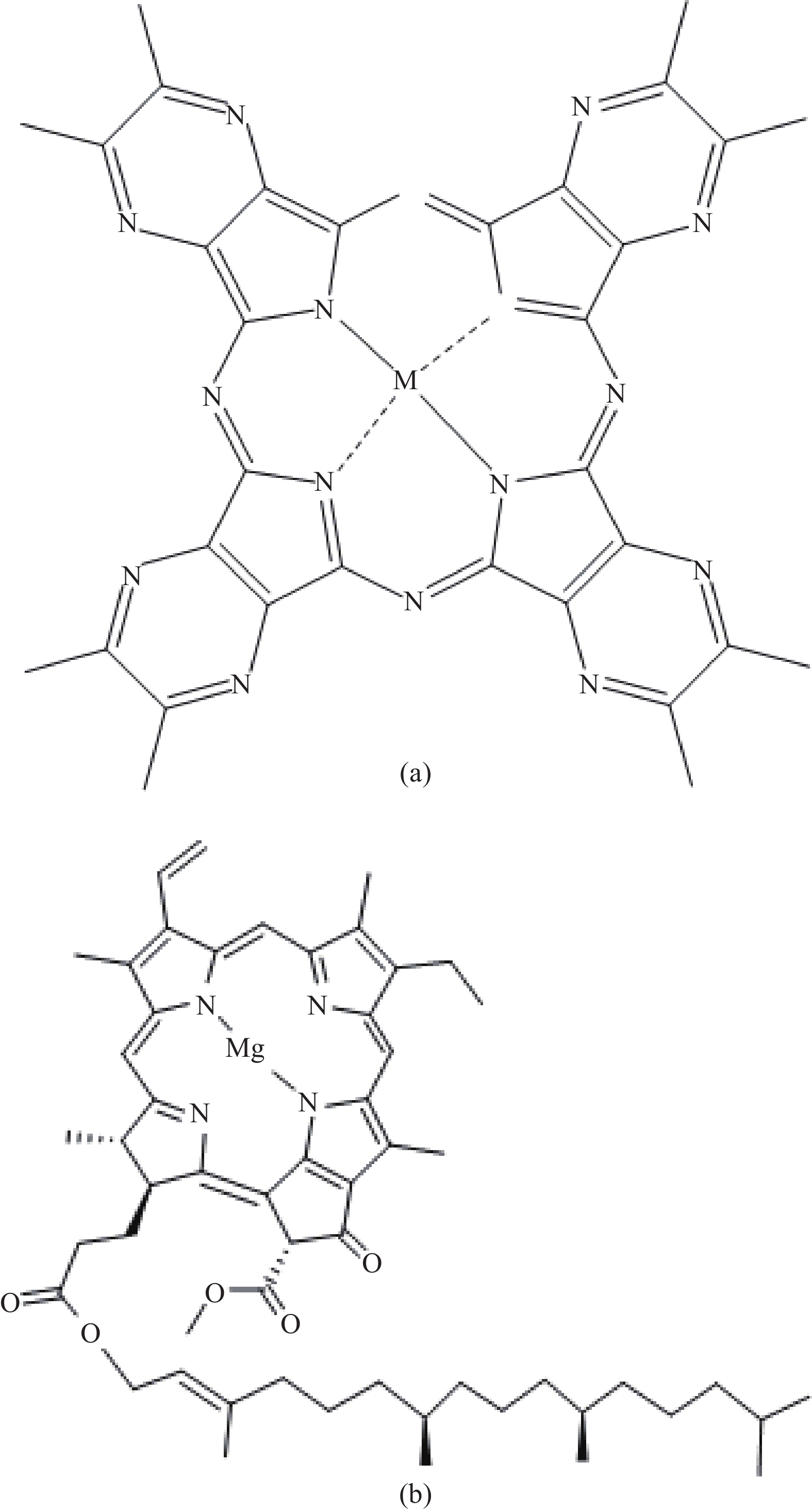

Supported cobalt azaphthalocyanine (NCoPc/CB) and methyl-substituted cobalt azaphthalocyanine (MeNCoPc/CB) composites were prepared, in which carbon black (CB) was used as a carrier, to solve the problem that polyacrylamide (HPAM) was difficult to be removed in the water. The physical and chemical properties of catalyst and photoelectrocatalytic degradation performance of HPAM was studied in a split photoelectric cooperative catalytic system, with 50 mg/L HPAM aqueous solution as the target pollutant and Na2SO4 as the electrolyte. The results confirm that the removal rate of HPAM by the photoelectrocatalysis is not only superior to the photocatalysis and electrocatalysis, but also to the algebraic sum of the two, which shows that the photoelectric combined system has an obvious synergistic enhancement effect. Among them, MeNCoPc/CB composite has the best effect, the pollutant removal rate reaches 76.07%, and the solution viscosity decreases from 8.33 mPa·s to 1.81 mPa·s. The photoelectrocatalytic reaction confirms that the process conforms to the quasi-first-order reaction kinetics, while the reaction rate constants are 6.03 times that of photocatalysis and 3.97 times that of electrocatalysis. Electron spin resonance technology (ESR) confirms that the main active substances in the reaction system are ·OH and O2·−.

Supported cobalt azaphthalocyanine (NCoPc/CB) and methyl-substituted cobalt azaphthalocyanine (MeNCoPc/CB) composites were prepared, in which carbon black (CB) was used as a carrier, to solve the problem that polyacrylamide (HPAM) was difficult to be removed in the water. The physical and chemical properties of catalyst and photoelectrocatalytic degradation performance of HPAM was studied in a split photoelectric cooperative catalytic system, with 50 mg/L HPAM aqueous solution as the target pollutant and Na2SO4 as the electrolyte. The results confirm that the removal rate of HPAM by the photoelectrocatalysis is not only superior to the photocatalysis and electrocatalysis, but also to the algebraic sum of the two, which shows that the photoelectric combined system has an obvious synergistic enhancement effect. Among them, MeNCoPc/CB composite has the best effect, the pollutant removal rate reaches 76.07%, and the solution viscosity decreases from 8.33 mPa·s to 1.81 mPa·s. The photoelectrocatalytic reaction confirms that the process conforms to the quasi-first-order reaction kinetics, while the reaction rate constants are 6.03 times that of photocatalysis and 3.97 times that of electrocatalysis. Electron spin resonance technology (ESR) confirms that the main active substances in the reaction system are ·OH and O2·−.

2021, 38(5): 1588-1593.

doi: 10.13801/j.cnki.fhclxb.20200731.001

Abstract:

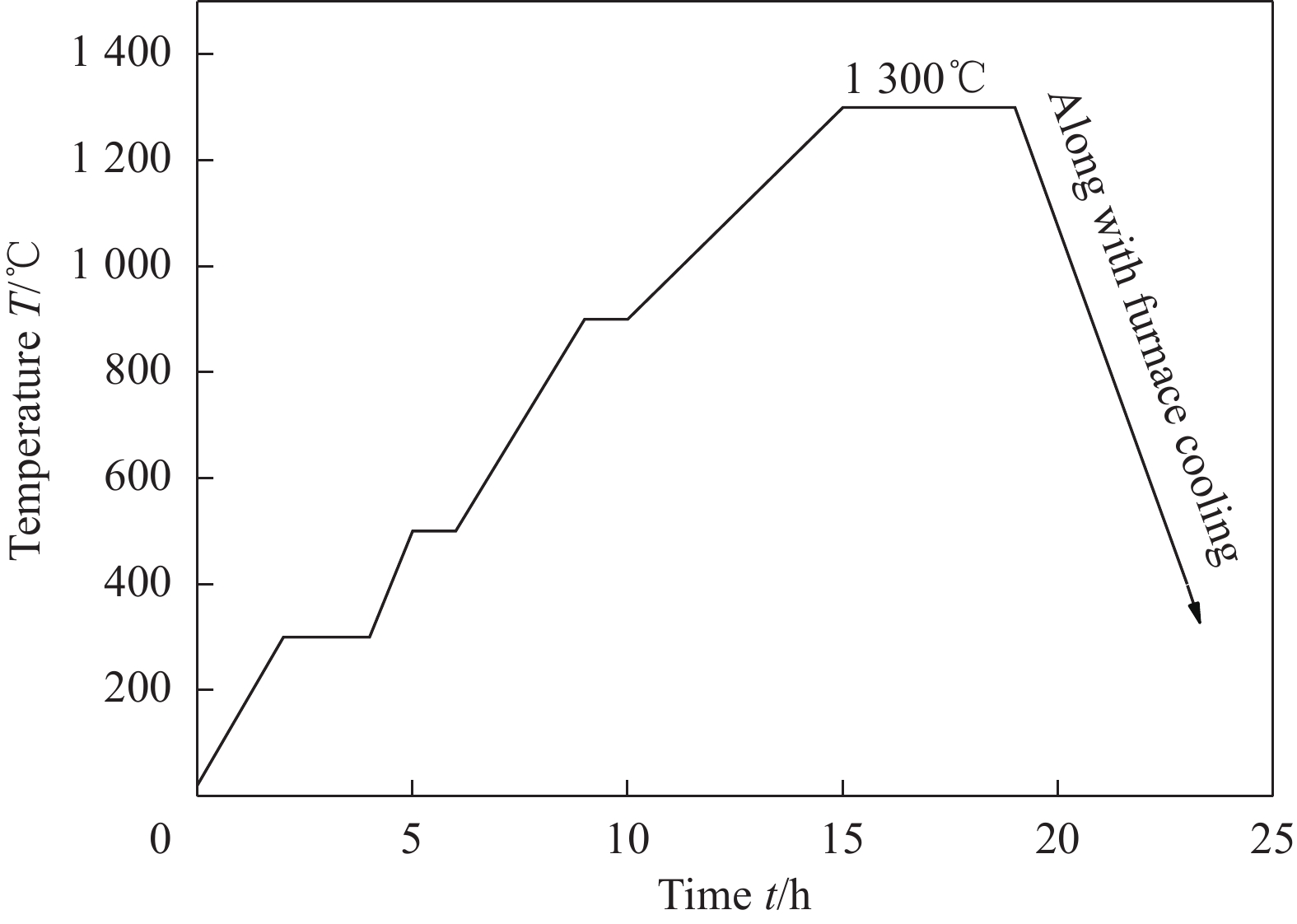

Cristobalite was added as the second phase and zircon sand as the mineralizer to the silicon-based ceramic core matrix material, and the ceramic core sample was prepared by hot press injection method. The effect of pre-added cristobalite content on the performance of silicon-based ceramic cores was studied, and the mechanism of the influence of pre-added cristobalite content on the high temperature creep of silicon-based ceramic cores at 1550℃ was analyzed. The results show that as the content of pre-added cristobalite increases, the bending strength and high-temperature deflection of the silicon-based ceramic core gradually decrease, and the porosity of the core gradually increases. When the pre-added cristobalite content is 10wt%, the crystallization rate of quartz glass is the fastest, cristobalite begins to form a high-temperature-resistant cristobalite skeleton, the core’s ability to resist high-temperature deformation is significantly improved, the bending strength is 5.13 MPa, the high temperature deflection is 1.18 mm, the porosity is 40.55%, the comprehensive performance of the ceramic core is the best.

Cristobalite was added as the second phase and zircon sand as the mineralizer to the silicon-based ceramic core matrix material, and the ceramic core sample was prepared by hot press injection method. The effect of pre-added cristobalite content on the performance of silicon-based ceramic cores was studied, and the mechanism of the influence of pre-added cristobalite content on the high temperature creep of silicon-based ceramic cores at 1550℃ was analyzed. The results show that as the content of pre-added cristobalite increases, the bending strength and high-temperature deflection of the silicon-based ceramic core gradually decrease, and the porosity of the core gradually increases. When the pre-added cristobalite content is 10wt%, the crystallization rate of quartz glass is the fastest, cristobalite begins to form a high-temperature-resistant cristobalite skeleton, the core’s ability to resist high-temperature deformation is significantly improved, the bending strength is 5.13 MPa, the high temperature deflection is 1.18 mm, the porosity is 40.55%, the comprehensive performance of the ceramic core is the best.

2021, 38(5): 1594-1603.

doi: 10.13801/j.cnki.fhclxb.20200723.004

Abstract:

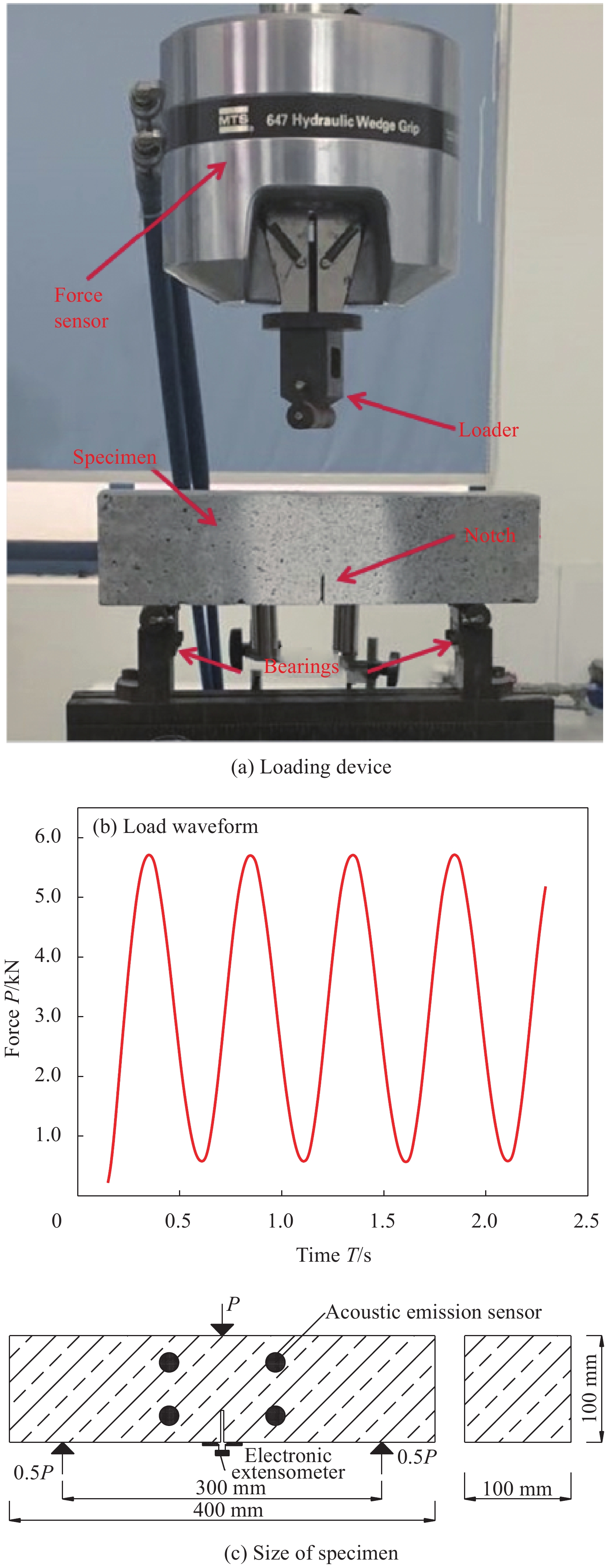

Although rubber concrete has better properties of plasticity and fatigue, due to the incorporation of rubber, its dispersion increases under fatigue load and the damage process and the ultimate fracture mechanism are not clear. In order to study the damage and fracture performance of rubber concrete under fatigue load, the three-point bending fatigue fracture test of concrete with different rubber contents under fatigue load based on acoustic emission was carried out. The effective crack length a was calculated and the change law of the crack length a of the rubber concrete with different rubber contents under the fatigue load was analyzed. The crack length ac and the acoustic emission cumulative energy EAE were used to define the damage variables Da and DAE.The variation law of the fracture energy GF of the rubber concrete with different rubber contents under the fatigue load and the law of the occurrence and propagation of cracks in the rubber concrete under the fatigue load were analyzed using the signal duration in the acoustic emission. The results show that the fracture energy of the concrete increases linearly with the increase of the rubber content. Under the fatigue load, both a and Da change in an inverted S-shaped law, while DAE shows a positive S-shaped law; The duration of the acoustic emission signal shows that the cracks in the rubber concrete always appear or expand when the load is small under the fatigue load.

Although rubber concrete has better properties of plasticity and fatigue, due to the incorporation of rubber, its dispersion increases under fatigue load and the damage process and the ultimate fracture mechanism are not clear. In order to study the damage and fracture performance of rubber concrete under fatigue load, the three-point bending fatigue fracture test of concrete with different rubber contents under fatigue load based on acoustic emission was carried out. The effective crack length a was calculated and the change law of the crack length a of the rubber concrete with different rubber contents under the fatigue load was analyzed. The crack length ac and the acoustic emission cumulative energy EAE were used to define the damage variables Da and DAE.The variation law of the fracture energy GF of the rubber concrete with different rubber contents under the fatigue load and the law of the occurrence and propagation of cracks in the rubber concrete under the fatigue load were analyzed using the signal duration in the acoustic emission. The results show that the fracture energy of the concrete increases linearly with the increase of the rubber content. Under the fatigue load, both a and Da change in an inverted S-shaped law, while DAE shows a positive S-shaped law; The duration of the acoustic emission signal shows that the cracks in the rubber concrete always appear or expand when the load is small under the fatigue load.

2021, 38(5): 1604-1610.

doi: 10.13801/j.cnki.fhclxb.20200722.001

Abstract:

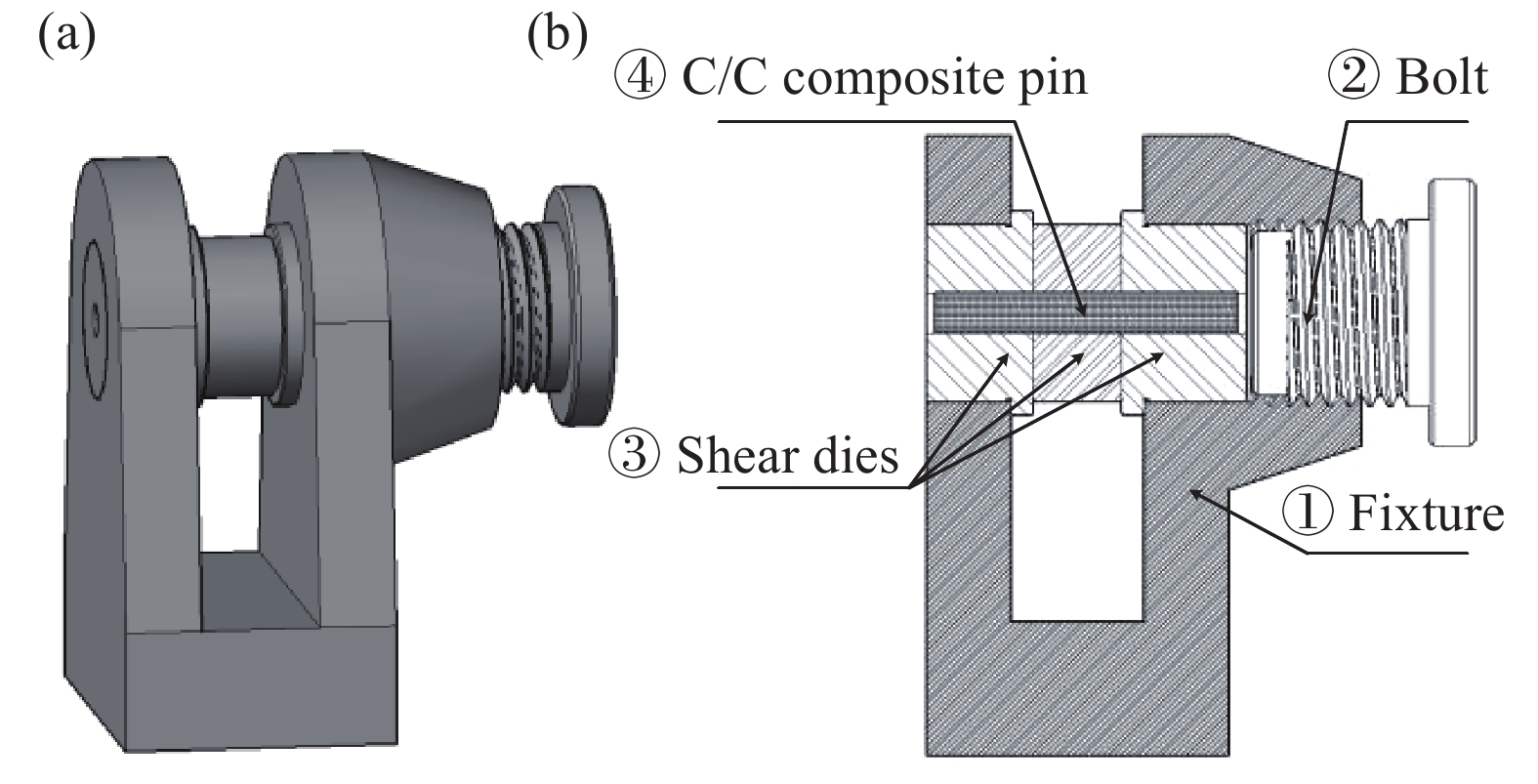

A shear test machine was designed according to the needs of composite pins’ shear tests. An electric universal testing machine was used to test the quasi-static in-plane shear properties of C/C composites, and a drop weight impact testing machine was used to test the dynamic in-plane shear properties of C/C composites. Then the shear failure mode and shear failure mechanism of C/C composite pins were analyzed using the SEM test apparatus. The results show that the shear failure strength of C/C composite pins is sensitive to strain rate, and it increases remarkably with the increasing strain rate. The shear failure mode of C/C composites is sensitive to the strain rate. Under quasi-static loading, the fiber/matrix interface is seriously debonded and the C/C composites show “pseudo-plastic” failure characteristics, while under dynamic loading, almost all the fibers are surrounded by matrix and the composites show “brittle” failure characteristics. The difference of C/C composites’ shear failure modes under different loading rates is related to the strain rate sensitivity of the expansion of internal-cracks.

A shear test machine was designed according to the needs of composite pins’ shear tests. An electric universal testing machine was used to test the quasi-static in-plane shear properties of C/C composites, and a drop weight impact testing machine was used to test the dynamic in-plane shear properties of C/C composites. Then the shear failure mode and shear failure mechanism of C/C composite pins were analyzed using the SEM test apparatus. The results show that the shear failure strength of C/C composite pins is sensitive to strain rate, and it increases remarkably with the increasing strain rate. The shear failure mode of C/C composites is sensitive to the strain rate. Under quasi-static loading, the fiber/matrix interface is seriously debonded and the C/C composites show “pseudo-plastic” failure characteristics, while under dynamic loading, almost all the fibers are surrounded by matrix and the composites show “brittle” failure characteristics. The difference of C/C composites’ shear failure modes under different loading rates is related to the strain rate sensitivity of the expansion of internal-cracks.

2021, 38(5): 1611-1622.

doi: 10.13801/j.cnki.fhclxb.20201106.002

Abstract:

In order to improve the crack resistance capacity, and avoid the brittle failure of the fiber-reinforced polymer composite (FRP) reinforced concrete beams, a mixed-use of glass fiber-reinforced polymer composite (GFRP) bars and crumb rubber concrete was adopted in beam components under bending. Finite element analysis software ABAQUS was used to simulate the flexural behavior of GFRP-reinforced crumb rubber concrete beams. Parametric studies were conducted to study the influence of rubber content, reinforcement ratio, concrete strength grade, and cross-section height on the flexural behavior of GFRP-reinforced crumb rubber concrete beams. The results show that the cracking load of beam increases with the increase of rubber content. The cracking load of beam increases by 29% when the rubber content of concrete is 15%. Increasing the reinforcement ratio could improve the cracking load and flexural strength of the beam. The cracking load of the GFRP-reinforced crumb rubber concrete beam with rubber replacement ratio of 10% has a 15% increase and the flexural strength of the beam has 85% increase induced by increasing the diameter of the GFRP bar from 10 mm to 18 mm. However, when the reinforcement ratio reaches a certain value, the influence is no longer obvious. Increasing the crumb rubber concrete strength can improve the cracking load and flexural strength of the beam. Increasing the crumb rubber concrete strength from C25 to C40 results in approximately 53.7% increase in cracking load, and more than 23% increase in flexural strength. The beams with higher section height are more likely to meet the requirements at normal serviceable limit state.

In order to improve the crack resistance capacity, and avoid the brittle failure of the fiber-reinforced polymer composite (FRP) reinforced concrete beams, a mixed-use of glass fiber-reinforced polymer composite (GFRP) bars and crumb rubber concrete was adopted in beam components under bending. Finite element analysis software ABAQUS was used to simulate the flexural behavior of GFRP-reinforced crumb rubber concrete beams. Parametric studies were conducted to study the influence of rubber content, reinforcement ratio, concrete strength grade, and cross-section height on the flexural behavior of GFRP-reinforced crumb rubber concrete beams. The results show that the cracking load of beam increases with the increase of rubber content. The cracking load of beam increases by 29% when the rubber content of concrete is 15%. Increasing the reinforcement ratio could improve the cracking load and flexural strength of the beam. The cracking load of the GFRP-reinforced crumb rubber concrete beam with rubber replacement ratio of 10% has a 15% increase and the flexural strength of the beam has 85% increase induced by increasing the diameter of the GFRP bar from 10 mm to 18 mm. However, when the reinforcement ratio reaches a certain value, the influence is no longer obvious. Increasing the crumb rubber concrete strength can improve the cracking load and flexural strength of the beam. Increasing the crumb rubber concrete strength from C25 to C40 results in approximately 53.7% increase in cracking load, and more than 23% increase in flexural strength. The beams with higher section height are more likely to meet the requirements at normal serviceable limit state.

2021, 38(5): 1623-1628.

doi: 10.13801/j.cnki.fhclxb.20200804.001

Abstract:

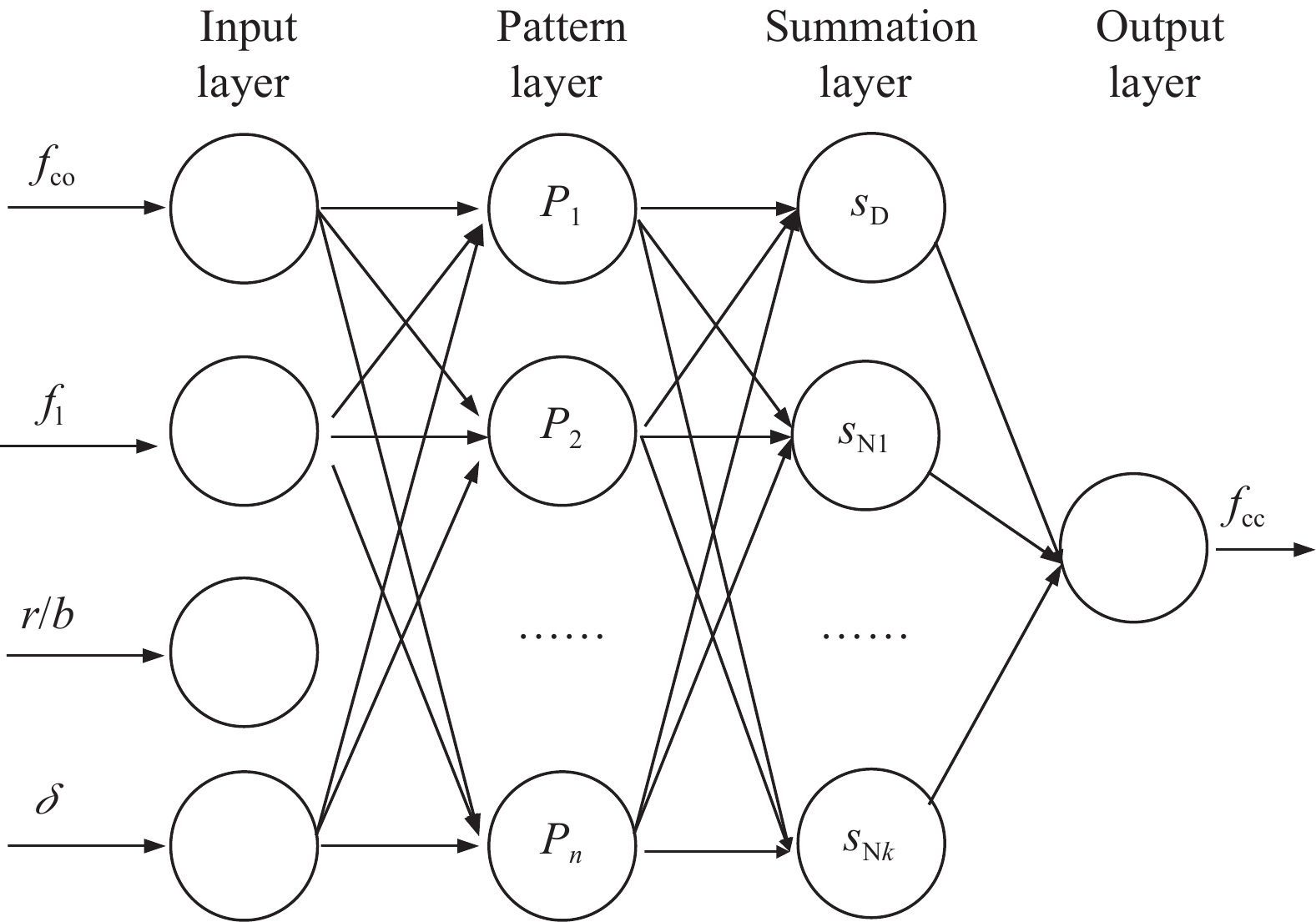

The compressive strength of damaged concrete reinforced with fiber reinforced polymer composite (FRP) has an important guiding significance in repairing of concrete columns. However, the existing model cannot capture the compressive strength of FRP hardening and softening confined damaged concrete with circular and square cross section. In order to fill this gap, an experimental database of 46 FRP hardening confined square damaged concrete, 210 FRP hardening confined circular damaged concrete and 35 FRP softening confined circular damaged concrete was established. Based on the characteristics of generalized regression neural network (GRNN) and database, the GRNN compressive strength model of FRP confined damaged concrete was developed. The GRNN model was compared with the existing model. The results show that the GRNN model can accurately predict the strength of FRP confined damaged concrete columns.

The compressive strength of damaged concrete reinforced with fiber reinforced polymer composite (FRP) has an important guiding significance in repairing of concrete columns. However, the existing model cannot capture the compressive strength of FRP hardening and softening confined damaged concrete with circular and square cross section. In order to fill this gap, an experimental database of 46 FRP hardening confined square damaged concrete, 210 FRP hardening confined circular damaged concrete and 35 FRP softening confined circular damaged concrete was established. Based on the characteristics of generalized regression neural network (GRNN) and database, the GRNN compressive strength model of FRP confined damaged concrete was developed. The GRNN model was compared with the existing model. The results show that the GRNN model can accurately predict the strength of FRP confined damaged concrete columns.

2021, 38(5): 1313-1330.

doi: 10.13801/j.cnki.fhclxb.20201215.007

Abstract:

Traditional lead anodes are widely used in production of zinc by electrowinning due to their low cost, good conductivity and easy processing. However, the corrosion of lead anodes during the electrolytic process has also lead to the pollution of zinc products and electrolyte and increase of anode use costs. Improving the electrochemical activity and corrosion resistance of the anodes has become one of the important research directions of zinc electrowinning technology. In recent years, based on the corrosion-resistant mechanism in zinc electrowinning processes, a variety of corrosion-resistant anodes with excellent electrochemical performance have been developed, including lead alloy, PbO2, and transition metal oxide coated anodes. This article reviews the research progress of zinc electrowinning anodes such as lead alloy, PbO2 and transition metal oxide coated anodes, and give a prospect of their future development.

Traditional lead anodes are widely used in production of zinc by electrowinning due to their low cost, good conductivity and easy processing. However, the corrosion of lead anodes during the electrolytic process has also lead to the pollution of zinc products and electrolyte and increase of anode use costs. Improving the electrochemical activity and corrosion resistance of the anodes has become one of the important research directions of zinc electrowinning technology. In recent years, based on the corrosion-resistant mechanism in zinc electrowinning processes, a variety of corrosion-resistant anodes with excellent electrochemical performance have been developed, including lead alloy, PbO2, and transition metal oxide coated anodes. This article reviews the research progress of zinc electrowinning anodes such as lead alloy, PbO2 and transition metal oxide coated anodes, and give a prospect of their future development.

2021, 38(5): 1331-1347.

doi: 10.13801/j.cnki.fhclxb.20201201.004

Abstract:

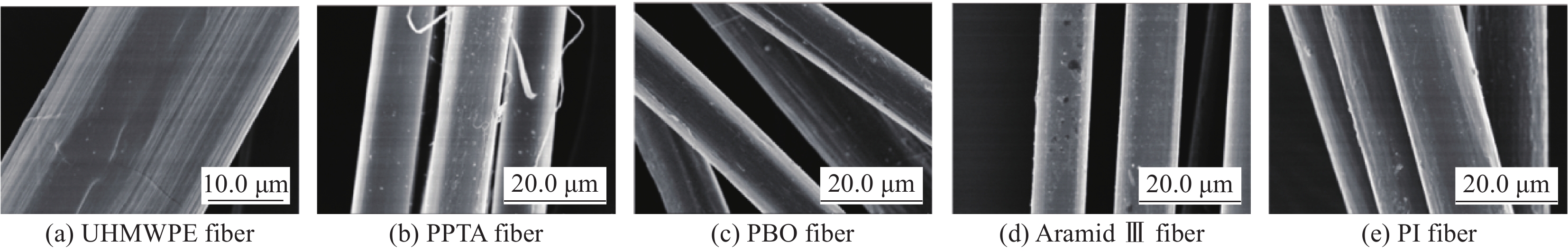

The ballistic response of advanced composite for ballistic protection and its application status in engineering field are reviewed in this paper. Firstly, the bulletproof performance of high-performance fiber is outlined based on the experimental results of engineering application research. Those high-performance fibers include ultra-high molecular weight polyethylene (UHMWPE) fiber, aramid Ⅲ fiber, poly para phenylene terepthalamide (PPTA) fiber, poly-p-phenylene-2,6-benzobisoxazole (PBO), and polyimide (PI) fiber. In addition, the application status of its composite is introduced in the field of ballistic protection engineering. The ballistic performance of advanced composite is gradually improved with the breakthrough of fiber mechanical properties in recent years. Secondly, the influence factors and its working-mechanism of ballistic behavior of advanced composites are discussed. It is found that the plastic tensile deformation of advanced composites is the main ballistic mechanism to resist projectile penetration. Finally, the research outlooks of advanced composite for ballistic application are proposed.

The ballistic response of advanced composite for ballistic protection and its application status in engineering field are reviewed in this paper. Firstly, the bulletproof performance of high-performance fiber is outlined based on the experimental results of engineering application research. Those high-performance fibers include ultra-high molecular weight polyethylene (UHMWPE) fiber, aramid Ⅲ fiber, poly para phenylene terepthalamide (PPTA) fiber, poly-p-phenylene-2,6-benzobisoxazole (PBO), and polyimide (PI) fiber. In addition, the application status of its composite is introduced in the field of ballistic protection engineering. The ballistic performance of advanced composite is gradually improved with the breakthrough of fiber mechanical properties in recent years. Secondly, the influence factors and its working-mechanism of ballistic behavior of advanced composites are discussed. It is found that the plastic tensile deformation of advanced composites is the main ballistic mechanism to resist projectile penetration. Finally, the research outlooks of advanced composite for ballistic application are proposed.

2021, 38(5): 1348-1357.

doi: 10.13801/j.cnki.fhclxb.20201201.001

Abstract:

With the acceleration of urbanization, the massive discharge of industrial wastewater and domestic sewage containing refractory organic pollutants has entered into waterbodies due to unreasonable disposal, which poses a serious threat to the water environment quality. Transition-metal ions mediated peroxymonosulfate (PMS) activation has been extensively studied as their ability to produce various active oxygen species for contaminants removal in water. However, the accompanied problems of secondary pollution and difficulty in catalyst recovery has limited their practical application. MoS2, an excellent two-dimensional semiconductor material of industrial production, has been widely used in energy conversion and catalysis area. In water treatment, MoS2 materials have been reported as an efficient heterogeneous catalyst for PMS activation to degrade refractory organic pollutants. This review summarized recent studies concerning MoS2-catalyzed PMS activation for organic pollutants removal in aqueous solution. The catalysis efficiencies of PMS activation mediated by MoS2, MoS2/metal ions and MoS2 supported materials were comparatively described, the relevant mechanisms were discussed and the development prospect of the current research were expected briefly.

With the acceleration of urbanization, the massive discharge of industrial wastewater and domestic sewage containing refractory organic pollutants has entered into waterbodies due to unreasonable disposal, which poses a serious threat to the water environment quality. Transition-metal ions mediated peroxymonosulfate (PMS) activation has been extensively studied as their ability to produce various active oxygen species for contaminants removal in water. However, the accompanied problems of secondary pollution and difficulty in catalyst recovery has limited their practical application. MoS2, an excellent two-dimensional semiconductor material of industrial production, has been widely used in energy conversion and catalysis area. In water treatment, MoS2 materials have been reported as an efficient heterogeneous catalyst for PMS activation to degrade refractory organic pollutants. This review summarized recent studies concerning MoS2-catalyzed PMS activation for organic pollutants removal in aqueous solution. The catalysis efficiencies of PMS activation mediated by MoS2, MoS2/metal ions and MoS2 supported materials were comparatively described, the relevant mechanisms were discussed and the development prospect of the current research were expected briefly.

2021, 38(5): 1358-1370.

doi: 10.13801/j.cnki.fhclxb.20201208.003

Abstract:

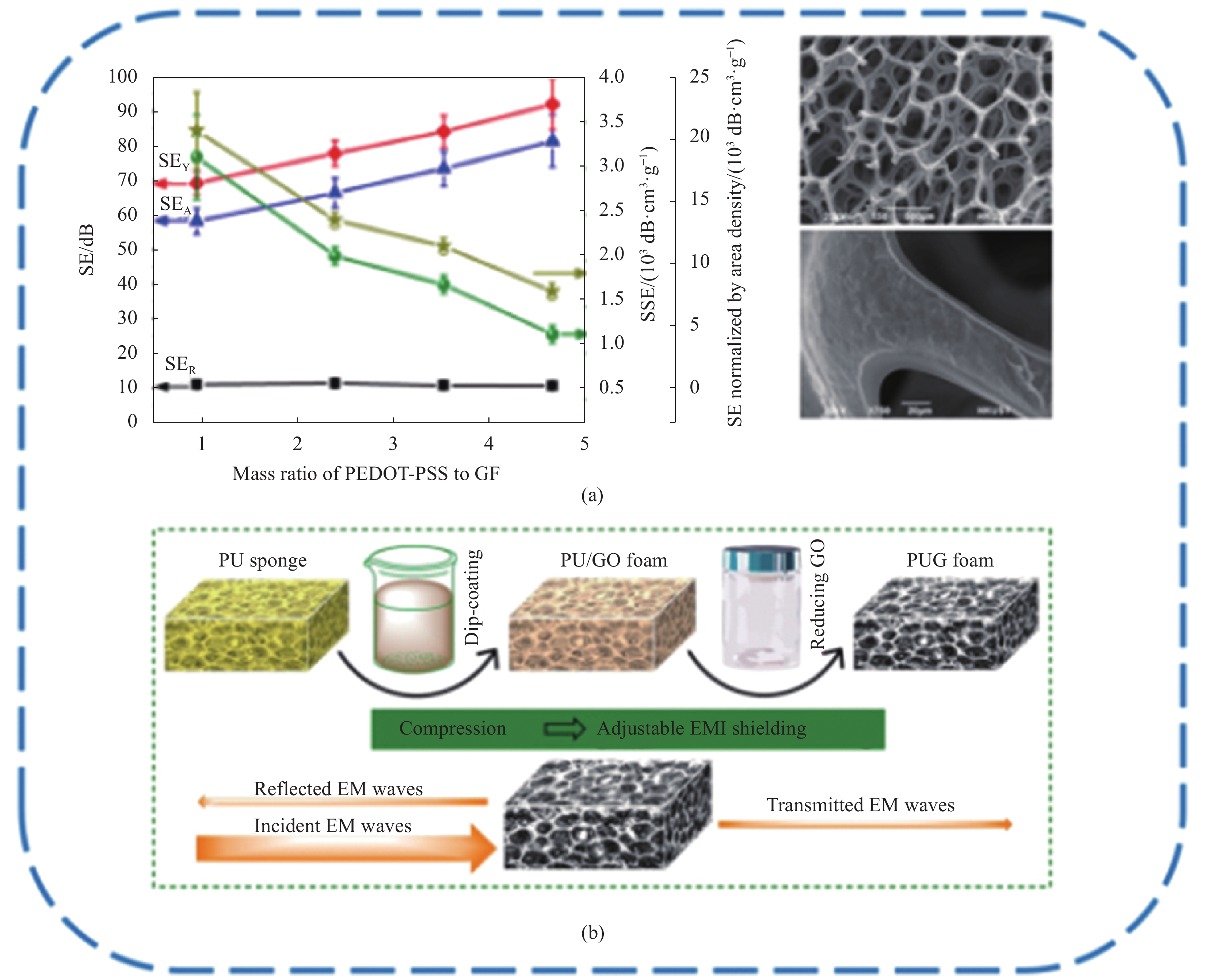

This review introduces the recent reports on polymer-based electromagnetic shielding materials. The shielding mechanism and shielding effectiveness of polymer-based electromagnetic shielding materials with different structures (porous structure, segregated structure and layered structure) and other special structures are summarized and analyzed emphatically. Compared with the composite materials with uniformly distributed fillers in the polymer matrix, the structure design can enrich, re-orient and connect the fillers to form efficient conductive networks, which can not only reduce the amount of fillers, but also improve the electromagnetic shielding performance of the composites. Finally, this review put forward the development direction of polymer-based electromagnetic shielding materials in the future.

This review introduces the recent reports on polymer-based electromagnetic shielding materials. The shielding mechanism and shielding effectiveness of polymer-based electromagnetic shielding materials with different structures (porous structure, segregated structure and layered structure) and other special structures are summarized and analyzed emphatically. Compared with the composite materials with uniformly distributed fillers in the polymer matrix, the structure design can enrich, re-orient and connect the fillers to form efficient conductive networks, which can not only reduce the amount of fillers, but also improve the electromagnetic shielding performance of the composites. Finally, this review put forward the development direction of polymer-based electromagnetic shielding materials in the future.

2021, 38(5): 1371-1386.

doi: 10.13801/j.cnki.fhclxb.20201216.002

Abstract:

3D printing technology, also known as additive manufacturing technology, is based on materials, mechanical control, computer-assisted design and other multi-cross disciplines. 3D printing enables fabrication of complex structure materials which cannot be fabricated by traditional methods. Fused deposition modeling (FDM) is one of the most well-known 3D printing technologies due to its merits like cost-effectiveness, simple in equipment and ease of operation, which has been widely used in aerospace, medical and auto industry. This review introduced the overall layout, development and planning of 3D printing technologies. This review also systematically summarized the characteristics and classifications of common 3D printing technologies, and mainly focused on the principles, advantages and requirements for the FDM technology. Especially, we aim to outline the basic requirements of polymer that suitable for FDM printing and introduce the applications of carbon-based polymer composite materials in the FDM manufacturing process. In addition, recent advances of FDM printing in fabrication of functional polymer composite materials and parts, including biomedical, electrical and thermal conductive polymer composites are reviewed in detail. The prospects for the research and applications of FDM towards manufacturing of high-performance and multifunctional polymer composite materials are proposed. At last, the challenges and key problems that need to be solved in FDM processing are considered and prospected.

3D printing technology, also known as additive manufacturing technology, is based on materials, mechanical control, computer-assisted design and other multi-cross disciplines. 3D printing enables fabrication of complex structure materials which cannot be fabricated by traditional methods. Fused deposition modeling (FDM) is one of the most well-known 3D printing technologies due to its merits like cost-effectiveness, simple in equipment and ease of operation, which has been widely used in aerospace, medical and auto industry. This review introduced the overall layout, development and planning of 3D printing technologies. This review also systematically summarized the characteristics and classifications of common 3D printing technologies, and mainly focused on the principles, advantages and requirements for the FDM technology. Especially, we aim to outline the basic requirements of polymer that suitable for FDM printing and introduce the applications of carbon-based polymer composite materials in the FDM manufacturing process. In addition, recent advances of FDM printing in fabrication of functional polymer composite materials and parts, including biomedical, electrical and thermal conductive polymer composites are reviewed in detail. The prospects for the research and applications of FDM towards manufacturing of high-performance and multifunctional polymer composite materials are proposed. At last, the challenges and key problems that need to be solved in FDM processing are considered and prospected.

2021, 38(5): 1387-1397.

doi: 10.13801/j.cnki.fhclxb.20200727.003

Abstract:

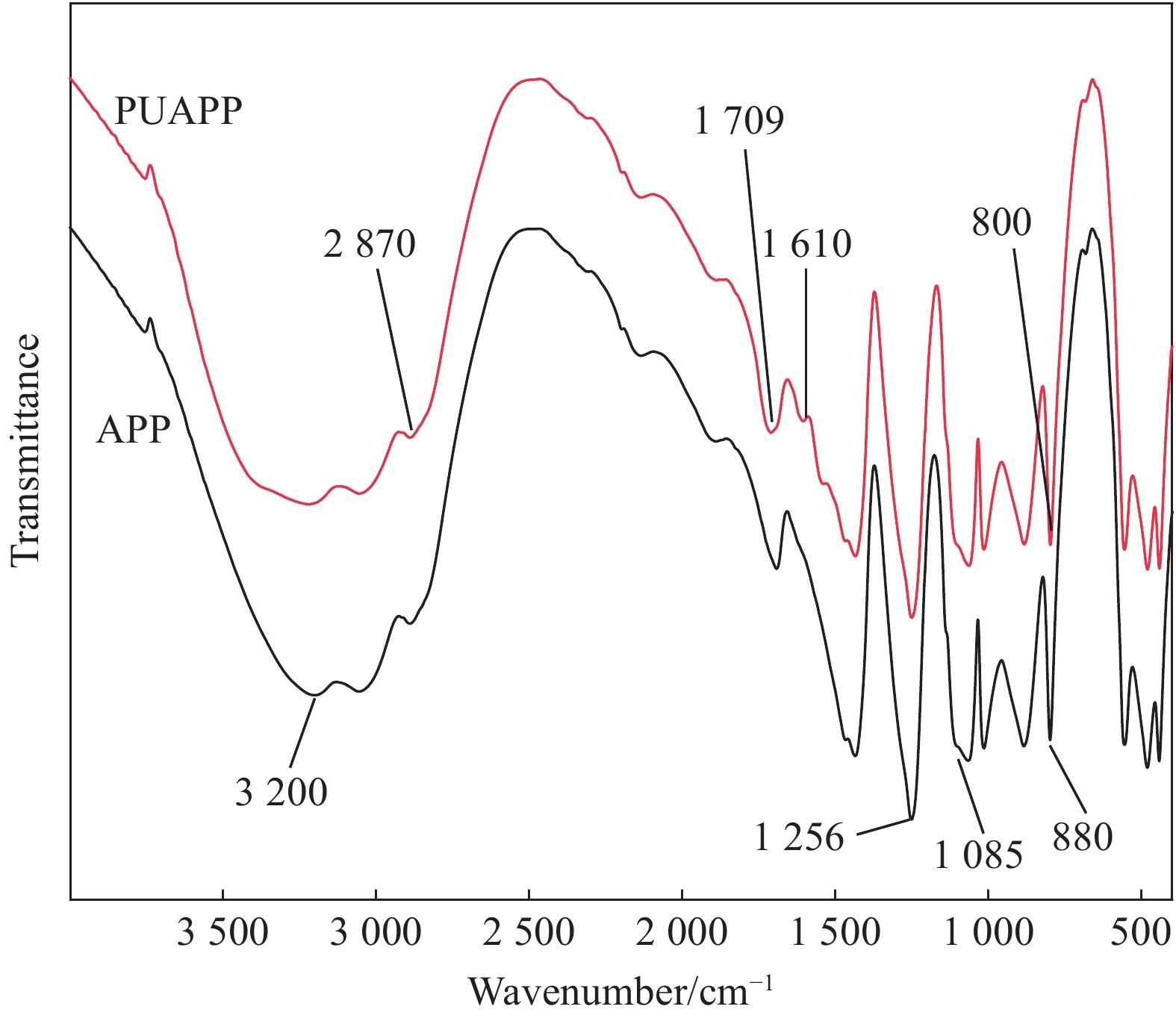

Microencapsulated ammonium polyphosphate (PUAPP) and microencapsulated expanded graphite (PUEG) were prepared by in situ polymerization with polyurethane as shell material. XPS, FTIR, TG and SEM were used to characterize PUAPP and PUEG. The results show that polyurethane is effectively coated on the surface of ammonium polyphosphate and expanded graphite, and PUAPP and PUEG are successfully fabricated. On this basis, a series of flame-retardant rigid polyurethane foam (RPUF) composites were prepared with PUAPP and PUEG loading by one-step water-blown method. The flame retardancy, mechanical properties, thermal insulation and thermal stability of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF composites were investigated by limiting oxygen index (LOI), underwriters laboratories vertical burning test (UL-94), TG, universal testing machine, heat conduction and density test. The results show that the thermal stability at high temperature of RPUF composites can be improved by the addition of PUAPP and PUEG. The charresidues of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF at 700℃ are increased from 1.2wt% to 6.9wt%, 11.2wt% and 10.7wt%, respectively. Flame retardant tests show that the microencapsulated flame retardant can effectively improve flame retardancy of RPUF composites. When 10.4wt% PUAPP is added, the LOI of the PUAPP/RPUF composite is increased to 22.3vol% with V-0 rating in UL-94 test; when 10.4 wt% PUEG is added, the LOI of the PUAPP/RPUF composite is increased to 25.3vol% with UL-94 V-0 rating; PUAPP-PUEG/RPUF composite presents LOI of 24.3vol% with UL-94 V-0 rating. SEM and Raman tests indicate that PUAPP and PUEG can increase graphitization degree of char residues for RPUF composites with enhanced compactness of the char residues.

Microencapsulated ammonium polyphosphate (PUAPP) and microencapsulated expanded graphite (PUEG) were prepared by in situ polymerization with polyurethane as shell material. XPS, FTIR, TG and SEM were used to characterize PUAPP and PUEG. The results show that polyurethane is effectively coated on the surface of ammonium polyphosphate and expanded graphite, and PUAPP and PUEG are successfully fabricated. On this basis, a series of flame-retardant rigid polyurethane foam (RPUF) composites were prepared with PUAPP and PUEG loading by one-step water-blown method. The flame retardancy, mechanical properties, thermal insulation and thermal stability of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF composites were investigated by limiting oxygen index (LOI), underwriters laboratories vertical burning test (UL-94), TG, universal testing machine, heat conduction and density test. The results show that the thermal stability at high temperature of RPUF composites can be improved by the addition of PUAPP and PUEG. The charresidues of PUAPP/RPUF, PUAPP/RPUF and PUAPP-PUEG/RPUF at 700℃ are increased from 1.2wt% to 6.9wt%, 11.2wt% and 10.7wt%, respectively. Flame retardant tests show that the microencapsulated flame retardant can effectively improve flame retardancy of RPUF composites. When 10.4wt% PUAPP is added, the LOI of the PUAPP/RPUF composite is increased to 22.3vol% with V-0 rating in UL-94 test; when 10.4 wt% PUEG is added, the LOI of the PUAPP/RPUF composite is increased to 25.3vol% with UL-94 V-0 rating; PUAPP-PUEG/RPUF composite presents LOI of 24.3vol% with UL-94 V-0 rating. SEM and Raman tests indicate that PUAPP and PUEG can increase graphitization degree of char residues for RPUF composites with enhanced compactness of the char residues.

2021, 38(5): 1398-1406.

doi: 10.13801/j.cnki.fhclxb.20201105.001

Abstract:

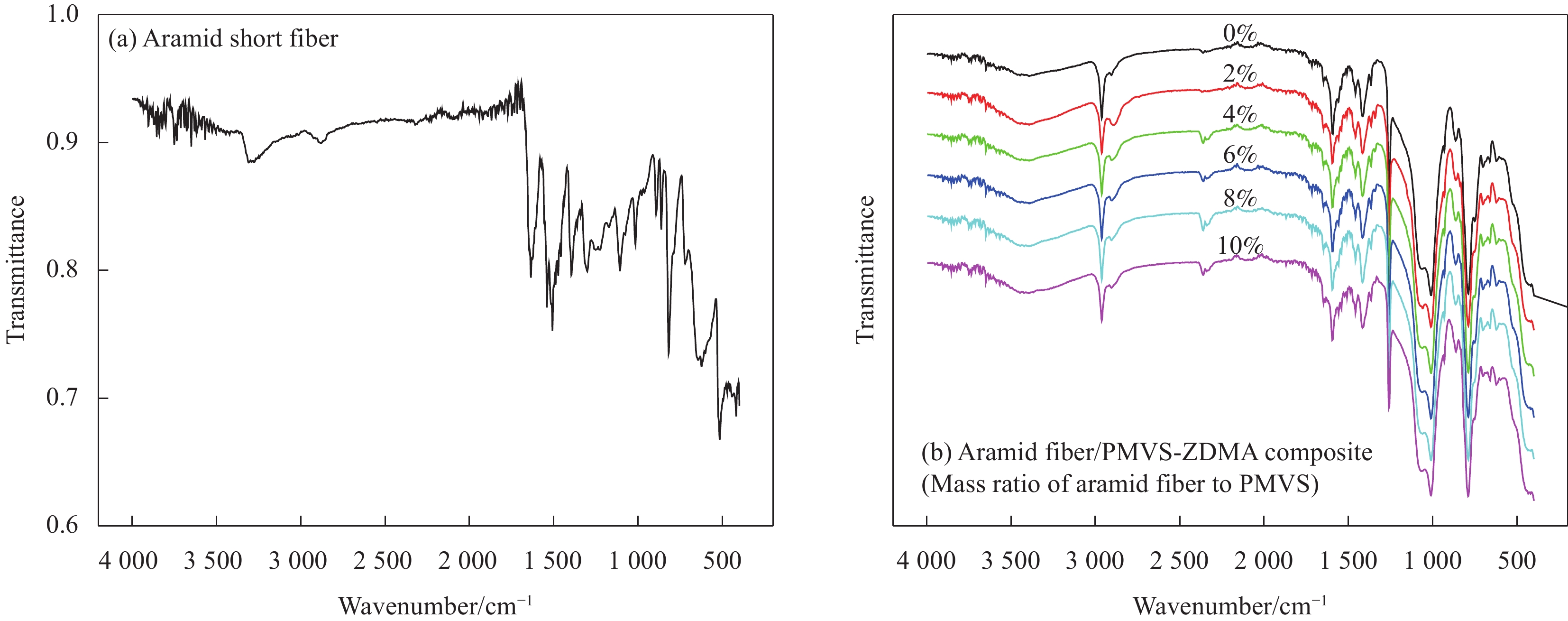

In order to improve the properties of polysiloxane-zinc dimethylate (ZDMA) resin, the short-cutted aramid fiber of general type was blended with polymethylvinylsiloxane-ZDMA compounds and cured at high temperature and pressure, and then the short-cutted aramid fiber/polysiloxane-ZDMA composites were gotten. The structure of short-cutted aramid fiber/polysiloxane-ZDMA composite was characterized by SEM and IR spectroscope, tensile and compressive properties were tested, the effects of the aramid fiber dosages and strain rates on the dynamic compression were also studied. The results show that the flowing property of the short-cutted aramid fiber/polysiloxane-ZDMA composites is affected by the short-cutted aramid fiber, which is not easy to disperse uniformly; the composite’s uniformity is not good at entirety. The fact is found that the fibers tends to aggregate together while the fiber dosage increasing, which causes the mechanical properties to fluctuate. The introduction of the aramid short fiber can improve the tensile strength and compressive stress of the short-cutted aramid fiber/polysiloxane-ZDMA composites, while its elongation at break decrease sharply. At the strain rate of 800 s−1, the addition of the aramid fiber shows no significant influence on the dynamic compressive property. While in the strain rate range of 1500-2500 s−1, the dynamic compressive stress of short-cutted aramid fiber/polysiloxane-ZDMA composites increases with the dosage of aramid short fiber. The polysiloxane-ZDMA composite without aramid fiber is relatively sensitive to the strain rate, while the dynamic compressive properties of short-cutted aramid fiber/polysiloxane-ZDMA composites with 8% mass ratio of aramid short fiber to polysiloxane are rather steady to the strain rate range of 1500-3000 s−1.

In order to improve the properties of polysiloxane-zinc dimethylate (ZDMA) resin, the short-cutted aramid fiber of general type was blended with polymethylvinylsiloxane-ZDMA compounds and cured at high temperature and pressure, and then the short-cutted aramid fiber/polysiloxane-ZDMA composites were gotten. The structure of short-cutted aramid fiber/polysiloxane-ZDMA composite was characterized by SEM and IR spectroscope, tensile and compressive properties were tested, the effects of the aramid fiber dosages and strain rates on the dynamic compression were also studied. The results show that the flowing property of the short-cutted aramid fiber/polysiloxane-ZDMA composites is affected by the short-cutted aramid fiber, which is not easy to disperse uniformly; the composite’s uniformity is not good at entirety. The fact is found that the fibers tends to aggregate together while the fiber dosage increasing, which causes the mechanical properties to fluctuate. The introduction of the aramid short fiber can improve the tensile strength and compressive stress of the short-cutted aramid fiber/polysiloxane-ZDMA composites, while its elongation at break decrease sharply. At the strain rate of 800 s−1, the addition of the aramid fiber shows no significant influence on the dynamic compressive property. While in the strain rate range of 1500-2500 s−1, the dynamic compressive stress of short-cutted aramid fiber/polysiloxane-ZDMA composites increases with the dosage of aramid short fiber. The polysiloxane-ZDMA composite without aramid fiber is relatively sensitive to the strain rate, while the dynamic compressive properties of short-cutted aramid fiber/polysiloxane-ZDMA composites with 8% mass ratio of aramid short fiber to polysiloxane are rather steady to the strain rate range of 1500-3000 s−1.

2021, 38(5): 1407-1415.

doi: 10.13801/j.cnki.fhclxb.20200826.002

Abstract:

The effect of nano TiO2 modified epoxy coating on the properties of glass fiber/unsaturated polyester composite was investigated by UV-condensation accelerated aging test. The change of color and hardness of epoxy coating modified by different content of nano TiO2 in UV-condensation environment was studied. Moreover, the color change, mass change, flexural and shear properties of glass fiber/unsaturated polyester composite without coating, with epoxy coating and 2wt% TiO2 modified epoxy coating were investigated. The results indicate that the flexural strength of the glass fiber/unsaturated polyester composites without coating, with epoxy coating and 2wt% TiO2 modified epoxy coating decreases by 14.7%, 10.0%, and 9.2% respectively after aging for 90 days in UV-condensation environment; the flexural modulus decreases by 5.9%, 5.4%, and 3.2%, respectively. Considering the interaction of UV, humidity and temperature, Gunyaev’s residual strength formula was modified, and the life of the glass fiber/unsaturated polyester composites was predicted.

The effect of nano TiO2 modified epoxy coating on the properties of glass fiber/unsaturated polyester composite was investigated by UV-condensation accelerated aging test. The change of color and hardness of epoxy coating modified by different content of nano TiO2 in UV-condensation environment was studied. Moreover, the color change, mass change, flexural and shear properties of glass fiber/unsaturated polyester composite without coating, with epoxy coating and 2wt% TiO2 modified epoxy coating were investigated. The results indicate that the flexural strength of the glass fiber/unsaturated polyester composites without coating, with epoxy coating and 2wt% TiO2 modified epoxy coating decreases by 14.7%, 10.0%, and 9.2% respectively after aging for 90 days in UV-condensation environment; the flexural modulus decreases by 5.9%, 5.4%, and 3.2%, respectively. Considering the interaction of UV, humidity and temperature, Gunyaev’s residual strength formula was modified, and the life of the glass fiber/unsaturated polyester composites was predicted.

2021, 38(5): 1416-1425.

doi: 10.13801/j.cnki.fhclxb.20200923.001

Abstract:

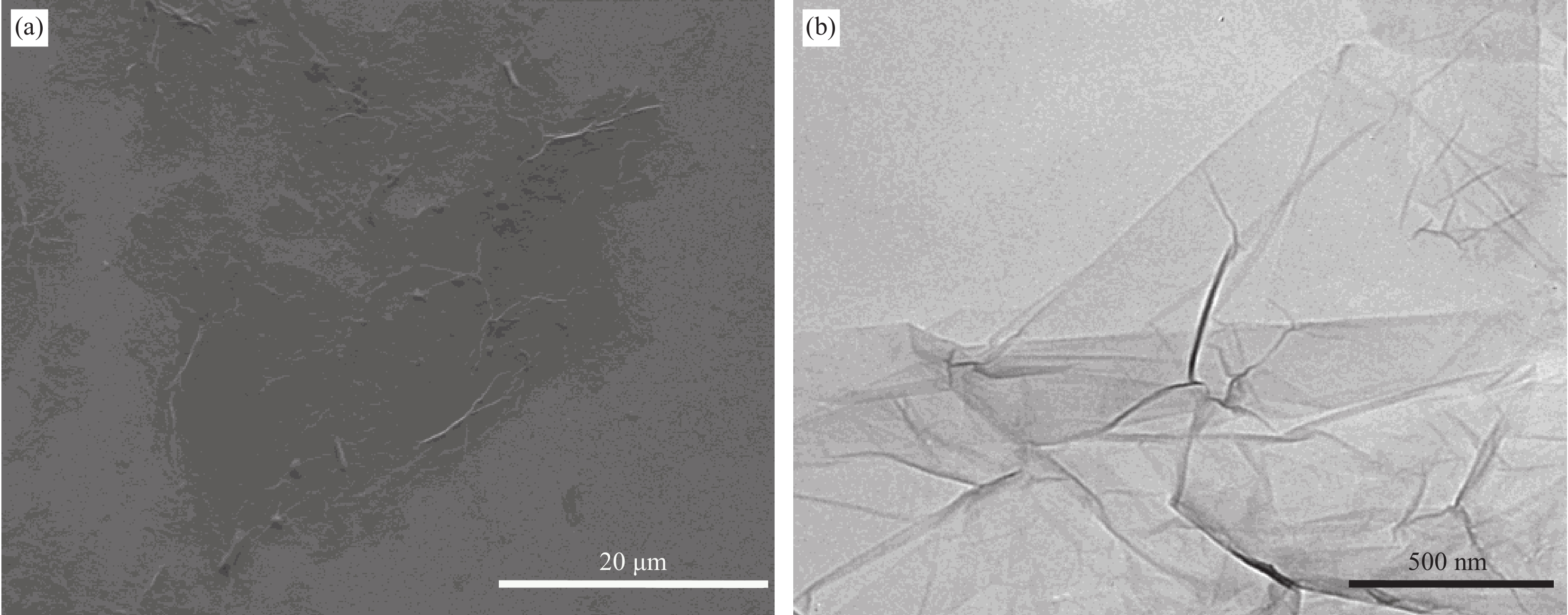

Graphene oxide (GO) modified carbon fiber/epoxy resin (CF/EP) composites were prepared by wet prepreg technology and molding process. The effects of GO on dynamic mechanical properties and interlaminar shear properties of the GO-CF/EP composites at room temperature and hygrothermal environment were studied. Micro morphology was used to analyze modification mechanism of the GO-CF/EP composites. The results show that when the addition amount of GO are 0.5% and 0.8%, respectively, the glass transition temperature (Tg) of the GO-CF/EP composites are significantly increased from 184.4℃ of the CF/EP composites to 197.7℃ and 199.5℃, respectively. After hygrothermal treatment, Tg retention rate of the GO-CF/EP composites is slightly lower than that of the CF/EP composites. The interlaminar shear strength of GO-CF/EP composite with GO content of 0.05% and GO-CF/EP composite with GO content of 0.1% are increased from 59.7 MPa of the CF/EP to 70.2 MPa and 72.2 MPa, respectively. The interlaminar shear strength after hygrothermal treatment of GO-CF/EP composite with GO content of 0.05% and GO-CF/EP composite with GO content of 0.1% are improved compared to the CF/EP composite. And the interlaminar shear strength retention rates of the GO-CF/EP composites before and after hygrothermal treatment are all lower than the CF/EP composite. Dynamic mechanical loss analysis of the composites shows that GO effectively improves the interface bonding between CF and EP matrix. Micro morphology shows that the existence of GO improves the ability of GO-CF/EP composites to resist crack growth.

Graphene oxide (GO) modified carbon fiber/epoxy resin (CF/EP) composites were prepared by wet prepreg technology and molding process. The effects of GO on dynamic mechanical properties and interlaminar shear properties of the GO-CF/EP composites at room temperature and hygrothermal environment were studied. Micro morphology was used to analyze modification mechanism of the GO-CF/EP composites. The results show that when the addition amount of GO are 0.5% and 0.8%, respectively, the glass transition temperature (Tg) of the GO-CF/EP composites are significantly increased from 184.4℃ of the CF/EP composites to 197.7℃ and 199.5℃, respectively. After hygrothermal treatment, Tg retention rate of the GO-CF/EP composites is slightly lower than that of the CF/EP composites. The interlaminar shear strength of GO-CF/EP composite with GO content of 0.05% and GO-CF/EP composite with GO content of 0.1% are increased from 59.7 MPa of the CF/EP to 70.2 MPa and 72.2 MPa, respectively. The interlaminar shear strength after hygrothermal treatment of GO-CF/EP composite with GO content of 0.05% and GO-CF/EP composite with GO content of 0.1% are improved compared to the CF/EP composite. And the interlaminar shear strength retention rates of the GO-CF/EP composites before and after hygrothermal treatment are all lower than the CF/EP composite. Dynamic mechanical loss analysis of the composites shows that GO effectively improves the interface bonding between CF and EP matrix. Micro morphology shows that the existence of GO improves the ability of GO-CF/EP composites to resist crack growth.

2021, 38(5): 1426-1434.

doi: 10.13801/j.cnki.fhclxb.20200922.006

Abstract:

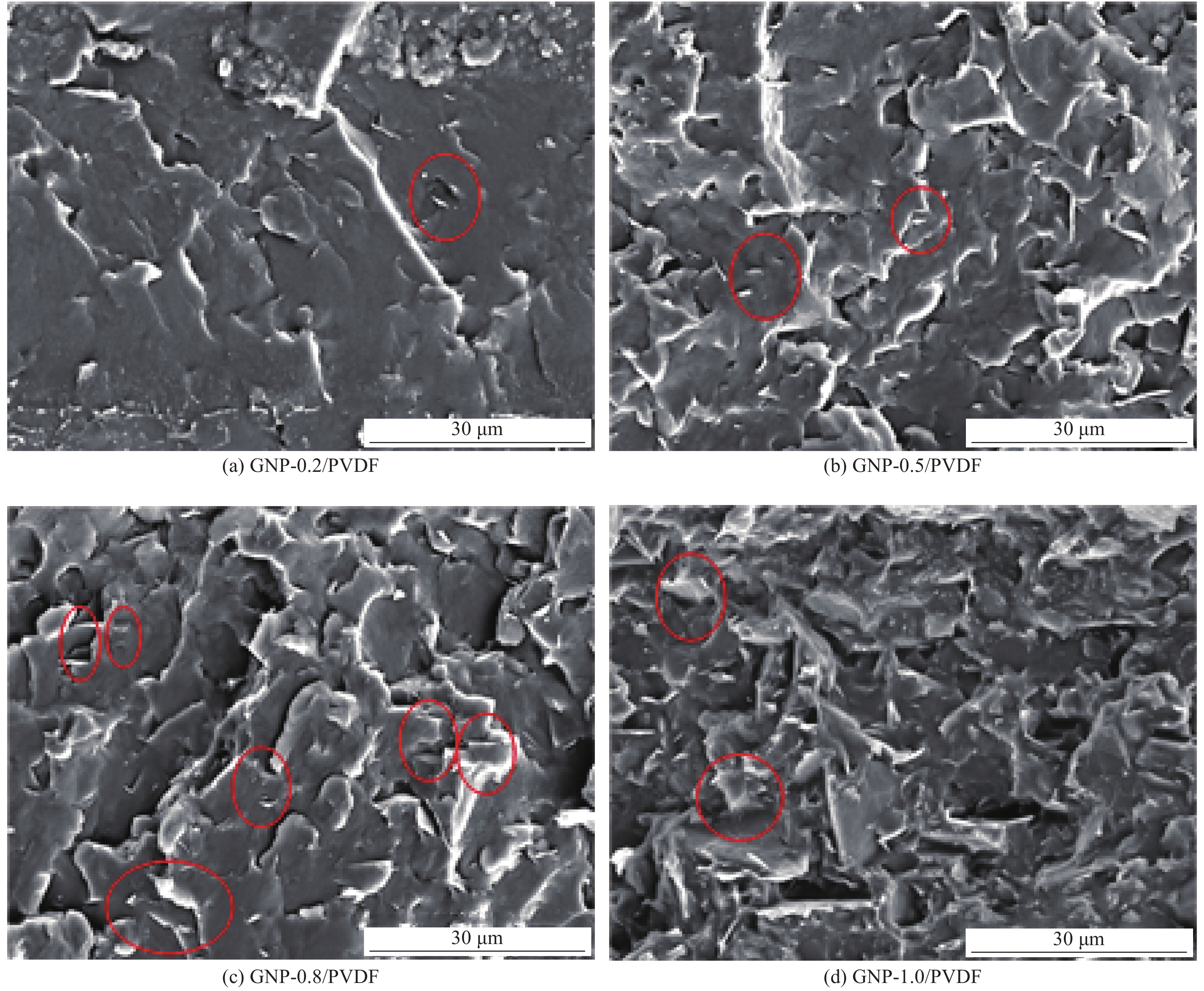

In order to effectively improve the dielectric properties of polymer matrix composites and consider the coexistence of high dielectric constant and low filler content, the microcapacitor structure was constructed in the barium titanate-graphene/polyvinylidene fluoride (BT-GNP/PVDF) composite system with PVDF as the matrix resin, BT and GNP as the dielectric filler and conductive filler respectively. The GNP/PVDF films and BT-GNP/PVDF composite films were prepared by solution method and hot pressing method. The results show that the BT and GNP fillers can be evenly distributed in both the BT-GNP/PVDF composite films and they are easier to form microcapacitor structure in the hot-pressing films. With the introduction of BT, the structure of the microcapacitor formed between GNP and BT is more conducive to the improvement of the dielectric constant of the BT-GNP/PVDF composite films. The dielectric constant of BT-GNP/PVDF composite films with BT content more than 50wt% are not lower than that of GNP/PVDF composites. The dielectric constant of BT-GNP/PVDF composite film with BT content of 50wt% is higher than that of the BT-GNP/PVDF composite films with BT content of 35wt%, 60wt% and 70wt%, respectively, the maximum is about 43, equivalent to 1.5 times of GNP/PVDF film with GNP content of 0.8wt%. The dielectric loss of BT-GNP/PVDF composite film with BT content of 50wt% is also smaller than other systems, the maximum value is no more than 0.09 and the minimum value is about 0.02. The conductivity of BT-GNP/PVDF composite films are in consistant change trend and there is no significant difference between them.

In order to effectively improve the dielectric properties of polymer matrix composites and consider the coexistence of high dielectric constant and low filler content, the microcapacitor structure was constructed in the barium titanate-graphene/polyvinylidene fluoride (BT-GNP/PVDF) composite system with PVDF as the matrix resin, BT and GNP as the dielectric filler and conductive filler respectively. The GNP/PVDF films and BT-GNP/PVDF composite films were prepared by solution method and hot pressing method. The results show that the BT and GNP fillers can be evenly distributed in both the BT-GNP/PVDF composite films and they are easier to form microcapacitor structure in the hot-pressing films. With the introduction of BT, the structure of the microcapacitor formed between GNP and BT is more conducive to the improvement of the dielectric constant of the BT-GNP/PVDF composite films. The dielectric constant of BT-GNP/PVDF composite films with BT content more than 50wt% are not lower than that of GNP/PVDF composites. The dielectric constant of BT-GNP/PVDF composite film with BT content of 50wt% is higher than that of the BT-GNP/PVDF composite films with BT content of 35wt%, 60wt% and 70wt%, respectively, the maximum is about 43, equivalent to 1.5 times of GNP/PVDF film with GNP content of 0.8wt%. The dielectric loss of BT-GNP/PVDF composite film with BT content of 50wt% is also smaller than other systems, the maximum value is no more than 0.09 and the minimum value is about 0.02. The conductivity of BT-GNP/PVDF composite films are in consistant change trend and there is no significant difference between them.

2021, 38(5): 1435-1445.

doi: 10.13801/j.cnki.fhclxb.20200921.003

Abstract:

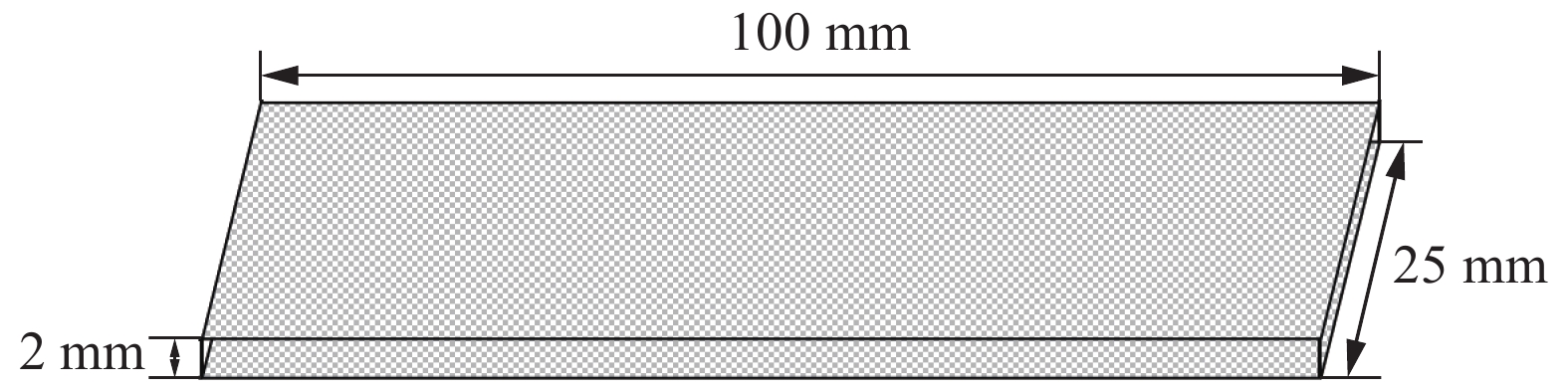

In this article, nanosecond laser was used to pretreat carbon fiber reinforced plastics (CFRP) composite surface, realizing modifying its surface component, roughness and surface wettability. Then the bonding strengths were tested through tensile shear experiment. The surface morphology, contact angle, surface roughness and chemical component were observed and characterized via SEM, contact angle measuring instrument, optical profiler and XPS. The results indicate that with different laser parameters, the epoxy resin on the surface of CFRP composite can be removed, changing the surface component, roughness and surface wettability, and then improving the bonding strength. Compared with the untreated CFRP composites, after laser surface treatment, the bonding strength of CFRP composites increases with the increase of surface wettability and surface roughness, and also changing with the change of chemical component. On the basis of untreated CFRP composites, when the laser defocus is 5 mm, 10 mm and 15 mm, respectively, the bonding strengths are increased by 129.41%, 112.13% and 105.88%, respectively. The surface wettability and surface roughness of laser treated CFRP composites are greater than those of the mechanically-treated CFRP composites. However, the heat damage caused by nanosecond laser treatment has a negative effect on improvement of bonding strength. Therefore, the bonding strength of the nanosecond laser treated CFRP composites are lower than that of mechanically- treated CFRP composites. That is to say, laser treatment process should be furtherly optimized to demonstrate the advantages of laser treatment.

In this article, nanosecond laser was used to pretreat carbon fiber reinforced plastics (CFRP) composite surface, realizing modifying its surface component, roughness and surface wettability. Then the bonding strengths were tested through tensile shear experiment. The surface morphology, contact angle, surface roughness and chemical component were observed and characterized via SEM, contact angle measuring instrument, optical profiler and XPS. The results indicate that with different laser parameters, the epoxy resin on the surface of CFRP composite can be removed, changing the surface component, roughness and surface wettability, and then improving the bonding strength. Compared with the untreated CFRP composites, after laser surface treatment, the bonding strength of CFRP composites increases with the increase of surface wettability and surface roughness, and also changing with the change of chemical component. On the basis of untreated CFRP composites, when the laser defocus is 5 mm, 10 mm and 15 mm, respectively, the bonding strengths are increased by 129.41%, 112.13% and 105.88%, respectively. The surface wettability and surface roughness of laser treated CFRP composites are greater than those of the mechanically-treated CFRP composites. However, the heat damage caused by nanosecond laser treatment has a negative effect on improvement of bonding strength. Therefore, the bonding strength of the nanosecond laser treated CFRP composites are lower than that of mechanically- treated CFRP composites. That is to say, laser treatment process should be furtherly optimized to demonstrate the advantages of laser treatment.

2021, 38(5): 1446-1454.

doi: 10.13801/j.cnki.fhclxb.20200914.001

Abstract:

In this paper, nano SiO2 microspheres with different particle sizes were prepared by the Stöber method, which were added to polymethyl methacrylate (PMMA)-based gel polymer electrolytes, and the size effect of nano SiO2 microspheres and its effect on the performance of all solid-state electrochromic devices were studied. The results show that the volume ratio of ethyl orthosilicate and ethanol affects the particle size of the obtained nano SiO2 microspheres. The larger the volume ratio, the smaller the particle size of the prepared nano SiO2 microspheres. In the PMMA-based gel polymer electrolyte, when nano SiO2 microspheres content is the same, the electrochemical window of the electrolyte first increases and then decreases with the decrease of nano SiO2 microspheres particle size, and the ionic conductivity increases with the increase of its particle size. The electrochemical window reached its maximum at 150 nm of nano SiO2 microspheres, where the increase in ionic conductivity became insignificant. Then, 150 nm SiO2 is added to PMMA gel electrolyte with a content of 7wt%, which has the electrochemical window of 4.8 V and the conductivity of 1.13 mS/cm. Besides, the electrolyte was used to assembly transmissive all-solid-state electrochromic device with a structure: Electrically conductive glass (ITO)‖SiO2/propylene carbonate (PC)-LiClO4/PMMA‖metal-supramolecular polymer‖ITO. The obtained device can change color between light green and dark blue with a high contrast of 60.1%, and the device stability is significantly improved.

In this paper, nano SiO2 microspheres with different particle sizes were prepared by the Stöber method, which were added to polymethyl methacrylate (PMMA)-based gel polymer electrolytes, and the size effect of nano SiO2 microspheres and its effect on the performance of all solid-state electrochromic devices were studied. The results show that the volume ratio of ethyl orthosilicate and ethanol affects the particle size of the obtained nano SiO2 microspheres. The larger the volume ratio, the smaller the particle size of the prepared nano SiO2 microspheres. In the PMMA-based gel polymer electrolyte, when nano SiO2 microspheres content is the same, the electrochemical window of the electrolyte first increases and then decreases with the decrease of nano SiO2 microspheres particle size, and the ionic conductivity increases with the increase of its particle size. The electrochemical window reached its maximum at 150 nm of nano SiO2 microspheres, where the increase in ionic conductivity became insignificant. Then, 150 nm SiO2 is added to PMMA gel electrolyte with a content of 7wt%, which has the electrochemical window of 4.8 V and the conductivity of 1.13 mS/cm. Besides, the electrolyte was used to assembly transmissive all-solid-state electrochromic device with a structure: Electrically conductive glass (ITO)‖SiO2/propylene carbonate (PC)-LiClO4/PMMA‖metal-supramolecular polymer‖ITO. The obtained device can change color between light green and dark blue with a high contrast of 60.1%, and the device stability is significantly improved.

2021, 38(5): 1455-1467.

doi: 10.13801/j.cnki.fhclxb.20200722.003

Abstract:

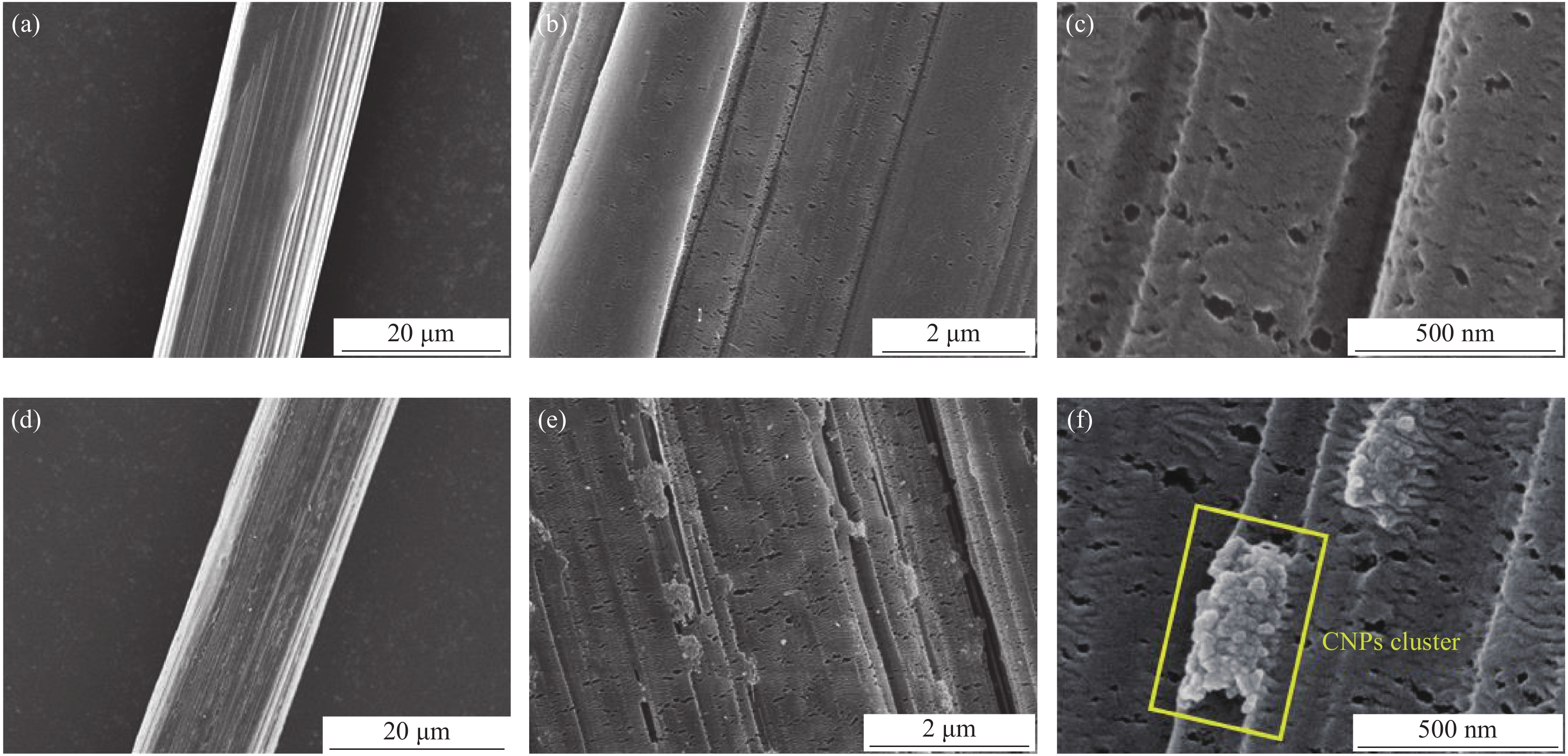

Two kinds of ultrahigh molecular weight polyethylene (UHMWPE) fiber, pristine and in-situ modified by carbon nanoparticles (CNPs), were used to prepare cross-ply unidirectional UHMWPE fiber/waterborne polyurethane (WPU) composite laminates by special process (winding, compound, and hot-pressing). The UHMWPE fiber/WPU composite laminates were impacted by mild-steel core projectile with size of 7.62 mm×39 mm at impacting velocity of (720±10) m/s. The ballistic behavior of UHMWPE fiber/WPU composite laminate was investigated by the X-ray computed tomography (CT) technology. The results show that the CNPs in-situ modification of CNPs-UHMWPE fiber may improve the single anti-penetration of its laminate, and this method may diminish the ability of resisting multiple strikes of its laminate. In addition, the penetration process of UHMWPE fiber/WPU composite laminate will be divided into three stages in a non-penetrating event: Shear plug, fracture failure and plastic deformation of the remaining sub-laminate. Moreover, the thickness ratios of every stages are about 11.51%, 44.40% and 44.09%, respectively. The delamination behavior of post-impact laminate is mainly distributed in the second stage, and approaches the impact point. Furthermore, the damage area of each projectile to the laminate may be contained in a circle with the impact point as the center and the dimeter of 70 mm.

Two kinds of ultrahigh molecular weight polyethylene (UHMWPE) fiber, pristine and in-situ modified by carbon nanoparticles (CNPs), were used to prepare cross-ply unidirectional UHMWPE fiber/waterborne polyurethane (WPU) composite laminates by special process (winding, compound, and hot-pressing). The UHMWPE fiber/WPU composite laminates were impacted by mild-steel core projectile with size of 7.62 mm×39 mm at impacting velocity of (720±10) m/s. The ballistic behavior of UHMWPE fiber/WPU composite laminate was investigated by the X-ray computed tomography (CT) technology. The results show that the CNPs in-situ modification of CNPs-UHMWPE fiber may improve the single anti-penetration of its laminate, and this method may diminish the ability of resisting multiple strikes of its laminate. In addition, the penetration process of UHMWPE fiber/WPU composite laminate will be divided into three stages in a non-penetrating event: Shear plug, fracture failure and plastic deformation of the remaining sub-laminate. Moreover, the thickness ratios of every stages are about 11.51%, 44.40% and 44.09%, respectively. The delamination behavior of post-impact laminate is mainly distributed in the second stage, and approaches the impact point. Furthermore, the damage area of each projectile to the laminate may be contained in a circle with the impact point as the center and the dimeter of 70 mm.

2021, 38(5): 1468-1475.

doi: 10.13801/j.cnki.fhclxb.20200629.002

Abstract:

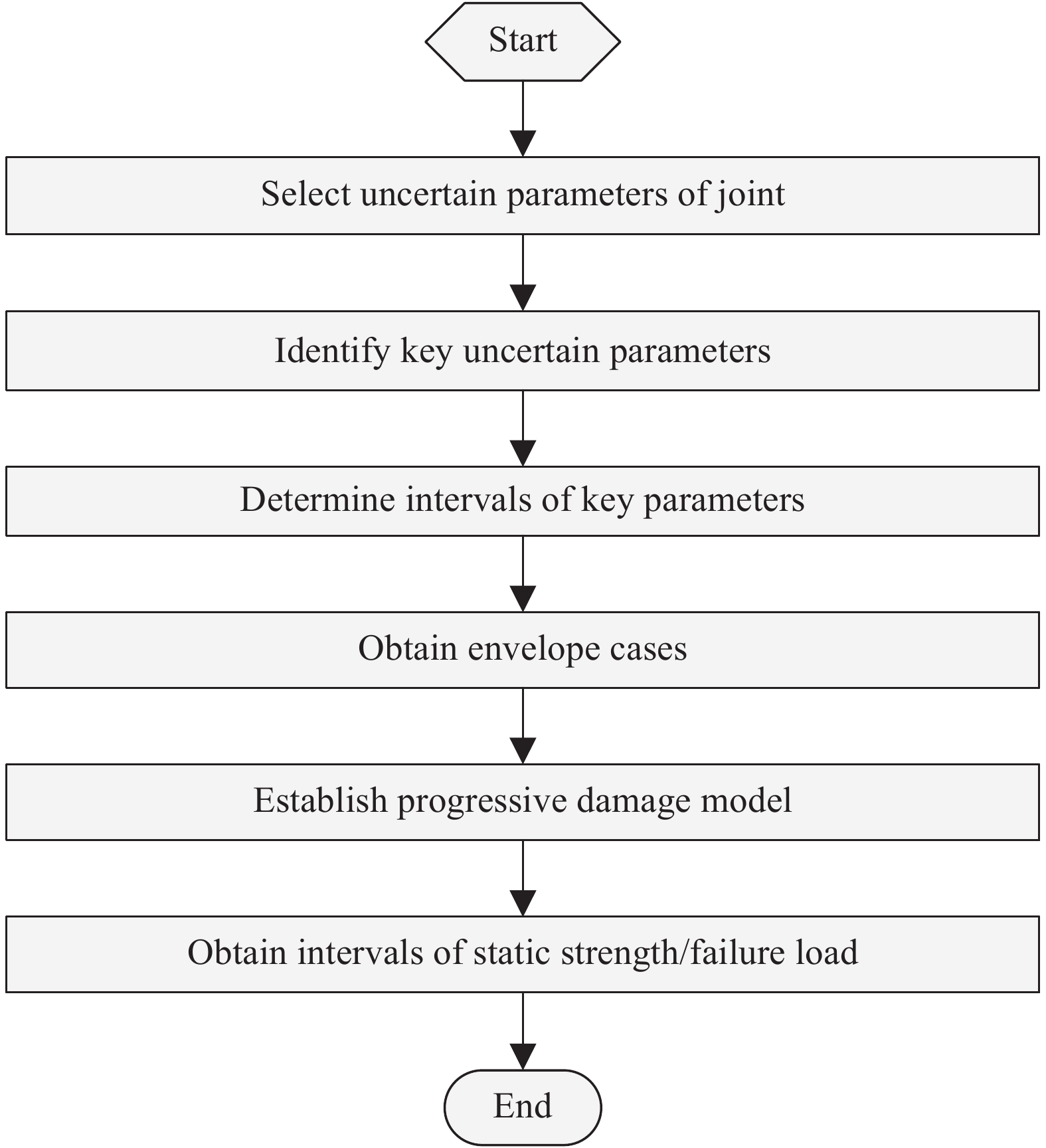

Bolted joints are the weak points of composite structures. Therefore, the considerable uncertainty in mechanical properties of the bolted joints not only prevents advanced composites from efficient applications, but also threatens the safety and reliability of the structures. In order to quantitatively evaluate the uncertainty in failure load of carbon fiber reinforced polymer (CFRP) composite bolted joints, an efficient and accurate analysis method was proposed based on the numerical progressive damage model and interval analysis method. The proposed method was used to predict the uncertain failure load of T800 carbon fiber/X850 epoxy composite bolted joint. The predicted results were compared with the experimental outcome. The small error less than 2% between the predicted and experimental results validates the effectiveness of the proposed method. According to the predicted results, the interval of failure load of the T800 carbon fiber/X850 epoxy composite bolted joint is [19.25 kN, 22.75 kN] with the deviations from the design expected values of [−9.8%, 6.6%].

Bolted joints are the weak points of composite structures. Therefore, the considerable uncertainty in mechanical properties of the bolted joints not only prevents advanced composites from efficient applications, but also threatens the safety and reliability of the structures. In order to quantitatively evaluate the uncertainty in failure load of carbon fiber reinforced polymer (CFRP) composite bolted joints, an efficient and accurate analysis method was proposed based on the numerical progressive damage model and interval analysis method. The proposed method was used to predict the uncertain failure load of T800 carbon fiber/X850 epoxy composite bolted joint. The predicted results were compared with the experimental outcome. The small error less than 2% between the predicted and experimental results validates the effectiveness of the proposed method. According to the predicted results, the interval of failure load of the T800 carbon fiber/X850 epoxy composite bolted joint is [19.25 kN, 22.75 kN] with the deviations from the design expected values of [−9.8%, 6.6%].

2021, 38(5): 1476-1486.

doi: 10.13801/j.cnki.fhclxb.20200723.005

Abstract:

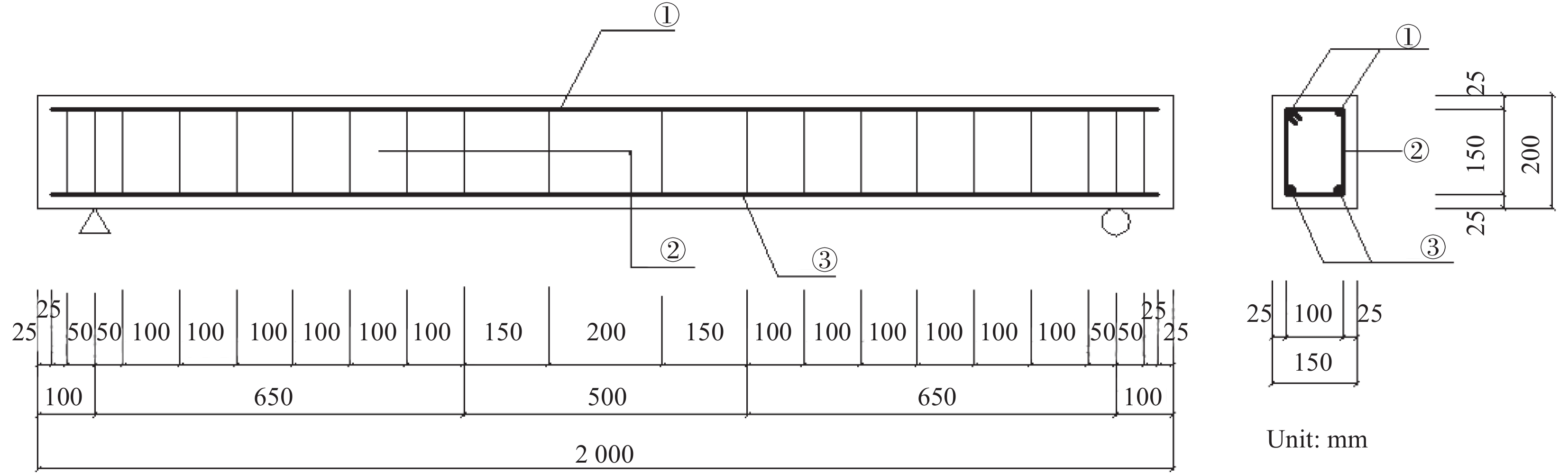

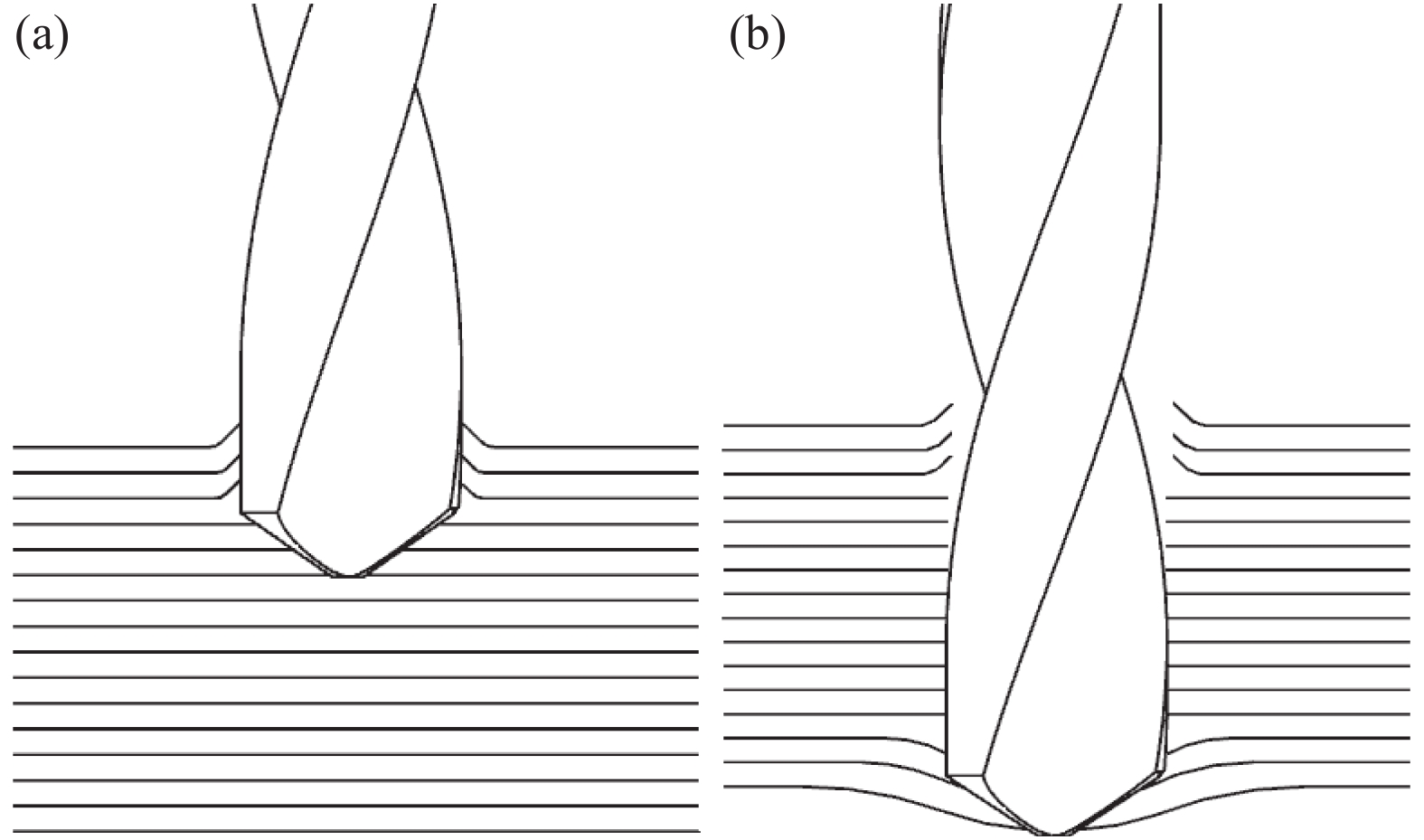

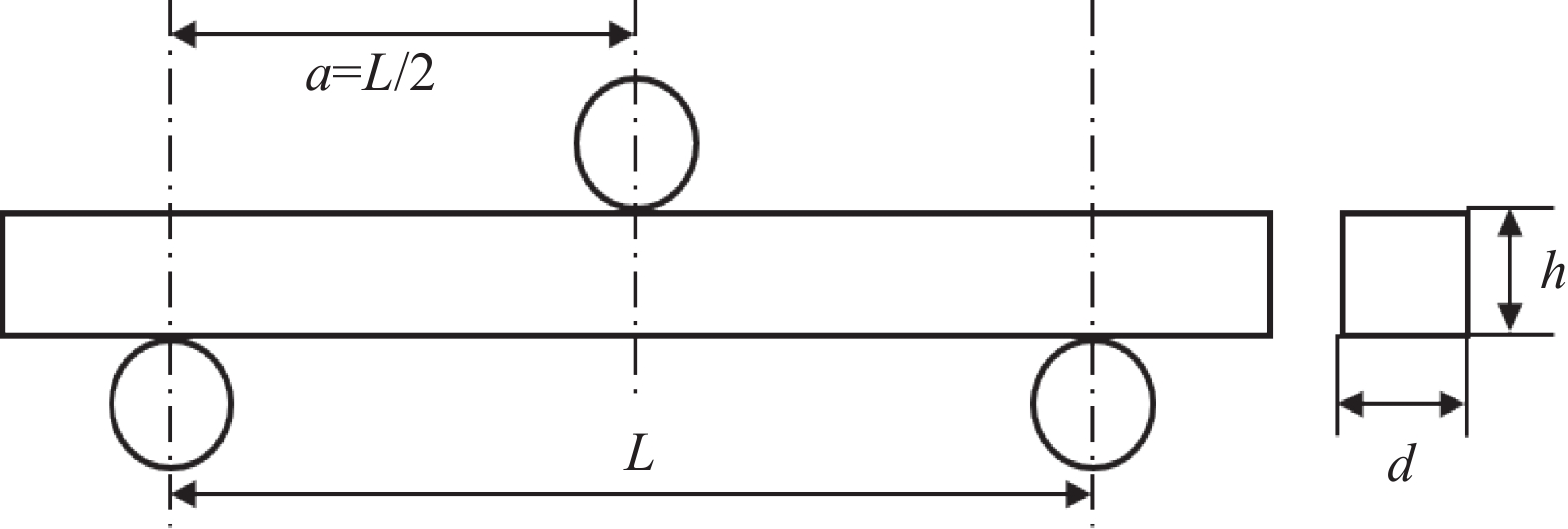

To improve the load capacity of the oil powered quadrotor unmanned aerial vehicle, carbon fiber reinforced polymer composite (CFRP)-metal transmission shafts are studied. The factors affecting the torsional strength of CFRP-metal transmission shafts are the quality of CFRP pipe holes and the extrusion effect of pins on connecting holes during transmission. By studing the mechanical behaviors causing delamination damage at the entrance and exit of CFRP tube, the influence mechanism of the quality of CFRP pipe holes was revealed and the hole making process was optimized. A comparative analysis between pin-connection CFRP-metal transmissions shafts and hybrid CFRP-metal transmission shafts with inner and outer bushing was carried out by torsion tests. The results show that the addition of the inside and outside aluminum alloy bushing of CFRP tubes can effectively reduce the delamination damage during drilling. The quality of the entrance and exit of holes can be increased by 4.4% and 8.3%, respectively. Meanwhile, the extrusion effect of the pins on the connecting holes is restrained. The torque values of the optimized transmission bearing is increased from 499 N·m to 952 N·m.

To improve the load capacity of the oil powered quadrotor unmanned aerial vehicle, carbon fiber reinforced polymer composite (CFRP)-metal transmission shafts are studied. The factors affecting the torsional strength of CFRP-metal transmission shafts are the quality of CFRP pipe holes and the extrusion effect of pins on connecting holes during transmission. By studing the mechanical behaviors causing delamination damage at the entrance and exit of CFRP tube, the influence mechanism of the quality of CFRP pipe holes was revealed and the hole making process was optimized. A comparative analysis between pin-connection CFRP-metal transmissions shafts and hybrid CFRP-metal transmission shafts with inner and outer bushing was carried out by torsion tests. The results show that the addition of the inside and outside aluminum alloy bushing of CFRP tubes can effectively reduce the delamination damage during drilling. The quality of the entrance and exit of holes can be increased by 4.4% and 8.3%, respectively. Meanwhile, the extrusion effect of the pins on the connecting holes is restrained. The torque values of the optimized transmission bearing is increased from 499 N·m to 952 N·m.

2021, 38(5): 1487-1496.

doi: 10.13801/j.cnki.fhclxb.20210202.004

Abstract:

Obvious process induced distortions usually take place in complex wing structures made of polymer-matrix composites. This leads to problems in the assembly and aerodynamics performance of composite wings. The objective of the present work is to develop a hot sizing process for large and complex composite structures, to solve the distortion control problem of composite wings. New sizing tools were designed according to the process induced distortions of wings, to carry out hot sizing experiments. A finite element simulation method was built up to predict the final shape of wings after hot sizing, based on characterizing the stress relaxation property of composites. The effects of process parameters were analyzed including temperature, sizing loads, et al, in order to optimize the hot sizing scheme. The simulation and experiments results show that hot sizing process is valid for large and complex composite structures. 89.5% of the process induced distortions of the composite wing structures is compensated by the hot sizing process, meeting the geometry requirements for assembly and aerodynamic characteristics.

Obvious process induced distortions usually take place in complex wing structures made of polymer-matrix composites. This leads to problems in the assembly and aerodynamics performance of composite wings. The objective of the present work is to develop a hot sizing process for large and complex composite structures, to solve the distortion control problem of composite wings. New sizing tools were designed according to the process induced distortions of wings, to carry out hot sizing experiments. A finite element simulation method was built up to predict the final shape of wings after hot sizing, based on characterizing the stress relaxation property of composites. The effects of process parameters were analyzed including temperature, sizing loads, et al, in order to optimize the hot sizing scheme. The simulation and experiments results show that hot sizing process is valid for large and complex composite structures. 89.5% of the process induced distortions of the composite wing structures is compensated by the hot sizing process, meeting the geometry requirements for assembly and aerodynamic characteristics.

2021, 38(5): 1497-1506.

doi: 10.13801/j.cnki.fhclxb.20200902.003

Abstract:

The graphite/Cu composites have excellent tribological properties and corrosion resistance so which show a broad application prospect in the field of high-speed railway. Due to the non-wetting of graphite with Cu and the low interfacial bonding strength of graphite/Cu composites, the graphite easily peels off under the high load and it could result in the poor performance of the composites. The interface of graphite/Cu composite could be modified by the surface treatment of the graphite with Sn element, which could not only improve the interfacial bonding but also improve the mechanical properties, so that the composites could meet the service conditions. The results show that there is no new phase formation in the microstructure of Sn coated graphite/Cu composites by the interfacial modification. A strong interdiffusion occurs at the interface of the Sn coated graphite/Cu composites and the interfacial bonding changes from mechanical bonding to diffusion bonding. The mechanical properties of the Sn coated graphite/Cu composites are significantly improved. The hardness and flexural strength increase 80.43% and 246.74%, respectively. When the graphite content is 6wt%, the hardness is (83.61±4.33) HV, and the bending strength is (410.41±20.52) MPa, which could meet the service requirements in the future.

The graphite/Cu composites have excellent tribological properties and corrosion resistance so which show a broad application prospect in the field of high-speed railway. Due to the non-wetting of graphite with Cu and the low interfacial bonding strength of graphite/Cu composites, the graphite easily peels off under the high load and it could result in the poor performance of the composites. The interface of graphite/Cu composite could be modified by the surface treatment of the graphite with Sn element, which could not only improve the interfacial bonding but also improve the mechanical properties, so that the composites could meet the service conditions. The results show that there is no new phase formation in the microstructure of Sn coated graphite/Cu composites by the interfacial modification. A strong interdiffusion occurs at the interface of the Sn coated graphite/Cu composites and the interfacial bonding changes from mechanical bonding to diffusion bonding. The mechanical properties of the Sn coated graphite/Cu composites are significantly improved. The hardness and flexural strength increase 80.43% and 246.74%, respectively. When the graphite content is 6wt%, the hardness is (83.61±4.33) HV, and the bending strength is (410.41±20.52) MPa, which could meet the service requirements in the future.

2021, 38(5): 1507-1516.

doi: 10.13801/j.cnki.fhclxb.20200814.003

Abstract: